| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: OP176 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700

Fax: 617/326-8703

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

Bipolar/JFET,

Audio Operational Amplifier

OP176*

FEATURES

Low Noise: 6 nV/

Hz

High Slew Rate: 25 V/

µ

s

Wide Bandwidth: 10 MHz

Low Supply Current: 2.5 mA

Low Offset Voltage: 1 mV

Unity Gain Stable

SO-8 Package

APPLICATIONS

Line Driver

Active Filters

Fast Amplifiers

Integrators

PIN CONNECTIONS

8-Lead Narrow-Body SO

8-Lead Epoxy DIP

(S Suffix)

(P Suffix)

NULL

≠IN

+IN

V≠

NC

V+

OUT

NULL

1

2

3

4

5

6

7

8

OP176

1

2

3

4

5

6

7

8

NULL

≠IN

+IN

V≠

OP-482

NC

V+

OUT

NULL

OP176

GENERAL DESCRIPTION

The OP176 is a low noise, high output drive op amp that

features the Butler Amplifier front-end. This new front-end

design combines both bipolar and JFET transistors to attain

amplifiers with the accuracy and low noise performance of

bipolar transistors, and the speed and sound quality of JFETs.

Total Harmonic Distortion plus Noise equals previous audio

amplifiers, but at much lower supply currents.

Improved dc performance is also provided with bias and offset

currents greatly reduced over purely bipolar designs. Input

offset voltage is guaranteed at 1 mV and is typically less than

200

µ

V. This allows the OP176 to be used in many dc coupled

or summing applications without the need for special selections

or the added noise of additional offset adjustment circuitry.

The output is capable of driving 600

loads to 10 V rms while

maintaining low distortion. THD + Noise at 3 V rms is a low

0.0006%.

The OP176 is specified over the extended industrial (≠40

∞

C to

+85

∞

C) temperature range. OP176s are available in both plastic

DIP and SO-8 packages. SO-8 packages are available in 2500

piece reels. Many audio amplifiers are not offered in SO-8

surface mount packages for a variety of reasons, however, the

OP176 was designed so that it would offer full performance in

surface mount packaging.

*Protected by U.S. Patent No. 5101126.

