| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HCPL-7710 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Features

∑ +5 V CMOS compatibility

∑ 8 ns maximum pulse width

distortion

∑ 20 ns maximum prop. delay skew

∑ High speed: 12 Mbd

∑ 40 ns maximum prop. delay

∑ 10 kV/

µ

s minimum common mode

rejection

∑ -40

∞

C to 100

∞

C temperature range

∑ Safety and regulatory approvals

UL Recognized

3750 V rms for 1 min. per

UL 1577

CSA Component Acceptance

Notice #5

IEC/EN/DIN EN 60747-5-2

≠ V

IORM

= 630 Vpeak for

HCPL-7710 Option 060

≠ V

IORM

= 560 Vpeak for

HCPL-0710 Option 060

Applications

∑ Digital fieldbus isolation:

DeviceNet, SDS, Profibus

∑ AC plasma display panel level

shifting

∑ Multiplexed data transmission

∑ Computer peripheral interface

∑ Microprocessor system interface

Description

Available in either an 8-pin DIP or

SO-8 package style respectively,

the HCPL-7710 or HCPL-0710

optocouplers utilize the latest

CMOS IC technology to achieve

outstanding performance with

very low power consumption. The

HCPL-x710 require only two

bypass capacitors for complete

CMOS compatibility.

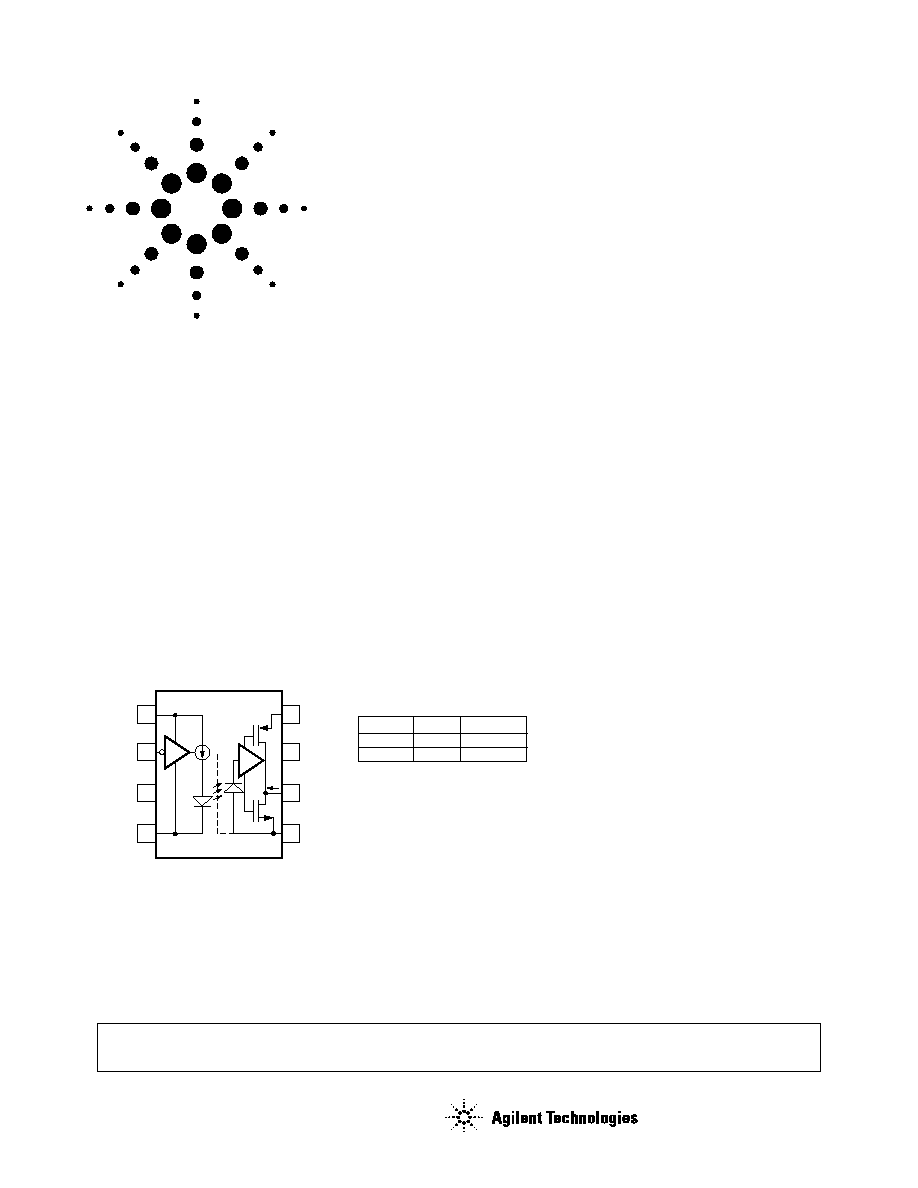

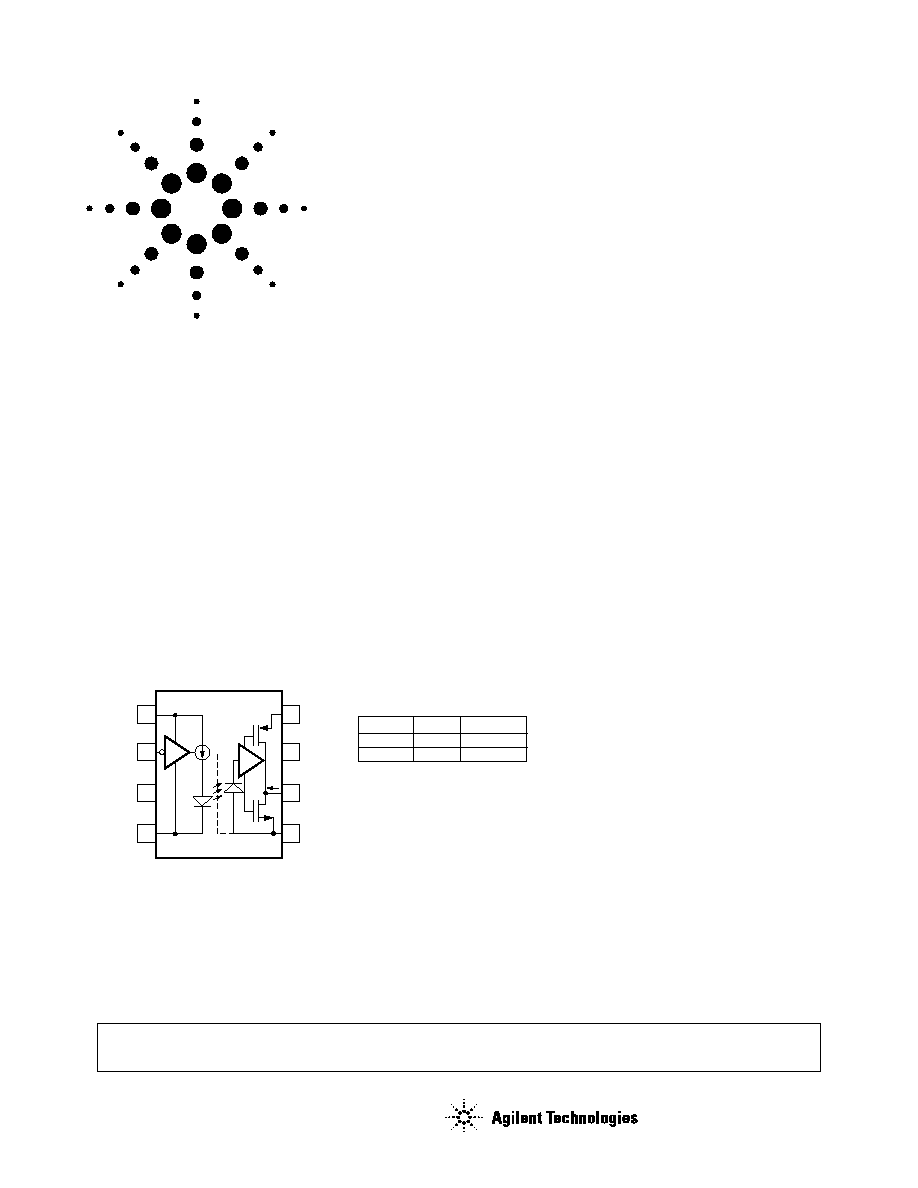

Functional Diagram

Basic building blocks of the

HCPL-x710 are a CMOS LED

driver IC, a high speed LED and a

CMOS detector IC. A CMOS logic

input signal controls the LED

driver IC which supplies current

to the LED. The detector IC

incorporates an integrated

photodiode, a high-speed

transimpedance amplifier, and a

voltage comparator with an

output driver.

