| ÐлекÑÑоннÑй компоненÑ: AD7715 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

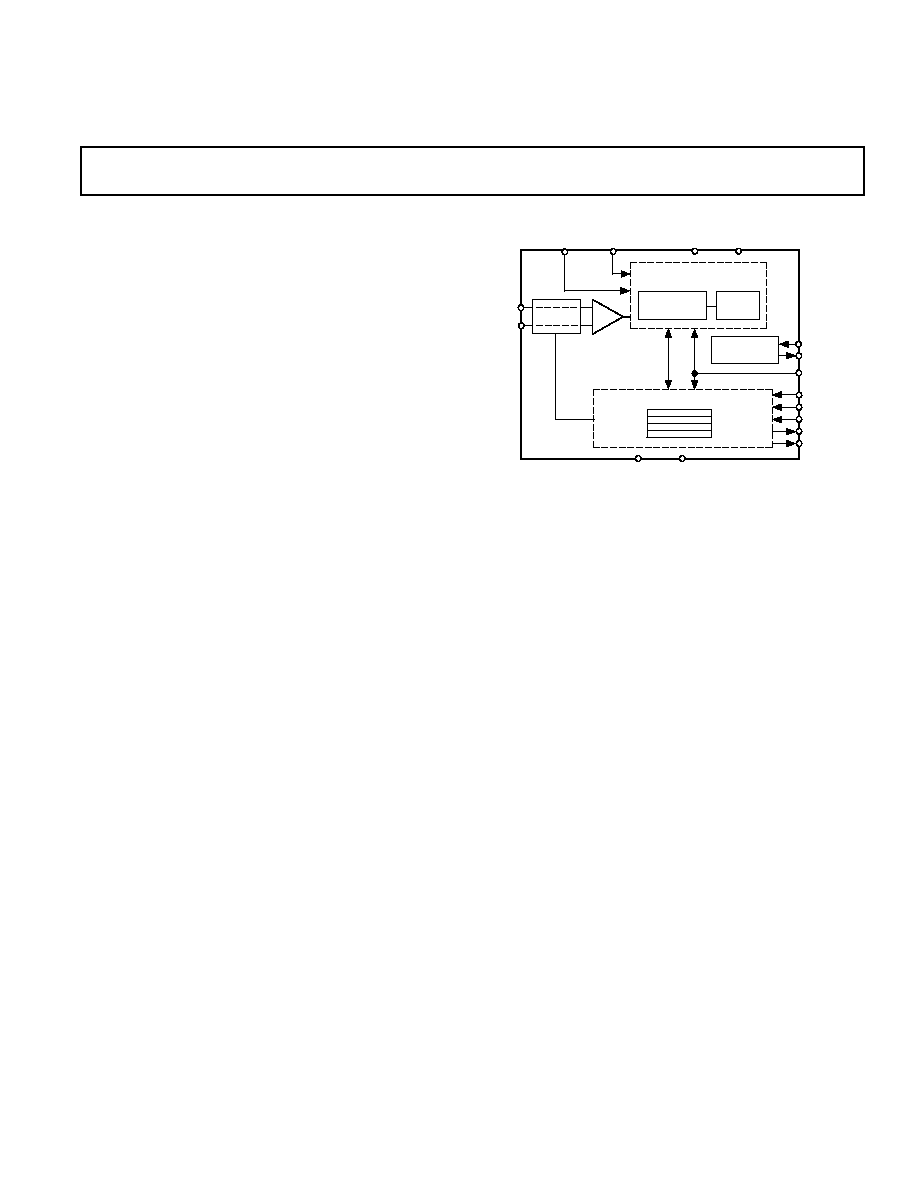

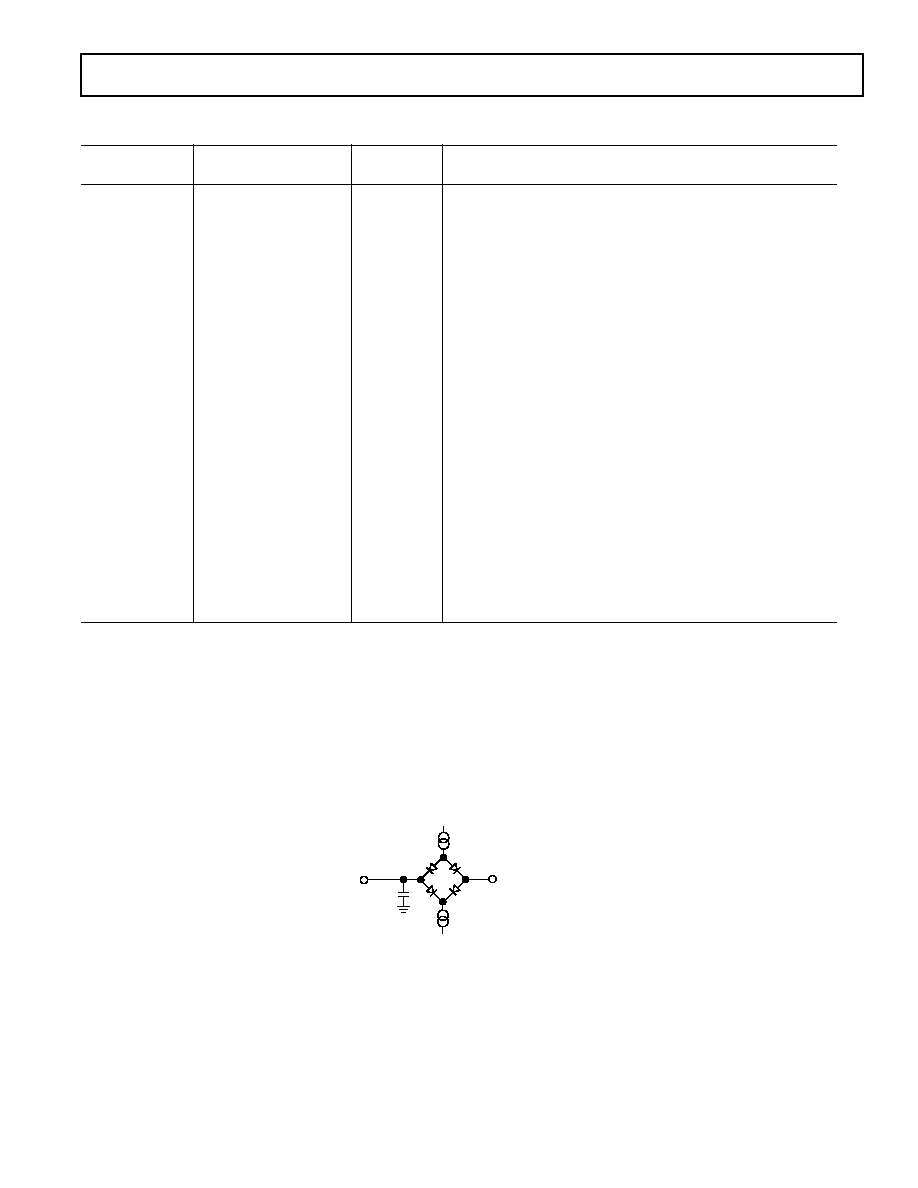

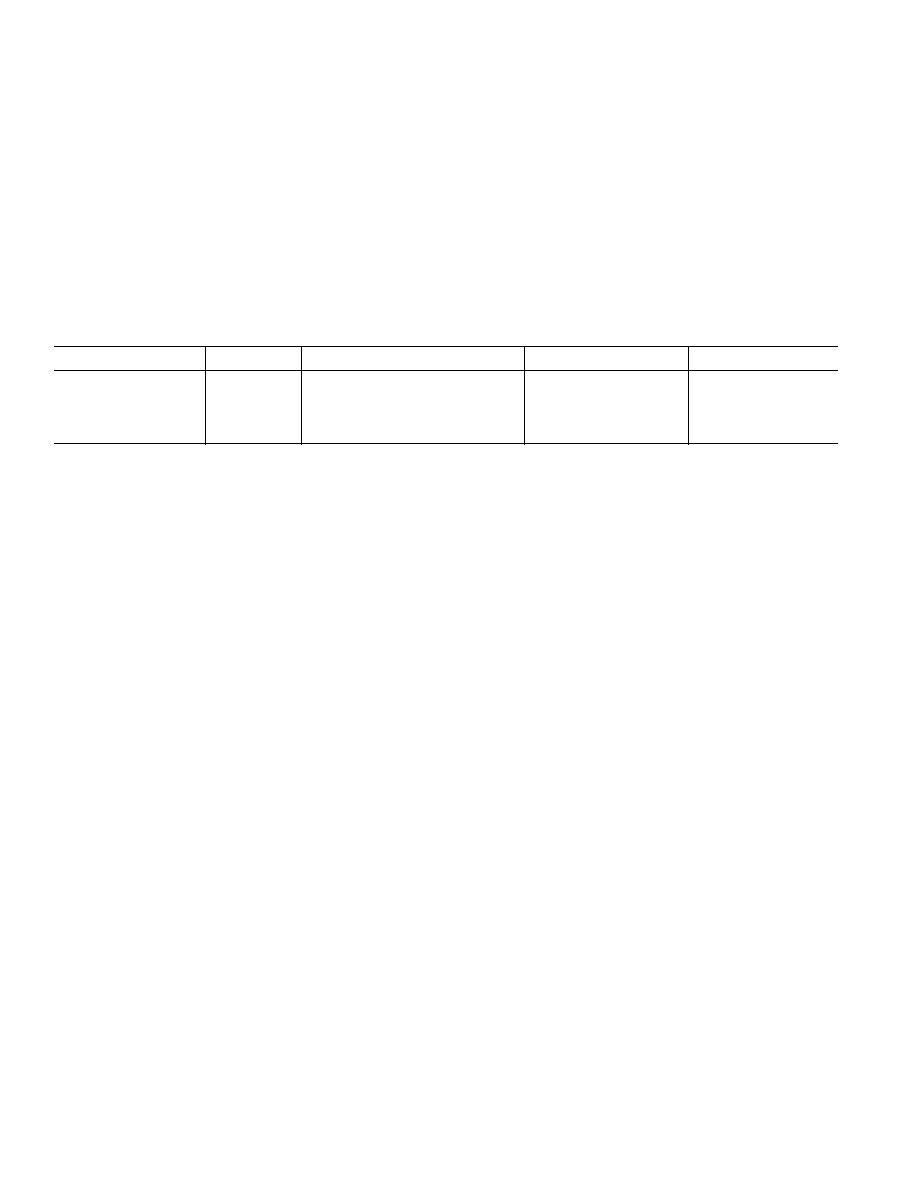

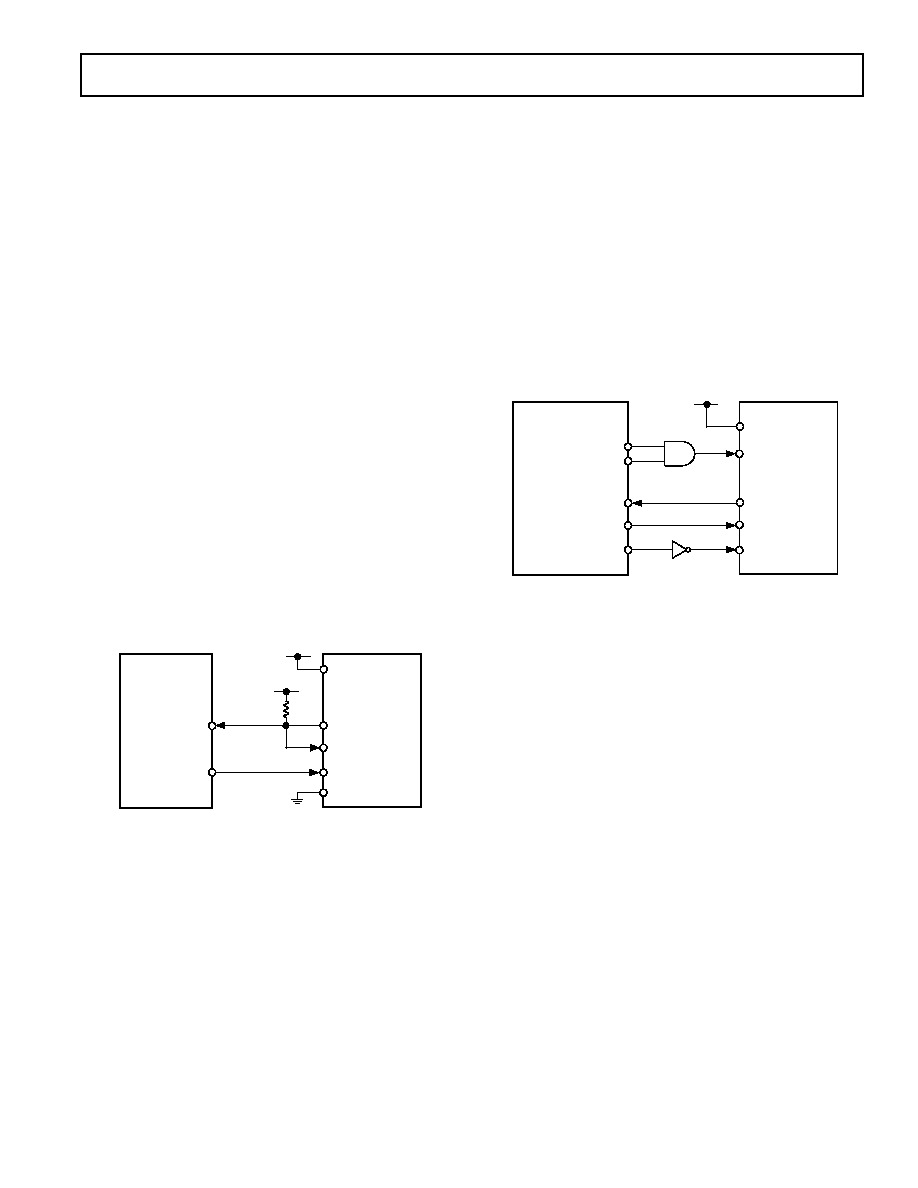

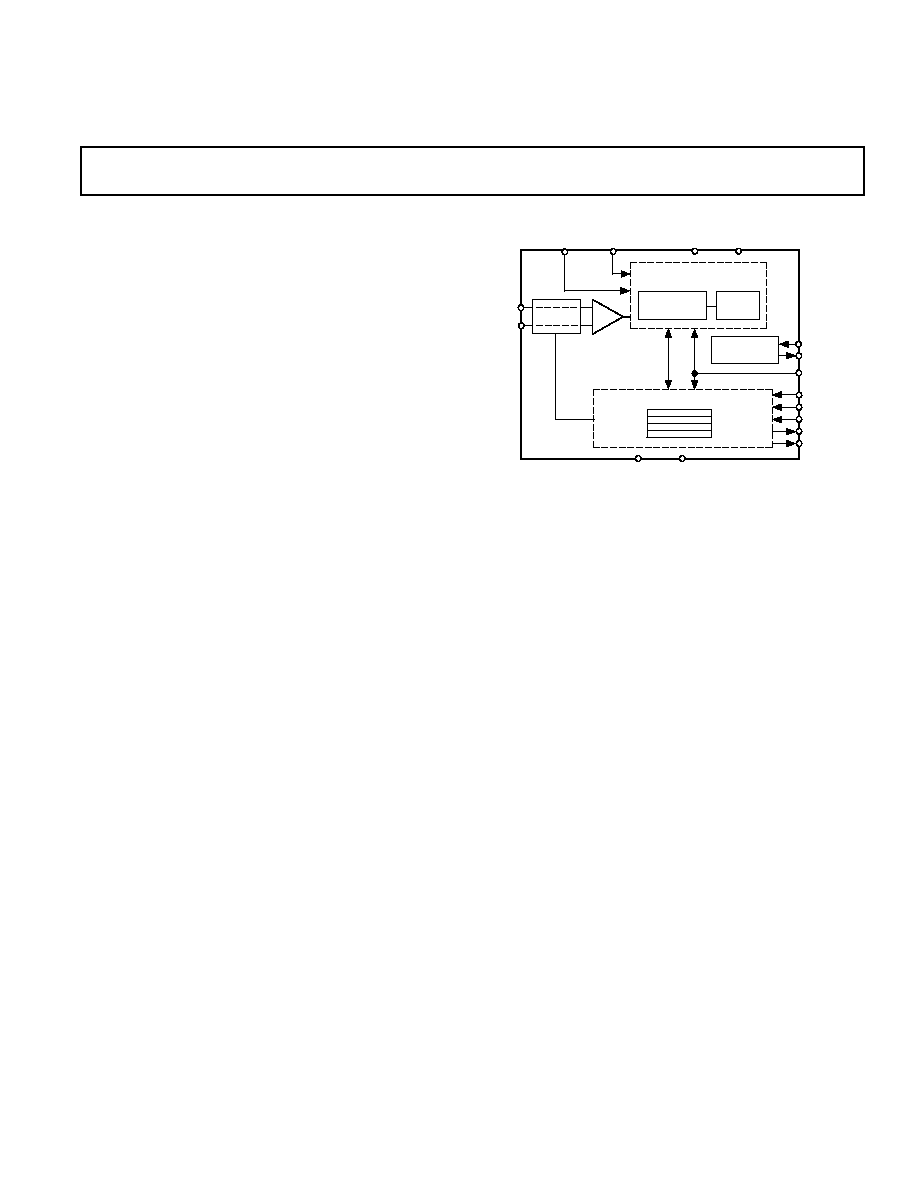

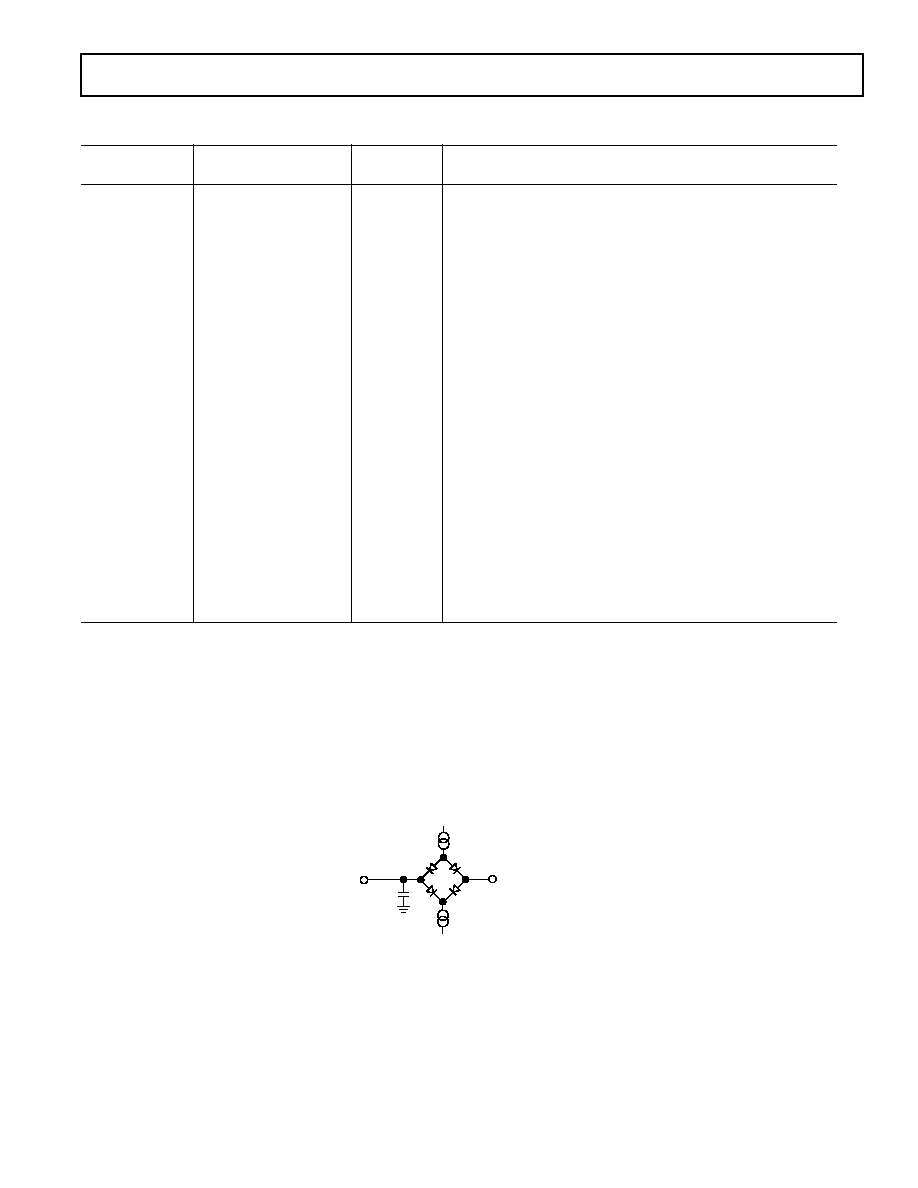

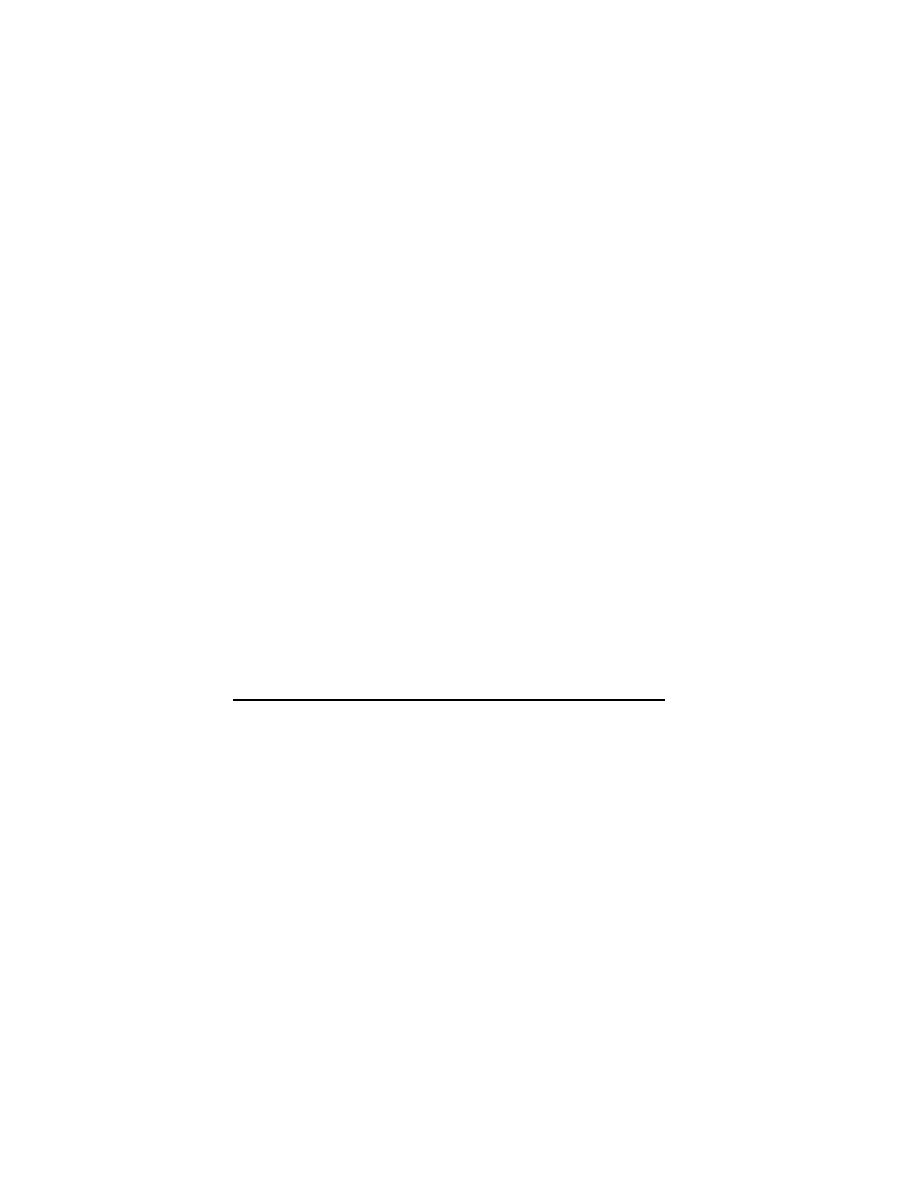

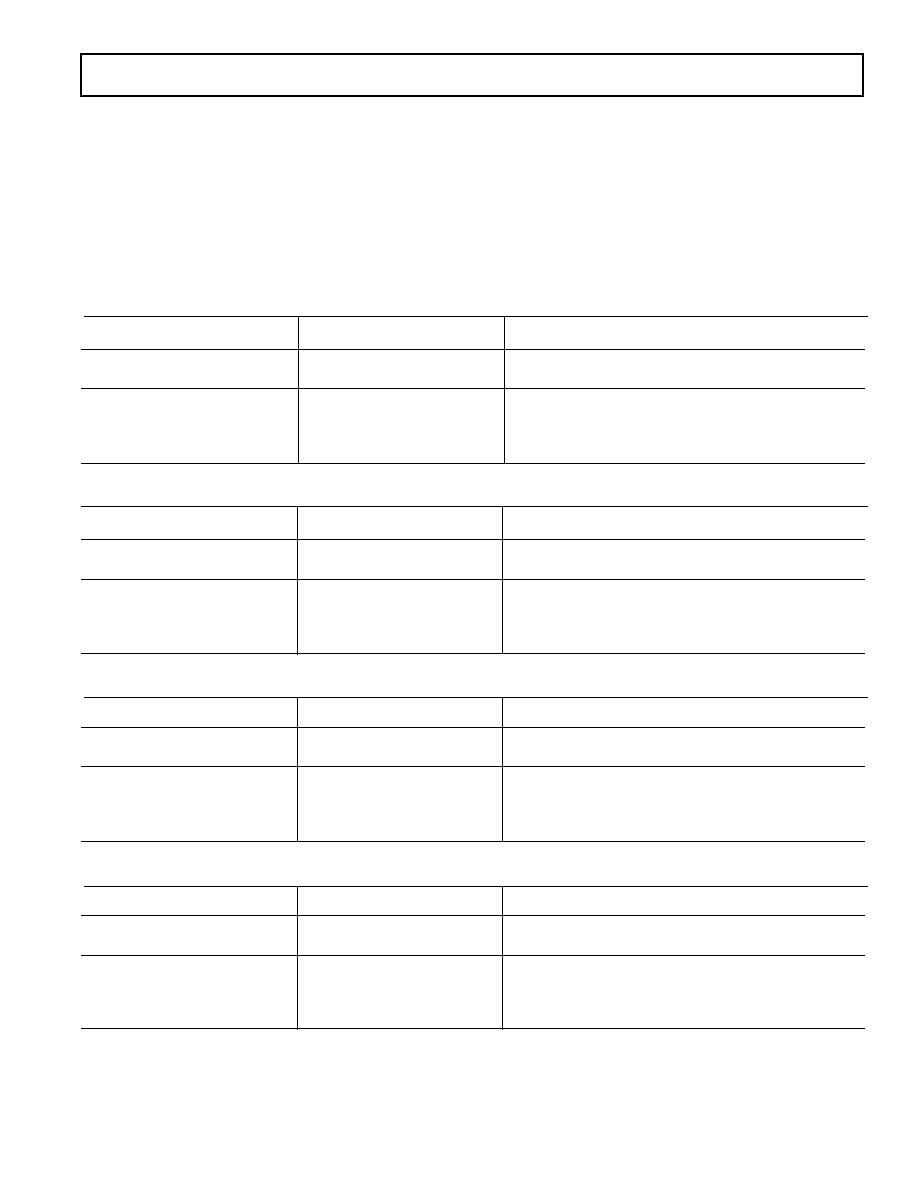

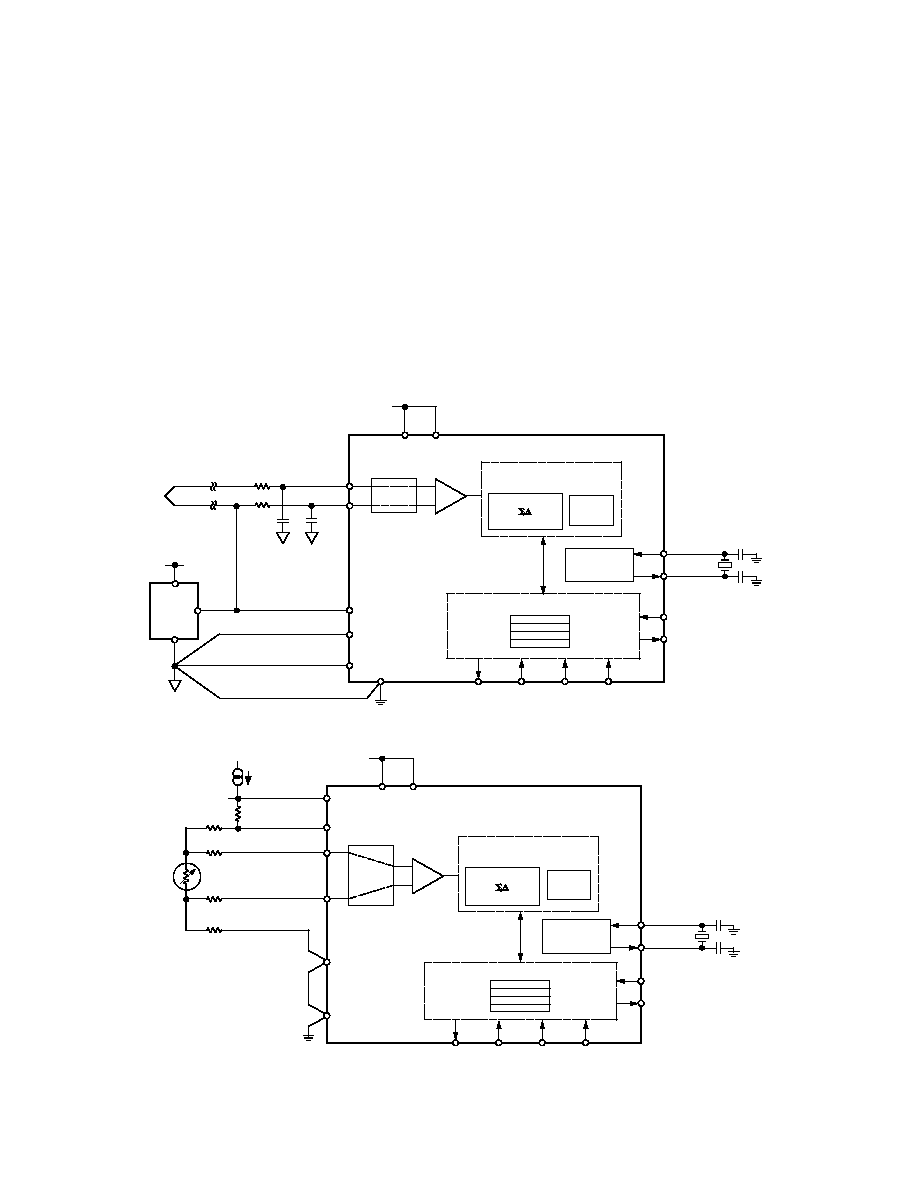

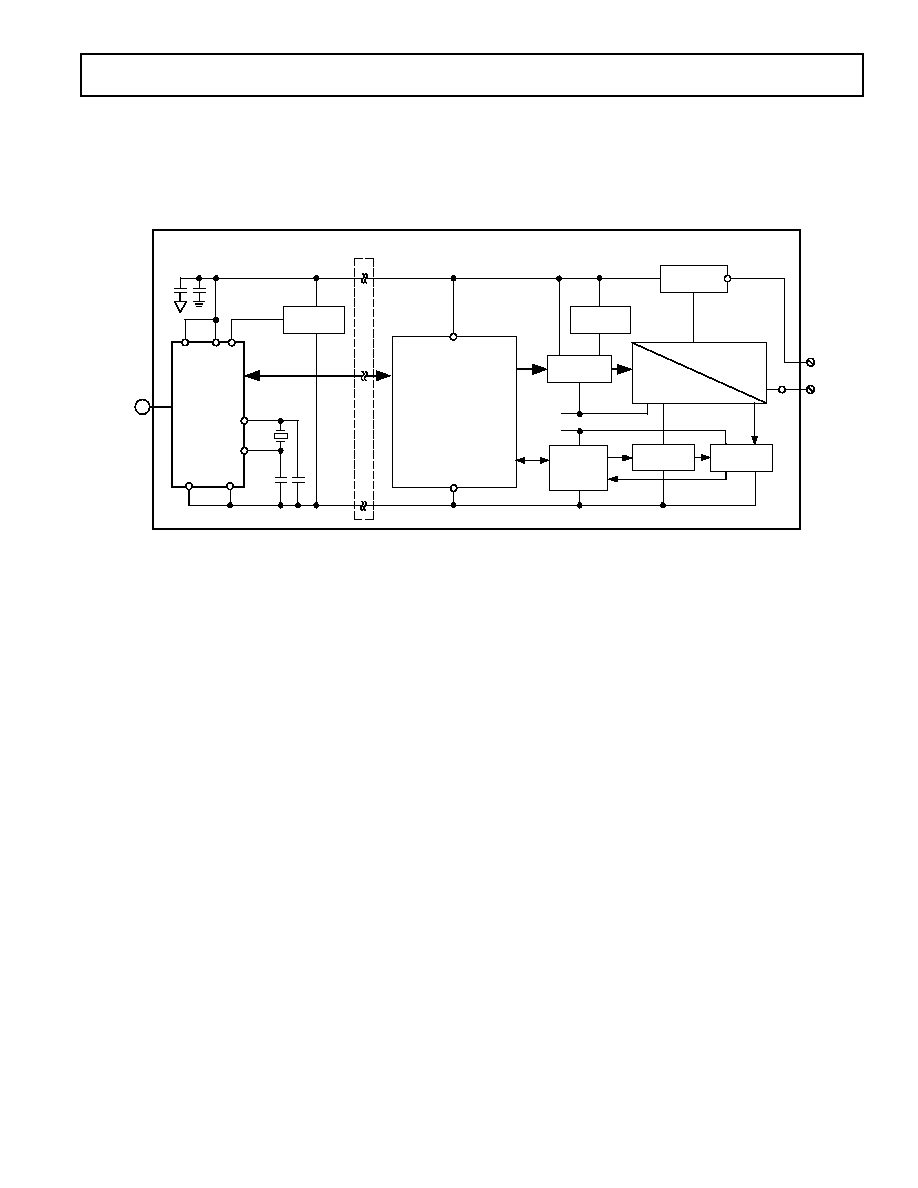

FUNCTIONAL BLOCK DIAGRAM

PGA

BUFFER

CHARGE BALANCING

A/D CONVERTER

SIGMA-DELTA

MODULATOR

DIGITAL

FILTER

REF IN() REF IN(+)

AV

DD

DV

DD

A = 1128

MCLK IN

MCLK OUT

RESET

AIN(+)

AIN()

SERIAL

INTERFACE

REGISTER BANK

SCLK

CS

DIN

DOUT

DRDY

CLOCK

GENERATION

AGND

DGND

AD7715

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

3 V/5 V, 450 A

16-Bit, Sigma-Delta ADC

AD7715*

FEATURES

Charge-Balancing ADC

16 Bits No Missing Codes

0.0015% Nonlinearity

Programmable Gain Front End

Gains of 1, 2, 32 and 128

Differential Input Capability

Three-Wire Serial Interface

SPITM, QSPITM, MICROWIRETM and DSP Compatible

Ability to Buffer the Analog Input

3 V (AD7715-3) or 5 V (AD7715-5) Operation

Low Supply Current: 450

A max @ 3 V Supplies

Low-Pass Filter with Programmable Output Update

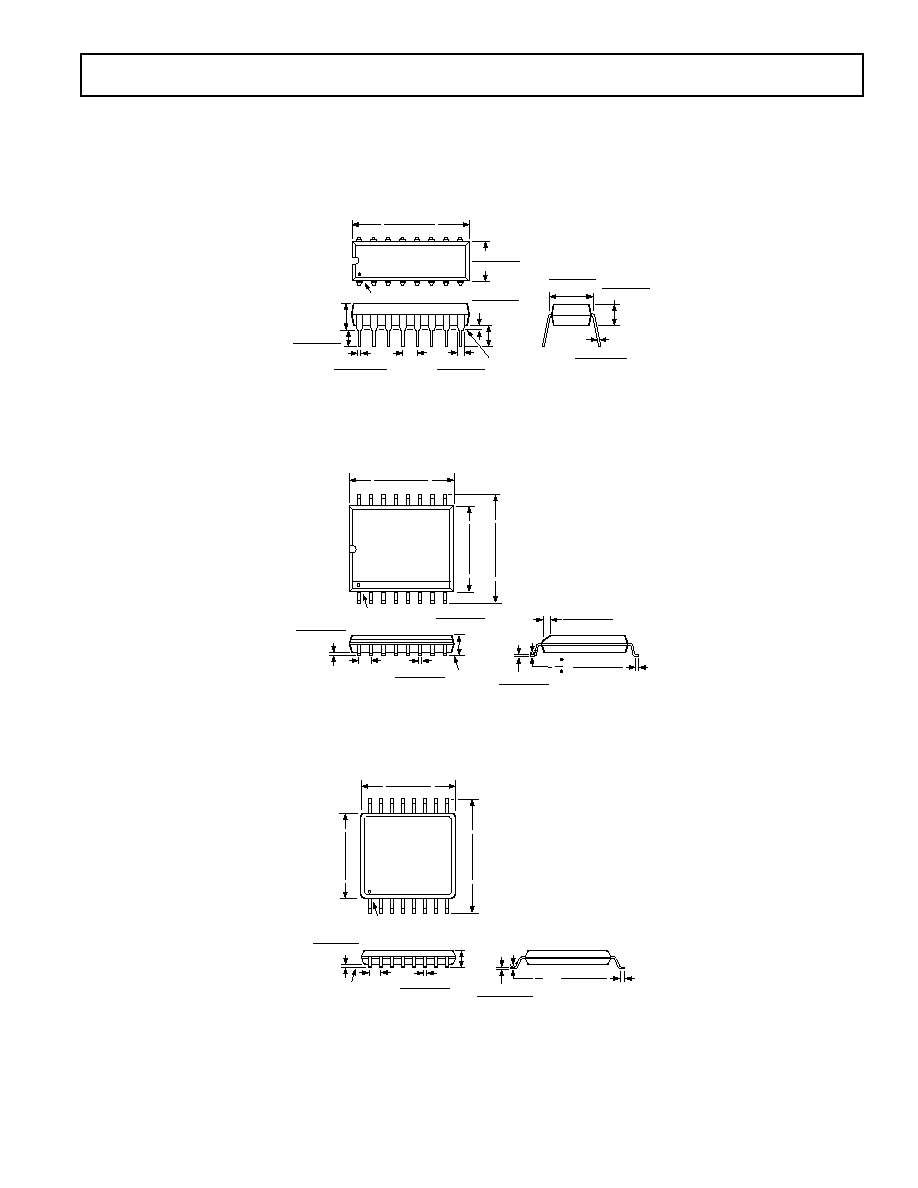

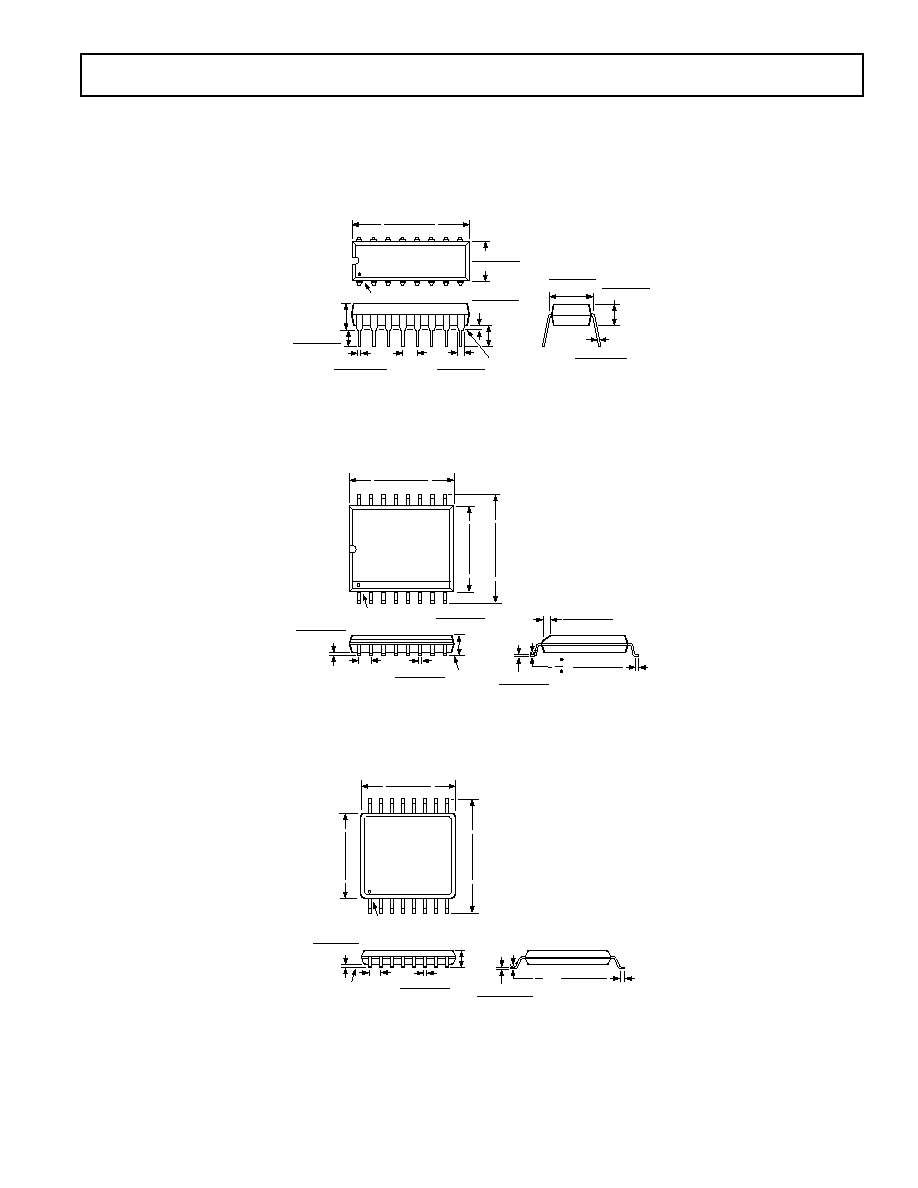

16-Lead SOIC/DIP/TSSOP

CMOS construction ensures very low power dissipation, and the

power-down mode reduces the standby power consumption to

50

µ

W typ. The part is available in a 16-lead, 0.3 inch-wide,

plastic dual-in-line package (DIP) as well as a 16-lead 0.3 inch-

wide small outline (SOIC) package and a 16-lead TSSOP package.

PRODUCT HIGHLIGHTS

1. The AD7715 consumes less than 450

µ

A in total supply

current at 3 V supplies and 1 MHz master clock, making it

ideal for use in low-power systems. Standby current is less

than 10

µ

A.

2. The programmable gain input allows the AD7715 to accept

input signals directly from a strain gage or transducer remov-

ing a considerable amount of signal conditioning.

3. The AD7715 is ideal for microcontroller or DSP processor

applications with a three-wire serial interface reducing the

number of interconnect lines and reducing the number of

opto-couplers required in isolated systems. The part con-

tains on-chip registers which allow software control over

output update rate, input gain, signal polarity and calibration

modes.

4. The part features excellent static performance specifications

with 16-bits no missing codes,

±

0.0015% accuracy and low

rms noise (<550 nV). Endpoint errors and the effects of

temperature drift are eliminated by on-chip calibration op-

tions, which remove zero-scale and full-scale errors.

GENERAL DESCRIPTION

