| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: AD8554 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

AD8551/AD8552/AD8554

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1999

Zero-Drift, Single-Supply,

Rail-to-Rail Input/Output

Operational Amplifiers

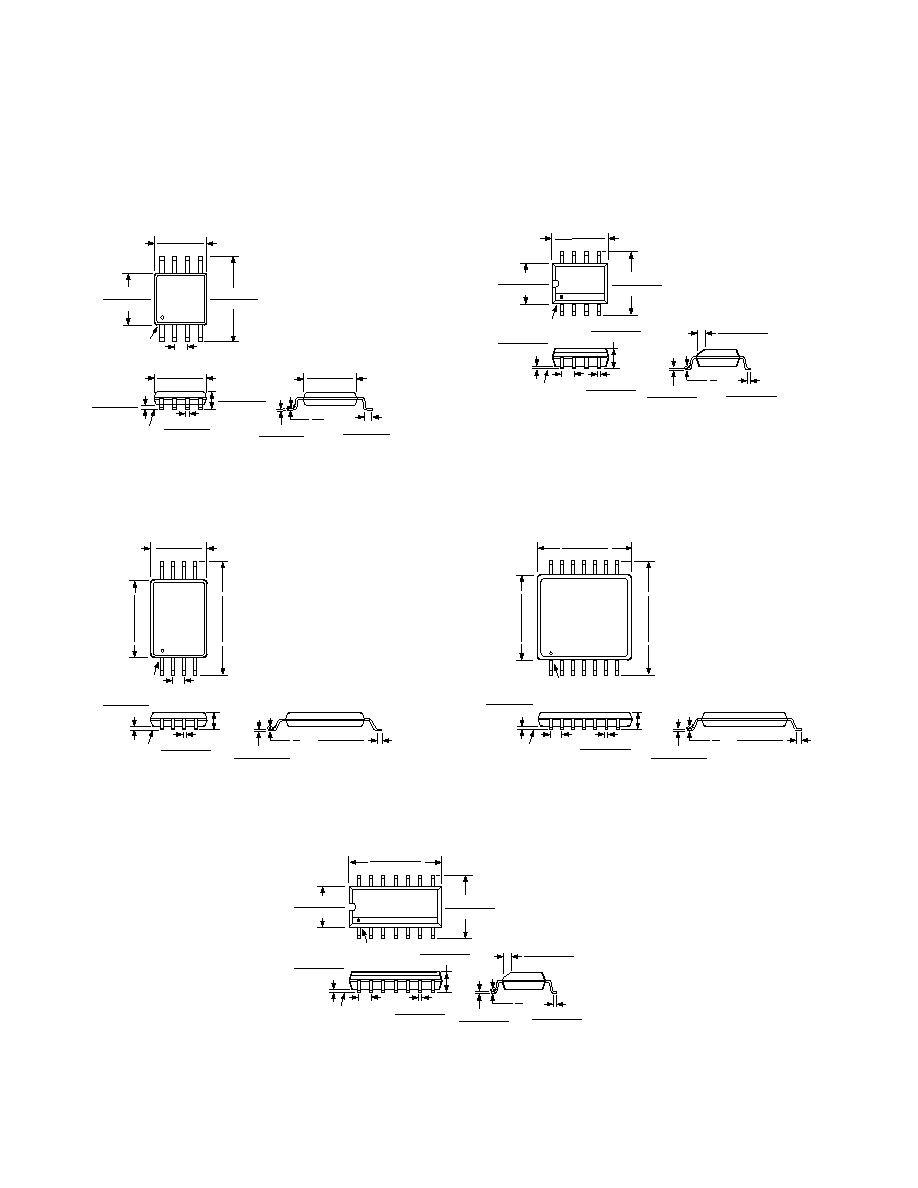

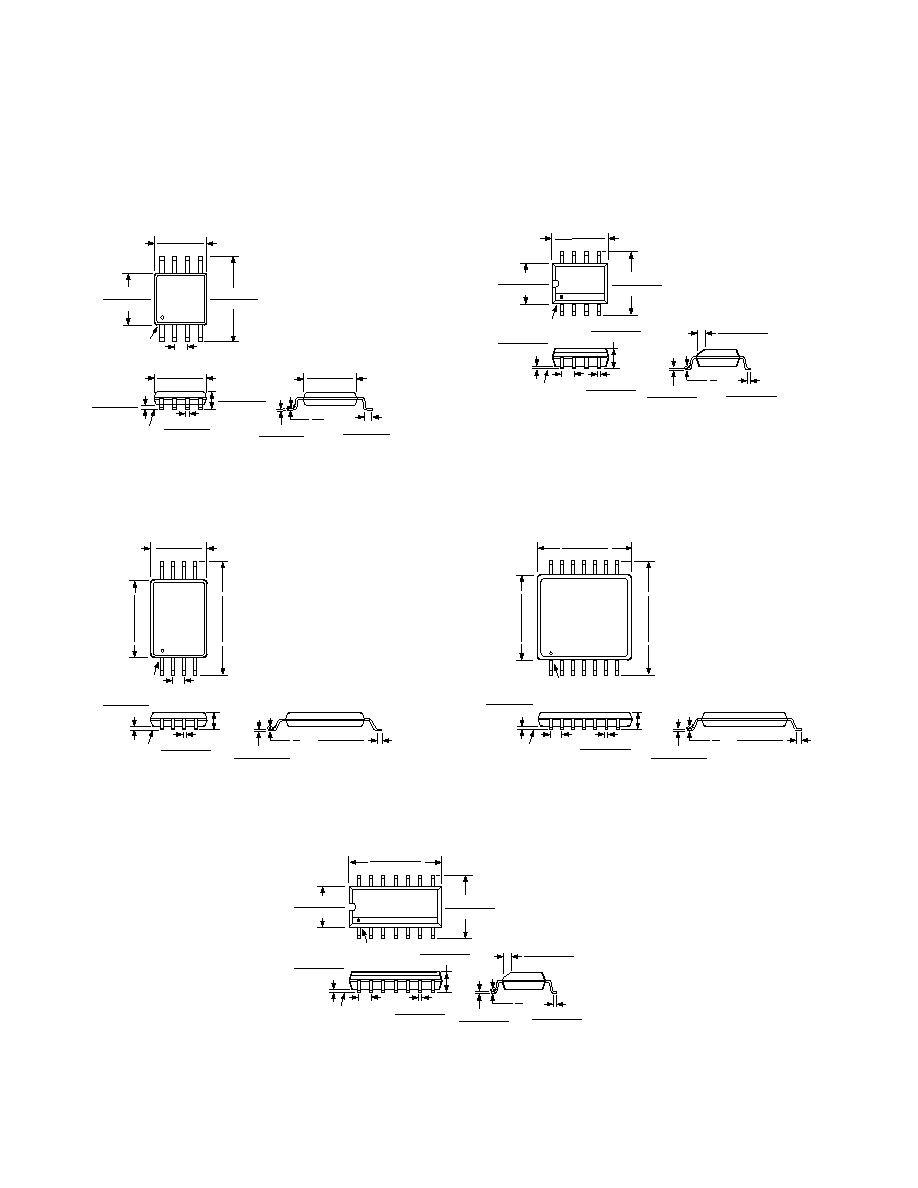

8-Lead SOIC

(R Suffix)

1

2

3

4

8

7

6

5

AD8551

IN A

V

+IN A

V+

OUT A

NC

NC

NC

NC = NO CONNECT

1

2

3

4

8

7

6

5

AD8552

IN A

V

+IN A

OUT B

IN B

V+

+IN B

OUT A

14-Lead SOIC

(R Suffix)

14

13

12

11

10

9

8

1

2

3

4

5

6

7

IN A

+IN A

V+

+IN B

IN B

OUT B

OUT D

IN D

+IN D

V

+IN C

IN C

OUT C

OUT A

AD8554

FEATURES

Low Offset Voltage: 1 V

Input Offset Drift: 0.005 V/ C

Rail-to-Rail Input and Output Swing

+5 V/+2.7 V Single-Supply Operation

High Gain, CMRR, PSRR: 130 dB

Ultralow Input Bias Current: 20 pA

Low Supply Current: 700 A/Op Amp

Overload Recovery Time: 50 s

No External Capacitors Required

APPLICATIONS

Temperature Sensors

Pressure Sensors

Precision Current Sensing

Strain Gage Amplifiers

Medical Instrumentation

Thermocouple Amplifiers

GENERAL DESCRIPTION

This new family of amplifiers has ultralow offset, drift and bias

current. The AD8551, AD8552 and AD8554 are single, dual and

quad amplifiers featuring rail-to-rail input and output swings. All

are guaranteed to operate from +2.7 V to +5 V single supply.

The AD855x family provides the benefits previously found only

in expensive autozeroing or chopper-stabilized amplifiers. Using

Analog Devices' new topology these new zero-drift amplifiers

combine low cost with high accuracy. No external capacitors are

required.

With an offset voltage of only 1

µ

V and drift of 0.005

µ

V/

∞

C,

the AD8551 is perfectly suited for applications where error

sources cannot be tolerated. Temperature, position and pres-

sure sensors, medical equipment and strain gage amplifiers

benefit greatly from nearly zero drift over their operating

temperature range. The rail-to-rail input and output swings

provided by the AD855x family make both high-side and low-

side sensing easy.

The AD855x family is specified for the extended industrial/

automotive (≠40

∞

C to +125

∞

C) temperature range. The AD8551

single is available in 8-lead MSOP and narrow 8-lead SOIC

packages. The AD8552 dual amplifier is available in 8-lead

narrow SO and 8-lead TSSOP surface mount packages. The

AD8554 quad is available in narrow 14-lead SOIC and 14-lead

TSSOP packages.

