| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HCPL-7800 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1-216

H

High CMR Isolation Amplifiers

Technical Data

HCPL-7800

HCPL-7800A

HCPL-7800B

applications, we recommend the

HCPL-7800 which exhibits a

part-to-part gain tolerance of

±

5%. For precision applications,

HP offers the HCPL-7800A and

HCPL-7800B, each with part-to-

part gain tolerances of

±

1%.

The HCPL-7800 utilizes sigma-

delta (

) analog-to-digital

converter technology, chopper

stabilized amplifiers, and a fully

differential circuit topology

fabricated using HP's 1

µ

m

CMOS IC process. The part also

couples our high-efficiency, high-

speed AlGaAs LED to a high-

speed, noise-shielded detector

∑ Switch-Mode Power Supply

Signal Isolation

∑ General Purpose Analog

Signal Isolation

∑ Transducer Isolation

Description

The HCPL-7800 high CMR

isolation amplifier provides a

unique combination of features

ideally suited for motor control

circuit designers. The product

provides the precision and

stability needed to accurately

monitor motor current in high-

noise motor control environ-

ments, providing for smoother

control (less "torque ripple") in

various types of motor control

applications.

This product paves the way for a

smaller, lighter, easier to produce,

high noise rejection, low cost

solution to motor current

sensing. The product can also be

used for general analog signal

isolation applications requiring

high accuracy, stability and

linearity under similarly severe

noise conditions. For general

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

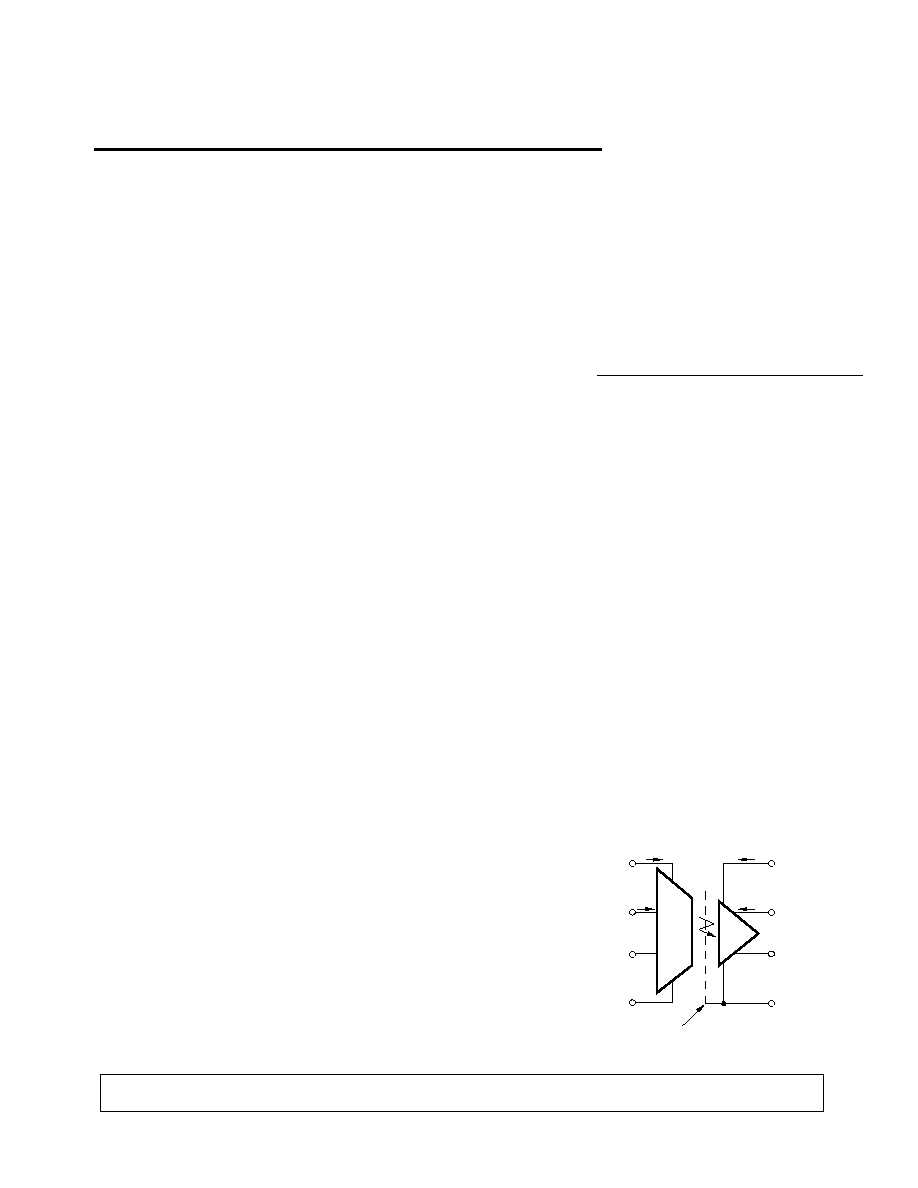

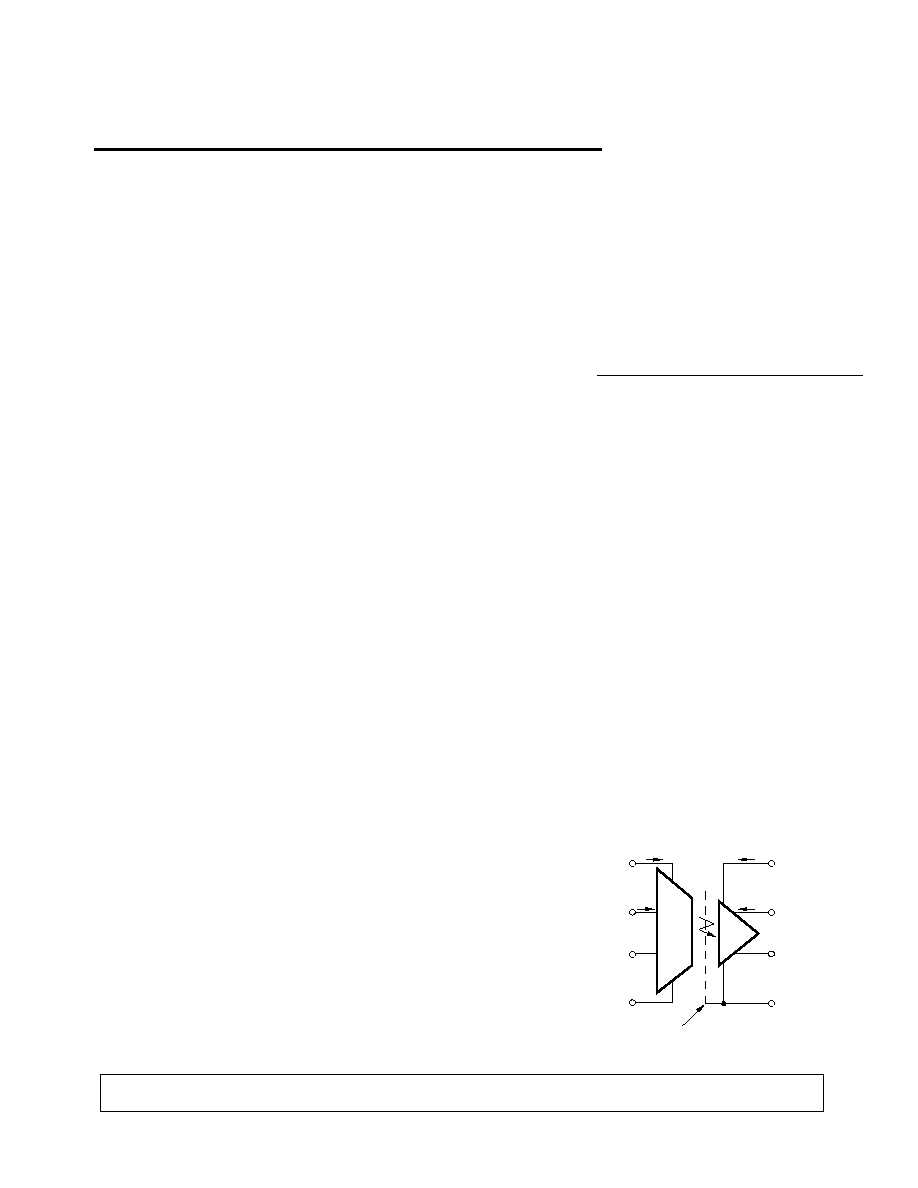

Functional Diagram

Features

∑ 15 kV/

µ

s Common-Mode

Rejection at V

CM

= 1000 V*

∑ Compact, Auto-Insertable

Standard 8-pin DIP Package

∑ 4.6

µ

V/

∞

C Offset Drift vs.

Temperature

∑ 0.9 mV Input Offset Voltage

∑ 85 kHz Bandwidth

∑ 0.1% Nonlinearity

∑ Worldwide Safety Approval:

UL 1577 (3750 V rms/1 min),

VDE 0884 and CSA

∑ Advanced Sigma-Delta (

)

A/D Converter Technology

∑ Fully Differential Circuit

Topology

∑ 1

µ

m CMOS IC Technology

Applications

∑ Motor Phase Current

Sensing

∑ General Purpose Current

Sensing

∑ High-Voltage Power Source

Voltage Monitoring

*The terms common-mode rejection

(CMR) and isolation-mode rejection (IMR)

are used interchangeably throughout this

data sheet.