The AD7715 is a complete analog front end for low frequency

measurement applications. The part can accept low level input

signals directly from a transducer and outputs a serial digital

word. It employs a sigma-delta conversion technique to realize

up to 16 bits of no missing codes performance. The input signal

is applied to a proprietary programmable gain front end based

around an analog modulator. The modulator output is pro-

cessed by an on-chip digital filter. The first notch of this digital

filter can be programmed via the on-chip control register allow-

ing adjustment of the filter cutoff and output update rate.

The AD7715 features a differential analog input as well as a dif-

ferential reference input. It operates from a single supply (+3 V

or +5 V). It can handle unipolar input signal ranges of 0 mV to

+20 mV, 0 mV to +80 mV, 0 V to +1.25 V and 0 V to +2.5 V.

It can also handle bipolar input signal ranges of

±

20 mV,

±

80 mV,

±

1.25 V and

±

2.5 V. These bipolar ranges are referenced to

the negative input of the differential analog input. The AD7715

thus performs all signal conditioning and conversion for a single-

channel system.

The AD7715 is ideal for use in smart, microcontroller or DSP

based systems. It features a serial interface that can be config-

ured for three-wire operation. Gain settings, signal polarity and

update rate selection can be configured in software using the

input serial port. The part contains self-calibration and system

calibration options to eliminate gain and offset errors on the

part itself or in the system.

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corporation.

*Protected by U.S. Patent No: 5,134,401.

See page 30 for data sheet index.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 2000

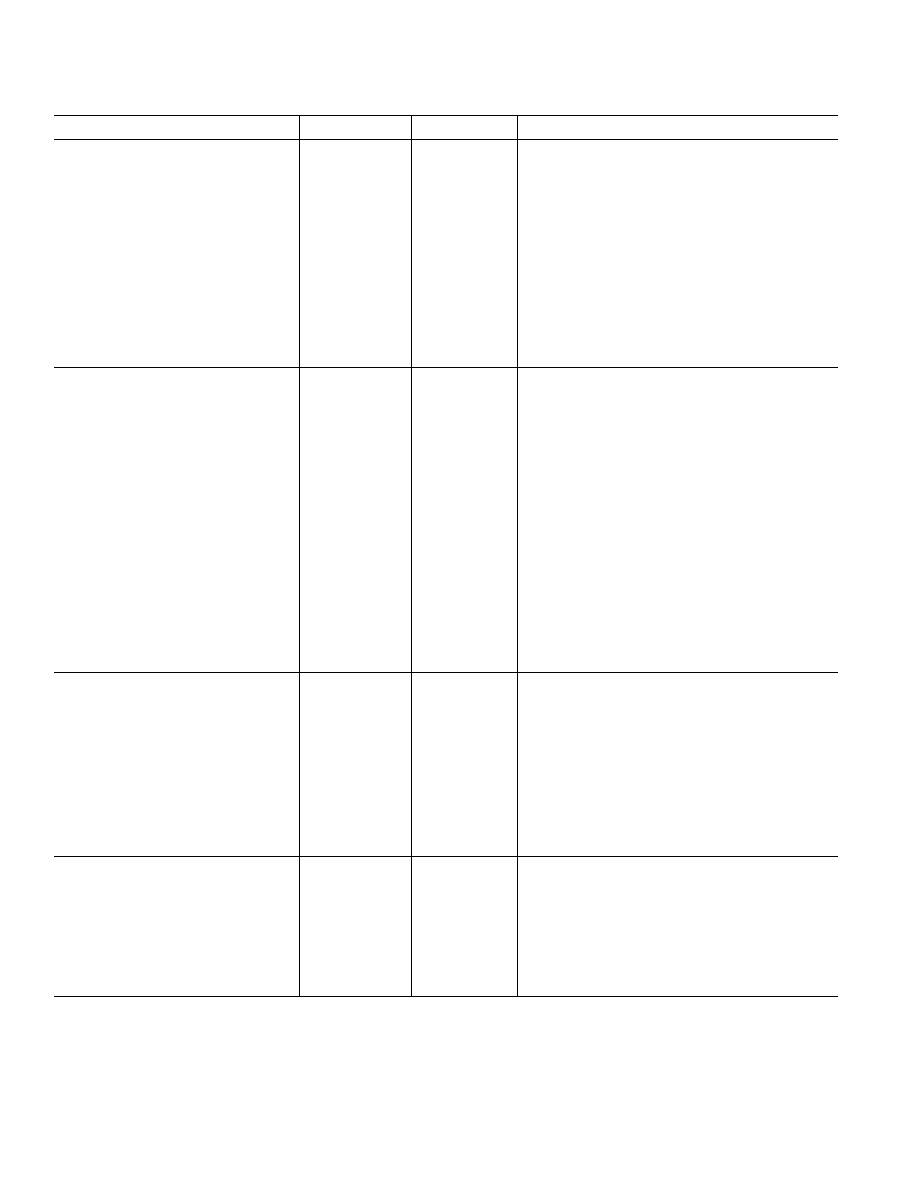

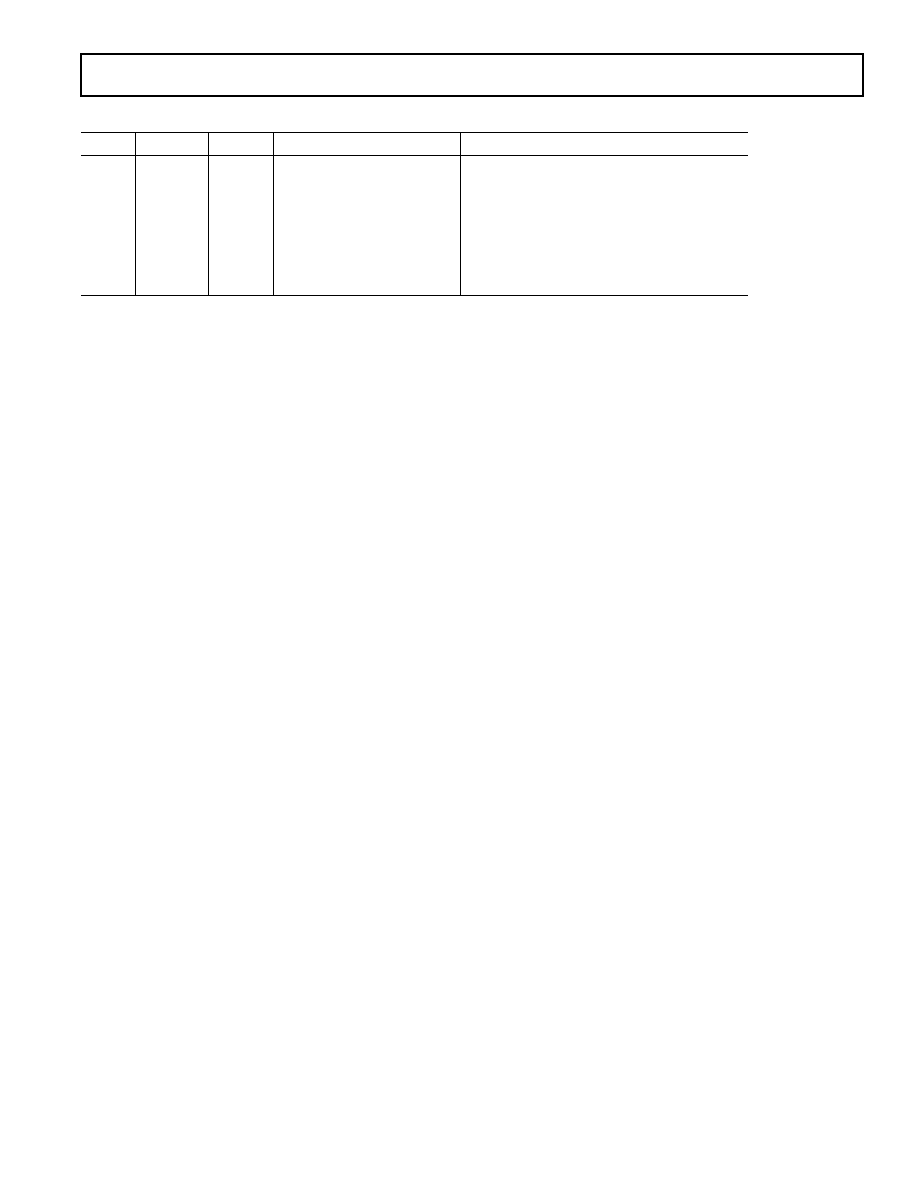

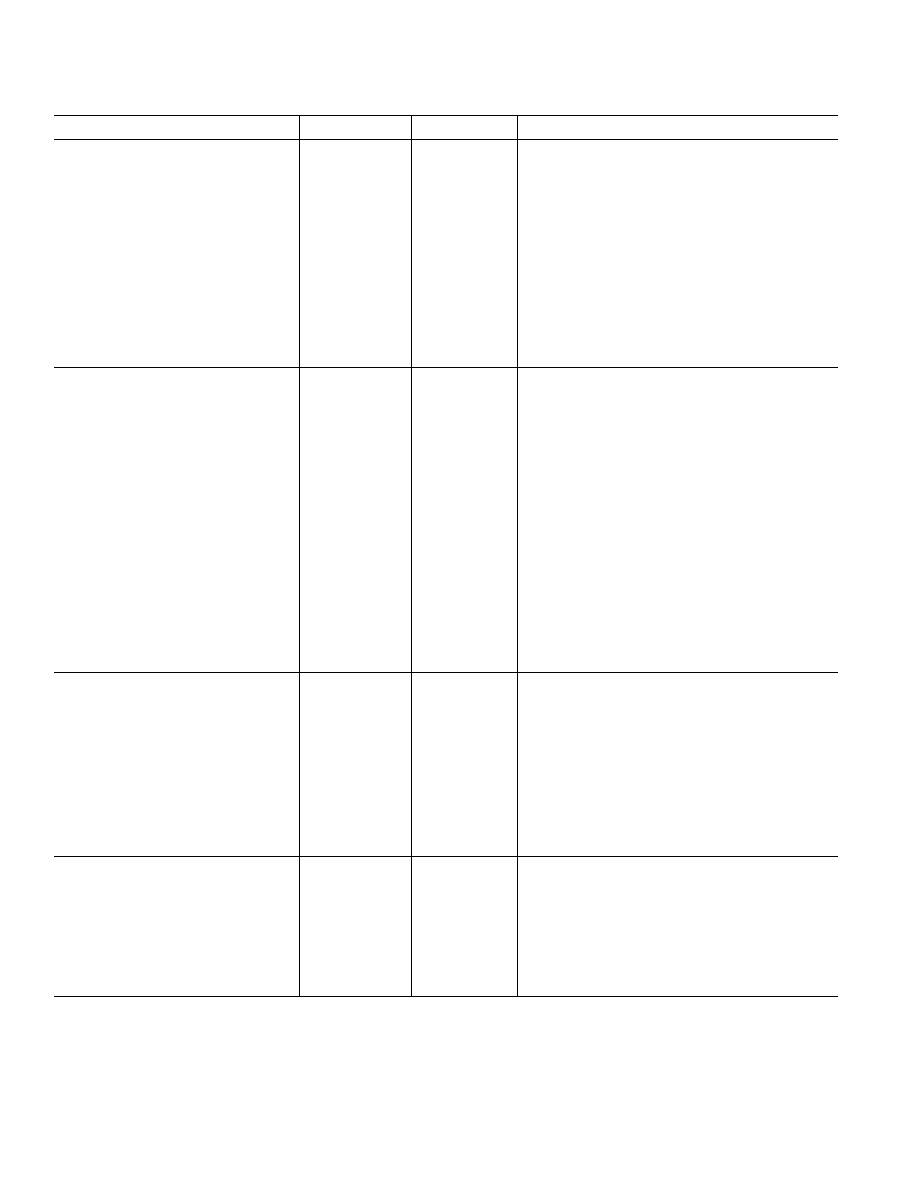

Parameter

A Version

1

Unit

Conditions/Comments

STATIC PERFORMANCE

No Missing Codes

16

Bits min

Guaranteed by Design. Filter Notch

60 Hz

Output Noise

See Tables V to VIII

Depends on Filter Cutoffs and Selected Gain

Integral Nonlinearity

±

0.0015

% of FSR max

Filter Notch

60 Hz

Unipolar Offset Error

See Note 2

Unipolar Offset Drift

3

0.5

µ

V/

°

C typ

Bipolar Zero Error

See Note 2

Bipolar Zero Drift

3

0.5

µ

V/

°

C typ

Positive Full-Scale Error

4

See Note 2

Full-Scale Drift

3, 5

0.5

µ

V/

°

C typ

Gain Error

6

See Note 2

Gain Drift

3, 7

0.5

ppm of FSR/

°

C typ

Bipolar Negative Full-Scale Error

2

±

0.0015

% of FSR max

Typically

±

0.0004%

Bipolar Negative Full-Scale Drift

3

1

µ

V/

°

C typ

For Gains of 1 and 2

0.6

µ

V/

°

C typ

For Gains of 32 and 128

ANALOG INPUTS/REFERENCE INPUTS

Specifications for AIN and REF IN Unless Noted

Input Common-Mode Rejection (CMR)