8-Lead MSOP

(RM Suffix)

IN A

IN A

V

V+

OUT A

NC

1

4

5

8

AD8551

NC

NC = NO CONNECT

NC

8-Lead TSSOP

(RU Suffix)

IN A

+IN A

V

OUT B

IN B

+IN B

V+

1

4

5

8

AD8552

OUT A

14-Lead TSSOP

(RU Suffix)

OUT A

IN A

IN A

V

IN D

IN D

V

OUT D

IN B

IN B

OUT B

IN C

OUT C

IN C

AD8554

1

14

7

8

PIN CONFIGURATIONS

8-Lead SOIC

(R Suffix)

≠2≠

REV. 0

AD8551/AD8552/AD8554≠SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Offset Voltage

V

OS

1

5

µ

V

≠40

∞

C

T

A

+125

∞

C

10

µ

V

Input Bias Current

I

B

10

50

pA

≠40

∞

C

T

A

+125

∞

C

1.0

1.5

nA

Input Offset Current

I

OS

20

70

pA

≠40

∞

C

T

A

+125

∞

C

150

200

pA

Input Voltage Range

0

5

V

Common-Mode Rejection Ratio

CMRR

V

CM

= 0 V to +5 V

120

140

dB

≠40

∞

C

T

A

+125

∞

C

115

130

dB

Large Signal Voltage Gain

1

A

VO

R

L

= 10 k

, V

O

= +0.3 V to +4.7 V

125

145

dB

≠40

∞

C

T

A

+125

∞

C

120

135

dB

Offset Voltage Drift

V

OS

/

T

≠40

∞

C

T

A

+125

∞

C

0.005 0.04

µ

V/

∞

C

OUTPUT CHARACTERISTICS

Output Voltage High

V

OH

R

L

= 100 k

to GND

4.99

4.998

V

≠40

∞

C to +125

∞

C

4.99

4.997

V

R

L

= 10 k

to GND

4.95

4.98

V

≠40

∞

C to +125

∞

C

4.95

4.975

V

Output Voltage Low

V

OL

R

L

= 100 k

to V+

1

10

mV

≠40

∞

C to +125

∞

C

2

10

mV

R

L

= 10 k

to V+

10

30

mV

≠40

∞

C to +125

∞

C

15

30

mV

Short Circuit Limit

I

SC

±

25

±

50

mA

≠40

∞

C to +125

∞

C

±

40

mA

Output Current

I

O

±

30

mA

≠40

∞

C to +125

∞

C

±

15

mA

POWER SUPPLY

Power Supply Rejection Ratio

PSRR

V

S

= +2.7 V to +5.5 V

120

130

dB

≠40

∞

C

T

A

+125

∞

C

115

130

dB

Supply Current/Amplifier

I

SY

V

O

= 0 V

850

975

µ

A

≠40

∞

C

T

A

+125

∞

C

1,000 1,075

µ

A

DYNAMIC PERFORMANCE

Slew Rate

SR

R

L

= 10 k

0.4

V/

µ

s

Overload Recovery Time

0.05

0.3

ms

Gain Bandwidth Product

GBP

1.5

MHz

NOISE PERFORMANCE

Voltage Noise

e

n

p-p

0 Hz to 10 Hz

1.0

µ

V p-p

e

n

p-p

0 Hz to 1 Hz

0.32

µ

V p-p

Voltage Noise Density

e

n

f = 1 kHz

42

nV/

Hz

Current Noise Density

i

n

f = 10 Hz

2

fA/

Hz

NOTE

1

Gain testing is highly dependent upon test bandwidth.

Specifications subject to change without notice.

(V

S

= +5 V, V

CM

= +2.5 V, V

O

= +2.5 V, T

A

= +25 C unless otherwise noted)

≠3≠

REV. 0

AD8551/AD8552/AD8554

ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Offset Voltage

V

OS

1

5

µ

V

≠40

∞

C

T

A

+125

∞

C

10

µ

V

Input Bias Current

I

B

10

50

pA

≠40

∞

C

T

A

+125

∞

C

1.0

1.5

nA

Input Offset Current

I

OS

10

50

pA

≠40

∞

C

T

A

+125

∞

C

150

200

pA

Input Voltage Range

0

2.7

V

Common-Mode Rejection Ratio

CMRR

V

CM

= 0 V to +2.7 V

115

130

dB

≠40

∞

C

T

A

+125

∞

C

110

130

dB

Large Signal Voltage Gain

1

A

VO

R

L

= 10 k

, V

O

= +0.3 V to +2.4 V

110

140

dB

≠40

∞

C

T

A

+125

∞

C

105

130

dB

Offset Voltage Drift

V

OS

/

T

≠40

∞

C

T

A

+125

∞

C

0.005 0.04

µ

V/

∞

C

OUTPUT CHARACTERISTICS

Output Voltage High

V

OH

R

L

= 100 k

to GND

2.685

2.697

V

≠40

∞

C to +125

∞

C

2.685

2.696

V

R

L

= 10 k

to GND

2.67

2.68

V

≠40

∞

C to +125

∞

C

2.67

2.675

V

Output Voltage Low

V

OL

R

L

= 100 k

to V+

1

10

mV

≠40

∞

C to +125

∞

C

2

10

mV

R

L

= 10 k

to V+

10

20

mV

≠40

∞

C to +125

∞

C

15

20

mV

Short Circuit Limit

I

SC

±

10

±

15

mA

≠40

∞

C to +125

∞

C

±

10

mA

Output Current

I

O

±

10

mA

≠40

∞

C to +125

∞

C

±

5

mA

POWER SUPPLY

Power Supply Rejection Ratio

PSRR

V

S

= +2.7 V to +5.5 V

120

130

dB

≠40

∞

C

T

A

+125

∞

C

115

130

dB

Supply Current/Amplifier

I

SY

V

O

= 0 V

750

900

µ

A

≠40

∞

C

T

A

+125

∞

C

950

1,000

µ

A

DYNAMIC PERFORMANCE

Slew Rate

SR

R

L

= 10 k

0.5

V/

µ

s

Overload Recovery Time

0.05

ms

Gain Bandwidth Product

GBP

1

MHz

NOISE PERFORMANCE

Voltage Noise

e

n

p-p

0 Hz to 10 Hz

1.6

µ

V p-p

Voltage Noise Density

e

n

f = 1 kHz

75

nV/

Hz

Current Noise Density

i

n

f = 10 Hz

2

fA/

Hz

NOTE

1

Gain testing is highly dependent upon test bandwidth.

Specifications subject to change without notice.

(V

S

= +2.7 V, V

CM

= +1.35 V, V

O

= +1.35 V, T

A

= +25 C unless otherwise noted)

AD8551/AD8552/AD8554

≠4≠

REV. 0

ORDERING GUIDE

Temperature

Package

Package

Model

Range

Description

Option

Brand

1

AD8551ARM

2

≠40

∞

C to +125

∞

C

8-Lead MSOP

RM-8

AHA

AD8551AR

≠40

∞

C to +125

∞

C

8-Lead SOIC

SO-8

AD8552ARU

3

≠40

∞

C to +125

∞

C

8-Lead TSSOP

RU-8

AD8552AR

≠40

∞

C to +125

∞

C

8-Lead SOIC

SO-8

AD8554ARU

3

≠40

∞

C to +125

∞

C

14-Lead TSSOP

RU-14

AD8554AR

≠40

∞

C to +125

∞

C

14-Lead SOIC

SO-14

NOTES

1

Due to package size limitations, these characters represent the part number.

2

Available in reels only. 1,000 or 2,500 pieces per reel.

3

Available in reels only. 2,500 pieces per reel.

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +6 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . GND to V

S

+ 0.3 V

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . .

±

5.0 V

ESD(Human Body Model) . . . . . . . . . . . . . . . . . . . . . 2,000 V

Output Short-Circuit Duration to GND . . . . . . . . . Indefinite

Storage Temperature Range

RM, RU and R Packages . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

Operating Temperature Range

AD8551A/AD8552A/AD8554A . . . . . . . . ≠40

∞

C to +125

∞

C

Junction Temperature Range

RM, RU and R Packages . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300

∞

C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum rating condi-

tions for extended periods may affect device reliability.

2

Differential input voltage is limited to

±

5.0 V or the supply voltage, whichever is less.

Package Type

JA

1

JC

Units

8-Lead MSOP (RM)

190

44

∞

C/W

8-Lead TSSOP (RU)

240

43

∞

C/W

8-Lead SOIC (R)

158

43

∞

C/W

14-Lead TSSOP (RU)

180

36

∞

C/W

14-Lead SOIC (R)

120

36

∞

C/W

NOTE

1

JA

is specified for worst case conditions, i.e.,

JA

is specified for device in socket

for P-DIP packages,

JA

is specified for device soldered in circuit board for

SOIC and TSSOP packages.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD8551/AD8552/AD8554 features proprietary ESD protection circuitry, permanent damage

