| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ADXL202J | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

Low Cost 2

g/ 10 g Dual Axis

i

MEM

S

Æ

Accelerometers

with Digital Output

ADXL202/ADXL210

FEATURES

2-Axis Acceleration Sensor on a Single IC Chip

Measures Static Acceleration as Well as Dynamic

Acceleration

Duty Cycle Output with User Adjustable Period

Low Power <0.6 mA

Faster Response than Electrolytic, Mercury or Thermal

Tilt Sensors

Bandwidth Adjustment with a Single Capacitor Per Axis

5 m

g Resolution at 60 Hz Bandwidth

+3 V to +5.25 V Single Supply Operation

1000

g Shock Survival

APPLICATIONS

2-Axis Tilt Sensing

Computer Peripherals

Inertial Navigation

Seismic Monitoring

Vehicle Security Systems

Battery Powered Motion Sensing

A

IN

2 =

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1999

FUNCTIONAL BLOCK DIAGRAM

DEMOD

R

FILT

32k

R

FILT

32k

OSCILLATOR

X SENSOR

Y SENSOR

ADXL202/

ADXL210

X OUT

Y OUT

SELF TEST

X

FILT

V

DD

V

DD

C

X

+3.0V TO +5.25V

C

DC

COM

Y

FILT

T2

C

Y

R

SET

C

O

U

N

T

E

R

P

T2

T1

A(

g) = (T1/T2 ≠ 0.5)/12.5%

0

g = 50% DUTY CYCLE

T2 = R

SET

/125M

DEMOD

DUTY

CYCLE

MODULATOR

(DCM)

GENERAL DESCRIPTION

The ADXL202/ADXL210 are low cost, low power, complete

2-axis accelerometers with a measurement range of either

±

2 g/

±

10 g. The ADXL202/ADXL210 can measure both dy-

namic acceleration (e.g., vibration) and static acceleration (e.g.,

gravity).

The outputs are digital signals whose duty cycles (ratio of pulse-

width to period) are proportional to the acceleration in each of

the 2 sensitive axes. These outputs may be measured directly

with a microprocessor counter, requiring no A/D converter or

glue logic. The output period is adjustable from 0.5 ms to 10 ms

via a single resistor (R

SET

). If a voltage output is desired, a

voltage output proportional to acceleration is available from the

X

FILT

and Y

FILT

pins, or may be reconstructed by filtering the

duty cycle outputs.

The bandwidth of the ADXL202/ADXL210 may be set from

0.01 Hz to 5 kHz via capacitors C

X

and C

Y

. The typical noise

floor is 500

µ

g/

Hz allowing signals below 5 mg to be resolved

for bandwidths below 60 Hz.

The ADXL202/ADXL210 is available in a hermetic 14-lead

Surface Mount CERPAK, specified over the 0

∞

C to +70

∞

C

commercial or ≠40

∞

C to +85

∞

C industrial temperature range.

i

MEM

S

is a registered trademark of Analog Devices, Inc.

