| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HSMB-C190 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Surface Mount Chip LEDs

Technical Data

HSMB-C190/C170/

C110/C150

Features

∑ Small Size

∑ Industry Standard Footprint

∑ Compatible with IR Solder

∑ Diffused Optics

∑ Operating Temperature

Range of -30

∞

C to +85

∞

C

∑ Right Angle Package

Available

∑ SiC Blue Color

∑ Available in 8 mm tape on 7"

(178 mm) Diameter Reels

Applications

∑ Keypad Backlighting

∑ Push-Button Backlighting

∑ LCD Backlighting

∑ Symbol Backlighting

∑ Front Panel Indicator

Description

These Blue chip LEDs are

designed in an industry standard

package for ease of handling

and use. Blue color chip LED is a

new product that offers color

differentiation for backlighting

applications.

The HSMB-C150 has the industry

standard 3.2 x 1.6 mm footprint

that is excellent for all around use.

The HSMB-C170 has the widely

used 2.0 x 1.25 mm footprint. The

HSMB-C190 has the industry

standard 1.6 x 0.8 mm footprint,

its low 0.8 mm profile and wide

viewing angle make this LED

exceptional for backlighting

applications.

The HSMB-C110 is a right-angle

package with the universally

accepted dimensions of 3.2 x 1.0

Footprint (mm)

SiC Blue

Parts Per Reel

2.00 x 1.25

HSMB-C170

4000

1.60 x 0.80

HSMB-C190

4000

3.20 x 1.00

[1]

HSMB-C110

3000

3.20 x 1.60

HSMB-C150

3000

Note:

1. Right-angle package.

x 1.5 mm. This part is ideal for

LCD backlighting and sidelighting

applications.

All packages are compatible with

IR reflow solder processes. The

small size and wide viewing angle

make these LEDs prime choices

for backlighting applications and

front panel illumination especially

where space is a premium.

Device Selection Guide

2

Package Dimensions

HSMB-C190

HSMB-C170

HSMB-C110

1.6

(0.063 )

0.3 (0.012)

0.3 ± 0.15

(0.012 ± 0.006)

0.3 (0.012)

POLARITY

CATHODE

MARK

0.8 (0.031)

0.3 ± 0.15

(0.012 ± 0.006)

1.0

(0.039)

0.4 (0.016)

LED DIE

DIFFUSED EPOXY

PC BOARD

SOLDERING

TERMINAL

0.8 (0.031)

2.0 (0.079 )

0.3 (0.012)

0.4 ± 0.15

(0.016 ± 0.006)

0.3 (0.012)

POLARITY

CATHODE

MARK

0.8 (0.031)

0.4 ± 0.15

(0.016 ± 0.006)

1.4

(0.055)

0.62 (0.024)

LED DIE

DIFFUSED

EPOXY

PC BOARD

SOLDERING

TERMINAL

1.25 (0.049)

3.2 (0.126 )

0.5 (0.020)

1.0 (0.039)

POLARITY

CATHODE

MARK

1.5 (0.059)

LED DIE

CLEAR

EPOXY

PC BOARD

SOLDERING

TERMINAL

1.0 (0.039)

1.0 (0.039)

2.6 (0.102 )

1.6 (0.063 )

CATHODE LINE

NOTE:

1. ALL DIMENSIONS IN MILLIMETERS (INCHES).

2. TOLERANCE IS ± 0.1 mm (± 0.004 IN.) UNLESS OTHERWISE SPECIFIED.

3.2 (0.126 )

0.5 (0.020)

0.50 ± 0.2

(0.020 ± 0.008)

0.6 (0.024)

POLARITY

CATHODE

MARK

1.1 (0.043)

0.50 ± 0.2

(0.020 ± 0.008)

2.0 (0.079)

0.8 (0.031)

LED DIE

DIFFUSED

EPOXY

PC BOARD

SOLDERING

TERMINAL

1.6 (0.063)

HSMB-C150

3

Absolute Maximum Ratings at T

A

=25

∞

C

Parameter

HSMB-C190/C170/C110/C150

Units

DC Forward Current

[1]

20

mA

Peak Pulsing Current

[2]

100

mA

Power Dissipation

92

mW

Reverse Voltage (I

R

= 100

µ

A)

5

V

Maximum LED Junction Temperature

95

∞

C

Operating Temperature Range

-30 to +85

∞

C

Storage Temperature Range

-40 to +85

∞

C

Soldering Temperature

See IR soldering profile (Figure 7)

Notes:

1. Derate linearly as shown in Figure 4 for temperature above 25

∞

C.