may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

AD8551/AD8552/AD8554

≠5≠

REV. 0

OFFSET VOLTAGE ≠ V

NUMBER OF AMPLIFIERS

180

0

2.5

0.5

120

100

60

20

2.5

V

SY

= +2.7V

V

CM

= +1.35V

T

A

= +25 C

40

80

140

160

1.5

0.5

1.5

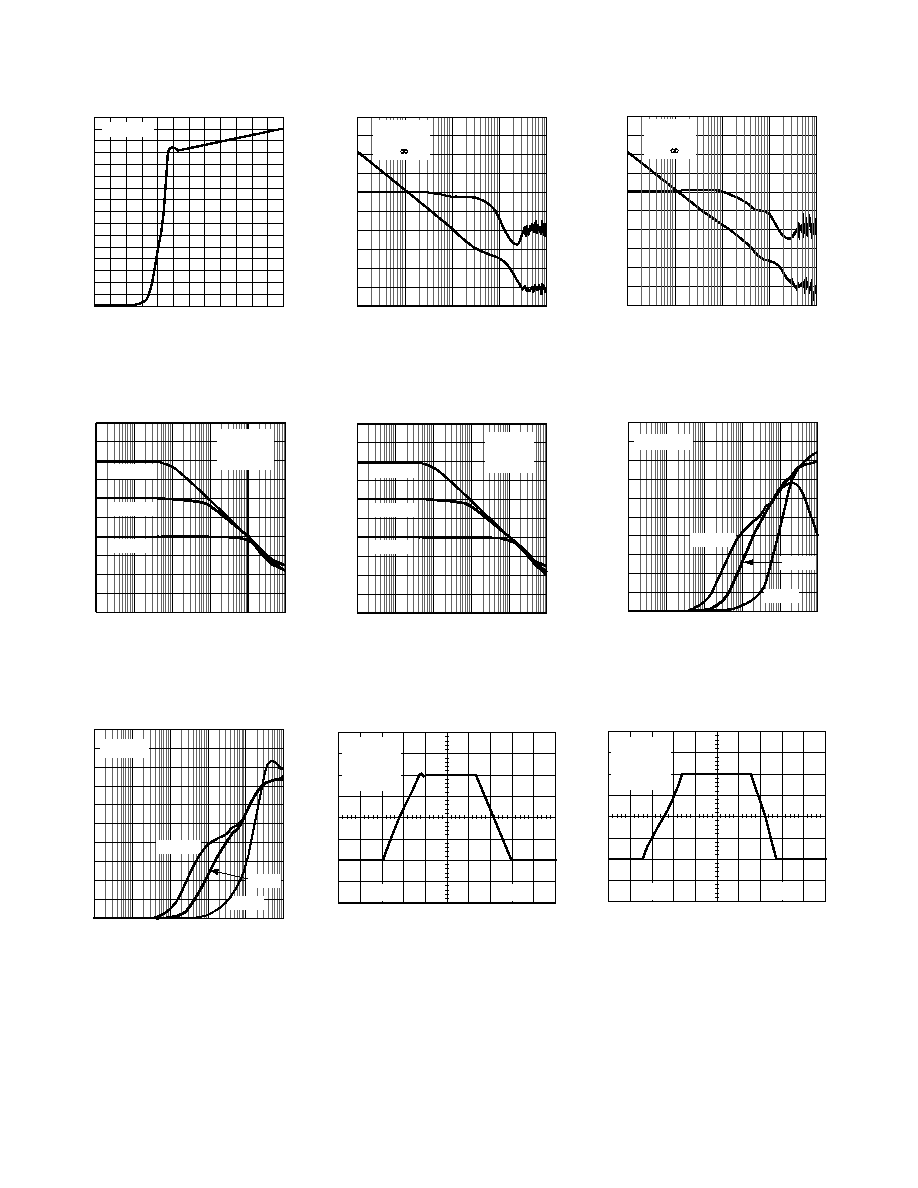

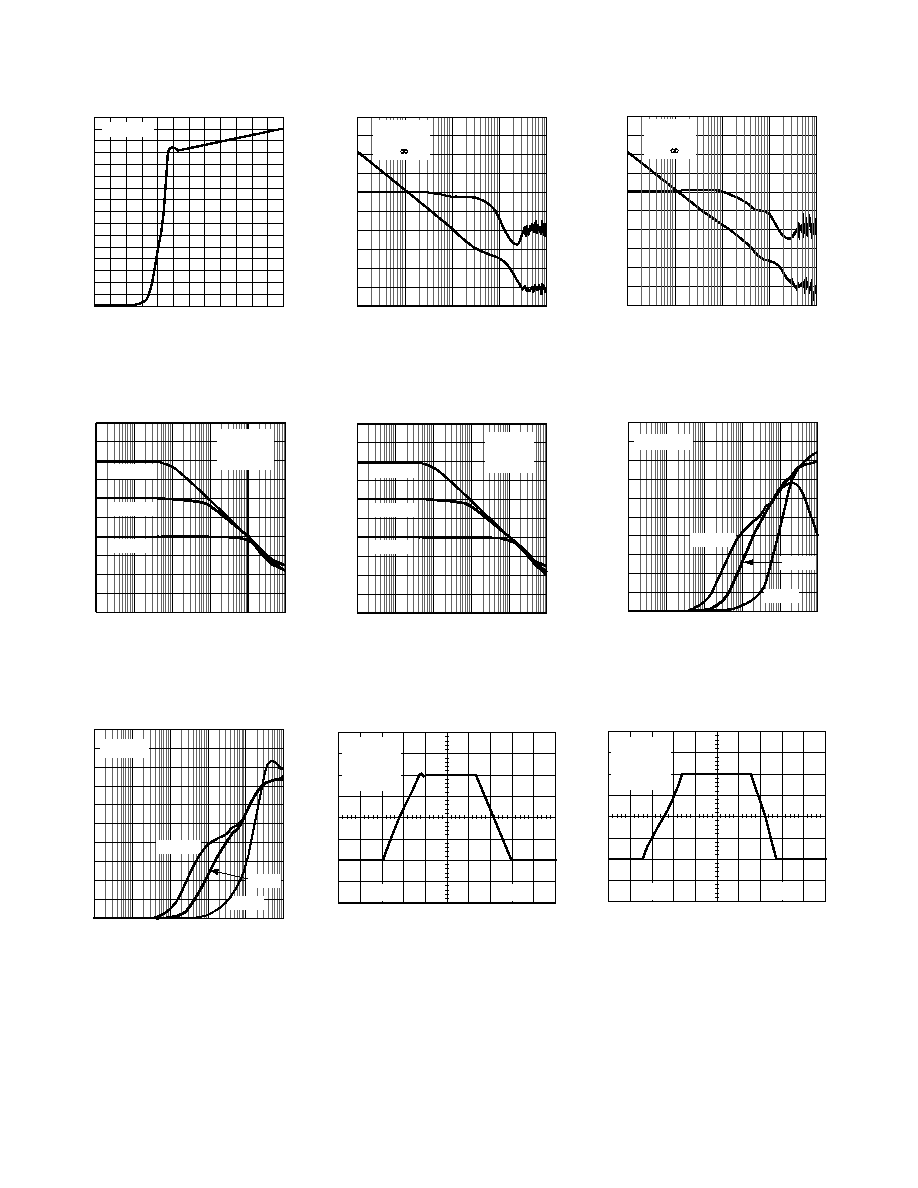

Figure 1. Input Offset Voltage

Distribution at +2.7 V

OFFSET VOLTAGE ≠ V

NUMBER OF AMPLIFIERS

180

0

120

100

60

20

V

SY

= +5V

V

CM

= +2.5V

T

A

= +25 C

40

80

140

160

2.5

0.5

2.5

1.5

0.5

1.5

Figure 4. Input Offset Voltage

Distribution at +5 V

LOAD CURRENT ≠ mA

10

0.1

0.001

OUTPUT VOLTAGE ≠ mV

0.1

1

10

1

100

10k

SOURCE

SINK

V

SY

= +2.7V

T

A

= +25 C

100

1k

0.0001

0.01

Figure 7. Output Voltage to Supply

Rail vs. Output Current at +2.7 V

INPUT COMMON-MODE VOLTAGE ≠ V

INPUT BIAS CURRENT ≠ pA

50

30

0

1

5

2

3

4

40

30

20

10

20

10

0

V

SY

= +5V

T

A

= 40 C, +25 C, +85 C

40 C

+25 C

+85 C

Figure 2. Input Bias Current vs.

Common-Mode Voltage

INPUT OFFSET DRIFT ≠ nV/ C

NUMBER OF AMPLIFIERS

12

0

0

1

6

2

3

4

5

10

8

4

2

6

V

SY

= +5V

V

CM

= +2.5V

T

A

= 40 C TO +125 C

Figure 5. Input Offset Voltage Drift

Distribution at +5 V

TEMPERATURE ≠ C

INPUT BIAS CURRENT ≠

p

A

0

1000

75

50

125

25

0

25

50

75 100

250

500

750

150

V

CM

= +2.5V

V

SY

= +5V

Figure 8. Bias Current vs. Temperature

INPUT COMMON-MODE VOLTAGE ≠ V

INPUT BIAS CURRENT ≠ pA

1,500

2,000

0

1

5

2

3

4

1,000

500

0

1,000

1,500

500

V

SY

= +5V

T

A

= +125 C

Figure 3. Input Bias Current vs.

Common-Mode Voltage

LOAD CURRENT ≠ mA

10

0.1

0.001

OUTPUT VOLTAGE ≠ mV

0.1

1

10

1

100

10k

100

1k

0.0001

0.01

SOURCE

SINK

V

SY

= +5V

T

A

= +25 C

Figure 6. Output Voltage to Supply

Rail vs. Output Current at +5 V

TEMPERATURE ≠ C

SUPPLY CURRENT ≠

m

A

1.0

0.8

0

75

50

125

25

0

25

50

75 100

0.6

0.4

0.2

150

+5V

+2.7V

Figure 9. Supply Current vs.

Temperature

Typical Performance Characteristics≠

AD8551/AD8552/AD8554

≠6≠

REV. 0

SUPPLY VOLTAGE ≠ V

SUPPLY CURRENT PER AMPLIFIER ≠

A

800

0

700

400

300

200

100

600

500

0

1

6

2

3

4

5

T

A

= +25 C

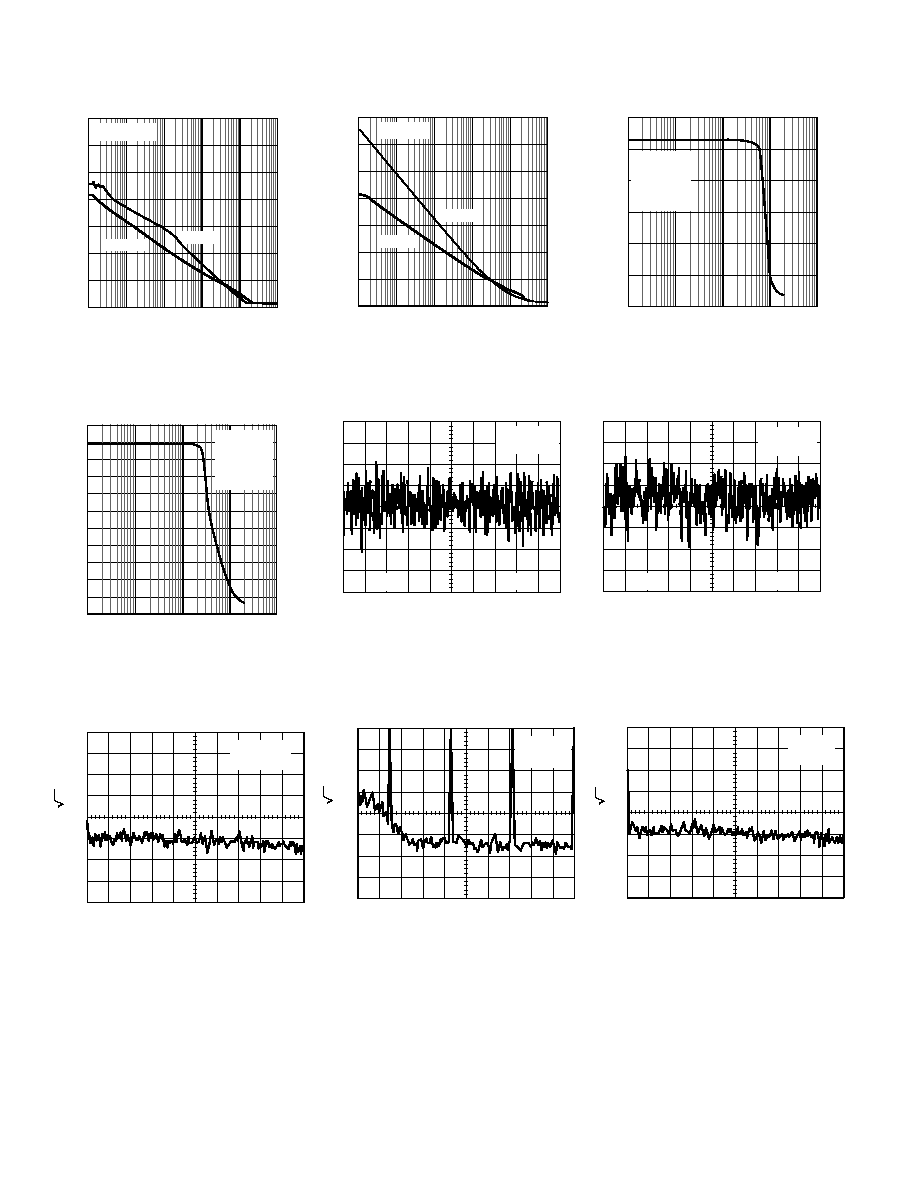

Figure 10. Supply Current vs.

Supply Voltage

FREQUENCY ≠ Hz

CLOSED-LOOP GAIN ≠ dB

100

1k

10M

10k

100k

1M

60

50

40

40

30

20

10

0

10

20

30

A

V

= 100

V

SY

= +2.7V

C

L

= 0pF

R

L

= 2k

A

V

= 10

A

V

= +1

Figure 13. Closed Loop Gain vs.

Frequency at +2.7 V

V

SY

= +5V

A

V

= 100

A

V

= 1

A

V

= 10

FREQUENCY ≠ Hz

OUTPUT IMPEDANCE ≠

100

1k

10M

10k

100k

1M

300

270

0

240

210

180

150

120

90

60

30

Figure 16. Output Impedance vs.

