| ÐлекÑÑоннÑй компоненÑ: AD8016 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

REV. A

a

AD8016

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 2000

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Low Power, High Output Current

xDSL Line Driver

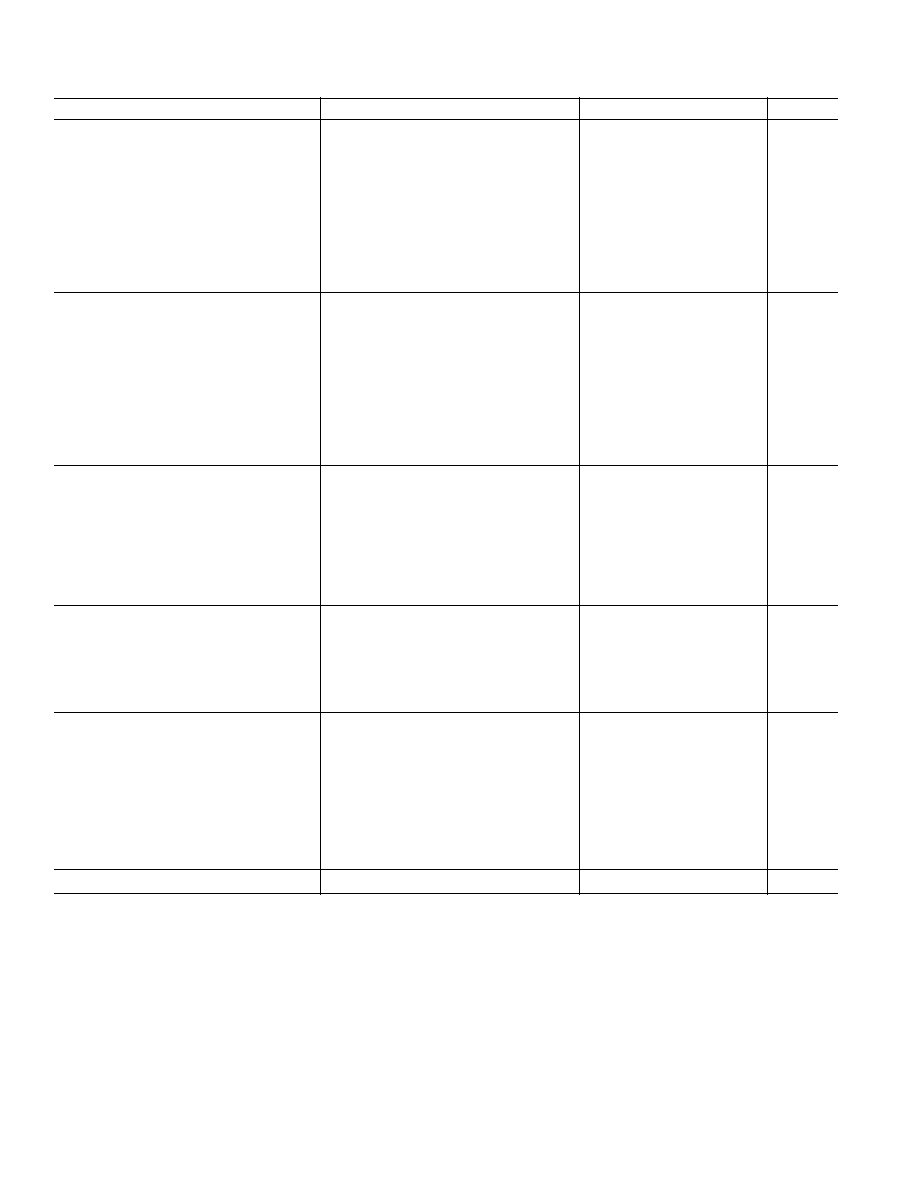

PIN CONFIGURATION

FEATURES

xDSL Line Driver that Features Full ADSL CO (Central

Office) Performance on 12 V Supplies

Low Power Operation

5 V to 12 V Voltage Supply

12.5 mA/Amp (Typ) Total Supply Current

Power-Reduced Keep-Alive Current of 4.5 mA/Amp

High Output Voltage and Current Drive

I

OUT

= 600 mA

40 V p-p Differential Output Voltage R

L

= 50 ,

V

S

= 12 V

Low Single Tone Distortion

75 dBc @ 1 MHz SFDR, R

L

= 100 , V

O

= 2 V p-p

MTPR = 75 dBc, 26 kHz to 1.1 MHz, Z

LINE

= 100 ,

P

LINE

= 20.4 dBm

High Speed

78 MHz Bandwidth (3 dB), G = +5

40 MHz Gain Flatness

1000 V/ s Slew Rates

PRODUCT DESCRIPTION

The AD8016 high output current dual amplifier is designed

for the line drive interface in Digital Subscriber Line systems

such as ADSL, HDSL2, and proprietary xDSL systems. The

drivers are capable, in full-bias operation, of providing 24.4 dBm

output power into low resistance loads, enough to power a

20.4 dBm line, including hybrid insertion loss.

FREQUENCY kHz

549.3

10dB/DIV

550.3 551.3 552.3 553.3 554.3 555.3 556.3 557.3 558.3 559.3

75dBc

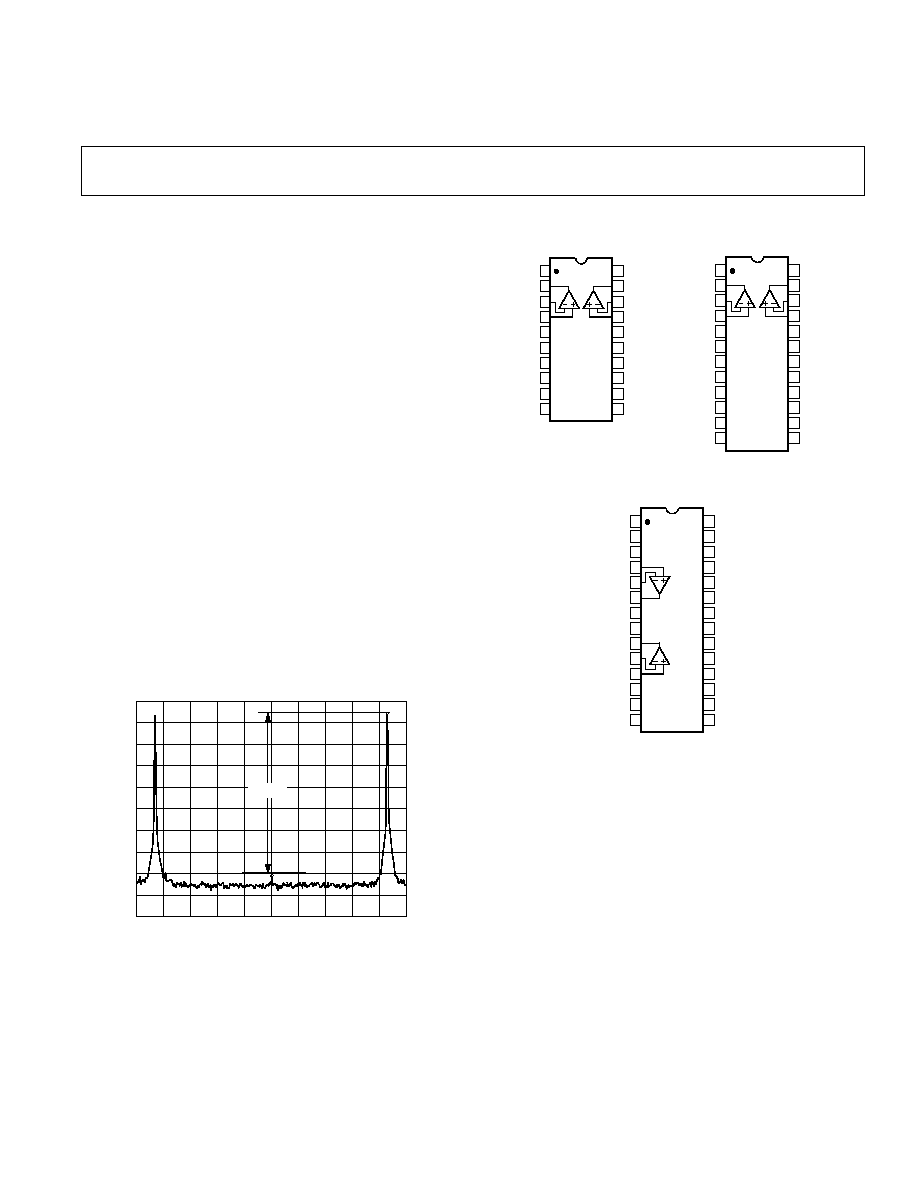

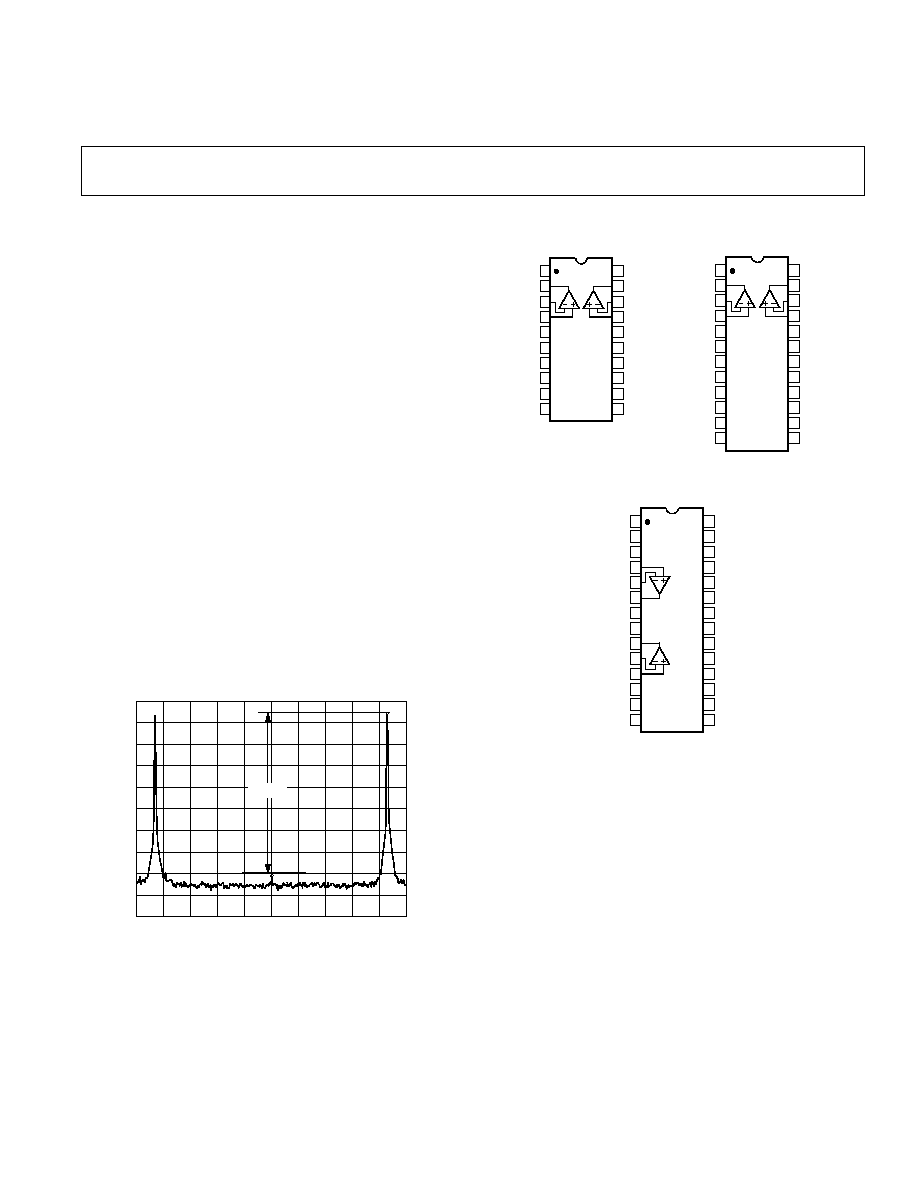

Figure 1. Multitone Power Ratio; V

S

=

±12 V, 20.4 dBm

Output Power into 100

, Downstream

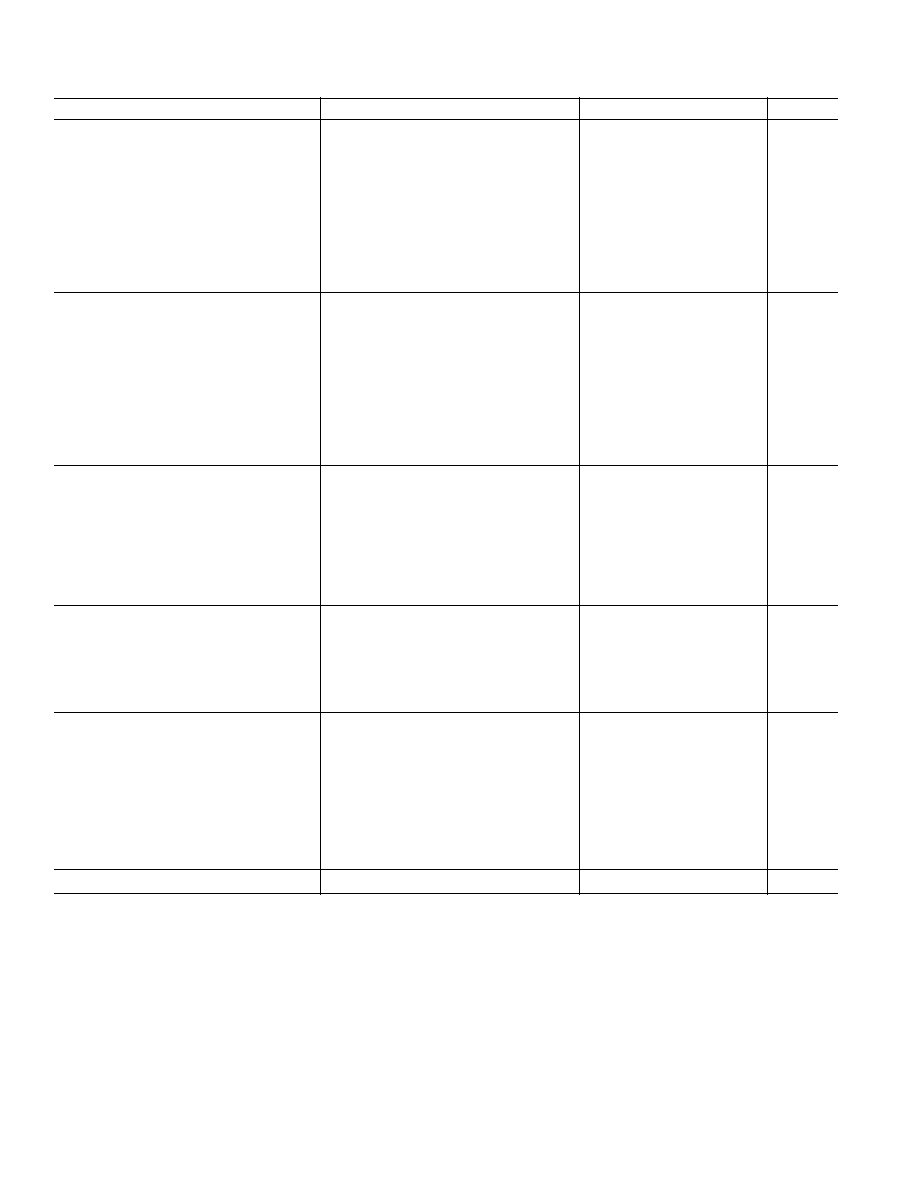

24-Lead Batwing

(RB-24)

20-Lead PSOP3

(RP-20)

20

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

8

9

10

AD8016

NC = NO CONNECT

V

OUT

1

+V1

+V2

V

INN

1

V

INP

1

NC

NC

NC

PWDN0

DGND

V1

V

OUT

2

V

INN

2

V

INP

2

NC

NC

NC

PWDN1

BIAS

V2

24

23

22

21

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

9

10

11

12

AD8016

NC = NO CONNECT

+V1

+V2

V

OUT

1

V

INN

1

V

INP

1

AGND

AGND

AGND

AGND

PWDN0

DGND

V1

NC

V

OUT

2

V

INN

2

V

INP

2

AGND

AGND

AGND

PWDN1

BIAS

V2

NC

AGND

28-Lead HTSSOP

(RE-28)

NC

NC

NC

BIAS

V2

+V1

+V2

V

OUT

1

V

IN

1

PWDN1

DGND

V1

V

OUT

2

+V

IN

2

PWDN0

NC = NO CONNECT

NC

NC

NC

V

IN

2

+V

IN

1

NC

NC

NC

NC

NC

NC

NC

NC

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AD8016ARE

The AD8016 is available in a low cost 24-lead SOIC, a ther-

mally enhanced 20-lead PSOP, and a 28-lead HTSSOP with

an exposed leadframe (ePAD). Operating from

±12 V supplies,

the AD8016 requires only 1.5 W of total power dissipation

(refer to the Power Dissipation section for details) while driving

20.4 dBm of power downstream using the xDSL hybrid in Figure

33a and Figure 33b. Two digital bits (PWDN0, PWDN1) allow

the driver to be capable of full performance, an output "keep-alive

state," or two intermediate bias states. The "keep-alive" state

biases the output transistors enough to provide a low imped-

ance at the amplifier outputs for back termination.

The low power dissipation, high output current, high output voltage

swing, flexible power-down, and robust thermal packaging enable

the AD8016 to be used as the Central Office (CO) terminal driver

in ADSL, HDSL2, VDSL, and proprietary xDSL systems.

REV. A

2

AD8016SPECIFICATIONS

Parameter

Conditions

Min

Typ

Max

Unit

DYNAMIC PERFORMANCE

3 dB Bandwidth

G = +1, R

F

= 1.5 k

, V

OUT

= 0.2 V p-p

380

MHz

G = +5, R

F

= 499

, V

OUT

< 0.5 V p-p

69

78

MHz

Bandwidth for 0.1 dB Flatness

G = +5, R

F

= 499

, V

OUT

= 0.2 V p-p

16

38

MHz

Large Signal Bandwidth

V

OUT

= 4 V p-p

90

MHz

Peaking

V

OUT

= 0.2 V p-p < 50 MHz

0.1

dB

Slew Rate

V

OUT

= 4 V p-p, G = +2

1000

V/

µs

Rise and Fall Time

V

OUT

= 2 V p-p

2

ns

Settling Time

0.1%, V

OUT

= 2 V p-p

23

ns

Input Overdrive Recovery Time

V

OUT

= 12.5 V p-p

350

ns

NOISE/DISTORTION PERFORMANCE

Distortion, Single-Ended

V

OUT

= 2 V p-p, G = +5, R

F

= 499

2nd Harmonic

f

C

= 1 MHz, R

L

= 100

/25

75/62

77/64

dBc

3rd Harmonic

f

C

= 1 MHz, R

L

= 100

/25

88/74

93/76

dBc

Multitone Power Ratio

1

26 kHz to 1.1 MHz, Z

LINE

= 100

,

P

LINE

= 20.4 dBm

75

dBc

IMD

500 kHz,

f = 10 kHz, R

L

= 100

/25

84/80

88/85

dBc

IP3

500 kHz, R

L

= 100

/25

42/40

43/41

dBm

Voltage Noise (RTI)

f = 10 kHz

2.6

4.5

nV/

Hz

Input Current Noise

f = 10 kHz

18

21

pA

Hz

INPUT CHARACTERISTICS

RTI Offset Voltage

3.0

1.0

+3.0

mV

+Input Bias Current

45

+45

µA

Input Bias Current

75

4

+75

µA

Input Resistance

400

k

Input Capacitance

2

pF

Input Common-Mode Voltage Range

10

+10

V

Common-Mode Rejection Ratio

58

64

dB

OUTPUT CHARACTERISTICS

Output Voltage Swing

Single-Ended, R

L

= 100

11

+11

V

Linear Output Current

G = 5, R

L

= 10

, f

1

= 100 kHz,

60 dBc SFDR

400

600

mA

Short Circuit Current

2000

mA

Capacitive Load Drive

80

pF

POWER SUPPLY

Operating Range

±3

±13

V

Quiescent Current

PWDN1, PWDN0 = (1, 1)

12.5

13.2

mA/Amp

PWDN1, PWDN0 =

(1, 0)

8

10

mA/Amp

PWDN1, PWDN0 =

(0, 1)

5

8

mA/Amp

PWDN1, PWDN0 =

(0, 0)

4

6

mA/Amp

Recovery Time

To 95% of I

Q

25

µs

Shutdown Current

250

µA Out of Bias Pin

1.5

4.0

mA/Amp

Power Supply Rejection Ratio

V

S

=

±1 V

63

75

dB

OPERATING TEMPERATURE RANGE

40

+85

°C

NOTES

1

See Figure 43, R20, R21 = 0

, R1 = open.

Specifications subject to change without notice.

(@ 25 C, V

S

= 12 V, R

L

= 100

, PWDN0, PWDN1 = (1, 1), T

MIN

= 40 C,

T

MAX

= +85 C, unless otherwise noted)

REV. A

3

AD8016

Parameter

Conditions

Min

Typ

Max

Unit

DYNAMIC PERFORMANCE

3 dB Bandwidth

G = +1, R

F

= 1.5 k

, V

OUT

= 0.2 V p-p

320

MHz

G = +5, R

F

= 499

, V

OUT

< 0.5 V p-p

70

71

MHz

Bandwidth for 0.1 dB Flatness

G = +5, R

F

= 499

, V

OUT

= 0.2 V p-p

10

15

MHz

Large Signal Bandwidth

V

OUT

= 1 V rms

80

MHz

Peaking

V

OUT

= 0.2 V p-p < 50 MHz

0.7

1.0

dB

Slew Rate

V

OUT

= 4 V p-p, G = +2

300

V/

µs

Rise and Fall Time

V

OUT

= 2 V p-p

2

ns

Settling Time

0.1%, V

OUT

= 2 V p-p

39

ns

Input Overdrive Recovery Time

V

OUT

= 6.5 V p-p

350

ns

NOISE/DISTORTION PERFORMANCE

Distortion, Single-Ended

G = +5, V

OUT

= 2 V p-p, R

F

= 499

2nd Harmonic

f

C

= 1 MHz, R

L

= 100

/25

73/61

75/63

dBc

3rd Harmonic

f

C

= 1 MHz, R

L

= 100

/25

80/68

82/70

dBc

Multitone Power Ratio

1

26 kHz to 138 kHz, Z

LINE

= 100

,

P

LINE

= 13 dBm

68

dBc

IMD

500 kHz,

f = 110 kHz, R

L

= 100

/25

87/82

88/83

dBc

IP3

500 kHz

42/39

42/39

dBm

Voltage Noise (RTI)

f = 10 kHz

4

5

nV/

Hz

Input Current Noise

f = 10 kHz

17

20

pA

Hz

INPUT CHARACTERISTICS

RTI Offset Voltage

3.0

0.2

+3.0

mV

+Input Bias Current

25

10

+25

µA

Input Bias Current

30

10

+30

µA

Input Resistance

400

k

Input Capacitance

2

pF

Input Common-Mode Voltage Range

4

+4

V

Common-Mode Rejection Ratio

60

66

dB

OUTPUT CHARACTERISTICS

Output Voltage Swing

Single-Ended, R

L

= 100

5

+5

V

Linear Output Current

G = 5, R

L

= 5

, f = 100 kHz,

60 dBc SFDR

300

420

mA

Short Circuit Current

830

mA

Capacitive Load Drive

R

S

= 10

50

pF

POWER SUPPLY

Quiescent Current

PWDN1, PWDN0 = (1, 1)

8

9.7

mA/Amp

PWDN1, PWDN0 =

(1, 0)

6

6.9

mA/Amp

PWDN1, PWDN0 =

(0, 1)

4

5.0

mA/Amp

PWDN1, PWDN0 =

(0, 0)

3

4.1

mA/Amp

Recovery Time

To 95% of I

Q

23

µs

Shutdown Current

250

µA Out of Bias Pin

1.0

2.0

mA/Amp

Power Supply Rejection Ratio

V

S

=

±1 V

63

80

dB

OPERATING TEMPERATURE RANGE

40

+85

°C

NOTES

1

See Figure 43, R20, R21 = 0

, R1 = open.