90

dB min

at DC. Typically 102 dB

Normal-Mode 50 Hz Rejection

8

98

dB min

For Filter Notches of 25 Hz, 50 Hz,

±

0.02

×

f

NOTCH

Normal-Mode 60 Hz Rejection

8

98

dB min

For Filter Notches of 20 Hz, 60 Hz,

±

0.02

×

f

NOTCH

Common-Mode 50 Hz Rejection

8

150

dB min

For Filter Notches of 25 Hz, 50 Hz,

±

0.02

×

f

NOTCH

Common-Mode 60 Hz Rejection

8

150

dB min

For Filter Notches of 20 Hz, 60 Hz,

±

0.02

×

f

NOTCH

Common-Mode Voltage Range

9

AGND to AV

DD

V min to V max

AIN for BUF Bit of Setup Register = 0 and REF IN

Absolute AIN/REF IN Voltage

8

AGND 30 mV

V min

AIN for BUF Bit of Setup Register = 0 and REF IN

AV

DD

+ 30 mV

V max

Absolute/Common-Mode AIN Voltage

9

AGND + 50 mV

V min

BUF Bit of Setup Register = 1

AV

DD

1.5 V

V max

AIN DC Input Current

8

1

nA max

AIN Sampling Capacitance

8

10

pF max

AIN Differential Voltage Range

10

0 to +V

REF

/GAIN

11

nom

Unipolar Input Range (B/U Bit of Setup Register = 1)

±

V

REF

/GAIN

nom

Bipolar Input Range (B/U Bit of Setup Register = 0)

AIN Input Sampling Rate, f

S

GAIN

×

f

CLK IN

/64

For Gains of 1 and 2

f

CLK IN

/8

For Gains of 32 and 128

REF IN(+) REF IN() Voltage

+2.5

V nom

±

1% for Specified Performance. Functional with

Lower V

REF

REF IN Input Sampling Rate, f

S

f

CLK IN

/64

LOGIC INPUTS

Input Current

±

10

µ

A max

All Inputs Except MCLK IN

V

INL

, Input Low Voltage

0.8

V max

DV

DD

= +5 V

V

INL

, Input Low Voltage

0.4

V max

DV

DD

= +3.3 V

V

INH

, Input High Voltage

2.4

V min

DV

DD

= +5 V

V

INH

, Input High Voltage

2.0

V min

MCLK IN Only

V

INL

, Input Low Voltage

0.8

V max

DV

DD

= +5 V

V

INL

, Input Low Voltage

0.4

V max

DV

DD

= +3.3 V

V

INH

, Input High Voltage

3.5

V min

DV

DD

= +5 V

V

INH

, Input High Voltage

2.5

V min

DV

DD

= +3.3 V

LOGIC OUTPUTS (Including MCLK OUT)

V

OL

, Output Low Voltage

0.4

V max

I

SINK

= 800

µ

A Except for MCLK OUT

12

. DV

DD

= +5 V

V

OL

, Output Low Voltage

0.4

V max

I

SINK

= 100

µ

A Except for MCLK OUT

12

. DV

DD

= +3.3 V

V

OH

, Output High Voltage

4.0

V min

I

SOURCE

= 200

µ

A Except for MCLK OUT

12

. DV

DD

= +5 V

V

OH

, Output High Voltage

DV

DD

0.6 V

V min

I

SOURCE

= 100

µ

A Except for MCLK OUT

12

. DV

DD

= +3.3 V

Floating State Leakage Current

±

10

µ

A max

Floating State Output Capacitance

13

9

pF typ

Data Output Coding

Binary

Unipolar Mode

Offset Binary

Bipolar Mode

AD7715-5SPECIFICATIONS

(AV

DD

= +5 V, DV

DD

= +3 V or +5 V, REF IN(+) = +2.5 V; REF IN() = AGND;

f

CLK IN

= 2.4576 MHz unless otherwise noted. All specifications T

MIN

to T

MAX

unless otherwise noted.)

REV. C

2

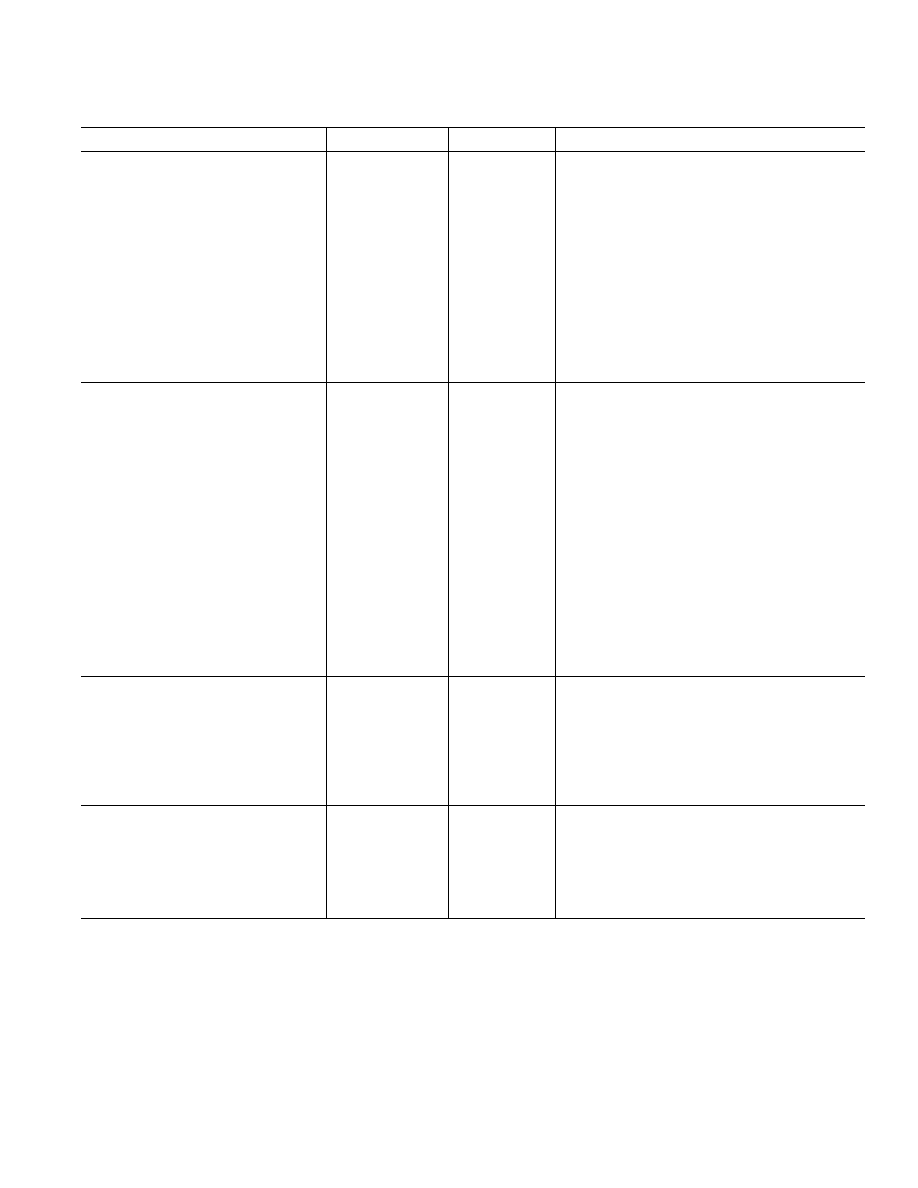

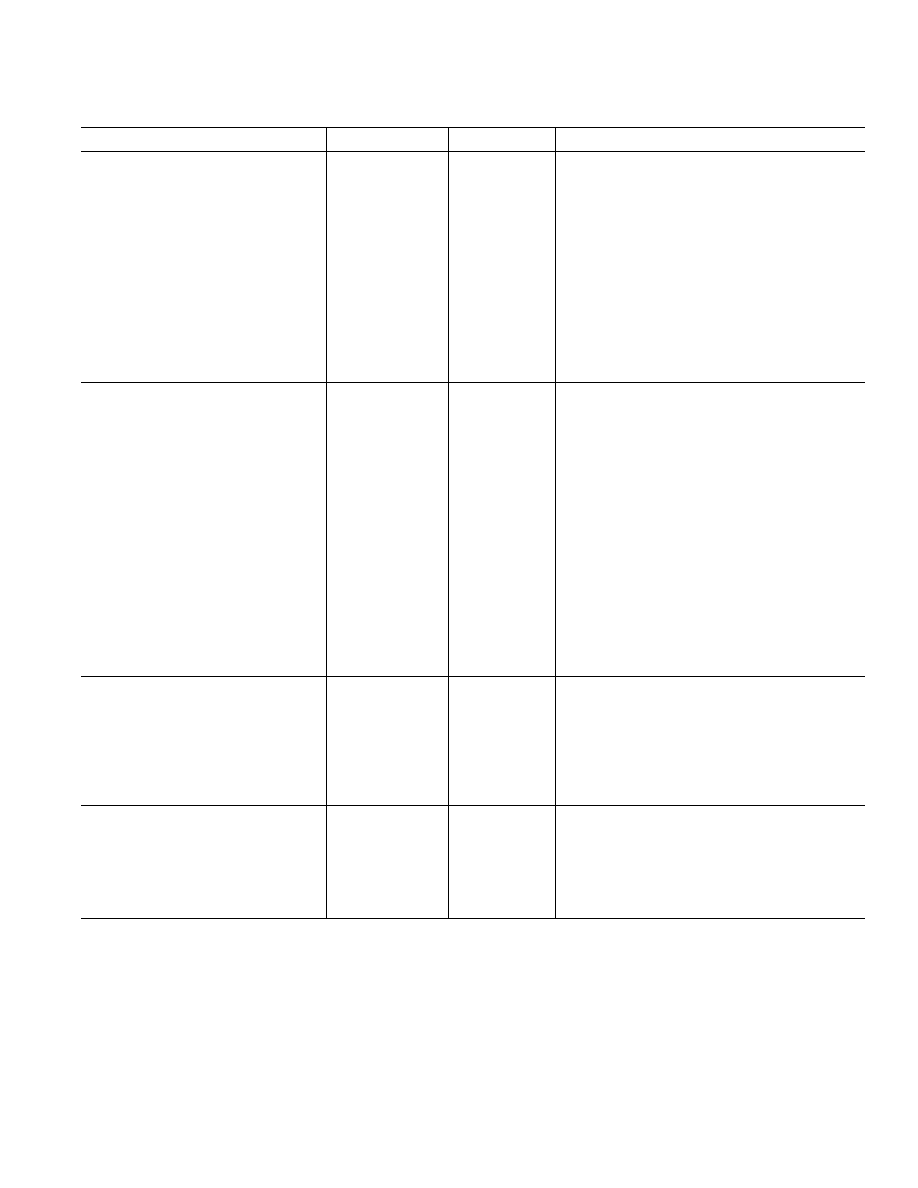

Parameter

A Version

1

Unit

Conditions/Comments

STATIC PERFORMANCE

No Missing Codes

16

Bits min

Guaranteed by Design. Filter Notch

60 Hz

Output Noise

See Tables IX to XII

Depends on Filter Cutoffs and Selected Gain

Integral Nonlinearity

±

0.0015

% of FSR max

Filter Notch

60 Hz

Unipolar Offset Error

See Note 2

Unipolar Offset Drift

3

0.2

µ

V/

°

C typ

Bipolar Zero Error

See Note 2

Bipolar Zero Drift

3

0.2

µ

V/

°

C typ

Positive Full-Scale Error

4

See Note 2

Full-Scale Drift

3, 5

0.2

µ

V/

°

C typ

Gain Error

6

See Note 2

Gain Drift

3, 7

0.2

ppm of FSR/

°

C typ

Bipolar Negative Full-Scale Error

2

±

0.003

% of FSR max

Typically

±

0.0004%

Bipolar Negative Full-Scale Drift

3

1

µ

V/

°

C typ

For Gains of 1 and 2

0.6

µ

V/

°

C typ

For Gains of 32 and 128

ANALOG INPUTS/REFERENCE INPUTS

Specifications for AIN and REF IN Unless Noted

Input Common-Mode Rejection (CMR)

90

dB min

at DC. Typically 102 dB

Normal-Mode 50 Hz Rejection

8

98

dB min

For Filter Notches of 25 Hz, 50 Hz,

±

0.02

×

f

NOTCH

Normal-Mode 60 Hz Rejection

8

98

dB min

For Filter Notches of 20 Hz, 60 Hz,

±

0.02

×

f

NOTCH

Common-Mode 50 Hz Rejection

8

150

dB min

For Filter Notches of 25 Hz, 50 Hz,

±

0.02

×

f

NOTCH

Common-Mode 60 Hz Rejection

8

150

dB min

For Filter Notches of 20 Hz, 60 Hz,

±

0.02

×

f

NOTCH

Common-Mode Voltage Range

9

AGND to AV

DD

V min to V max

AIN for BUF Bit of Setup Register = 0 and REF IN

Absolute AIN/REF IN Voltage

8

AGND 30 mV

V min

AIN for BUF Bit of Setup Register = 0 and REF IN

AV

DD

+ 30 mV

V max

Absolute/Common-Mode AIN Voltage

9

AGND + 50 mV

V min

BUF Bit of Setup Register = 1

AV

DD

1.5 V

V max

AIN DC Input Current

8

1

nA max

AIN Sampling Capacitance

8

10

pF max

AIN Differential Voltage Range

10

0 to +V

REF

/GAIN

11

nom

Unipolar Input Range (B/U Bit of Setup Register = 1)

±

V

REF

/GAIN

nom

Bipolar Input Range (B/U Bit of Setup Register = 0)

AIN Input Sampling Rate, f

S

GAIN

×

f

CLK IN

/64

For Gains of 1 and 2

f

CLK IN

/8

For Gains of 32 and 128

REF IN(+) REF IN() Voltage

+1.25

V nom

±

1% for Specified Performance. Functional with Lower V

REF

REF IN Input Sampling Rate, f

S

f

CLK IN

/64

LOGIC INPUTS

Input Current

±

10

µ

A max

All Inputs Except MCLK IN

V

INL

, Input Low Voltage

0.8

V max

V

INH

, Input High Voltage

2.0

V min

MCLK IN Only

V

INL

, Input Low Voltage

0.4

V max

V

INH

, Input High Voltage

2.5

V min

LOGIC OUTPUTS (Including MCLK OUT)

V

OL

, Output Low Voltage

0.4

V max

I

SINK

= 100

µ

A Except for MCLK OUT

12

V

OH

, Output High Voltage

DV

DD

0.6

V min

I

SOURCE

= 100

µ

A Except for MCLK OUT

12

Floating State Leakage Current

±

10

µ

A max

Floating State Output Capacitance

13

9

pF typ

Data Output Coding

Binary

Unipolar Mode

Offset Binary

Bipolar Mode

AD7715

AD7715-3SPECIFICATIONS

(AV

DD

= +3 V, DV

DD

= +3 V, REF IN (+) = +1.25 V;

REF IN() = AGND; f

CLK IN

= 2.4576 MHz unless otherwise noted. All specifications T

MIN

to T

MAX

unless otherwise noted.)

3

REV. C

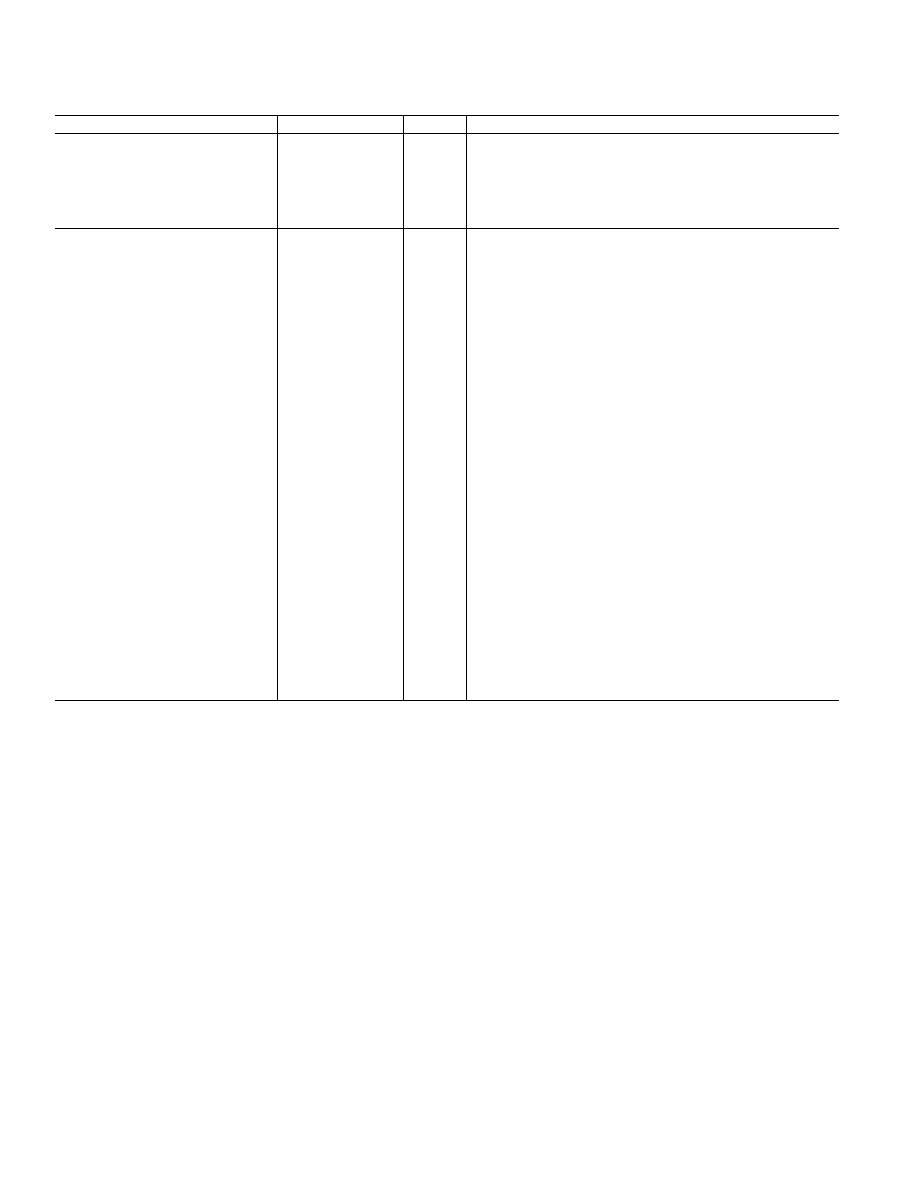

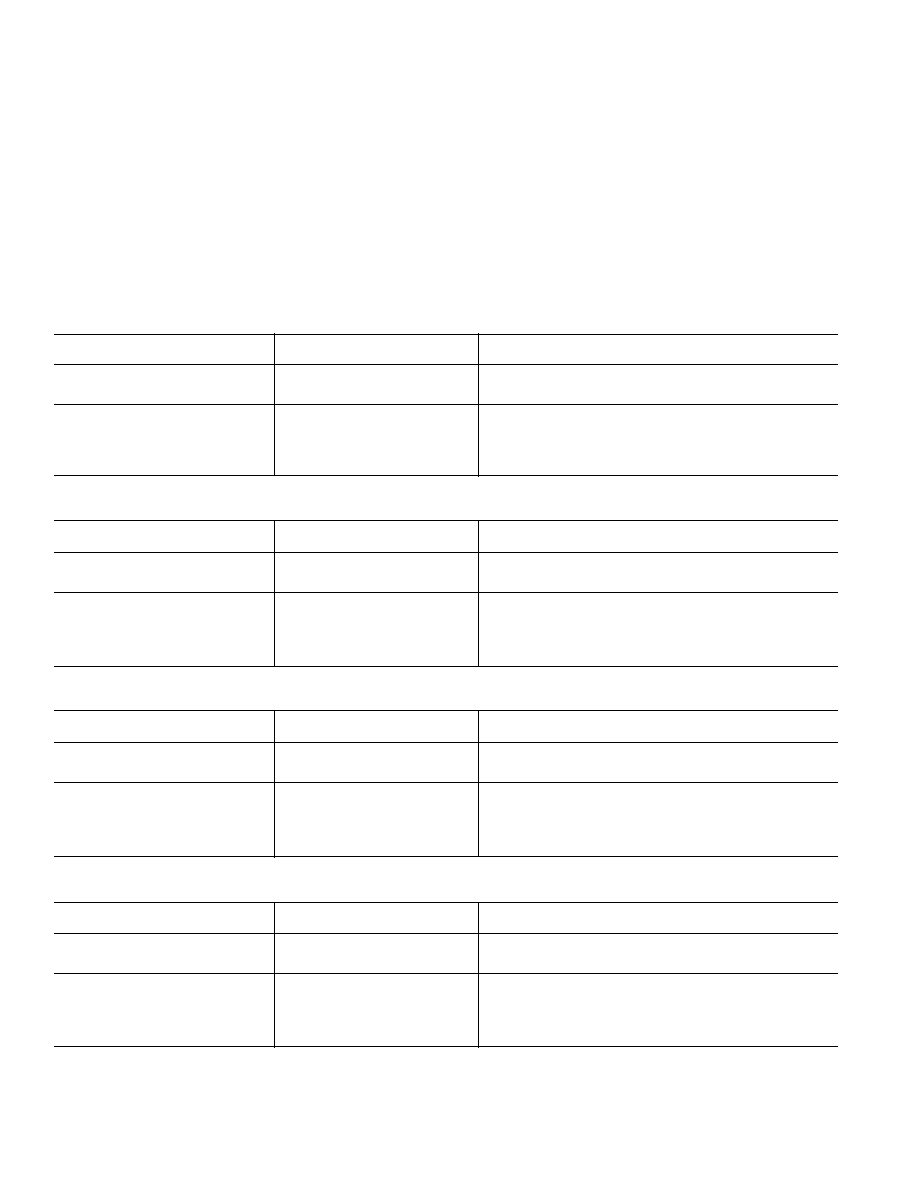

Pa

rameter

A Version

Unit

Conditions/Comments

SYSTEM CALIBRATION

Positive Full-Scale Calibration Limit

14

(1.05

×

V

REF

)/GAIN

V max

GAIN Is the Selected PGA Gain (1, 2, 32 or 128)

Negative Full-Scale Calibration Limit

14

(1.05

×

V

REF

)/GAIN

V max

GAIN Is the Selected PGA Gain (1, 2, 32 or 128)

Offset Calibration Limit

15

(1.05

×

V

REF

)/GAIN

V max

GAIN Is the Selected PGA Gain (1, 2, 32 or 128)

Input Span

15

0.8

×

V

REF

/GAIN

V min

GAIN Is the Selected PGA Gain (1, 2, 32 or 128)

(2.1

×

V

REF

)/GAIN

V max

GAIN Is the Selected PGA Gain (1, 2, 32 or 128)

POWER REQUIREMENTS

Power Supply Voltages

AV

DD

Voltage (AD7715-3)

+3 to +3.6

V

For Specified Performance

AV

DD

Voltage (AD7715-5)

+4.75 to +5.25

V

For Specified Performance

DV

DD

Voltage

+3 to +5.25

V

For Specified Performance

Power Supply Currents

AV

DD

Current

AV

DD

= 3.3 V or 5 V. Gain = 1 to 128 (f

CLK IN

= 1 MHz) or

Gain = 1 or 2 (f

CLK IN

= 2.4576 MHz)

0.27

mA max

Typically 0.2 mA. BUF Bit of Setup Register = 0

0.6

mA max

Typically 0.4 mA. BUF Bit of Setup Register = 1

AV

DD

= 3.3 V or 5 V. Gain = 32 or 128 (f

CLK IN

= 2.4576 MHz)

16

0.5

mA max

Typically 0.3 mA. BUF Bit of Setup Register = 0

1.1

mA max

Typically 0.8 mA. BUF Bit of Setup Register = 1

DV

DD

Current

17

Digital I/Ps = 0 V or DV

DD

. External MCLK IN

0.18

mA max

Typically 0.15 mA. DV

DD

= 3.3 V. f

CLK IN

= 1 MHz

0.4

mA max

Typically 0.3 mA. DV

DD

= 5 V. f

CLK IN

= 1 MHz

0.5

mA max

Typically 0.4 mA. DV

DD

= 3.3 V. f

CLK IN

= 2.4576 MHz

0.8

mA max

Typically 0.6 mA. DV

DD

= 5 V. f

CLK IN

= 2.4576 MHz

Power Supply Rejection

18

See Note 19

dB typ

Normal-Mode Power Dissipation

17

AV

DD

= DV

DD

= +3.3 V. Digital I/Ps = 0 V or DV

DD

. External MCLK IN

1.5

mW max

BUF Bit = 0. All Gains 1 MHz Clock

2.65

mW max

BUF Bit = 1. All Gains 1 MHz Clock

3.3

mW max

BUF Bit = 0. Gain = 32 or 128 @ f

CLK IN

= 2.4576 MHz

5.3

mW max

BUF Bit = 1. Gain = 32 or 128 @ f

CLK IN

= 2.4576 MHz

Normal-Mode Power Dissipation

17

AV

DD

= DV

DD

= +5 V. Digital I/Ps = 0 V or DV

DD

. External MCLK IN

3.25

mW max

BUF Bit = 0. All Gains 1 MHz Clock

5

mW max

BUF Bit = 1. All Gains 1 MHz Clock

6.5

mW max

BUF Bit = 0. Gain = 32 or 128 @ f

CLK IN

= 2.4576 MHz

9.5

mW max

BUF Bit = 1. Gain = 32 or 128 @ f

CLK IN

= 2.4576 MHz

Standby (Power-Down) Current

20

20

µ

A max

External MCLK IN = 0 V or DV

DD

. Typically 10

µ

A. V

DD

= +5 V

Standby (Power-Down) Current

20

10

µ

A max

External MCLK IN = 0 V or DV

DD

. Typically 5

µ

A. V

DD

= +3.3 V

NOTES

1

Temperature Range as follows: A Version, 40

°

C to +85

°

C.