Frequency at +5 V

FREQUENCY ≠ Hz

OPEN-LOOP GAIN ≠ dB

10k

100k

100M

1M

10M

60

50

40

40

30

20

10

0

10

20

30

45

90

135

180

225

270

0

PHASE SHIFT ≠ De

g

rees

V

SY

= +2.7V

C

L

= 0pF

R

L

=

Figure 11. Open-Loop Gain and

Phase Shift vs. Frequency at +2.7 V

A

V

= 100

V

SY

= +5V

C

L

= 0pF

R

L

= 2k

A

V

= 10

A

V

= +1

FREQUENCY ≠ Hz

CLOSED-LOOP GAIN ≠ dB

100

1k

10M

10k

100k

1M

60

50

40

40

30

20

10

0

10

20

30

Figure 14. Closed Loop Gain vs.

Frequency at +5 V

2 s

500mV

V

SY

= +2.7V

C

L

= 300pF

R

L

= 2k

A

V

= +1

Figure 17. Large Signal Transient

Response at +2.7 V

FREQUENCY ≠ Hz

OPEN-LOOP GAIN ≠ dB

10k

100k

100M

1M

10M

60

50

40

40

30

20

10

0

10

20

30

45

90

135

180

225

270

0

PHASE SHIFT ≠ Degrees

V

SY

= +5V

C

L

= 0pF

R

L

=

Figure 12. Open-Loop Gain and

Phase Shift vs. Frequency at +5 V

FREQUENCY ≠ Hz

OUTPUT IMPEDANCE ≠

100

1k

10M

10k

100k

1M

300

270

0

240

210

180

150

120

90

60

30

V

SY

= +2.7V

A

V

= 100

A

V

= 1

A

V

= 10

Figure 15. Output Impedance vs.

Frequency at +2.7 V

5 s

1V

V

SY

= +5V

C

L

= 300pF

R

L

= 2k

A

V

= +1

Figure 18. Large Signal Transient

Response at +5 V

AD8551/AD8552/AD8554

≠7≠

REV. 0

5 s

50mV

V

SY

= 1.35V

C

L

= 50pF

R

L

=

A

V

= +1

Figure 19. Small Signal Transient

Response at +2.7 V

CAPACITANCE ≠ pF

SMALL SIGNAL OVERSHOOT ≠ %

10

100

10k

1k

45

0

40

35

30

25

20

15

10

5

+OS

OS

V

SY

= 2.5V

R

L

= 2k

T

A

= +25 C

Figure 22. Small Signal Overshoot

vs. Load Capacitance at +5 V

200 s

1V

V

S

= 2.5V

R

L

= 2k

A

V

= 100

V

IN

= 60mV p-p

Figure 25. No Phase Reversal

5 s

50mV

V

SY

= 2.5V

C

L

= 50pF

R

L

=

A

V

= +1

Figure 20. Small Signal Transient

Response at +5 V

V

SY

= 2.5V

V

IN

= 200mV p-p

(RET TO GND)

C

L

= 0pF

R

L

= 10k

A

V

= 100

20 s

1V

0V

V

IN

V

OUT

0V

BOTTOM SCALE: 1V/DIV

TOP SCALE: 200mV/DIV

Figure 23. Positive Overvoltage

Recovery

V

SY

= +2.7V

FREQUENCY ≠ Hz

CMRR ≠ dB

140

80

0

100

1k

10M

10k

100k

1M

60

120

20

40

100

Figure 26. CMRR vs. Frequency

at +2.7 V

CAPACITANCE ≠ pF

SMALL SIGNAL OVERSHOOT ≠ %

10

100

10k

1k

50

45

0

40

35

30

25

20

15

10

5

+OS

OS

V

SY

= 1.35V

R

L

= 2k

T

A

= +25 C

Figure 21. Small Signal Overshoot

vs. Load Capacitance at +2.7 V

V

SY

= 2.5V

V

IN

= +200mV p-p

(RET TO GND)