Specifications subject to change without notice.

(@ 25 C, V

S

= 6 V, R

L

= 100

, PWDN0, PWDN1 = (1, 1), T

MIN

= 40 C,

T

MAX

= +85 C, unless otherwise noted)

SPECIFICATIONS

LOGIC INPUTS (CMOS-Compatible Logic)

Parameter

Min

Typ

Max

Unit

Logic "1" Voltage

2.2

+V

CC

V

Logic "0" Voltage

0

0.8

V

(PWDN0, PWDN1, V

CC

= 12 V or 6 V; Full Temperature Range)

REV. A

AD8016

4

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8016 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.4 V

Internal Power Dissipation

PSOP3 Package

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 W

Batwing Package

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 W

EPAD Package

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 W

Input Voltage (Common-Mode) . . . . . . . . . . . . . . . . . . . .

±V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . .

±V

S

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range . . . . . . . . . . . . . 65

°C to +125°C

Operating Temperature Range . . . . . . . . . . . . 40

°C to +85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . . 300

°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device on a four-layer board with 10 inches

2

of 1 oz. copper at

85

°C 20-lead PSOP3 package:

JA

= 18

°C/W.

3

Specification is for device on a four-layer board with 10 inches

2

of 1 oz. copper at

85

°C 24-lead Batwing package:

JA

= 28

°C/W.

4

Specification is for device on a four-layer board with 9 inches

2

of 1 oz. copper at

85

°C 28-lead (EPAD) package:

JA

= 29

°C/W.

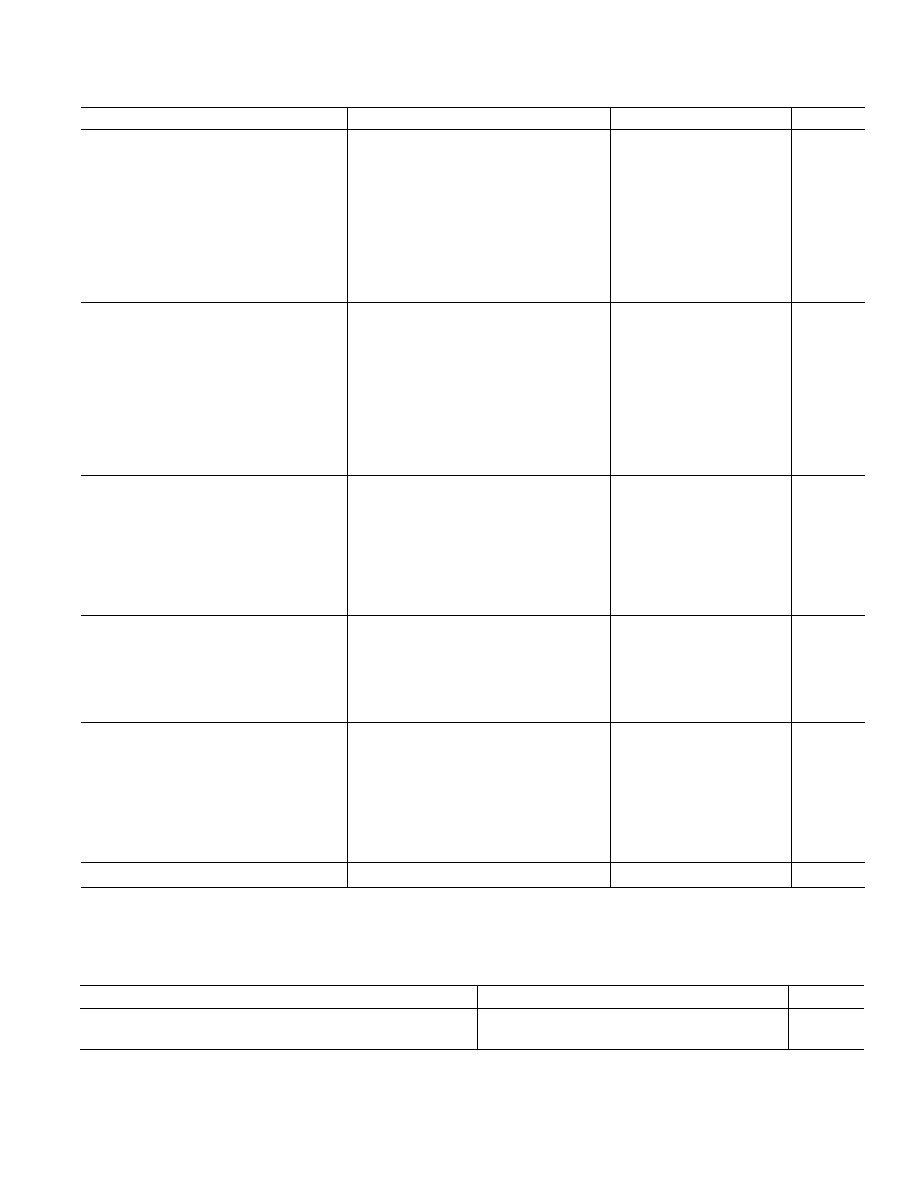

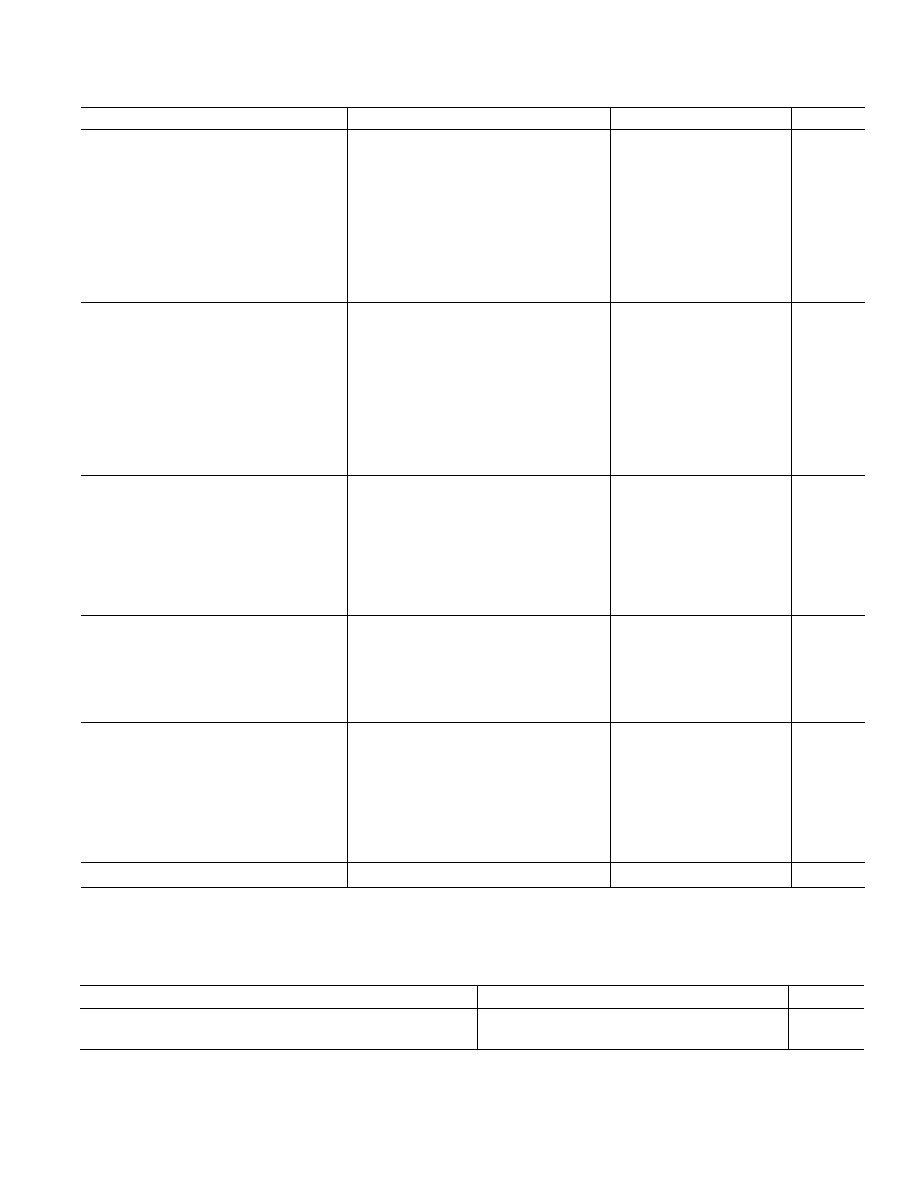

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the AD8016

is limited by the associated rise in junction temperature. The

maximum safe junction temperature for plastic encapsulated

device is determined by the glass transition temperature of the

plastic, approximately 150

°C. Temporarily exceeding this limit

may cause a shift in parametric performance due to a change in

the stresses exerted on the die by the package.

The output stage of the AD8016 is designed for maximum load

current capability. As a result, shorting the output to common

can cause the AD8016 to source or sink 2000 mA. To ensure

proper operation, it is necessary to observe the maximum power

derating curves. Direct connection of the output to either power

supply rail can destroy the device.

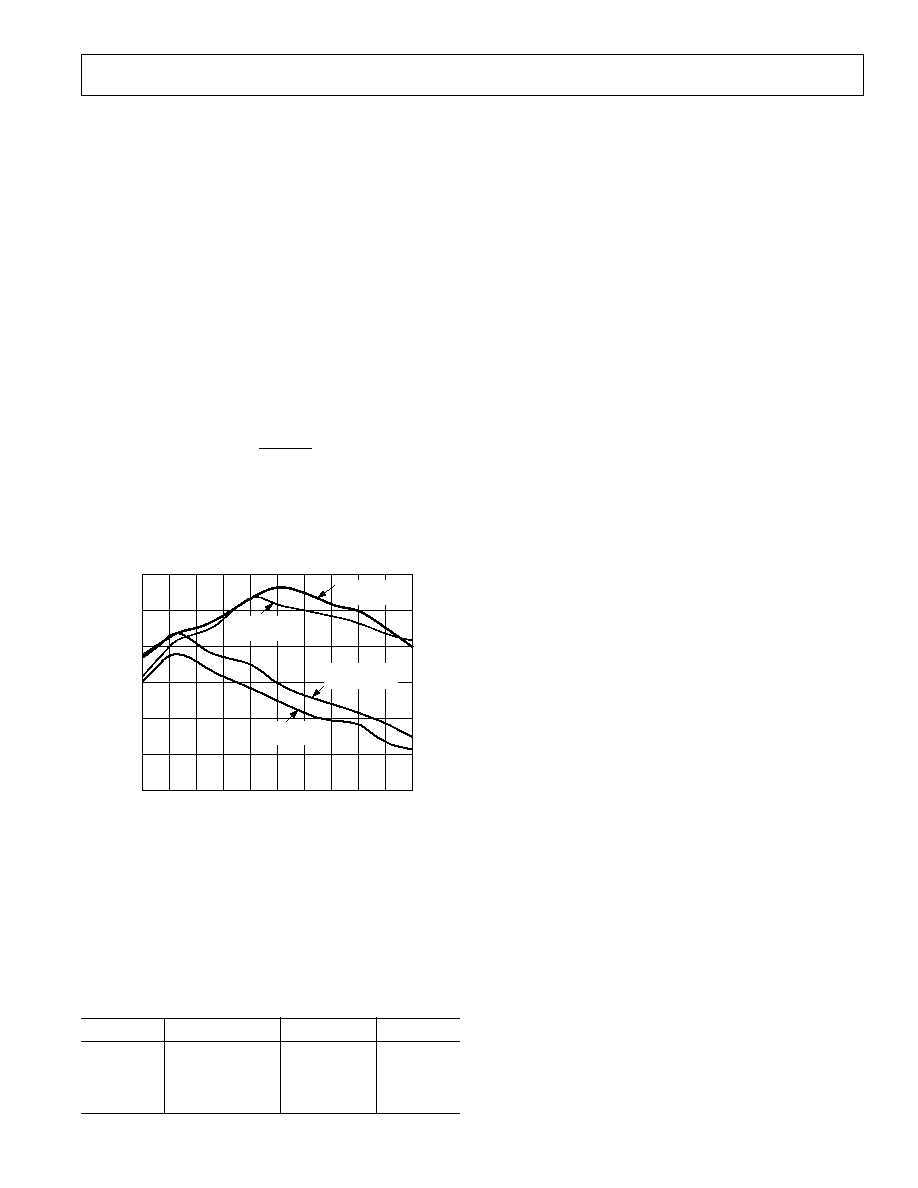

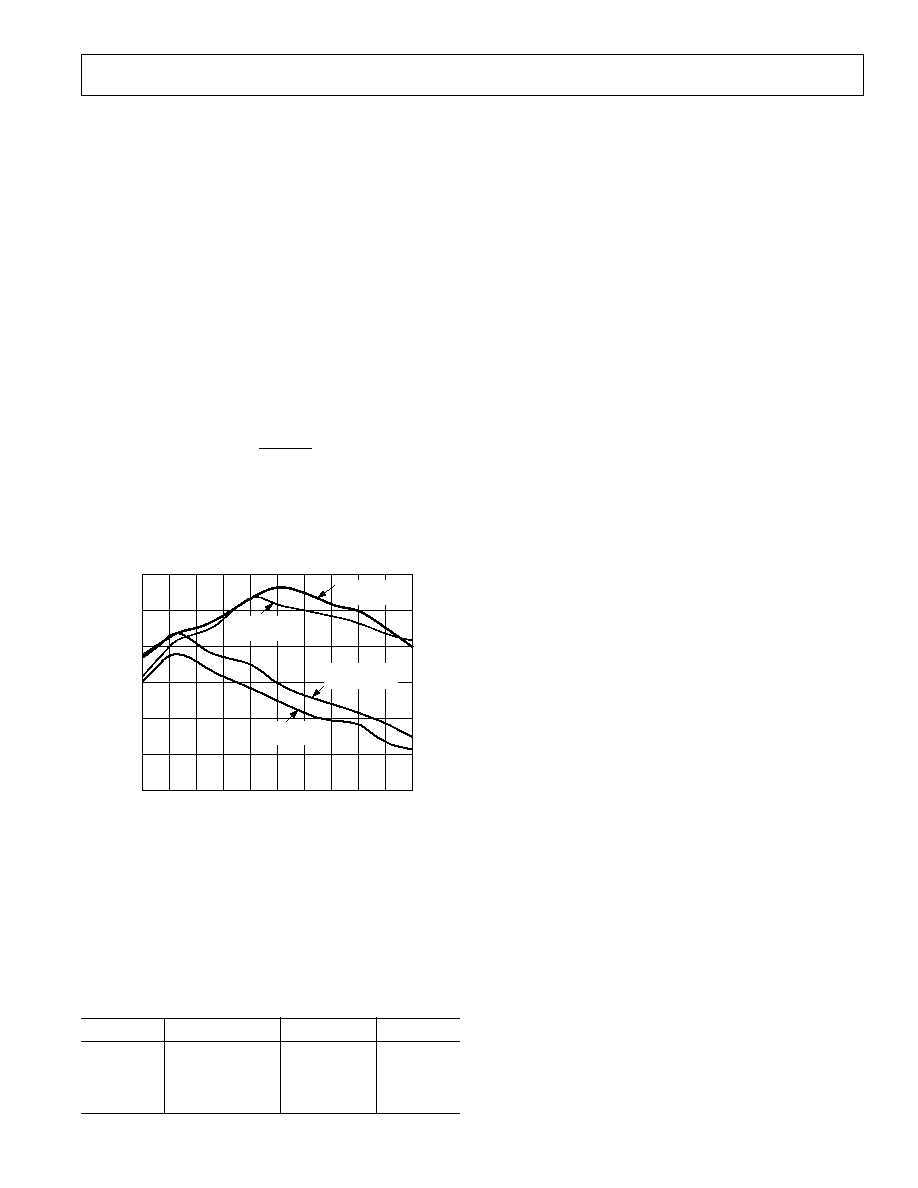

AMBIENT TEMPERATURE C

7

0

MAXIMUM POWER DISSIPATION

Watts

6

5

4

3

2

1

0

10

20

30

40

50

60

70

80

90

PSOP3

BATWING

8

EPAD

Figure 2. Plot of Maximum Power Dissipation vs.