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this

component to prevent damage and/or degradation which may be induced by ESD.

* Pin 3 is the anode of the internal LED and must be left unconnected for guaranteed data sheet

performance. Pin 7 is not connected internally.

** A 0.1

µ

F bypass capacitor must be connected between pins 1 and 4, and 5 and 8.

8

7

6

1

3

SHIELD

5

2

4

**VDD1

VI

*

GND1

VDD2**

VO

GND2

VI, INPUT

LED1

H

L

OFF

ON

TRUTH TABLE

(POSITIVE LOGIC)

NC*

IO

LED1

VO, OUTPUT

H

L

Agilent HCPL-7710, HCPL-0710

40 ns Propagation Delay,

CMOS Optocoupler

Data Sheet

2

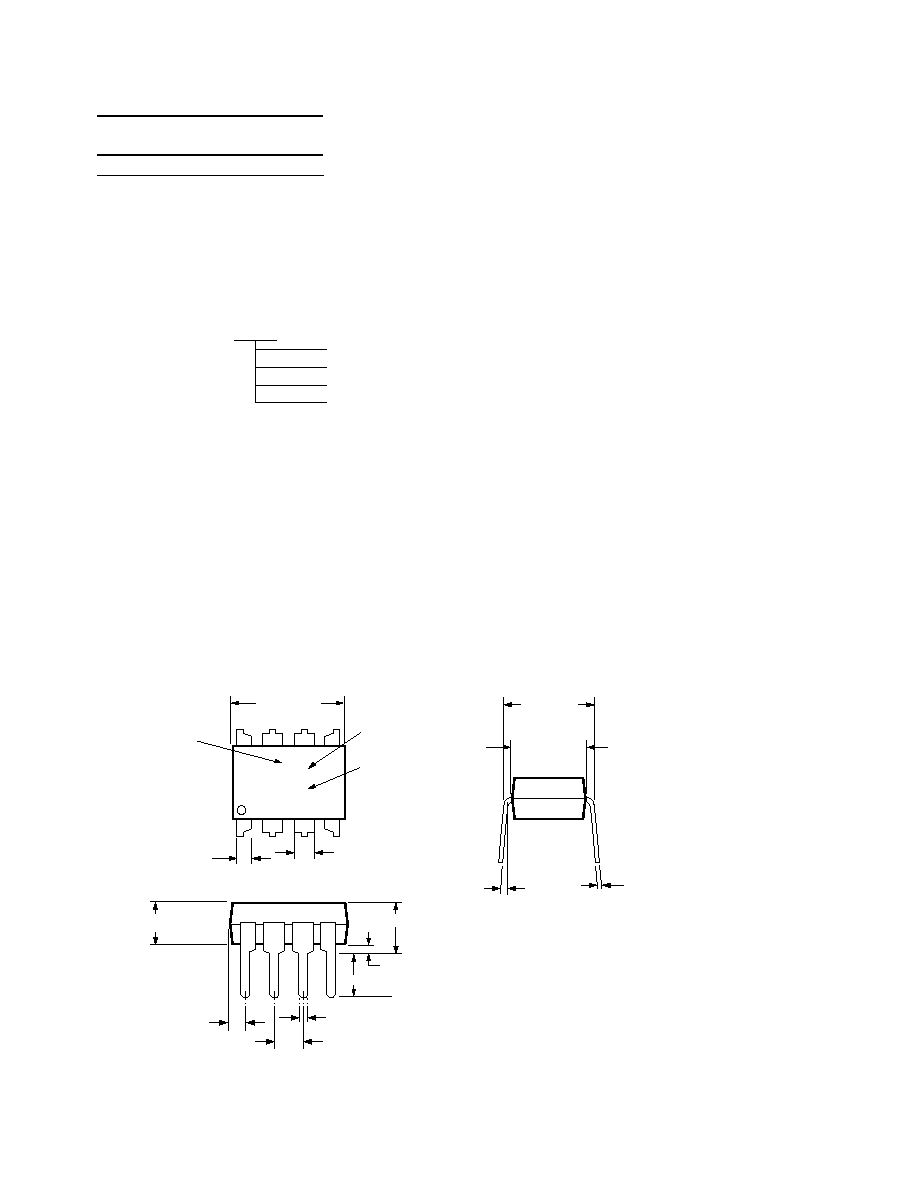

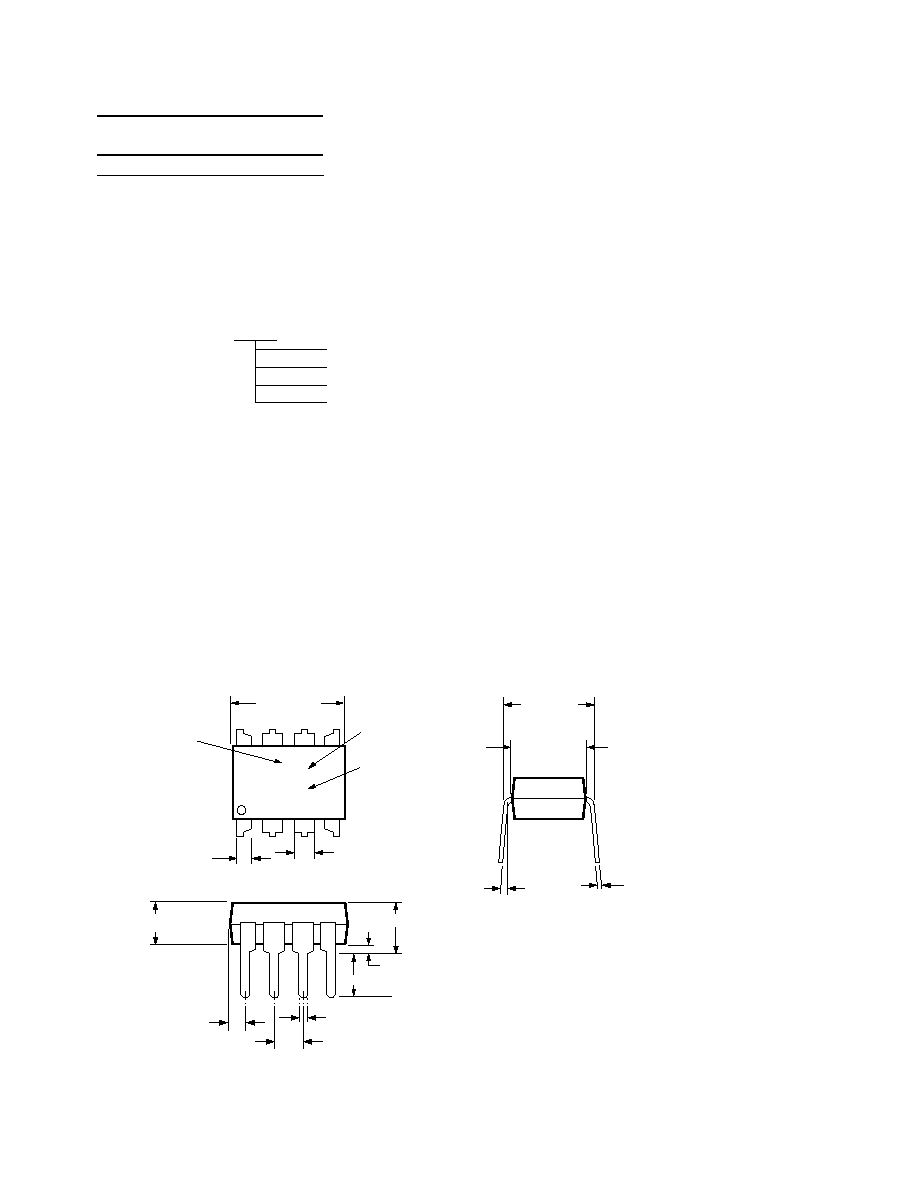

Package Outline Drawing

HCPL-7710 8-Pin DIP Package

9.65 ± 0.25

(0.380 ± 0.010)

1.78 (0.070) MAX.

1.19 (0.047) MAX.

A XXXXV

YYWW

DATE CODE

1.080 ± 0.320

(0.043 ± 0.013)

2.54 ± 0.25

(0.100 ± 0.010)

0.51 (0.020) MIN.

0.65 (0.025) MAX.

4.70 (0.185) MAX.

2.92 (0.115) MIN.

DIMENSIONS IN MILLIMETERS AND (INCHES).