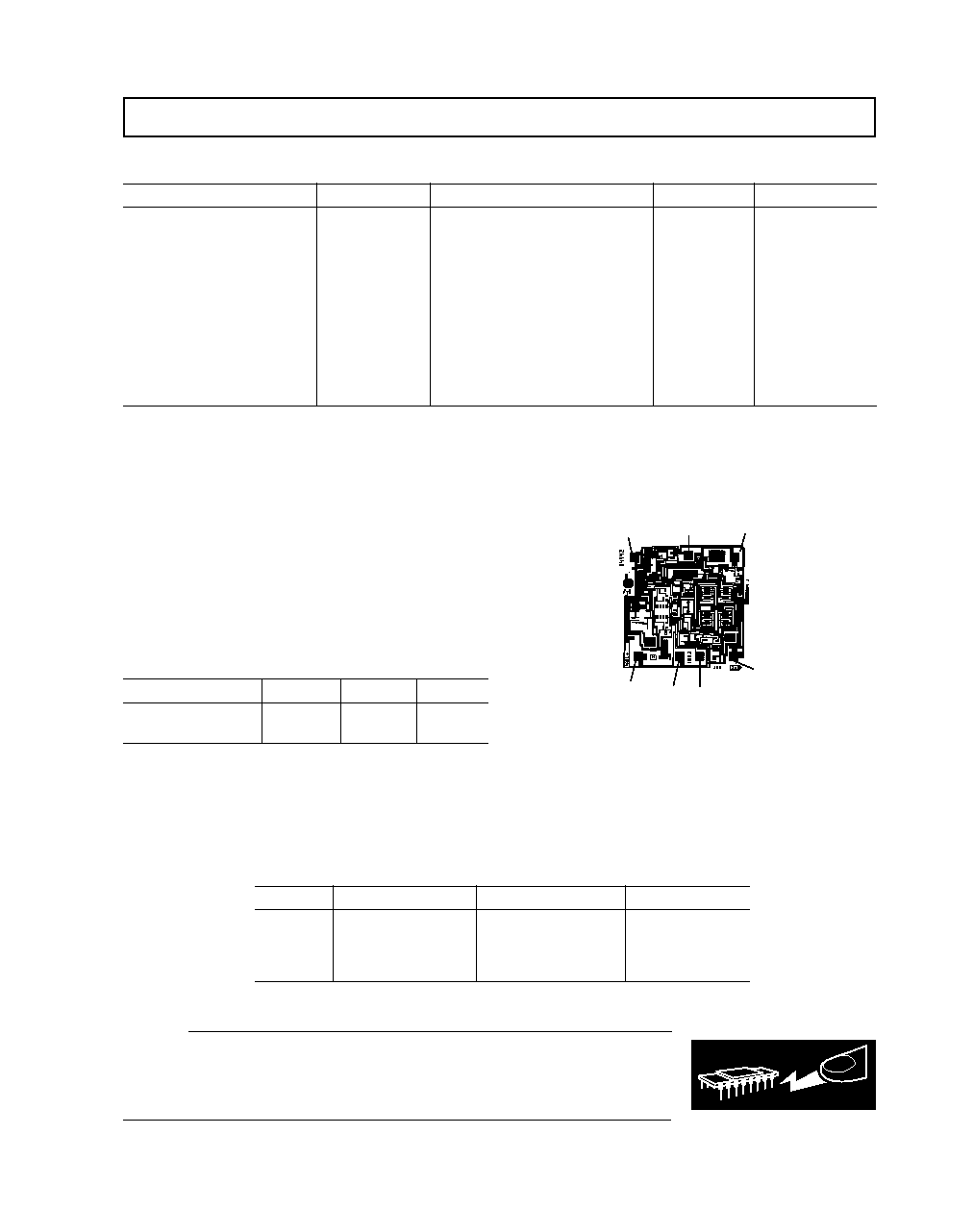

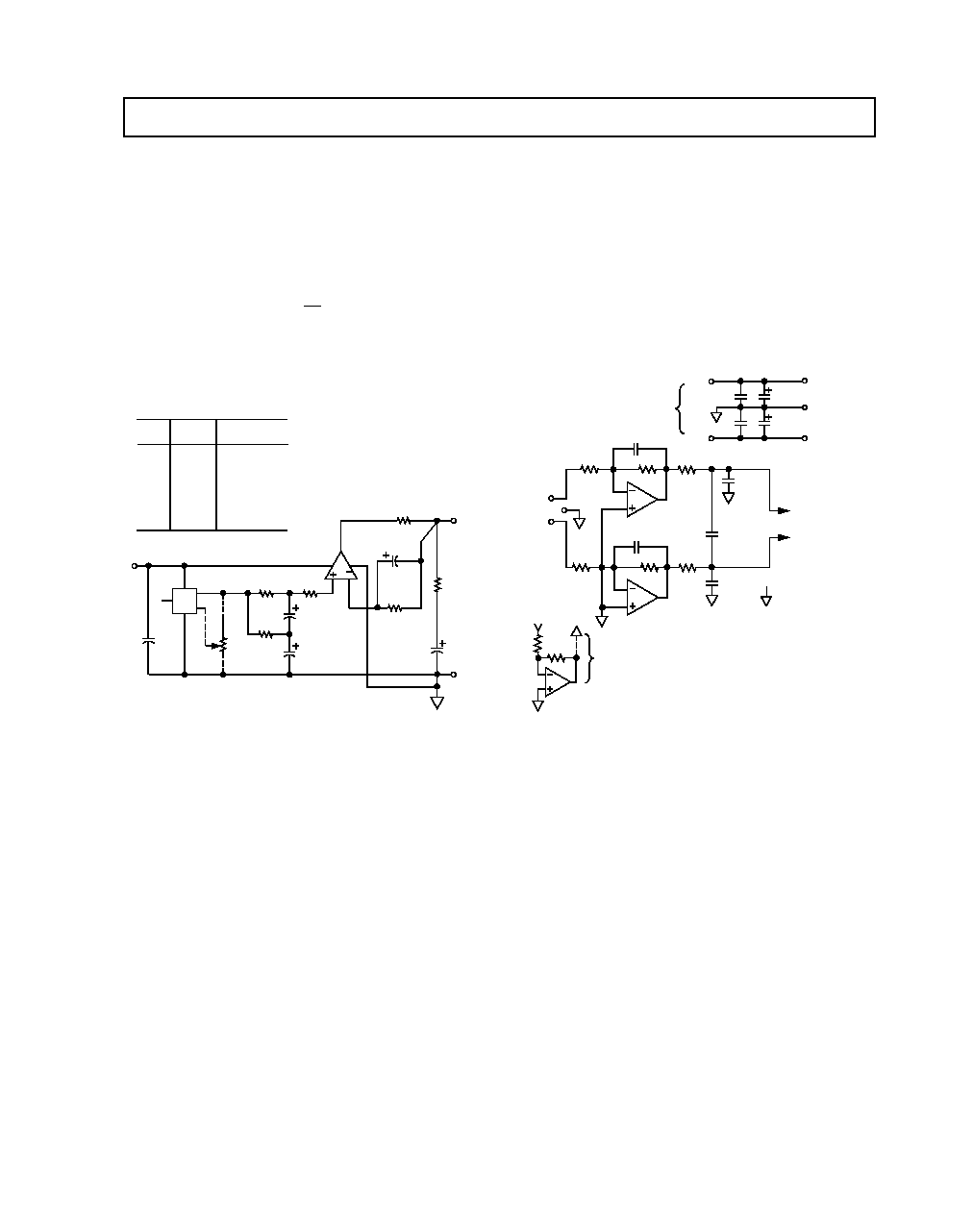

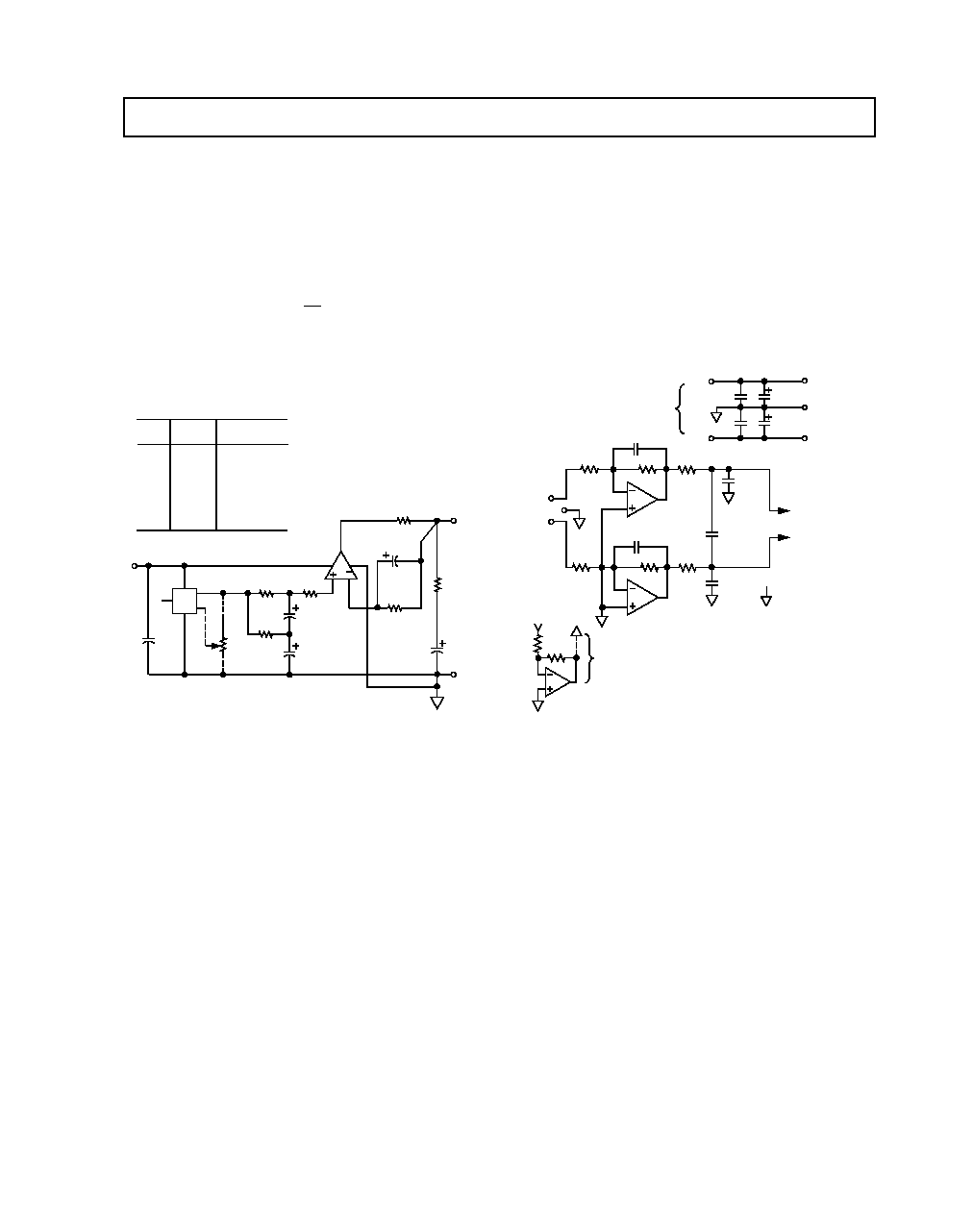

Simplified Schematic

RB4

RB3

QB5

RB5

QB6

RB7

RB6

QB7

J1

R4

Q9

Q10

J2

Q2

Q1

Z2

Q6

Q5

CCB

CF

QS1

RS1

R5

6

RS2

QS2

R3

Q3

Q4

QS3

QB9

Q8

Q11

Q7

CC2

4

QB8

R2L

R2P1

R2A

R2P2

R2S

5

R1P2

1

R1P1

R1L

R1A

R1S

QB3

Z1

QB1

JB1

QB4

CB1

QB2

RB1

RB2

CC1

3

2

7

ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Conditions

Min

Typ

Max

Units

INPUT CHARACTERISTICS

Offset Voltage

V

OS

1

mV

Offset Voltage

V

OS

≠40

∞

C

T

A

+85

∞

C

1.25

mV

Input Bias Current

I

B

V

CM

= 0 V

350

nA

V

CM

= 0 V, ≠40

∞

C

T

A

+85

∞

C

400

nA

Input Offset Current

I

OS

V

CM

= 0 V

±

50

nA

V

CM

= 0 V, ≠40

∞

C

T

A

+85

∞

C

±

100

nA

Input Voltage Range

V

CM

≠10.5

+10.5

V

Common-Mode Rejection

CMRR

V

CM

=

±

10.5 V,

≠40

∞

C

T

A

+85

∞

C

80

106

dB

Large Signal Voltage Gain

A

VO

R

L

= 2 k

250

V/mV

R

L

= 2 k

, ≠40

∞

C

T

A

+85

∞

C

175

V/mV

R

L

= 600

200

V/mV

Offset Voltage Drift

V

OS

/

T

5

µ

V/

∞

C

OUTPUT CHARACTERISTICS

Output Voltage Swing

V

O

R

L

= 2 k

, ≠40

∞

C

T

A

+85

∞

C

≠13.5

+13.5

V

R

L

= 600

, V

S

=

±

18 V

≠14.8

+14.8

V

Output Short Circuit Current

I

SC

±

25

±

50

mA

POWER SUPPLY

Power Supply Rejection Ratio

PSRR

V

S

=

±

4.5 V to

±

18 V

86

108

dB

≠40

∞

C

T

A

+85

∞

C

80

dB

Supply Current

I

SY

V

S

=

±

4.5 V to

±

18 V, V

O

= 0 V,

R

L

=

, ≠40

∞

C

T

A

+85

∞

C

2.5

mA

Supply Current

I

SY

V

S

=

±

22 V, V

O

= 0 V, R

L

=

,

≠40

∞

C

T

A

+85

∞

C

2.75

mA

Supply Voltage Range

V

S

±

4.5

±

22

V

DYNAMIC PERFORMANCE

Slew Rate

SR

R

L

= 2 k

15

25

V/

µ

s

Gain Bandwidth Product

GBP

10

MHz

AUDIO PERFORMANCE

THD + Noise

V

IN

= 3 V rms,

R

L

= 2 k

, f = 1 kHz

0.001

%

Voltage Noise Density

e

n

f = 1 kHz

6

nV/

Hz

Current Noise Density

i

n

f = 1 kHz

0.5

pA/

Hz

Specifications subject to change without notice.

REV. 0

≠2≠

OP176≠SPECIFICATIONS

(@ V

S

=

±

15.0 V, T

A

= +25

∞

C unless otherwise noted)

OP176

REV. 0

≠3≠

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

22 V

Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±

18 V

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . .

±

7.5 V

Output Short-Circuit Duration to GND . . . . . . . . . . Indefinite

Storage Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

Operating Temperature Range

OP176G . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≠40

∞

C to +85

∞

C

Junction Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . ≠65

∞

C to +150

∞

C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300

∞

C

Package Type

JA

3

JC

Units

8-Pin Plastic DIP (P)

103

43

∞

C/W

8-Pin SOIC (S)

158

43

∞

C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

For input voltages greater than

±

7.5 V limit input current to less than 5 mA.

3

JA

is specified for the worst case conditions, i.e.,

JA

is specified for device in socket

for P-DIP packages;

JA

is specified for device soldered in circuit board for SOIC

package.

(@ V

S

=

±

15.0 V, T

A

= +25

∞

C unless otherwise noted)

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP176 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

Parameter

Symbol

Conditions

Limit

Units

Offset Voltage

V

OS

1

mV max

Input Bias Current

I

B

V

CM

= 0 V

350

nA max

Input Offset Current

I

OS

V

CM

= 0 V

±

50

nA max

Input Voltage Range

1

V

CM

±

10.5

V min

Common-Mode Rejection

CMRR

V

CM

=

±

10.5 V

80

dB min

Power Supply Rejection Ratio

PSRR

V =

±

4.5 V to

±

18 V

86

dB min

Large Signal Voltage Gain

A

VO

R

L

= 2 k

250

V/mV min

Output Voltage Range

V

O

R

L

= 2 k

13.5

V min

V

S

=

±

18.0 V, R

L

= 600

14.8

V min

Supply Current

I

SY

V

S

=

±

22.0 V, V

O

= 0 V, R

L

=

2.75

mA max

V

S

=

±

4.5 V to

±

18 V,

2.5

mA max

V

O

= 0 V, R

L

=

NOTES

Electrical tests and wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed for standard

product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

1

Guaranteed by CMR test.