Temperature for AD8016 for T

J

= 125

°C

ORDERING GUIDE

Temperature

Package

Package

Model

Range

Description

Option

AD8016ARP

40

°C to +85°C

20-Lead PSOP3

RP-20

AD8016ARP-Reel

40

°C to +85°C

20-Lead PSOP3

ARP-Reel

AD8016ARP-EVAL

40

°C to +85°C

Evaluation Board

ARP-EVAL

AD8016ARB

40

°C to +85°C

24-Lead Batwing

RB-24

AD8016ARB-Reel

40

°C to +85°C

24-Lead Batwing

ARB-Reel

AD8016ARB-EVAL

40

°C to +85°C

Evaluation Board

ARB-EVAL

AD8016ARE

40

°C to +85°C

28-Lead HTSSOP

RE-28

AD8016ARE-Reel

40

°C to +85°C

28-Lead HTSSOP

ARE-Reel

AD8016ARE-EVAL

40

°C to +85°C

Evaluation Board

ARE-EVAL

REV. A

AD8016

5

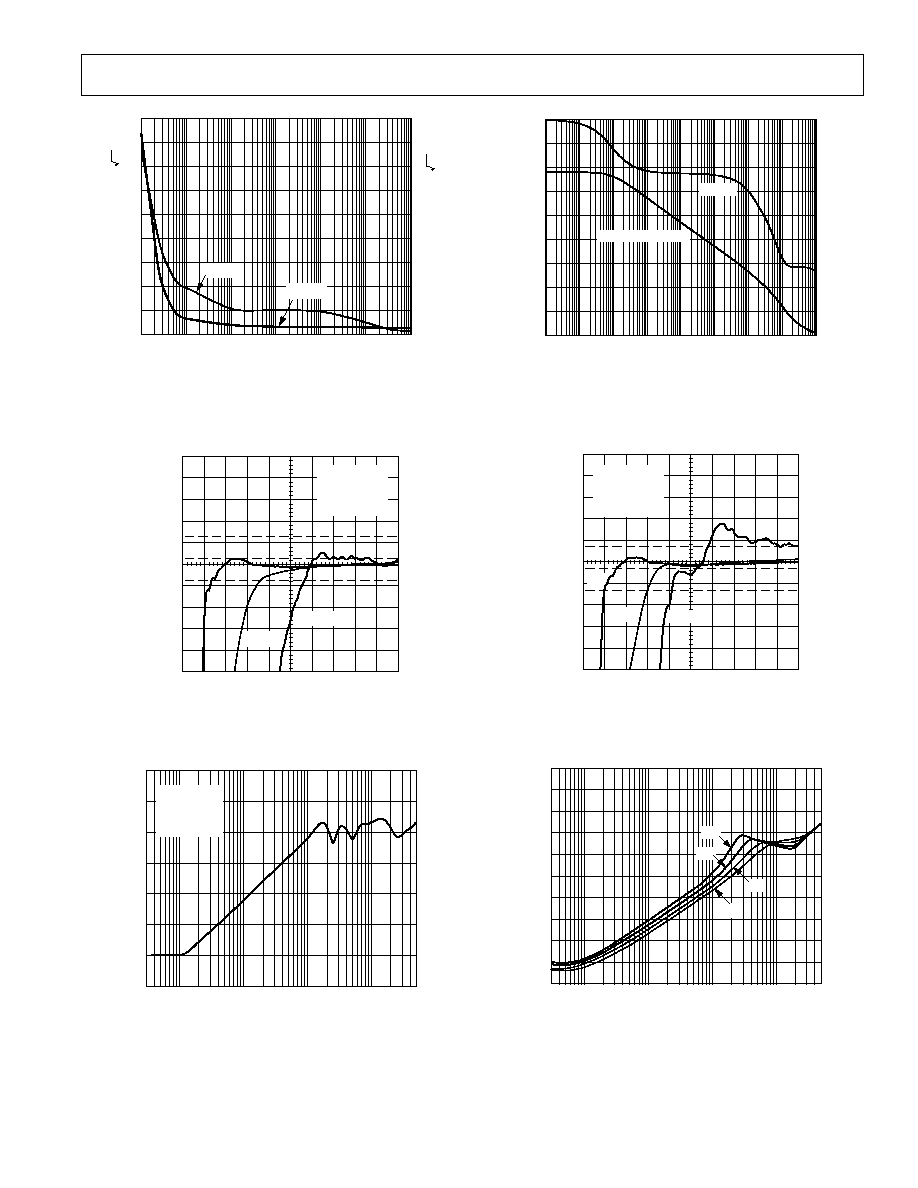

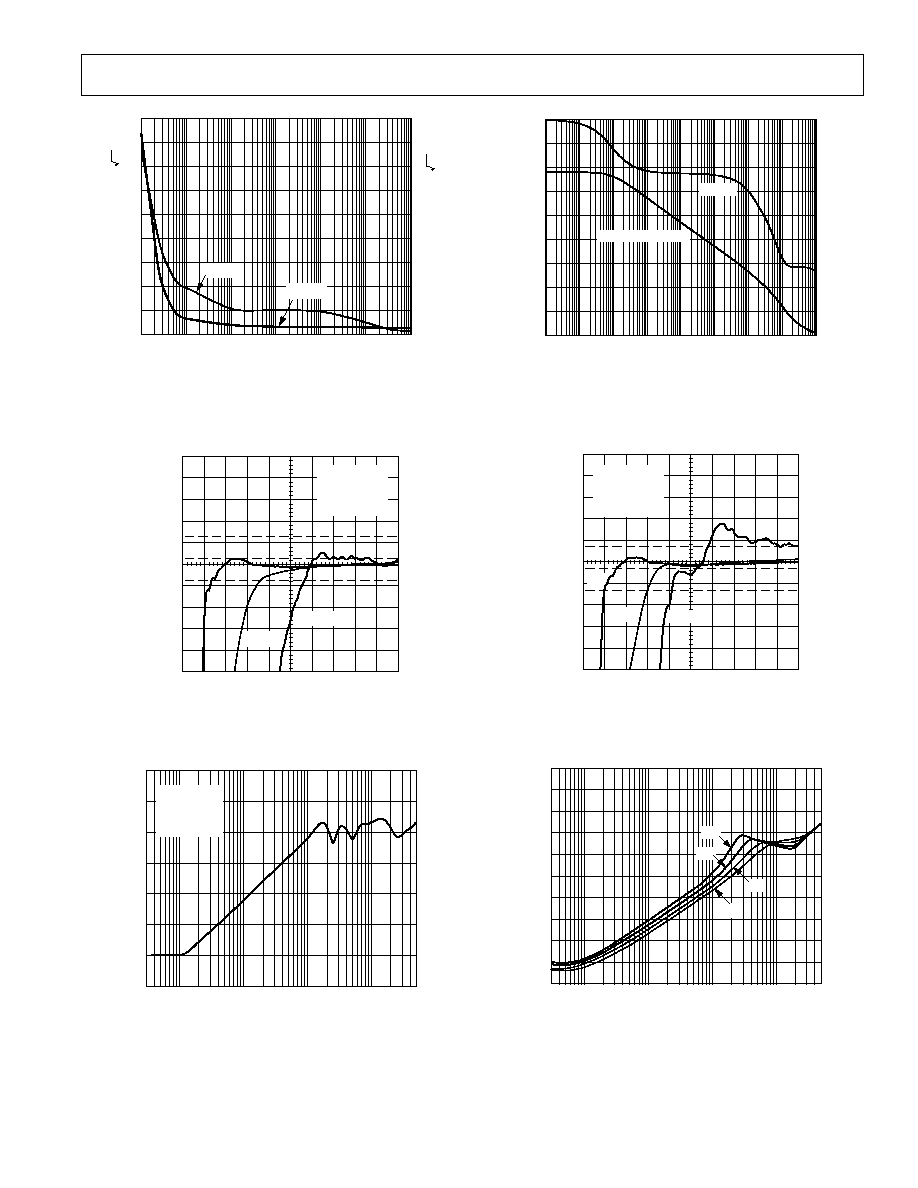

Typical Performance Characteristics

0.1 F

0.1 F

10 F

10 F

49.9

124

499

R

L

V

OUT

+V

S

V

S

+

+

V

IN

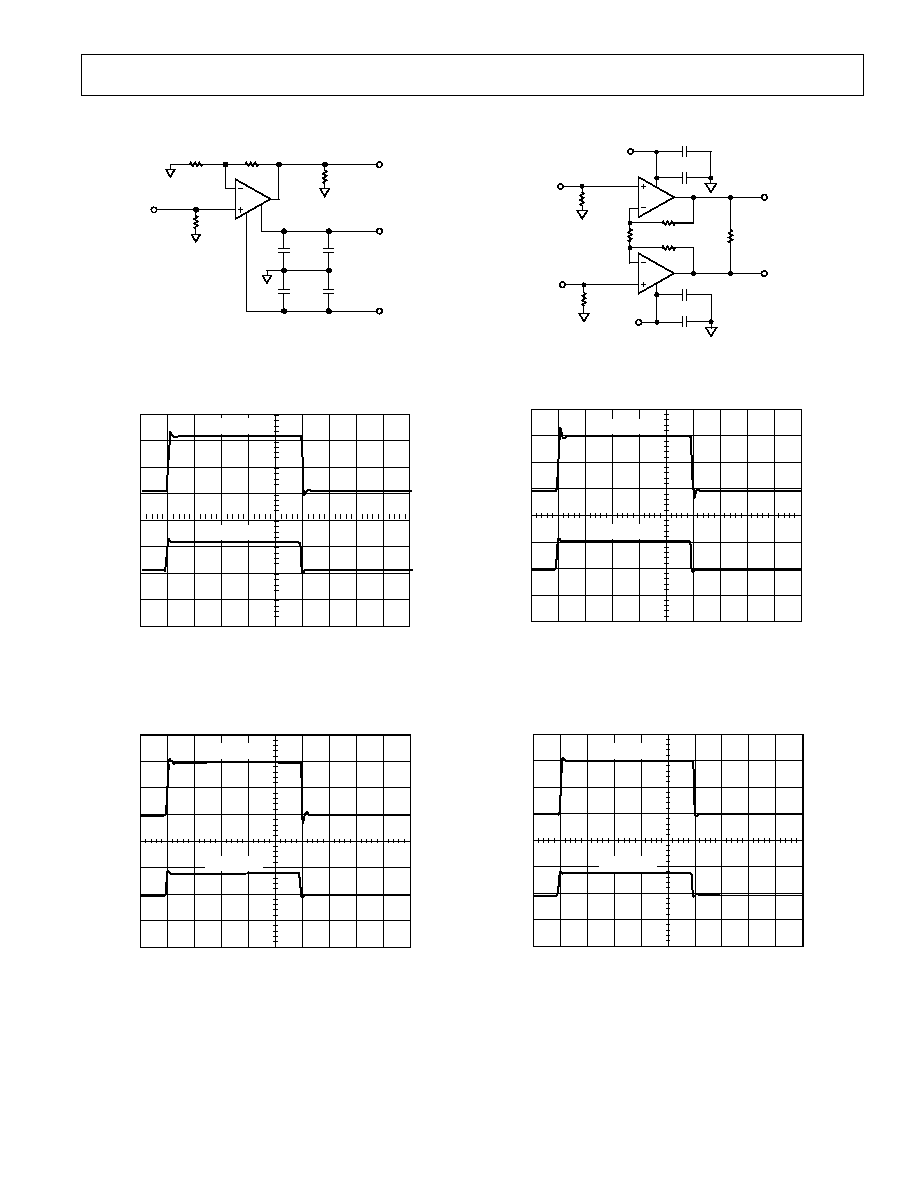

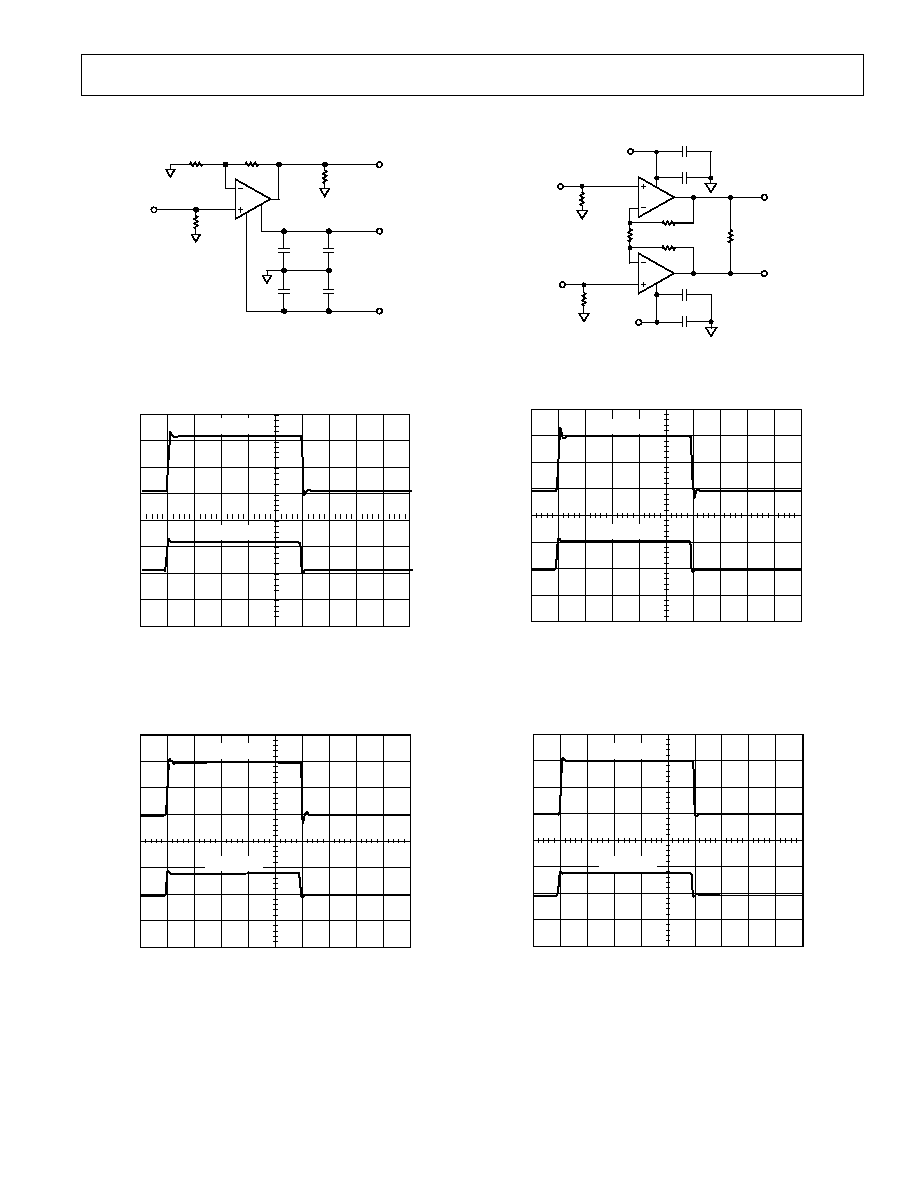

Figure 3. Single-Ended Test Circuit; G = +5

V

OUT

= 100mV

V

IN

= 20mV

VOLTS

TIME 100ns/DIV

Figure 4. 100 mV Step Response; G = +5, V

S

=

±6 V,

R

L

= 25

, Single-Ended

V

OUT

= 5V

V

IN

= 800mV

TIME 100ns/DIV

VOLTS

Figure 5. 4 V Step Response; G = +5, V

S

=

±6 V,

R

L

= 25

, Single-Ended

499

49.9

+V

IN

R

L

499

111

49.9

V

IN

+V

O

V

O

+V

S

V

S

0.1 F

10 F

+

0.1 F

10 F

+

Figure 6. Differential Test Circuit; G = +10

V

OUT

= 100mV

V

IN

= 20mV

VOLTS

TIME 100ns/DIV

Figure 7. 100 mV Step Response; G = +5, V

S

=

±12 V,

R

L

= 25

, Single-Ended

V

OUT

= 4V

V

IN

= 800mV

VOLTS

TIME 100ns/DIV

Figure 8. 4 V Step Response; G = +5, V

S

=

±12 V,

R

L

= 25

, Single-Ended

REV. A

AD8016

6

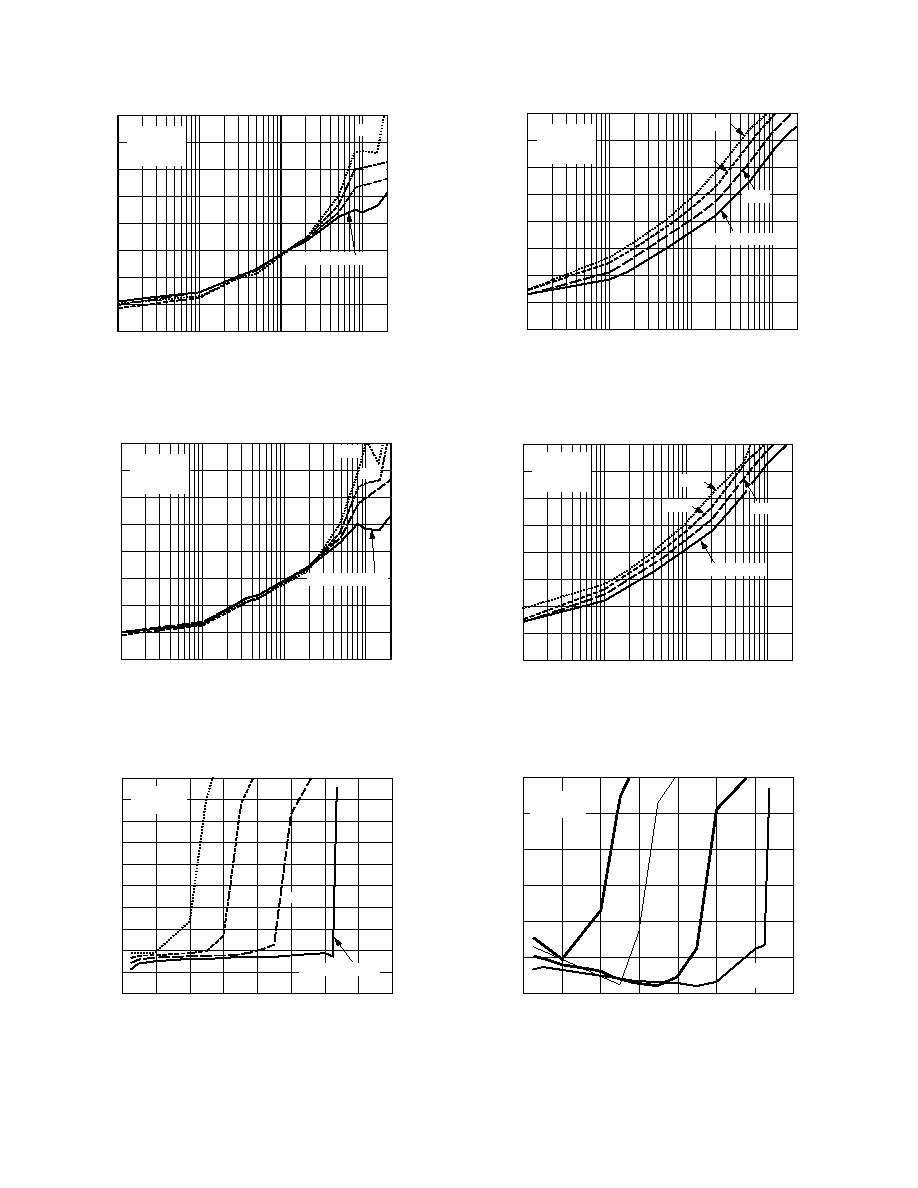

(0,1)

(1,0)

FREQUENCY MHz

30

0.01

10

DISTORTION

dBc

1

0.1

110

100

90

80

70

60

50

40

20

R

F

= 499

G = +10

V

O

= 4V p-p

PWDN 1,0 = (1,1)

(0,0)

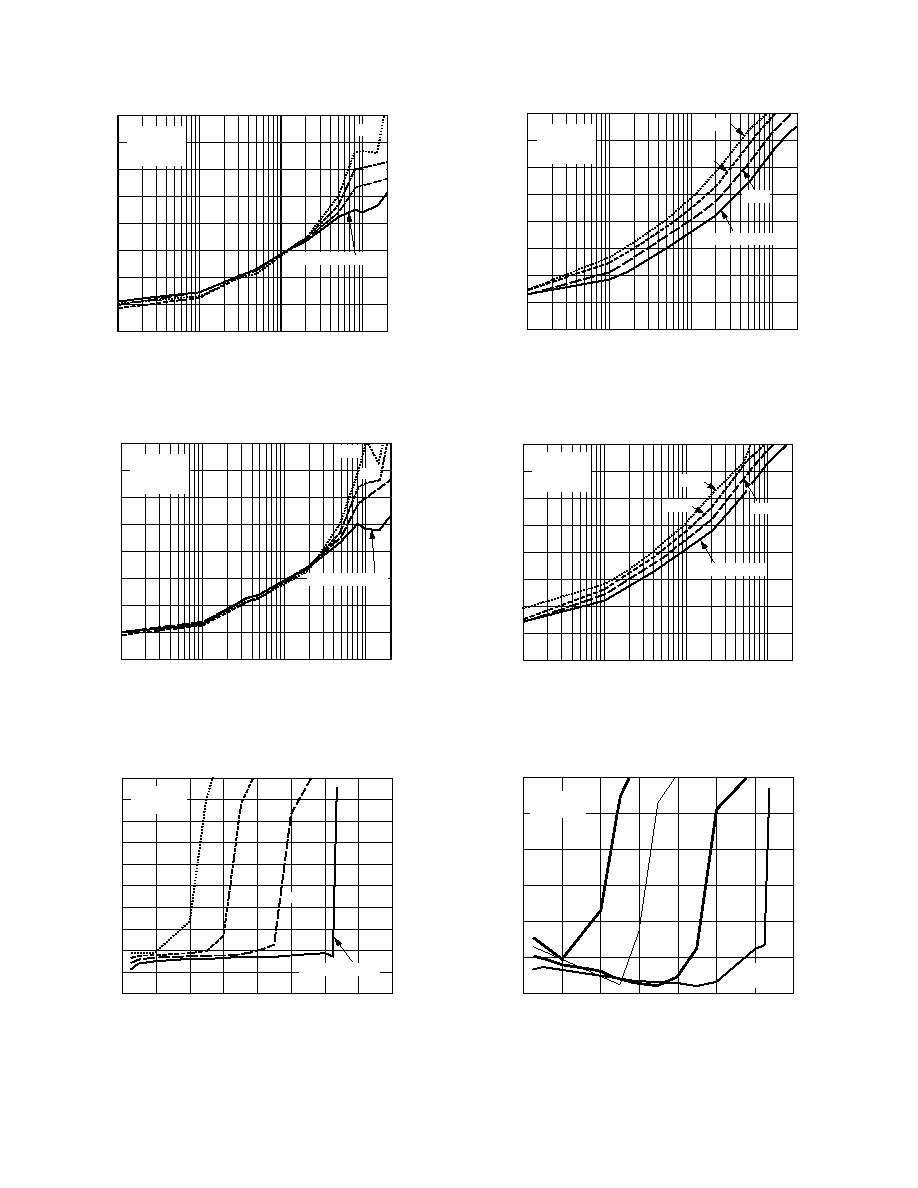

Figure 10. Distortion vs. Frequency; Second Harmonic,

V

S

=

±6 V, R

L

= 50

, Different

(0,1)

PEAK OUTPUT CURRENT mA

30

0

100

DISTORTION

dBc

200

80

75

70

65

60

55

50

40

R

F

= 499

G = +5

PWDN 1,0 = (1,1)

(0,0)

35

45

300

400

500

600

700

800

(1,0)

Figure 11. Distortion vs. Peak Output Current; Second

Harmonic, V

S

=

±12 V, R

L

= 10

, f = 100 kHz, Single-Ended

(1,0)

(0,1)

FREQUENCY MHz

30

0.01

10

DISTORTION

dBc

1

0.1

110

100

90

80

70

60

50

40

20

R

F

= 499

G = +10

V

O

= 4V p-p

PWDN 1,0 = (1,1)

(0,0)

Figure 9. Distortion vs. Frequency; Second Harmonic,

V

S

=

±12 V, R

L

= 50

, Differential

(0,1)

FREQUENCY MHz

30

0.01

10

DISTORTION

dBc

1

0.1

110

100

90

80

70

60

50

40

20

R

F

= 499

G = +10

V

O

= 4V p-p

PWDN 1,0 = (1,1)

(0,0)

(1,0)

Figure 12. Distortion vs. Frequency; Third Harmonic,

V

S

=

±12 V, R

L

= 50

, Differential

(1,0)

(0,1)

FREQUENCY MHz

30

0.01

10

DISTORTION

dBc

1

0.1

110

100

90

80

70

60

50

40

20

R

F

= 499

G = +10

V

O

= 4V p-p

PWDN 1,0 = (1,1)

(0,0)

Figure 13. Distortion vs. Frequency; Third Harmonic,

V

S

=

±6 V, R

L

= 50

, Differential

(1,0)

(0,1)

PEAK OUTPUT CURRENT mA

30

0

100

DISTORTION

dBc

200

90

80

70

50

R

F

= 499

G = +5

PWDN

1,0 = (1,1)

(0,0)

40

60

300

400

500

600

700

Figure 14. Distortion vs. Peak Output Current, Third

Harmonic; V

S

=

±12 V, R

L

= 10

, G = +5, f = 100 kHz,

Single-Ended

REV. A

AD8016

7

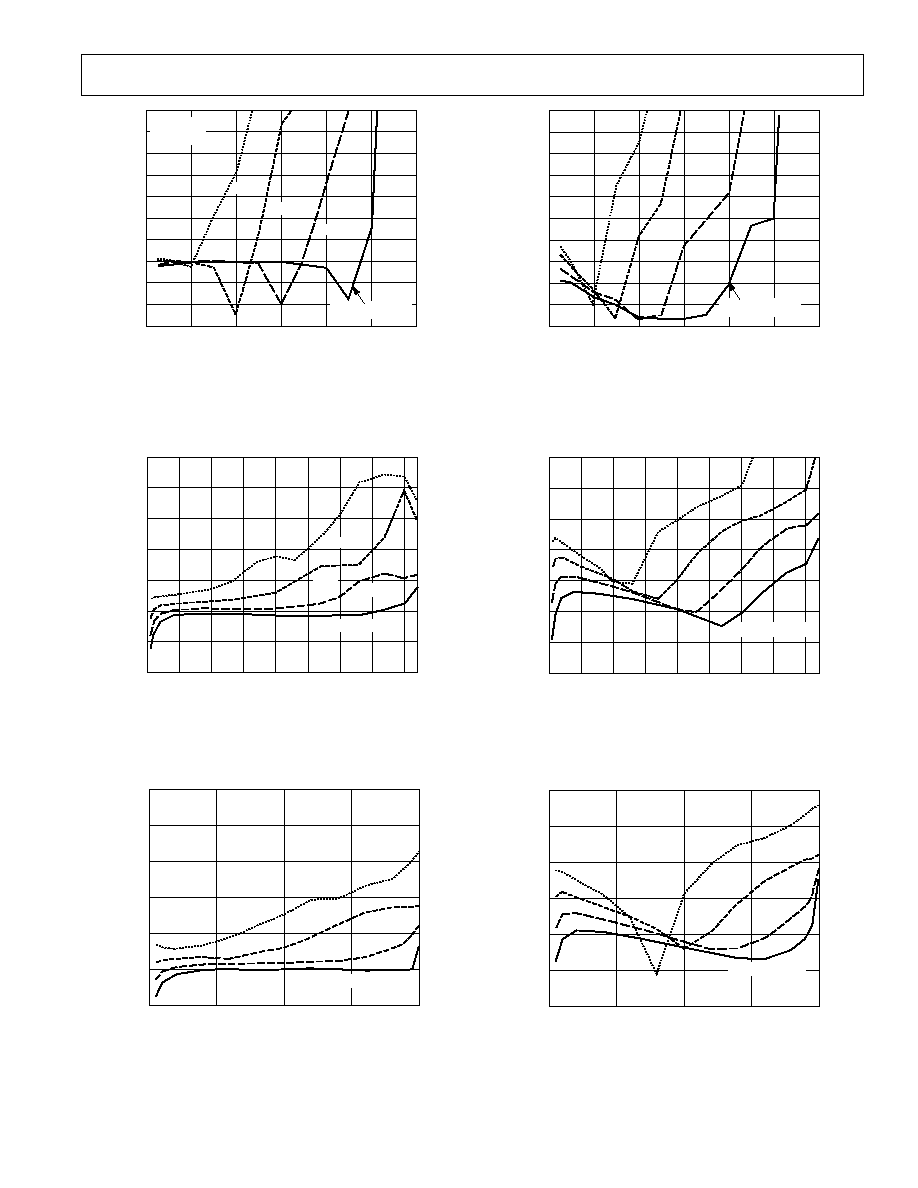

(1,0)

(0,1)

PEAK OUTPUT CURRENT mA

30

0

100

DISTORTION

dBc

200

80

75

70

65

60

55

50

40

R

F

= 499

G = +5

PWDN 1,0 = (1,1)

(0,0)

35

45

300

400

500

600

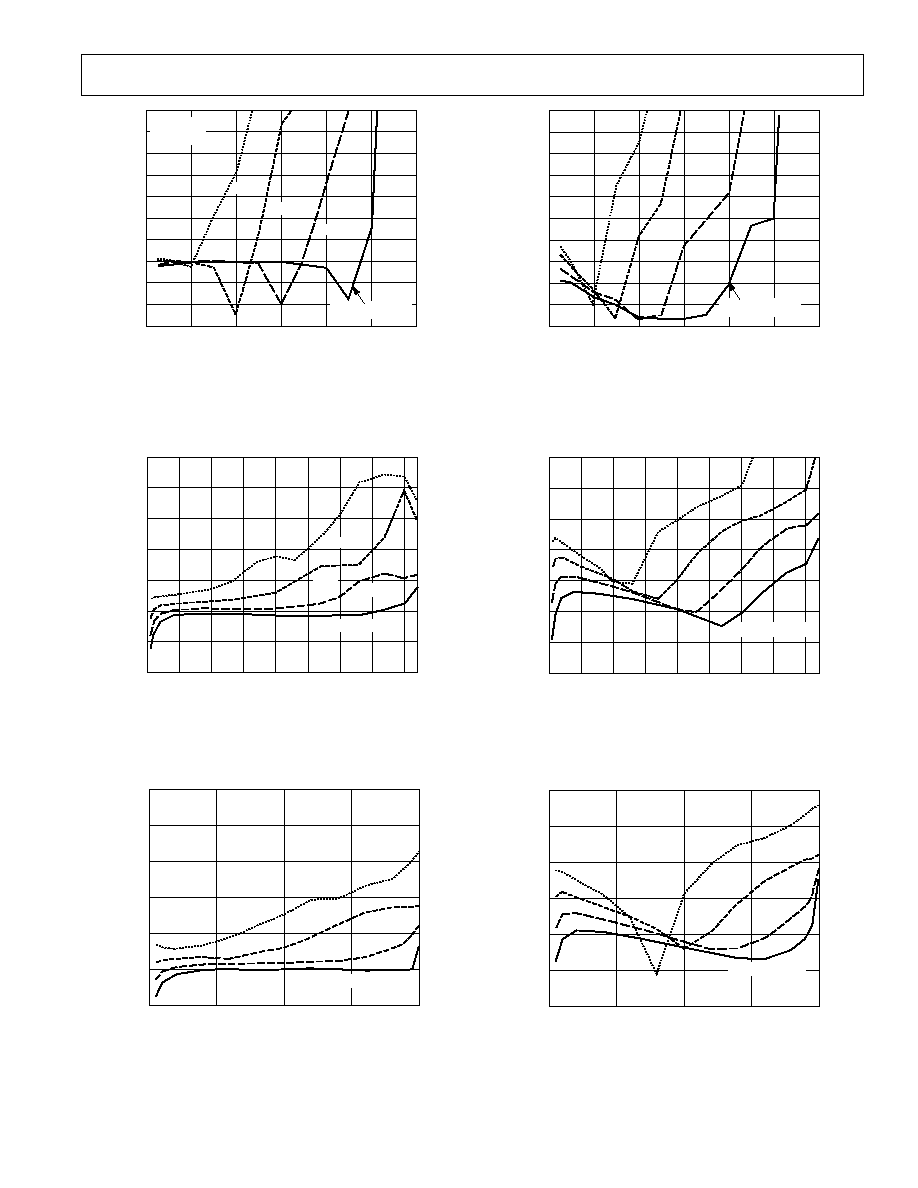

Figure 15. Distortion vs. Peak Output Current; Second

Harmonic, V

S

=

±6 V, R

L

= 5

, f = 100 kHz, Single-Ended

(0,1)

