1-441

60 V/0.7 Ohm,

General Purpose, 1 Form A,

Solid State Relay

Technical Data

HSSR-8060

· Telecommunication

Switching Equipment

· Reed Relay Replacement

· 28 Vdc, 24 Vac, 48 Vdc Load

Driver

· Industrial Relay Coil Driver

Description

The HSSR-8060 consists of a

high-voltage circuit, optically

coupled with a light emitting

diode (LED). This device is a

solid-state replacement for single-

pole, normally-open (1 Form A)

electromechanical relays used for

general purpose switching of

signals and low-power loads. The

relay turns on (contact closes)

with a minimum input current, I

F

,

of 5 mA through the input LED.

The relay turns off (contact

opens) with an input voltage, V

F

,

of 0.8 V or less. The detector

contains a high speed photosensi-

tive FET driver circuit and two

high voltage MOSFETs.

This relay's logic level input con-

trol and very low typical output

on-resistance of 0.4

makes it

suitable for both ac and dc loads.

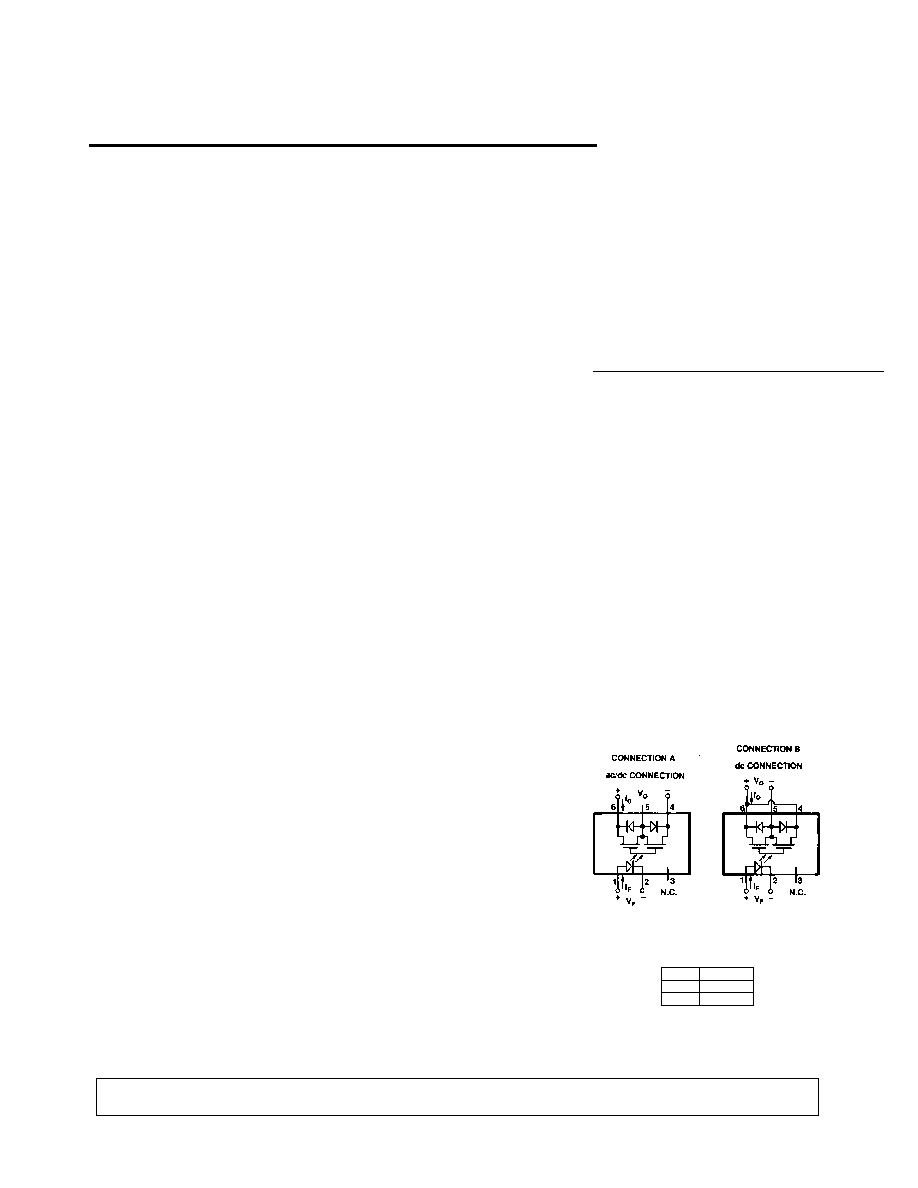

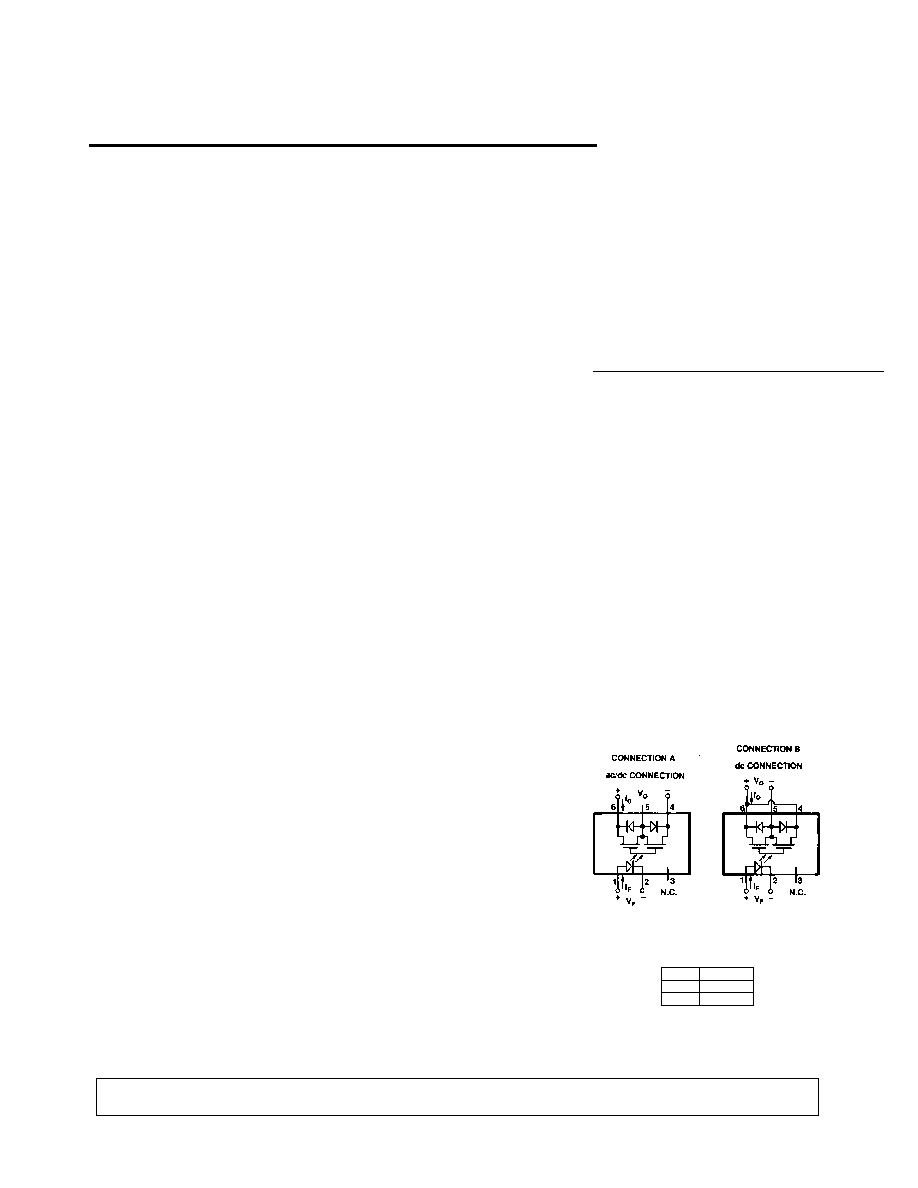

Connection A, as shown in the

schematic, allows the relay to

switch either ac or dc loads.