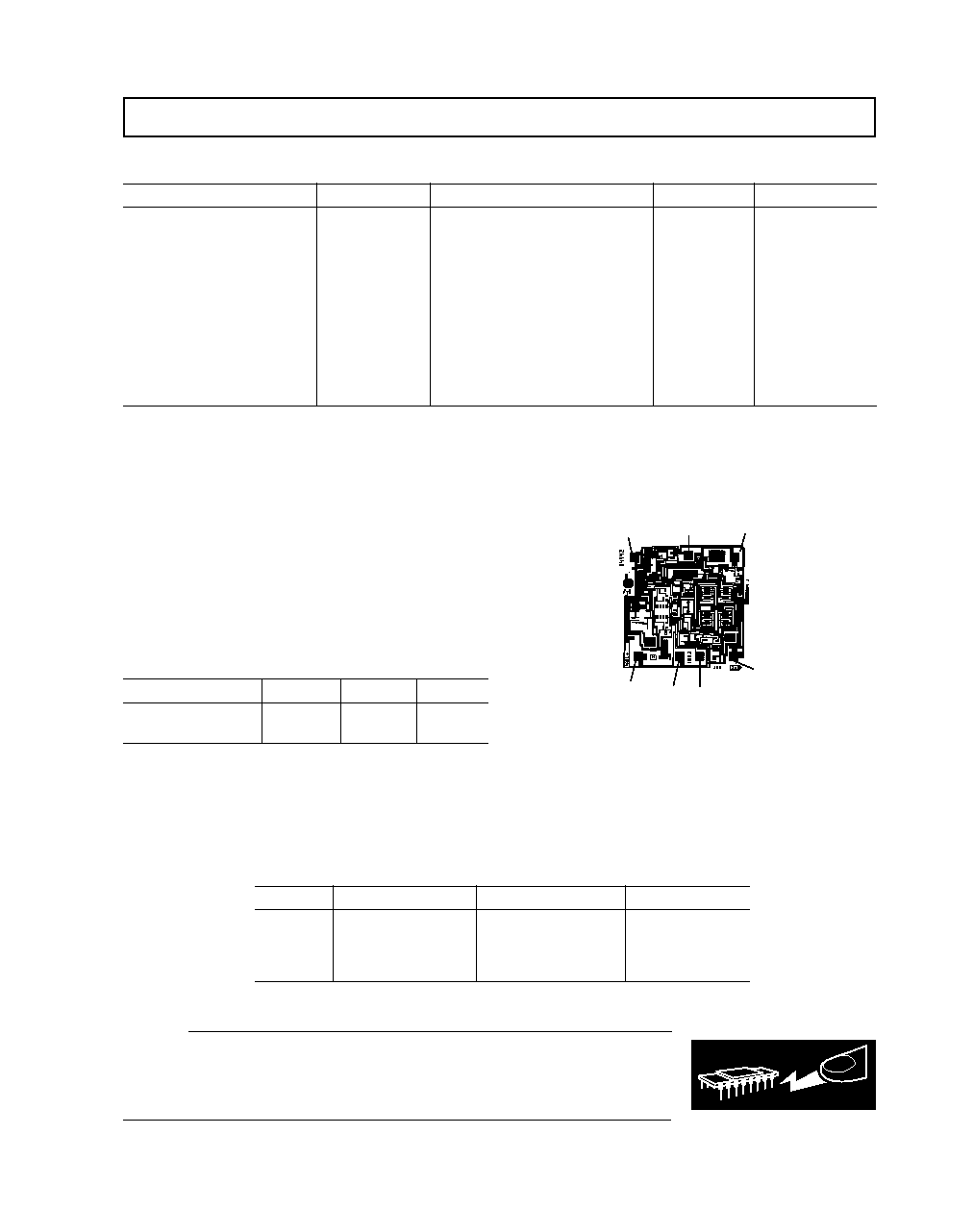

OP176 Die Size 0.069

◊

0.067 Inch, 4,623 Sq. Mils.

Substrate (Die Backside) Is Connected to V≠.

Transistor Count, 26.

WAFER TEST LIMITS

NULL

V

+

OUT

NULL

≠IN

+IN

V

≠

DICE CHARACTERISTICS

ORDERING GUIDE

Model

Temperature Range

Package Description

Package Option

OP176GP

≠40

∞

C to +85

∞

C

8-Pin Plastic DIP

N-8

OP176GS

≠40

∞

C to +85

∞

C

8-Pin SOIC

SO-8

OP176GSR

≠40

∞

C to +85

∞

C

SO-8 Reel, 2500 Pieces

OP176GBC

+25

∞

C

DICE

Figure 3. Input Bias Current vs. Temperature

Figure 6. Supply Current per Amplifier vs. Supply Voltage

OP176≠Typical Characteristics

REV. 0

≠4≠

Figure 1. Input Offset Voltage Drift Distribution @

±

15 V

Figure 4. Maximum Output Swing vs. Frequency

Figure 2. Output Swing vs. Temperature

Figure 5. Maximum Output Swing vs. Load Resistance

120

0

8

60

20

1

40

0

100

80

7

5

4

3

6

2

µ

t

C

V

OS

≠

µ

V/∞C

±

V

S

=

±

15V

≠40∞C

T

A

+85∞C

BASED ON 300 OP AMPS

16

8

0

10

100

10k

1k

4

12

14

10

6

2

LOAD RESISTANCE ≠

OUTPUT SWING ≠ Volts

POSITIVE SWING

NEGATIVE SWING

V

S

= ±15V

T

A

= +25∞C

2.50

1.50

0

±

25

±

2.25

1.75

±

5

±

2.00

±

15

±

±

20

±

±

10

±

SUPPLY VOLTAGE ≠ V

SUPPLY CURRENT ≠ mA

T

A

= +85∞C

T

A

= +25∞C

T

A

= ≠40∞C

16

12

100

13

≠25

≠50

14

15

75

50

25

0

TEMPERATURE ≠ ∞C

ABSOLUTE OUTPUT VOLTAGE ≠ V

V

S

=

±

18V, +V

OM

, R

L

= 600

V

S

=

±

15V, +V

OM

, R

L

= 600

V

S

=

±

15V, +V

OM

, R

L

= 2k

V

S

=

±

18V,

≠V

OM

, R

L

= 600

V

S

=

±

15V,

≠V

OM

, R

L

= 2k

V

S

=

±

15V,

≠V

OM

, R

L

= 600

30

15

0

10k

10M

1M

100k

1k

10

5

20

25

±

V

S

=

±

15V

T

A

= +25∞C

FREQUENCY ≠ Hz

MAXIMUM OUTPUT SWING ≠ Volts

R

L

= 2k

300

0

100

150

50

≠25

100

≠50

250

200

75

50

25

0

TEMPERATURE ≠ ∞C

INPUT BIAS CURRENT ≠ nA

±

V

S

=

±

15V

V

CM

= 0V

OP176

REV. 0

≠5≠

Figure 10. Power Supply Rejection vs. Frequency

Figure 7. Short Circuit Current vs. Temperature @

±

15 V

Figure 8. Open-Loop Gain & Phase vs. Frequency

Figure 11. Open-Loop Gain vs. Temperature

Figure 12. Closed-Loop Output Impedance vs. Frequency

Figure 9. Closed-Loop Gain vs. Frequency

120

60

0

1k

1M

100k

10k

100

40

20

80

100

FREQUENCY ≠ Hz

POWER SUPPLY REJECTION ≠ dB

±

V

S

=

±

15V

T

A

= +25∞C

+PSRR

≠PSRR

FREQUENCY ≠ Hz

GAIN ≠ dB

120

100

≠60

1k

10k

100M

10M

1M

100k

80

60

40

20

0

≠20

≠40

GAIN

PHASE

PHASE MARGIN = 60∞

90

135

180

225 PHASE ≠ Degrees

T

A

= +25∞C

V

S

= ±15V

R

L

= >600

50

10

≠30

1k

10k

100M

10M

1M

100k

20

30

40

≠20

≠10

0

FREQUENCY ≠ Hz

GAIN ≠ dB

T

A

= +25∞C

V

S

= ±15V

2000

0

100

500

250

≠25

≠50

1000

750

1250

1500

1750

75

50

25

0

TEMPERATURE ≠ ∞C

OPEN-LOOP GAIN ≠ V/mV

±

V

S

=

±

15V

±

V

O

=

±

10V

≠GAIN, R

L

= 2k

+GAIN, R

L

= 600

≠GAIN, R

L

= 600

+GAIN, R

L

= 2k

40

20

0

1k

1M

100k

10k

100

10

30

FREQUENCY ≠ Hz

IMPEDANCE ≠

A

V

= +100

A

V

= +10

A

V

= +1

T

A

= +25∞C

V

S

= ±15V

80

0

100

20

10

≠25

≠50

40

30

50

60

70

75

50

25

0

TEMPERATURE ≠ ∞C

ABSOLUTE OUTPUT CURRENT ≠ mA

SINK

SOURCE

±

V

S

=

±

15V

OP176

REV. 0

≠6≠

Figure 16. Gain Bandwidth Product & Phase Margin vs.

Temperature

Figure 13. Common-Mode Rejection vs. Frequency

Figure 14. Small Signal Overshoot vs. Load Capacitance

Figure 17. Slew Rate vs. Load Capacitance

Figure 18. Slew Rate vs. Temperature

Figure 15. Slew Rate vs. Differential Input Voltage

65

45

≠75

125

60

50

≠50

55

75

100

50

25

0

≠25

±

V

S

=

±

15V

14

6

12

8

10

TEMPERATURE ≠ ∞C

PHASE MARGIN ≠ Degrees

GAIN BANDWIDTH PRODUCT ≠ MHz

PHASE

GAIN

50

0

2000

30

10

200

20

0

40

1800

1600

1400

1200

1000

800

600

400

LOAD CAPACITANCE ≠ pF

SLEW RATE ≠ V/µ

s

NEGATIVE SLEW RATE

POSITIVE SLEW RATE

V

S

= ±15V

R

L

= 2k

SWING = ±10V

SLEW WINDOW = ±5V

T

A

= +25∞C

140

100

0

1k

1M

100k

10k

100

120

60

80

20

40

FRERQUENCY ≠ Hz

COMMON-MODE REJECTION ≠ dB

T

A

= +25∞C

V

S

= ±15V

100

0

1000

30

10

100

20

0

60

40

50

70

80

90

900

800

700

600

500

400

300

200

±

V

S

=

±

15V

LOAD CAPACITANCE ≠ pF

OVERSHOOT ≠ %

NEGATIVE SWING

POSITIVE SWING

R

L

= 2k

V

IN

= 100mVp-p

AV

CL

= 1

40

0

100

10

5

≠25

≠50

20

15

25

30

35

75

50

25

0

±

V

S

=

±

15V

R

L

= 2k

SLEW RATE ≠ V/µs

TEMPERATURE ≠ ∞C

SR≠

SR+

35

0

2.0

15

5

0.4

10

0

30

20

25

1.6

1.2

0.8

SLEW RATE ≠ V/µ

s

DIFFERENTIAL INPUT VOLTAGE ≠ V

SR+ AND SR≠

V

S

= ±15V

R

L

= 2k

T

A

= +25∞C

OP176

REV. 0

≠7≠

Figure 22. Large Signal Transient Response

25

20

0

10

100

10k

1k

15

10

5

±

V

S

=

±

15V

T

A

= +25∞C

FREQUENCY ≠ Hz

VOLTAGE NOISE ≠ nV/ Hz

Figure 21. Current Noise Density vs. Frequency

Figure 19. Voltage Noise Density vs. Frequency

10k

2.5

2.0

0

10

100

1k

1.5

1.0

0.5

FREQUENCY ≠ Hz

CURRENT NOISE ≠ pA/ Hz

V

S

= ±15V

T

A

= +25∞C

Figure 20. Small Signal Transient Response

TIME ≠ 500ns/DIV

V

OUT

(5V/DIV)