DIFFERENTIAL OUTPUT V p-p

30

0

5

DISTORTION

dBc

10

100

90

80

70

50

PWDN 1,0 = (1,1)

(0,0)

40

60

15

20

25

30

35

40

(1,0)

Figure 16. Distortion vs. Output Voltage; Second

Harmonic, V

S

=

±12 V, G = +10, f = 1 MHz, R

L

= 50

,

Differential

(1,0)

(0,1)

DIFFERENTIAL OUTPUT V p-p

30

0

5

DISTORTION

dBc

10

90

80

70

50

PWDN 1,0 = (1,1)

(0,0)

40

60

15

20

Figure 17. Distortion vs. Output Voltage; Second

Harmonic, V

S

=

±6 V, G = +10, f = 1 MHz, R

L

= 50

,

Differential

(1,0)

(0,1)

PEAK OUTPUT CURRENT mA

30

0

100

DISTORTION

dBc

200

80

75

70

65

60

55

50

40

PWDN 1,0 = (1,1)

(0,0)

35

45

300

400

500

600

Figure 18. Distortion vs. Peak Output Current; Third

Harmonic, V

S

=

±6 V, G = +5, R

L

= 5

, f = 100 kHz,

Single-Ended

(1,0)

(0,1)

DIFFERENTIAL OUTPUT V p-p

30

0

5

DISTORTION

dBc

10

100

90

80

70

50

PWDN 1,0 = (1,1)

(0,0)

40

60

15

20

25

30

35

40

Figure 19. Distortion vs. Output Voltage; Third

Harmonic, V

S

=

±12 V, G = +10, f = 1 MHz, R

L

= 50

,

Differential

(1,0)

(0,1)

DIFFERENTIAL OUTPUT V p-p

30

0

5

DISTORTION

dBc

10

90

80

70

50

PWDN 1,0 = (1,1)

(0,0)

40

60

15

20

Figure 20. Distortion vs. Output Voltage, Third Harmonic,

V

S

=

±6 V, G = +10, f = 1 MHz, R

L

= 50

, Differential

REV. A

AD8016

8

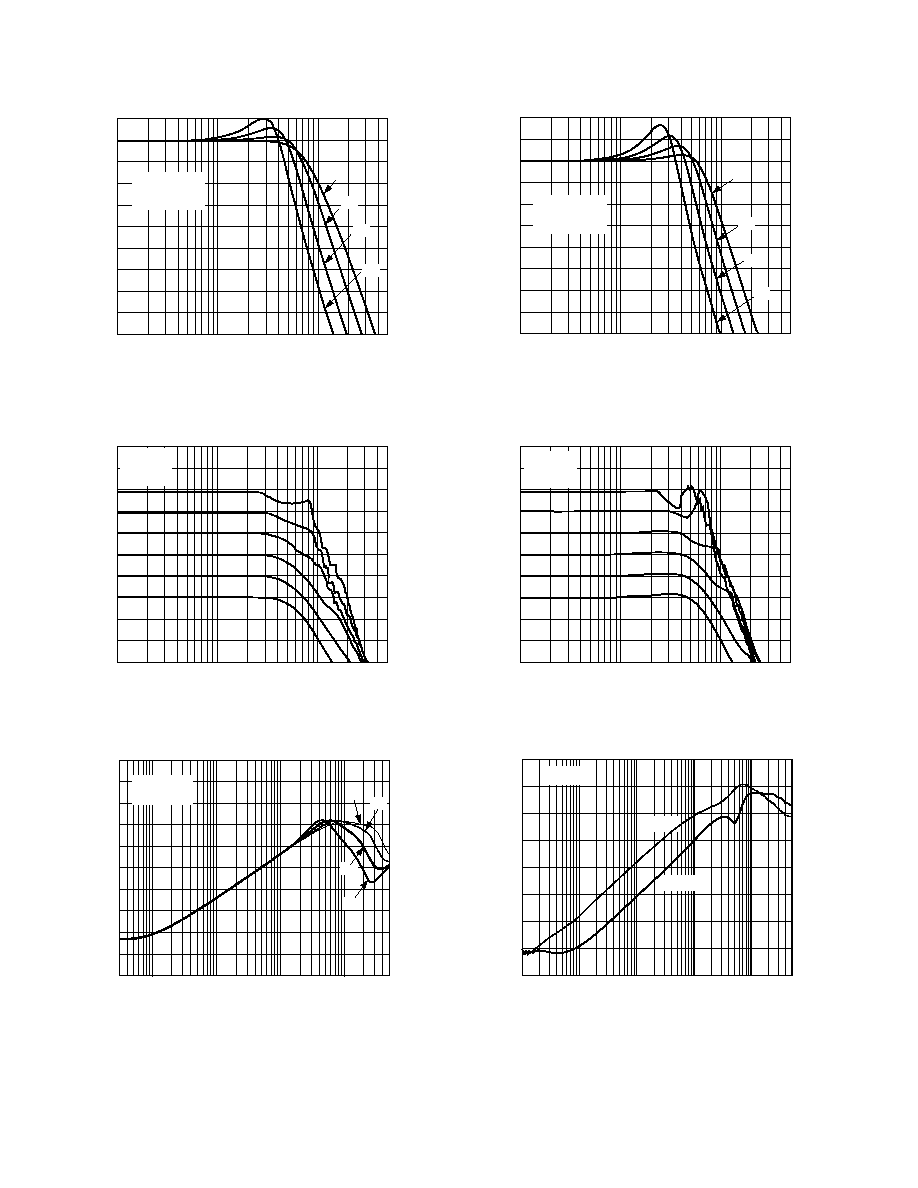

FREQUENCY MHz

1

10

100

500

3

0

3

6

9

12

15

18

21

24

27

NORMALIZED FREQUENCY RESPONSE

dB

V

IN

= 40mV p-p

G = +5

R

L

= 100

1,1

1,0

0,1

0,0

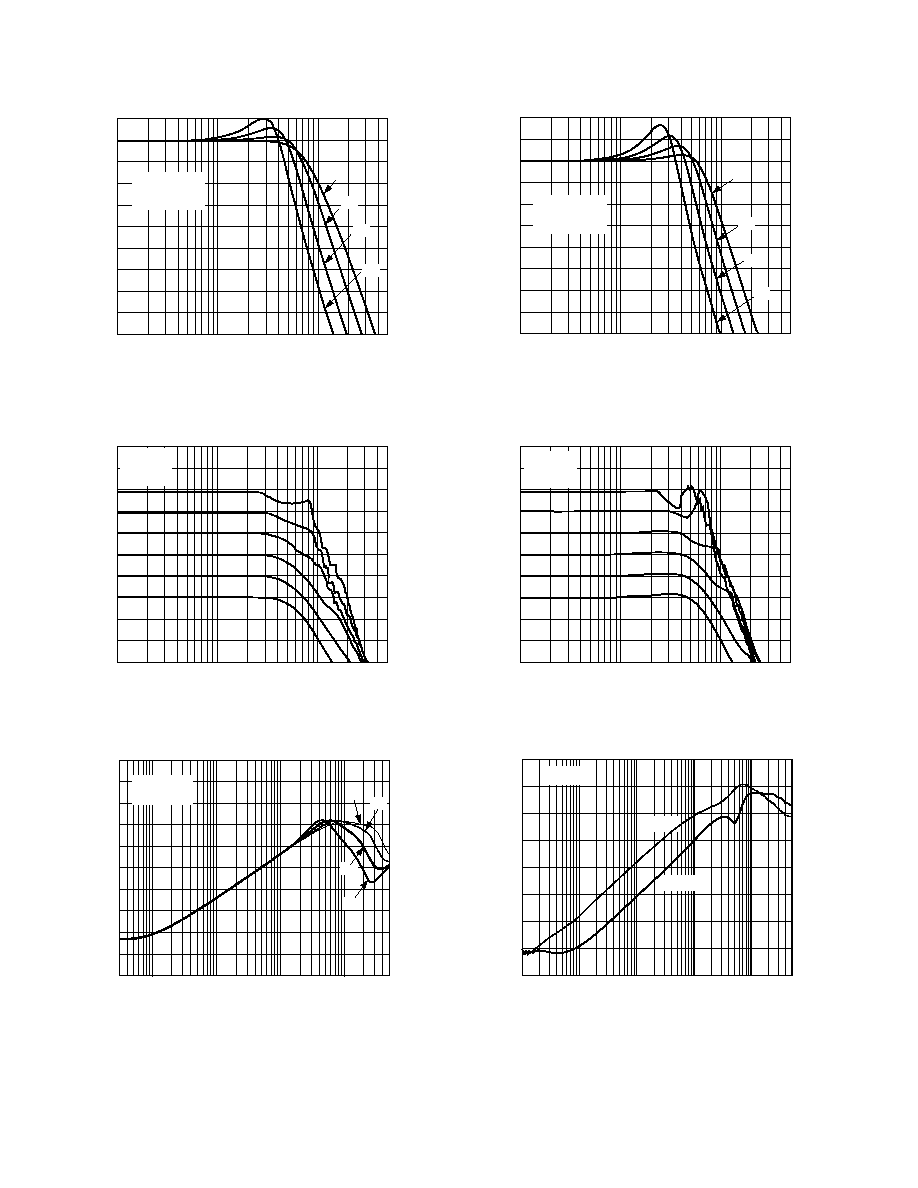

Figure 21. Frequency Response; V

S

=

±12 V,

@ PWDN1, PWDN0 Codes

FREQUENCY MHz

1

OUTPUT VOLTAGE

dBV

16

19

10

100

500

G = +5

R

L

= 100

R

F

= 499

13

10

7

4

1

2

5

8

11

Figure 22. Output Voltage vs. Frequency; V

S

=

±12 V

FREQUENCY MHz

20

0.03

CMRR

dB

0.1

1

10

100

500

10

0

10

20

30

40

50

60

70

80

V

IN

= 2V rms

R

F

= 602

1,1

1,0

0,1

0,0

Figure 23. CMRR vs. Frequency; V

S

=

±12 V

@ PWDN1, PWDN0 Codes

FREQUENCY MHz

1

10

100

500

3

0

3

6

9

12

15

18

21

24

6

NORMALIZED FREQUENCY RESPONSE

dB

V

IN

= 40mV p-p

G = +5

R

L

= 100

1,1

0,1

1,0

0,0

Figure 24. Frequency Response; V

S

=

±6 V,

@ PWDN1, PWDN0 Codes

FREQUENCY MHz

1

PSRR

dB

16

19

10

100

500

13

10

7

4

1

2

5

8

11

G = +5

R

L

= 100

R

F

= 499

Figure 25. PSRR vs. Frequency; V

S

=

±6 V

FREQUENCY MHz

10

0.01

PSRR

dB

20

30

40

50

60

70

80

90

0.1

1

10

100

500

+PSRR

PSRR

R

F

= 499

Figure 26. PSRR vs. Frequency; V

S

=

±12 V

REV. A

AD8016

9

0

FREQUENCY MHz

10

INPUT VOLTAGE NOISE

nV/ Hz

100

80

60

40

20

100

1k

10k

10M

10

20

30

40

50

60

70

80

90

+ INPUT CURRENT NOISE

pA/ Hz

0

120

140

160

180

100k

1M

+I

NOISE

V

IN NOISE

Figure 27. Noise vs. Frequency

+2mV

(0.1%)

2mV

(0.1%)

0

0

5

10

15

20

25

30

35

40

45

5

G = +2

R

F

= 1k

V

OUT

= 2V

STEP

R

L

= 100

OUTPUT VOLTAGE ERROR

2mV/DIV (0.1%/DIV)

V

IN

V

OUT

TIME ns

V

OUT

V

IN

Figure 28. Settling Time 0.1%; V

S

=

±12 V

FREQUENCY MHz

30

0.03

CROSSTALK

dB

0.1

1

10

100

500

40

50

60

70

80

90

V

OUT

= 2V p-p

R

F

= 499

G = +5

R

L

= 100

20

Figure 29. Output Crosstalk vs. Frequency

FREQUENCY MHz

1000000

0.0001

TRANSIMPEDANCE

k

100000

10000

1000

100

10

1

0.1

0.01

0

0.001

0.01

0.1

1

10

100

1000

10000

0

40

80

120

160

200

240

280

320

360

PHASE

Degrees

TRANSIMPEDANCE

PHASE

Figure 30. Open-Loop Transimpedance and Phase

vs. Frequency

0

5

10

15

20

25

30

35

40

45

5

G = +2

R

F

= 1k

V

OUT

= 2V

STEP

R

L

= 100

OUTPUT VOLTAGE ERROR

2mV/DIV (0.1%/DIV)

TIME ns

+2mV

(0.1%)

2mV

(0.1%)

0

V

OUT

V

IN

V

OUT

V

IN

Figure 31. Settling Time 0.1%; V

S

=

±6 V

FREQUENCY MHz

1000

0.03

OUTPUT IMPEDANCE

0.1

1

10

100

500

100

10

1

0.1

0.01

0,0

0,1

1,1

1,0

Figure 32. Output Impedance vs. Frequency

@ PWDN1, PWDN0 Codes

REV. A

AD8016

10

V

IN

= 2V/DIV

V

OUT

= 5V/DIV

V

IN

V

OUT

100

0

100

200

300

400

500

600

700

800

900

TIME ns

0V

0V

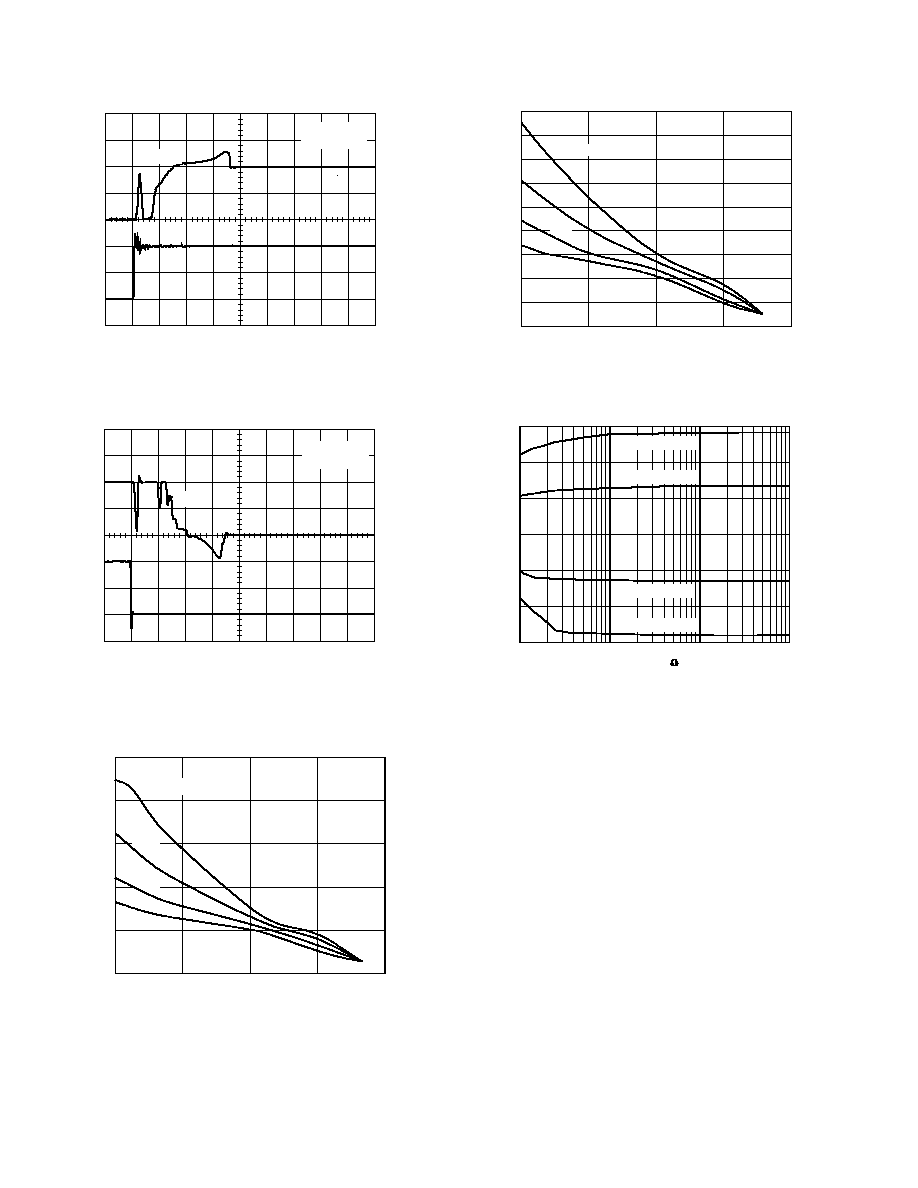

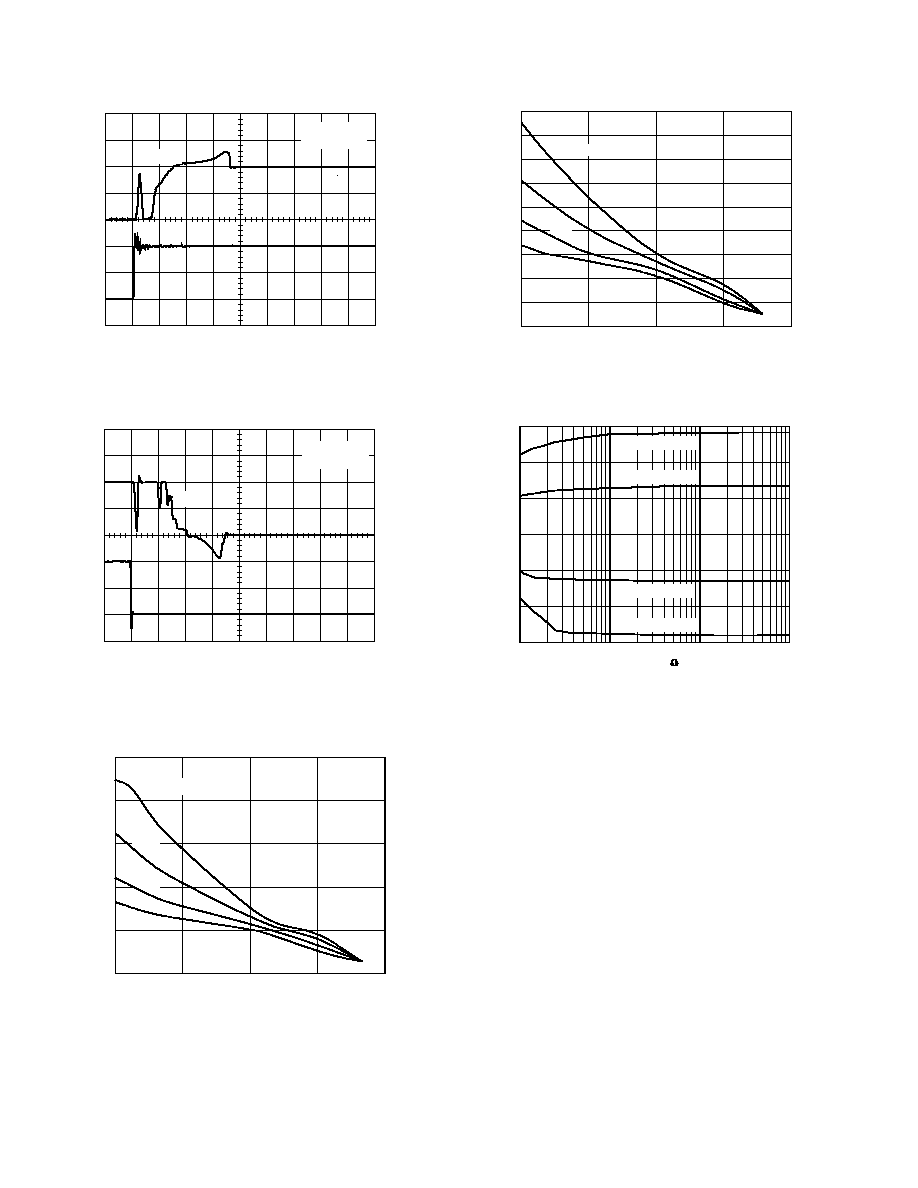

a. Overload Recovery; V

S

=

±12 V, G = +5, R

L

= 100

100

0

100

200

300

400

500

600

700

800

900

TIME ns

V

IN

V

OUT

0V

0V

V

IN

= 2V/DIV

V

OUT

= 5V/DIV

b. Overload Recovery; V

S

=

±12 V, G = +5, R

L

= 100

Figure 33.

I

BIAS

A

25

0

I

Q

mA

20

15

10

5

0

50

100

150

200

[0,1]

[0,0]

[1,0]

PWDN 1,0 = [1,1]

Figure 34. I

Q

vs. I

BIAS

Pin Current; V

S

=

±12 V

I

BIAS

A

18

0

I

Q

mA

16

14

12

10

8

50

100

150

200

6

4

2

0

PWDN 1,0 = [1.1]

[1,0]

[0,1]

[0,0]

Figure 35. I

Q

vs. I

BIAS

Pin Current; V

S

=

±6 V

R

LOAD

OUTPUT SWING

Volts

12

8

10

100

1k

10k

4

0

4

8

12

+V

OUT

, V

S

= 12V

+V

OUT

, V

S

= 6V

V

OUT

, V

S

= 6V

V

OUT

, V

S

= 12V

Figure 36. Output Voltage vs. R

LOAD

REV. A

AD8016

11

FEEDBACK RESISTOR SELECTION

In current feedback amplifiers, selection of feedback and gain

resistors will have an impact on the MTPR performance, band-

width and gain flatness. Care should be exercised in the selec-

tion of these resistors so that optimum performance is achieved.

The table below shows the recommended resistor values for use

in a variety of gain settings. These values are suggested as a

good starting point when designing for any application.

Table I. Resistor Selection Guide

Gain

R

F

( )

R

G

( )

+1

1 k

1

500

500

+2

650

650

+5

750

187

+10

1 k

111

BIAS PIN AND PWDN FEATURES

The AD8016 is designed to cover both CO (Central Office) and

CPE (Customer Premise Equipment) ends of an xDSL applica-

tion. It offers full versatility in setting quiescent bias levels for

the particular application from full ON to reduced bias (in three

steps) to full OFF (via BIAS pin). This versatility gives the

modem designer the flexibility to maximize efficiency while

maintaining reasonable levels of Multitone Power Ratio (MTPR)

performance. Optimizing driver efficiency while delivering the

required DMT power is accomplished with the AD8016 through

the use of on-chip power management features. Two digitally

programmable logic pins, PWDN1 and PWDN0, may be used

to select four different bias levels; 100%, 60%, 40%, and 25%

of full quiescent power (see Table II).