5

6

7

8

4

3

2

1

5∞ TYP.

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

7.62 ± 0.25

(0.300 ± 0.010)

6.35 ± 0.25

(0.250 ± 0.010)

TYPE NUMBER

*OPTION 300 AND 500 NOT MARKED.

NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.

OPTION 060 CODE*

3.56 ± 0.13

(0.140 ± 0.005)

Selection Guide

8-Pin DIP

Small Outline

(300 Mil)

SO-8

HCPL-7710

HCPL-0710

Ordering Information

Specify Part Number followed by Option Number (if desired)

Example

HCPL-7710#XXXX

060 = IEC/EN/DIN EN 60747-5-2 Option.

300 = Gull Wing Surface Mount Option (HCPL-7710 only).

500 = Tape and Reel Packaging Option.

XXXE = Lead Free Option

No Option and Option 300 contain 50 units (HCPL-7710), 100 units (HCPL-0710) per tube.

Option 500 contain 1000 units (HCPL-7710), 1500 units (HCPL-0710) per reel.

Option data sheets available. Contact Agilent sales representative or authorized distributor.

Remarks: The notation "#" is used for existing products, while (new) products launched since 15th July 2001 and lead free option will use "≠"

3

Package Outline Drawing

HCPL-7710 Package with Gull Wing Surface Mount Option 300

Package Outline Drawing

HCPL-0710 Outline Drawing (Small Outline SO-8 Package)

0.635 ± 0.25

(0.025 ± 0.010)

12∞ NOM.

9.65 ± 0.25

(0.380 ± 0.010)

0.635 ± 0.130

(0.025 ± 0.005)

7.62 ± 0.25

(0.300 ± 0.010)

5

6

7

8

4

3

2

1

9.65 ± 0.25

(0.380 ± 0.010)

6.350 ± 0.25

(0.250 ± 0.010)

1.016 (0.040)

1.27 (0.050)

10.9 (0.430)

2.0 (0.080)

LAND PATTERN RECOMMENDATION

1.080 ± 0.320

(0.043 ± 0.013)

3.56 ± 0.13

(0.140 ± 0.005)

1.780

(0.070)

MAX.

1.19

(0.047)

MAX.

2.54

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES).

NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

XXXV

YWW

8

7

6

5

4

3

2

1

5.994 ± 0.203

(0.236 ± 0.008)

3.937 ± 0.127

(0.155 ± 0.005)

0.406 ± 0.076

(0.016 ± 0.003)

1.270

(0.050)

BSC

5.080 ± 0.127

(0.200 ± 0.005)

3.175 ± 0.127

(0.125 ± 0.005)

1.524

(0.060)

45∞ X

0.432

(0.017)

0.228 ± 0.025

(0.009 ± 0.001)

TYPE NUMBER

(LAST 3 DIGITS)

DATE CODE

0.305

(0.012)

MIN.

TOTAL PACKAGE LENGTH (INCLUSIVE OF MOLD FLASH)

5.207 ± 0.254 (0.205 ± 0.010)

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES) MAX.

OPTION NUMBER 500 NOT MARKED.

NOTE: FLOATING LEAD PROTRUSION IS 0.15 mm (6 mils) MAX.

0.203 ± 0.102

(0.008 ± 0.004)

7∞

PIN ONE

0 ~ 7∞

*

*

7.49 (0.295)

1.9 (0.075)

0.64 (0.025)

LAND PATTERN RECOMMENDATION

4

All Agilent data sheets report the

creepage and clearance inherent

to the optocoupler component

itself. These dimensions are

needed as a starting point for the

equipment designer when

determining the circuit insulation

requirements. However, once

mounted on a printed circuit

board, minimum creepage and

clearance requirements must be

met as specified for individual

equipment standards. For

creepage, the shortest distance

path along the surface of a

printed circuit board between the

solder fillets of the input and

output leads must be considered.

There are recommended

techniques such as grooves and

ribs which may be used on a

printed circuit board to achieve

desired creepage and clearances.

Creepage and clearance distances

will also change depending on

factors such as pollution degree

and insulation level.

Regulatory Information

The HCPL-x710 have been

approved by the following

organizations:

UL

Recognized under UL 1577,

component recognition program,

File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

IEC/EN/DIN EN 60747-5-2

Approved under:

IEC 60747-5-2:1997 + A1:2002

EN 60747-5-2:2001 + A1:2002

DIN EN 60747-5-2 (VDE 0884

Teil 2):2003-01.