10

90

100

0%

5V

500nS

V

OUT

(50mV/DIV)

TIME ≠100ns/DIV

10

90

100

0%

50mV

100nS

OP176

REV. 0

≠8≠

APPLICATIONS

Short Circuit Protection

The OP176 has been designed with output short circuit

protection. The typical output drive current is

±

50 mA. This

high output current and wide output swing combine to yield an

excellent audio amplifier, even when driving large signals, at low

power and in a small package.

Total Harmonic Distortion

Total Harmonic Distortion + Noise (THD + N) of the OP176

is well below 0.001% with any load down to 600

. However,

this is dependent upon the peak output swing. In Figure 23 it is

seen that the THD + Noise with 3 V rms output is below

0.001%. In the following Figure 24, THD + Noise is below

0.001% for the 10 k

and 2 k

loads but increases to above

0.01% for the 600

load condition. This is a result of the

output swing capability of the OP176. Notice the results in

Figure 25, showing THD vs. V

IN

(V rms).

FIGURE 23. THD + Noise vs. Frequency

0.1

0.010

0.001

0.0001

20

100

1k

10k

20k

±

V

S

=

±

18V

V

O

= 10Vrms

600

2k

10k

Figure 24. THD + Noise vs. R

LOAD

Figure 25. THD + Noise vs. Output Amplitude (V rms)

The output of the OP176 is designed to maintain low harmonic

distortion while driving 600

loads. However, driving 600

loads with very high output swings results in higher distortion if

clipping occurs.

To attain low harmonic distortion with large output swings,

supply voltages may be increased. Figure 26 shows the perfor-

mance of the OP176 driving 600

loads with supply voltages

varying from

±

18 volts to

±

20 volts. Notice that with

±

18 volt

supplies the distortion is fairly high, while with

±

20 volt supplies

it is a very low 0.0007%.

0.1

0.010

0.001

0.0001

20

100

1k

10k

20k

R

L

= 600

V

O

=

±

18V

V

O

=

±

20V

V

O

=

±

19V

V

O

=

±

22V

Figure 26. THD + Noise vs. Supply Voltage

±

V

S

=

±

15V

V

O

= 3Vrms

0.1

0.010

0.001

.0001

20

100

1k

10k

20k

600

0.1

0.010

0.001

.0001

20

100

1k

10k

20k

±

V

S

=

±

18V

R

L

= 600

10Vrms

5Vrms

3Vrms

1Vrms

OP176

REV. 0

≠9≠

Noise

The voltage noise density of the OP176 is below 6 nV/

Hz

from

30 Hz. This enables low noise designs to have good perfor-

mance throughout the full audio range. Figure 27 shows a

typical OP176 with a 1/f corner at 6 Hz.

Figure 27. 1/f Noise Corner

Noise Testing

For audio applications the noise density is usually the most

important noise parameter. For characterization the OP176 is

tested using an Audio Precision, System One. The input signal

to the Audio Precision must be amplified enough to measure

accurately. For the OP176 the noise is gained by approximately

1020 using the circuit shown in Figure 28. Any readings on the

Audio Precision must then be divided by the gain. In imple-

menting this test fixture, good supply bypassing is essential.

Figure 28. Noise Test

Upgrading "5534`' Sockets

The OP176 is a superior amplifier for upgrading existing

designs using the industry standard 5534. In most application

circuits, the OP176 can directly replace the 5534 without any

modifications to the surrounding circuitry. Like the 5534, the

OP176 follows the industry standard, single op amp pinout. The

difference between these two devices is the location of the null

pins and the 5534's compensation capacitor.

The 5534 normally requires a 22 pF capacitor between Pins 5

and 8 for stable operation. Since the OP176 is internally

compensated for unity gain operation, it does not require

external compensation. Nevertheless, if the 5534 socket already

includes a capacitor, the OP176 can be inserted without

removing it. Since the OP176's Pin 8 is a "NO CONNECT''

pin, there is no internal connection to that pin. Thus, the 22 pF

capacitor would be electrically connected through Pin 5 to the

internal nulling circuitry. With the other end left open, the

capacitor should have no effect on the circuit. However, to

avoid altogether any possibility for noise injection, it is recom-

mended that the 22 pF capacitor be cut out of the circuit

entirely.

If the original 5534 socket includes offset nulling circuitry, one

would find a 10 k

to 100 k

potentiometer connected between

Pins 1 and 8 with said potentiometer's wiper arm connected to

V+. In order to upgrade the socket to the OP176, this circuit

should be removed before inserting the OP176 for its offset

nulling scheme uses Pins 1 and 5. Whereas the wiper arm of the

5534 trimming potentiometer is connected to the positive

supply, the OP176's wiper arm is connected to the negative

supply. Directly substituting the OP176 into the original socket

would inject a large current imbalance into its input stage. In

this case, the potentiometer should be removed altogether, or, if

nulling is still required, the trimming potentiometer should be

rewired to match the nulling circuit as illustrated in Figure 29.

Figure 29. Offset Voltage Nulling Scheme

Input Overcurrent Protection

The maximum input differential voltage that can be applied to

the OP176 is determined by a pair of internal Zener diodes

connected across its inputs. They limit the maximum differen-

tial input voltage to

±

7.5 V. This is to prevent emitter-base

junction breakdown from occurring in the input stage of the

OP176 when very large differential voltages are applied.

However, in order to preserve the OP176's low input noise

voltage, internal resistances in series with the inputs were not

used to limit the current in the clamp diodes. In small signal

applications, this is not an issue; however, in applications where

large differential voltages can be inadvertently applied to the

device, large transient currents can flow through these diodes.

Although these diodes have been designed to carry a current of

±

5 mA, external resistors as shown in Figure 30 should be used

in the event that the OP176's differential voltage were to exceed

±

7.5 V.

Figure 30. Input Overcurrent Protection

OP176

2

3

7

6

5

4

1

P1

≠V

S

V

OUT

P1 = 10k

V

OS

TRIM RANGE = ±2mV

+V

S

OP176

1.4k

1.4k

≠

+

2

3

6

50Hz /

300 mHz

\ 0 Hz

MKR:

5.4 Hz

10.0 µV /DIV

CH A: 80.0 µV FS

BW:

MKR: 15.9 µV/

Hz

OP176

OP37

OP37

OUTPUT

4.42k

909

909

100

490

100

OP176

REV. 0

≠10≠

Figure 33. Unity Gain Follower

Figure 34. Unity Gain Inverter

In inverting and noninverting applications, the feedback

resistance forms a pole with the source resistance and capaci-

tance (R

S

and C

S

) and the OP176's input capacitance (C

IN

), as

shown in Figure 35. With R

S

and R

F

in the k

range, this pole

can create excess phase shift and even oscillation. A small

capacitor, C

FB

, in parallel with R

FB

eliminates this problem. By

setting R

S

(C

S

+ C

IN

) = R

FB

C

FB

, the effect of the feedback pole is

completely removed.

Figure 35. Compensating the Feedback Pole

Output Voltage Phase Reversal

Since the OP176's input stage combines bipolar transistors for

low noise and p-channel JFETs for high speed performance, the

output voltage of the OP176 may exhibit phase reversal if either

of its inputs exceeds the specified negative common-mode input

voltage. This might occur in some applications where a trans-

ducer, or a system, fault might apply very large voltages upon

the inputs of the OP176. Even though the input voltage range

of the OP176 is

±

10.5 V, an input voltage of approximately

≠13.5 V will cause output voltage phase reversal. In inverting

amplifier configurations, the OP176's internal 7.5 V clamping

diodes will prevent phase reversal; however, they will not

prevent this effect from occurring in noninverting applications.

For these applications, the fix is a 3.92 k

resistor in series

with the noninverting input of the device and is illustrated in

Figure 31.

Figure 31. Output Voltage Phase Reversal Fix

Overdrive Recovery

The overdrive recovery time of an operational amplifier is the

time required for the output voltage to recover to a rated output

level from a saturated condition. This recovery time is impor-

tant in applications where the amplifier must recover quickly

after a large abnormal transient event. The circuit shown in

Figure 32 was used to evaluate the OP176's overload recovery

time. The OP176 takes approximately 1

µ

s to recover to V

OUT

=

+10 V and approximately 900 ns to recover to V

OUT

= ≠10 V.

Figure 32. Overload Recovery Time Test Circuit

High Speed Operation

As with most high speed amplifiers, care should be taken with

supply decoupling, lead dress, and component placement.

Recommended circuit configurations for inverting and

noninverting applications are shown in Figure 33 and Figure 34.