Table II. PWDN Code Selection Guide

PWDN1

PWDN0

Code

Code

Quiescent Bias Level

1

1

100% (Full ON)

1

0

60%

0

1

40%

0

0

25% (Low Z

OUT

but Not OFF)

X

X

Full OFF (High Z

OUT

via 250

µA

Pulled Out of BIAS Pin)

The bias level can be controlled with TTL logic levels (HI = 1)

applied to PWDN1 and PWDN0 pins alone or in combination

with BIAS control pin. The DGND or digital ground pin is the

logic ground reference for PWDN1 and PWDN0 pins. In typical

ADSL applications where

± 12 V or ± 6 V supplies (also single

supplies) are used, the DGND pin is connected to analog ground.

The BIAS control pin by itself is a means to continuously adjust

the AD8016 internal biasing and thus quiescent current I

Q

. By

pulling out a current of 0

µA (or open) to approximately 200 µA,

the quiescent current can be adjusted from 100% (full ON) to a

full OFF condition. The full OFF condition yields a high output

impedance. Because of on-chip resistor variation of up to

±20%

the actual amount of current required to fully shut down the

AD8016 can vary. To institute a full chip shutdown, a pull-

down current of 250

µA is recommended. See Figure 38 for

logic drive circuit for complete amplifier shutdown. Figures 34

and 35 show the relationship between current pulled out of

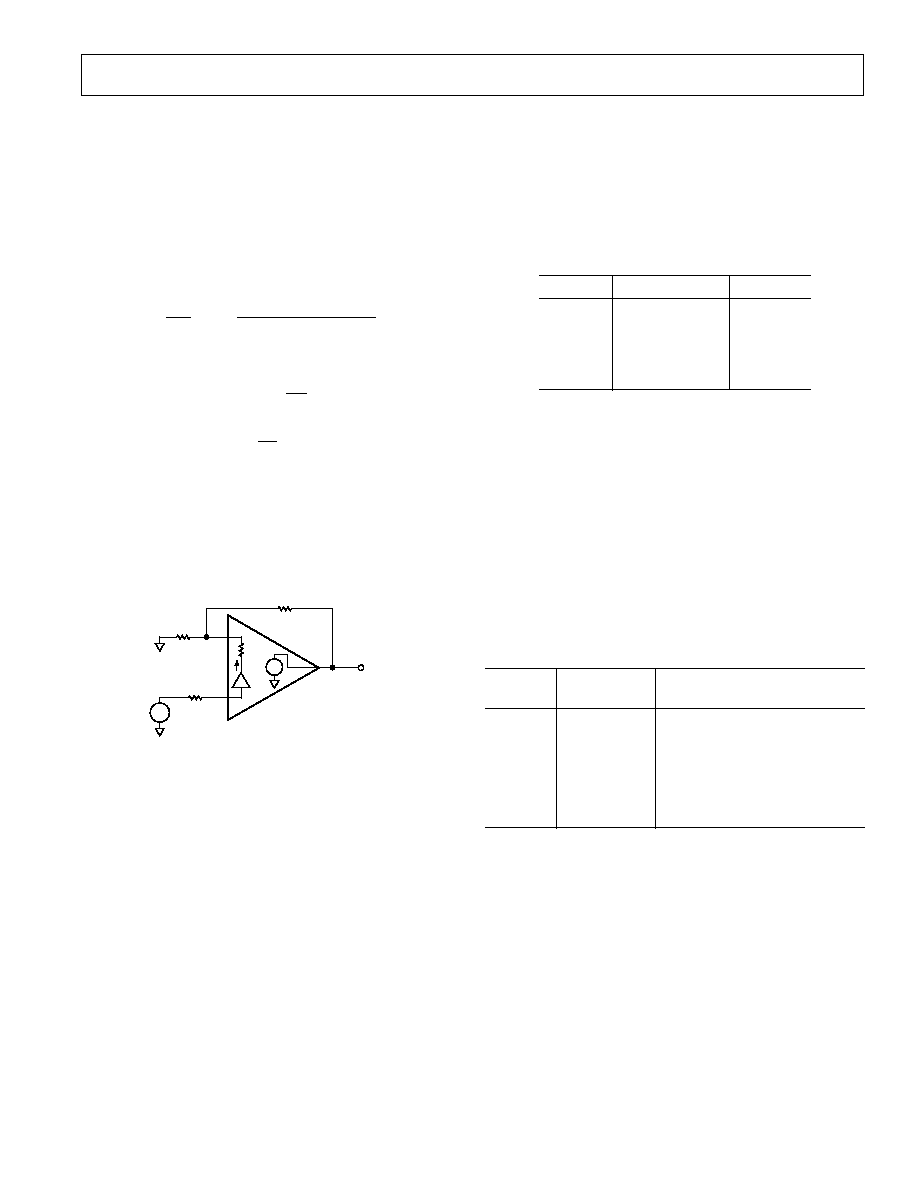

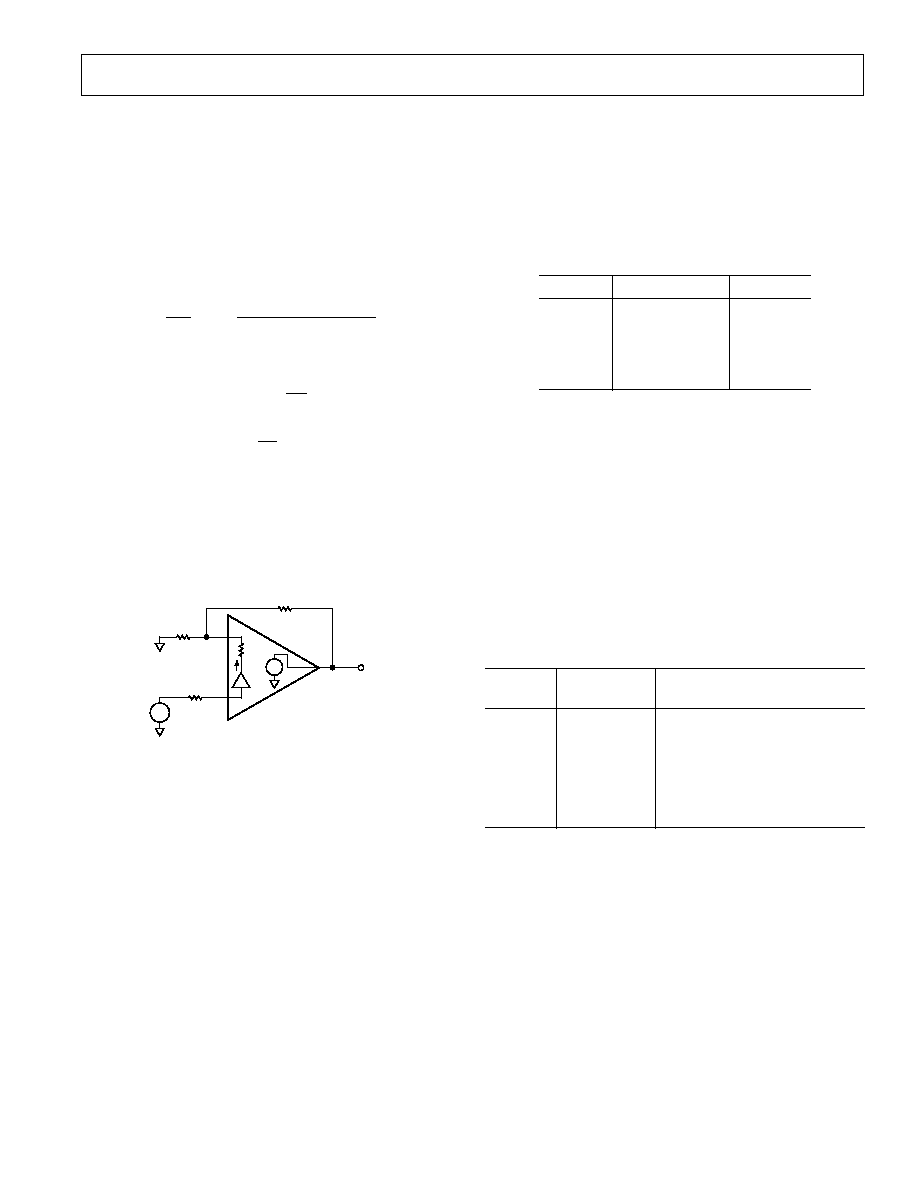

THEORY OF OPERATION

The AD8016 is a current feedback amplifier with high (500 mA)

output current capability. With a current feedback amplifier the

current into the inverting input is the feedback signal and the

open-loop behavior is that of a transimpedance, dVo/dIin or T

Z

.

The open-loop transimpedance is analogous to the open-loop

voltage gain of a voltage feedback amplifier. Figure 37 shows a

simplified model of a current feedback amplifier. Since R

IN

is

proportional to 1/g

m

, the equivalent voltage gain is just T

Z

× g

m

,

where g

m

is the transconductance of the input stage. Basic

analysis of the follower with gain circuit yields:

V

V

G

T

S

T

S

G

R

R

O

IN

Z

Z

IN

F

=

×

+

×

+

( )

( )

where:

G

R

R

R

g

F

G

IN

m

= +

=

1

1

25

Recognizing that G

× R

IN

<< R

F

for low gains, the familiar

result of constant bandwidth with gain for current feedback

amplifiers is evident, the 3 dB point being set when |T

Z

| = R

F

.

Of course, for a real amplifier there are additional poles that

contribute excess phase and there will be a value for R

F

below

which the amplifier is unstable. Tolerance for peaking and desired

flatness will determine the optimum R

F

in each application.

T

Z

R

IN

I

IN

+

+

R

F

V

OUT

R

N

R

G

V

IN

Figure 37. Simplified Block Diagram

The AD8016 is the first current feedback amplifier capable of

delivering 400 mA of output current while swinging to within

2 V of either power supply rail. This enables full CO ADSL

performance on only 12 V rails, an immediate 20% power saving.

The AD8016 is also unique in that it has a power management

system included on-chip. It features four user programmable

power levels (all of which provide a low output impedance of the

driver), as well as the provision for complete shutdown (high

impedance state). Also featured is a thermal shutdown with

alarm signal.

POWER SUPPLY AND DECOUPLING

The AD8016 should be powered with a good quality (i.e., low

noise) dual supply of

±12 V for the best distortion and Multi-

tone Power Ratio (MTPR) performance. Careful attention must

be paid to decoupling the power supply pins. A 10

µF capacitor

located in near proximity to the AD8016 is required to provide

good decoupling for lower frequency signals. In addition, 0.1

µF

decoupling capacitors should be located as close to each of the

four power supply pins as is physically possible. All ground pins

should be connected to a common low impedance ground

plane.

REV. A

AD8016

12

BIAS pin (I

BIAS

) and the supply current (I

Q

). A typical shut-

down I

Q

is less than 1 mA total. Alternatively, an external pull-

down resistor to ground or a current sink attached to the BIAS

pin can be used to set I

Q

to lower levels (see Figure 39). The

BIAS pin may be used in combination with the PWDN1 and

PWDN0 pins; however, diminished MTPR performance may

result when I

Q

is lowered too much. Current pulled away from

the BIAS pin will shunt away a portion of the internal bias cur-

rent. Setting PWDN1 or PWDN0 to Logic 0 also shunts away a

portion of the internal bias current. The reduction of quiescent

bias levels due to the use of PWDN1 and PWDN0 is consistent

with the percentages established in Table II. When PWDN0 alone

is set to Logic 0, and no other means of reducing the internal

bias currents is used, full-rate ADSL signals may be driven while

maintaining reasonable levels of MTPR.

R2

50k

BIAS

R1

*

3.3V LOGIC

2N3904

*R1 = 47k FOR 12V

S

OR +12V

S

,

R1 = 22k FOR 6V

S

.

Figure 38. Logic Drive of BIAS Pin for Complete Amplifier

Shutdown

THERMAL SHUTDOWN

The AD8016ARB and ARP have been designed to incorporate

shutdown protection against accidental thermal overload. In the

event of thermal overload, the AD8016 was designed to shut

down at a junction temperature of 165

°C and return to normal

operation at a junction temperature 140

°C The AD8016 will

continue to operate, cycling on and off, as long as the thermal

overload condition remains. The frequency of the protection

cycle depends on the ambient environment, severity of the ther-

mal overload condition, the power being dissipated and the ther-

mal mass of the PCB beneath the AD8016. When the AD8016

begins to cycle due to thermal stress, the internal shutdown

circuitry draws current out of the node connected in common

with the BIAS pin, while the voltage at the BIAS pin goes to the

negative rail. When the junction temperature returns to 140

°C,

current is no longer drawn from this node and the BIAS pin

voltage returns to the positive rail. Under these circumstances,

the BIAS pin can be used to trip an alarm indicating the pres-

ence of a thermal overload condition.

Figure 39 also shows three circuits for converting this signal to a

standard logic level.

V

CC

+5V

BIAS

10k

ALARM

1/4 HCF 40109B

SGS - THOMSON

10k

+5V

100k

1M

BIAS

ALARM

MIN 350

OR

V

EE

10k

200 A

V

CC

BIAS

PWDN1

BIAS

OR

0200 A

V = V

CC

0.2V

SHUT-

DOWN

AD8016

PWDN0

Figure 39. Shutdown and Alarm Circuit

APPLICATIONS

The AD8016ARP and AD8016ARB dual xDSL line driver

amplifiers are the most efficient xDSL line drivers available to

the market today. The AD8016 may be applied in driving modu-

lated signals including Discrete Multitone (DMT) in either

direction; upstream from Customer Premise Equipment (CPE)

to the Central Office (CO) and downstream from CO to CPE.

The most significant thermal management challenge lies in

driving downstream information from CO sites to the CPE.

Driving xDSL information downstream suggests the need to

locate many xDSL modems in a single CO site. The implication

is that several modems will be placed onto a single printed cir-

cuit board residing in a card cage located in a variety of ambient

conditions. Environmental conditioners such as fans or air con-

ditioning may or may not be available, depending on the density

of modems and the facilities contained at the CO site. To achieve

long-term reliability and consistent modem performance, designers

of CO solutions must consider the wide array of ambient condi-

tions that exist within various CO sites.

MULTITONE POWER RATIO OR MTPR

ADSL systems rely on Discrete Multitone (or DMT) modulation

to carry digital data over phone lines. DMT modulation appears

in the frequency domain as power contained in several individual

frequency subbands, sometimes referred to as tones or bins, each

of which is uniformly separated in frequency. (See Figure 1 for

example of downstream DMT signals used in evaluating MTPR

performance.) A uniquely encoded, Quadrature Amplitude Modu-

lation (QAM) signal occurs at the center frequency of each

subband or tone. Difficulties will exist when decoding these

subbands if a QAM signal from one subband is corrupted by the

QAM signal(s) from other subbands, regardless of whether the

corruption comes from an adjacent subband or harmonics of

other subbands. Conventional methods of expressing the output

signal integrity of line drivers, such as spurious free dynamic range

(SFDR), single-tone harmonic distortion or THD, two-tone

Intermodulation Distortion (IMD) and 3rd order intercept (IP3)

become significantly less meaningful when amplifiers are required

to drive DMT and other heavily modulated waveforms. A typical

xDSL downstream DMT signal may contain as many as 256

carriers (subbands or tones) of QAM signals. Multitone Power

Ratio (MTPR) is the relative difference between the measured

power in a typical subband (at one tone or carrier) versus the

power at another subband specifically selected to contain no QAM

data. In other words, a selected subband (or tone) remains open

or void of intentional power (without a QAM signal) yielding an

empty frequency bin. MTPR, sometimes referred to as the "empty

bin test," is typically expressed in dBc, similar to expressing the

relative difference between single-tone fundamentals and 2nd or

3rd harmonic distortion components.

See Figure 1 for a sample of the ADSL downstream spectrum

showing MTPR results while driving 20.4 dBm of power onto a

100

line. Measurements of MTPR are typically made at the

output (line side) of ADSL hybrid circuits. (See Figure 46a for

an example of Analog Devices' hybrid schematic.) MTPR can

be affected by the components contained in the hybrid circuit,

including the quality of the capacitor dielectrics, voltage ratings

and the turns ratio of the selected transformers. Other compo-

nents aside, an ADSL driver hybrid containing the AD8016 can be

optimized for the best MTPR performance by selecting the turns

ratio of the transformers. The voltage and current demands from

the differential driver changes, depending on the transformer

REV. A

AD8016

13

turns ratio. The point on the curve indicating maximum dynamic

headroom is achieved when the differential driver delivers both

the maximum voltage and current while maintaining the lowest

possible distortion. Below this point the driver has reserve cur-

rent-driving capability and experiences voltage clipping while

above this point the amplifier runs out of current drive capabil-

ity before the maximum voltage drive capability is reached.

Since a transformer reflects the secondary load impedance back

to the primary side by the square of the turns ratio, varying the

turns ratio changes the load across the differential driver. In the

transformer configuration of Figure 46a and 46b, the turns ratio

of the selected transformer is effectively doubled due to the

parallel wiring of the transformer primaries within this ADSL

driver hybrid. The following equation may be used to calculate

the load impedance across the output of the differential driver,

reflected by the transformers, from the line side of the xDSL

driver hybrid. Z' is the primary side impedance as seen by the

differential driver; Z

2

is the line impedance and N is the trans-

former turns ratio.

Z

Z

N

'

×

(

)