2. Pulse condition of 1/10 duty and 0.1 msec. width.

Optical Characteristics at T

A

=25

∞

C

Luminous

Peak

Dominant

Viewing

Intensity

[1]

Wavelength

Wavelength

Angle 2

1/2

Part No.

Color

I

v

(mcd) @ 20 mA

peak

(nm)

d

(nm)

(degrees)

[2]

Min.

Typ.

Typ.

Typ.

Typ.

HSMB-

SiC Blue

1.60

6.0

428

466

170

C190/C170/C150

HSMB-C110

SiC Blue

1.60

6.5

428

466

130

Notes:

1. The luminous intensity, I

v

, is measured at the peak of the spatial radiation pattern, which may not be aligned with the mechanical

axis of the lamp package.

2.

1/2

is the off-axis angle where the luminous intensity is 1/2 the peak intensity.

Electrical Characteristics at T

A

=25

∞

C

Reverse

Forward Voltage

Breakdown

Thermal

Capacitance C

V

F

(Volts)

V

R

(Volts)

Resistance

(pF) @ V

F

= 0 V,

Part No.

@ I

F

= 20 mA

@ I

R

= 100

µ

A

R

J-P

(

∞

C/W)

f = 1 MHz

Typ.

Max.

Min.

Typ.

Typ.