V

IN

R

S

909

V

OUT

R

L

2.43k

R2

10k

R1

1k

4Vp-p

@ 100Hz

6

2

3

OP176

+15V

+

10µF

0.1µF

2

3

7

6

4

V

IN

V

OUT

R

L

2k

≠15V

10µF

0.1µF

OP176

+15V

+

10µF

0.1µF

2

3

7

6

4

V

IN

V

OUT

2k

≠15V

10µF

0.1µF

OP176

10pF

4.99k

2.49k

4.99k

+

C

FB

R

FB

C

IN

V

OUT

R

S

C

S

R

S

3.92k

R

L

2k

R

FB

*

V

IN

V

OUT

*R

FB

IS OPTIONAL

OP176

2

3

6

OP176

REV. 0

≠11≠

Attention to Source Impedances Minimizes Distortion

Since the OP176 is a very low distortion amplifier, careful

attention should be given to source impedances seen by both

inputs. As with many FET-type amplifiers, the p-channel

JFETs in the OP176's input stage exhibit a gate-to-source

capacitance that varies with the applied input voltage. In an

inverting configuration, the inverting input is held at a virtual

ground and, as such, does not vary with input voltage. Thus,

since the gate-to-source voltage is constant, there is no distor-

tion due to input capacitance modulation. In noninverting

applications, however, the gate-to-source voltage is not

constant. The resulting capacitance modulation can cause

distortion above 1 kHz if the input impedance is > 2 k

and

unbalanced.

Figure 36 shows some guidelines for maximizing the distortion

performance of the OP176 in noninverting applications. The

best way to prevent unwanted distortion is to ensure that the

parallel combination of the feedback and gain setting resistors

(R

F

and R

G

) is less than 2 k

. Keeping the values of these

resistors small has the added benefits of reducing the thermal

noise of the circuit and dc offset errors. If the parallel combina-

tion of R

F

and R

G

is larger than 2 k

, then an additional

resistor, R

S

, should be used in series with the noninverting

input. The value of R

S

is determined by the parallel combina-

tion of R

F

and R

G

to maintain the low distortion performance of

the OP176. For a more generalized treatment on circuit

impedances and their effects on circuit distortion, please review

the section on Active Filters at the end of the Applications

section.

Driving Capacitive Loads

As with any high speed amplifier, care must be taken when

driving capacitive loads. The graph in Figure 14 shows the

OP176's overshoot versus capacitive load. The test circuit is a

standard noninverting voltage follower; it is this configuration

that places the most demand on an amplifier's stability. For

capacitive loads greater than 400 pF, overshoot exceeds 40%

and is roughly equivalent to a 45

∞

phase margin. If the applica-

tion requires the OP176 to drive loads larger than 400 pF, then

external compensation should be used.

Figure 37 shows a simple circuit which uses an in-the-loop

compensation technique that allows the OP176 to drive any

capacitive load. The equations in the figure allow optimization

of the output resistor, R

X

, and the feedback capacitor, C

F

, for

optimal circuit stability. One important note is that the circuit

bandwidth is reduced by the feedback capacitor, C

F

, and is

given by:

BW =

1

2

R

F

C

F

Figure 37. In-the-Loop Compensation Technique for

Driving Capacitive Loads

APPLICATIONS USING THE OP176

A High Speed, Low Noise Differential Line Driver

The circuit of Figure 38 is a unique line driver widely used in

many applications. With

±

18 V supplies, this line driver can

deliver a differential signal of 30 V p-p into a 2.5 k

load. The

high slew rate and wide bandwidth of the OP176 combine to

yield a full power bandwidth of 130 kHz while the low noise

front end produces a referred-to-input noise voltage spectral

density of 15 nV/

Hz

. The circuit is capable of driving lower

impedance loads as well. For example, with a reduced output

level of 5 V rms (14 V p-p), the circuit exhibits a full-power

bandwidth of 190 kHz while driving a differential load of 249

!

The design is a transformerless, balanced transmission system

where output common-mode rejection of noise is of paramount

importance. Like the transformer-based design, either output

can be shorted to ground for unbalanced line driver applications

without changing the circuit gain of 1. Other circuit gains can

be set according to the equation in the diagram. This allows the

design to be easily set for noninverting, inverting, or differential

operation.

Figure 38. A High Speed, Low Noise Differential Line

Driver

6

2

3

A2

6

3

2

A1

3

2

6

A3

V

IN

V

O1

V

O2

R3

2k

R9

50

R11

1k

P1

10k

R12

1k

R10

50

R8

2k

R2

2k

R5

2k

R4

2k

R1

2k

R7

2k

R6

2k

V

O2

≠ V

O1

= V

IN

A1, A2, A3 = OP176

GAIN =

SET R2, R4, R5 = R1 AND R6, R7, R8 = R3

R3

R1

OP176

V

IN

V

OUT

R

F

R

G

R

S

*

*

R

S

= R

G

//R

F

IF R

G

//R

F

>

2k

FOR MINIMUM DISTORTION

Figure 36. Balanced Input Impedance to Mininize

Distortion in Noninverting Amplifier Circuits

R

X =

R

O

R

G

R

F

OP176

C

F

R

X

C

L

R

G

R

F

V

OUT

WHERE R

O

= OPEN-LOOP OUTPUT RESISTANCE

V

IN

C

F

=

I

+

(

I

|

A

CL

|

)

(

R

F

+

R

G

R

F

)

C

L

R

O

[ ]

OP176

REV. 0

≠12≠

A Low Noise Microphone Preamplifier with a Phantom

Power Option

Figure 39 is an example of a circuit that combines the strengths

of the SSM2017 and the OP176 into a variable gain micro-

phone preamplifier with an optional phantom power feature.

The SSM2017's strengths lie in its low noise and distortion, and

gain flexibility/simplicity. However, rated only for 2 k

or

higher loads, this makes driving 600

loads somewhat limited

with the SSM2017 alone. A pair of OP176s are used in the

circuit as a high current output buffer (U2) and a DC servo

stage (U3). The OP176's high output current drive capability

provides a high level drive into 600

loads when operating

from

±

18 V supplies. For a complete treatment of the circuit

design details, the interested reader should consult application

note AN-242, available from Analog Devices.

This amplifier's performance is quite good over programmed

gain ranges of 2 to 2000. For a typical audio load of 600

,

THD + N at various gains and an output level of 10 V rms is

illustrated in Figure 40. For all but the very highest gain, the

THD + N is consistent and well below 0.01%, while the gain of

2000 becomes more limited by noise. The noise performance of

the circuit is exceptional with a referred-to-input noise voltage

spectral density of 1 nV/

Hz

at a circuit gain of 1000.

1.0

0.1

0.010

0.001

20

100

1k

10k

20k

G = 2000

G = 200

G = 20

G = 4

±

V

S

=

±

18V

80kHz LPF

Figure 40. Low Noise Microphone Preamplifier THD + N

Performance at Various Gains (V

OUT

= 10 V rms and

R

L

= 600

)

Figure 39. A Low Noise Microphone Preamplifier

+

+

+

+

+

R10

100

+48V

R9

6.81k

R8

6.81k

C8

47µF/

63V

PHANTOM POWER SUPPLY CONNECTIONS,

INTERLOCKED WITH +/≠V

S

(SEE NOTE 5).

Z1

Z2

TO MICROPHONE

≠IN

+IN

R

P

1

49.9

C

IN

1

47µF/

63V

R

P

2

49.9

C

IN

2

47µF/

63V

COMMON

Z3

Z4

C

G

2

2200µF/ 10V

C

G

1

2200µF/ 10V

R

G

R

B

1

10k

R

B

2

10k

C

N

4.7nF/

FILM

1)

3)

+V

S

3

8 1

2

6

5

4

7

U1

SSM2017P

≠V

S

C

RF

2

100pF

C

RF

1

100pF

R1

10k

R6

10k

R7

1k

C5

33pF

OUTPUT

6

4

2

3

7

6

2

3

R3

49.9

R5

221k

R2

20k

C1

1µF FILM

R4

221k

D1

D2

1N458

+V

S

≠V

S

U2

OP176

U3

OP176

C2

1µF FILM

OUT COMMON

NOTES:

1) Z1≠Z4 1N752 (SEE TEXT).

2) C

INX

, C

GX

LOW LEAKAGE ELECTROLYTIC TYPES (SEE TEXT).

3) GAIN = G = 2 x ((10k/R

G

) +1) (SEE TEXT).

4) ALL RESISTORS 1% METAL FILM.

5) DOTTED PHANTOM POWER RELATED COMPONENTS OPTIONAL (SEE TEXT).

+V

S

≠V

S

+18V

≠18V

C6

0.1µF

C7

0.1µF

C3

100µF/25V

C4

100µF/25V

+

+

1N458

4

7

≠V

S

+V

S

OP176

REV. 0

≠13≠

A Low Noise, +5 V/+10 V Reference

In many high resolution applications, voltage reference noise

can be a major contributor to overall system error. Monolithic

voltage references often exhibit too much wide band noise to be

used alone in these systems. Only through careful filtering and

buffering of these monolithic references can one realize wide-

band microvolt noise levels. The circuit illustrated in Figure 41

is an example of a low noise precision reference optimized for

both ac and dc performance around the OP176. With a +10 V

reference (the AD587), the circuit exhibits a 1 kHz spot output

noise spectral density < 10 nV/

Hz

. The reference output

voltage is selectable between 5 V and 10 V, depending only on

the selection of the monolithic reference. The output table

illustrated in the figure provides a selection of monolithic

references compatible with this circuit.