C

L

= 0pF

R

L

= 10k

A

V

= 100

20 s

1V

V

IN

0V

0V

V

OUT

BOTTOM SCALE: 1V/DIV

TOP SCALE: 200mV/DIV

Figure 24. Negative Overvoltage

Recovery

FREQUENCY ≠ Hz

CMRR ≠ dB

140

80

0

100

1k

10M

10k

100k

1M

60

120

20

40

100

V

SY

= +5V

Figure 27. CMRR vs. Frequency

at +5 V

AD8551/AD8552/AD8554

≠8≠

REV. 0

FREQUENCY ≠ Hz

PSRR ≠ dB

140

80

0

100

1k

10M

10k

100k

1M

60

120

20

40

100

+PSRR

PSRR

V

SY

= 1.35V

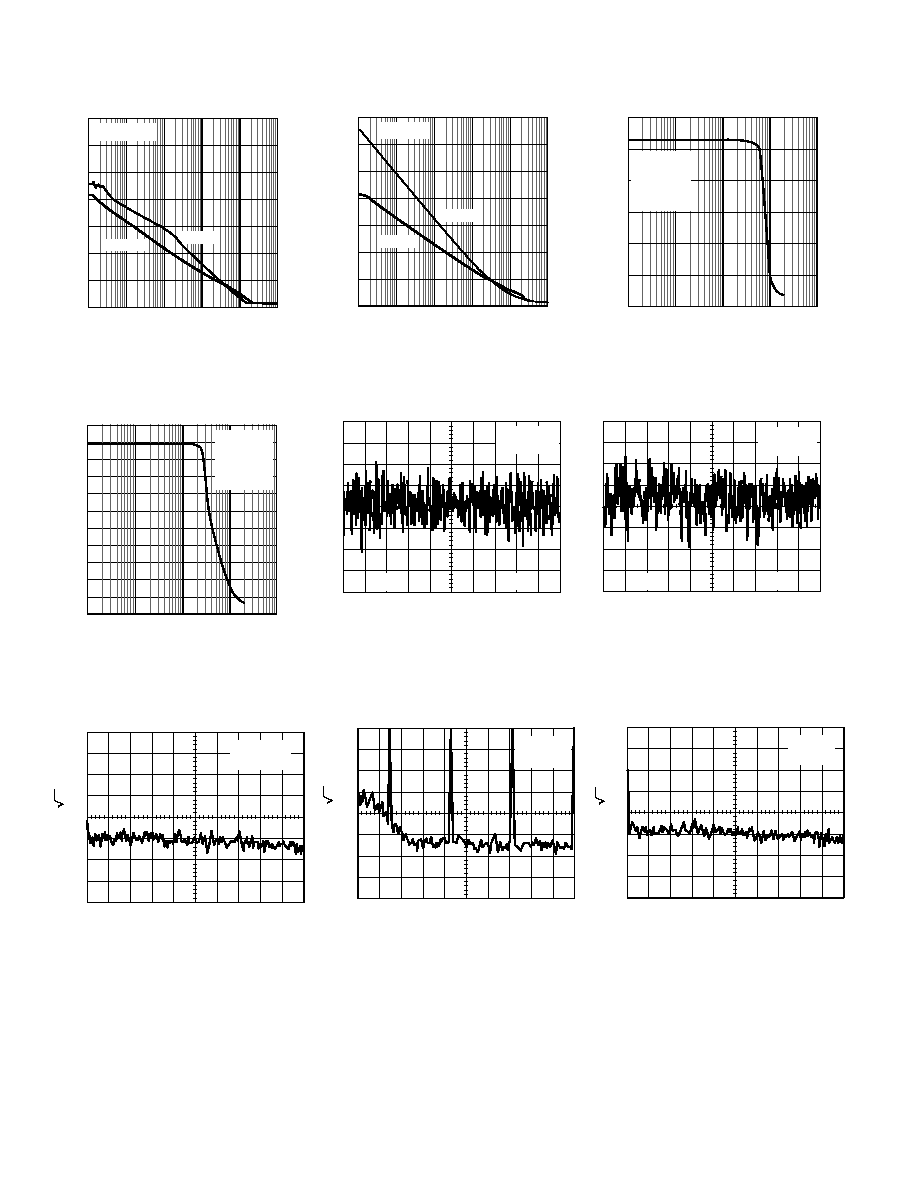

Figure 28. PSRR vs. Frequency

at

±

1.35 V

3.0

2.5

2.0

1.5

0.5

1.0

V

SY

= 2.5V

R

L

= 2k

A

V

= +1

THD+N < 1%

T

A

= +25 C

3.5

4.0

4.5

5.0

5.5

FREQUENCY ≠ Hz

OUTPUT SWING ≠ V p-p

0

100

1k

1M

10k

100k

Figure 31. Maximum Output Swing

vs. Frequency at +5 V

e

n

≠ nV/ Hz

V

SY

= +2.7V

R

S

= 0

0.5

FREQUENCY ≠ kHz

1.0

1.5

2.0

2.5

0

52

78

104

130

156

182

26

Figure 34. Voltage Noise Density at

+2.7 V from 0 Hz to 2.5 kHz

+PSRR

PSRR

V

SY

= 2.5V

FREQUENCY ≠ Hz

PSRR ≠ dB

140

80

0

100

1k

10M

10k

100k

1M

60

120

20

40

100

Figure 29. PSRR vs. Frequency

at

±

2.5 V

1s

2mV

V

SY

= 1.35V

A

V

= 10,000

0V

Figure 32. 0.1 Hz to 10 Hz Noise

at +2.7 V

e

n

≠ nV/ Hz

V

SY

= +2.7V

R

S

= 0

5

FREQUENCY ≠ kHz

10

15

20

25

0

32

48

64

80

96

112

16

Figure 35. Voltage Noise Density at

+2.7 V from 0 Hz to 25 kHz

FREQUENCY ≠ Hz

OUTPUT SWING ≠ V p-p

3.0

2.5

0

100

1k

1M

10k

100k

2.0

1.5

0.5

1.0

V

SY

= 1.35V

R

L

= 2k

A

V

= +1

THD+N < 1%

T

A

= +25 C

Figure 30. Maximum Output Swing

vs. Frequency at +2.7 V

1s

2mV

V

SY

= 2.5V

A

V

= 10,000

Figure 33. 0.1 Hz to 10 Hz Noise at +5 V

V

SY

= +5V

R

S

= 0

0.5

FREQUENCY ≠ kHz

1.0

1.5

2.0

2.5

0

26

39

52

65

78

91

13

e

n

≠ nV/ Hz

Figure 36. Voltage Noise Density at

+5 V from 0 Hz to 2.5 kHz

AD8551/AD8552/AD8554

≠9≠

REV. 0

e

n

≠ nV/ Hz

5

10

15

20

25

0

V

SY

= ±5V

R

S

= 0

FREQUENCY ≠ kHz

32

48

64

80

96

112

16

Figure 37. Voltage Noise Density

at +5 V from 0 Hz to 25 kHz

10

TEMPERATURE ≠ C

SHORT-CIRCUIT CURRENT ≠ mA

50

30

50

75

50

125

25

0

25

50

75 100

10

150

V

SY

= +2.7V

40

30

20

0

20

40

I

SC

I

SC+

Figure 40. Output Short-Circuit

Current vs. Temperature

100

TEMPERATURE ≠ C

OUTPUT VOLTAGE SWING ≠ mV

250

200

0

75

50

125

25

0

25

50

75 100

150

150

V

SY

= +5.0V

25

50

75

125

175

225

R

L

= 1k

R

L

= 10k

R

L

= 100k

Figure 43. Output Voltage to Supply

Rail vs. Temperature

e

n

≠ nV/ Hz

V

SY

= +5V

R

S

= 0

5

10

0

FREQUENCY ≠ Hz

48

72

96

120

144

168

24

Figure 38. Voltage Noise Density

at +5 V from 0 Hz to 10 Hz

20

TEMPERATURE ≠ C

SHORT-CIRCUIT CURRENT ≠ mA

100

60

100

75

50

125

25

0

25

50

75 100

20

150

V

SY

= +5.0V

80

60

40

0

40

80

I

SC

I

SC+

Figure 41. Output Short-Circuit

Current vs. Temperature

TEMPERATURE ≠ C

POWER SUPPLY REJECTION ≠ dB

150

145

125

75

50

125

25

0

25

50

75 100

140

135

130

150

V

SY

= +2.7V TO +5.5V

Figure 39. Power-Supply Rejection

vs. Temperature

100

TEMPERATURE ≠ C

OUTPUT VOLTAGE SWING ≠ mV

250

200

0

75

50

125

25

0

25

50

75 100

150

150

V

SY

= +5.0V

25

50

75

125

175

225

R

L

= 1k

R

L

= 10k

R

L

= 100k

Figure 42. Output Voltage to

Supply Rail vs. Temperature

AD8551/AD8552/AD8554

≠10≠

REV. 0

FUNCTIONAL DESCRIPTION

The AD855x family of amplifiers are high precision rail-to-rail

operational amplifiers that can be run from a single supply volt-

age. Their typical offset voltage of less than 1

µ

V allows these

amplifiers to be easily configured for high gains without risk of

excessive output voltage errors. The extremely small tempera-

ture drift of 5 nV/

∞

C ensures a minimum of offset voltage error

over its entire temperature range of ≠40

∞

C to +125

∞

C, making

the AD855x amplifiers ideal for a variety of sensitive measure-

ment applications in harsh operating environments such as

under-hood and braking/suspension systems in automobiles.

The AD855x family are CMOS amplifiers and achieve their

high degree of precision through autozero stabilization. This

autocorrection topology allows the AD855x to maintain its low

offset voltage over a wide temperature range and over its operat-

ing lifetime.

Amplifier Architecture

Each AD855x op amp consists of two amplifiers, a main amplifier

and a secondary amplifier, used to correct the offset voltage of the

main amplifier. Both consist of a rail-to-rail input stage, allowing

the input common-mode voltage range to reach both supply rails.

The input stage consists of an NMOS differential pair operating

concurrently with a parallel PMOS differential pair. The outputs

from the differential input stages are combined in another gain

stage whose output is used to drive a rail-to-rail output stage.

The wide voltage swing of the amplifier is achieved by using two

output transistors in a common-source configuration. The output

voltage range is limited by the drain to source resistance of these

transistors. As the amplifier is required to source or sink more

output current, the r

DS

of these transistors increases, raising the

voltage drop across these transistors. Simply put, the output volt-

age will not swing as close to the rail under heavy output current

conditions as it will with light output current. This is a character-

istic of all rail-to-rail output amplifiers. Figures 6 and 7 show how

close the output voltage can get to the rails with a given output

current. The output of the AD855x is short circuit protected to

approximately 50 mA of current.

The AD855x amplifiers have exceptional gain, yielding greater

than 120 dB of open-loop gain with a load of 2 k

. Because the

output transistors are configured in a common-source configu-

ration, the gain of the output stage, and thus the open-loop gain

of the amplifier, is dependent on the load resistance. Open-loop

gain will decrease with smaller load resistances. This is another

characteristic of rail-to-rail output amplifiers.

Basic Autozero Amplifier Theory

Autocorrection amplifiers are not a new technology. Various IC

implementations have been available for over 15 years and some

improvements have been made over time. The AD855x design

offers a number of significant performance improvements over

older versions while attaining a very substantial reduction in de-

vice cost. This section offers a simplified explanation of how the

AD855x is able to offer extremely low offset voltages and high

open-loop gains.

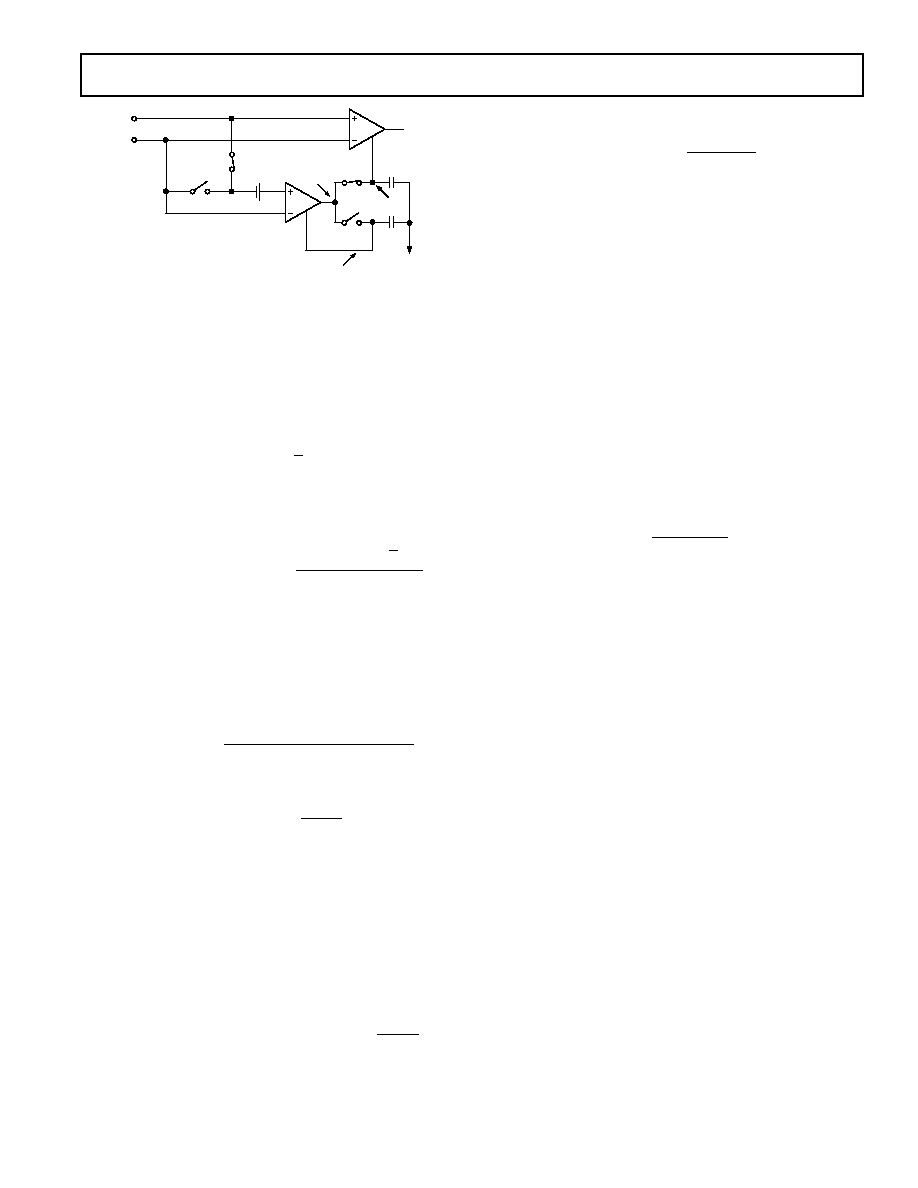

As noted in the previous section on amplifier architecture, each

AD855x op amp contains two internal amplifiers. One is used as

the primary amplifier, the other as an autocorrection, or nulling,

amplifier. Each amplifier has an associated input offset voltage,

which can be modeled as a dc voltage source in series with the

noninverting input. In Figures 44 and 45 these are labeled as

V

OSX

, where x denotes the amplifier associated with the offset; A

for the nulling amplifier, B for the primary amplifier. The open-

loop gain for the +IN and ≠IN inputs of each amplifier is given

as A

X

. Both amplifiers also have a third voltage input with an

associated open-loop gain of B

X

.

There are two modes of operation determined by the action of

two sets of switches in the amplifier: An autozero phase and an

amplification phase.

Autozero Phase

In this phase, all

A switches are closed and all

B switches are

opened. Here, the nulling amplifier is taken out of the gain loop

by shorting its two inputs together. Of course, there is a degree of

offset voltage, shown as V

OSA

, inherent in the nulling amplifier

which maintains a potential difference between the +IN and ≠IN

inputs. The nulling amplifier feedback loop is closed through

A

2

and V

OSA

appears at the output of the nulling amp and on C

M1

,

an internal capacitor in the AD855x. Mathematically, we can ex-

press this in the time domain as:

V

t

A V

t

B V

t

OA

A OSA

A OA

[ ]

=

[ ]

-

[ ]

(1)

which can be expressed as,

V

t

A V

t

B

OA

A OSA

A

[ ]

=

[ ]

+

1

(2)

This shows us that the offset voltage of the nulling amplifier

times a gain factor appears at the output of the nulling amplifier

and thus on the C

M1

capacitor.