ADXL202/ADXL210≠SPECIFICATIONS

ADXL202/JQC/AQC

ADXL210/JQC/AQC

Parameter

Conditions

Min

Typ

Max

Min

Typ

Max

Units

SENSOR INPUT

Each Axis

Measurement Range

1

±

1.5

±

2

±

8

±

10

g

Nonlinearity

Best Fit Straight Line

0.2

0.2

% of FS

Alignment Error

2

±

1

±

1

Degrees

Alignment Error

X Sensor to Y Sensor

±

0.01

±

0.01

Degrees

Transverse Sensitivity

3

±

2

±

2

%

SENSITIVITY

Each Axis

Duty Cycle per g

T1/T2 @ +25

∞

C

10

12.5

15

3.2

4.0

4.8

%/g

Sensitivity, Analog Output

At Pins X

FILT

, Y

FILT

312

100

mV/g

Temperature Drift

4

from +25

∞

C

±

0.5

±

0.5

% Rdg

ZERO g BIAS LEVEL

Each Axis

0 g Duty Cycle

T1/T2

25

50

75

42

50

58

%

Initial Offset

±

2

±

2

g

0 g Duty Cycle vs. Supply

1.0

4.0

1.0

4.0

%/V

0 g Offset vs. Temperature

4

from +25

∞

C

2.0

2.0

mg/

∞

C

NOISE PERFORMANCE

Noise Density

5

@ +25

∞

C

500

1000

500

1000

µ

g/

Hz

FREQUENCY RESPONSE

3 dB Bandwidth

Duty Cycle Output

500

500

Hz

3 dB Bandwidth

At Pins X

FILT

, Y

FILT

5

5

kHz

Sensor Resonant Frequency

10

14

kHz

FILTER

R

FILT

Tolerance

32 k

Nominal

±

15

±

15

%

Minimum Capacitance

At X

FILT

, Y

FILT

1000

1000

pF

SELF TEST

Duty Cycle Change

Self-Test "0" to "1"

10

10

%

DUTY CYCLE OUTPUT STAGE

F

SET

125 M

/R

SET

125 M

/R

SET

F

SET

Tolerance

R

SET

= 125 k

0.7

1.3

0.7

1.3

kHz

Output High Voltage

I = 25

µ

A

V

S

≠ 200 mV

V

S

≠ 200 mV

mV

Output Low Voltage

I = 25

µ

A

200

200

mV

T2 Drift vs. Temperature

35

35

ppm/

∞

C

Rise/Fall Time

200

200

ns

POWER SUPPLY

Operating Voltage Range

3.0

5.25

2.7

5.25

V

Specified Performance

4.75

5.25

4.75

5.25

V

Quiescent Supply Current

0.6

1.0

0.6

1.0

mA

Turn-On Time

6

To 99%

160 C

FILT

+ 0.3

160 C

FILT

+ 0.3

ms

TEMPERATURE RANGE

Operating Range

JQC

0

+70

0

+70

∞

C

Specified Performance

AQC

≠40

+85

≠40

+85

∞

C

NOTES

1

For all combinations of offset and sensitivity variation.

2

Alignment error is specified as the angle between the true and indicated axis of sensitivity.

3

Transverse sensitivity is the algebraic sum of the alignment and the inherent sensitivity errors.

4

Specification refers to the maximum change in parameter from its initial at +25

∞

C to its worst case value at T

MIN

to T

MAX

.

5

Noise density (

µ

g/

Hz) is the average noise at any frequency in the bandwidth of the part.

6

C

FILT

in

µ

F. Addition of filter capacitor will increase turn on time. Please see the Application section on power cycling.

All min and max specifications are guaranteed. Typical specifications are not tested or guaranteed.

Specifications subject to change without notice.

(T

A

= T

MIN

to T

MAX

, T

A

= +25 C for J Grade only, V

DD

= +5 V,

R

SET

= 125 k , Acceleration = 0

g, unless otherwise noted)

REV. B

≠2≠

ADXL202/ADXL210

≠3≠

REV. B

PIN FUNCTION DESCRIPTIONS

Pin

Name

Description

1

NC

No Connect

2

V

TP

Test Point, Do Not Connect

3

ST

Self Test

4

COM

Common

5

T2

Connect R

SET

to Set T2 Period

6

NC

No Connect

7

COM

Common

8

NC

No Connect

9

Y

OUT

Y Axis Duty Cycle Output

10

X

OUT

X Axis Duty Cycle Output

11

Y

FILT

Connect Capacitor for Y Filter

12

X

FILT

Connect Capacitor for X Filter

13

V

DD

+3 V to +5.25 V, Connect to 14

14

V

DD

+3 V to +5.25 V, Connect to 13

PACKAGE CHARACTERISTICS

Package

JA

JC

Device Weight

14-Lead CERPAK

110

∞

C/W

30

∞

C/W

5 Grams

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . . 1000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . . . 500 g

+V

S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≠0.3 V to +7.0 V

Output Short Circuit Duration

(Any Pin to Common) . . . . . . . . . . . . . . . . . . . . . . Indefinite

Operating Temperature . . . . . . . . . . . . . . . . . ≠55

∞

C to +125

∞

C

Storage Temperature . . . . . . . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL202/ADXL210 features proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

Drops onto hard surfaces can cause shocks of greater than 1000 g

and exceed the absolute maximum rating of the device. Care

should be exercised in handling to avoid damage.