Figure 41. A Low Noise, +5 V/+10 V Reference

In operation, the basic reference voltage is set by U1, either a

5 V or 10 V 3-terminal reference chosen from the table. In this

case, the reference used is a 10 V buried Zener reference, but

all U1 IC types shown can plug into the pinout and can be

optionally trimmed. The stable 10 V from the reference is then

applied to the R1-C1-C2

noise filter, which uses electrolytic

capacitors for a low corner frequency. When electrolytic

capacitors are used for filtering, one must be cognizant of their

dc leakage current errors. Here, however, a dc bootstrap of C1

is used, so this capacitor sees only the small R2 dc drop as bias,

effectively lowering its leakage current to negligible levels. The

resulting low noise, dc-accurate output of the filter is then

buffered by a low noise, unity gain op amp using an OP176.

With the OP176's low V

OS

and control of the source resistances,

the dc performance of this circuit is quite good and will not

compromise voltage reference accuracy and/or drift. Also, the

OP176 has a typical current limit of 50 mA, so it can provide

higher output currents when compared to a typical IC reference

alone.

A Differential ADC Driver

High performance audio sigma-delta ADCs, such as the stereo

16-bit AD1878 and the 18-bit AD1879, present challenging

design problems with regards to input interfacing. Because of

an internal switched capacitor input circuit, the ADC input

structure presents a difficult dynamic load to the drive amplifier

with fast transient input currents due to their 3 MHz ADC

sampling rate. Also, these ADCs inputs are differential with a

rated full-scale range of

±

6.3 V, or about 4.4 V rms. Hence, the

ADC interface circuit of Figure 42 is designed to accept a

balanced input signal to drive the low dynamic impedances seen

at the inputs of these ADCs. The circuit uses two OP176

Figure 42. A Balanced Driver Circuit for Sigma-Delta ADCs

amplifiers as inverting low-pass filters for their speed and high

output current drive. The outputs of the OP176s then drive the

differential ADC inputs through an RC network. This RC

network buffers the amplifiers against step changes at the ADC

sampling inputs using one differential (C3) and two common-

mode connected capacitors (C4 and C5). The 51

series

resistors isolate the OP176s from the heavily capacitive loads,

while the capacitors absorb the transient currents. Operating on

±

12 V supplies, this circuit exhibits a very low THD + N of

0.001% at 5 V rms outputs. For single-ended drive sources, a

third op amp unity gain inverter can be added between R2's (+)

input terminal and R4. For best results, short-lead, noninduc-

tive capacitors are suggested for C3, C4, and C5 (which are

placed close to the ADC), and 1% metal-film types for R1

through R6. For surface mount PCBs, these components can

be NPO ceramic chip capacitors and thin-film chip resistors.

C1

100pF

R1

5.76k

R2

5.62k

R5

51

C2 100pF

R3

5.49k

R4

5.62k

R6

51

C4

0.01µF

U1

U2

C3

0.0047µF

C5

0.01µF

BALANCED

INPUTS

= AG, PIN 10 OR 18

V

IN

≠

V

IN

+

TO

AD1878/

AD1879

SIGMA-

DELTA

ADC

L & R

INPUTS

U1, U2 = OP176

≠12V

ANALOG

(+)

(≠)

NOTES

C1≠C5 = NPO CERAMIC, NON-INDUCTIVE,

C3-C5 CLOSE TO ADC

R1≠R6 = 1% METAL FILM

0.1µF

0.1µF

100µ/25V

+12V

ANALOG

COM

+V

S

≠V

S

TO

U1, U2

100µ/25V

(+)

USE

FOR

SINGLE-ENDED

INPUTS

5k

5k

OUTPUT TABLE

V

OUT

10V

10V

10V

10V

5V

5V

5V

5V

U1

AD587

REF01

REF10

AD581

REF195

AD586

REF02

REF05

TOLERANCE

(+/≠mV)

5 TO 10

30 TO 100

30 TO 50

5 TO 30

2 TO 10

2.5 TO 20

15 TO 50

15 TO 25

U2

OP176

4

7

6

2

3

+15V

R1

1k

R3

100

R2

10k

C4

0.1µF

C2

100µF/25V

6

5

8

4

R

TRIM

10k

C1

100µF/25V

C3

100µF/25V

R5

1.1k

R4

100

R6

3.3

C5

10µF/25V

V

OUT

REF

COMMON

(OPTIONAL)

2

U1

OP176

REV. 0

≠14≠

An RIAA Phono Preamp

Figure 43 illustrates a simple phono preamplifier using RIAA

equalization. The OP176 is used here to provide gain and is

chosen for its low input voltage noise and high speed perfor-

mance. The feedback equalization network (R1, R2, C1, and

C2) forms a three time constant network, providing reasonably

accurate equalization with standard component values. The

input components terminate a moving magnet phono cartridge

as recommended by the manufacturer, the element values

shown being typical. When this ac coupled circuit is built with a

low noise bipolar input device such as the OP176, amplifier bias

current makes direct cartridge coupling difficult. This circuit

uses input and output capacitor coupling to minimize biasing

interactions.

Input ac coupling to the amplifier is provided via C5, and the

low frequency termination resistance, R

T

, is the parallel equiva-

lent of R6 and R7. R3 of the feedback network is ac grounded

via C4, a large value electrolytic. Additionally, this resistor is

set to a low value to minimize circuit noise from nonamplifier

sources. These design measures reduce the dc offset at the

output of the OP176 to a few millivolts. The output coupling

network of C3 and R4 is shown as suitable for wide band

response, but it can be set to a 7950

µ

s time constant for use as

a 20 Hz rumble filter.

The 1 kHz gain ("G") of this circuit, controlled by R3, is

calculated as:

G (@ 1 kHz) = 0.101

◊

1 + R1

R3

For an R3 of 200

,

the circuit gain is just under 50

◊ (

34 dB),

and higher gains are possible by decreasing R3. For any value

of R3, the R5-C6 time constant should be equal to R3 and the

series equivalent of C1 and C2.

Using readily available standard values for network elements

(R1, R2, C1, and C2) makes the design easily reproducible and

inexpensive. These components are ideally high quality

precision types, for low equalization errors and minimum

parasitics. One percent metal-film resistors and two percent

film capacitors of polystyrene or polypropylene are recom-

mended. Using the suggested values, the frequency response

relative to the ideal RIAA characteristic is within

±

0.2 dB over

20 Hz≠20 kHz. Even tighter response can be achieved by using

the alternate values, shown in brackets "[ ]," with the trade-off

of a non off-the-shelf part.

As previously mentioned, the OP176 was chosen for three

reasons: (1) For optimal circuit noise performance, the

amplifier used should exhibit voltage and current noise densities

of 5 nV/

Hz

and 1 pA/

Hz

, respectively. (2) For high gain

accuracy, especially at high stage gains, the amplifier should

exhibit a gain bandwidth product in excess of 5 MHz. (3)

Equally important because of the 100% feedback through the

network at high frequencies, the amplifier must be unity gain

stable. With the OP176, the circuit exhibits low distortion over

the entire range, generally well below 0.01% at outputs levels of

5 V

rms using

±

18 V supplies. To achieve maximum perfor-

mance from this high gain, low level circuit, power supplies

should be well regulated and noise free, and care should be

taken with shielding and conductor layout.

Active Filter Circuits Using the OP176

A general active filter topology that lends itself to both high-pass

(HP) and low-pass (LP) filters is the well known Sallen-Key

(SK) VCVS (Voltage-Controlled, Voltage Source) architecture.

This filter type uses the op amp as a fixed gain voltage follower

at either unity or a higher gain. Discussed here are simplified 2-

pole, unity gain forms of these filters, which are attractive for

several reasons: One, at audio frequencies, using an amplifier

with a 10 MHz bandwidth such as the OP176, these filters

exhibit reasonably low sensitivities for unity gain and high

damping (low Q). Second, as voltage followers, they are also

inherently gain accurate within their pass band; hence, no gain

resistor scaling errors are generated. Third, they can also be

made "dc accurate," with output dc errors of only a few

millivolts. The specific filter response in terms of HP, LP and

damping is determined by the RC network around the op amp,

as shown in Figure 44a.

Figure 43. An RIAA Phono Preamplifier Circuit

R6

100k

R7

100k

Ct

150pF

C5

100

µ

F/25V

MOVING

MAGNET

PICKUP

3

2

7

6

4

OP176

U1

+V

S

≠V

S

Rt = R6

| |

R7

~ 50k

≠

C1

0.03µF

2%

C2

0.01µF

2%

R3

200

(34dB)

100

(40dB)

C4

1000µF/16V

C3

100

µ

F/25V

R5

499

R4

100k

C6

3nF

V

OUT

0.1µF

0.1µF

+V

S

≠V

S

100µF

100µF

+18V

≠18V

R1

100k

1%

[97.6k

]

R2

8.25k

1%

[7.87k

]

OP176

REV. 0

≠15≠

High Pass Sections

Figure 44a illustrates the high-pass form of a 2-pole SK filter

using an OP176. For simplicity and practicality, capacitors C1

and C2

are set equal ("C"), and resistors R2 and R1

are

adjusted to a ratio, N, which provides the filter damping

coefficient,

, as per the design expressions. This high pass

design is begun with selection of standard capacitor values for

C1 and C2 and a calculation of N. The values for R1 and R2

are then determined from the following expressions:

R1

=

1

2

◊

FREQ

◊

C

◊

N

and

R2

=

N

◊

R1

Figures 44a. Two-Pole Unity Gain HP/LP Active Filters

In this examples, circuit

(or 1/Q) is set equal to

2

, providing

a Butterworth (maximally flat) characteristic. The filter corner

frequency is normalized to 1 kHz, with resistor values shown in

both rounded and (exact) form. Various other 2-pole response

shapes are possible with appropriate selection of

, and fre-

quency can be easily scaled, using inversely proportional R or

C values for a given

. The 22 V/

µ

s slew rate of the OP176 will

support 20 V p-p outputs above 100 kHz with low distortion.

The frequency response resulting with this filter is shown as the

dotted HP portion of Figure 45.