V

IN+

V

IN

V

OUT

A

B

A

A

A

B

V

OSA

+

B

B

C

M2

C

M1

A

B

V

NB

V

NA

B

A

V

OA

Figure 44. Autozero Phase of the AD855x

Amplification Phase

When the

B switches close and the

A switches open for the

amplification phase, this offset voltage remains on C

M1

and

essentially corrects any error from the nulling amplifier. The

voltage across C

M1

is designated as V

NA

. Let us also designate

V

IN

as the potential difference between the two inputs to the

primary amplifier, or V

IN

= (V

IN+

≠ V

IN≠

). Now the output of the

nulling amplifier can be expressed as:

V

t

A V

t

V

t

B V

t

OA

A

IN

OSA

A

NA

[ ]

=

[ ]

-

[ ]

(

)

-

[ ]

(3)

AD8551/AD8552/AD8554

≠11≠

REV. 0

V

IN+

V

IN

V

OUT

A

B

A

A

A

B

V

OSA

+

B

B

C

M2

C

M1

A

B

V

NB

V

NA

B

A

V

OA

Figure 45. Output Phase of the Amplifier

Because

A is now open and there is no place for C

M1

to dis-

charge, the voltage V

NA

at the present time t is equal to the

voltage at the output of the nulling amp V

OA

at the time when

A was closed. If we call the period of the autocorrection

switching frequency T

S

, then the amplifier switches between

phases every 0.5

T

S

. Therefore, in the amplification phase:

V

t

V

t

T

NA

NA

S

[ ]

=

-

1

2

(4)

And substituting Equation 4 and Equation 2 into Equation 3 yields:

V

t

A V

t

A V

t

A B V

t

T

B

OA

A

IN

A OSA

A

A OSA

S

A

[ ]

=

[ ]

+

[ ]

-

-

+

1

2

1

(5)

For the sake of simplification, let us assume that the autocorrection

frequency is much faster than any potential change in V

OSA

or

V

OSB

. This is a good assumption since changes in offset voltage are

a function of temperature variation or long-term wear time, both of

which are much slower than the auto-zero clock frequency of the

AD855x. This effectively makes V

OS

time invariant and we can re-

arrange Equation 5 and rewrite it as:

V

t

A V

t

A

B

V

A B V

B

OA

A

IN

A

A

OSA

A

A OSA

A

[ ]

=

[ ]

+

+

(

)

-

+

1

1

(6)

or,

V

t

A

V

t

V

B

OA

A

IN

OSA

A

[ ]

=

[ ]

+

+

1

(7)

We can already get a feel for the autozeroing in action. Note the

V

OS

term is reduced by a 1 + B

A

factor. This shows how the

nulling amplifier has greatly reduced its own offset voltage error

even before correcting the primary amplifier. Now the primary

amplifier output voltage is the voltage at the output of the

AD855x amplifier. It is equal to:

V

t

A V

t

V

B V

OUT

B

IN

OSB

B

NB

[ ]

=

[ ]

+

(

)

+

(8)

In the amplification phase, V

OA

= V

NB

, so this can be rewritten as:

V

t

A V

t

A V

B

A

V

t

V

B

OUT

B

IN

B OSB

B

A

IN

OSA

A

[ ]

=

[ ]

+

+

[ ]

+

+

1

(9)

Combining terms,

V

t

V

t A

A B

A B V

B

A V

OUT

IN

B

A

B

A

B OSA

A

B OSB

[ ]

=

[ ]

+

(

)

+

+

+

1

(10)

The AD855x architecture is optimized in such a way that

A

A

= A

B

and B

A

= B

B

and B

A

>> 1. Also, the gain product of

A

A

B

B

is much greater than A

B

. These allow Equation 10 to be

simplified to:

V

t

V

t A B

A V

V

OUT

IN

A

A

A

OSA

OSB

[ ]

[ ]

+

+

(

)

(11)

Most obvious is the gain product of both the primary and nulling

amplifiers. This A

A

B

A

term is what gives the AD855x its extremely

high open-loop gain. To understand how V

OSA

and V

OSB

relate to

the overall effective input offset voltage of the complete amplifier,

we should set up the generic amplifier equation of:

V

k

V

V

OUT

IN

OS

EFF

= ◊

+

(

)

,

(12)

Where k is the open-loop gain of an amplifier and V

OS, EFF

is its

effective offset voltage. Putting Equation 12 into the form of

Equation 11 gives us:

V

t

V

t A B

V

A B

OUT

IN

A

A

OS

EFF

A

A

[ ]

[ ]

+

,

(13)

And from here, it is easy to see that:

V

V

V

B

OS

EFF

OSA

OSB

A

,

+

(14)

Thus, the offset voltages of both the primary and nulling ampli-

fiers are reduced by the gain factor B

A

. This takes a typical input

offset voltage from several millivolts down to an effective input

offset voltage of submicrovolts. This autocorrection scheme is

what makes the AD855x family of amplifiers among the most

precise amplifiers in the world.

High Gain, CMRR, PSRR

Common-mode and power supply rejection are indications of

the amount of offset voltage an amplifier has as a result of a

change in its input common-mode or power supply voltages. As

shown in the previous section, the autocorrection architecture of

the AD855x allows it to quite effectively minimize offset volt-

ages. The technique also corrects for offset errors caused by

common-mode voltage swings and power supply variations.

This results in superb CMRR and PSRR figures in excess of

130 dB. Because the autocorrection occurs continuously, these

figures can be maintained across the device's entire temperature

range, from ≠40

∞

C to +125

∞

C.

Maximizing Performance Through Proper Layout

To achieve the maximum performance of the extremely high

input impedance and low offset voltage of the AD855x, care

should be taken in the circuit board layout. The PC board sur-

face must remain clean and free of moisture to avoid leakage

currents between adjacent traces. Surface coating of the circuit

board will reduce surface moisture and provide a humidity

barrier, reducing parasitic resistance on the board. The use of

guard rings around the amplifier inputs will further reduce leak-

age currents. Figure 46 shows how the guard ring should be

configured and Figure 47 shows the top view of how a surface

mount layout can be arranged. The guard ring does not need to

AD8551/AD8552/AD8554

≠12≠

REV. 0

be a specific width, but it should form a continuous loop around

both inputs. By setting the guard ring voltage equal to the volt-

age at the noninverting input, parasitic capacitance is minimized

as well. For further reduction of leakage currents, components

can be mounted to the PC board using Teflon standoff insulators.

V

OUT

V

IN

AD8552

V

OUT

V

IN

AD8552

V

OUT

V

IN

AD8552

Figure 46. Guard Ring Layout and Connections to Reduce

PC Board Leakage Currents

V

V+

V

REF

V

IN1

V

IN2

GUARD

RING

R

2

R

2

R

1

R

1

AD8552

V

REF

GUARD

RING

Figure 47. Top View of AD8552 SOIC Layout with

Guard Rings

Other potential sources of offset error are thermoelectric voltages

on the circuit board. This voltage, also called Seebeck voltage,

occurs at the junction of two dissimilar metals and is proportional

to the temperature of the junction. The most common metallic

junctions on a circuit board are solder-to-board trace and solder-

to-component lead. Figure 48 shows a cross-section diagram view

of the thermal voltage error sources. If the temperature of the PC

board at one end of the component (T

A1

) is different from the

temperature at the other end (T

A2

), the Seebeck voltages will not

be equal, resulting in a thermal voltage error.

This thermocouple error can be reduced by using dummy com-

ponents to match the thermoelectric error source. Placing the

dummy component as close as possible to its partner will ensure

both Seebeck voltages are equal, thus canceling the thermo-

couple error. Maintaining a constant ambient temperature on

the circuit board will further reduce this error. The use of a

ground plane will help distribute heat throughout the board and

will also reduce EMI noise pickup.

SURFACE MOUNT

COMPONENT

COMPONENT

LEAD

SOLDER

PC BOARD

COPPER

TRACE

V

SC2

+

+

V

TS2

T

A2

T

A1

V

SC1

+

+

V

TS1

IF T

A1

fi

T

A2

, THEN

V

TS1

+ V

SC1

fi

V

TS2

+ V

SC2

Figure 48. Mismatch in Seebeck Voltages Causes a

Thermoelectric Voltage Error

V

OUT

V

IN

AD855x

A

V

= 1 + (R

F

/R

1

)

R

1

R

F

R

S

= R

1

NOTE: R

S

SHOULD BE PLACED IN CLOSE PROXIMITY AND

ALIGNMENT TO R

1

TO BALANCE SEEBECK VOLTAGES

Figure 49. Using Dummy Components to Cancel

Thermoelectric Voltage Errors

1/f Noise Characteristics

Another advantage of autozero amplifiers is their ability to cancel

flicker noise. Flicker noise, also known as 1/f noise, is noise inher-

ent in the physics of semiconductor devices and increases 3 dB

for every octave decrease in frequency. The 1/f corner frequency

of an amplifier is the frequency at which the flicker noise is equal

to the broadband noise of the amplifier. At lower frequencies,

flicker noise dominates, causing higher degrees of error for sub-

Hertz frequencies or dc precision applications.

Because the AD855x amplifiers are self-correcting op amps,

they do not have increasing flicker noise at lower frequencies.

In essence, low frequency noise is treated as a slowly varying

offset error and is greatly reduced as a result of autocorrection.

The correction becomes more effective as the noise frequency

approaches dc, offsetting the tendency of the noise to increase

exponentially as frequency decreases. This allows the AD855x

to have lower noise near dc than standard low-noise amplifiers

that are susceptible to 1/f noise.

Intermodulation Distortion

The AD855x can be used as a conventional op amp for gain/

bandwidth combinations up to 1.5 MHz. The autozero correc-

tion frequency of the device is fixed at 4 kHz. Although a trace

amount of this frequency will feed through to the output, the

amplifier can be used at much higher frequencies. Figure 50

shows the spectral output of the AD8552 with the amplifier

configured for unity gain and the input grounded.

The 4 kHz autozero clock frequency appears at the output with

less than 2

µ

V of amplitude. Harmonics are also present, but at

reduced levels from the fundamental autozero clock frequency.

The amplitude of the clock frequency feedthrough is proportional

to the closed-loop gain of the amplifier. Like other autocorrection

amplifiers, at higher gains there will be more clock frequency

feedthrough. Figure 51 shows the spectral output with the ampli-

fier configured for a gain of 60 dB.

AD8551/AD8552/AD8554

≠13≠

REV. 0

FREQUENCY ≠ kHz

0

140

0

10

1

OUTPUT SIGNAL

2

3

4

5

6

7

8

9

20

40

60

80

100

120

V

SY

= +5V

A

V

= 0dB

Figure 50. Spectral Analysis of AD855x Output in Unity

Gain Configuration

FREQUENCY ≠ kHz

0

140

0

10

1

OUTPUT SIGNAL

2

3

4

5

6

7

8

9

20

40

60

80

100

120

V

SY

= +5V

A

V

= +60dB

Figure 51. Spectral Analysis of AD855x Output with

+60 dB Gain

When an input signal is applied, the output will contain some

degree of Intermodulation Distortion (IMD). This is another

characteristic feature of all autocorrection amplifiers. IMD will

show up as sum and difference frequencies between the input sig-

nal and the 4 kHz clock frequency (and its harmonics) and is at a

level similar to or less than the clock feedthrough at the output.

The IMD is also proportional to the closed loop gain of the ampli-

fier. Figure 52 shows the spectral output of an AD8552 configured

as a high gain stage (+60 dB) with a 1 mV input signal applied.

The relative levels of all IMD products and harmonic distortion

add up to produce an output error of ≠60 dB relative to the input

signal. At unity gain, these would add up to only ≠120 dB relative

to the input signal.

FREQUENCY ≠ kHz

0

0

10

1

OUTPUT SIGNAL

2

3

4

5

6

7

8

9

20

40

60

80

100

120

OUTPUT SIGNAL

1Vrms @ 200Hz

IMD < 100 Vrms

V

SY

= +5V

A

V

= +60dB

Figure 52. Spectral Analysis of AD855x in High Gain with

a 1 mV Input Signal

For most low frequency applications, the small amount of auto-

zero clock frequency feedthrough will not affect the precision of the

measurement system. Should it be desired, the clock frequency

feedthrough can be reduced through the use of a feedback capaci-

tor around the amplifier. However, this will reduce the bandwidth

of the amplifier. Figures 53a and 53b show a configuration for

reducing the clock feedthrough and the corresponding spectral

analysis at the output. The ≠3 dB bandwidth of this configuration

is 480 Hz.