2

2

2

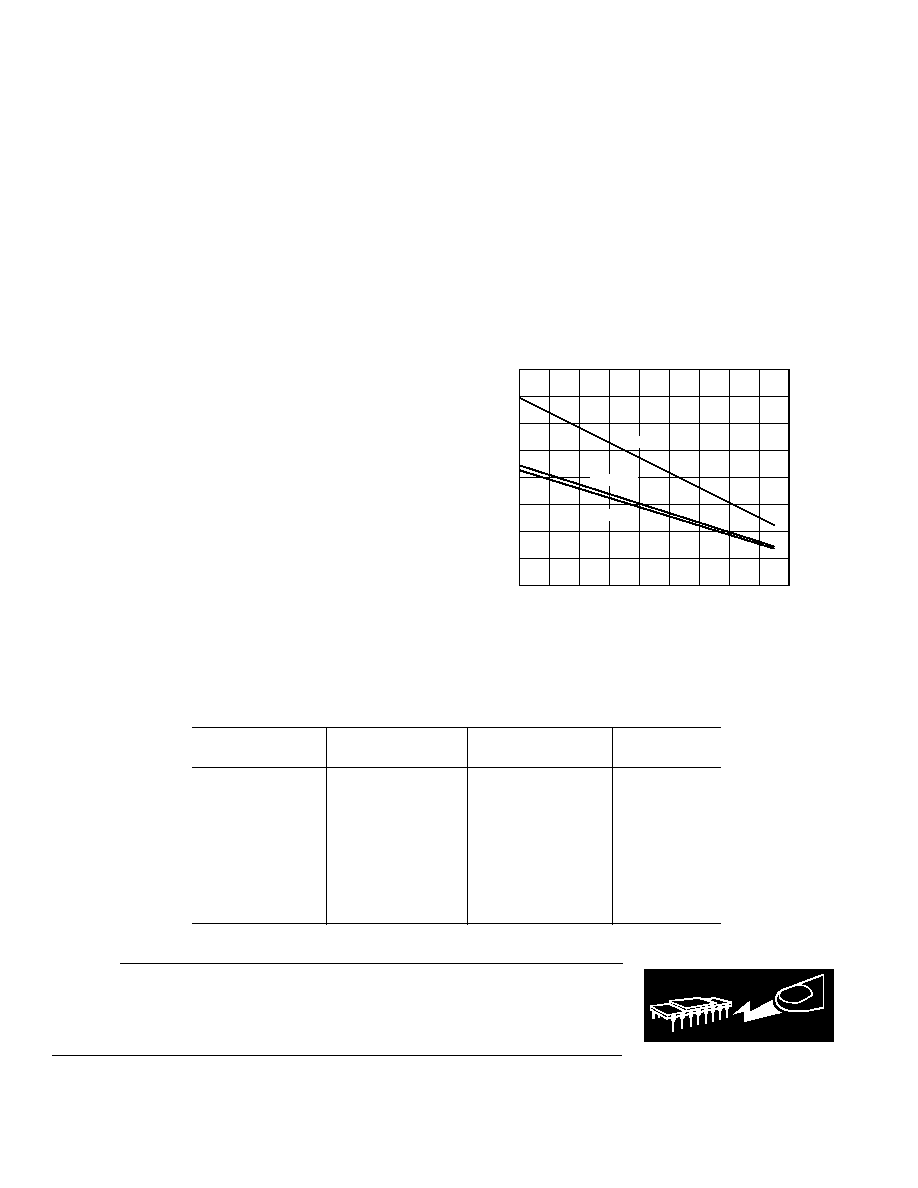

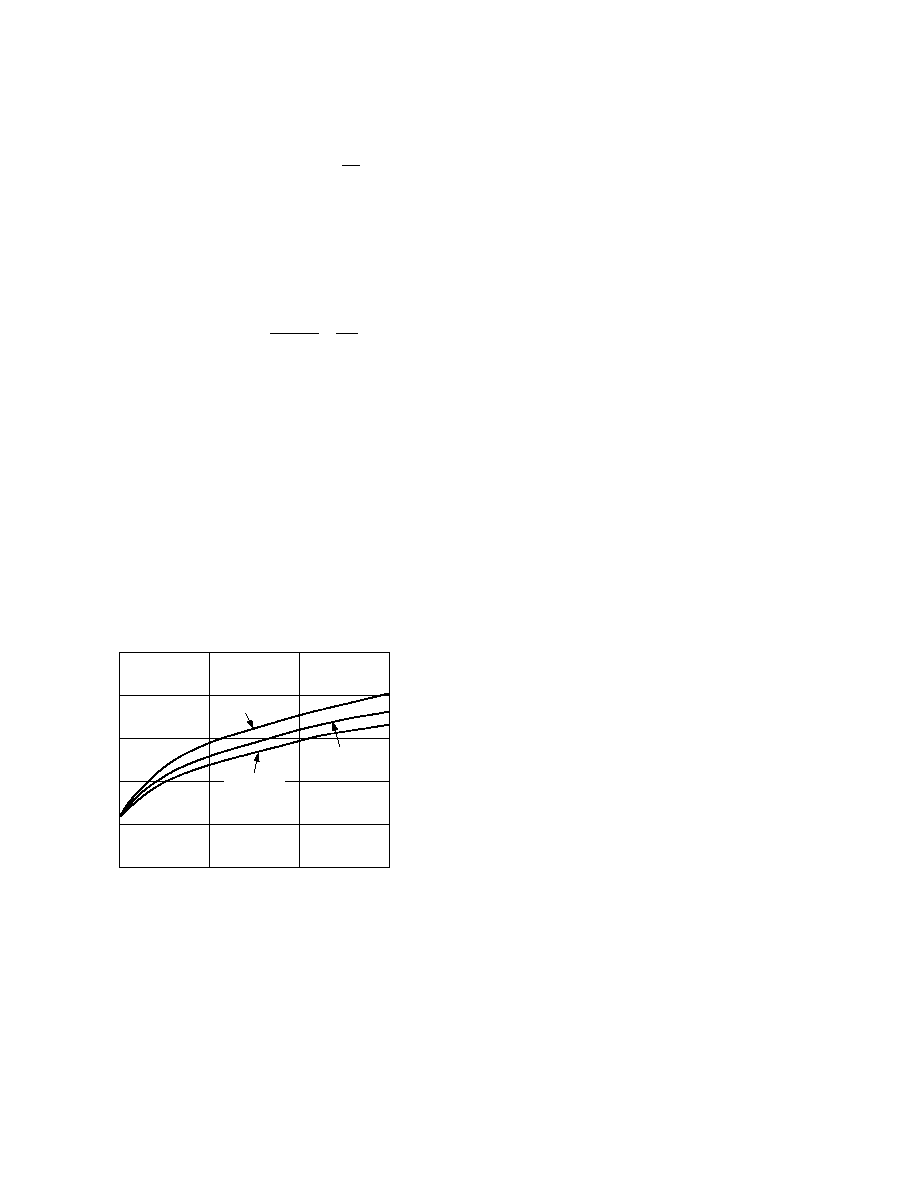

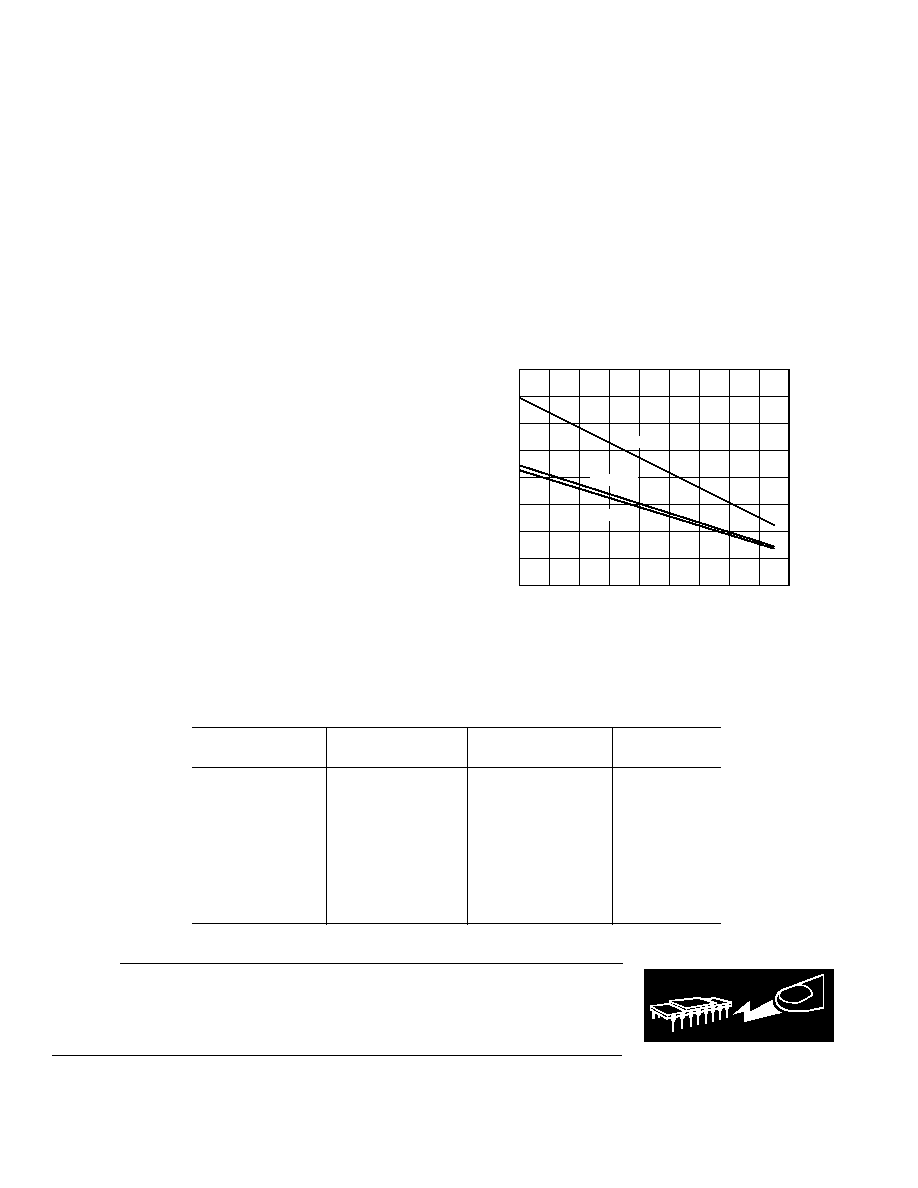

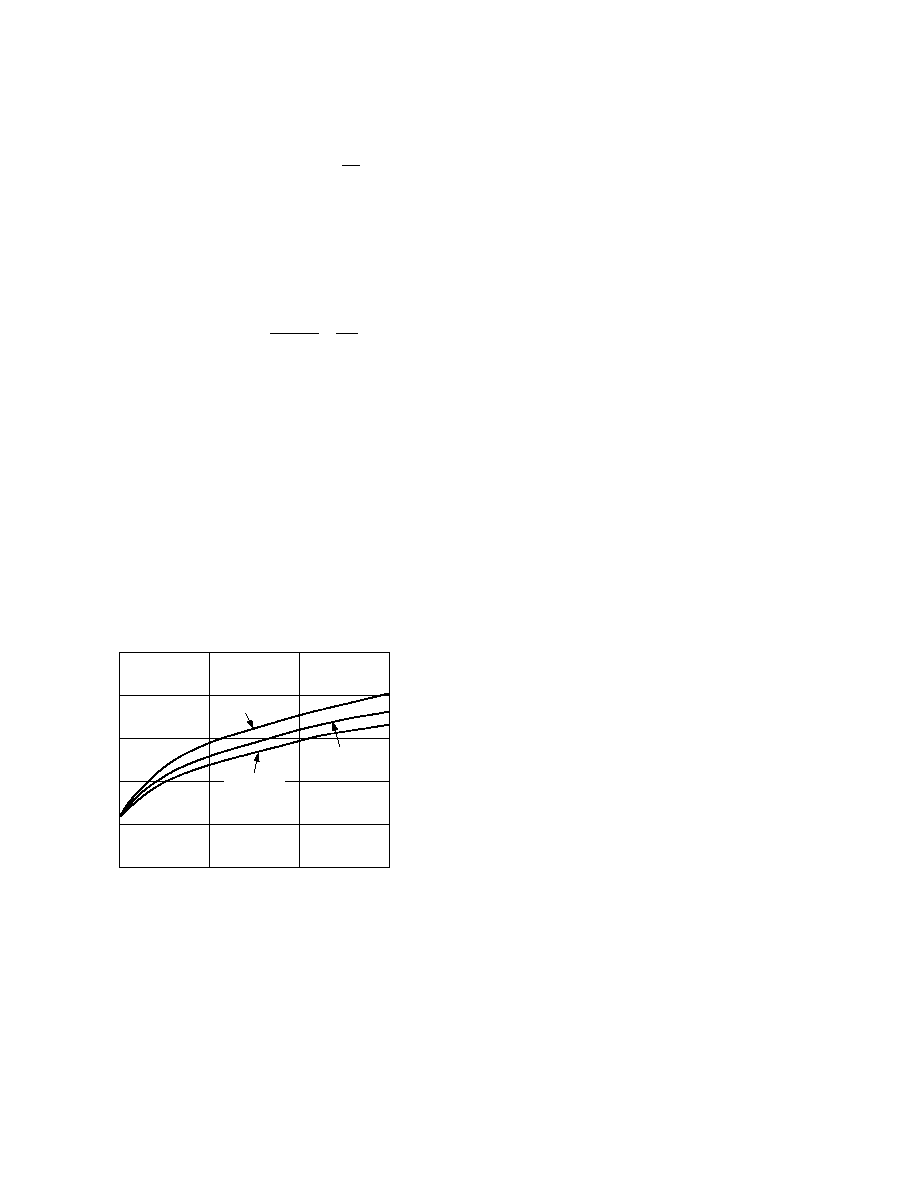

Figure 40 shows the dynamic headroom in each subband of a

downstream DMT waveform versus turns ratio running at 100%

and 60% of the quiescent power while maintaining 65 dBc of

MTPR at V

S

=

±12 V.

4

1

3

2

1.2

1.4

2

1

0

1

1.6

1.8

2

1.1

1.3

1.5

1.7

1.9

DOWNSTREAM TURNS RATIO

DYNAMIC HEADROOM

dB

V

S

= 12V

PWDN1,0 = (1,1)

V

S

= 11.4V

PWDN1,0 = (1,1)

V

S

= 11.4V

PWDN1,0 = (1,0)

V

S

= 12V

PWDN1,0 = (1,0)

Figure 40. Dynamic Headroom vs. XFMR Turns Ratio,

V

S

=

±12 V

Once an optimum turns ratio is determined, the amplifier will

have an MTPR performance for each setting of the power-down

pins. The table below demonstrates the effects of reducing the

total power dissipated by using the PWDN pins on MTPR

performance when driving 20.4 dBm downstream onto the line

with a transformer turns ratio of 1:1.4.

Table III. Dynamic Power Dissipation for Downstream

Transmission

PWDN1

PWDN0

PD (W)

MTPR

1

1

1.454

78 dBc

1

0

1.262

75.3 dBc

0

1

1.142

57.2 dBc

0

*

0

0.120

N/A

*This mode is quiescent power dissipation.

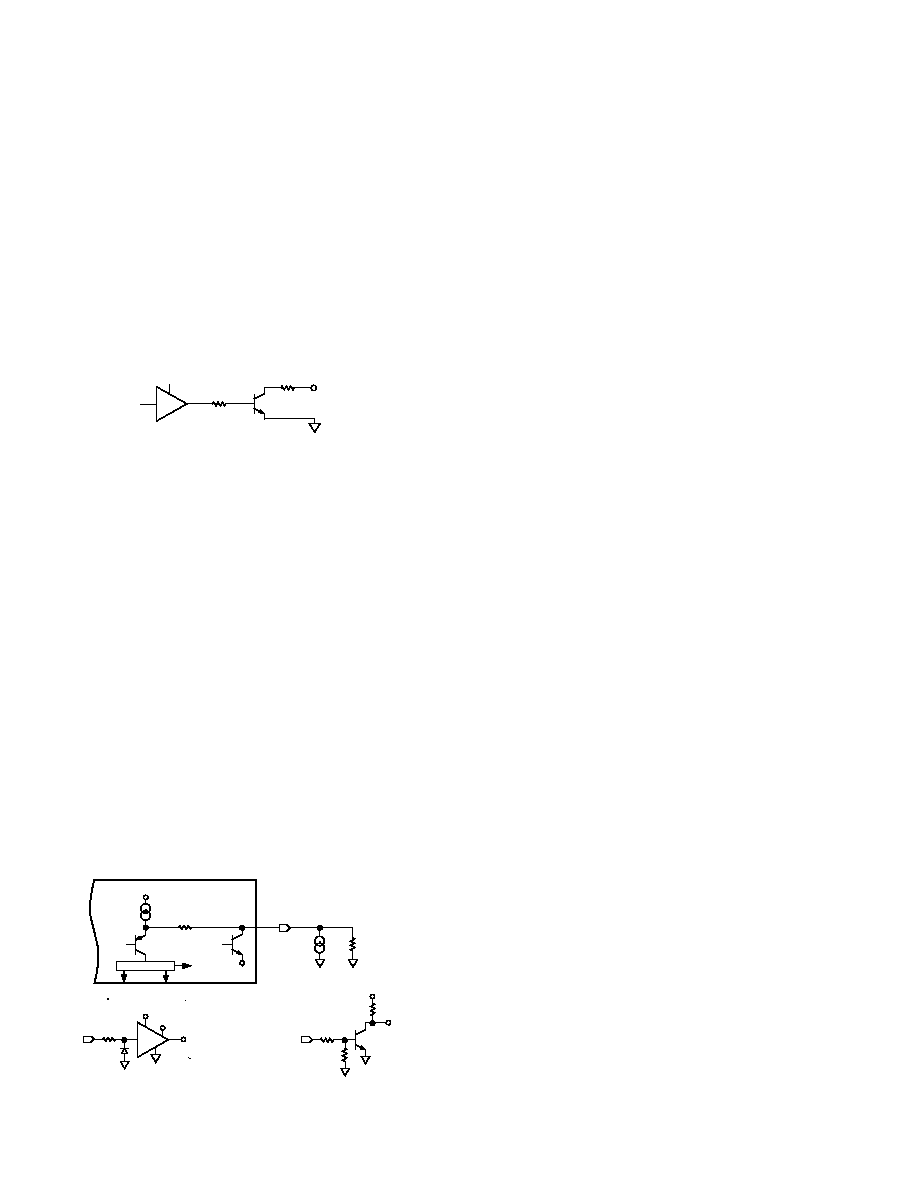

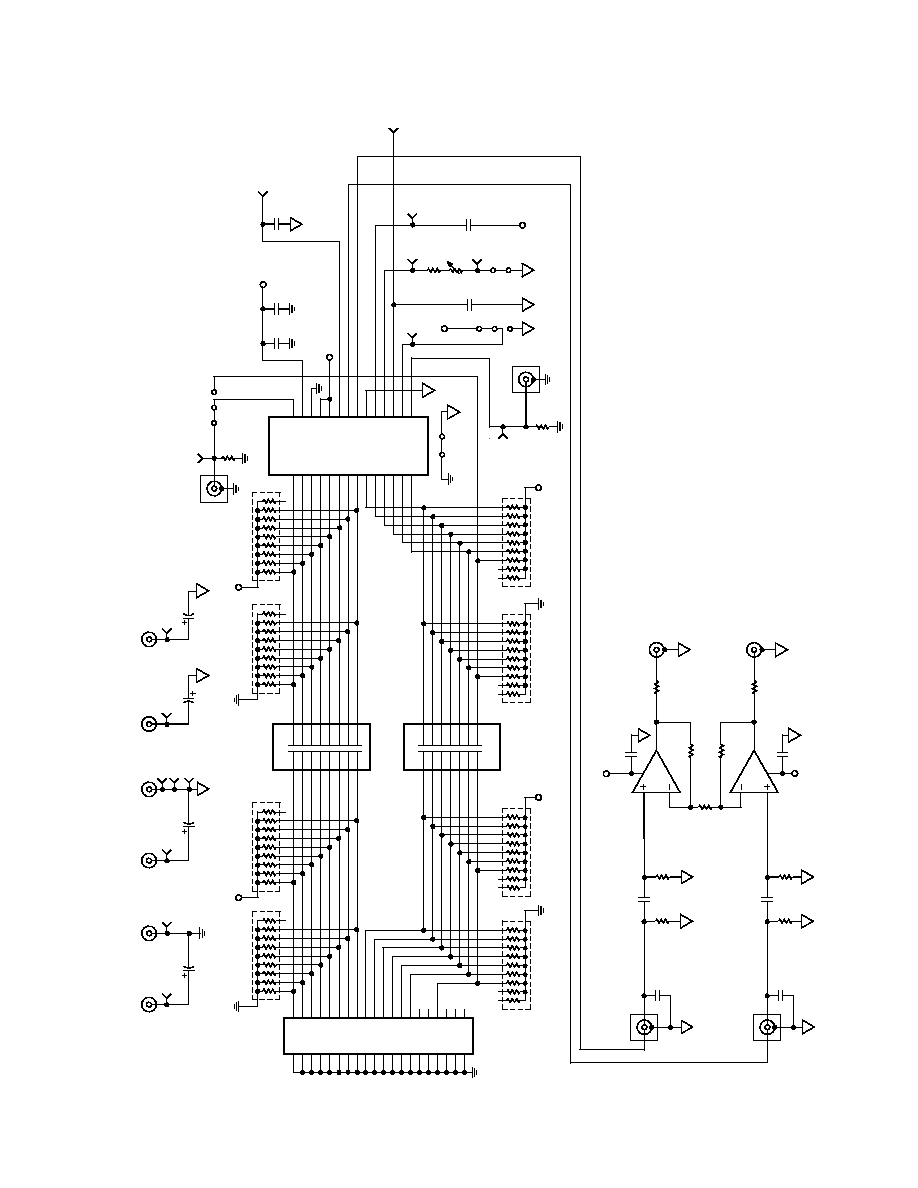

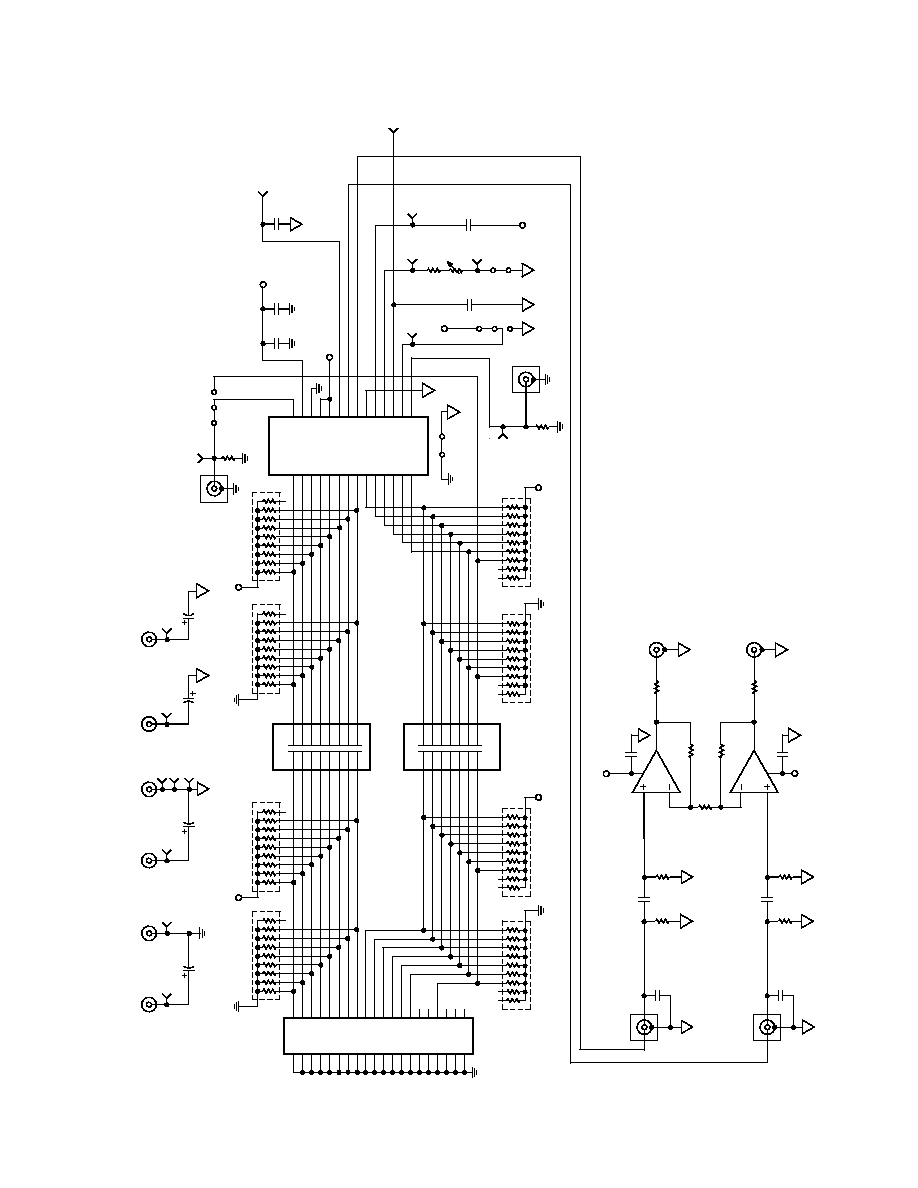

GENERATING DMT

At this time, DMT-modulated waveforms are not typically menu-

selectable items contained within arbitrary waveform generators.

Even using (AWG) software to generate DMT signals, AWGs

that are available today may not deliver DMT signals sufficient

in performance with regard to MTPR due to limitations in the

D/A converters and output drivers used by AWG manufactur-

ers. Similar to evaluating single-tone distortion performance of

an amplifier, MTPR evaluation requires a DMT signal generator

capable of delivering MTPR performance better than that of the

driver under evaluation. Generating DMT signals can be accom-

plished using a Tektronics AWG 2021 equipped with opt 4,

(12/24-Bit, TTL Digital Data Out), digitally coupled to Analog

Devices AD9754, a 14-bit TxDAC, buffered by an AD8002

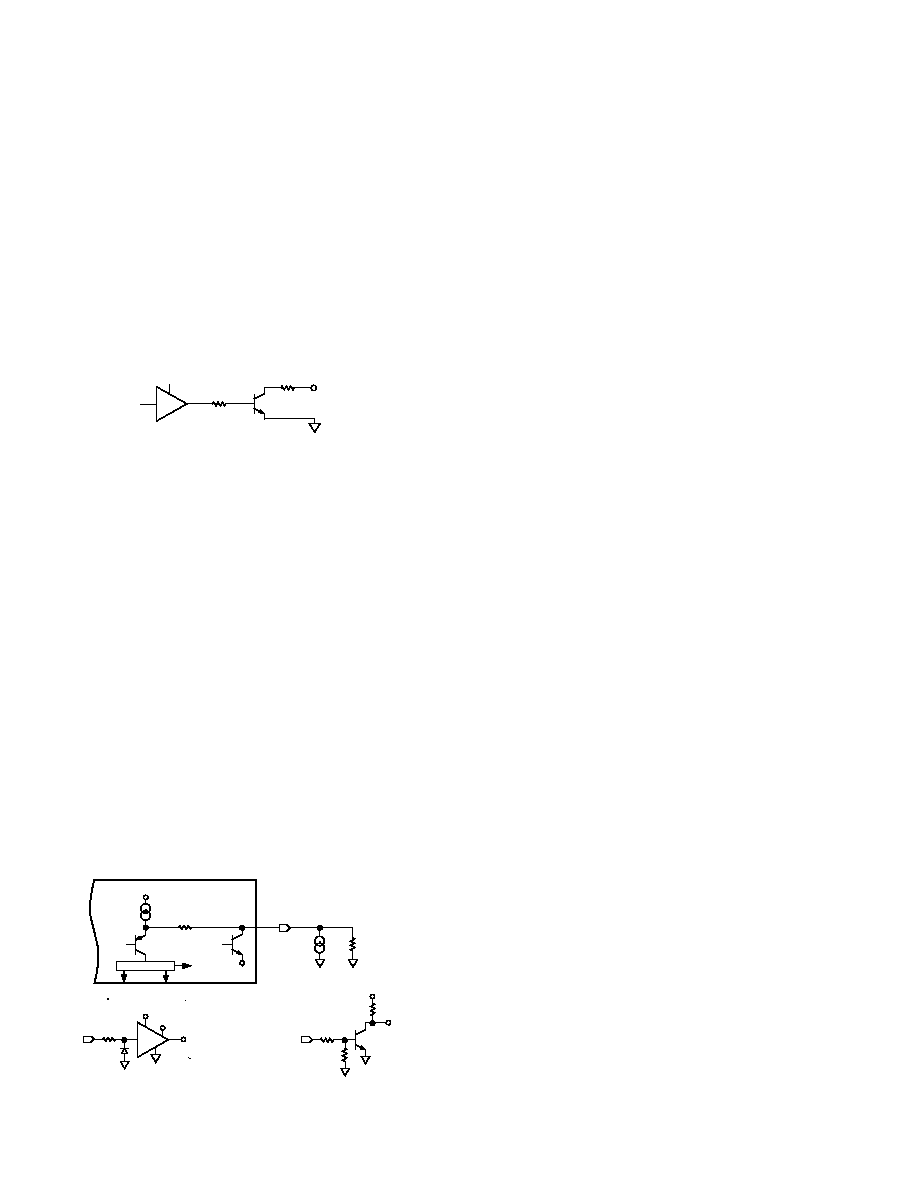

amplifier configured as a differential driver. See Figure 45 for

schematics of a circuit used to generate DMT signals that can

achieve down to 80 dBc of MTPR performance, sufficient for

use in evaluating xDSL drivers. Note that the DMT waveforms

available with the AD8016ARP-EVAL and AD8016ARB-EVAL

boards or similar WFM files are needed to produce the neces-

sary digital data required to drive the TxDAC from the optional

TTL Digital Data output of the TEK AWG2021. Copies of

these WFM files can be obtained through the Analog Devices

website. http://www.analog.com/.