Connection B, with the polarity

and pin configuration as indicated

in the schematic, allows the relay

to switch dc loads only. The

advantage of Connection B is that

the on-resistance is significantly

reduced, and the output current

capability increases by a factor of

two.

The electrical and switching char-

acteristics of the HSSR-8060 are

specified from -40

°

C to +85

°

C.

Features

· Compact Solid-State

Bidirectional Switch

· Normally-Off Single-Pole

Relay Function (1 Form A)

· 60 V Output Withstand

Voltage in Both Polarities at

25

°

C

· 0.75/1.5 Amp Current

Ratings (See Schematic for

Connections A & B)

· Low Input Current; CMOS

Compatibility

· Very Low On-resistance:

0.4

Typical at 25

°

C

· ac/dc Signal and Power

Switching

· Input-to-Output Momentary

Withstand Insulation

Voltage: 2500 Vac, 1 Minute

· 16-kV ESD Immunity: MIL-

STD-883, Method 3015

· IEEE Surge Withstand

Capability (IEEE STD

472-1974)

· CSA Approved

· UL 508 Approved

Applications

· Programmable Logic

Controllers

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

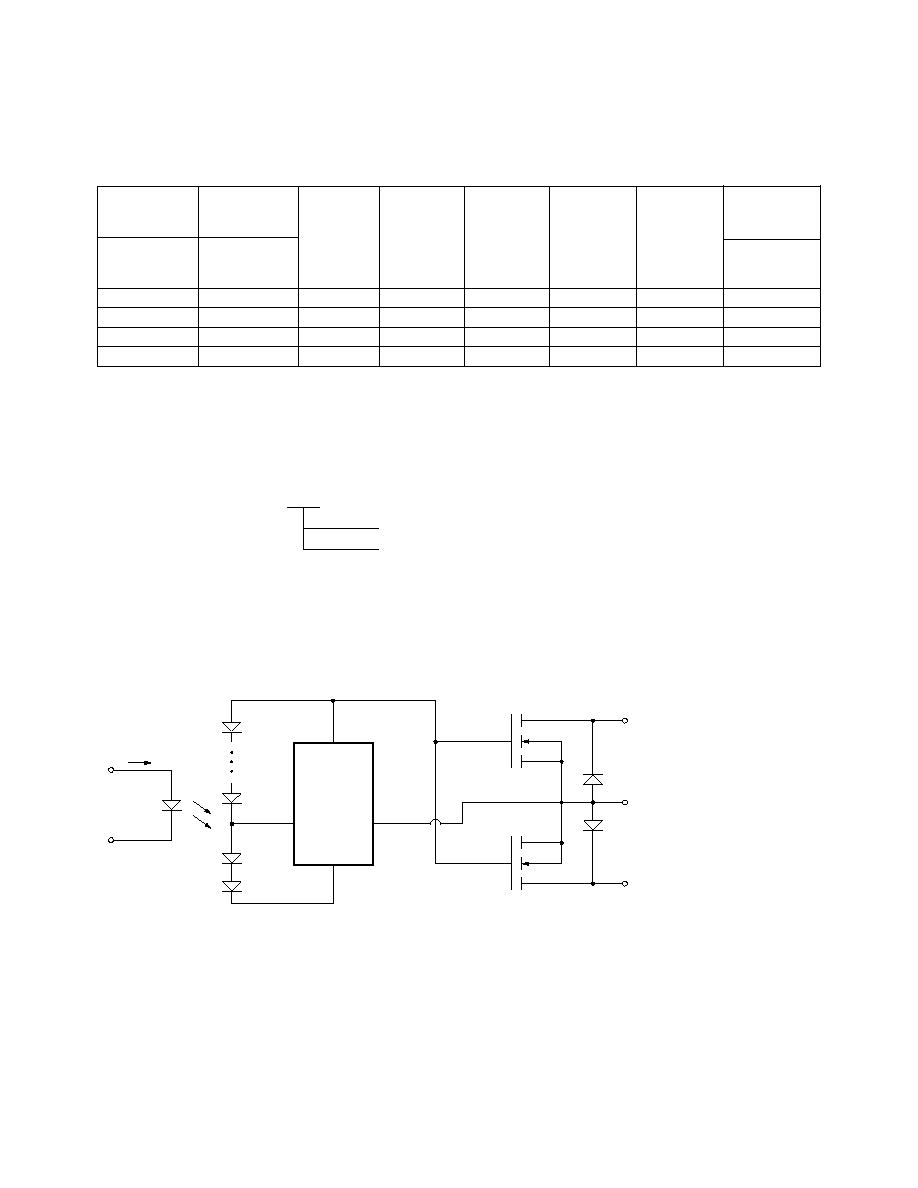

Functional Diagram

TRUTH TABLE

(POSITIVE LOGIC)