1

2

3

4

8

7

6

5

V

DD1

V

IN+

V

IN-

GND1

V

DD2

V

OUT+

V

OUT-

GND2

CMR SHIELD

I

DD1

I

DD2

I

IN

I

O

+

+

-

-

5965-3592E

1-217

Ordering Information:

HCPL-7800x

No Specifier =

±

5% Gain Tol.; Mean Gain Value = 8.00

A =

±

1% Gain Tol.; Mean Gain Value = 7.93

B =

±

1% Gain Tol.; Mean Gain Value = 8.07

Option yyy

300 = Gull Wing Surface Mount Lead Option

500 = Tape/Reel Package Option (1 k min.)

Option datasheets available. Contact your Hewlett-Packard sales representative or authorized distributor for

information.

using our patented "light-pipe"

optocoupler packaging

technology.

Together, these features deliver

unequaled isolation-mode noise

rejection, as well as excellent

offset and gain accuracy and

stability over time and tempera-

ture. This performance is

delivered in a compact, auto-

insertable, industry standard 8-

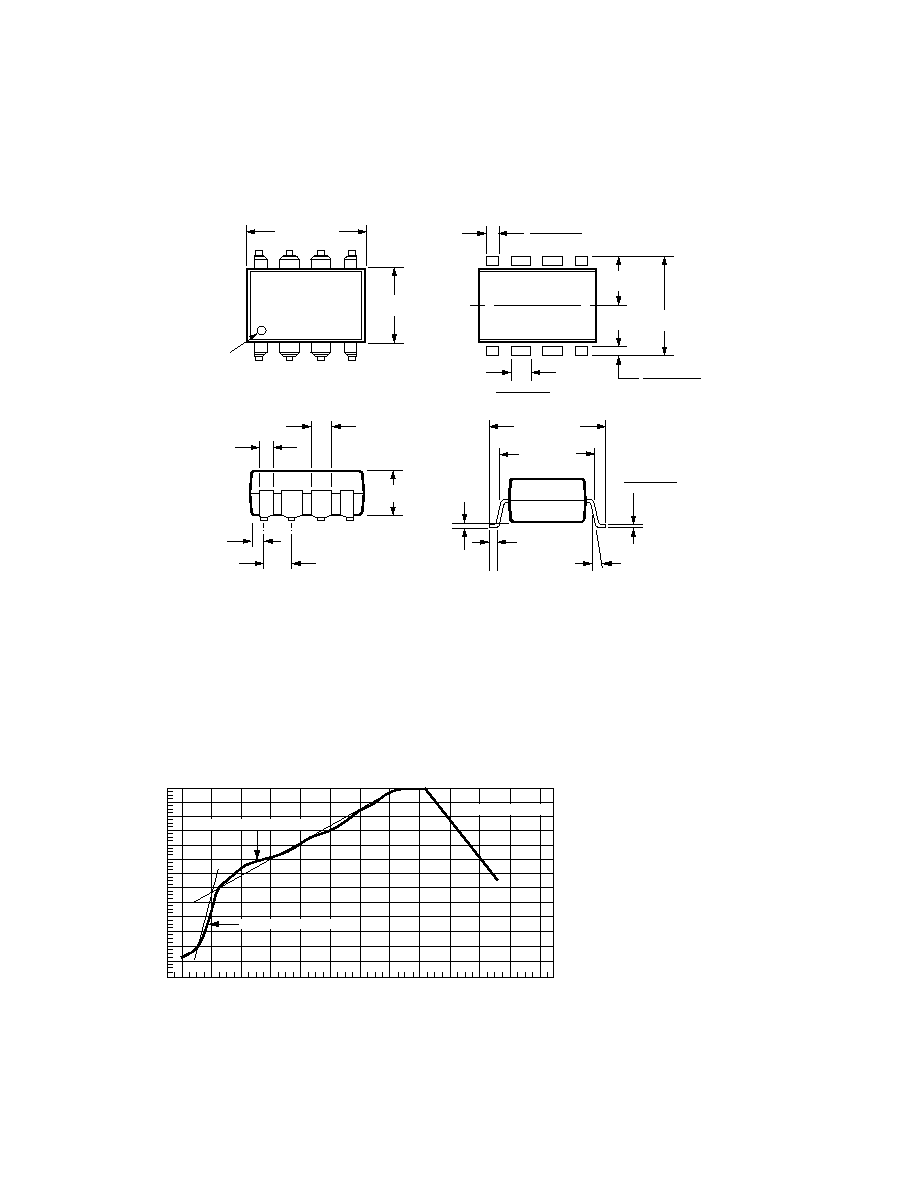

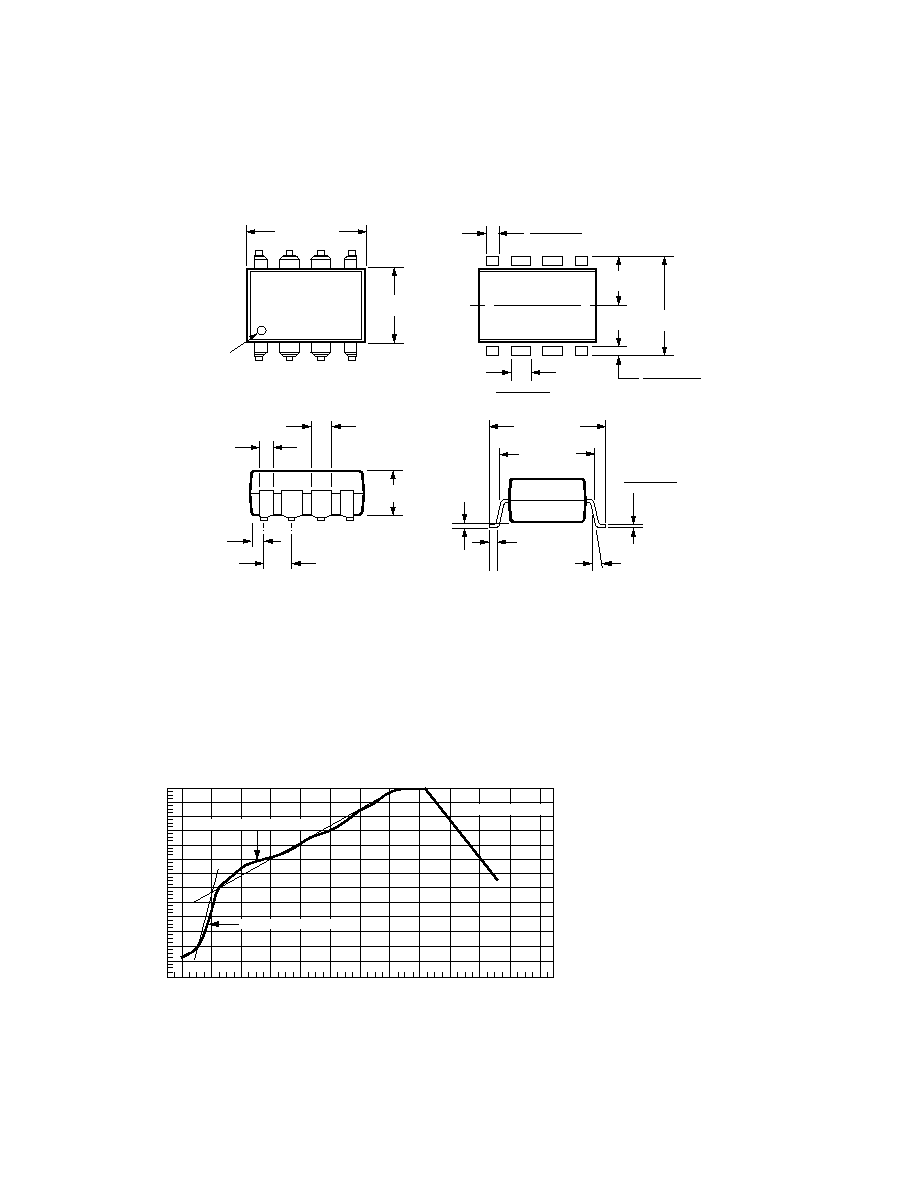

Package Outline Drawings

Standard DIP Package

pin DIP package that meets

worldwide regulatory safety

standards (gull-wing surface

mount option #300 also

available).

9.40 (0.370)

9.90 (0.390)

PIN ONE

1.78 (0.070) MAX.

1.19 (0.047) MAX.

HP 7800

YYWW

DATE CODE

0.76 (0.030)

1.24 (0.049)

2.28 (0.090)

2.80 (0.110)

0.51 (0.020) MIN.

0.65 (0.025) MAX.

4.70 (0.185) MAX.

2.92 (0.115) MIN.

6.10 (0.240)

6.60 (0.260)

0.20 (0.008)

0.33 (0.013)

5∞ TYP.

7.36 (0.290)

7.88 (0.310)

* TYPE NUMBER FOR: HCPL-7800 = 7800

1

2

3

4

8

7

6

5

5

6

7

8

4

3

2

1

GND1

VDD1

VIN+

VIN≠

GND2

VDD2

VOUT+

VOUT≠

PIN DIAGRAM

PIN ONE

TYPE NUMBER*

HCPL-7800A = 7800A

HCPL-7800B = 7800B

DIMENSIONS IN MILLIMETERS AND (INCHES).

