| ÐлекÑÑоннÑй компоненÑ: AS5021-E | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Microsoft Word - AS5021-E_datasheet.doc

Revision December 2002

Page 1 of 8

Key Features

-

2 channel quadrature TTL squarewave outputs (A/B) with

16 pulses per revolution

-

Rotary direction information available

-

Optional 3

rd

channel index (one pulse per revolution)

which is user programmable. This allows cost effective

manufacturing of the encoder system.

-

Rotation speed of magnetic source up to 30,000 rpm

-

Extended temperature range: - 40° C to +125° C

(-40° F to +257° F)

-

System on Chip: Hall effect sensors and signal

processing combined on a single chip

-

Simple permanent magnetic source required

Benefits

-

Non-contact switching providing high reliability and

long mechanical life time. Ideal for electrically isolated

applications.

-

Extremely compact SOIC-8 package

-

Ease of implementation with reduced number of external

components

-

No calibration needed

-

Extremely tolerant to magnetic and harsh environment

-

Tolerant to magnetic source misalignment

Applications

-

Motor control

-

Incremental encoders

-

Precision angular position sensing

-

Angular Speed Sensing

-

Motion control

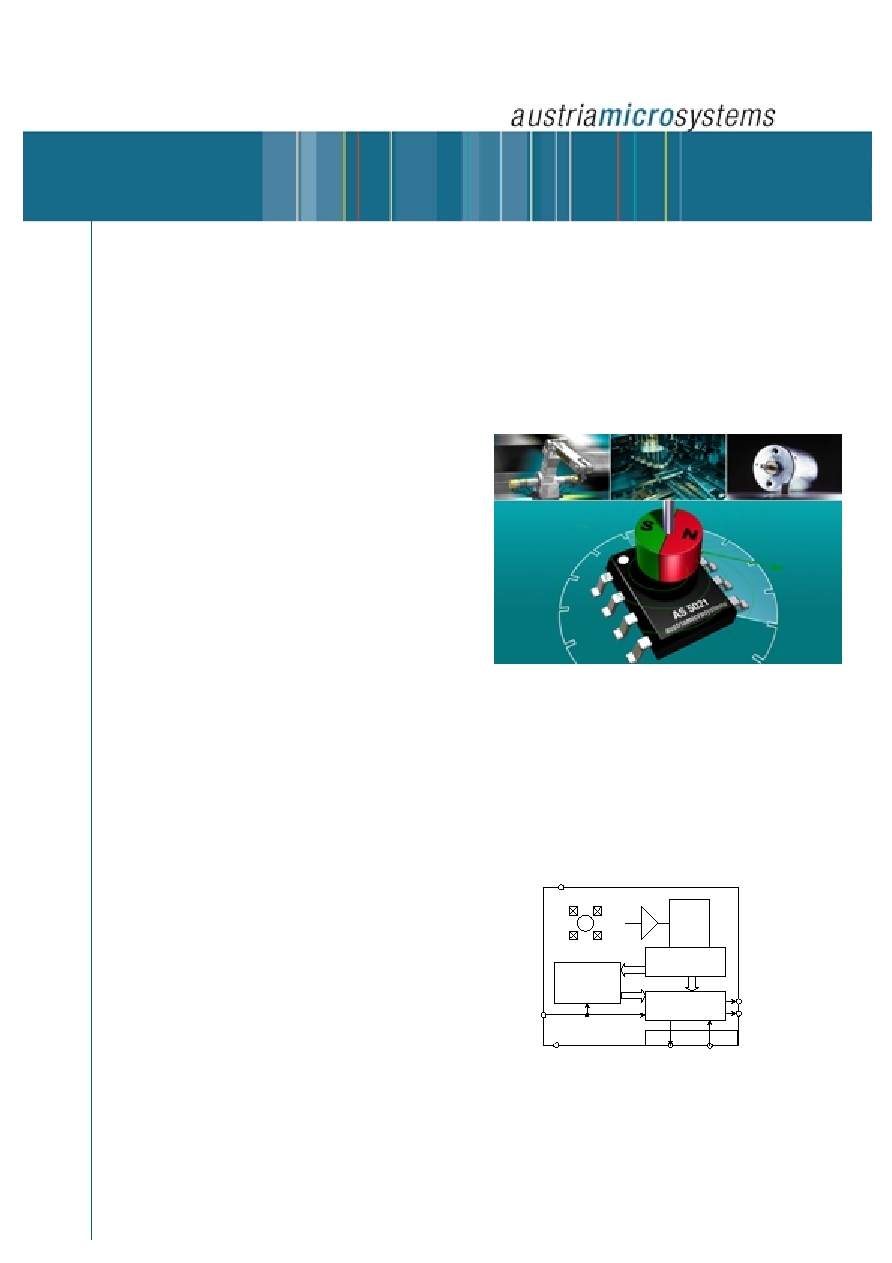

General Description

The AS5021 device provides a 2 x 16 pulse quad A/B signal

within one rotation, encoding 64 state changes. These

incremental steps are encoded by a simple magnet source

that is placed above the device surface. A total of 64

incremental angular positions are available within the full

360° range (typical step size: 5.625° ).

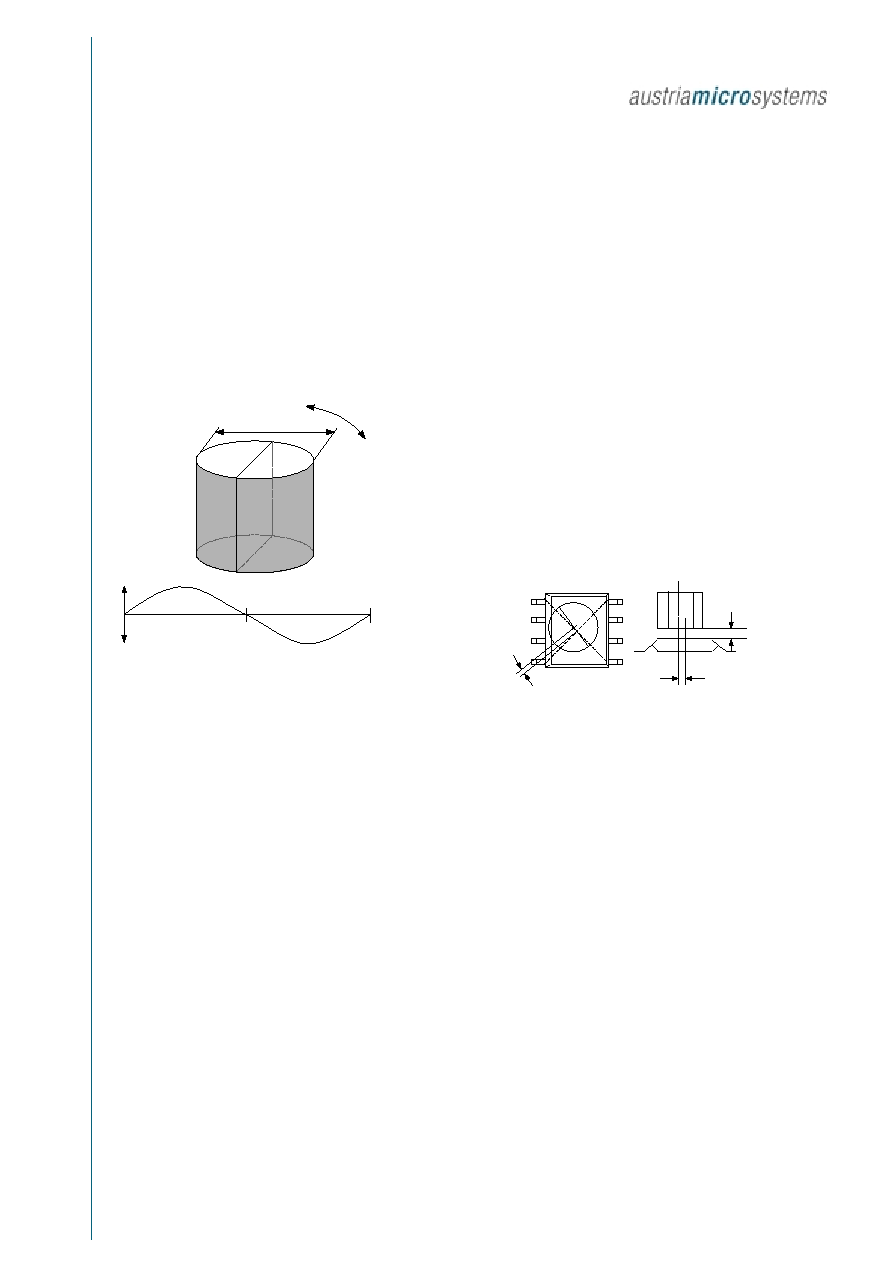

Figure 1

Placement of AS5021 device and magnet source

The optional 3

rd

channel index (one pulse per revolution) is

user programmable and allows one time programming of a

user specific index-position between the device and the

magnet source.