LED

ON

OFF

OUTPUT

L

H

H

5965-3575E

1-444

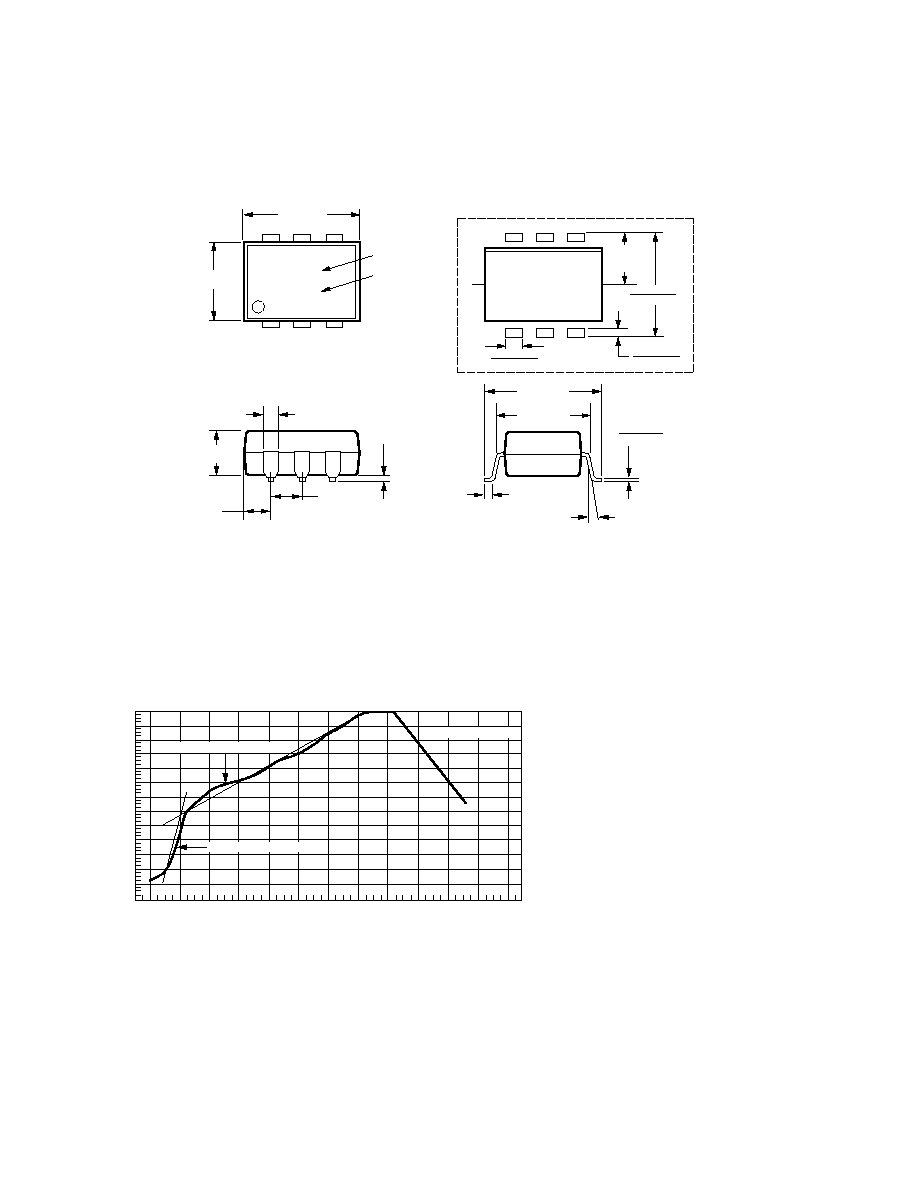

240

T = 115°C, 0.3°C/SEC

0

T = 100°C, 1.5°C/SEC

T = 145°C, 1°C/SEC

TIME MINUTES

TEMPERATURE °C

220

200

180

160

140

120