EVALUATION BOARDS

The AD8016ARP-EVAL, AD8016ARB-EVAL, AD8016ARE-EVAL

boards available through Analog Device provide a platform for

evaluating the AD8016 in an ADSL differential line driver

circuit. The board is laid out to accommodate Analog Devices

two transformer line driver hybrid circuit (see Figures 46a and

46b) including line matching network, an RJ11 jack for interfac-

ing to line simulators, transformer coupled input for single-to-

differential input conversion and accommodations for the receiver

function. Schematics and layout information are available for both

versions of the EVAL board. Also included in the package are

WFM files for use in generating 14-bit DMT waveforms.

Upstream data is contained in the ...24.wfm files and down-

stream data in the ...128.wfm files.

These DMT modulated signals are used to evaluate xDSL

products for Multitone Power Ratio or MTPR performance.

The data files are used in pairs (adslu24.wfm and adsll24.wfm

go together, etc.) and are loaded into Tektronics AWG2021

arbitrary waveform generator. The adslu24.wfm is loaded via

the TEK AWG2021 floppy drive into Channel 1, while the

adsll24.wfm is simultaneously loaded into Channel 2. The num-

ber in the file name, prefixed with "u," goes into CH1 or upper

channel and the "l" goes into CH2 or the lower channel. 12 bits

from CH1 are combined with 2 bits from CH2 to achieve 14-

bit digital data at the digital outputs of the TEK 2021. The

resulting waveforms produced at the AD9754-EB outputs are

then buffered and amplified by the AD8002 differential driver to

achieve 14-bit performance from this DMT signal source.

POWER DISSIPATION

In order to properly size the heat sinking area for your applica-

tion, it is important to consider the total power dissipation of

the AD8016. The dc power dissipation for V

IN

= 0 is I

Q

(VCC

VEE), or 2

× I

Q

× V

S

.

For the AD8016 powered on +12 V and 12 V supplies (

±V

S

),

the number is 0.6 W. In a differential driver circuit (Figure 6),

REV. A

AD8016

14

we can use symmetry to simplify the computation for a dc input

signal.

P

I

V

V

V

V

R

D

Q

S

S

O

O

L

= ×

×

+ ×

2

4

(

)

where

V

O

is the peak output voltage of an amplifier.

This formula is slightly pessimistic due to the fact that some of

the quiescent supply current is commutated during sourcing or

sinking current into the load. For a sine wave source, integration

over a half cycle yields:

P

I

V

V V

R

V

R

D

Q

S

O

S

L

O

L

= ×

×

+

-

2

2

4

2

The situation is more complicated with a complex modulated

signal. In the case of a DMT signal, taking the equivalent sine

wave power overestimates the power dissipation by ~23%. For

example:

P

OUT

= 23.4 dBm = 220 mW

V

OUT

@ 50

= 3.31 V rms

V

O

= 2.354 V

at each amplifier output, which yields a P

D

of 1.81 W.

Through measurement, a DMT signal of 23.4 dBm requires

1.47 W of power to be dissipated by the AD8016. Figure 41

shows the results of calculation and actual measurements

detailing the relationship between the power dissipated by the

AD8016 versus the total output power delivered to the back

termination resistors and the load combined. A 1:2 transformer

turns ratio was used in the calculations and measurements.

OUTPUT POWER mW

2.5

0

POWER DISSIPATION

2.0

1.5

100

200

300

1.0

0.5

0

MEASURED

SINE

MEASURED

DMT

CALCULATED

Figure 41. Power Dissipation vs. Output Power (Including

Back Terminations). See Figure 7 for Test Circuit

THERMAL ENHANCEMENTS AND PCB LAYOUT

There are several ways to enhance the thermal capacity of the

CO solution. Additional thermal capacity can be created using

enhanced PCB layout techniques such as interlacing (sometimes

referred to as stitching or interconnection) of the layers immedi-

ately beneath the line driver. This technique serves to increase

the thermal mass or capacity of the PCB immediately beneath

the driver. (See AD8016-EVAL boards for an example of this

method of thermal enhancement.) A cooling fan that draws

moving air over the PCB and xDSL drivers, while not always

required, may be useful in reducing the operating temperature

of the die, allowing more drivers/square-inch within the CO

design. The AD8016, whether in a PSOP3 (ARP) or batwing

(ARB) package, can be designed to operate in the CO solution

using prudent measures to manage the power dissipation through

careful PCB design. The PSOP3 package is available for use in

designing the highest density CO solutions. Maximum heat trans-

fer to the PCB can be accomplished using the PSOP3 package

when the thermal slug is soldered to an exposed copper pad

directly beneath the AD8016. Optimum thermal performance

can be achieved in the ARE package only when the back of the

package is soldered to a PCB designed for maximum thermal

capacity (see Figure 44). Thermal experiments with the PS0P3

package were conducted without soldering the heat slug to the

PCB. Heat transfer was through physical contact only. The

following offers some insight into the AD8016 power dissipation

and relative junction temperature, the effects of PCB size and

composition on the junction-to-air thermal resistance or

JA

.

THERMAL TESTING

A wind tunnel study was conducted to determine the relationship

between thermal capacity (i.e., printed circuit board copper area),

air flow and junction temperature. Junction-to-ambient ther-

mal resistance,

JA

, was also calculated for the AD8016ARP,

AD8016ARE, and AD8016ARB packages. The AD8016 was

operated in a noninverting differential driver configuration, typical

of an xDSL application yet isolated from any other modem

components. Testing was conducted using a 1 ounce copper

board in an ambient temperature of ~24

°C over air flows of

200, 150, 100, and 50 (0.200 and 400 for AD8016ARE) linear

feet per minute (LFM) and for ARP and ARB packages as well

as in still air. The four-layer PCB was designed to maximize the

area of copper on the outer two layers of the board while the

inner layers were used to configure the AD8016 in a differential

driver circuit. The PCB measured 3

× 4 inches in the beginning

of the study and was progressively reduced in size to approxi-

mately 2

× 2 inches. The testing was performed in a wind tunnel to

control air flow in units of LFM. The tunnel is approximately

11 inches in diameter.

AIR FLOW TEST CONDITIONS

DUT Power: Typical DSL DMT signal produces about 1.5 W

of power dissipation in the AD8016 package. The fully biased

(PWDN0 and PWDN1 = Logic 1) quiescent current of the

AD8016 is ~25 mA. A 1 MHz differential sine wave at an ampli-

tude of 8 V p-p/amplifier into an R

LOAD

of 100

differential

(50

per side) will produce the 1.5 W of power typical in the

AD8016 device. (See the Power Dissipation section for details.)

Thermal Resistance: The junction-to-case thermal resistance

(

JC

) of the AD8016ARB or batwing package is 8.6

°C/W,

AD8016ARE is 5.6

°C/W, and the AD8016ARP or PSOP3

package is 0.86

°C/W. These package specifications were used in

this study to determine junction temperature based on the mea-

sured case temperature.

PCB Dimensions of a Differential Driver Circuit: Several

components are required to support the AD8016 in a differential

driver circuit. The PCB area necessary for these components (i.e.,

feedback and gain resistors, ac coupling and decoupling capaci-

tors, termination and load resistors) dictated the area of the

smallest PCB in this study, 4.7 square inches. Further reduction

in PCB area, although possible, will have consequences in terms

of the maximum operating junction temperature.

REV. A

AD8016

15

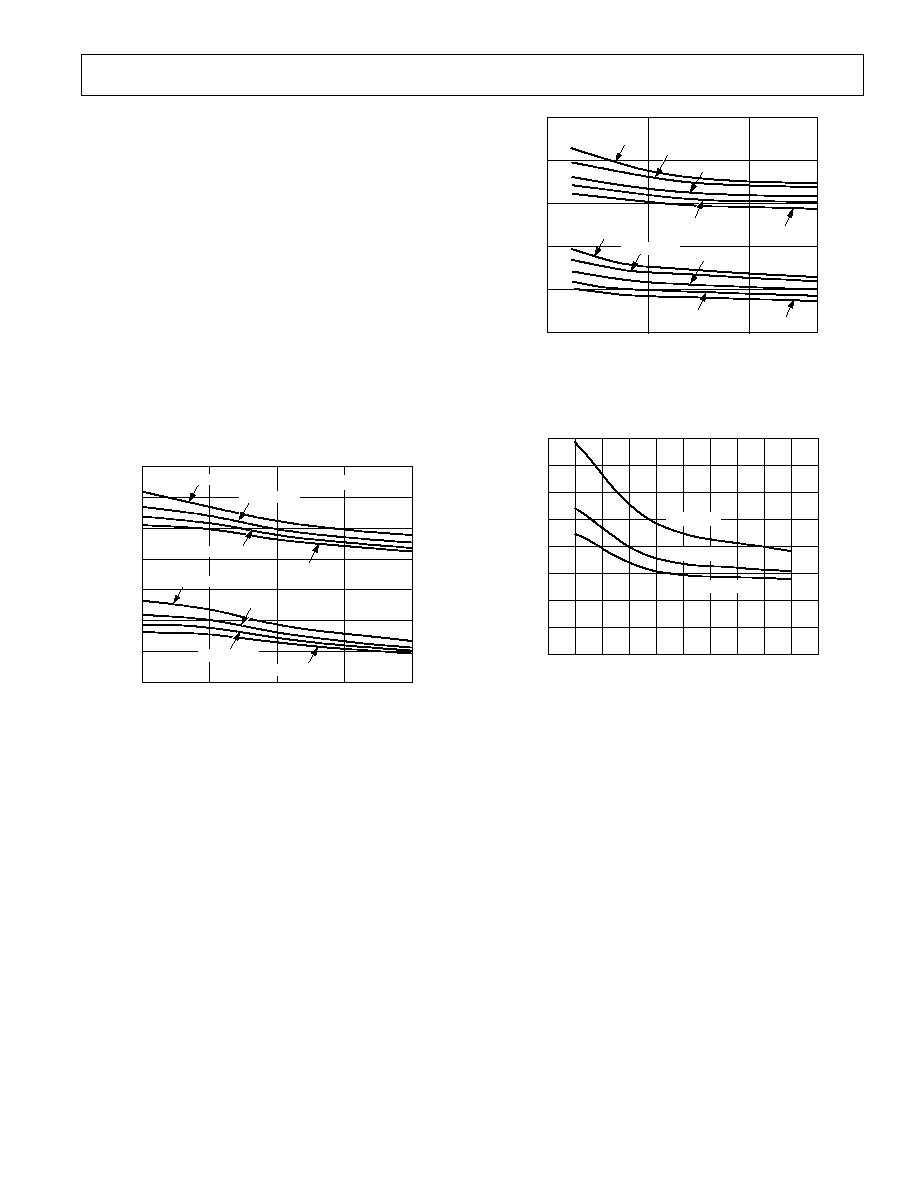

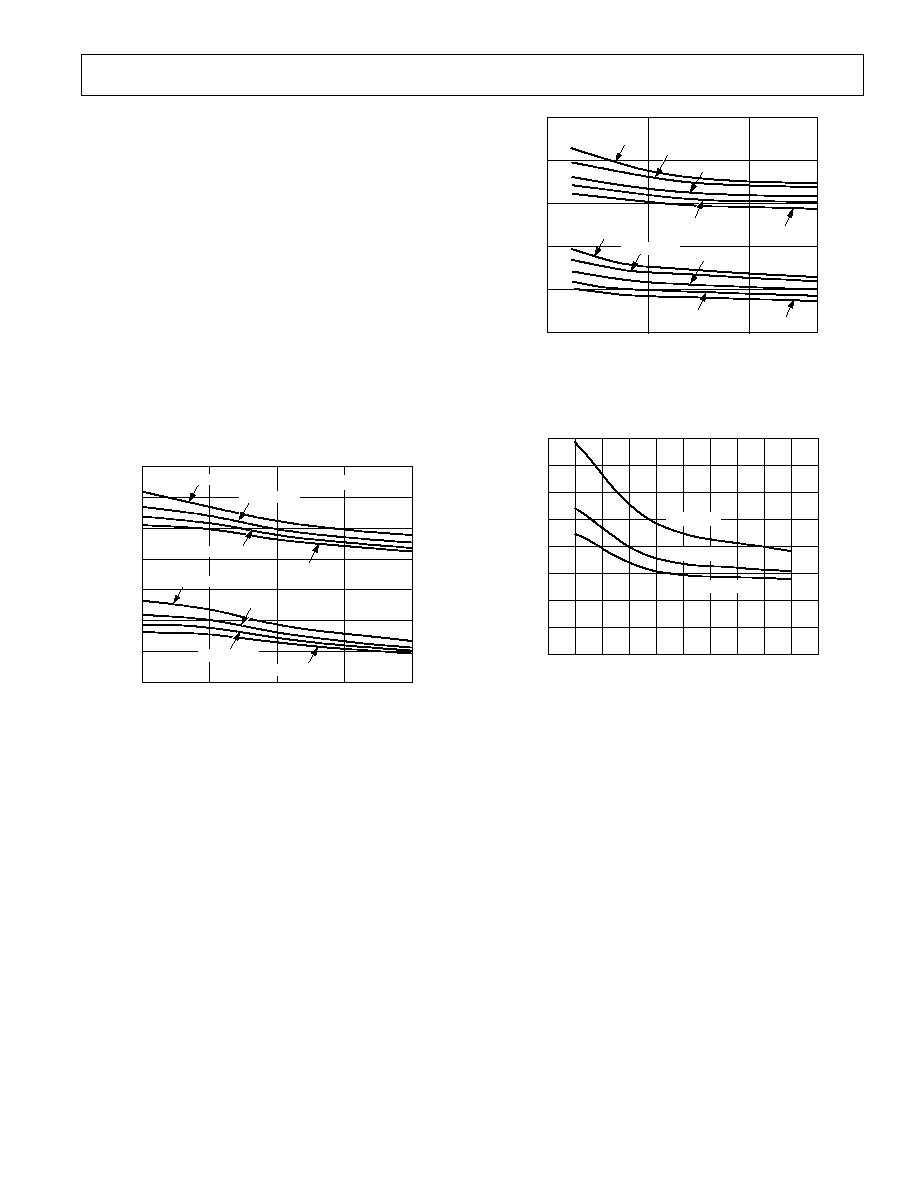

EXPERIMENTAL RESULTS

The experimental data suggests that for both packages, and a

PCB as small as 4.7 square inches, reasonable junction tempera-

tures can be maintained even in the absence of air flow. The graph

in Figure 42 shows junction temperature versus air flow for various

dimensions of 1 ounce copper PCBs at an ambient temperature

of 24

°C in both the ARB and ARP packages. For the worst case

package, the AD8016ARB and the worst case PCB at 4.7 square

inches, the extrapolated junction temperature for an ambient

environment of 85

°C would be approximately 132°C with 0 LFM

of air flow. If the target maximum junction temperature of the

AD8016ARB is 125

°C, a 4-layer PCB with 1 oz. copper covering

the outer layers and measuring 9 square inches is required

with 0 LFM of air flow.

Note that the AD8016ARE is targeted at xDSL applications

other than full-rate CO ADSL. The AD8016ARE is targeted at

g.lite and other xDSL applications where reduced power dissi-

pation can be achieved through a reduction in output power.

Extreme temperatures associated with full-rate ADSL using the

AD8016ARE should be avoided whenever possible.

AIR FLOW LFM

75

0

JUNCTION TEMPERATURE

C

70

65

60

55

50

45

40

50

100

150

200

ARP 6 SQ-IN

ARP 4.7 SQ-IN

ARP 12 SQ-IN

ARB 4.7 SQ-IN

ARB 7.125 SQ-IN

ARB 9 SQ-IN

ARB 6 SQ-IN

ARP 9 SQ-IN

+24 C AMBIENT

Figure 42. Junction Temperature vs. Air Flow

PCB AREA SQ-IN

35

4

JA

C/W

30

25

20

15

10

7

10

ARB 0 LFM

ARB 50 LFM

ARB 100 LFM

ARB 200 LFM

ARB 150 LFM

ARP 0 LFM

ARP 100 LFM

ARP 200 LFM

ARP 150 LFM

ARP 50 LFM

Figure 43. Junction-to-Ambient Thermal Resistance vs.

PCB Area

40

0

35

30

2

4

10

25

20

15

6

8

10

1

3

5

7

9

50

45

PCB AREA SQ-IN

JA

C/W

ARE 0 LFM

ARE 200 LFM

ARE 400 LFM

Figure 44. Junction-to-Ambient Thermal Resistance vs.