PIN CONFIGURATION

14

13

12

11

10

9

8

1

2

3

4

7

6

5

TOP VIEW

(Not to Scale)

A

Y

A

X

NC = NO CONNECT

NC

Y

FILT

X

FILT

V

DD

V

DD

V

TP

ST

COM

NC

Y

OUT

X

OUT

T2

NC

COM

ADXL202/

ADXL210

Figure 1 shows the response of the ADXL202 to the Earth's

gravitational field. The output values shown are nominal. They

are presented to show the user what type of response to expect

from each of the output pins due to changes in orientation with

respect to the Earth. The ADXL210 reacts similarly with out-

put changes appropriate to its scale.

TYPICAL OUTPUT AT PIN:

9 = 50% DUTY CYCLE

10 = 62.5% DUTY CYCLE

11 = 2.5V

12 = 2.188V

TYPICAL OUTPUT AT PIN:

9 = 62.5% DUTY CYCLE

10 = 50% DUTY CYCLE

11 = 2.188V

12 = 2.5V

TYPICAL OUTPUT AT PIN:

9 = 37.5% DUTY CYCLE

10 = 50% DUTY CYCLE

11 = 2.812V

12 = 2.5V

TYPICAL OUTPUT AT PIN:

9 = 50% DUTY CYCLE

10 = 37.5% DUTY CYCLE

11 = 2.5V

12 = 2.812V

EARTH'S SURFACE

1

g

Figure 1. ADXL202/ADXL210 Nominal Response Due to

Gravity

WARNING!