2

A calibration is effectively a conversion so these errors will be of the order of the conversion noise shown in Tables V to XII. This applies after calibration at the

temperature of interest.

3

Recalibration at any temperature will remove these drift errors.

4

Positive Full-Scale Error includes Zero-Scale Errors (Unipolar Offset Error or Bipolar Zero Error) and applies to both unipolar and bipolar input ranges.

5

Full-Scale Drift includes Zero-Scale Drift (Unipolar Offset Drift or Bipolar Zero Drift) and applies to both unipolar and bipolar input ranges.

6

Gain Error does not include Zero-Scale Errors. It is calculated as Full-Scale ErrorUnipolar Offset Error for unipolar ranges and Full-Scale ErrorBipolar Zero Error

for bipolar ranges.

7

Gain Error Drift does not include Unipolar Offset Drift/Bipolar Zero Drift. It is effectively the drift of the part if zero scale calibrations only were performed.

8

These numbers are guaranteed by design and/or characterization.

9

This common-mode voltage range is allowed provided that the input voltage on AIN(+) or AIN() does not go more positive than A V

DD

+ 30 mV or go more nega-

tive than AGND 30 mV.

10

The analog input voltage range on AIN(+) is given here with respect to the voltage on AIN(). The absolute voltage on the analog inputs should not go more posi-

tive than AV

DD

+ 30 mV or go more negative than AGND 30 mV.

11

V

REF

= REF IN(+) REF IN().

12

These logic output levels apply to the MCLK OUT only when it is loaded with one CMOS load.

13

Sample tested at +25

°

C to ensure compliance.

14

After calibration, if the analog input exceeds positive full scale, the converter will output all 1s. If the analog input is less than negative full scale, then the device will

output all 0s.

15

These calibration and span limits apply provided the absolute voltage on the analog inputs does not exceed AV

DD

+ 30 mV or go more negative than AGND

30 mV. The offset calibration limit applies to both the unipolar zero point and the bipolar zero point.

16

Assumes CLK Bit of Setup Register is set to correct status corresponding to the master clock frequency.

17

When using a crystal or ceramic resonator across the MCLK pins as the clock source for the device, the DV

DD

current and power dissipation will vary depending on

the crystal or resonator type (see Clocking and Oscillator Circuit section).

18

Measured at dc and applies in the selected passband. PSRR at 50 Hz will exceed 120 dB with filter notches of 25 Hz or 50 Hz. PSRR at 60 Hz will exceed 120 dB

with filter notches of 20 Hz or 60 Hz.

19

PSRR depends on gain. Gain of 1: 85 dB typ; Gain of 2: 90 dB typ; Gains of 32 and 128: 95 dB typ.

20

If the external master clock continues to run in standby mode, the standby current increases to 50

µ

A typical. When using a crystal or ceramic resonator across the

MCLK pins as the clock source for the device, the internal oscillator continues to run in standby mode and the power dissipation depends on the crystal or

resonator type (see Standby Mode section).

Specifications subject to change without notice.

AD7715SPECIFICATIONS

A (AV

DD

= +3 V to +5 V, DV

DD

= +3 V to +5 V, REF IN(+) = +1.25 V (AD7715-3) or +2.5 V

(AD7715-5); REF IN() = AGND; MCLK IN = 1 MHz to 2.4576 MHz unless otherwise noted. All specifications T

MIN

to T

MAX

unless otherwise noted.)

4

REV. C

AD7715

5

REV. C

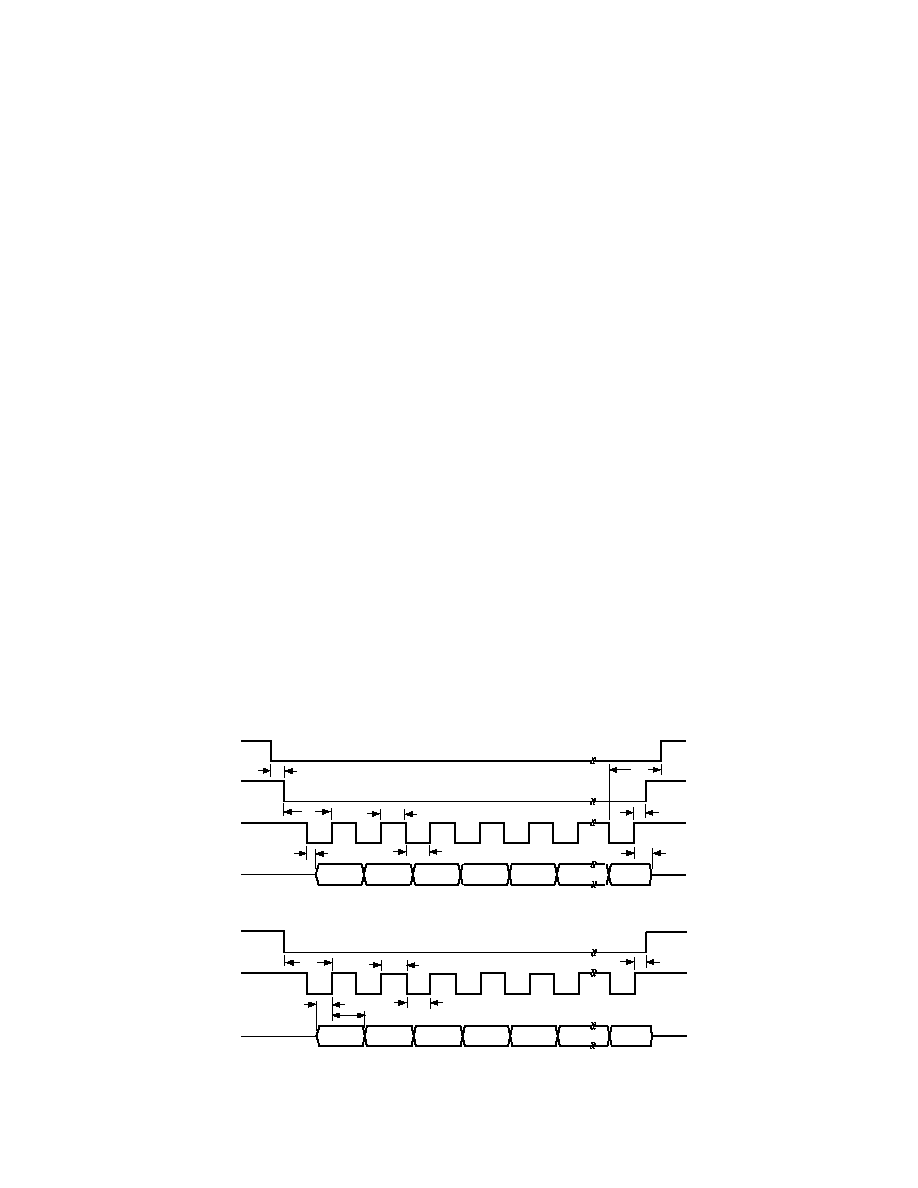

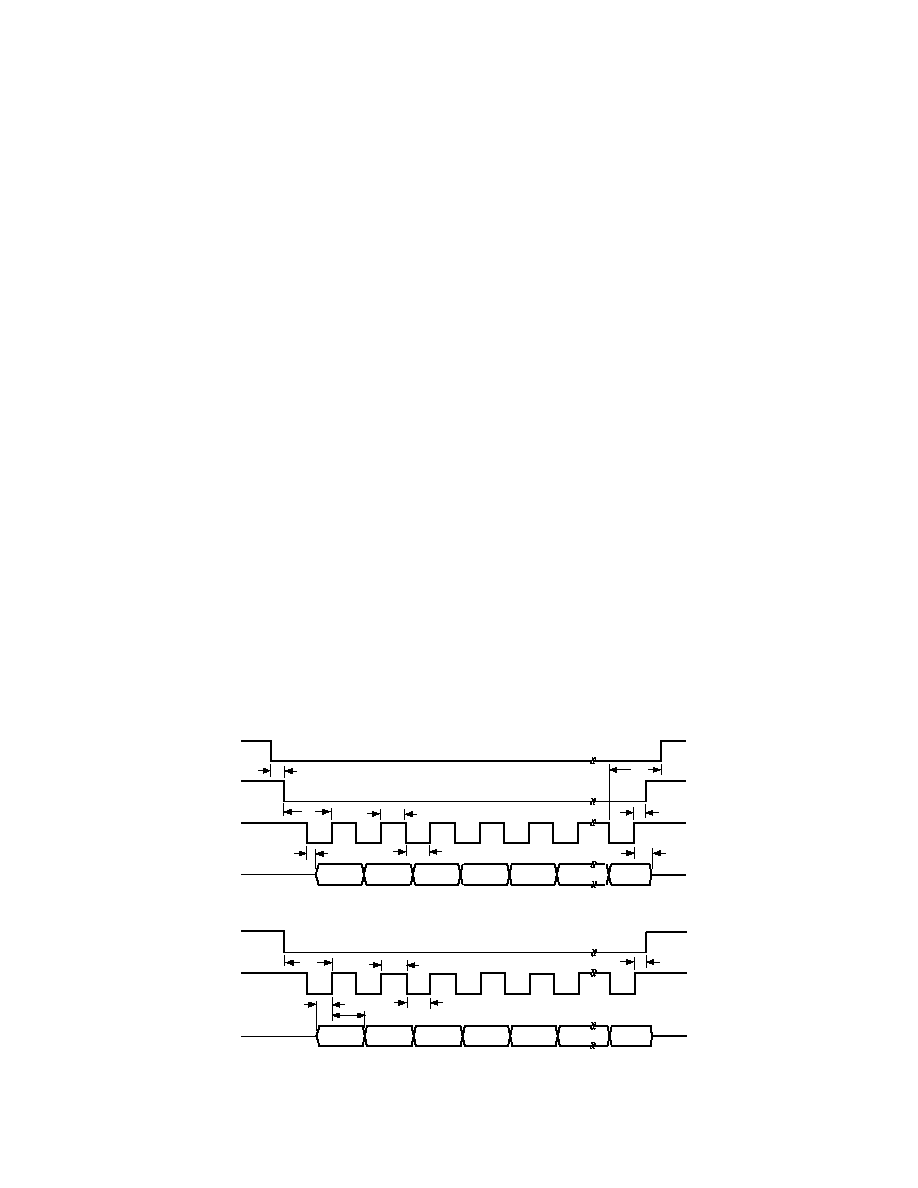

TIMING CHARACTERISTICS

1, 2

Limit at T

MIN

, T

MAX

Parameter

(A Version)

Unit

Conditions/Comments

f

CLKIN

3, 4

400

kHz min

Master Clock Frequency: Crystal Oscillator or Externally Supplied

2.5

MHz max

for Specified Performance

t

CLK IN LO

0.4

×

t

CLK IN

ns min

Master Clock Input Low Time. t

CLK IN

= 1/f

CLK IN

t

CLK IN HI

0.4

×

t

CLK IN

ns min

Master Clock Input High Time

t

1

500

×

t

CLK IN

ns nom

DRDY High Time

t

2

100

ns min

RESET Pulsewidth

Read Operation

t

3

0

ns min

DRDY to CS Setup Time

t

4

120

ns min

CS Falling Edge to SCLK Rising Edge Setup Time

t

5

5

0

ns min

SCLK Falling Edge to Data Valid Delay

80

ns max

DV

DD

= +5 V

100

ns max

DV

DD

= +3.3 V

t

6

100

ns min

SCLK High Pulsewidth

t

7

100

ns min

SCLK Low Pulsewidth

t

8

0

ns min

CS Rising Edge to SCLK Rising Edge Hold Time

t

9

6

10

ns min

Bus Relinquish Time after SCLK Rising Edge

60

ns max

DV

DD

= +5 V

100

ns max

DV

DD

= +3.3 V

t

10

100

ns max

SCLK Falling Edge to

DRDY High

7

Write Operation

t

11

120

ns min

CS Falling Edge to SCLK Rising Edge Setup Time

t

12

30

ns min

Data Valid to SCLK Rising Edge Setup Time

t

13

20

ns min

Data Valid to SCLK Rising Edge Hold Time

t

14

100

ns min

SCLK High Pulsewidth

t

15

100

ns min

SCLK Low Pulsewidth

t

16

0

ns min

CS Rising Edge to SCLK Rising Edge Hold Time

NOTES

1

Sample tested at +25

°

C to ensure compliance. All input signals are specified with tr = tf = 5 ns (10% to 90% of D V

DD

) and timed from a voltage level of 1.6 V.

2

See Figures 6 and 7.

3

CLKIN Duty Cycle range is 45% to 55%. CLKIN must be supplied whenever the AD7715 is not in Standby mode. If no clock is present in this case, the

device can draw higher current than specified and possibly become uncalibrated.

4

The AD7715 is production tested with f

CLKIN

at 2.4576 MHz (1 MHz for some I

DD

tests). It is guaranteed by characterization to operate at 400 kHz.

5

These numbers are measured with the load circuit of Figure 1 and defined as the time required for the output to cross the V

OL

or V

OH

limits.

6

These numbers are derived from the measured time taken by the data output to change 0.5 V when loaded with the circuit of Figure 1. The measured number is

then extrapolated back to remove effects of charging or discharging the 50 pF capacitor. This means that the times quoted in the timing characteristics are the

true bus relinquish times of the part and as such are independent of external bus loading capacitances.

7

DRDY returns high after the first read from the device after an output update. The same data can be read again, if required, while DRDY is high although care

should be taken that subsequent reads do not occur close to the next output update.

Specifications subject to change without notice.