PCB Area

REV. A

AD8016

16

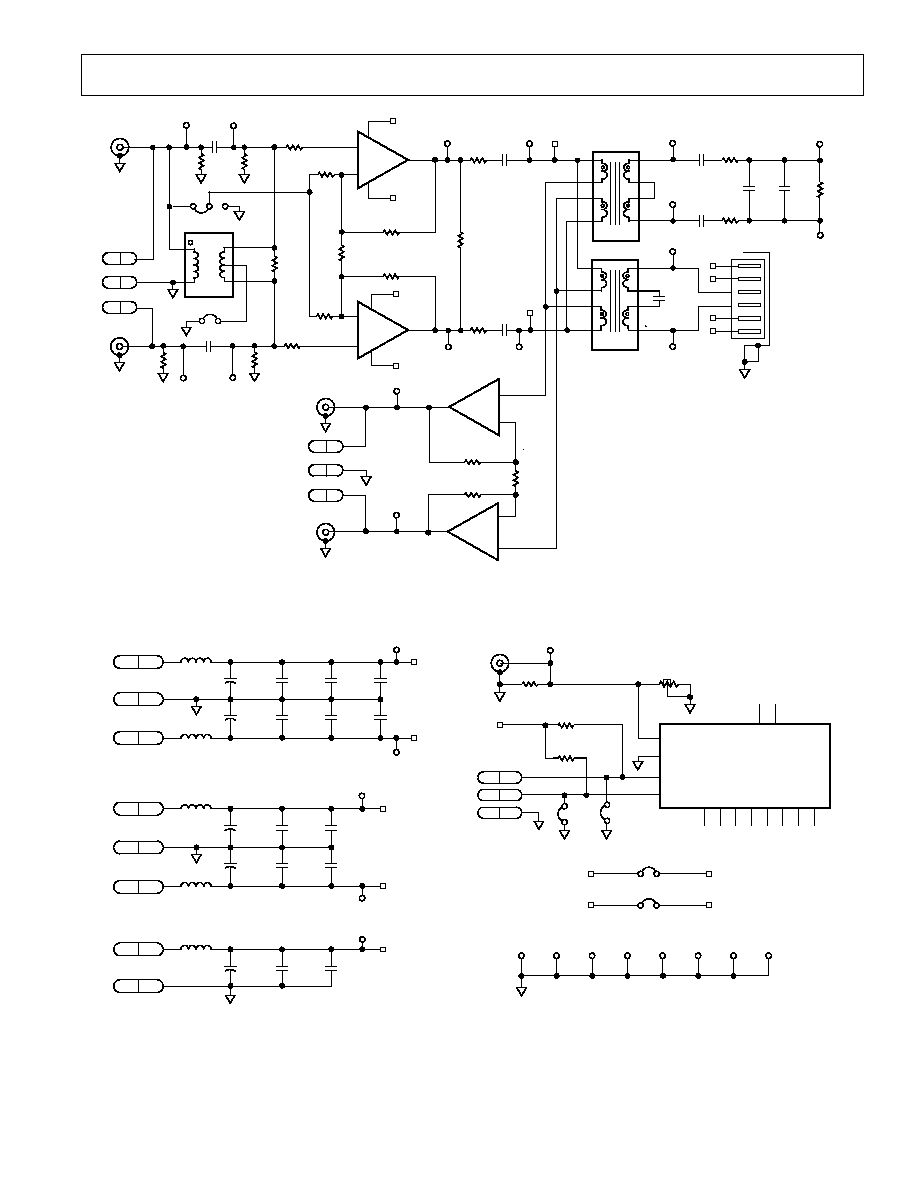

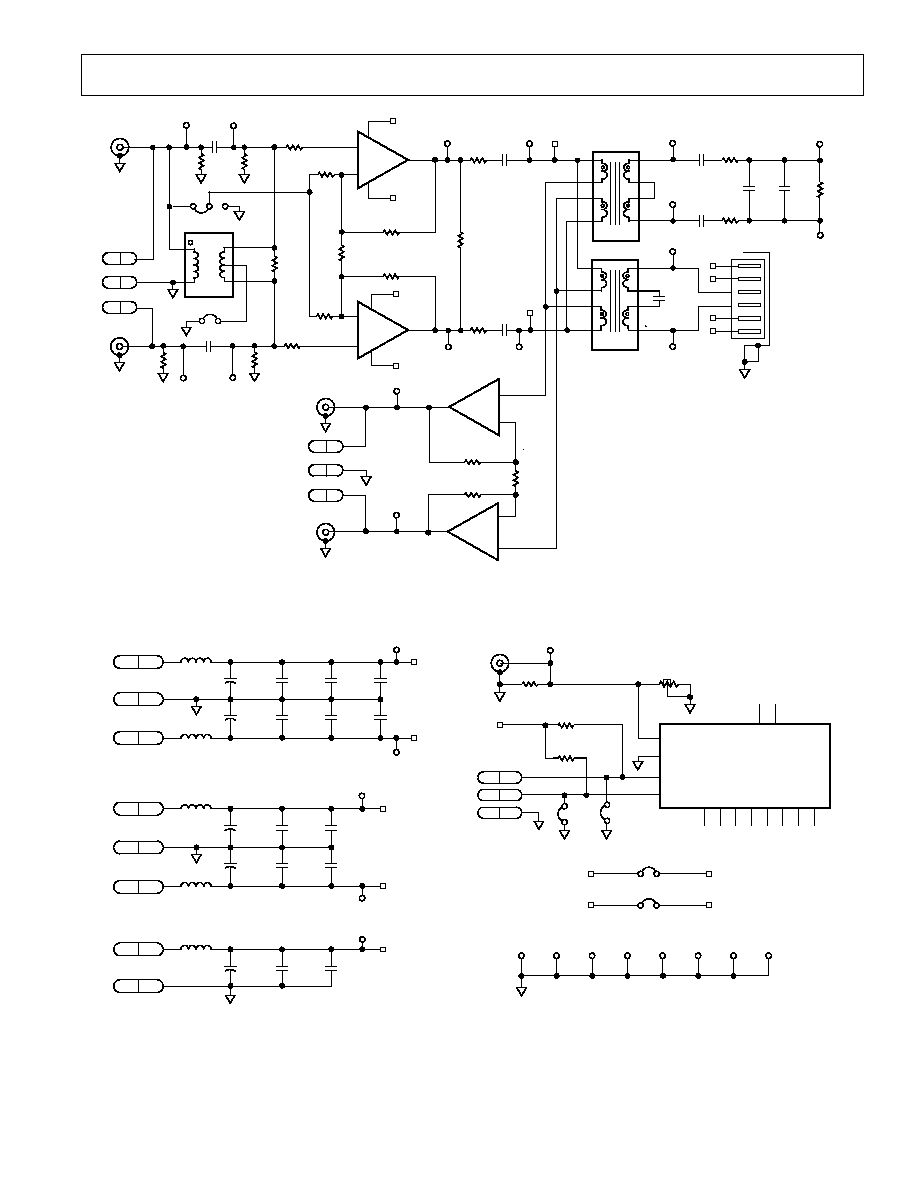

Figure 45. DMT Signal Generator Schematic

1

0

98

76

54

32

1

R4

10

9

8

7

6

5

4

3

2

1

R7

DVDD

10

9

8

7

6

5

4

3

2

1

R3

1

0

98

76

54

32

1

DVDD

R6

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

P1

10

9

8

7

6

5

4

3

2

1

R5

DVDD

10

9

8

7

6

5

4

3

2

1

R1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

C19

C1

C2

C25

C26

C27

C28

C29

16 PINDIP

RES PK

16

15

14

13

12

11

10

1

2

3

4

5

6

7

C30

C31

C32

C33

C34

C35

C36

16 PINDIP

RES PK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

DB13

DB12

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

CLOCK

DVDD

DCOM

NC

AVDD

COMP2

I

OUTA

ACOM

COMP1

FS ADJ

REFIO

REFLO

SLEEP

U1

AD9754

I

OUTB

AVDD

CT1

A

1

A

R15

49.9

CLK

JP1

AB

3

2

1

J1

TP1

EXTCLK

C7

1

F

C8

0.1

F

AVDD

A

C9

0.1

F

TP8

2

AVDD

TP11

C11

0.1

F

TP10

TP9

R16

2k

TP14

JP4

C10

0.1

F

OUT1

OUT2

TP13

R17

49.9

PDIN

J2

A

A

A

AVDD

3

JP2

TP12

TP7

A

C6

10

F

AVCC

B6

TP6

A

C5

10

F

AVEE

B5

TP19

A

AGND

B4

TP18

TP5

C4

10

F

TP4

AVDD

B3

TP2

DGND

B2

C3

10

F

TP3

DVDD

B1

J3

C12

22pF

A

J4

C13

22pF

98

76

54

32

1

R2

10

1

0

98

76

54

32

1

DVDD

R8

OUT2

OUT1

A

R

20k

49.9

A

49.9

A

10k

A

10k

A

1

F

1

F

AD8002

A

AVCC

249

A

0.1

F

AD8002

A

AVEE

A

0.1

F

226

750

750

249

DIFFERENTIAL

DMT OUTPUTS

TO TEK

AWG

2021

REV. A

AD8016

17

P4 3

AD8016

14

22

21

U1

+V

+VT

VT

AD8016

1

4

3

11

2

NC = 5, 6

AGND3,4,5

S5

TP10

TP5

C8

R11

R13

A

B

JP6

1

2

3

R24

R25

R23

1

2

3

6

4

T3

NC = 5

1:1

JP5

R15

R16

TP11

AGND3,4,5

S6

S3

S4

TP17

TP18

AD8022

AD8022

5

6

7

+VR;8

VR;4

+VR;8

VR;4

2

3

1

R1

5 WATT

1

2

R17

TP6

TP7

C11

R20

PR1

PR2

1

2

3

4

T2

10

8

9

7

TP13

TP14

TP1

C4

C5

R2

C6

C7

TP15

TP16

R4

C9

P1

1

2

3

4

5

6

7 8

TP2

R5

TP8

P4 1

P4 2

NC = 5, 6

1

2

3

4

T1

10

8

9

7

R3

TP9

C12

R21

R18

R19

+V

V

U1

+VT

VT

24

23

V

R9

R6

U2

R7

U2

R14

TP4

C10

P3 1

P3 3

P3 2

Figure 46a. Schematic AD8016ARB-EVAL

S2

R10

P2

P2

P2

1

2

3

TP3

+VL

R22

R12

JP1

JP2

R9

CW

15

10

9

16

5

6

7

8

17

18

U1

AD8016

BIAS

DGND

PDN0

PDN1

AGND

19

20

AGND

AGND

AGND

AGND

AGND

AGND

AGND

13

12

NC

+

+

TP19

TB1

3

TB1

2

TB1

1

L5

BEAD

L1

BEAD

C14

10 F

25V

C1

10 F

25V

C17

0.1 F

C15

0.1 F

C26

0.1 F

C19

0.1 F

C16

0.1 F

C25

0.1 F

TP20

+VT

VT

+

+

TB2

2

TB2

3

TB2

1

L4

BEAD

L3

BEAD

C13

10 F

25V

C3

10 F

25V

C21

0.1 F

C23

0.1 F

C24

0.1 F

C22

0.1 F

TP21

TP22

+VR

VR

+

TB3

1

TB3

2

L2

BEAD

C2

10 F

25V

C20

0.1 F

C18

0.1 F

TP12

+VL

+VT

+VR

JP3

VT

VR

JP4

TP24

TP23

TP25

TP26

TP27

TP28

TP29

TP30

NC

Figure 46b. Schematic AD8016ARB-EVAL

REV. A

AD8016

18

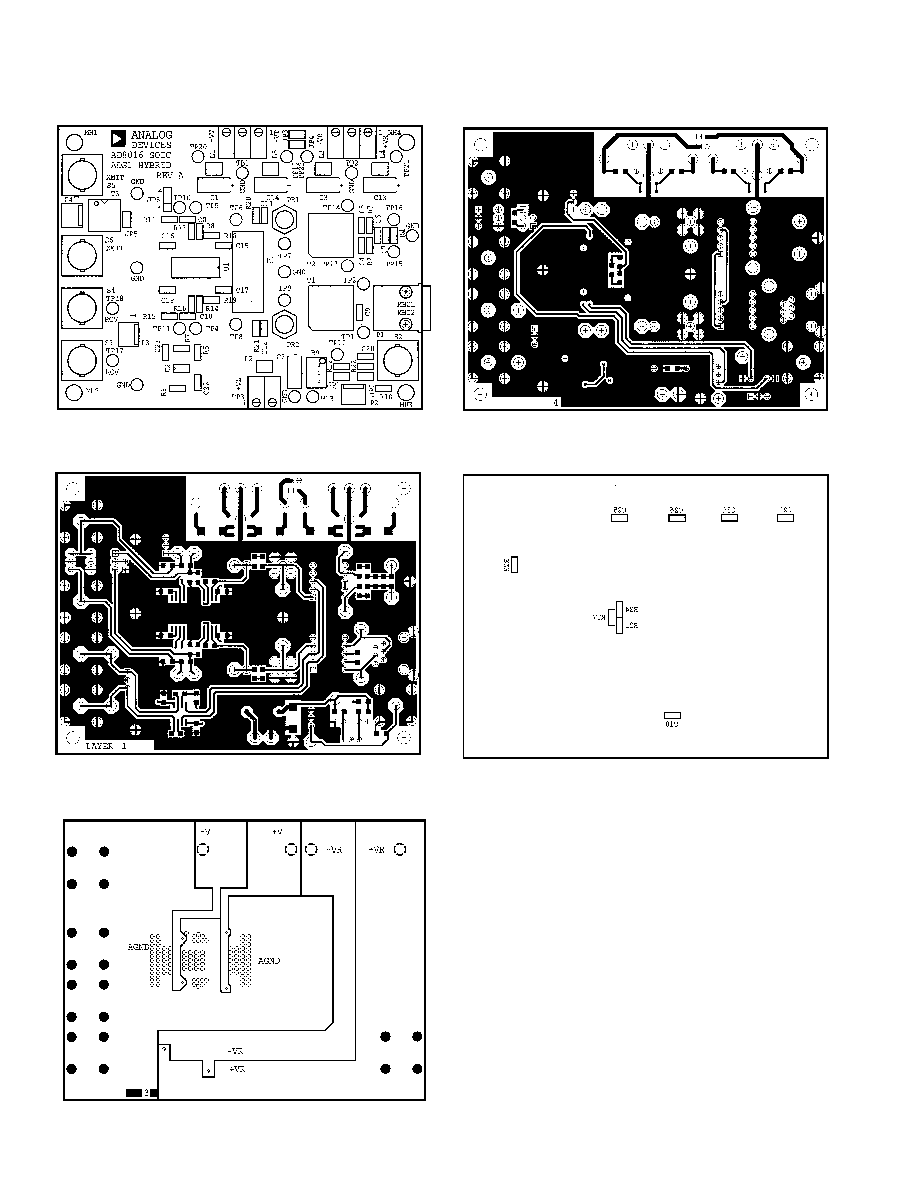

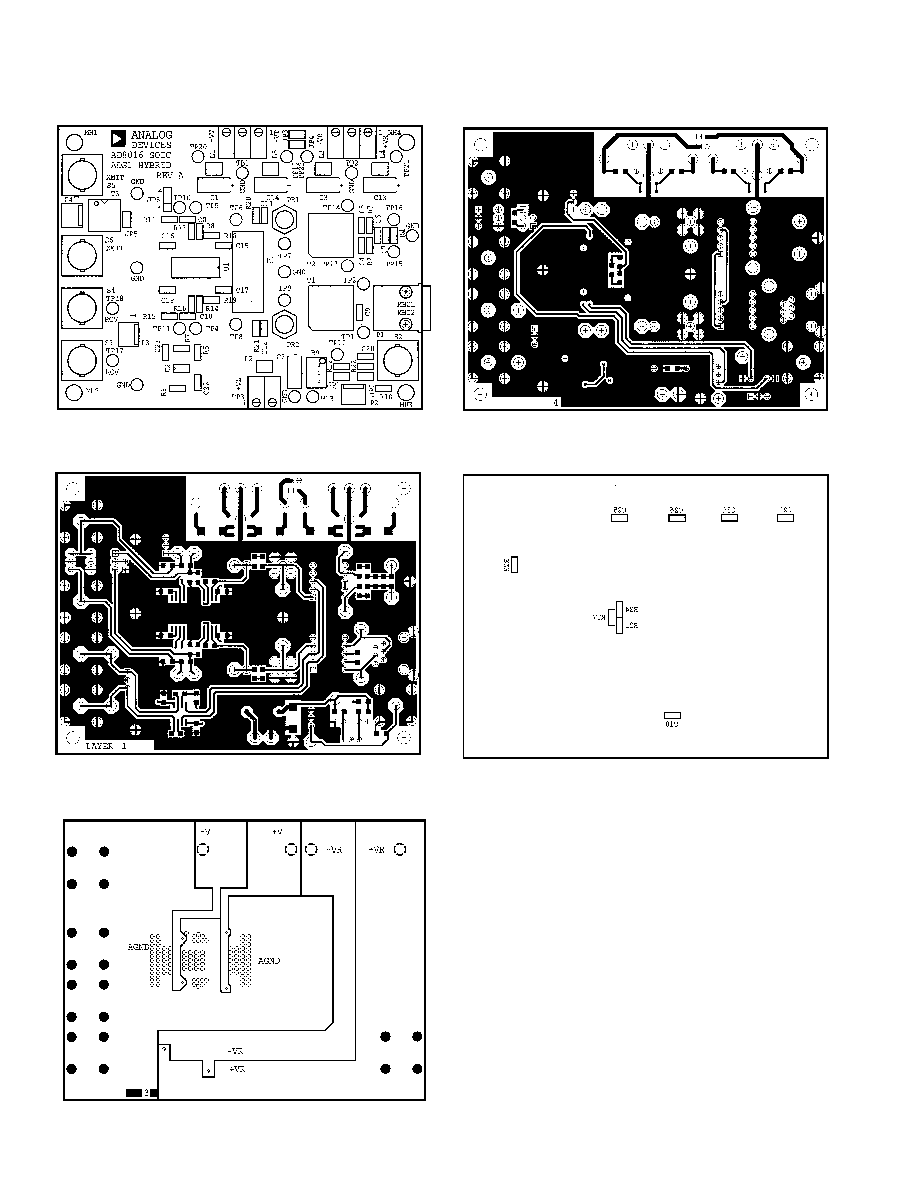

LAYOUT AD8016ARB-EVAL

Figure 47. Assembly

Figure 48. Layer 1

Figure 49. Power/Ground Plane

Figure 50. Layer 1

Figure 51. Silkscreen Bottom

REV. A

AD8016

19

ALP EVALUATION BOARD BILL OF MATERIALS

Qty.

Description

Vendor

Ref Desc.

5

10

µF 25 V Size Tantalum Chip Capacitor

ADS# 4-7-2

C13, 13, 14

10

0.1

µF 50 V 1206 Size Ceramic Chip Capacitor

ADS# 4-5-18

C1521, 2426

2

49.9

1% 1/8 W 1206 Size Chip Resistor

ADS# 3-14-26

R11, 15

2

100

1% 1/8 W 1206 Size Chip Resistor

ADS# 3-18-40

R8, 14

1

100

5% 3.0 W Metal Film Power Resistor

ADS# 3-24-1

R1

3

1.00 k

1% 1/6 W 1206 Size Chip Resistor

ADS# 3-18-11

R17R19

2

10.0 k

1% 1/6 W 1206 Size Chip Resistor

ADS# 3-18-119

R13 and 16

1

Test Point (Black) [GND]

ADS# 12-18-44

GND

2

Test Point (Brown)

ADS# 12-18-59

TP10, 11

4

Test Point (Red)

ADS# 12-18-43

TP1719, 21

2

Test Point (Orange)

ADS# 12-18-60

TP3, 15, 16

1

Test Point (Yellow)

ADS# 12-18-32

TP12

2

Test Point (Green)

ADS# 12-18-61

TP7, 9

2

Test Point (Blue)

ADS# 12-18-62

TP20, 22

2

Test Point (Violet)

ADS# 12-18-63

TP4, 5

4

Test Point (Grey)

ADS# 12-18-64

TP1, 2, 13, 14

2

Test Point (White)

ADS# 12-18-42

TP6, 8

2

3 Green Terminal Block. ONSHORE# EDZ250/3

ADS# 12-19-14

TB1, TB2

1

2 Green Terminal Block. ONSHORE# EDZ250/2

ADS# 12-19-13

TB3

5

1 Inch Center Shunt Berg# 65474-001

ADS# 11-2-38

J1J5

5

Male Header. 1 Inch Center. Berg #69157-102

ADS# 11-2-37

J1J5

5

Conn. BNC Vert. MT Telegartner # J01001A1944

ADS# 12-6-22

S2S6

1

AMP# 555154-1 MOD. JACK (SHIELDED) 6 6

DK# A 9024

P1

1

3-Pin Gold Male Header Waldom #WM 2723-ND

DK# WM 2723-ND

JP6

3

3-Pin Gold Male Locking Header Waldom #WM 2701-ND

DK# WM 2701-ND

P24

1

AD8016 ARB

ADS# AD 8016 XRP

D.U.T.

1

AD8016 SOIC Rev. A Evaluation PC Board

SIERRA/PROTO EXPRESS

Eval. PC Board

4

# 4 40

× 1/4" Panhead SS Machine Screw

ADS# 30-1-1

4

# 4 40

× 1/2" Threaded Alum. Standoffs

ADS# 30-16-2

OPTION

2

1:1.4 Turns Ratio RF Transformer from CoEv

C1374 Rev. 2

T1, T2

REV. A

AD8016

20

C01019a18/00 (rev. A)

PRINTED IN U.S.A.

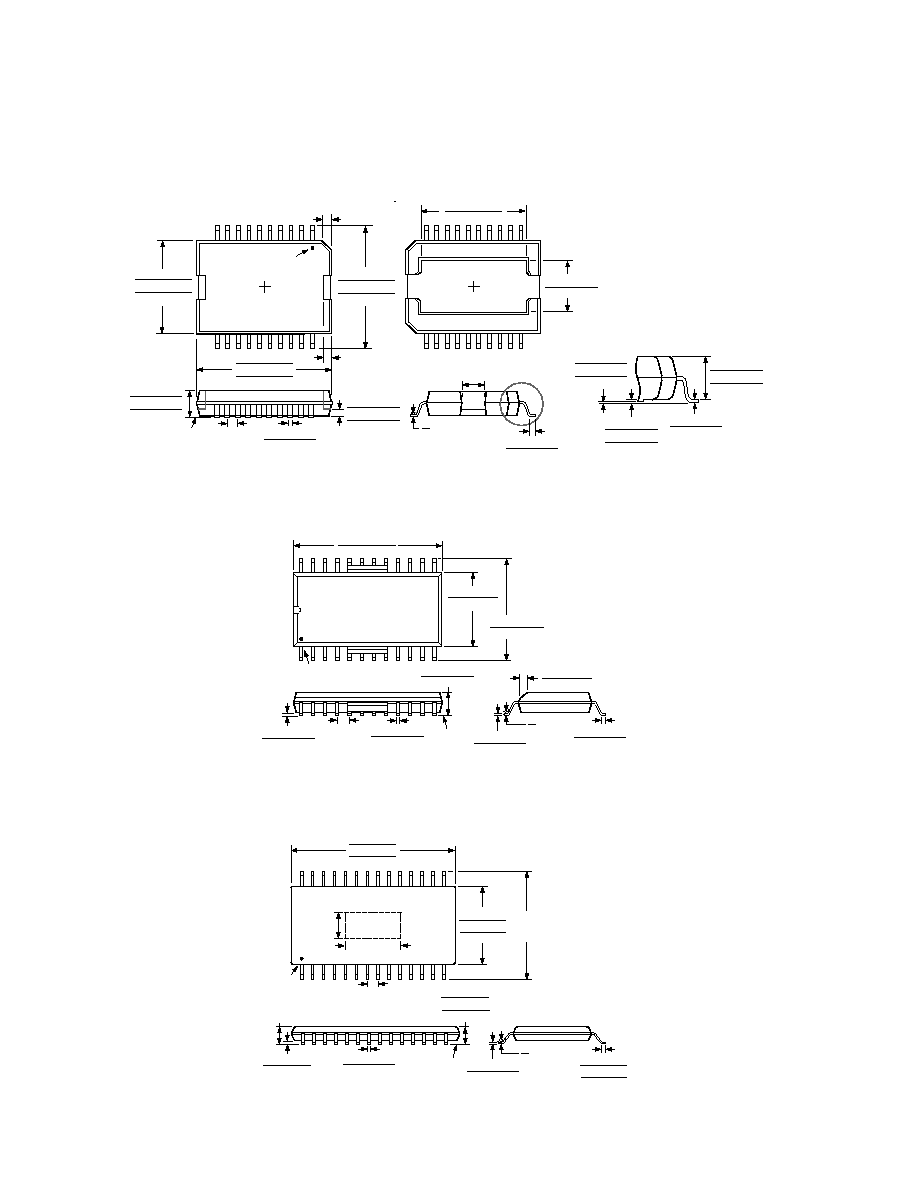

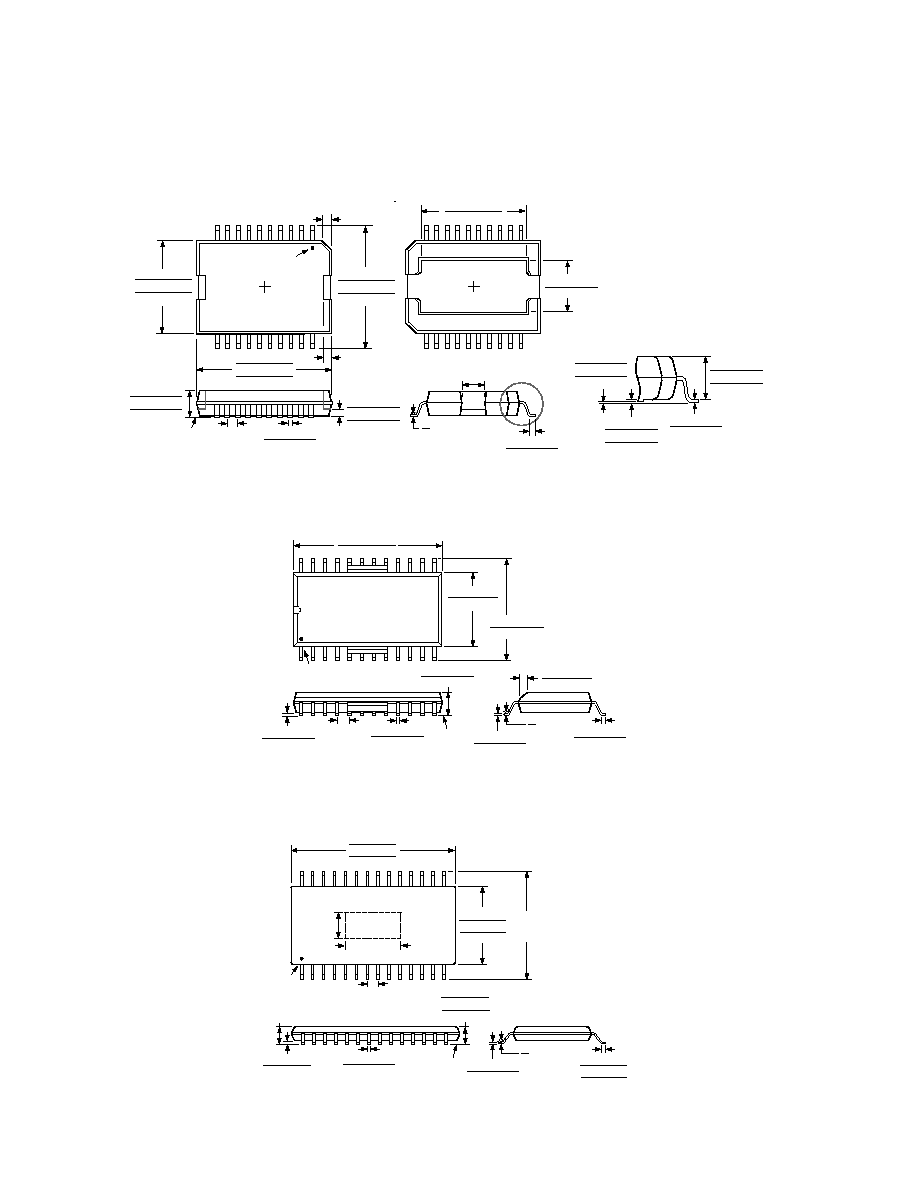

20-Lead PSOP3

(RP-20A)

BOTTOM VIEW

0.2441 (6.20)

0.2283 (5.80)

0.5118 (13.00)

0.3543 (9.00)

8°

0°

0.1142 (2.90) MAX

2 PLACES

END VIEW

DETAIL A

0.0433 (1.10)

0.0315 (0.80)

SEATING

PLANE

0.0500

(1.27)

BSC

0.0209 (0.53)

0.0157 (0.40)

0.5709 (14.50)

0.5591 (14.20)

0.5472 (13.90)

0.4370 (11.10)

0.4331 (11.00)

0.4252 (10.80)

1

10

20

11

0.1417 (3.60)

0.1319 (3.35)

0.1220 (3.10)

0.6299 (16.00)

0.6260 (15.90)

0.6220 (15.80)

TOP VIEW

0.0433 (1.10) MAX 45

0.0433

(1.10) MAX

2 PLACES

PIN 1

SIDE VIEW

0.0394 (1.00)

0.0354 (0.90)

0.0315 (0.80)

0.1299 (3.30)

0.1240 (3.15)

0.1181 (3.00)

0.1118 (0.30)

0.0079 (0.20)

0.0039 (0.10)

0.0039 (0.10)

0.0020 (0.05)

0.0000 (0.00)

0.0126 (0.32)

0.0090 (0.23)

DETAIL A

24-Lead Batwing

(RB-24)

0.0125 (0.32)

0.0091 (0.23)

0.0500 (1.27)

0.0157 (0.40)

8°

0°

0.0291 (0.74)

0.0098 (0.25)

45°

24

13

12

1

0.6141 (15.60)

0.5985 (15.20)

0.2992 (7.60)

0.2914 (7.40)

PIN 1

0.4193 (10.65)

0.3937 (10.00)

SEATING

PLANE

0.0118 (0.30)

0.0040 (0.10)

0.0201 (0.51)

0.0130 (0.33)

0.1043 (2.65)

0.0926 (2.35)

0.0500

(1.27)

BSC

28-Lead HTSSOP

(RE-28)

0.041 (1.05)

0.039 (1.00)

0.031 (0.80)

SEATING

PLANE

0.047

(1.20)

MAX

0.006 (0.15)

0.000 (0.00)

0.0118 (0.30)

0.0075 (0.19)

0.177 (4.50)

0.173 (4.40)

0.169 (4.30)

28

15

14

1

0.386 (9.80)

0.382 (9.70)

0.378 (9.60)

PIN 1

0.059

(1.50)

MIN

0.130 (3.30)

MIN

0.252

(6.40)

BSC

EXPOSED PAD

ON BOTTOM

0.0256 (0.65)

BSC

0.0079 (0.20)

0.0035 (0.09)

8

0

0.030 (0.75)

0.024 (0.60)

0.177 (0.45)

CONTROLLING DIMENSIONS ARE IN MILLIMETERS (mm)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).