(Option 060 only)

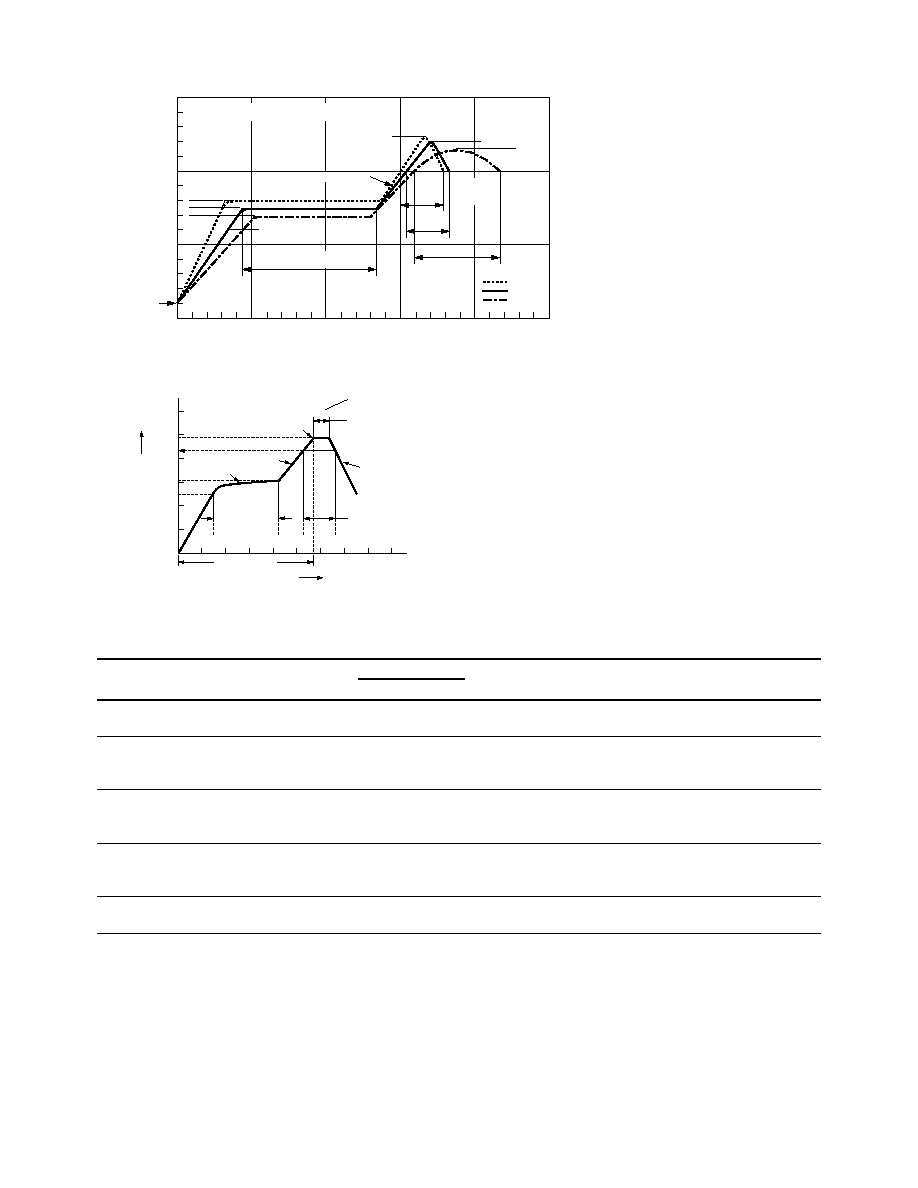

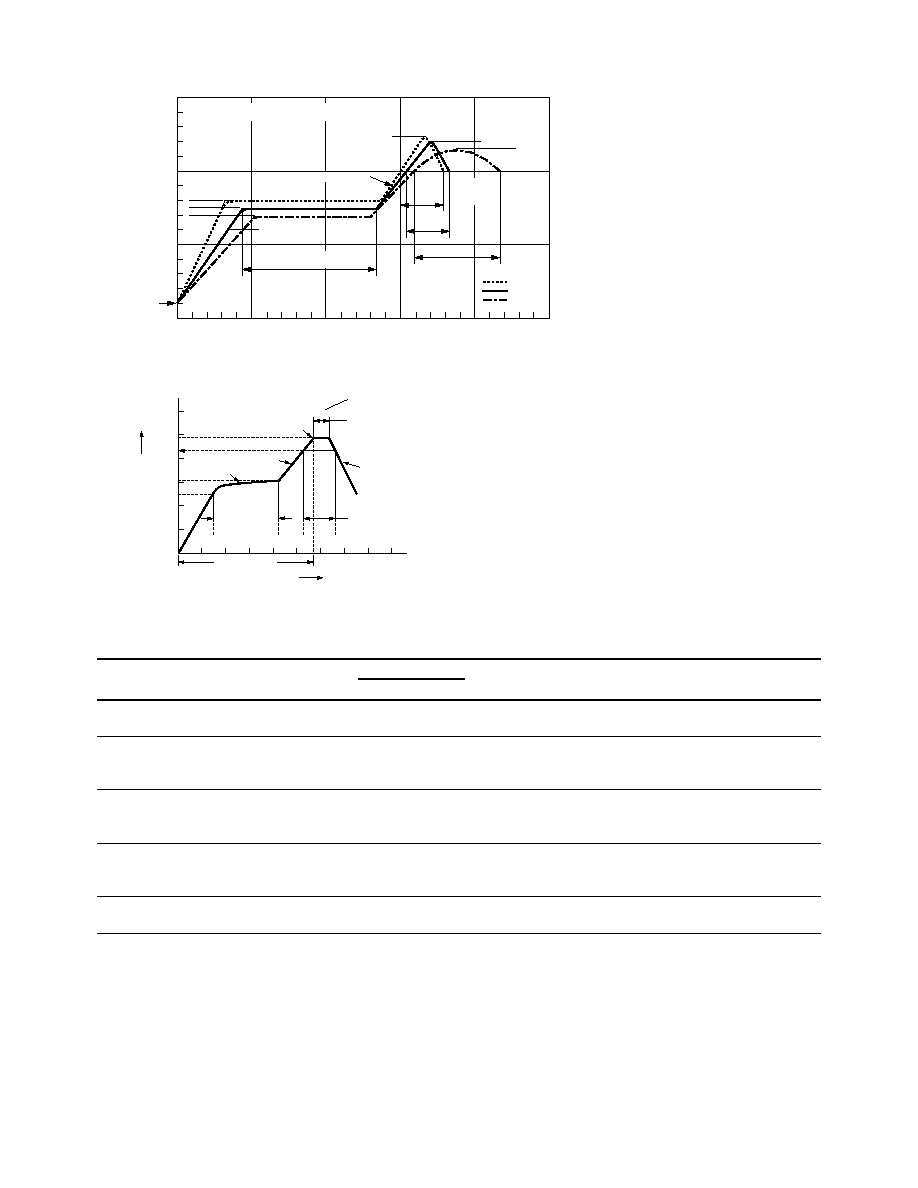

Recommended Pb-Free IR Profile

0

TIME (SECONDS)

TEMPERATURE (

∞

C)

200

100

50

150

100

200

250

300

0

30

SEC.

50 SEC.

30

SEC.

160∞C

140∞C

150∞C

PEAK

TEMP.

245∞C

PEAK

TEMP.

240∞C

PEAK

TEMP.

230∞C

SOLDERING

TIME

200∞C

PREHEATING TIME

150∞C, 90 + 30 SEC.

2.5∞C ± 0.5∞C/SEC.

3∞C + 1∞C/≠0.5∞C

TIGHT

TYPICAL

LOOSE

ROOM

TEMPERATURE

PREHEATING RATE 3∞C + 1∞C/≠0.5∞C/SEC.

REFLOW HEATING RATE 2.5∞C ± 0.5∞C/SEC.

Solder Reflow Thermal Profile

Insulation and Safety Related Specifications

Value

Parameter

Symbol

7710

0710

Units

Conditions

Minimum External Air

L(I01)

7.1

4.9

mm

Measured from input terminals to output

Gap (Clearance)

terminals, shortest distance through air.

Minimum External

L(I02)

7.4

4.8

mm

Measured from input terminals to output

Tracking (Creepage)

terminals, shortest distance path along

body.