100

80

60

40

20

0

260

1

2

3

4

5

6

7

8

9

10

11

12

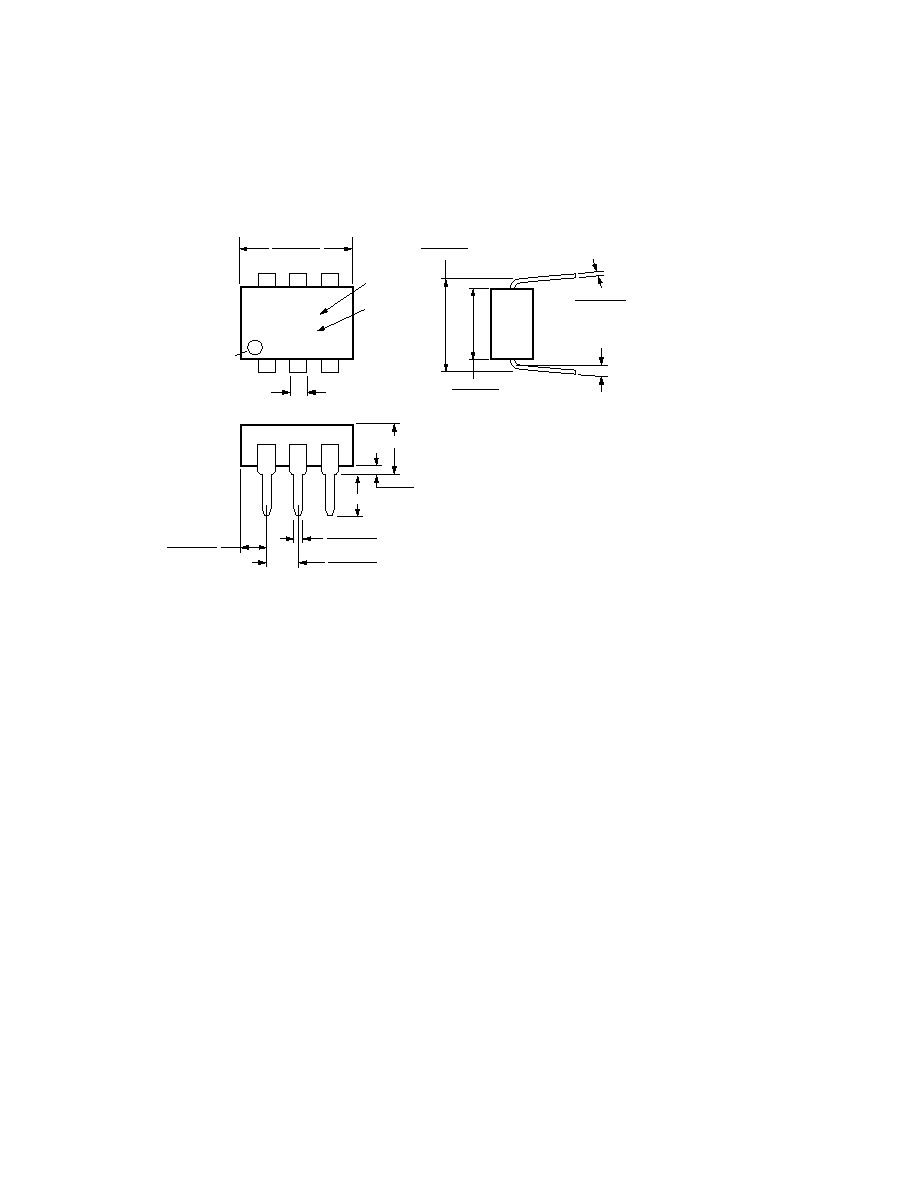

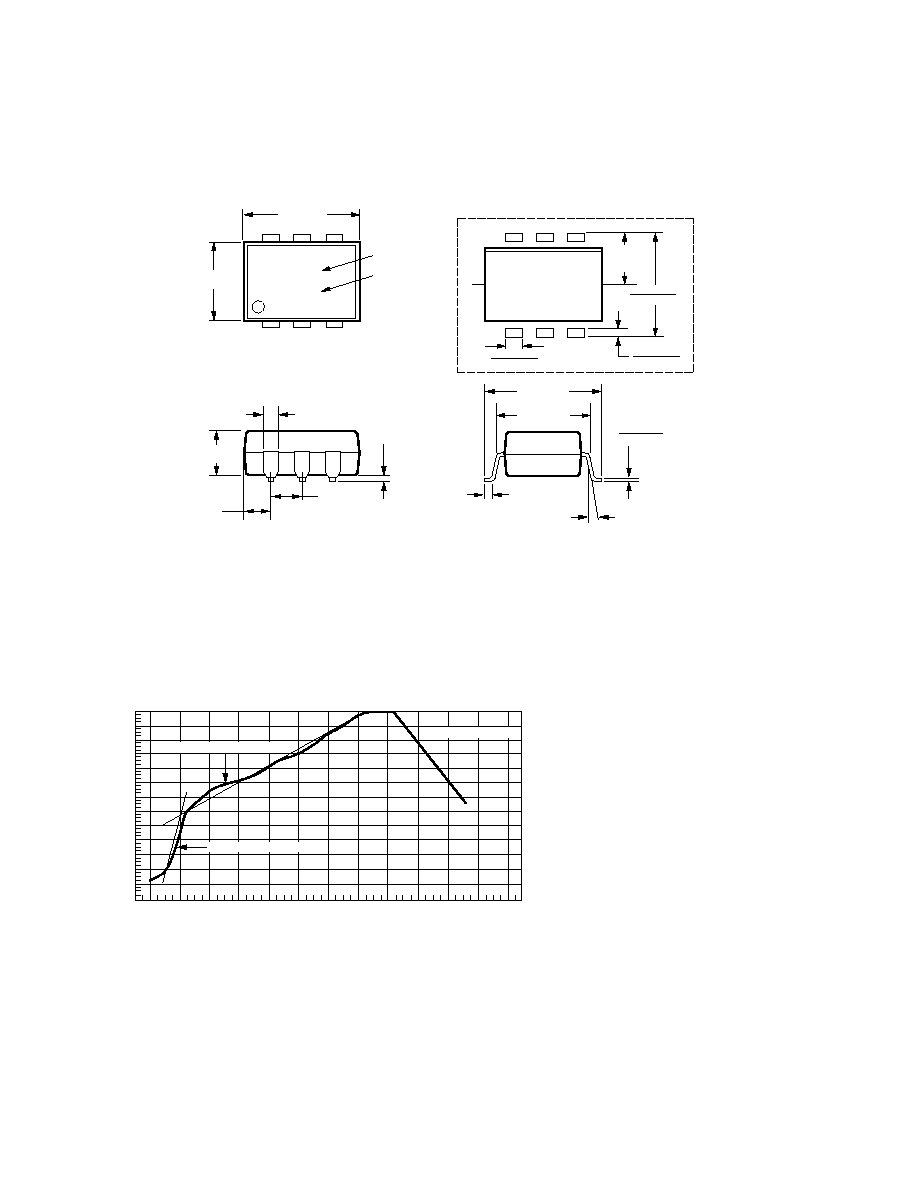

6-Pin Device Outline Drawing Option #300 (Gull Wing Surface Mount)

Thermal Profile (Option #300)

Regulatory Information

The HSSR-8060 has been

approved by the following

organizations:

UL

Recognized under UL 508,

Component Recognition Program,

Industrial Control Switches, File

E142465.