ESD SENSITIVE DEVICE

ORDERING GUIDE

g

Temperature

Package

Package

Model

Range

Range

Description

Option

ADXL202JQC

±

2

0

∞

C to +70

∞

C

14-Lead CERPAK

QC-14

ADXL202AQC

±

2

≠40

∞

C to +85

∞

C

14-Lead CERPAK

QC-14

ADXL210JQC

±

10

0

∞

C to +70

∞

C

14-Lead CERPAK

QC-14

ADXL210AQC

±

10

≠40

∞

C to +85

∞

C

14-Lead CERPAK

QC-14

ADXL202/ADXL210

REV. B

≠4≠

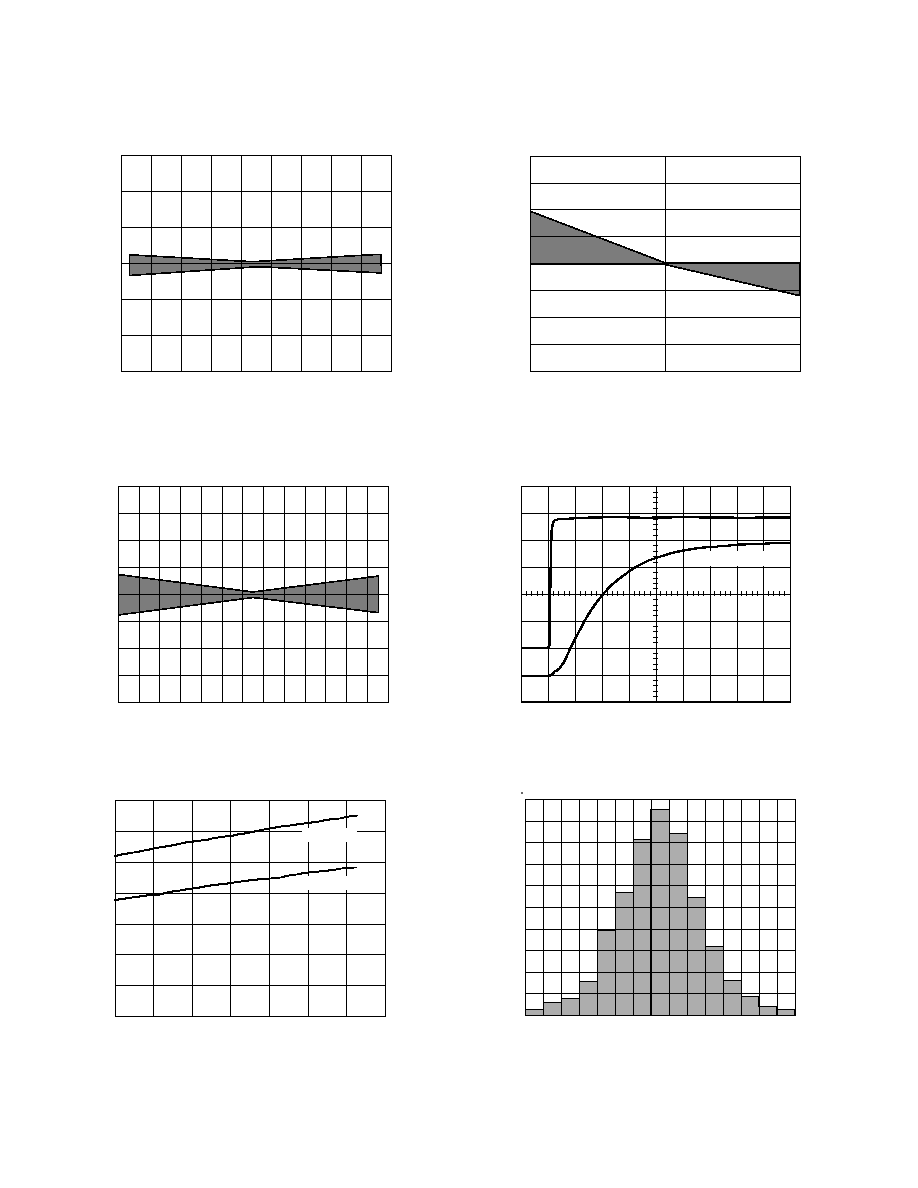

TEMPERATURE ≠ C

1.06

0.94

≠45

90

≠30

PERIOD NORMALIZED TO 1 AT 25

C

≠15

0

15

30

45

60

75

1.04

1.02

1.00

0.98

0.96

Figure 2. Normalized DCM Period (T2) vs. Temperature

TEMPERATURE ≠ C

0.8

≠0.2

≠0.8

≠40

90

≠30

ZERO

g

OFFSET SHIFT IN

g

≠20 ≠10

0

10

20

30

40

50

60

70

80

0.6

0

≠0.4

≠0.6

0.4

0.2

Figure 3. Typical Zero g Offset vs. Temperature

TEMPERATURE ≠ C

0.7

0

≠40

100

≠20

SUPPLY CURRENT ≠ mA

0

20

40

60

80

0.6

0.4

0.3

0.2

0.1

0.5

V

S

= 5 VDC

V

S

= 3.5 VDC

Figure 4. Typical Supply Current vs. Temperature

(@ +25 C R

SET

= 125 k

, V

DD

= +5 V, unless otherwise noted)