V

IN

= 1mV rms

@ 200Hz

100

100k

3.3nF

Figure 53a. Reducing Autocorrection Clock Noise with a

Feedback Capacitor

FREQUENCY ≠ kHz

0

0

10

1

OUTPUT SIGNAL

2

3

4

5

6

7

8

9

20

40

60

80

100

120

V

SY

= +5V

A

V

= +60dB

Figure 53b. Spectral Analysis Using a Feedback Capacitor

AD8551/AD8552/AD8554

≠14≠

REV. 0

Broadband and External Resistor Noise Considerations

The total broadband noise output from any amplifier is primarily

a function of three types of noise: Input voltage noise from the

amplifier, input current noise from the amplifier and Johnson

noise from the external resistors used around the amplifier. Input

voltage noise, or e

n

, is strictly a function of the amplifier used.

The Johnson noise from a resistor is a function of the resistance

and the temperature. Input current noise, or i

n

, creates an equiva-

lent voltage noise proportional to the resistors used around the

amplifier. These noise sources are not correlated with each other

and their combined noise sums in a root-squared-sum fashion.

The full equation is given as:

e

e

kTr

i r

n TOTAL

n

S

n S

,

=

+

+

( )

2

2

1

2

4

(15)

Where, e

n

= The input voltage noise of the amplifier,

i

n

= The input current noise of the amplifier,

r

S

= Source resistance connected to the noninverting

terminal,

k = Boltzmann's constant (1.38 10

-23

J/K)

T = Ambient temperature in Kelvin (K = 273.15 +

∞

C)

The input voltage noise density, e

n

of the AD855x is 42 nV/

Hz,

and the input noise, i

n,

is 2 fA/

Hz. The e

n, TOTAL

will be domi-

nated by input voltage noise provided the source resistance is less

than 106 k

. With source resistance greater than 106 k

, the

overall noise of the system will be dominated by the Johnson

noise of the resistor itself.

Because the input current noise of the AD855x is very small, i

n

does not become a dominant term unless r

S

is greater than 4 G

,

which is an impractical value of source resistance.

The total noise, e

n, TOTAL

, is expressed in volts per square-root

Hertz, and the equivalent rms noise over a certain bandwidth

can be found as:

e

e

BW

n

n TOTAL

=

◊

,

(16)

Where BW is the bandwidth of interest in Hertz.

For a complete treatise on circuit noise analysis, please refer to the

1995 Linear Design Seminar book available from Analog Devices.

Output Overdrive Recovery

The AD855x amplifiers have an excellent overdrive recovery of

only 200

µ

s from either supply rail. This characteristic is particu-

larly difficult for autocorrection amplifiers, as the nulling amplifier

requires a nontrivial amount of time to error correct the main am-

plifier back to a valid output. Figure 23 and Figure 24 show the

positive and negative overdrive recovery time for the AD855x.

The output overdrive recovery for an autocorrection amplifier is

defined as the time it takes for the output to correct to its final

voltage from an overload state. It is measured by placing the

amplifier in a high gain configuration with an input signal that

forces the output voltage to the supply rail. The input voltage is

then stepped down to the linear region of the amplifier, usually

to half-way between the supplies. The time from the input signal

step-down to the output settling to within 100

µ

V of its final

value is the overdrive recovery time. Most competitors' auto-

correction amplifiers require a number of autozero clock cycles

to recover from output overdrive and some can take several

milliseconds for the output to settle properly.

Input Overvoltage Protection

Although the AD855x is a rail-to-rail input amplifier, care should

be taken to ensure that the potential difference between the in-

puts does not exceed +5 V. Under normal operating conditions,

the amplifier will correct its output to ensure the two inputs are at

the same voltage. However, if the device is configured as a com-

parator, or is under some unusual operating condition, the input

voltages may be forced to different potentials. This could cause

excessive current to flow through internal diodes in the AD855x

used to protect the input stage against overvoltage.

If either input exceeds either supply rail by more than 0.3 V, large

amounts of current will begin to flow through the ESD protection

diodes in the amplifier. These diodes are connected between the

inputs and each supply rail to protect the input transistors against

an electrostatic discharge event and are normally reverse-biased.

However, if the input voltage exceeds the supply voltage, these

ESD diodes will become forward-biased. Without current limit-

ing, excessive amounts of current could flow through these diodes

causing permanent damage to the device. If inputs are subject to

overvoltage, appropriate series resistors should be inserted to

limit the diode current to less than 2 mA maximum.

Output Phase Reversal

Output phase reversal occurs in some amplifiers when the input

common-mode voltage range is exceeded. As common-mode volt-

age is moved outside of the common-mode range, the outputs of

these amplifiers will suddenly jump in the opposite direction to the

supply rail. This is the result of the differential input pair shutting

down, causing a radical shifting of internal voltages which results in

the erratic output behavior.

The AD855x amplifier has been carefully designed to prevent

any output phase reversal, provided both inputs are maintained

within the supply voltages. If one or both inputs could exceed

either supply voltage, a resistor should be placed in series with

the input to limit the current to less than 2 mA. This will ensure

the output will not reverse its phase.

Capacitive Load Drive

The AD855x has excellent capacitive load driving capabilities

and can safely drive up to 10 nF from a single +5 V supply.

Although the device is stable, capacitive loading will limit the

bandwidth of the amplifier. Capacitive loads will also increase

the amount of overshoot and ringing at the output. An R-C

snubber network, Figure 54, can be used to compensate the

amplifier against capacitive load ringing and overshoot.

+5V

R

X

60

V

OUT

V

IN

200mV p-p

AD855x

C

L

4.7nF

C

X

0.47 F

Figure 54. Snubber Network Configuration for Driving

Capacitive Loads

Although the snubber will not recover the loss of amplifier band-

width from the load capacitance, it will allow the amplifier to drive

larger values of capacitance while maintaining a minimum of

overshoot and ringing. Figure 55 shows the output of an AD855x

driving a 1 nF capacitor with and without a snubber network.

AD8551/AD8552/AD8554

≠15≠

REV. 0

10 s

100mV

WITH

SNUBBER

WITHOUT

SNUBBER

V

SY

= +5V

C

LOAD

= 4.7nF

Figure 55. Overshoot and Ringing are Substantially

Reduced Using a Snubber Network

The optimum value for the resistor and capacitor is a function of

the load capacitance and is best determined empirically since

actual C

LOAD

will include stray capacitances and may differ sub-

stantially from the nominal capacitive load. Table I shows some

snubber network values that can be used as starting points.

Table I. Snubber Network Values for Driving Capacitive Loads

C

LOAD

R

X

C

X

1 nF

200

1 nF

4.7 nF

60

0.47

µ

F

10 nF

20

10

µ

F

Power-Up Behavior

On power-up, the AD855x will settle to a valid output within 5

µ

s.

Figure 56a shows an oscilloscope photo of the output of the ampli-

fier along with the power supply voltage, and Figure 56b shows

the test circuit. With the amplifier configured for unity gain, the

device takes approximately 5

µ

s to settle to its final output voltage.

This turn-on response time is much faster than most other auto-

correction amplifiers, which can take hundreds of microseconds or

longer for their output to settle.

5 s

1V

V

OUT

V+

0V

0V

BOTTOM TRACE = 2V/DIV

TOP TRACE = 1V/DIV

Figure 56a. AD855x Output Behavior on Power-Up

V

SY

= 0V TO +5V

100k

AD855x

100k

V

OUT

Figure 56b. AD855x Test Circuit for Turn-On Time

APPLICATIONS

A +5 V Precision Strain-Gage Circuit

The extremely low offset voltage of the AD8552 makes it an

ideal amplifier for any application requiring accuracy with high

gains, such as a weigh scale or strain-gage. Figure 57 shows a

configuration for a single supply, precision strain-gage measure-

ment system.

A REF192 provides a +2.5 V precision reference voltage for A2.

The A2 amplifier boosts this voltage to provide a +4.0 V reference

for the top of the strain-gage resistor bridge. Q1 provides the cur-

rent drive for the 350

bridge network. A1 is used to amplify the

output of the bridge with the full-scale output voltage equal to:

2

1

2

◊

+

(

)

R

R

R

B

(17)

Where R

B

is the resistance of the load cell. Using the values given

in Figure 57, the output voltage will linearly vary from 0 V with

no strain to +4.0 V under full strain.

V

OUT

350

LOAD

CELL

AD8552-A

R

1

17.4k

R

2

100

0V TO +4.0V

NOTE: USE 0.1% TOLERANCE RESISTORS.

20k

A1

A2

AD8552-B

REF192

12.0k

1k

+5V

+2.5V

6

4

3

2

+4.0V

40mV

FULL-SCALE

Q1

2N2222

OR

EQUIVALENT

R

3

17.4k

R

4

100

Figure 57. A +5 V Precision Strain-Gage Amplifier

+3 V Instrumentation Amplifier

The high common-mode rejection, high open-loop gain, and

operation down to +3 V of supply voltage makes the AD855x

an excellent choice of op amp for discrete single supply instru-

mentation amplifiers. The common-mode rejection ratio of

the AD855x is greater than 120 dB, but the CMRR of the sys-

tem is also a function of the external resistor tolerances. The

gain of the difference amplifier shown in Figure 58 is given as:

V

V

R

R

R

R

R

V

R

R

OUT

=

+

+

-

1

1

2

4

3

4

1

2

2

1

(18)

AD8551/AD8552/AD8554

≠16≠

REV. 0

V2

V1

V

OUT

R

1

R

3

R

4

R

2

AD855x

IF

R

3

R

4

=

R

1

R

2

, THEN V

OUT

=

R

1

R

2

(V1 V2)

Figure 58. Using the AD855x as a Difference Amplifier

In an ideal difference amplifier, the ratio of the resistors are set

exactly equal to:

A

R

R

R

R

V

=

=

2

1

4

3

(19)

Which sets the output voltage of the system to:

V

A V

V

OUT

V

=

-

(

)

1

2

(20)

Due to finite component tolerance the ratio between the four

resistors will not be exactly equal, and any mismatch results in a

reduction of common-mode rejection from the system. Referring

to Figure 58, the exact common-mode rejection ratio can be ex-

pressed as:

CMRR

R R

R R

R R

R R

R R

=

+

+

-

1

4

2

4

2

3

1

4

2

3

2

2

2

(21)

In the 3 op amp instrumentation amplifier configuration shown

in Figure 59, the output difference amplifier is set to unity gain

with all four resistors equal in value. If the tolerance of the resis-

tors used in the circuit is given as

, the worst-case CMRR of

the instrumentation amplifier will be:

CMRR

MIN

=

1

2

(22)

V

OUT

R

R

R

R

AD8554-C

V2

R

R

V1

R

G

AD8554-B

AD8554-A

V

OUT

= 1 +

2R

R

G

(V1 V2)

R

TRIM

Figure 59. A Discrete Instrumentation Amplifier

Configuration

Thus, using 1% tolerance resistors would result in a worst-case

system CMRR of 0.02, or 34 dB. Therefore either high precision

resistors or an additional trimming resistor, as shown in Figure

59, should be used to achieve high common-mode rejection. The

value of this trimming resistor should be equal to the value of R

multiplied by its tolerance. For example, using 10 k

resistors

with 1% tolerance would require a series trimming resistor equal to

100

.