+V

S

R1

11k

(11.254k)

C1

0.01µF

7

4

6

3

2

OUT

IN

OP176

C2

0.01µF

≠V

S

R2

22k

(22.508k)

GIVEN:

,

FREQ

SET C1 = C2 = C

= =

2

N

1

Q

N = =

4

2

R2

R1

R1 =

1

R2 = N x R1

Z

COMP

Z

COMP

(HIGH PASS)

IN (≠)

R2

OUTPUT

C1

C2

R1

1 kHz BW SHOWN

2

FREQ x C x N

Low Pass Sections

In the LP SK arrangement of Figure 44b, the R and C elements

are interchanged where the resistors are made equal. Here, the

ratio of C2/C1 ("M") is used to set the filter

, as noted.

Otherwise, this filter is similar to the HP section, and the

resulting 1 kHz LP response is shown in Figure 45. The design

begins with a choice of a standard capacitor value for C1 and a

calculation of M. This then forces a value of "M

◊

C1" for C2.

Then, the value for R1 and R2 ("R") is calculated according to

the following equation:

R

=

1

2

◊

FREQ

◊

C1

◊

M

Figures 44b. Two-Pole Unity Gain HP/LP Active Filters

Figure 45. Relative Frequency Response of 2-Pole, 1 kHz

Butterworth LP (Left) and HP (Right) Active Filters

+V

S

R1

11k

(11.254k)

C1

0.02µF

7

4

6

3

2

OUT

IN

OP176

C2

0.01µF

≠V

S

R2

11k

(11.254k)

GIVEN:

,

FREQ

= =

2

M

1

Q

M = =

4

2

C2

C1

C2 = M x C1

Z

COMP

IN (≠)

R2

OUTPUT

C1

C2

R1

1 kHz BW SHOWN

CHOOSE C1

R =

1

2

FREQ x C1 x M

Z

COMP

(LOW PASS)

100 50k

10k

1k

20

10.000

≠30.00

≠70.00

≠50.00

≠10.00

≠20.00

≠40.00

≠60.00

0.0

LP

HP

FREQUENCY ≠ Hz

dBr

OP176

REV. 0

≠16≠

Passive Component Selection for Active Filters

The passive components suitable for active filters deserve more

than casual attention. Resistors should be 1%, low TC, metal-

film types of the RN55 or RN60 style. Capacitors should be 1%

or 2% film types preferably, such as polypropylene or polysty-

rene, or NPO (COG) ceramic for smaller values.

Active Filter Circuit Subtleties

In designing active filter circuits with the OP176, moderately

low values (10 k

or less) for R1 and R2 can be used to

minimize the effects of Johnson noise when critical. The

practical tradeoff is, of course, capacitor size and expense. DC

errors will result for larger values of resistance, unless compen-

sation for amplifier input bias current is used. To add bias

compensation in the HP filter section of Figure 42a, a feedback

compensation resistor equal to R2 can be used. This will

minimize bias current induced offset to the product of the

OP176's I

OS

and R2. For an R2 of 25 k

, this produces a typical

compensated offset voltage of 50

µ

V. Similar compensation is

applied to Figure 42b, using a resistance equal to R1+ R2.

Using dc compensation, filter output dc errors using the OP176

will be dominated by its V

OS

, which is typically 1 mV or less. A

caveat here is that the additional resistors can increase noise

substantially. For example, a 10 k

resistor generates ~ 12 nV/

Hz

of noise and is about twice that of the OP176. These

resistors can be ac bypassed to eliminate their noise using a

simple shunt capacitor chosen such that its reactance (X

C

) is

much less than R at the lowest frequency of interest.

A more subtle form of ac degradation is also possible in these

filters, namely nonlinear input capacitance modulation. This

issue was previously covered for general cases in the section on

minimizing distortion. In active filter circuits, a fully compen-

sating network (for both dc and ac performance) can be used to

minimize this distortion. To be most effective, this network

(Z

COMP

) should include R1

through C2 as noted for either filter

type, of the same style and value as their counterparts in the

forward path. The effects of a Z

COMP

network on the THD + N

performance of two 1 kHz HP filters is illustrated in Figure 46.

One filter (A) is the example shown in Figure 44a (Curves A1

and A2), while the second (B) uses RC values scaled 10 times

upward in impedance (Curves B1 and B2). Both filters operate

with a 2 V rms input,

±

18 V supplies, 100 k

loading, and

analyzer bandwidth of 80 kHz.

Figure 46. THD + N (%) vs. Frequency for Various 1 kHz HP

Active Filters Illustrating the Effects of the Z

COMP

Network

Curves A1 and B1 show performance with Z

COMP

shorted,

while curves A2 and B2 illustrate operation with Z

COMP

active.

For the "A" example values, distortion in the pass band of

1 kHz≠20 kHz is below 0.001% compensated, and slightly

higher uncompensated. With the higher impedance "B" net-

work, there is a much greater difference between compensated

and uncompensated responses, underscoring the sensitivity to

higher impedances. Although the positive effect of Z

COMP

is seen

for both "A" and "B" cases, there is a buffering effect which

takes place with lower impedances. As case "A" shows, when

using larger capacitance values in the source, the amplifier's

nonlinear C-V input characteristics have less effect on the

signal.

Thus, to minimize the necessity for the complete Z

COMP

com-

pensation, effective filter designs should use the lowest capaci-

tive impedances practical, with an 0.01

µ

F lower value limit as a

goal for lowest distortion (while lower values can certainly be

used, they may suffer higher distortion without the use of full

compensation). Since most designs are likely to use low relative

impedances for reasons of low noise and offset, the effects of

CM distortion may or may not actually be apparent to a given

application.

20

100 20k

1k

1

0.010

0.0001

0.001

0.1

10 k

B1

A1

B2

A2

FREQUENCY ≠ Hz

THD +N ≠ %

OP176

REV. 0

≠17≠

Figure 47. OP176 Spice Model Schematic

35

10

11

V

N1

V

N2

D

N1

D

N2

12

13

14

V

N3

V

N4

D

N3

D

N4

15

16

17

V

N5

V

N6

D

N5

D

N6

C

N1

C

1

E

M

R

4

C

2

5

6

Q1

Q2

3

7

8

9

R

3

36

D2

D1

C

IN

2

1

≠IN

+IN

I

OS

R

5

R

6

4

I

1

E

P

97

E

N

E

OS

98

98

CM1

CM2

I

SY

R

15

V

5

D8

G9

R

16

G8

R

17

V

4

D7

R

18

27

G5

R

14

C8

C

9

D6

D5

99

28

30

29

F

1

31

32

33

D10

G7

G6

D9

50

98

F

2

34

L

2

G

1

R

7

21

C

3

V

3

97

51

D

4

20

G

2

R

8

C

4

R

9

23

G

3

R

10

C

5

24

G

4

R

11

C

6

V

2

D

3

19

26

E

2

R

13

25

R

12

C7

98

22

98

E

REF

OP176

REV. 0

≠18≠

OP176 SPICE Model

*

* Node Assignments

*

Noninverting Input

*

|

Inverting Input

*

|

|

Positive Supply

*

|

|

|

Negative Supply

*

|

|

|

|

Output

*

|

|

|

|

|

*

|

|

|

|

|

.SUBCKT OP176

1

2

99

50

34

*

* INPUT STAGE & POLE AT 100 MHz

*

R3

5

51

2.487

R4

6

51

2.487

CIN 1

2

3.7E-12

CM1 1

98

7.5E-12

CM2 2

98

7.5E-12

C2

5

6

320E-12

I1

97

4

100E-3

IOS

1

2

1E-9

EOS 9

3

POLY(1)

(26,28)

0.2E-3

1

Q1

5

2

7

QX

Q2

6

9

8

QX

R5

7

4

1.970

R6

8

4

1.970

D1

2

36

DZ

D2

1

36

DZ

EN

3

1

(10,0)

1

GN1 0

2

(13,0)

1E-3

GN2 0

1

(16,0)

1E-3

*

EREF 98

0

(28,0)

1

EP

97

0

(99,0)

1

EM

51

0

(50,0)

1

*

* VOLTAGE NOISE SOURCE

*

DN1 35

10

DEN

DN2 10

11

DEN

VN1 35

0

DC 2

VN2 0

11

DC 2

*

* CURRENT NOISE SOURCE

*

DN3 12

13

DIN

DN4 13

14

DIN

VN3 12

0

DC 2

VN4 0

14

DC 2

*

* CURRENT NOISE SOURCE

*

DN5 15

16

DIN

DN6 16

17

DIN

VN5 15

0

DC 2

VN6 0

17

DC 2

*

* GAIN STAGE & DOMINANT POLE AT 32 Hz

*

R7

18

98

1.243E6

C3

18

98

4E-9

G1

98

18

(5,6) 4.021E-1

V2

97

19

1.35

V3

20

51

1.35

D3

18

19

DX

D4

20 18 DX

*

* POLE/ZERO PAIR AT 1.5 MHz/2.7 MHz

*

R8

21

98

1E3

R9

21

22

1.25E3

C4

22

98

47.2E-12

G2

98

21

(18,28)

1E-3

*

* POLE AT 100 MHz

*

R10

23

98

1

C5

23

98

1.59E-9

G3

98

23

(21,28)

1

*

* POLE AT 100 MHz

*

R11

24

98

1

C6

24

98

1.59E-9

G4

98

24

(23,28)

1

*

* COMMON-MODE GAIN NETWORK WITH ZERO AT

1 kHz

*

R12

25

26

1E6

C7

25

26

60E-12

R13

26

98

1

E2

25

98

POLY(2)

(1,98) (2,98) 0 2.50 2.50

*

* POLE AT 100 MHz

*

R14

27

98

1

C8

27

98

1.59E-9

G5

98

27

(24,28)

1

*

* OUTPUT STAGE

*

R15

28

99

58.333E3

R16

28

50

58.333E3

C9

28

50

1E-6

ISY

99

50

1.743E-3

R17

29

99

100

R18

29

50

100

L2

29

34

1E-9

G6

32

50

(27,29)