TYPICAL CHARACTERISTICS

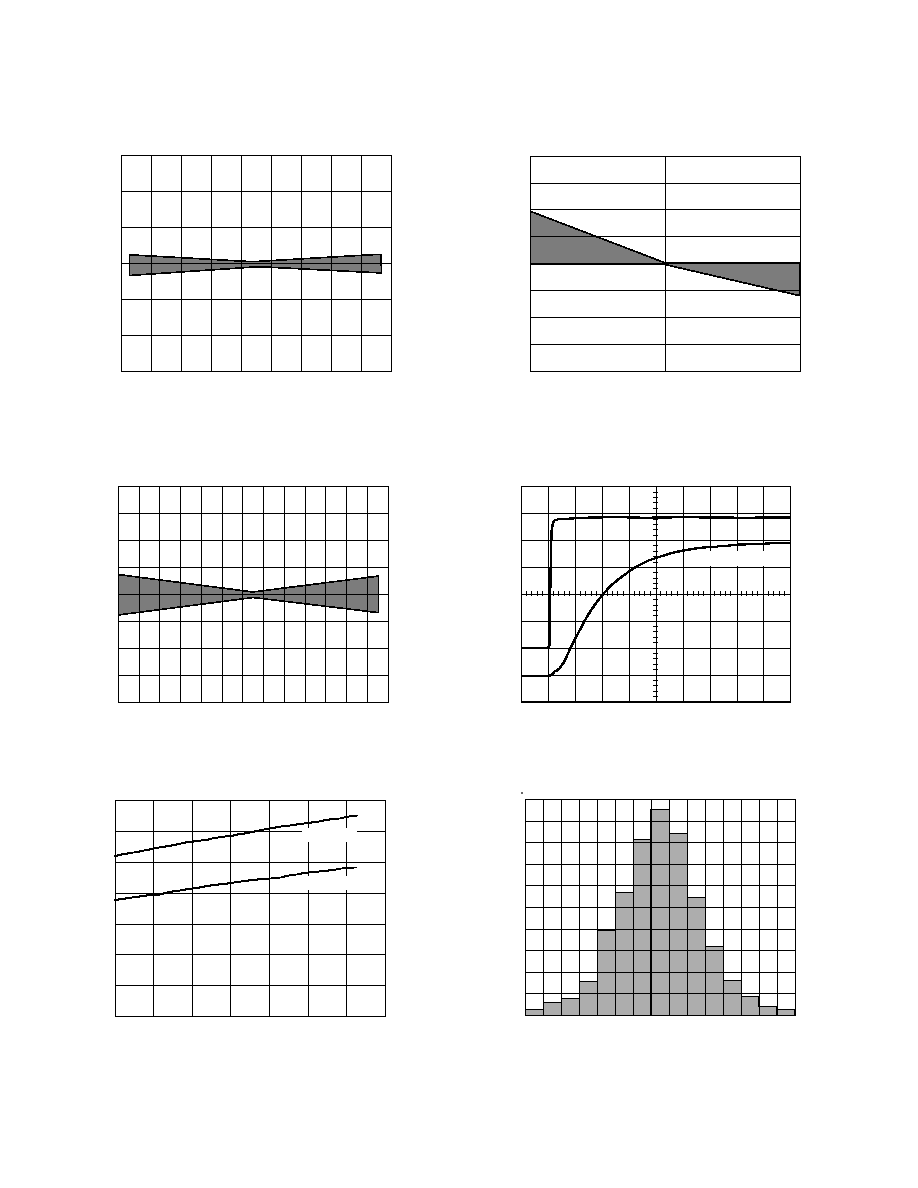

TEMPERATURE ≠ C

4%

3%

≠4%

≠40

85

25

0%

≠1%

≠2%

≠3%

2%

1%

CHANGE IN SENSITIVITY

Figure 5. Typical X Axis Sensitivity Drift Due to

Temperature

0

0.4

0.8

1.2

1.4

FREQUENCY ≠ ms

3

2

1

0

VOLTS

C

FILT

= 0.01 F

Figure 6. Typical Turn-On Time

g/DUTY CYCLE OUTPUT

20

6

0

≠0.87g

PERCENTAGE OF SAMPLES

≠0.64g

≠0.41g ≠0.17g

0.06g

0.29g

0.52g

0.75g

18

8

4

2

14

10

16

12

Figure 7. Typical Zero g Distribution at +25

∞

C

ADXL202/ADXL210

≠5≠

REV. B

DUTY CYCLE OUTPUT ≠ % per

g

11.3

11.5 11.7 11.9 12.2 12.4 12.6 12.8 13.1 13.3 13.5 13.7

9

8

0

PERCENTAGE OF SAMPLES

4

3

2

1

6

5

7

Figure 8. Typical Sensitivity per g at +25

∞

C

C

X

, C

Y

BANDWIDTH

14

12

0

0.01 F

500Hz

0.47 F

10Hz

0.047 F

100Hz

TOTAL RMS NOISE ≠ m

g

0.1 F

50Hz

8

6

4

2

10

Figure 9. Typical Noise at X

FILT

Output

NUMBER OF AVERAGE SAMPLES

14

12

0

1

64

4

TOTAL RMS NOISE ≠ m

g

16

8

6

4

2

10

C

FILT

= 0.047 F

BW = 100Hz

C

FILT

= 0.1 F

BW = 50Hz

C

FILT

= 0.47 F

BW = 10Hz

C

FILT

= 0.01 F

BW = 500Hz

T2 = 1ms

Figure 10. Typical Noise at Digital Outputs

DEGREES OF MISALIGNMENT

20

6

0

≠1.375

0.375

% OF PARTS

≠1.125

≠0.875

≠0.625

≠0.375

≠0.0125

18

8

4

2

16

12

14

10

0.625

0.875

1.125

1.375

0.0125

Figure 11. Rotational Die Alignment