1-218

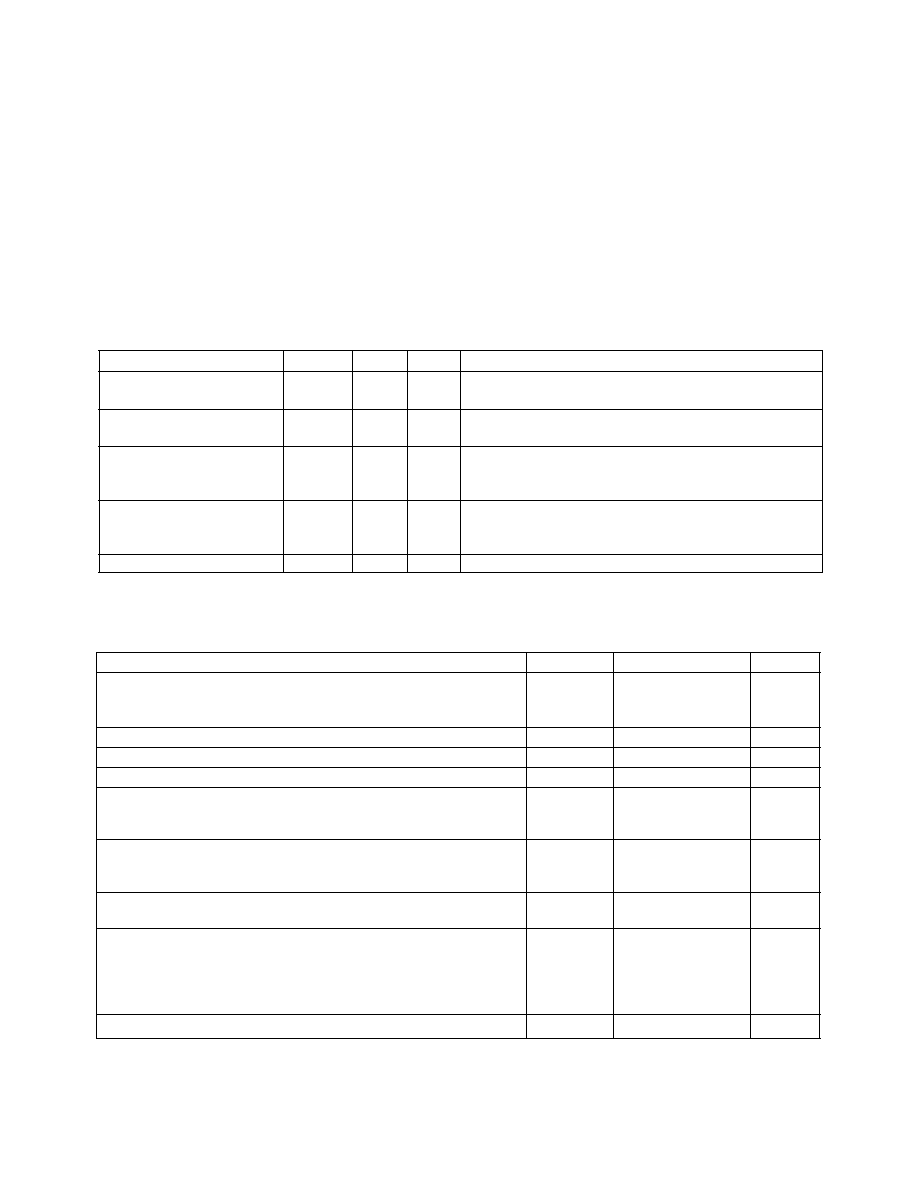

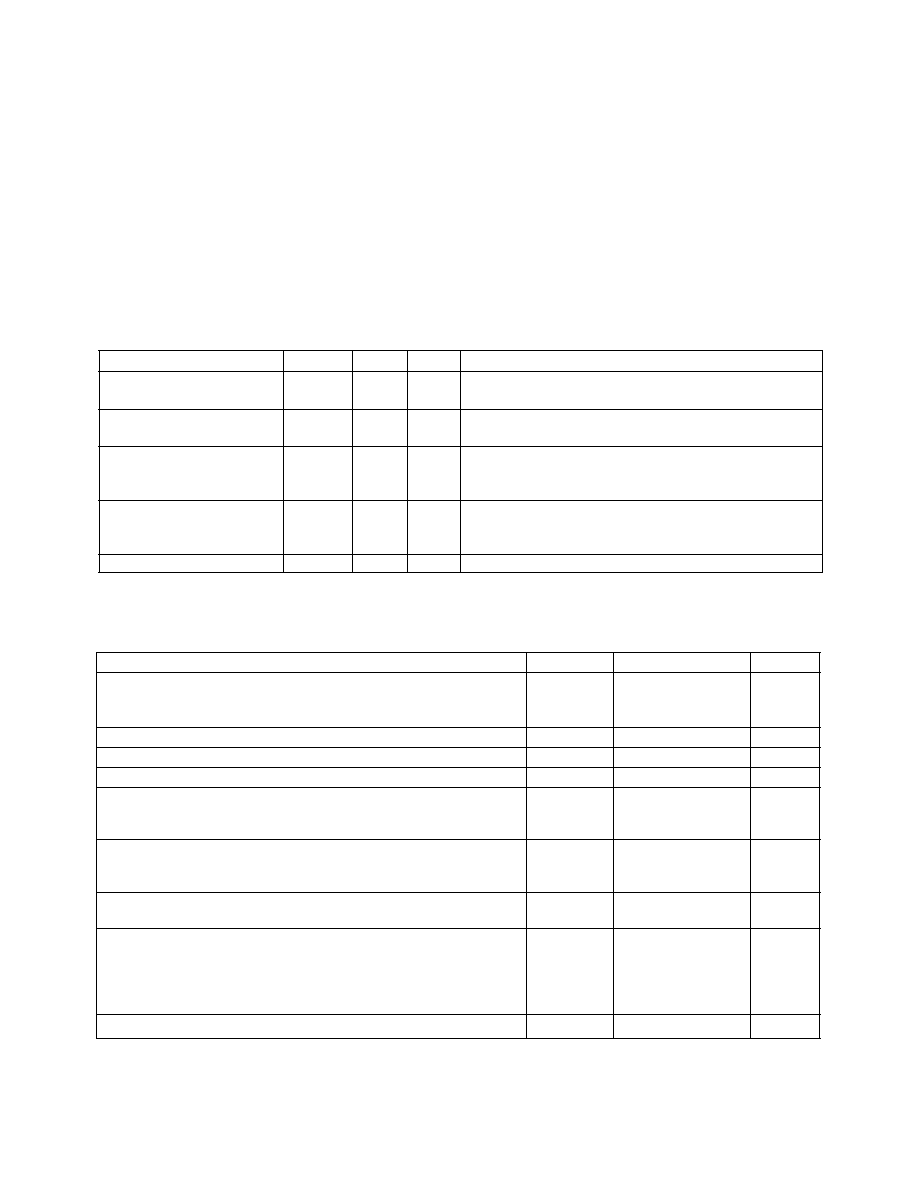

Maximum Solder Reflow Thermal Profile

240

T = 115∞C, 0.3∞C/SEC

0

T = 100∞C, 1.5∞C/SEC

T = 145∞C, 1∞C/SEC

TIME ≠ MINUTES

TEMPERATURE ≠ ∞C

220

200

180

160

140

120

100

80

60

40

20

0

260

1

2

3

4

5

6

7

8

9

10

11

12

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

Gull Wing Surface Mount Option 300*

0.635 ± 0.25

(0.025 ± 0.010)

12∞ NOM.

0.20 (0.008)

0.33 (0.013)

9.65 ± 0.25

(0.380 ± 0.010)

0.51 ± 0.130

(0.020 ± 0.005)

7.62 ± 0.25

(0.300 ± 0.010)

5

6

7

8

4

3

2

1

9.65 ± 0.25

(0.380 ± 0.010)

6.350 ± 0.25

(0.250 ± 0.010)

1.02 (0.040)

1.19 (0.047)

1.19 (0.047)

1.78 (0.070)

9.65 ± 0.25

(0.380 ± 0.010)

4.83

(0.190)

TYP.

0.380 (0.015)

0.635 (0.025)

PIN LOCATION (FOR REFERENCE ONLY)

1.080 ± 0.320

(0.043 ± 0.013)

4.19

(0.165)

MAX.

1.780

(0.070)

MAX.

1.19

(0.047)

MAX.

2.540

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES (UNLESS OTHERWISE SPECIFIED):

* REFER TO OPTION 300 DATA SHEET FOR MORE INFORMATION.