10E-3

G7

33

50

(29,27)

10E-3

G8

29

99

(99,27)

10E-3

G9

50

29

(27,50)

10E-3

V4

30

29

1.74

V5

29

31

1.74

F1

29

0

V4

1

F2

0

29

V5

1

D5

27

30

DX

D6

31

27

DX

D7

99

32

DX

D8

99

33

DX

D9

50

32

DY

D10 50

33

DY

*

* MODELS USED

*

.MODEL QX PNP(BF=5E5)

.MODEL DX D(IS=1E-12)

.MODEL DY D(IS=1E-15 BV=50)

.MODEL DZ D(IS=1E-15 BV=7.0)

.MODEL DEN D(IS=1E-12 RS=4.35K KF=1.95E-15 AF=1)

.MODEL DIN D(IS=1E-12 RS=268 KF=1.08E-15 AF=1)

.ENDS OP176

OP176

REV. 0

≠19≠

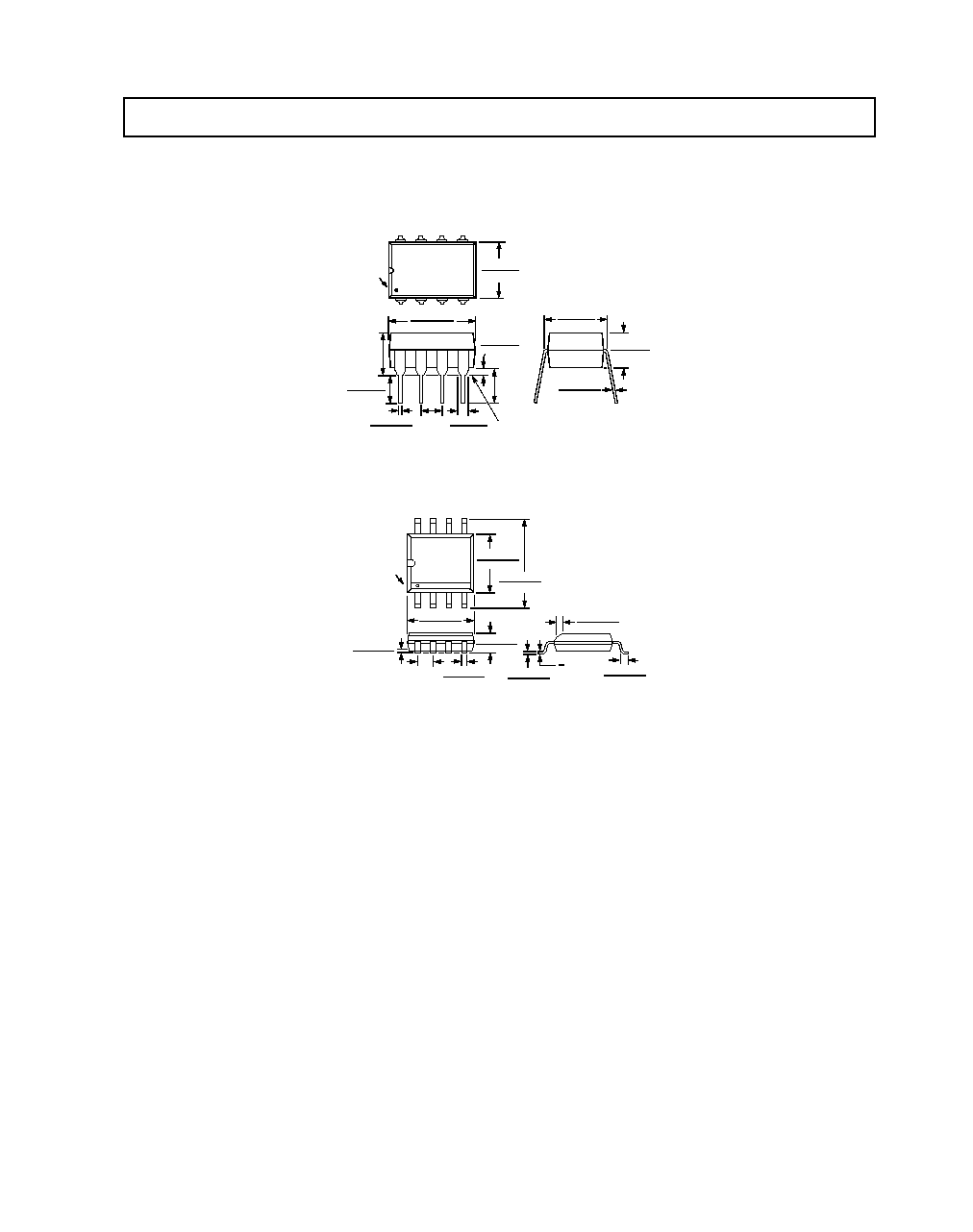

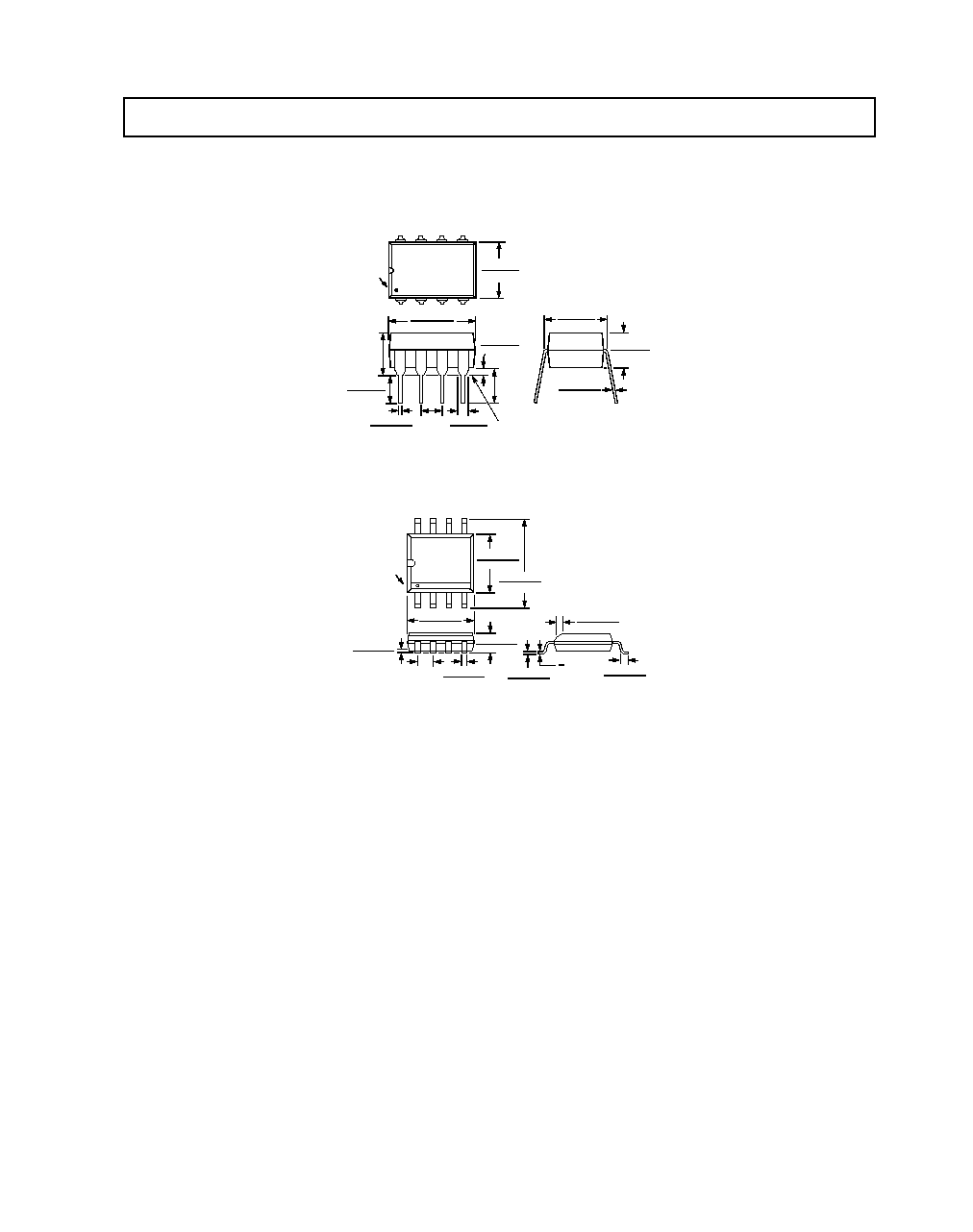

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic DIP (N-8)

PIN 1

0.280 (7.11)

0.240 (6.10)

4

5

8

1

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.430 (10.92)

0.348 (8.84)

0.022 (0.558)

0.014 (0.356)

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

8-Lead Narrow-Body SO (SO-8)

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8

∞

0

∞

0.0196 (0.50)

0.0099 (0.25)

x 45

∞

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.2440 (6.20)

0.2284 (5.80)

4

5

1

8

0.0192 (0.49)

0.0138 (0.35)

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0040 (0.10)

0.1968 (5.00)

0.1890 (4.80)

≠20≠

PRINTED IN U.S.A.

C1878≠10≠1/94

OP176

REV. 0

≠21≠

FOR CATALOG

ORDERING GUIDE

Model

Temperature Range

Package Description

Package Option*

OP176GP

≠40

∞

C to +85

∞

C

8-Pin Plastic DIP

N-8

OP176GS

≠40

∞

C to +85

∞

C

8-Pin SOIC

SO-8

OP176GSR

≠40

∞

C to +85

∞

C

SO-8 Reel, 2500 Pieces

OP176GBC

+25

∞

C

DICE

*For outline information see Package Information section.