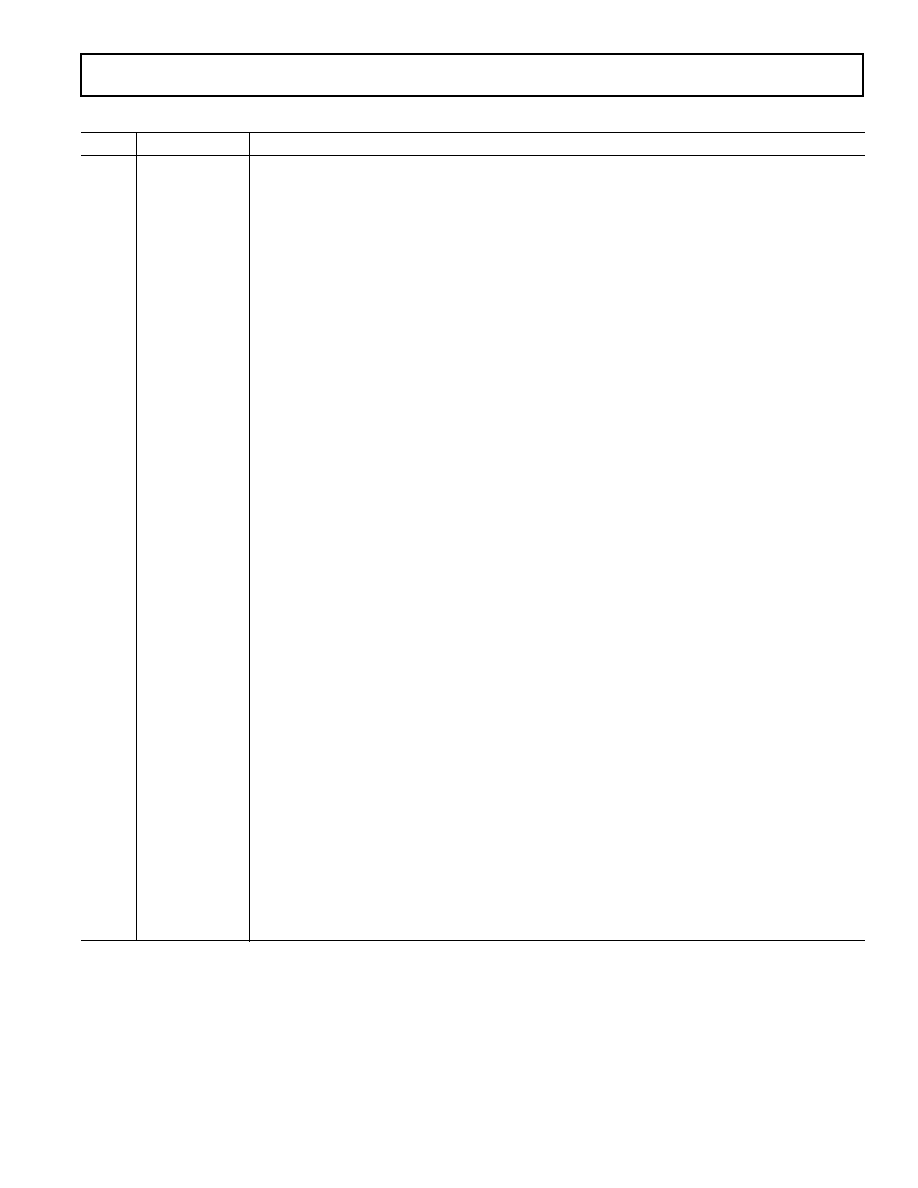

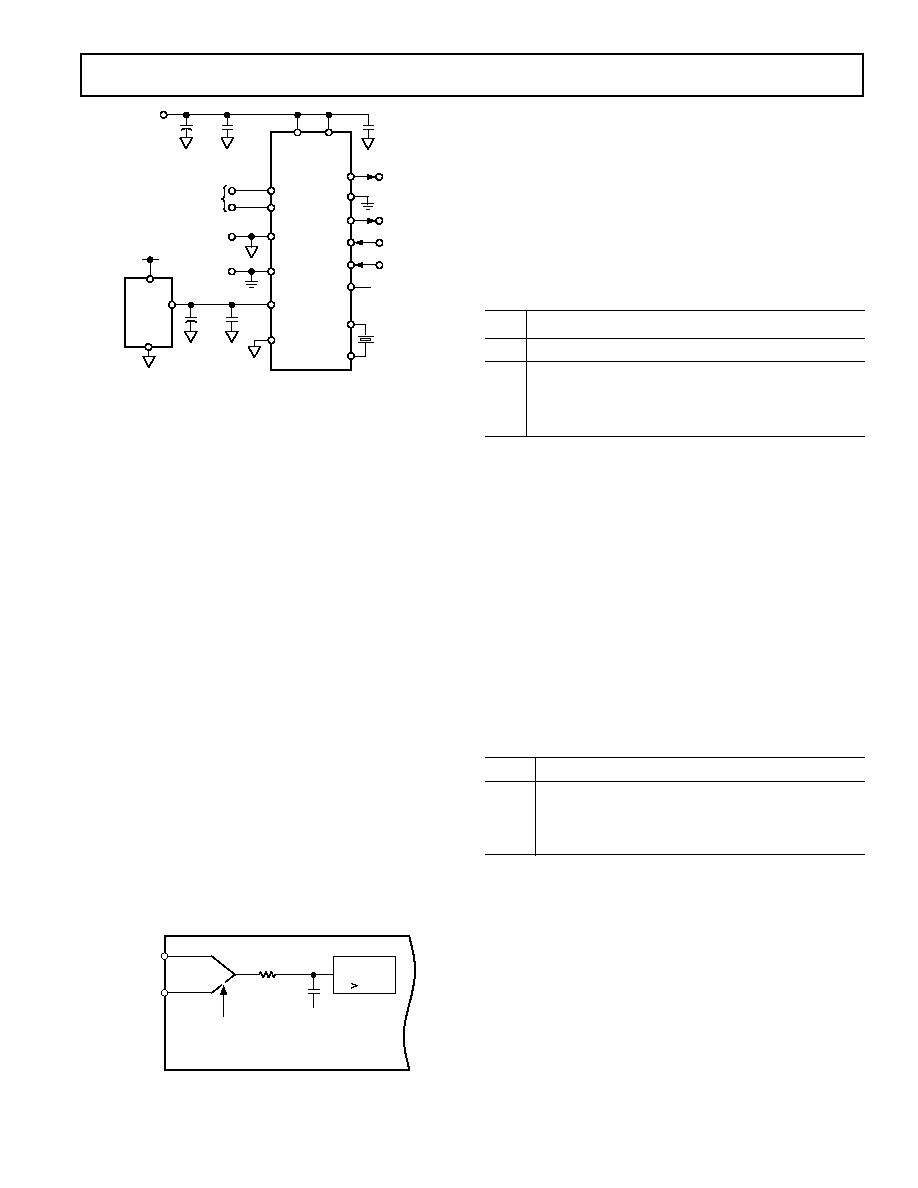

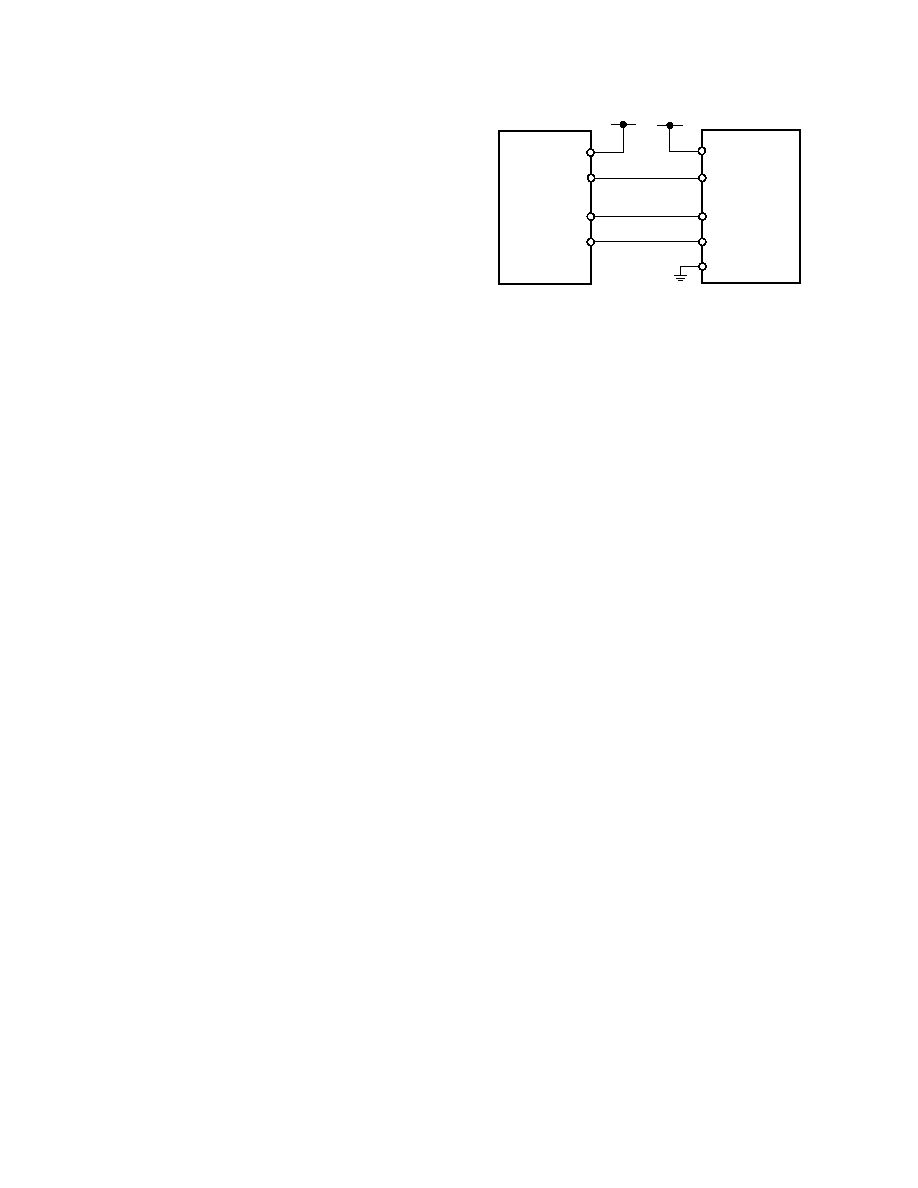

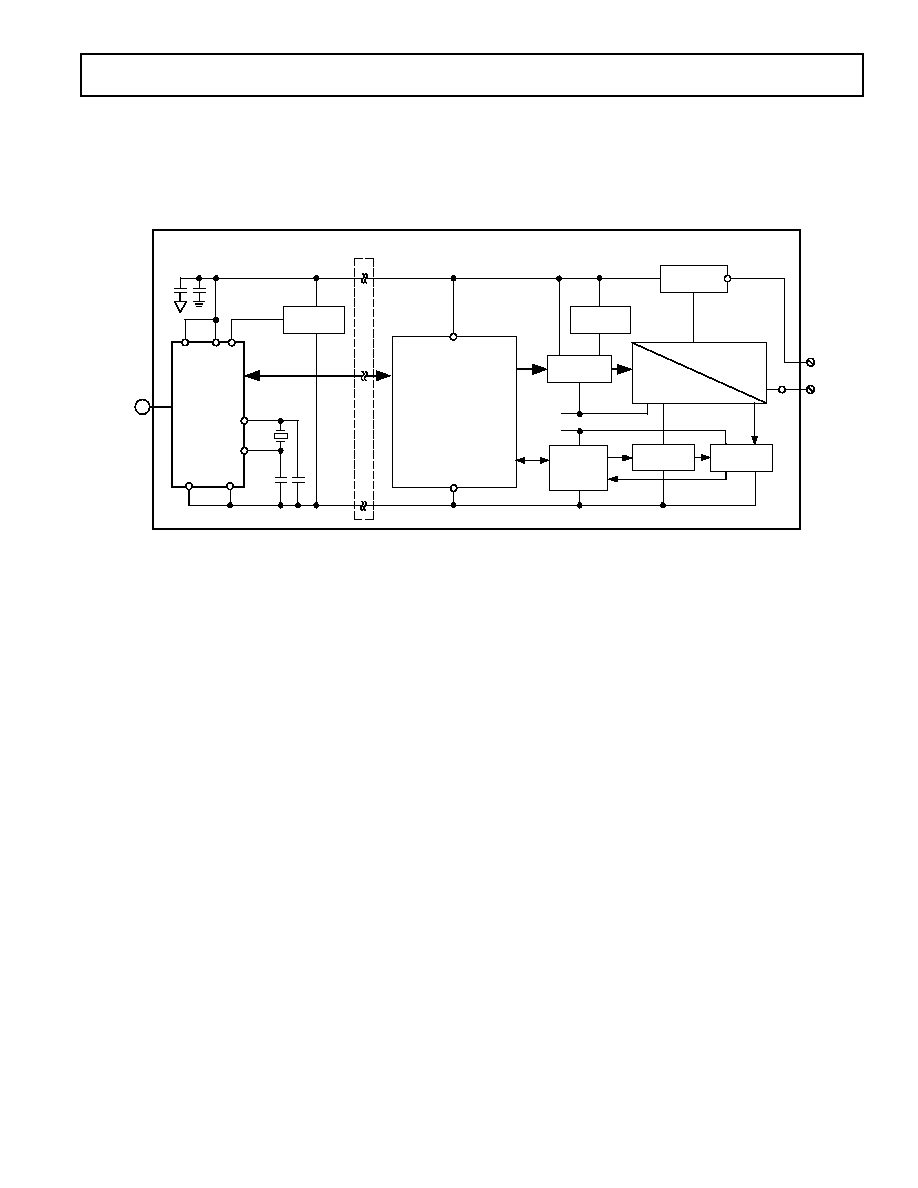

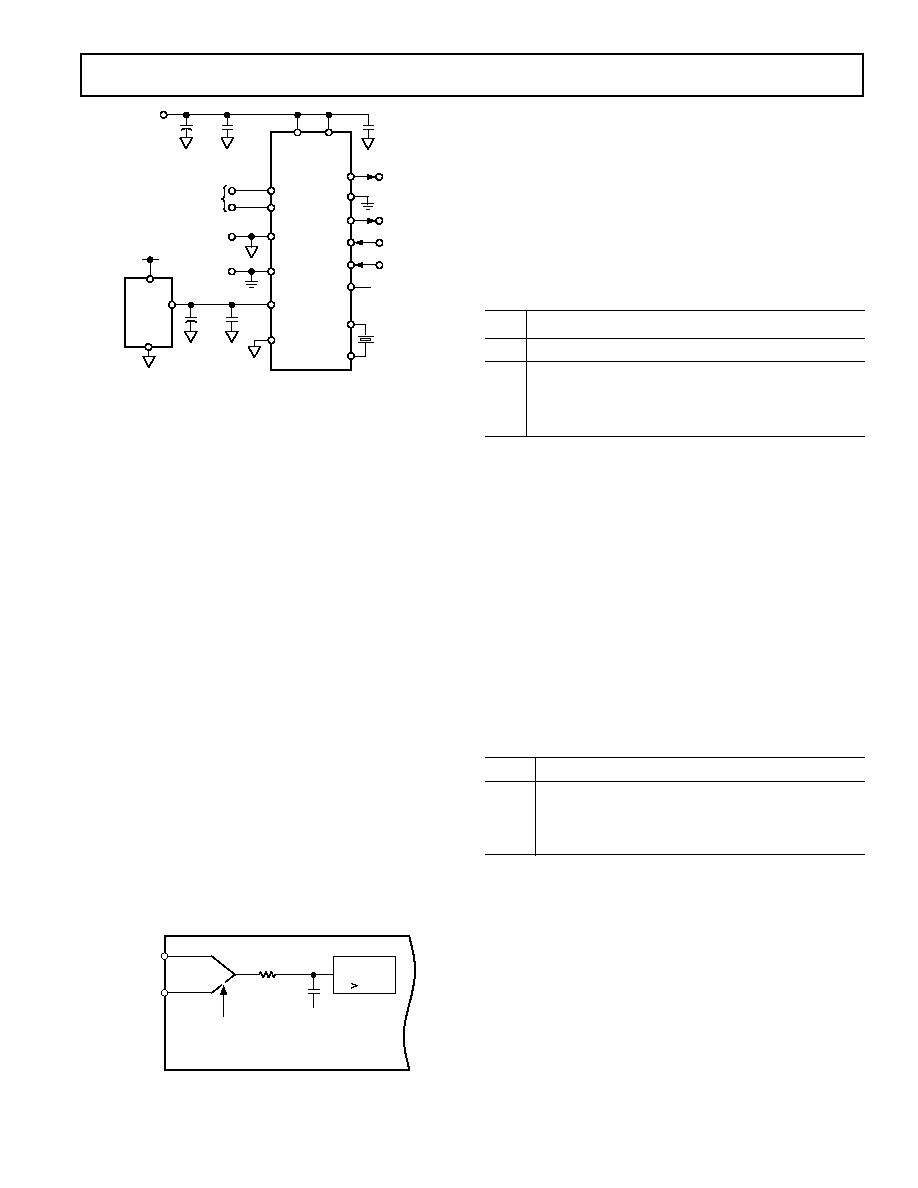

TO

OUTPUT

PIN

+1.6V

I

SINK

(800 A AT DV

DD

= 5V

100 A AT DV

DD

= 3.3V)

50pF

I

SOURCE

(200 A AT DV

DD

= 5V

100 A AT DV

DD

= 3.3V)

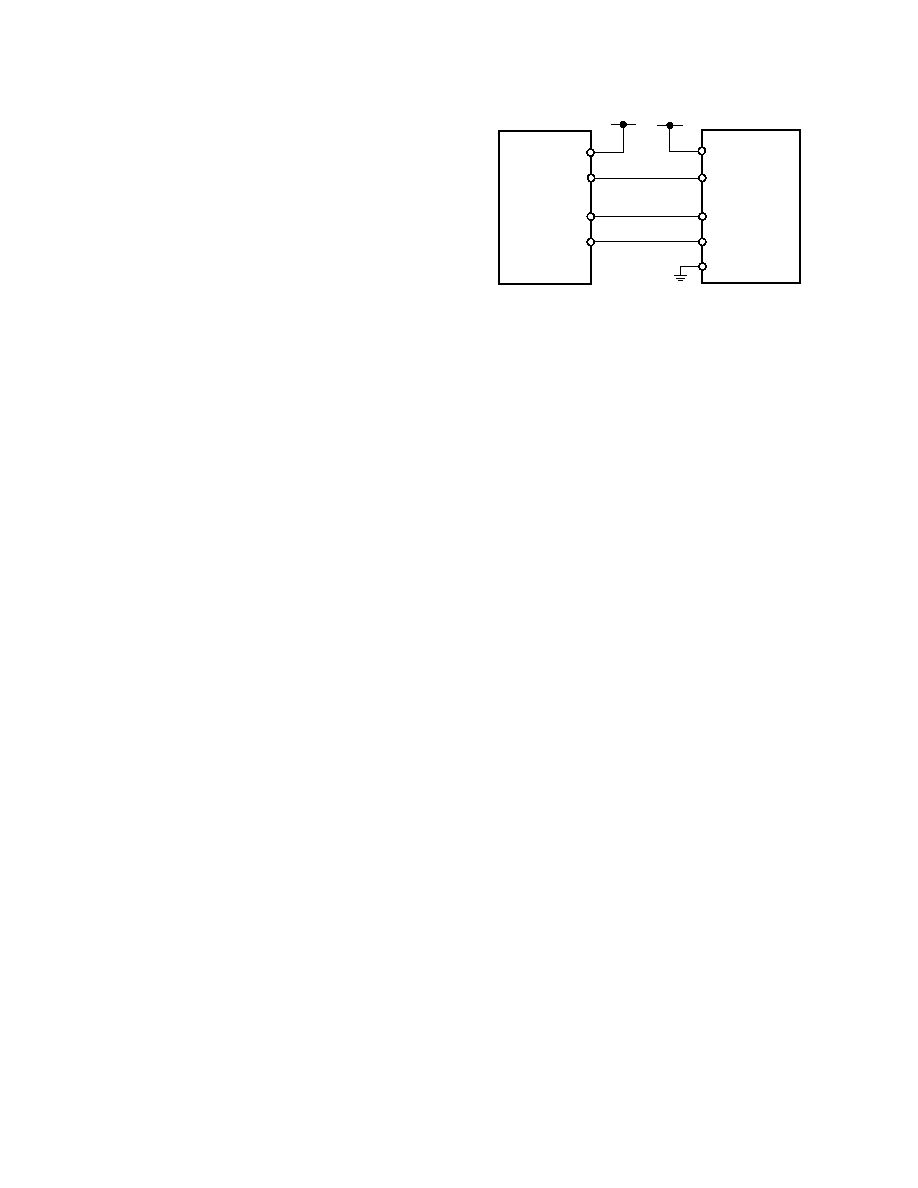

Figure 1. Load Circuit for Access Time and Bus Relinquish Time

(DV

DD

= +3 V to +5.25 V; AV

DD

= +3 V to +5.25 V; AGND = DGND = 0 V; f

CLKIN

= 2.4576 MHz;

Input Logic 0 = 0 V, Logic 1 = DV

DD

, unless otherwise noted)

REV. C

AD7715

6

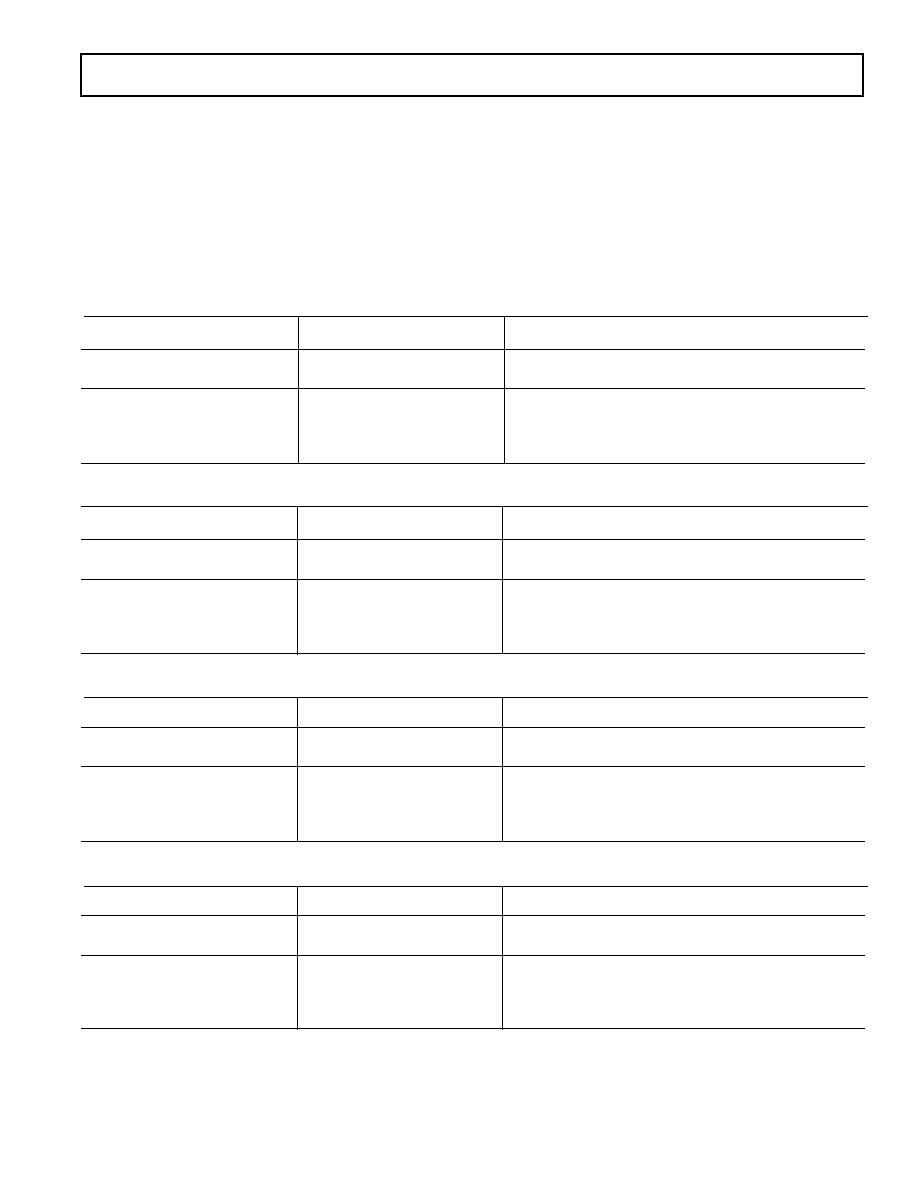

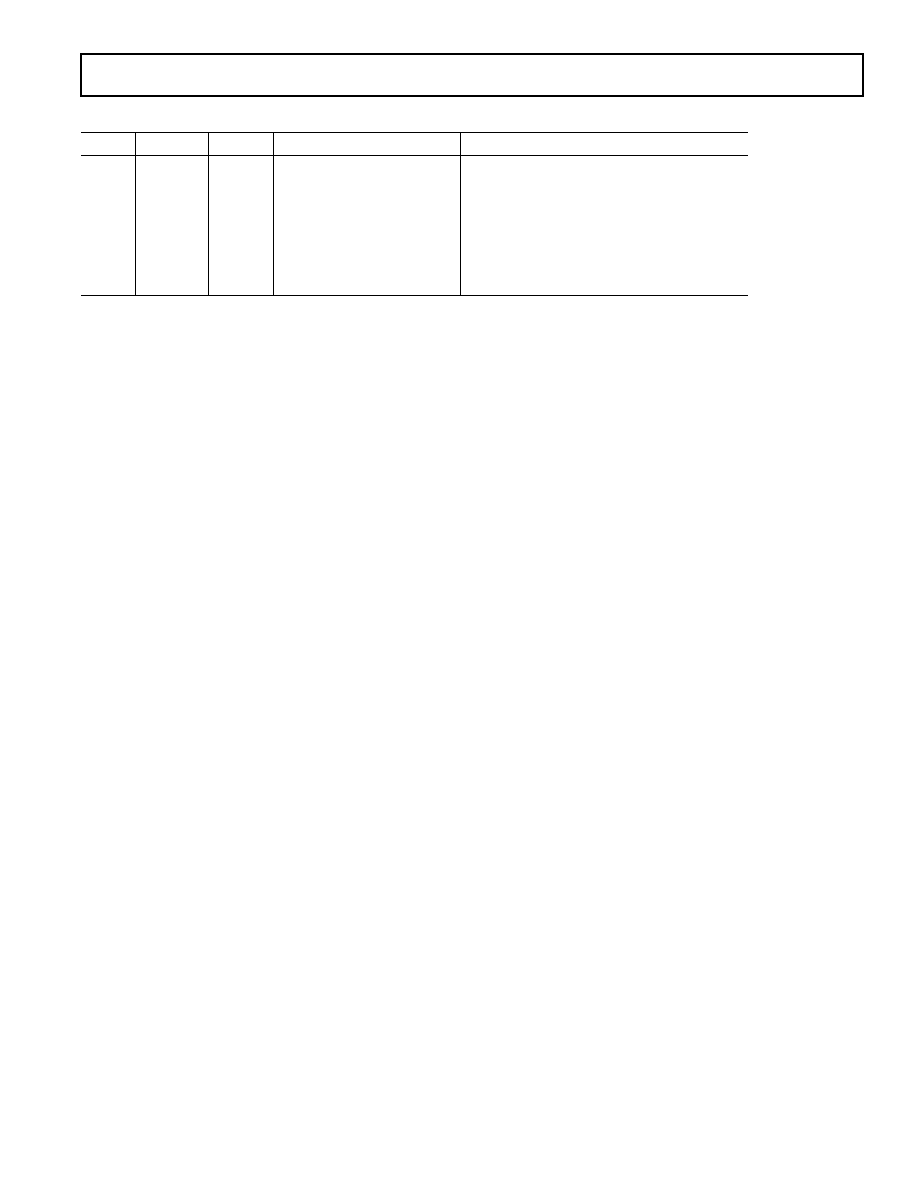

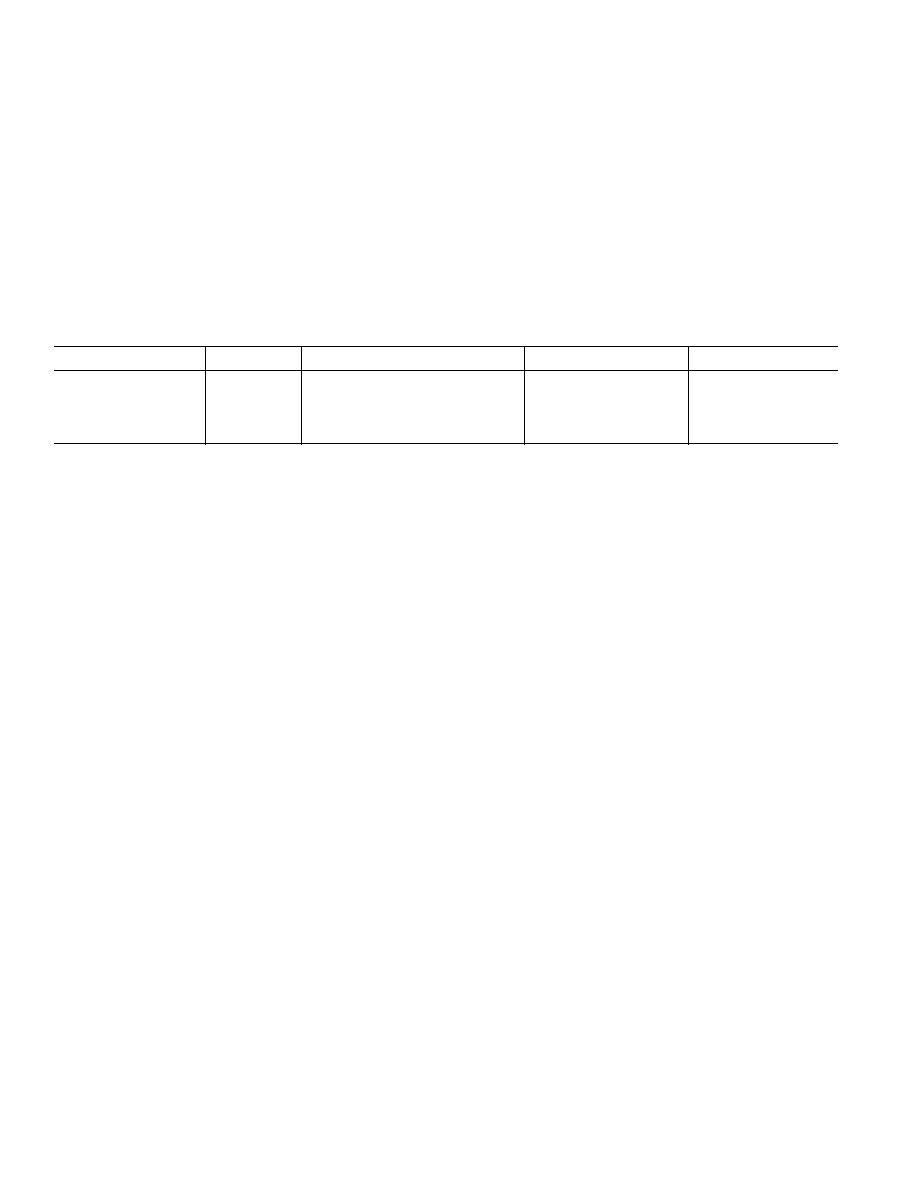

ORDERING GUIDE

AV

DD

Temperature

Package

Model

Supply

Range

Options*

AD7715AN-5

5 V

40

°

C to +85

°

C

N-16

AD7715AR-5

5 V

40

°

C to +85

°

C

R-16

AD7715ARU-5

5 V

40

°

C to +85

°

C

RU-16

AD7715AN-3

3 V

40

°

C to +85

°

C

N-16

AD7715AR-3

3 V

40

°

C to +85

°

C

R-16

AD7715ARU-3

3 V

40

°

C to +85

°

C

RU-16

AD7715AChips-5

5 V

40

°

C to +85

°

C

Die

AD7715AChips-3

3 V

40

°

C to +85

°

C

Die

EVAL-AD7715-5EB

5 V

Evaluation Board

EVAL-AD7715-3EB

3 V

Evaluation Board

*N = Plastic DIP; R = SOIC RU = TSSOP.

ABSOLUTE MAXIMUM RATINGS*

(T

A

= +25

°

C unless otherwise noted)

AV

DD

to AGND . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

AV

DD

to DGND . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

AV

DD

to DV

DD

. . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

DV

DD

to AGND . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

DV

DD

to DGND . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

DGND to AGND . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to +7 V

Analog Input Voltage to AGND . . . . . 0.3 V to AV

DD

+ 0.3 V

Reference Input Voltage to AGND . . . 0.3 V to AV

DD

+ 0.3 V

Digital Input Voltage to DGND . . . . . 0.3 V to DV

DD

+ 0.3 V

Digital Output Voltage to DGND . . . . 0.3 V to DV

DD

+ 0.3 V

Operating Temperature Range

Commercial (A Version) . . . . . . . . . . . . . . . 40

°

C to +85

°

C

Storage Temperature Range . . . . . . . . . . . . . 65

°

C to +150

°

C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +150

°

C

Plastic DIP Package, Power Dissipation . . . . . . . . . . . 450 mW

JA

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 105

°

C/W

Lead Temperature, (Soldering, 10 sec) . . . . . . . . . . +260

°

C

SOIC Package, Power Dissipation . . . . . . . . . . . . . . . . 450 mW

JA

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . 75

°

C/W

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . +215

°

C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . +220

°

C

TSSOP Package, Power Dissipation . . . . . . . . . . . . . . 450 mW

JA

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . 128

°

C/W

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . +215

°

C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . +220

°

C

Power Dissipation (Any Package) to +75

°

C . . . . . . . . 450 mW

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . >4000 V

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

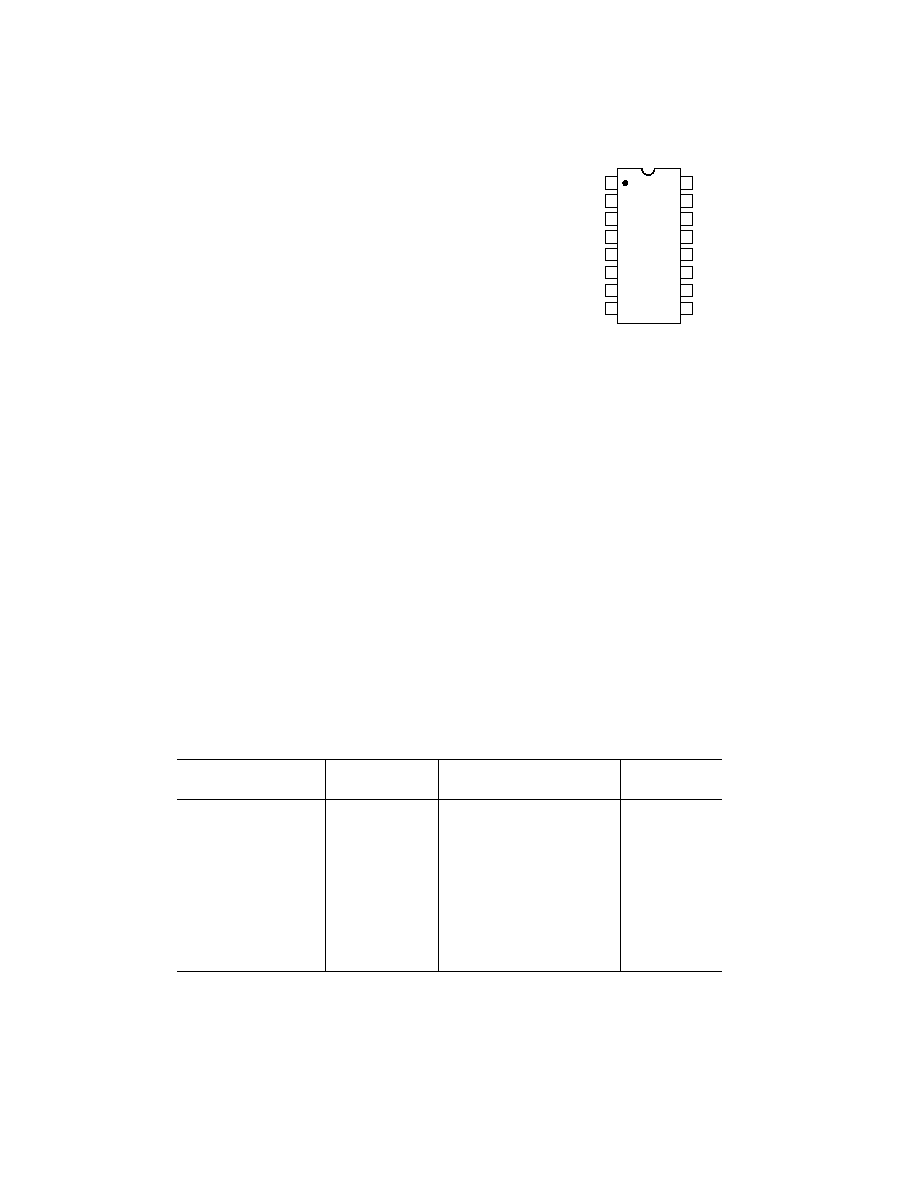

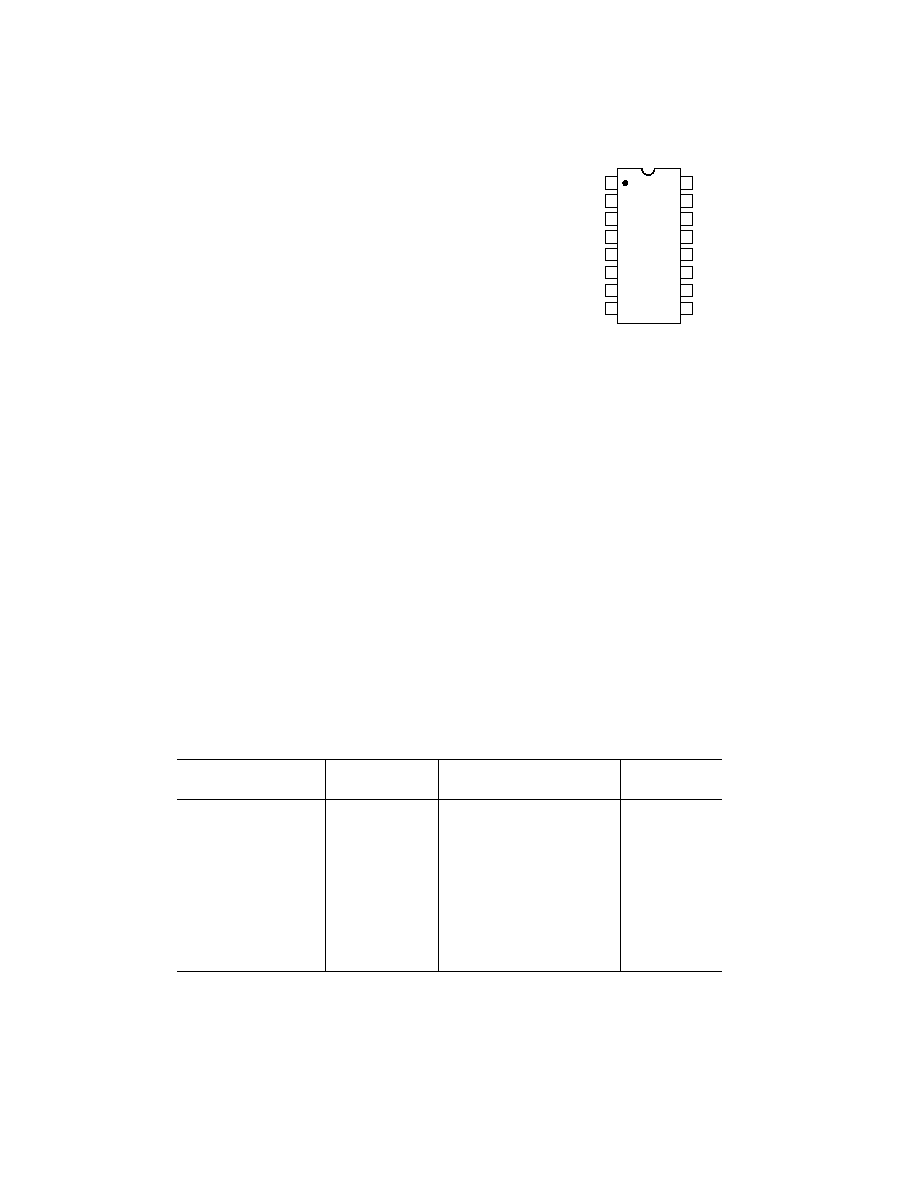

PIN CONFIGURATION

DIP, SOIC and TSSOP

14

13

12

11

16

15

10

9

8

1

2

3

4

7

6

5

TOP VIEW

(Not to Scale)

AD7715

SCLK

DOUT

DIN

DV

DD

DGND

MCLK IN

MCLK OUT

CS

REF IN(+)

AGND

DRDY

RESET

AV

DD

AIN(+)

AIN()

REF IN()

AD7715

7

REV. C

PIN FUNCTION DESCRIPTION

Pin No.