xx.xx = 0.01

xx.xxx = 0.005

HP 7800

YYWW

MOLDED

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

1-219

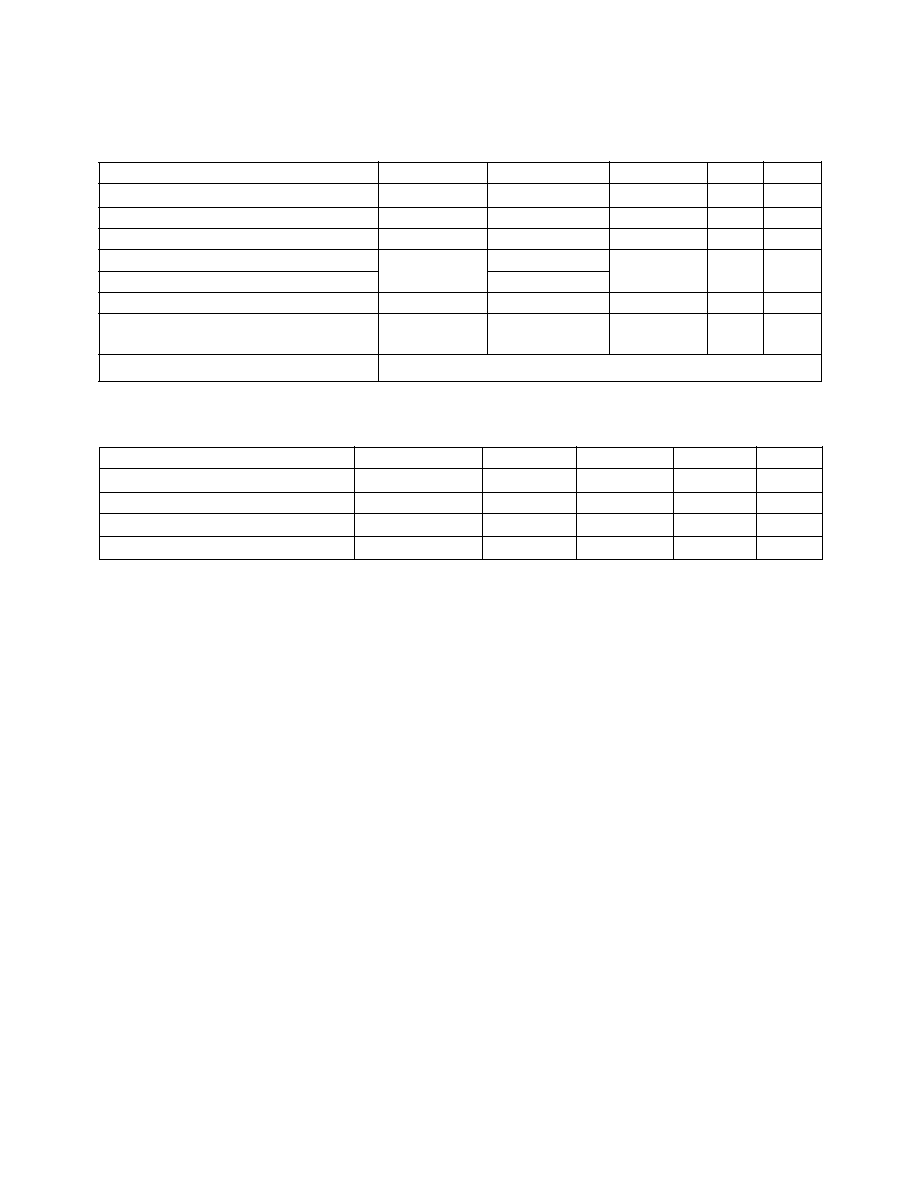

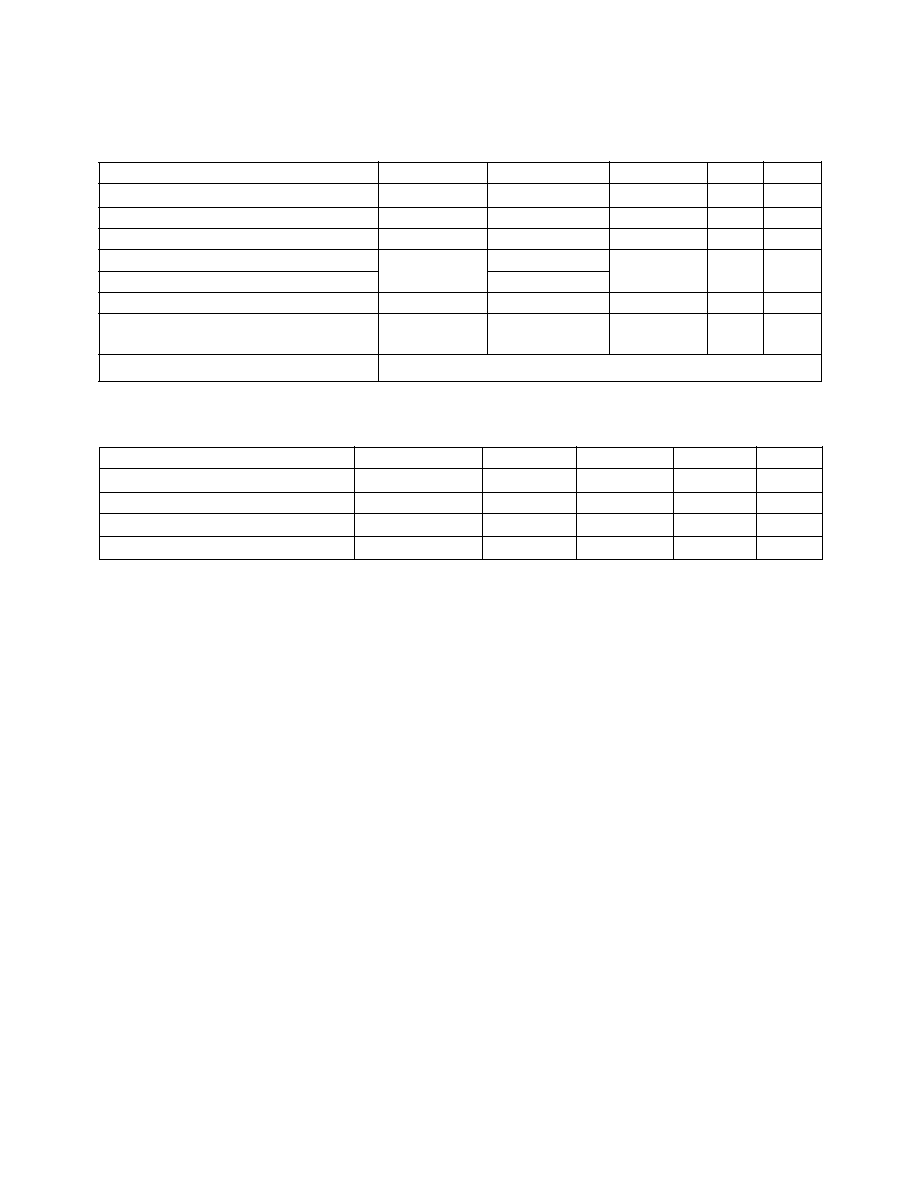

VDE 0884 (06.92) Insulation Characteristics

Description

Symbol

Characteristic

Unit

Installation classification per DIN VDE 0110, Table 1

for rated mains voltage

300 V rms

I-IV

for rated mains voltage

600 V rms

I-III

Climatic Classification

40/100/21

Pollution Degree (DIN VDE 0110, Table 1)*

2

Maximum Working Insulation Voltage

V

IORM

848

V

peak

Input to Output Test Voltage, Method b**

V

PR

1591

V

peak

V

PR

= 1.875 x V

IORM

, Production test with t

p

= 1 sec,

Partial discharge < 5 pC

Input to Output Test Voltage, Method a**

V

PR

1273

V

peak

V

PR

= 1.5 x V

IORM

, Type and sample test with t

p

= 60 sec,

Partial discharge < 5 pC

Highest Allowable Overvoltage**

(Transient Overvoltage t

TR

= 10 sec)

V

TR

6000

V

peak

Safety-limiting values (Maximum values allowed in the event

of a failure, also see Figure 27)

Case Temperature

T

S

175

∞

C

Input Power

P

S,Input

80

mW

Output Power

P

S,Output

250

mW

Insulation Resistance at T

S

, V

IO

= 500 V

R

S

1x10

12

*This part may also be used in Pollution Degree 3 environments where the rated mains voltage is

300 V rms (per DIN VDE 0110).

**Refer to the front of the optocoupler section of the current catalog for a more detailed description of VDE 0884 and other product

safety requirements.

Note: Optocouplers providing safe electrical separation per VDE 0884 do so only within the safety-limiting values to which they are

qualified. Protective cut-out switches must be used to ensure that the safety limits are not exceeded.

Regulatory Information

The HCPL-7800 has been

approved by the following