Minimum Internal Plastic

0.08

0.08

mm

Insulation thickness between emitter and

Gap (Internal Clearance)

detector; also known as distance through

insulation.

Tracking Resistance

CTI

175

175

Volts

DIN IEC 112/VDE 0303 Part 1

(Comparative Tracking

Index)

Isolation Group

IIIa

IIIa

Material Group (DIN VDE 0110, 1/89,

Table 1)

217 ∞C

RAMP-DOWN

6 ∞C/SEC. MAX.

RAMP-UP

3 ∞C/SEC. MAX.

150 - 200 ∞C

260 +0/-5 ∞C

t 25 ∞C to PEAK

60 to 150 SEC.

20-40 SEC.

TIME WITHIN 5 ∞C of ACTUAL

PEAK TEMPERATURE

t

p

t

s

PREHEAT

60 to 180 SEC.

t

L

T

L

T

smax

T

smin

25

T

p

TIME

TEMPERA

TURE

NOTES:

THE TIME FROM 25 ∞C to PEAK TEMPERATURE = 8 MINUTES MAX.

T

smax

= 200 ∞C, T

smin

= 150 ∞C

5

IEC/EN/DIN EN 60747-5-2 Insulation Related Characteristics (Option 060)

HCPL-7710

HCPL-0710

Description

Symbol

Option 060

Option 060

Units

Installation classification per DIN VDE 0110/1.89, Table 1

for rated mains voltage

150 V rms

I-IV

I-IV

for rated mains voltage

300 V rms

I-IV

I-III

for rated mains voltage

450 V rms

I-III

Climatic Classification

55/100/21

55/100/21

Pollution Degree (DIN VDE 0110/1.89)

2

2

Maximum Working Insulation Voltage

V

IORM

630

560

V peak

Input to Output Test Voltage, Method b

V

PR

1181

1050

V peak

V

IORM

x 1.875 = V

PR

, 100% Production

Test with t

m

= 1 sec, Partial Discharge < 5 pC

Input to Output Test Voltage, Method a

V

PR

945

840

V peak

V

IORM

x 1.5 = V

PR

, Type and Sample Test,

t

m

= 60 sec, Partial Discharge < 5 pC

Highest Allowable Overvoltage

V

IOTM

6000

4000

V peak

(Transient Overvoltage, t

ini

= 10 sec)

Safety Limiting Values

(Maximum values allowed in the event of a failure,

also see Thermal Derating curve, Figure 11.)

Case Temperature

T

S

175

150

∞

C

Input Current

I

S,INPUT

230

150

mA

Output Power

P

S,OUTPUT

600

600

mW

Insulation Resistance at T

S

, V

10

= 500 V

R

IO

10

9

10

9

Refer to the front of the optocoupler section of the Isolation and Control Component Designer's Catalog, under Product Safety Regulations section

IEC/EN/DIN EN 60747-5-2, for a detailed description.

Note: These optocouplers are suitable for "safe electrical isolation" only within the safety limit data. Maintenance of the safety data shall be ensured

by means of protective circuits.

Note: The surface mount classification is Class A in accordance with CECC 00802.

Absolute Maximum Ratings

Parameter

Symbol

Min.

Max.

Units

Figure

Storage Temperature

T

S

≠55

125

∞

C

Ambient Operating Temperature

T

A

≠40

+100

∞

C

Supply Voltages

V

DD1

, V

DD2

0

6.0

Volts

Input Voltage

V

I

≠0.5

V

DD1

+0.5

Volts

Output Voltage

V

O

≠0.5

V

DD2

+0.5

Volts

Input Current

I

I

≠10

+10

mA

Average Output Current

I

O

10

mA

Lead Solder Temperature

260

∞

C for 10 sec., 1.6 mm below seating plane

Solder Reflow Temperature Profile

See Solder Reflow Temperature Profile Section

Recommended Operating Conditions

Parameter

Symbol

Min.

Max.

Units

Figure

Ambient Operating Temperature

T

A

≠40

+100

∞

C

Supply Voltages

V

DD1

, V

DD2

4.5

5.5

V

Logic High Input Voltage

V

IH

2.0

V

DD1

V

1, 2

Logic Low Input Voltage

V

IL

0.0

0.8

V

Input Signal Rise and Fall Times

t

r

, t

f

1.0

ms