Mnemonic

Function

1

SCLK

Serial Clock. Logic Input. An external serial clock is applied to this input to access serial data from

the AD7715. This serial clock can be a continuous clock with all data transmitted in a continuous

train of pulses. Alternatively, it can be a noncontinuous clock with the information being transmit-

ted to the AD7715 in smaller batches of data.

2

MCLK IN

Master Clock signal for the device. This can be provided in the form of a crystal/resonator or exter-

nal clock. A crystal/resonator can be tied across the MCLK IN and MCLK OUT pins. Alterna-

tively, the MCLK IN pin can be driven with a CMOS-compatible clock and MCLK OUT left

unconnected. The part is specified with clock input frequencies of both 1 MHz and 2.4576 MHz.

3

MCLK OUT

When the master clock for the device is a crystal/resonator, the crystal/resonator is connected be-

tween MCLK IN and MCLK OUT. If an external clock is applied to MCLK IN, MCLK OUT

provides an inverted clock signal. This clock can be used to provide a clock source for external

circuitry.

4

CS

Chip Select. Active low Logic Input used to select the AD7715. With this input hardwired low, the

AD7715 can operate in its three-wire interface mode with SCLK, DIN and DOUT used to inter-

face to the device.

CS can be used to select the device in systems with more than one device on the

serial bus or as a frame synchronization signal in communicating with the AD7715.

5

RESET

Logic Input. Active low input which resets the control logic, interface logic, calibration coefficients,

digital filter and analog modulator of the part to power-on status.

6

AV

DD

Analog Positive Supply Voltage, +3.3 V nominal (AD7715-3) or +5 V nominal (AD7715-5).

7

AIN(+)

Analog Input. Positive input of the programmable gain differential analog input to the AD7715.

8

AIN()

Analog Input. Negative input of the programmable gain differential analog input to the AD7715.

9

REF IN(+)

Reference Input. Positive input of the differential reference input to the AD7715. The reference

input is differential with the provision that REF IN(+) must be greater than REF IN().

REF IN(+) can lie anywhere between AV

DD

and AGND.

10

REF IN()

Reference Input. Negative input of the differential reference input to the AD7715. The REF IN()

can lie anywhere between AV

DD

and AGND provided REF IN(+) is greater than REF IN().

11

AGND

Ground reference point for analog circuitry. For correct operation of the AD7715, no voltage on

any of the other pins should go more than 30 mV negative with respect to AGND.

12

DRDY

Logic Output. A logic low on this output indicates that a new output word is available from the

AD7715 data register. The

DRDY pin will return high upon completion of a read operation of a full

output word. If no data read has taken place between output updates, the

DRDY line will return

high for 500

×

t

CLK IN

cycles prior to the next output update. While

DRDY is high, a read operation

should not be attempted or in progress to avoid reading from the data register as it is being updated.

The

DRDY line will return low again when the update has taken place. DRDY is also used to indi-

cate when the AD7715 has completed its on-chip calibration sequence.

13

DOUT

Serial Data Output with serial data being read from the output shift register on the part. This output

shift register can contain information from the setup register, communications register or data regis-

ter depending on the register selection bits of the Communications Register.

14

DIN

Serial Data Input with serial data being written to the input shift register on the part. Data from this

input shift register is transferred to the setup register or communications register depending on the

register selection bits of the Communications Register.

15

DV

DD

Digital Supply Voltage, +3.3 V or +5 V nominal.

16

DGND

Ground reference point for digital circuitry.

REV. C

AD7715

8

TERMINOLOGY

Integral Nonlinearity

This is the maximum deviation of any code from a straight line

passing through the endpoints of the transfer function. The end-

points of the transfer function are Zero-Scale (not to be confused

with Bipolar Zero), a point 0.5 LSB below the first code transition

(000 . . . 000 to 000 . . . 001) and Full-Scale, a point 0.5 LSB

above the last code transition (111 . . . 110 to 111 . . . 111). The

error is expressed as a percentage of full scale.

Positive Full-Scale Error

Positive Full-Scale Error is the deviation of the last code transi-

tion (111 . . . 110 to 111 . . . 111) from the ideal AIN(+) voltage

(AIN() + V

REF

/GAIN 3/2 LSBs). It applies to both unipolar

and bipolar analog input ranges.

Unipolar Offset Error

Unipolar Offset Error is the deviation of the first code transition

from the ideal AIN(+) voltage (AIN() + 0.5 LSB) when oper-

ating in the unipolar mode.

Bipolar Zero Error

This is the deviation of the midscale transition (0111 . . . 111

to 1000 . . . 000) from the ideal AIN(+) voltage (AIN()

0.5 LSB) when operating in the bipolar mode.

Gain Error

This is a measure of the span error of the ADC. It includes full-

scale errors but not zero-scale errors. For unipolar input ranges

it is defined as (full scale errorunipolar offset error) while for

bipolar input ranges it is defined as (full-scale errorbipolar zero

error).

Bipolar Negative Full-Scale Error

This is the deviation of the first code transition from the ideal

AIN(+) voltage (AIN() V

REF

/GAIN + 0.5 LSB), when oper-

ating in the bipolar mode.

Positive Full-Scale Overrange

Positive full-scale overrange is the amount of overhead available

to handle input voltages on AIN(+) input greater than AIN() +

V

REF

/GAIN (for example, noise peaks or excess voltages due to

system gain errors in system calibration routines) without intro-

ducing errors due to overloading the analog modulator or over-

flowing the digital filter.

Negative Full-Scale Overrange

This is the amount of overhead available to handle voltages on

AIN(+) below AIN() V

REF

/GAIN without overloading the

analog modulator or overflowing the digital filter. Note that the

analog input will accept negative voltage peaks even in the uni-

polar mode provided that AIN(+) is greater than AIN() and

greater than AGND 30 mV.

Offset Calibration Range

In the system calibration modes, the AD7715 calibrates its

offset with respect to the analog input. The offset calibration

range specification defines the range of voltages that the

AD7715 can accept and still calibrate offset accurately.

Full-Scale Calibration Range

This is the range of voltages that the AD7715 can accept in the

system calibration mode and still calibrate full scale correctly.

Input Span

In system calibration schemes, two voltages applied in sequence

to the AD7715's analog input define the analog input range.

The input span specification defines the minimum and maxi-

mum input voltages from zero to full scale that the AD7715 can

accept and still calibrate gain accurately.

ON-CHIP REGISTERS

The part contains four on-chip registers which can be accessed by via the serial port on the part. The first of these is a Communica-

tions Register that decides whether the next operation is a read or write operation and also decides which register the read or write

operation accesses. All communications to the part must start with a write operation to the Communications Register. After power-

on or RESET, the device expects a write to its Communications Register. The data written to this register determines whether the

next operation to the part is a write or a read operation and also determines to which register this read or write operation occurs.

Therefore, write access to any of the other registers on the part starts with a write operation to the Communications Register fol-

lowed by a write to the selected register. A read operation from any register on the part (including the Communications Register itself

and the output data register) starts with a write operation to the Communications Register followed by a read operation from the

selected register. The Communication Register also controls the standby mode and the operating gain of the part. The

DRDY status

is also available by reading from the Communications Register. The second register is a Setup Register that determines calibration

modes, filter selection and bipolar/unipolar operation. The third register is the Data Register from which the output data from the

part is accessed. The final register is a Test Register that is accessed when testing the device. It is advised that the user does not

attempt to access or change the contents of the test register as it may lead to unspecified operation of the device. The registers are

discussed in more detail in the following sections.

AD7715

9

REV. C

Communications Register (RS1, RS0 = 0, 0)

The Communications Register is an eight-bit register from which data can either be read or to which data can be written. All com-

munications to the part must start with a write operation to the Communications Register. The data written to the Communications

Register determines whether the next operation is a read or write operation and to which register this operation takes place. Once the

subsequent read or write operation to the selected register is complete, the interface returns to where it expects a write operation to

the Communications Register. This is the default state of the interface, and on power-up or after a

RESET, the AD7715 is in this

default state waiting for a write operation to the Communications Register. In situations where the interface sequence is lost, if a

write operation to the device of sufficient duration (containing at least 32 serial clock cycles) takes place with DIN high, the AD7715

returns to this default state. Table I outlines the bit designations for the Communications Register.

Table I. Communications Register

0/

DRDY

ZERO

RS1

RS0

R/

W

STBY

G1

G0

0/

DRDY

For a write operation, a 0 must be written to this bit so that the write operation to the Communications Reg-

ister actually takes place. If a 1 is written to this bit, the part will not clock on to subsequent bits in the regis-

ter. It will stay at this bit location until a 0 is written to this bit. Once a 0 is written to this bit, the next 7 bits

will be loaded to the Communications Register. For a read operation, this bit provides the status of the

DRDY flag from the part. The status of this bit is the same as the DRDY output pin.

ZERO

For a write operation, a 0 must be written to this bit for correct operation of the part. Failure to do this will

result in unspecified operation of the device. For a read operation, a 0 will be read back from this bit location.

RS1 RS0

Register Selection Bits. These bits select to which one of four on-chip registers the next read or write opera-

tion takes place as shown in Table II along with the register size. When the read or write to the selected regis-

ter is complete, the part returns to where it is waiting for a write operation to the Communications Register.

It does not remain in a state where it will continue to access the selected register.

R/

W

Read/Write Select. This bit selects whether the next operation is a read or write operation to the selected

register. A 0 indicates a write cycle as the next operation to the appropriate register, while a 1 indicates a read

operation from the appropriate register.

Table II. Register Selection

RS1

RS0

Register

Register Size

0

0

Communications Register

8 Bits

0

1

Setup Register

8 Bits

1

0

Test Register

8 Bits

1

1

Data Register

16 Bits

STBY

Standby. Writing a 1 to this bit puts the part in its standby or power-down mode. In this mode, the part

consumes only 10

µ

A of power supply current. The part retains its calibration and control word information

when in STANDBY. Writing a 0 to this bit places the part in its normal operating mode. The default value

for this bit after power-on or RESET is 0.

G2

G1

Gain Setting

0

0

1

0

1

2

1

0

32

1

1

128

REV. C

AD7715

10

Setup Register (RS1, RS0 = 0, 1); Power On/Reset Status: 28 Hex

The Setup Register is an eight-bit register from which data can either be read or to which data can be written. This register controls

the setup which the device is to operate in such as the calibration mode, output rate, unipolar/bipolar operation etc. Table III out-

lines the bit designations for the Setup Register.

Table III. Setup Register

MD1 MD0 CLK FS1 FS0

B/U BUF FSYNC

MD1

MD0

Operating Mode

0

0

Normal Mode; this is the normal mode of operation of the device whereby the device is performing normal

conversions. This is the default condition of these bits after Power-On or RESET.

0

1

Self-Calibration; this activates self-calibration on the part. This is a one step calibration sequence and when

complete the part returns to Normal Mode with MD1 and MD0 returning to 0, 0. The

DRDY output or bit

goes high when calibration is initiated and returns low when this self-calibration is complete and a new valid

word is available in the data register. The zero-scale calibration is performed at the selected gain on internally

shorted (zeroed) inputs and the full-scale calibration is performed at the selected gain on an internally

generated V

REF

/Selected Gain.

1

0

Zero-Scale System Calibration; this activates zero-scale system calibration on the part. Calibration is per-

formed at the selected gain on the input voltage provided at the analog input during this calibration sequence.

This input voltage should remain stable for the duration of the calibration. The

DRDY output or bit goes

high when calibration is initiated and returns low when this zero-scale calibration is complete and a new valid

word is available in the data register. At the end of the calibration, the part returns to Normal Mode with

MD1 and MD0 returning to 0, 0.

1

1

Full-Scale System Calibration; this activates full-scale system calibration on the part. Calibration is per-

formed at the selected gain on the input voltage provided at the analog input during this calibration sequence.

This input voltage should remain stable for the duration of the calibration. Once again, the

DRDY output or

bit goes high when calibration is initiated and returns low when this full-scale calibration is complete and a

new valid word is available in the data register. At the end of the calibration, the part returns to Normal

Mode with MD1 and MD0 returning to 0, 0.

CLK

Clock Bit. This bit should be set in accordance with the operating frequency of the AD7715. If the device has

a master clock frequency of 2.4576 MHz, then this bit should be set to a 1. If the device has a master clock

frequency of 1 MHz, then this bit should be set to a 0. This bit sets up the correct scaling currents for a given

master clock and also chooses (along with FS1 and FS0) the output update rate for the device. If this bit is

not set correctly for the master clock frequency of the device, then the device may not operate to specifica-

tion. The default value for this bit after power-on or RESET is 1.

FS1, FS0

Filter Selection Bits. Along with the CLK bit, FS1 and FS0 determine the output update rate, filter first

notch and 3 dB frequency as outlined in Table IV. The on-chip digital filter provides a Sinc

3

(or (Sinx/x)

3

)

filter response. In association with the gain selection, it also determines the output noise (and hence the

resolution) of the device. Changing the filter notch frequency, as well as the selected gain, impacts resolution.

Tables V through XII show the effect of the filter notch frequency and gain on the output noise and effective

resolution of the part. The output data rate (or effective conversion time) for the device is equal to the fre-

quency selected for the first notch of the filter. For example, if the first notch of the filter is selected at 50 Hz

then a new word is available at a 50 Hz rate or every 20 ms. If the first notch is at 500 Hz, a new word is

available every 2 ms. The default value for these bits is 1, 0.

The settling-time of the filter to a full-scale step input change is worst case 4

×

1/(output data rate). For

example, with the first filter notch at 50 Hz, the settling time of the filter to a full-scale step input change is

80 ms max. If the first notch is at 500 Hz, the settling time of the filter to a full-scale input step is 8 ms max.

This settling-time can be reduced to 3

×

1/(output data rate) by synchronizing the step input change to a

reset of the digital filter. In other words, if the step input takes place with the FSYNC bit high, the settling-

time time will be 3

×

1/(output data rate) from when FSYNC returns low.

The 3 dB frequency is determined by the programmed first notch frequency according to the relationship:

filter 3 dB frequency = 0.262

×

filter first notch frequency.

AD7715

11

REV. C

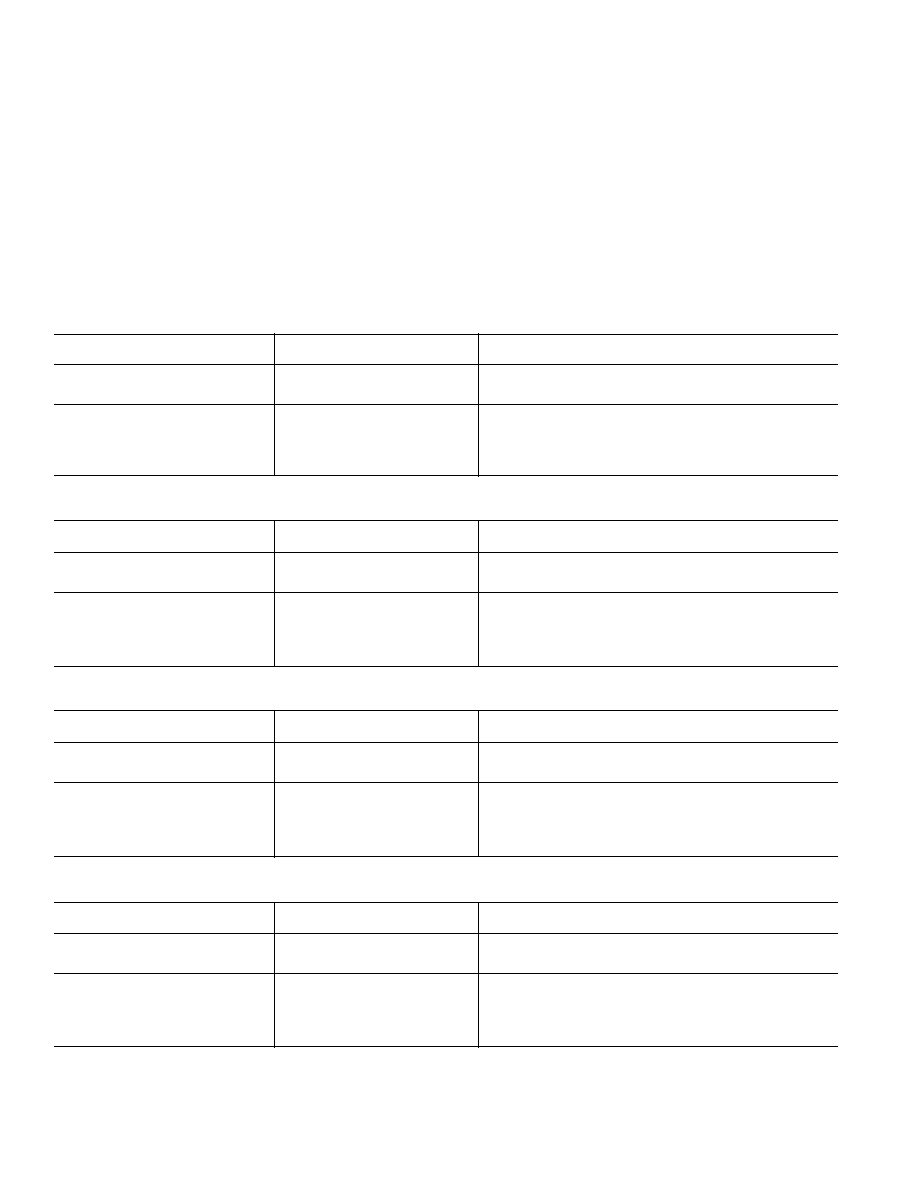

Table IV. Output Update Rates

CLK*

FS1

FS0

Output Update Rate

3 dB Filter Cutoff

0

0

0

20 Hz

5.24 Hz

0

0

1

25 Hz

6.55 Hz

0

1

0

100 Hz

26.2 Hz

0

1

1

200 Hz

52.4 Hz

1

0

0

50 Hz

13.1 Hz

1

0

1

60 Hz

15.7 Hz

Default Status

1

1

0

250 Hz

65.5 Hz

1

1

1

500 Hz

131 Hz

*Assumes correct clock frequency at MCLK IN pin

B/U

Bipolar/Unipolar Operation. A 0 in this bit selects Bipolar Operation. This is the default (Power-On or

RESET) status of this bit. A 1 in this bit selects unipolar operation.

BUF

Buffer Control. With this bit low, the on-chip buffer on the analog input is shorted out. With the buffer

shorted out, the current flowing in the AV

DD

line is reduced to 250

µ

A (all gains at f

CLK IN

= 1 MHz and gain

of 1 or 2 at f

CLK IN

= 2.4576 MHz) or 500

µ

A (gains of 32 and 128 @ f

CLK IN

= 2.4576 MHz) and the output

noise from the part is at its lowest. When this bit is high, the on-chip buffer is in series with the analog input

allowing the input to handle higher source impedances.

FSYNC

Filter Synchronization. When this bit is high, the nodes of the digital filter, the filter control logic and the

calibration control logic are held in a reset state and the analog modulator is also held in its reset state. When

this bit goes low, the modulator and filter start to process data and a valid word is available in 3

×

1/(output

update rate), i.e., the settling-time of the filter. This FSYNC bit does not affect the digital interface and does

not reset the

DRDY output if it is low.

Test Register (RS1, RS0 = 1, 0)

The part contains a Test Register which is used in testing the device. The user is advised not to change the status of any of the

bits in this register from the default (Power-On or RESET) status of all 0s as the part will be placed in one of its test modes and

will not operate correctly. If the part enters one of its test modes, exercising

RESET will exit the part from the mode. An alterna-

tive scheme for getting the part out of one of its test modes, is to reset the interface by writing 32 successive 1s to the part and

then load all 0s to the Test Register.

Data Register (RS1, RS0 = 1, 1)

The Data Register on the part is a read-only 16-bit register which contains the most up-to-date conversion result from the

AD7715. If the Communications Register data sets up the part for a write operation to this register, a write operation must actu-

ally take place to return the part to where it is expecting a write operation to the Communications Register (the default state of

the interface). However, the 16 bits of data written to the part will be ignored by the AD7715.

REV. C

AD7715

12

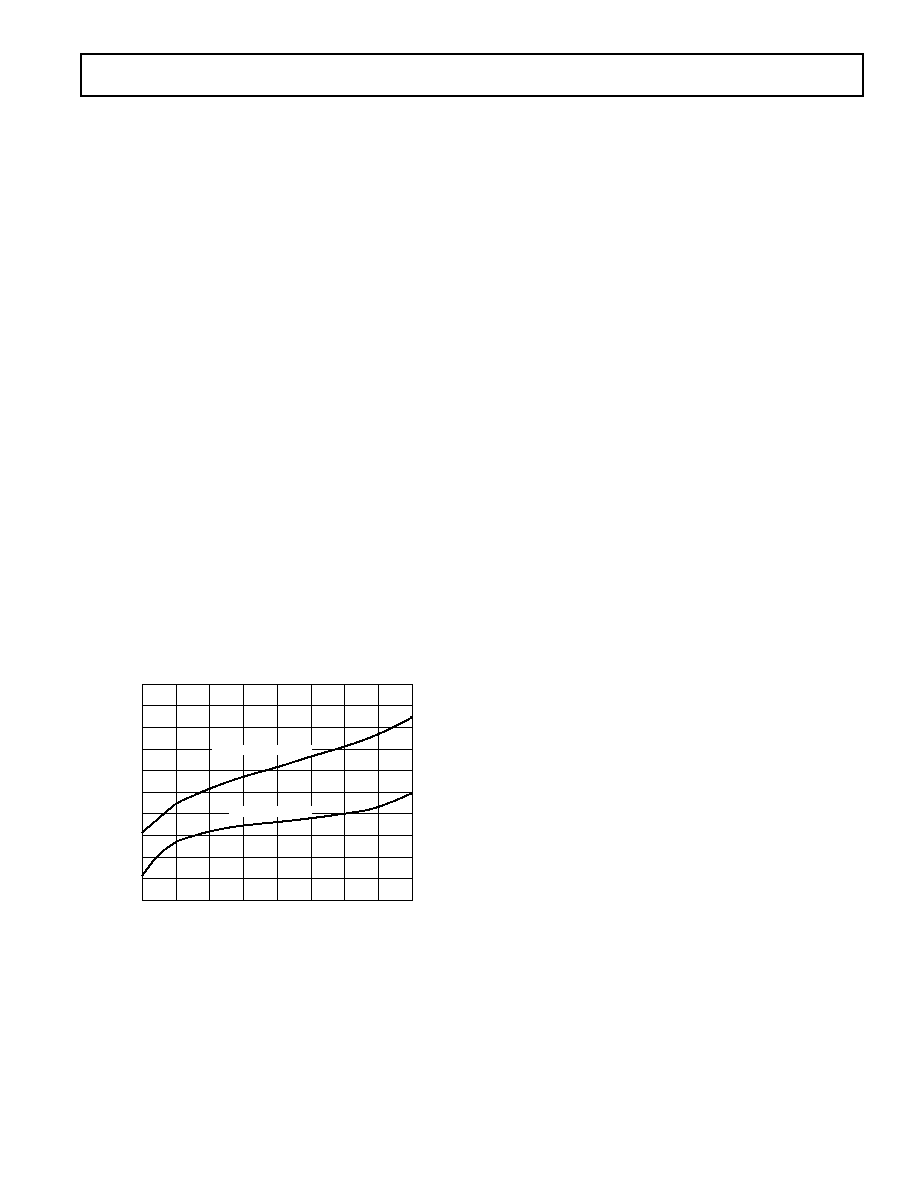

OUTPUT NOISE

AD7715-5

Table V shows the AD7715-5 output rms noise for the selectable notch and 3 dB frequencies for the part, as selected by FS1 and

FS0 of the Setup Register. The numbers given are for the bipolar input ranges with a V

REF

of +2.5 V. These numbers are typical

and are generated at a differential analog input voltage of 0 V with the part used in unbuffered mode (BUF bit of the Setup Register

= 0). Table VI meanwhile shows the output peak-to-peak noise for the selectable notch and 3 dB frequencies for the part. It is im-

portant to note that these numbers represent the resolution for which there will be no code flicker. They are not calculated based on rms noise but

on peak-to-peak noise. The numbers given are for the bipolar input ranges with a V

REF

of +2.5 V and for the BUF bit of the Setup

Register = 0. These numbers are typical, are generated at an analog input voltage of 0 V and are rounded to the nearest LSB.