HSMB-C190/C170/C150

3.8

4.6

5

300

67

HSMB-C110

3.8

4.6

5

300

67

4

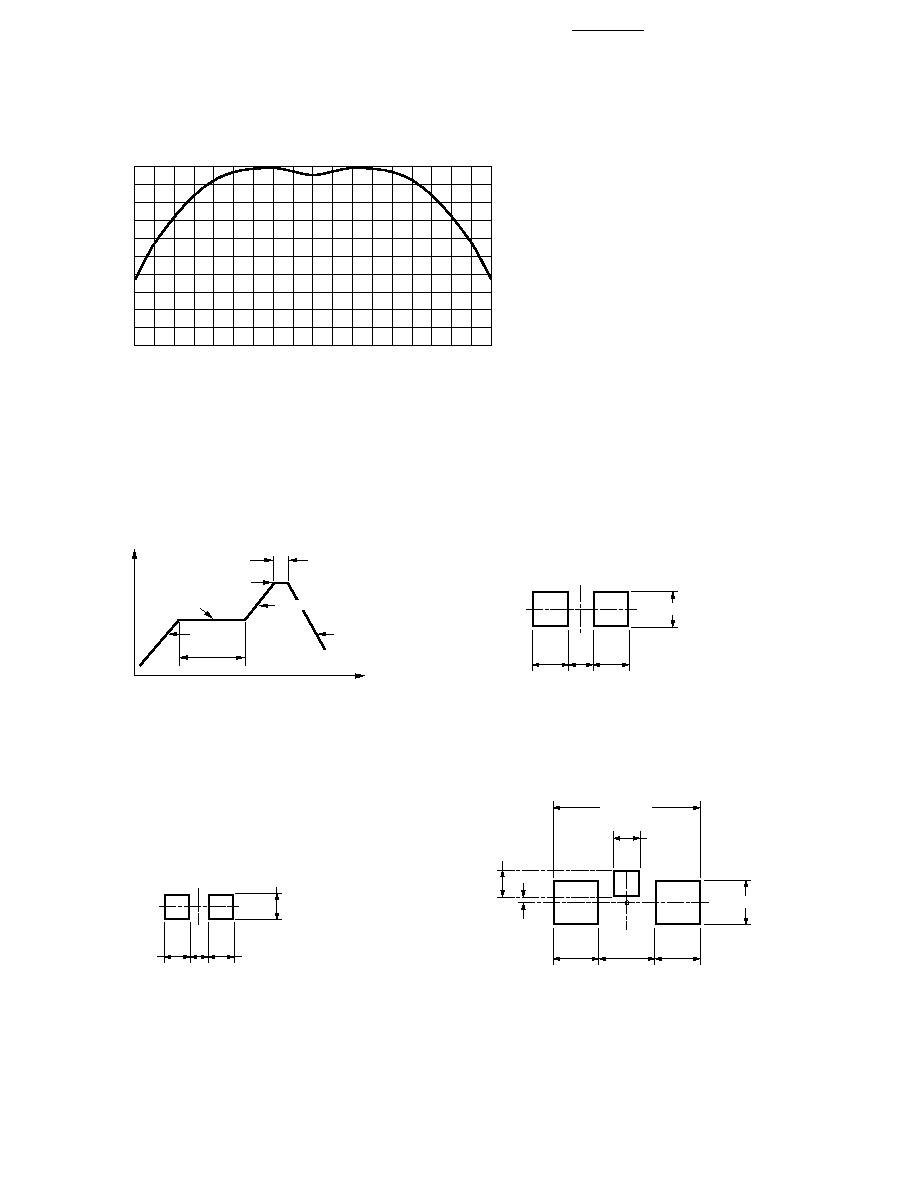

Figure 1. Relative Intensity vs.

Wavelength.

Figure 3. Relative Luminous Intensity

vs. Forward Current.

Figure 4. Maximum Forward Current

vs. Ambient Temperature.

Figure 5. Relative Intensity vs. Angle for HSMB-C110.

Figure 2. Forward Current vs.

Forward Voltage.

100

10

1

0.1

3.0

3.2

3.6

3.8

4.0

VF ≠ FORWARD VOLTAGE ≠ V

I F

≠ FORWARD CURRENT ≠ mA

3.4

0

5

15

25

IF ≠ FORWARD CURRENT ≠ mA

0

0.4

1.0

1.2

RELATIVE LUMINOUS INTENSITY

(NORMALIZED AT 20 mA)

20

0.6

0.2

0.8

10

0

25

0

20

60

80

100

5

I F MAX.

≠ MAXIMUM FORWARD CURRENT ≠ mA

TA ≠ AMBIENT TEMPERATURE ≠ ∞C

40

15

10

20

380

100

0

580

680

20

RELATIVE INTENSITY ≠ %

WAVELENGTH ≠ nm

480

60

40

80

RELATIVE INTENSITY ≠ %

100

0

ANGLE

80

60

50

70

20

10

30

40

90

-70

-50

-30

0

20 30

50

70

90

-90

-20

-80

-60

-40

-10

10

40

60

80

RELATIVE INTENSITY ≠ %

100

0

ANGLE

80

60

50

70

20

10

30

40

90

-70

-50

-30

0

20 30

50

70

90

-90

-20

-80

-60

-40

-10

10

40

60

80

5

Figure 6. Relative Intensity vs. Angle for HSMB-C170, HSMB-C190, and

HSMB-C150.

Figure 8. Recommended Soldering Pattern for

HSMB-C170.

Figure 9. Recommended Soldering Pattern for

HSMB-C190.

Figure 10. Recommended Soldering Pattern for

HSMB-C110.