A High Accuracy Thermocouple Amplifier

Figure 60 shows a K-type thermocouple amplifier configuration

with cold-junction compensation. Even from a +5 V supply, the

AD8551 can provide enough accuracy to achieve a resolution

of better than 0.02

∞

C from 0

∞

C to 500

∞

C. D1 is used as a

temperature measuring device to correct the cold-junction error

from the thermocouple and should be placed as close as possible

to the two terminating junctions. With the thermocouple mea-

suring tip immersed in a zero-degree ice bath, R

6

should be

adjusted until the output is at 0 V.

Using the values shown in Figure 60, the output voltage will

track temperature at 10 mV/

∞

C. For a wider range of tempera-

ture measurement, R

9

can be decreased to 62 k

. This will

create a 5 mV/

∞

C change at the output, allowing measurements

of up to 1000

∞

C.

AD8551

3

2

8

4

0V TO 5.00V

(0 C TO 500 C)

+5V

0.1 F

+

10 F

R

9

124k

R

8

453

R

5

40.2k

R

1

10.7k

R

2

2.74k

REF02EZ

0.1 F

+12V

2

6

4

+

+

≠

≠

D1

1N4148

R

3

53.6

R

4

5.62k

+5.000V

K-TYPE

THERMOCOUPLE

40.7 V/ C

R

6

200

1

Figure 60. A Precision K-Type Thermocouple Amplifier

with Cold-Junction Compensation

Precision Current Meter

Because of its low input bias current and superb offset voltage at

single supply voltages, the AD855x is an excellent amplifier for

precision current monitoring. Its rail-to-rail input allows the

amplifier to be used as either a high-side or low-side current

monitor. Using both amplifiers in the AD8552 provides a simple

method to monitor both current supply and return paths for

load or fault detection.

Figure 61 shows a high-side current monitor configuration. Here,

the input common-mode voltage of the amplifier will be at or near

the positive supply voltage. The amplifier's rail-to-rail input provides

a precise measurement even with the input common-mode voltage at

the supply voltage. The CMOS input structure does not draw any

input bias current, ensuring a minimum of measurement error.

The 0.1

resistor creates a voltage drop to the noninverting

input of the AD855x. The amplifier's output is corrected until

this voltage appears at the inverting input. This creates a current

through R

1

, which in turn flows through R

2

. The Monitor Output

is given by:

Monitor Output

R

R

R

I

SENSE

L

=

◊

◊

2

1

(23)

Using the components shown in Figure 61, the Monitor Output

transfer function is 2.5 V/A.

AD8551/AD8552/AD8554

≠17≠

REV. 0

Figure 62 shows the low-side monitor equivalent. In this circuit,

the input common-mode voltage to the AD8552 will be at or near

ground. Again, a 0.1

resistor provides a voltage drop propor-

tional to the return current. The output voltage is given as:

V

V

R

R

R

I

OUT

SENSE

L

= + -

◊

◊

2

1

(24)

For the component values shown in Figure 62, the output trans-

fer function decreases from V+ at ≠2.5 V/A.

8

1

4

3

+3V

0.1 F

R

SENSE

0.1

V+

I

L

G

S

D

2

M1

Si9433

MONITOR

OUTPUT

+3V

R

2

2.49k

R

1

100

1/2

AD8552

Figure 61. A High-Side Load Current Monitor

V+

RETURN TO

GROUND

1/2 AD8552

V+

R

2

2.49k

V

OUT

R

1

100

0.1

R

SENSE

Q1

Figure 62. A Low-Side Load Current Monitor

Precision Voltage Comparator

The AD855x can be operated open-loop and used as a precision

comparator. The AD855x has less than 50

µ

V of offset voltage

when run in this configuration. The slight increase of offset

voltage stems from the fact that the autocorrection architecture

operates with lowest offset in a closed loop configuration, that

is, one with negative feedback. With 50 mV of overdrive, the de-

vice has a propagation delay of 15

µ

s on the rising edge and

8

µ

s on the falling edge.

Care should be taken to ensure the maximum differential volt-

age of the device is not exceeded. For more information, please

refer to the section on Input Overvoltage Protection.

SPICE Model

The SPICE macro-model for the AD855x amplifier is given in

Listing 1. This model simulates the typical specifications for the

AD855x, and it can be downloaded from the Analog Devices

website at http://www.analog.com. The schematic of the

macro-model is shown in Figure 63.

Transistors M1 through M4 simulate the rail-to-rail input differ-

ential pairs in the AD855x amplifier. The EOS voltage source in

series with the noninverting input establishes not only the 1

µ

V

offset voltage, but is also used to establish common-mode and

power supply rejection ratios and input voltage noise. The dif-

ferential voltages from nodes 14 to 16 and nodes 17 to 18 are

reflected to E1, which is used to simulate a secondary pole-zero

combination in the open-loop gain of the amplifier.

The voltage at node 32 is then reflected to G1, which adds an

additional gain stage and, in conjunction with CF, establishes

the slew rate of the model at 0.5 V/

µ

s. M5 and M6 are in a

common-source configuration, similar to the output stage of the

AD855x amplifier. EG1 and EG2 fix the quiescent current in

these two transistors at 100

µ

A, and also help accurately simu-

late the V

OUT

vs. I

OUT

characteristic of the amplifier.

The network around ECM1 creates the common-mode voltage

error, with CCM1 setting the corner frequency for the CMRR

roll-off. The power supply rejection error is created by the

network around EPS1, with CPS3 establishing the corner fre-

quency for the PSRR roll-off. The two current loops around

nodes 80 and 81 are used to create a 42 nV/

Hz noise figure

across RN2. All three of these error sources are reflected to the

input of the op amp model through EOS. Finally, GSY is used

to accurately model the supply current versus supply voltage in-

crease in the AD855x.

This macro-model has been designed to accurately simulate a

number of specifications exhibited by the AD855x amplifier,

and is one of the most true-to-life macro-models available for

any op amp. It is optimized for operation at +27

∞

C. Although

the model will function at different temperatures, it may lose

accuracy with respect to the actual behavior of the AD855x.

AD8551/AD8552/AD8554

≠18≠

REV. 0

17

18

99

11

12

C2

R

C7

R

C8

R

C3

R

C4

D2

I2

V1

10

50

99

+

8

9

EOS

I1

D1

V1

2

R

C2

R

C1

C1

R

C6

R

C5

50

16

M2

M1

1

14

7

M3

M4

13

31

C2

R

2

32

R

3

+

E1

+

EREF

0

98

21

CCM1

R

CM1

22

R

CM2

ECM1

98

+

81

80

+

HN

R

N2

R

N1

VN1

98

72

CPS3

R

PS3

73

R

PS4

EPS1

98

+

99

50

GSY

M5

99

EG1

CF

+

D3

97

D4

+

EVP

EVN

98

51

M6

R

1

98

G1

+

EG2

50

47

30

45

98

+

46

99

CPS1

70

R

PS1

0

R

PS2

CPS2

50

71

Figure 63. Schematic of the AD855x SPICE Macro-Model

AD8551/AD8552/AD8554

≠19≠

REV. 0

SPICE macro-model for the AD855x

* AD8552 SPICE Macro-model

* Typical Values

* 7/99, Ver. 1.0

* TAM / ADSC

*

* Copyright 1999 by Analog Devices

*

* Refer to "README.DOC" file for License

* Statement. Use of this model indicates

* your acceptance of the terms and

* provisions in the License Statement.

*

* Node Assignments

*

noninverting input

*

|

inverting input

*

|

|

positive supply

*

|

|

|

negative supply

*

|

|

|

|

output

*

|

|

|

|

|

*

|

|

|

|

|

.SUBCKT AD8552

1

2

99 50 45

*

* INPUT STAGE

*

M1 4 7 8 8 PIX L=1E-6 W=355.3E-6

M2 6 2 8 8 PIX L=1E-6 W=355.3E-6

M3 11 7 10 10 NIX L=1E-6 W=355.3E-6

M4 12 2 10 10 NIX L=1E-6 W=355.3E-6

RC1 4 14 9E+3

RC2 6 16 9E+3

RC3 17 11 9E+3

RC4 18 12 9E+3

RC5 14 50 1E+3

RC6 16 50 1E+3

RC7 99 17 1E+3

RC8 99 18 1E+3

C1 14 16 30E-12

C2 17 18 30E-12

I1 99 8 100E-6

I2 10 50 100E-6

V1 99 9 0.3

V2 13 50 0.3

D1 8 9 DX

D2 13 10 DX

EOS 7 1 POLY(3) (22,98) (73,98) (81,98)

+ 1E-6 1 1 1

IOS 1 2 2.5E-12

*

* CMRR 120dB, ZERO AT 20Hz

*

ECM1 21 98 POLY(2) (1,98) (2,98) 0 .5 .5

RCM1 21 22 50E+6

CCM1 21 22 159E-12

RCM2 22 98 50

*

* PSRR=120dB, ZERO AT 1Hz

*

RPS1 70 0 1E+6

RPS2 71 0 1E+6

CPS1 99 70 1E-5

CPS2 50 71 1E-5

EPSY 98 72 POLY(2) (70,0) (0,71) 0 1 1

RPS3 72 73 15.9E+6

CPS3 72 73 10E-9

RPS4 73 98 16

* VOLTAGE NOISE REFERENCE OF 42nV/rt(Hz)

*

VN1 80 98 0

RN1 80 98 16.45E-3

HN 81 98 VN1 42

RN2 81 98 1

*

* INTERNAL VOLTAGE REFERENCE

*

EREF 98 0 POLY(2) (99,0) (50,0) 0 .5 .5

GSY 99 50 (99,50) 48E-6

EVP 97 98 (99,50) 0.5

EVN 51 98 (50,99) 0.5

*

* LHP ZERO AT 7MHz, POLE AT 50MHz

*

E1 32 98 POLY(2) (4,6) (11,12) 0 .5814 .5814

R2 32 33 3.7E+3

R3 33 98 22.74E+3

C3 32 33 1E-12

*

* GAIN STAGE

*

G1 98 30 (33,98) 22.7E-6

R1 30 98 259.1E+6

CF 45 30 45.4E-12

D3 30 97 DX

D4 51 30 DX

*

* OUTPUT STAGE

*

M5 45 46 99 99 POX L=1E-6 W=1.111E-3

M6 45 47 50 50 NOX L=1E-6 W=1.6E-3

EG1 99 46 POLY(1) (98,30) 1.1936 1

EG2 47 50 POLY(1) (30,98) 1.2324 1

*

* MODELS

*

.MODEL POX PMOS (LEVEL=2,KP=10E-6,

+ VTO=-1,LAMBDA=0.001,RD=8)