Meanwhile, Table VII and Table VIII show rms noise and peak-to-peak resolution respectively with the AD7715-5 operating under

the same conditions as above except that now the part is operating in buffered mode (BUF Bit of the Setup Register = 1).

Table V. Output RMS Noise vs. Gain and Output Update Rate for AD7715-5 (Unbuffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Output RMS Noise in V

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

3.8

1.9

0.6

0.52

60 Hz

25 Hz

15.72 Hz

6.55 Hz

4.8

2.4

0.6

0.62

250 Hz

100 Hz

65.5 Hz

26.2 Hz

103

45

3.0

1.6

500 Hz

200 Hz

131 Hz

52.4 Hz

530

250

18

5.5

Table VI. Peak-to-Peak Resolution vs. Gain and Output Update Rate for AD7715-5 (Unbuffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Peak-to-Peak Resolution in Bits

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

16

16

16

14

60 Hz

25 Hz

15.72 Hz

6.55 Hz

16

16

16

13

250 Hz

100 Hz

65.5 Hz

26.2 Hz

13

13

13

12

500 Hz

200 Hz

131 Hz

52.4 Hz

10

10

10

10

Table VII. Output RMS Noise vs. Gain and Output Update Rate for AD7715-5 (Buffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Output RMS Noise in V

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

4.3

2.2

0.9

0.9

60 Hz

25 Hz

15.72 Hz

6.55 Hz

5.1

3.1

1.0

1.0

250 Hz

100 Hz

65.5 Hz

26.2 Hz

103

50

3.9

2.1

500 Hz

200 Hz

131 Hz

52.4 Hz

550

280

18

6

Table VIII. Peak-to-Peak Resolution vs. Gain and Output Update Rate for AD7715-5 (Buffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Peak-to-Peak Resolution in Bits

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

16

16

15

13

60 Hz

25 Hz

15.72 Hz

6.55 Hz

16

16

15

13

250 Hz

100 Hz

65.5 Hz

26.2 Hz

13

13

13

12

500 Hz

200 Hz

131 Hz

52.4 Hz

10

10

10

10

AD7715

13

REV. C

AD7715-3

Table IX shows the AD7715-3 output rms noise for the selectable notch and 3 dB frequencies for the part, as selected by FS1 and

FS0 of the Setup Register. The numbers given are for the bipolar input ranges with a V

REF

of +1.25 V. These numbers are typical

and are generated at an analog input voltage of 0 V with the part used in unbuffered mode (BUF bit of the Setup Register = 0).

Table X meanwhile shows the output peak-to-peak noise for the selectable notch and 3 dB frequencies for the part. It is important to

note that these numbers represent the resolution for which there will be no code flicker. They are not calculated based on rms noise but on peak-

to-peak noise. The numbers given are for the bipolar input ranges with a V

REF

of +1.25 V and for the BUF bit of the Setup Register =

0. These numbers are typical, are generated at an analog input voltage of 0 V and are rounded to the nearest LSB.

Meanwhile, Table XI and Table XII show rms noise and peak-to-peak resolution respectively with the AD7715-3 operating under

the same conditions as above except that now the part is operating in buffered mode (BUF Bit of the Setup Register = 1).

Table IX. Output RMS Noise vs. Gain and Output Update Rate for AD7715-3 (Unbuffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Output RMS Noise in V

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

3.0

1.7

0.7

0.65

60 Hz

25 Hz

15.72 Hz

6.55 Hz

3.4

2.1

0.7

0.7

250 Hz

100 Hz

65.5 Hz

26.2 Hz

45

20

2.2

1.6

500 Hz

200 Hz

131 Hz

52.4 Hz

270

135

9.7

3.3

Table X. Peak-to-Peak Resolution vs. Gain and Output Update Rate for AD7715-3 (Unbuffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Peak-to-Peak Resolution in Bits

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

16

16

14

12

60 Hz

25 Hz

15.72 Hz

6.55 Hz

16

16

14

12

250 Hz

100 Hz

65.5 Hz

26.2 Hz

13

13

13

11

500 Hz

200 Hz

131 Hz

52.4 Hz

11

11

10

10

Table XI. Output RMS Noise vs. Gain and Output Update Rate for AD7715-3 (Buffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Output RMS Noise in V

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

4.5

2.4

0.9

0.9

60 Hz

25 Hz

15.72 Hz

6.55 Hz

5.1

2.9

0.9

1.0

250 Hz

100 Hz

65.5 Hz

26.2 Hz

50

25

2.6

2

500 Hz

200 Hz

131 Hz

52.4 Hz

270

135

9.7

3.3

Table XII. Peak-to-Peak Resolution vs. Gain and Output Update Rate for AD7715-3 (Buffered Mode)

Filter First Notch & O/P Data Rate

3 dB Frequency

Typical Peak-to-Peak Resolution in Bits

MCLK IN =

MCLK IN =

MCLK IN =

MCLK IN =

2.4576 MHz

1 MHz

2.4576 MHz

1 MHz

GAIN = 1

GAIN = 2

GAIN = 32

GAIN = 128

50 Hz

20 Hz

13.1 Hz

5.24 Hz

16

16

14

12

60 Hz

25 Hz

15.72 Hz

6.55 Hz

16

16

14

12

250 Hz

100 Hz

65.5 Hz

26.2 Hz

13

13

12

11

500 Hz

200 Hz

131 Hz

52.4 Hz

10

11

10

10

REV. C

AD7715

14

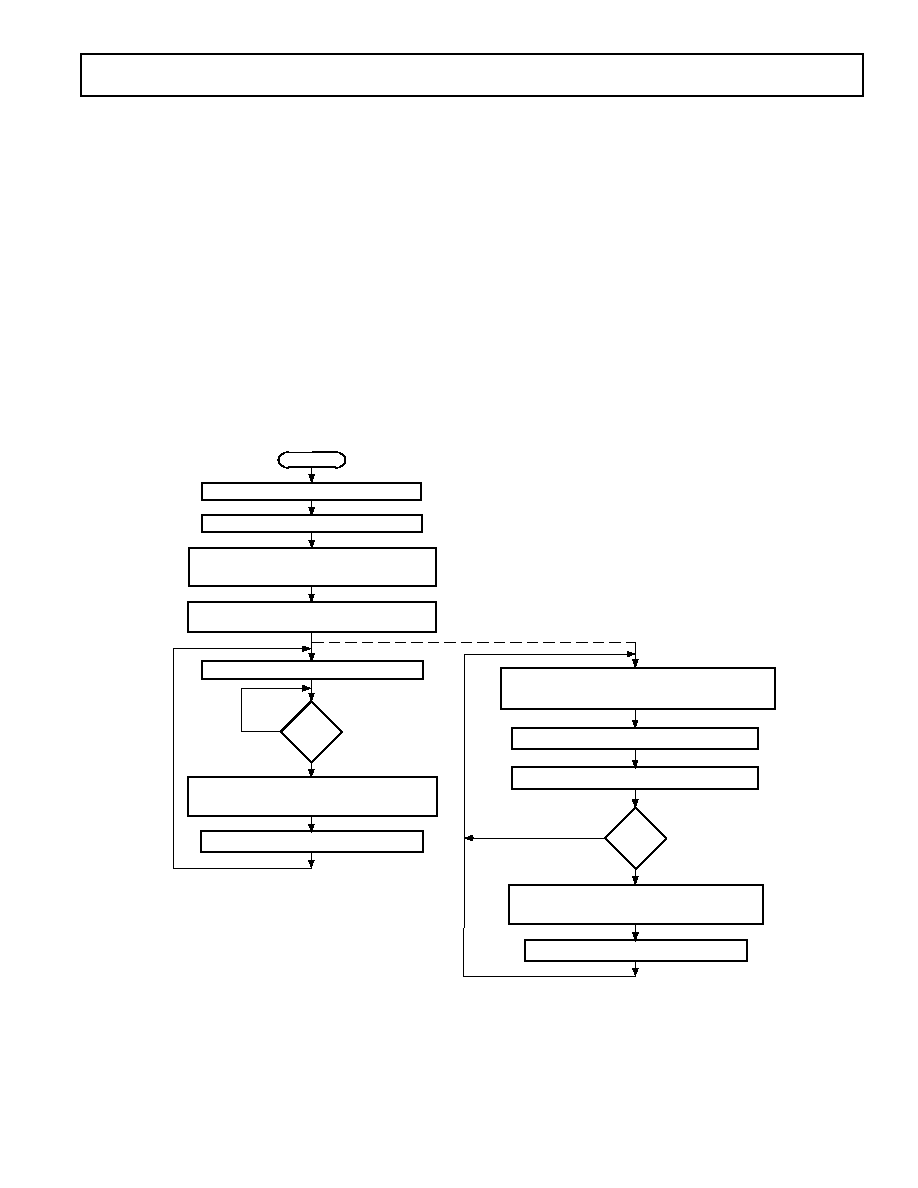

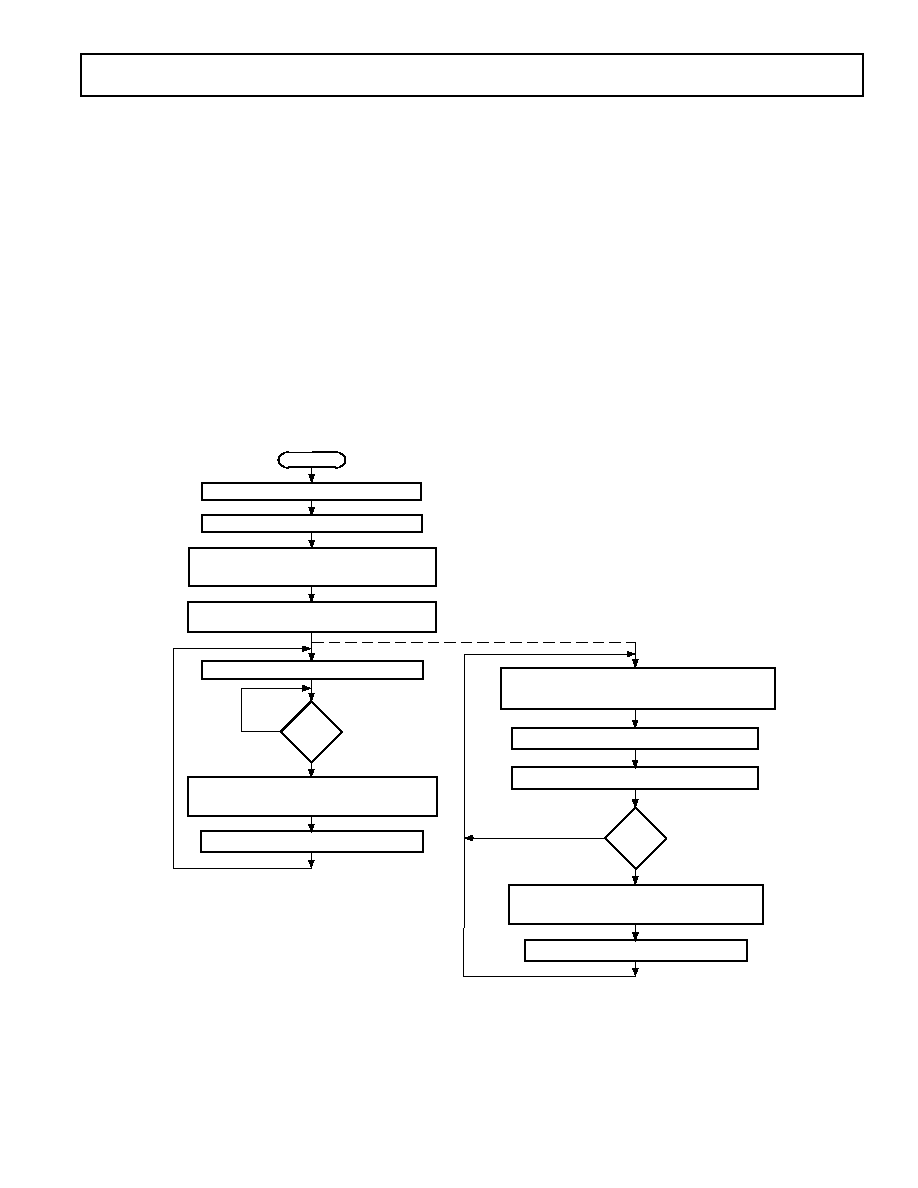

CALIBRATION SEQUENCES

The AD7715 contains a number of calibration options as outlined previously. Table XIII summarizes the calibration types, the op-

erations involved and the duration of the operations. There are two methods of determining the end of calibration. The first is to

monitor when

DRDY returns low at the end of the sequence. DRDY not only indicates when the sequence is complete but also that

the part has a valid new sample in its data register. This valid new sample is the result of a normal conversion which follows the cali-

bration sequence. The second method of determining when calibration is complete is to monitor the MD1 and MD0 bits of the

Setup Register. When these bits return to 0, 0 following a calibration command, it indicates that the calibration sequence is com-

plete. This method does not give any indication of there being a valid new result in the data register. However, it gives an earlier

indication than

DRDY that calibration is complete. The duration to when the Mode Bits (MD1 and MD0) return to 0, 0 represents

the duration of the calibration carried out. The sequence to when

DRDY goes low also includes a normal conversion and a pipeline

delay, t

P

, to correctly scale the results of this first conversion. t

P

will never exceed 2000

×

t

CLK IN

. The time for both methods is given

in the table.

Table XIII. Calibration Sequences

Calibration Type

MD1, MD0

Calibration Sequence

Duration to Mode Bits

Duration to

DRDY

Self Calibration

0, 1

Internal ZS Cal @ Selected Gain +

6

×

1/Output Rate

9

×

1/Output Rate + t

P

Internal FS Cal @ Selected Gain

ZS System Calibration

1, 0

ZS Cal on AIN @ Selected Gain

3

×

1/Output Rate

4

×

1/Output Rate + t

P

FS System Calibration

1, 1

FS Cal on AIN @ Selected Gain

3

×

1/Output Rate

4

×

1/Output Rate + t

P

CIRCUIT DESCRIPTION

The AD7715 is a sigma-delta A/D converter with on-chip digital

filtering, intended for the measurement of wide dynamic range,

low frequency signals such as those in industrial control or pro-

cess control applications. It contains a sigma-delta (or charge-

balancing) ADC, a calibration microcontroller with on-chip

static RAM, a clock oscillator, a digital filter and a bidirectional

serial communications port. The part consumes only 450

µ

A of

power supply current, making it ideal for battery-powered or

loop-powered instruments. The part comes in two versions, the

AD7715-5 which is specified for operation from a nominal

+5 V analog supply (AV

DD

) and the AD7715-3 which is speci-

fied for operation from a nominal +3.3 V analog supply. Both

versions can be operated with a digital supply (DV

DD

) voltage of

+3.3 V or +5 V.

The part contains a programmable-gain fully differential analog

input channel. The selectable gains on this input are 1, 2, 32

and 128 allowing the part to accept unipolar signals of between

0 mV to +20 mV and 0 V to +2.5 V or bipolar signals in the

range from

±

20 mV to

±

2.5 V when the reference input voltage

equals +2.5 V. With a reference voltage of +1.25 V, the input

ranges are from 0 mV to +10 mV to 0 V to +1.25 V in unipolar

mode and from

±

10 mV to

±

1.25 V in bipolar mode. Note that

the bipolar ranges are with respect to AIN() and not with re-

spect to AGND.

The input signal to the analog input is continuously sampled at

a rate determined by the frequency of the master clock,

MCLK IN, and the selected gain. A charge-balancing A/D

converter (sigma-delta modulator) converts the sampled signal

into a digital pulse train whose duty cycle contains the digital

information. The programmable gain function on the analog

input is also incorporated in this sigma-delta modulator with the

input sampling frequency being modified to give the higher

gains. A sinc

3

digital low-pass filter processes the output of the

sigma-delta modulator and updates the output register at a rate

determined by the first notch frequency of this filter. The out-

put data can be read from the serial port randomly or periodi-

cally at any rate up to the output register update rate. The first

notch of this digital filter (and hence its 3 dB frequency) can be

programmed via the Setup Register bits FS0 and FS1. With a

master clock frequency of 2.4576 MHz, the programmable

range for this first notch frequency is from 50 Hz to 500 Hz

giving a programmable range for the 3 dB frequency of

13.1 Hz to 131 Hz. With a master clock frequency of 1 MHz,

the programmable range for this first notch frequency is from

20 Hz to 200 Hz giving a programmable range for the 3 dB

frequency of 5.24 Hz to 52.4 Hz.

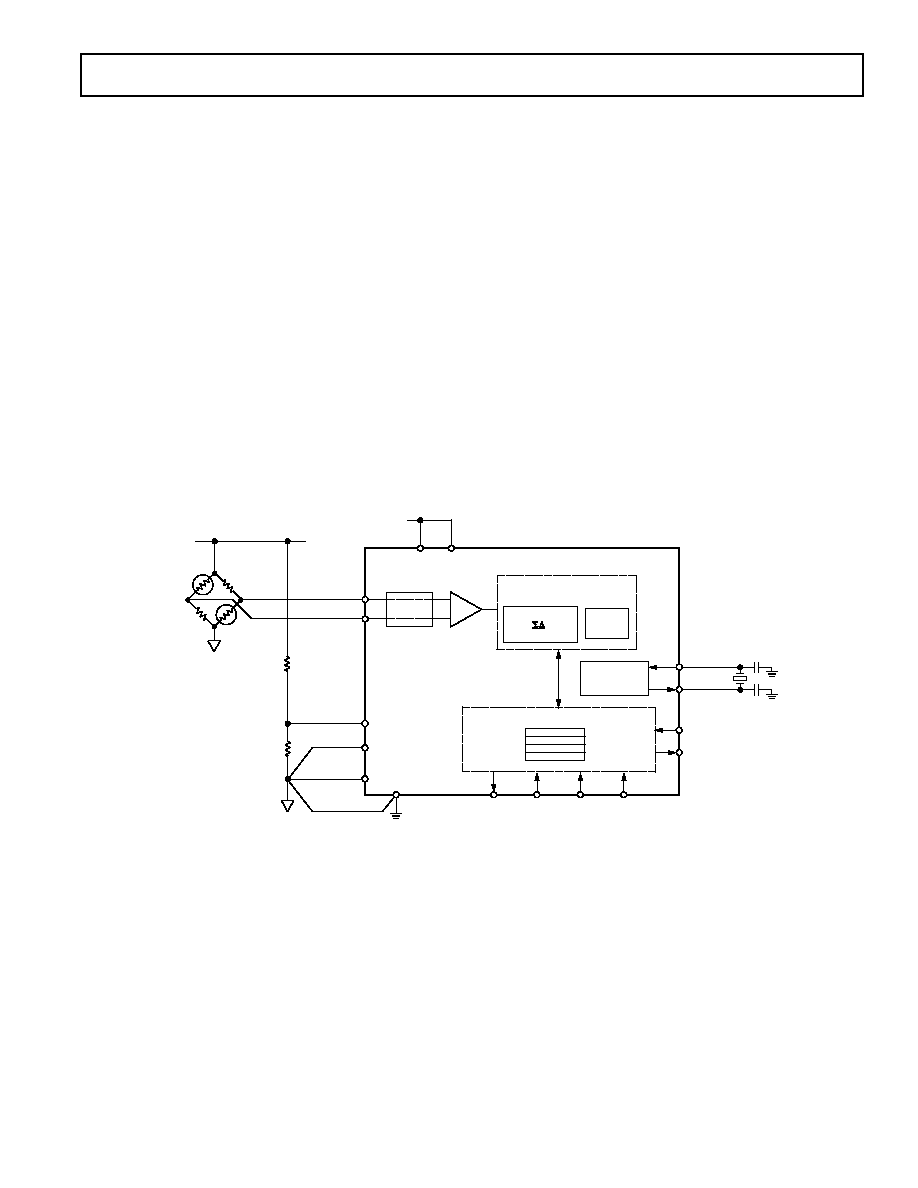

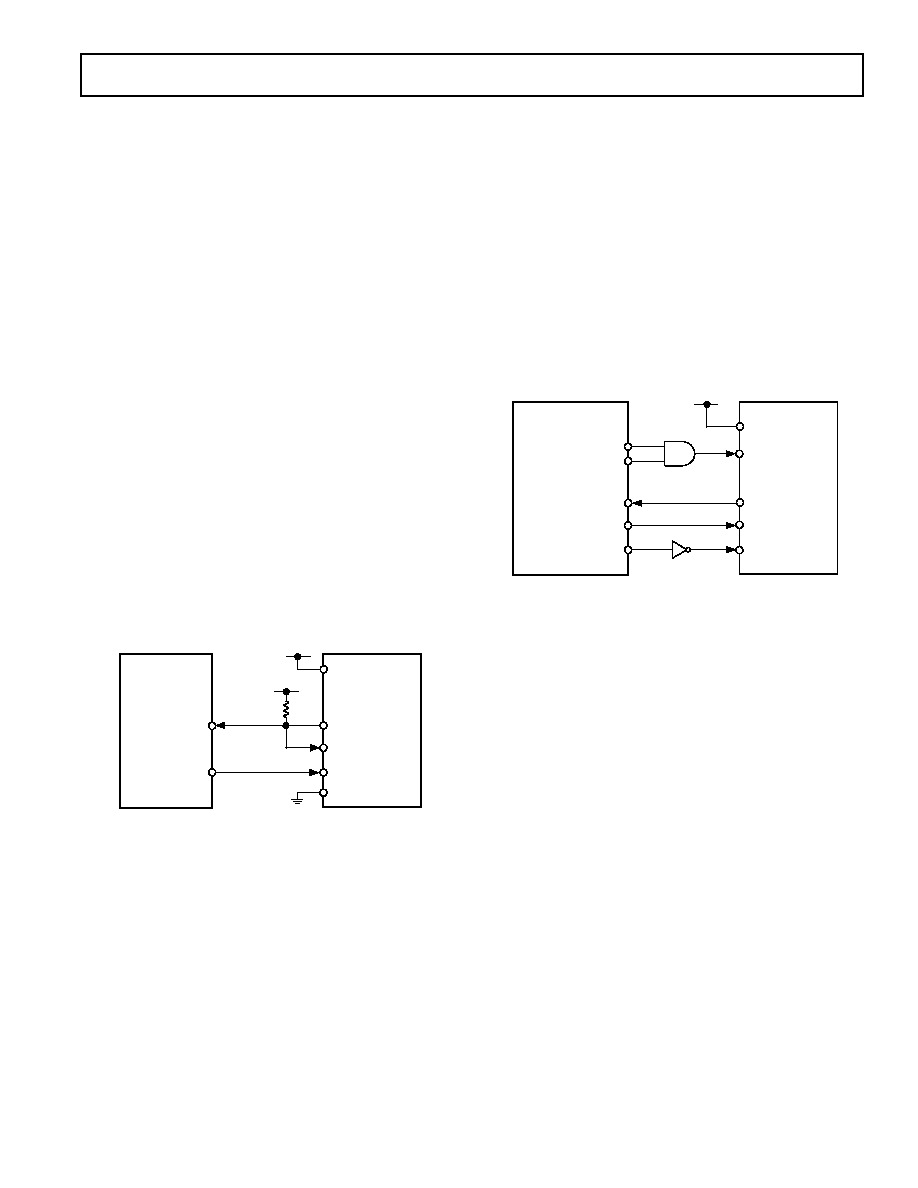

The basic connection diagram for the AD7715-5 is shown in

Figure 2. This shows both the AV

DD

and DV

DD

pins of the

AD7715 being driven from the analog +5 V supply. Some

applications will have AV

DD

and DV

DD

driven from separate

supplies. An AD780, precision +2.5 V reference, provides the

reference source for the part. On the digital side, the part is

configured for three-wire operation with

CS tied to DGND. A

quartz crystal or ceramic resonator provides the master clock

source for the part. In most cases, it will be necessary to connect

capacitors on the crystal or resonator to ensure that it does

not oscillate at overtones of its fundamental operating fre-

quency. The values of capacitors will vary depending on the

manufacturer's specifications.

AD7715

15

REV. C

C

SAMP

must be charged through R

SW

and through any external

source impedances every input sample cycle. Therefore, in

unbuffered mode, source impedances mean a longer charge time

for C

SAMP

, and this may result in gain errors on the part. Table

XIV shows the allowable external resistance/capacitance values,

for unbuffered mode, such that no gain error to the 16-bit level

is introduced on the part. Note that these capacitances are total

capacitances on the analog input, external capacitance plus

10 pF capacitance from the pins and lead frame of the device.

Table XIV. External R, C Combination for No 16-Bit Gain

Error (Unbuffered Mode Only)

Gain

External Capacitance (pF)

10

50

100

500

1000

5000

1

152 k

53.9 k

31.4 k

8.4 k

4.76 k

1.36 k

2

75.1 k

26.6 k

15.4 k

4.14 k

2.36 k

670

32

16.7 k

5.95 k

3.46 k

924

526

150

128

16.7 k

5.95 k

3.46 k

924

526

150

In buffered mode, the analog inputs look into the high imped-

ance inputs stage of the on-chip buffer amplifier. C

SAMP

is

charged via this buffer amplifier such that source impedances do

not affect the charging of C

SAMP

. This buffer amplifier has an

offset leakage current of 1 nA. In this buffered mode, large

source impedances result in a small dc offset voltage developed

across the source impedance but not in a gain error.