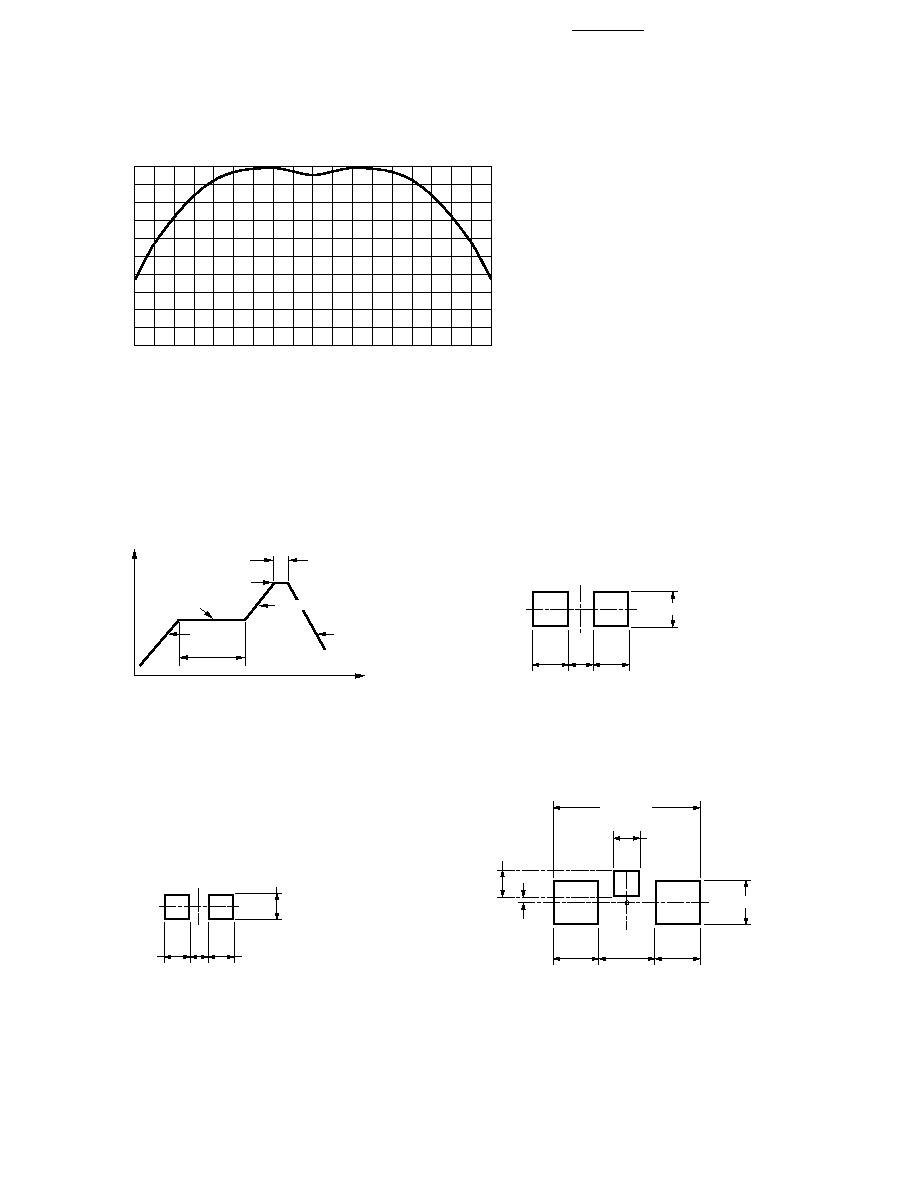

Figure 7. Recommended Reflow Soldering Profile.

Note:

1. All dimensions in millimeters (inches).

230∞C MAX.

10 SEC. MAX.

4∞C/SEC.

MAX.

OVER 2 MIN.

TIME

TEMPERATURE

4∞C/SEC. MAX.

140-160∞C

≠3∞C/SEC. MAX.

1.2 (0.047)

1.2

(0.047)

0.9

(0.035)

1.2

(0.047)

0.8 (0.031)

0.8

(0.031)

0.7

(0.028)

0.8

(0.031)

5.0 (0.200)

1.5 (0.059)

1.5

(0.059)

1.5

(0.059)

2.0

(0.079)

0.9 (0.035)

0.2 (0.008)

0.9 (0.035)

RELATIVE INTENSITY ≠ %

100

0

ANGLE

80

60

50

70

20

10

30

40

90

-70

-50

-30

0

20 30

50

70

90

-90

-20

-80

-60

-40

-10

10

40

60

80