CSA

Approved under CAN/CSA-C22.2

No. 14-95, Industrial Control

Equipment, File LR 87683.

Figure 1. Maximum Solder Reflow Thermal Profile.

(Note: Use of non-chlorine activated fluxes is recommended.)

4.19

(0.165)

2.29

(0.090)

2.54

(0.100)

TYP.

0.635 ± 0.130

(0.025 ± 0.005)

9.65 ± 0.25

(0.380 ± 0.010)

7.62 ± 0.25

(0.300 ± 0.010)

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

0.20 (0.008)

0.30 (0.013)

1.78

(0.070)

MAX.

9.65 ± 0.25

(0.380 ± 0.010)

6.35 ± 0.25

(0.250 ± 0.010)

DIMENSIONS IN mm (INCHES)

TOLERANCES: xx.xx = 0.01

xx.xxx = 0.001

(unless otherwise specified)

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

[3] [5]

1.194 (0.047)

1.778 (0.070)

4.826

(0.190)

TYP.

9.398 (0.370)

9.906 (0.390)

MAX.

PAD LOCATION (FOR REFERENCE ONLY)

0.381 (0.015)

0.635 (0.025)

HP RXXXX

YYWW

TYPE NUMBER

DATE CODE

1-445

Insulation and Safety Related Specifications

Parameter

Symbol

Value

Units

Conditions

Min. External Air Gap

L(IO1)

7.0

mm

Measured from input terminals to output

(External Clearance)

terminals, shortest distance through air

Min. External Tracking Path

L(IO2)

8.5

mm

Measured from input terminals to output

(External Creepage)

terminals, shortest distance path along body

Min. Internal Plastic Gap

0.5

mm

Through insulation distance, conductor to

(Internal Clearance)

conductor, usually the direct distance

between the photoemitter and photodetector

inside the optocoupler cavity

Tracking Resistance

CTI

200

V

DIN IEC 112/VDE 0303 PART 1

(Comparative Tracking Index)

Isolation Group

IIIa

Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 surface mount classification is Class A in accordance with CECC 00802.

Absolute Maximum Ratings

Storage Temperature ................................................... -55

°

C to+125

°

C

Operating Temperature - T

A

.......................................... -40

°

C to +85

°

C

Case Temperature - T

C

.......................................................... +105

°

C

[1]

Average Input Current - I

F

............................................................ 20 mA

Repetitive Peak Input Current - I

F

............................................... 40 mA

(Pulse Width

1 ms; duty cycle

50%)

Transient Peak Input Current - I

F

............................................... 100 mA

(Pulse Width

200

µ

s; duty cycle

1%)

Reverse Input Voltage - V

R

................................................................ 3 V

Input Power Dissipation .............................................................. 40 mW

Output Voltage (T

A

= 25

°

C)

Connection A - V

O

......................................................... - 60 to +60 V

Connection B - V

O

............................................................. 0 to +60 V

Average Output Current - Figure 3 (T

A

= 25

°

C, T

C

70

°

C)

Connection A - I

O

..................................................................... 0.75 A

Connection B - I

O

..................................................................... 1.50 A

Single Shot Peak Output Current

(100 ms pulse width, T

A

= 25

°

C, I

F

= 10 mA)

Connection A - I

O

.................................................................... 3.75 A

Connection B - I

O

...................................................................... 7.0 A

Output Power Dissipation ..................................................... 750 mW

[2]

Lead Solder Temperature .... 260

°

C for 10 S (1.6 mm below seating plane)

Infrared and Vapor Phase Reflow Temperature

(Option #300) ......................................... See Fig. 1, Thermal Profile

Thermal Resistance

Typical Output MOSFET Junction

to Case

JC

= 55

°

C/W

Demonstrated ESD

Performance

Human Body Model: MIL-STD-

883 Method 3015.7 - 16 kV

Machine Model: EIAJ 1988.3.28

Version 2), Test Method 20,

Condition C 1200 V

Surge Withstand

Capability

IEEE STD 472-1974