organizations:

UL

Recognized under UL 1577,

Component Recognition

Program, File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

Insulation and Safety Related Specifications

Parameter

Symbol

Value Units

Conditions

Min. External Air Gap

L(IO1)

7.4

mm

Measured from input terminals to output terminals,

(External Clearance)

shortest distance through air

Min. External Tracking

L(IO2)

8.0

mm

Measured from input terminals to output terminals,

Path (External Creepage)

shortest distance path along body

Min. Internal Plastic Gap

0.5

mm

Through insulation distance, conductor to conductor,

(Internal Clearance)

usually the direct distance between the photoemitter

and photodetector inside the optocoupler cavity

Tracking Resistance

CTI

175

V

DIN IEC 112/VDE 0303 Part 1

(Comparative Tracking

Index)

Isolation Group

III a

Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 ≠ surface mount classification is Class A in accordance with CECC 00802.

VDE

Approved according to VDE

0884/06.92.

1-220

Absolute Maximum Ratings

Parameter

Symbol

Min.

Max.

Unit

Note

Storage Temperature

T

S

-55

125

∞

C

Ambient Operating Temperature

T

A

-

40

100

∞

C

Supply Voltages

V

DD1

, V

DD2

0.0

5.5

V

Steady-State Input Voltage

V

IN+

, V

IN-

-2.0

V

DD1

+0.5

V

Two Second Transient Input Voltage

-6.0

Output Voltages

V

OUT+

, V

OUT-

-0.5

V

DD2

+0.5

V

Lead Solder Temperature

T

LS

260

∞

C

1

(1.6 mm below seating plane, 10 sec.)

Reflow Temperature Profile

See Package Outline Drawings Section

Recommended Operating Conditions

Parameter

Symbol

Min.

Max.

Unit

Note

Ambient Operating Temperature

T

A

-40

85

∞

C

2

Supply Voltages

V

DD1

, V

DD2

4.5

5.5

V

3

Input Voltage

V

IN+

, V

IN-

-200

200

mV

4

Output Current

|I

O

|

1

mA

5