Input Sample Rate

The modulator sample frequency for the AD7715 remains at

f

CLK IN

/128 (19.2 kHz @ f

CLK IN

= 2.4576 MHz) regardless of

the selected gain. However, gains greater than 1 are achieved by

a combination of multiple input samples per modulator cycle

and a scaling of the ratio of reference capacitor to input capaci-

tor. As a result of the multiple sampling, the input sample rate

of the device varies with the selected gain (see Table XV). In

buffered mode, the input is buffered before the input sampling

Table XV. Input Sampling Frequency vs. Gain

Gain

Input Sampling Freq (f

S

)

1

f

CLK IN

/64 (38.4 kHz @ f

CLK IN

= 2.4576 MHz)

2

2

×

f

CLK IN

/64 (76.8 kHz @ f

CLK IN

= 2.4576 MHz)

32

8

×

f

CLK IN

/64 (307.2 kHz @ f

CLK IN

= 2.4576 MHz)

128

8

×

f

CLK IN

/64 (307.2 kHz @ f

CLK IN

= 2.4576 MHz)

capacitor. In unbuffered mode, where the analog input looks

directly into the sampling capacitor, the effective input imped-

ance is 1/C

SAMP

×

f

S

where C

SAMP

is the input sampling capaci-

tance and f

S

is the input sample rate.

Bipolar/Unipolar Inputs

The analog input on the AD7715 can accept either unipolar or

bipolar input voltage ranges. Bipolar input ranges do not imply

that the part can handle negative voltages on its analog input

since the analog input cannot go more negative than 30 mV to

ensure correct operation of the part. The input channel is fully

differential. As a result, the voltage to which the unipolar and

bipolar signals on the AIN(+) input are referenced is the voltage

on the respective AIN() input. For example, if AIN() is

+2.5 V and the AD7715 is configured for unipolar operation

SCLK

MCLK IN

DGND

DV

DD

MCLK OUT

DIN

DOUT

AGND

AIN(+)

AIN()

REF IN(+)

REF IN()

AV

DD

AD7715

0.1 F

ANALOG

GROUND

DIFFERENTIAL

ANALOG INPUT

DIGITAL

GROUND

0.1 F

10 F

V

OUT

V

IN

GND

AD780

ANALOG

+5V SUPPLY

DATA READY

RECEIVE (READ)

SERIAL DATA

SERIAL CLOCK

CRYSTAL OR

CERAMIC

RESONATOR

+5V

0.1 F

10 F

ANALOG

+5V SUPPLY

RESET

CS

DRDY

Figure 2. AD7715-5 Basic Connection Diagram

ANALOG INPUT

Analog Input Ranges

The AD7715 contains a differential analog input pair AIN(+)

and AIN(). This input pair provides a programmable-gain,

differential input channel which can handle either unipolar or

bipolar input signals. It should be noted that the bipolar input

signals are referenced to the respective AIN() input of the

input pair.

In unbuffered mode, the common-mode range of the input is

from AGND to AV

DD

provided that the absolute value of the

analog input voltage lies between AGND 30 mV and

AV

DD

+ 30 mV. This means that in unbuffered mode the part

can handle both unipolar and bipolar input ranges for all gains.

In buffered mode, the analog inputs can handle much larger

source impedances but the absolute input voltage range is re-

stricted to between AGND + 50 mV to AV

DD

1.5 V which

also places restrictions on the common-mode range. This means

that in buffered mode there are some restrictions on the allow-

able gains for bipolar input ranges. Care must be taken in set-

ting up the common-mode voltage and input voltage range so

that the above limits are not exceeded, otherwise there will be a

degradation in linearity performance.

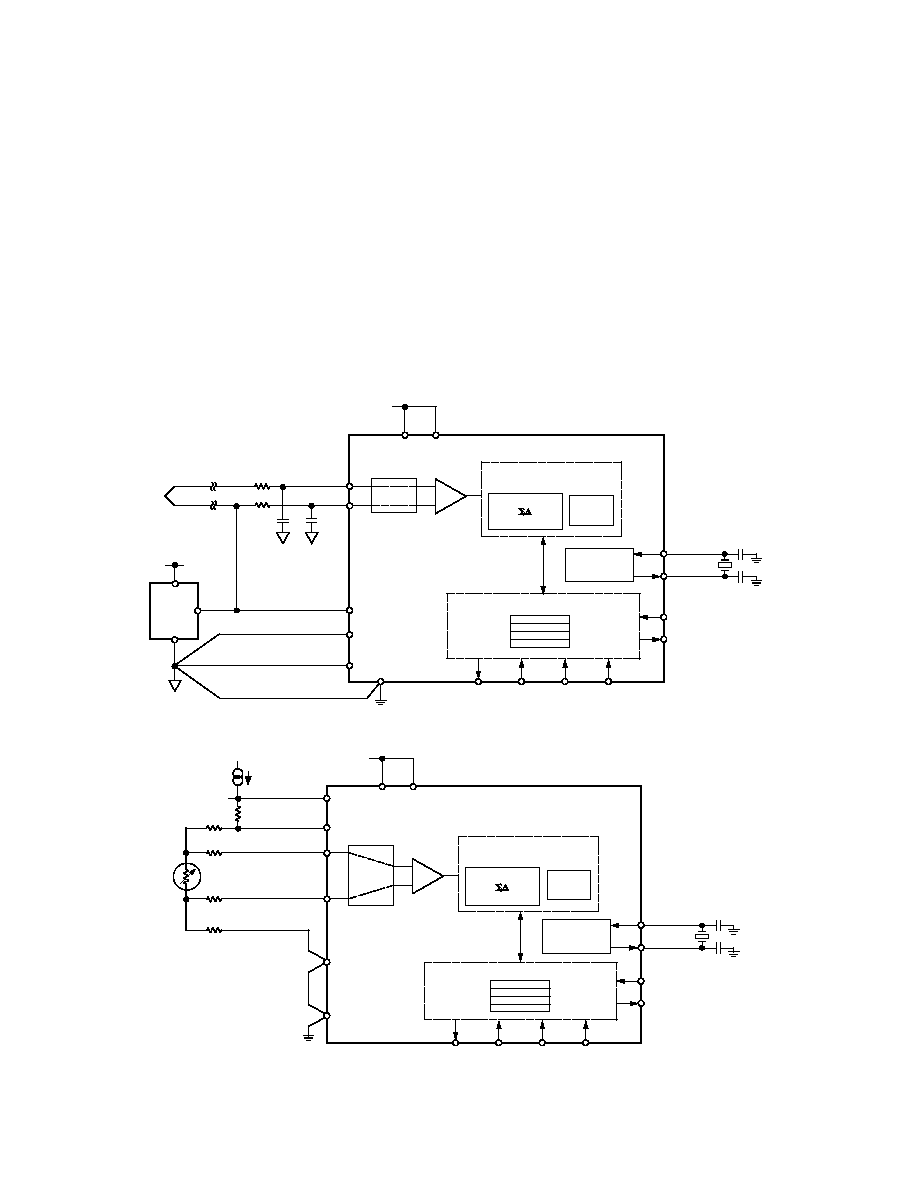

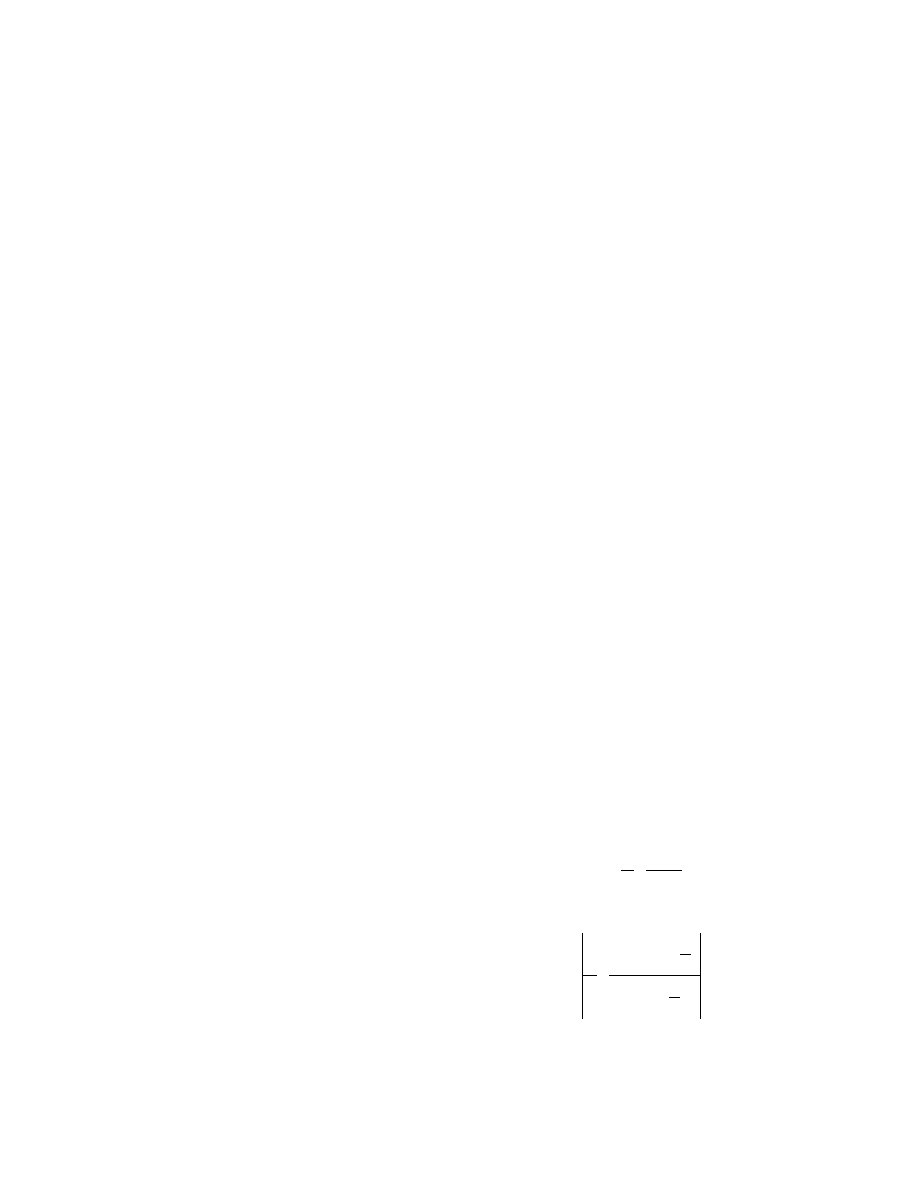

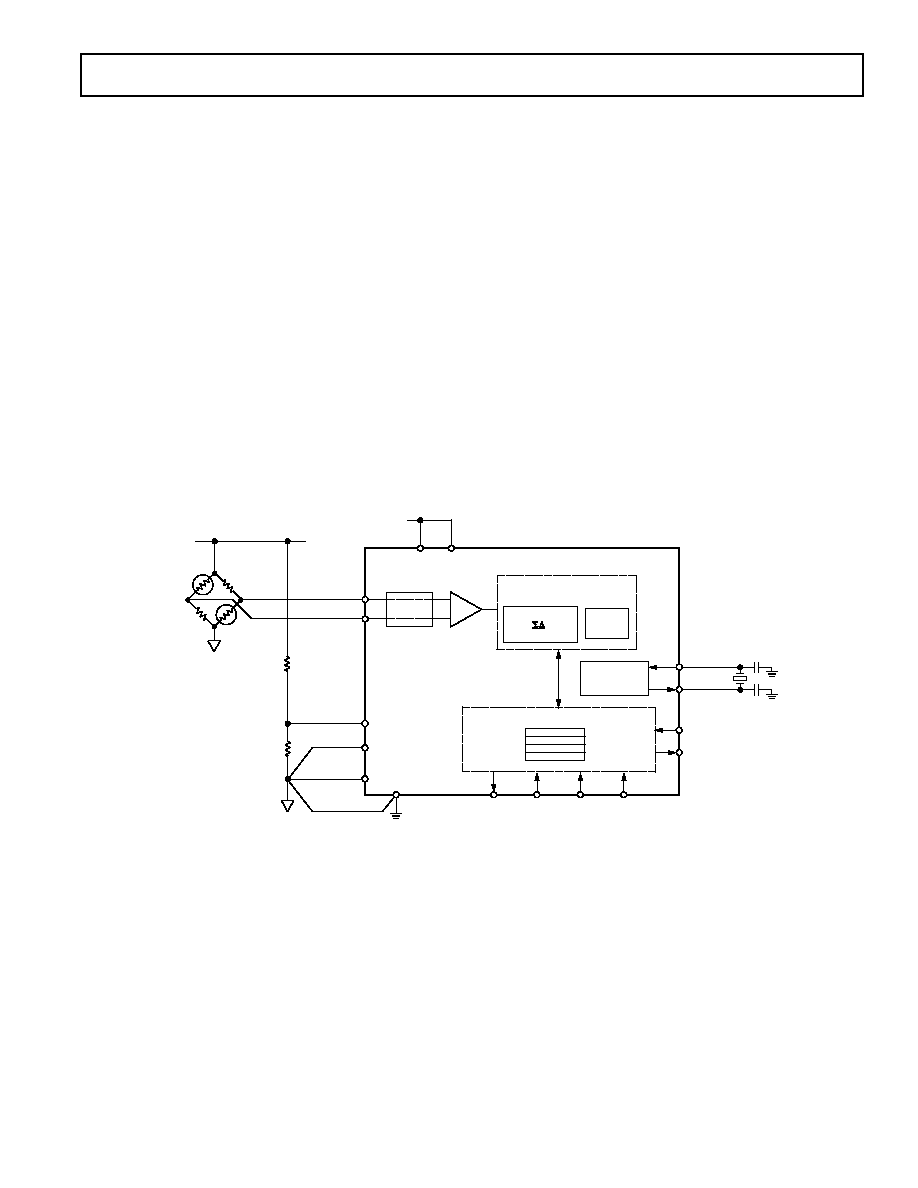

In unbuffered mode, the analog inputs look directly into the

input sampling capacitor, C

SAMP

. The dc input leakage current

in this unbuffered mode is 1 nA maximum. As a result, the

analog inputs see a dynamic load that is switched at the input

sample rate (see Figure 3). This sample rate depends on master

clock frequency and selected gain. C

SAMP

is charged to AIN(+)

and discharged to AIN() every input sample cycle. The effec-

tive on-resistance of the switch, R

SW

, is typically 7 k

.

HIGH

IMPEDANCE

1G

R

SW

(7k TYP)

C

SAMP

(10pF )

V

BIAS

SWITCHING FREQUENCY

DEPENDS ON

f

CLKIN

AND SELECTED GAIN

AIN(+)

AIN()

Figure 3. Unbuffered Analog Input Structure

REV. C

AD7715

16

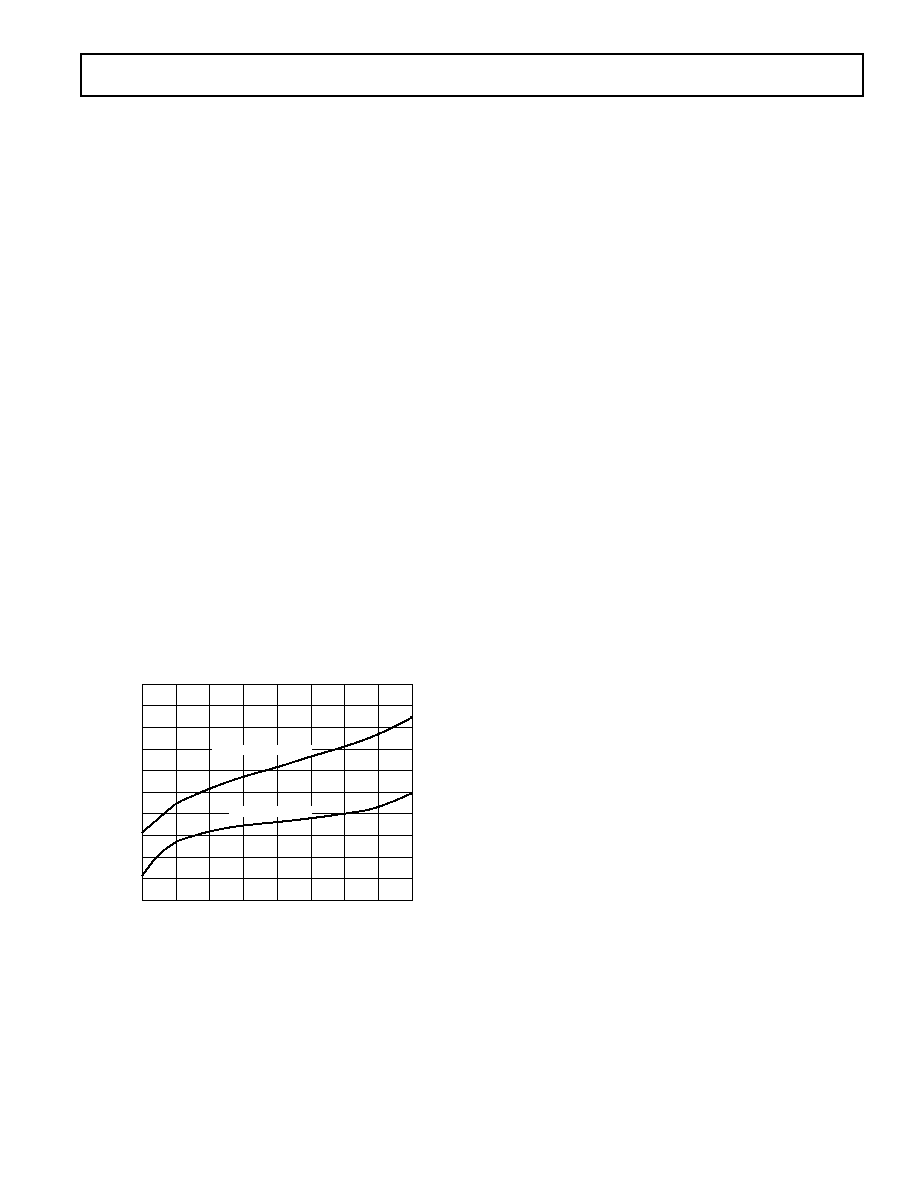

DIGITAL FILTERING

The AD7715 contains an on-chip low-pass digital filter that

processes the output of the part's sigma-delta modulator. There-

fore, the part not only provides the analog-to-digital conversion

function but it also provides a level of filtering. There are a

number of system differences when the filtering function is

provided in the digital domain rather than the analog domain

and the user should be aware of these.

First, since digital filtering occurs after the A-to-D conversion

process, it can remove noise injected during the conversion

process. Analog filtering cannot do this. Also, the digital filter

can be made programmable far more readily than an analog

filter. Depending on the digital filter design, this gives the user

the capability of programming cutoff frequency and output

update rate.

On the other hand, analog filtering can remove noise superim-

posed on the analog signal before it reaches the ADC. Digital

filtering cannot do this and noise peaks riding on signals near

full scale have the potential to saturate the analog modulator

and digital filter, even though the average value of the signal is

within limits. To alleviate this problem, the AD7715 has over-

range headroom built into the sigma-delta modulator and digital

filter which allows overrange excursions of 5% above the analog

input range. If noise signals are larger than this, consideration

should be given to analog input filtering, or to reducing the

input channel voltage so that its full scale is half that of the

analog input channel full scale. This will provide an overrange

capability greater than 100% at the expense of reducing the

dynamic range by 1 bit (50%).

In addition, the digital filter does not provide any rejection at

integer multiples of the digital filter's sample frequency. How-

ever, the input sampling on the part provides attenuation at

multiples of the digital filter's sampling frequency so that the

unattenu-ated bands actually occur around multiples of the

sampling frequency f

S

(as defined in Table XV). Thus the unat-

tenuated bands occur at n

×

f

S

(where n = 1, 2, 3. . . ). At these

frequencies, there are frequency bands,

±

f

3 dB

wide (f

3 dB

is the

cutoff frequency of the digital filter) at either side where noise

passes unattenuated to the output.

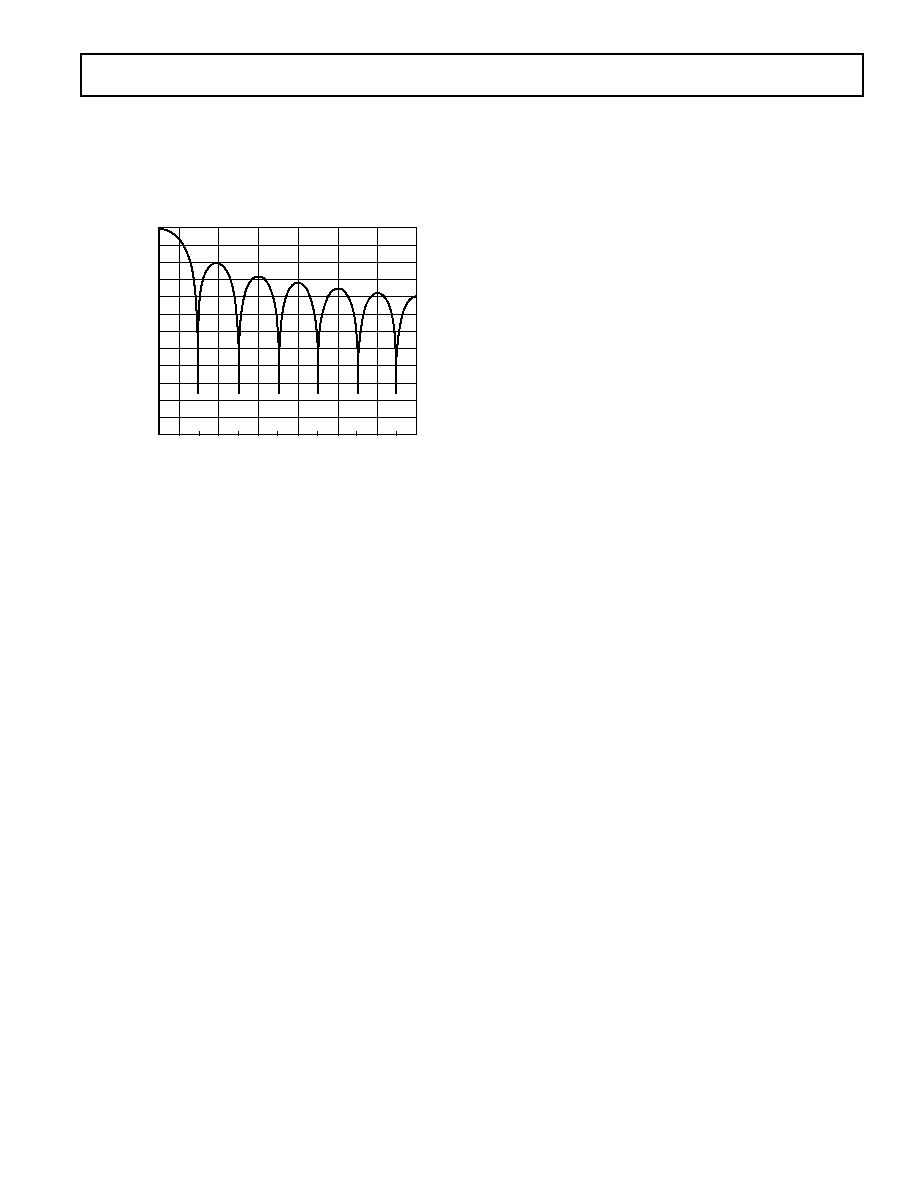

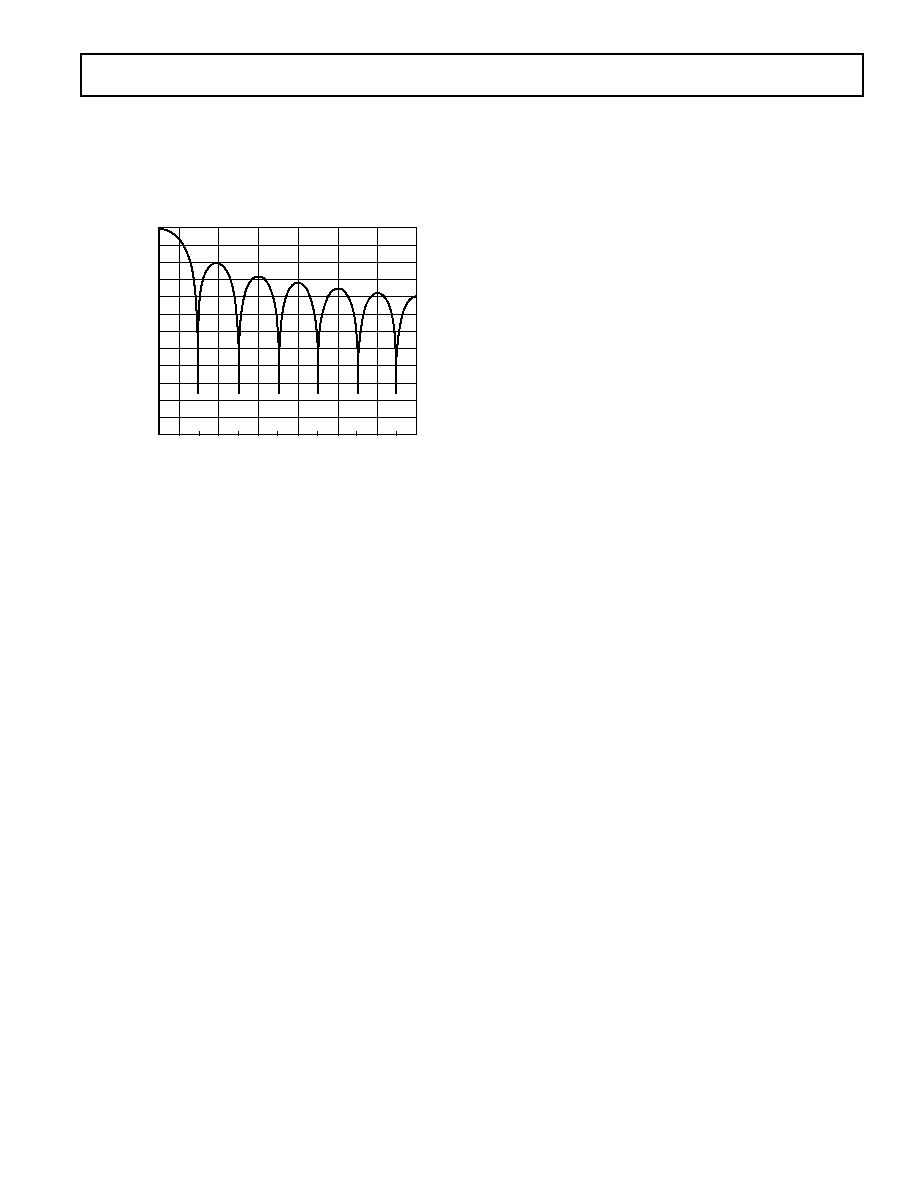

Filter Characteristics

The AD7715's digital filter is a low-pass filter with a (sinx/x)

3

response (also called sinc

3

). The transfer function for this filter

is described in the z-domain by:

and in the frequency domain by:

where N is the ratio of the modulator rate to the output rate and

f

MOD

is the modulator rate.