The device includes a Hall sensor array as well as the signal

conditioning and the post processing circuits. Figure 2 shows

the working principal of the AS5021 device.

6bit

ADC

Measurement

Register

Adder & Output-

Register

OTP-ROM

Index-Position

Programming

-

+

Sensor-Array

VDD

PROG

GND

A

CSn

Index

B

Figure 2

Block diagram

DATA SHEET

AS5021-E

INCREMENTAL ROTARY ENCODER

(Extended Temperature Range)

AS5021 - INCREMENTAL ROTARY ENCODER

Revision December 2002

Page 2 of 8

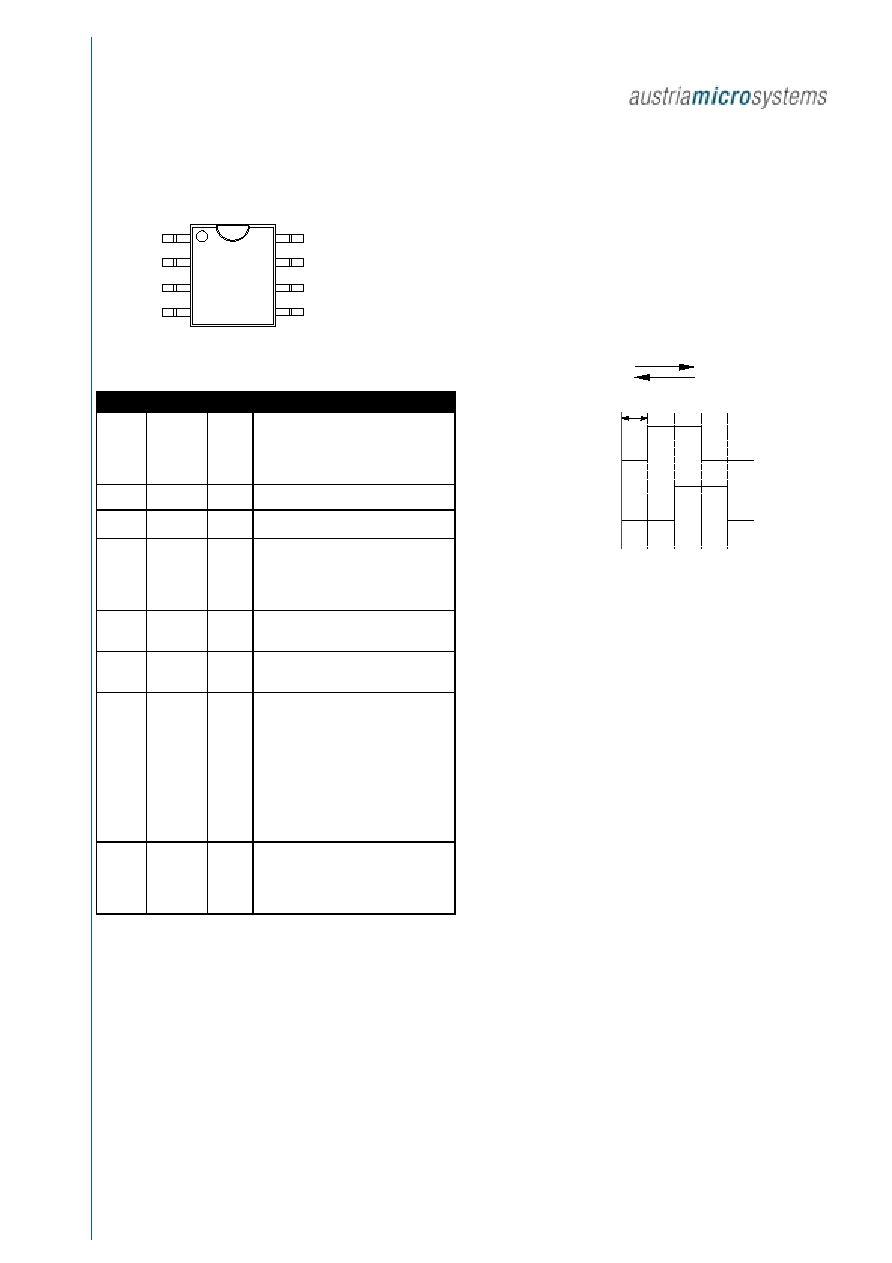

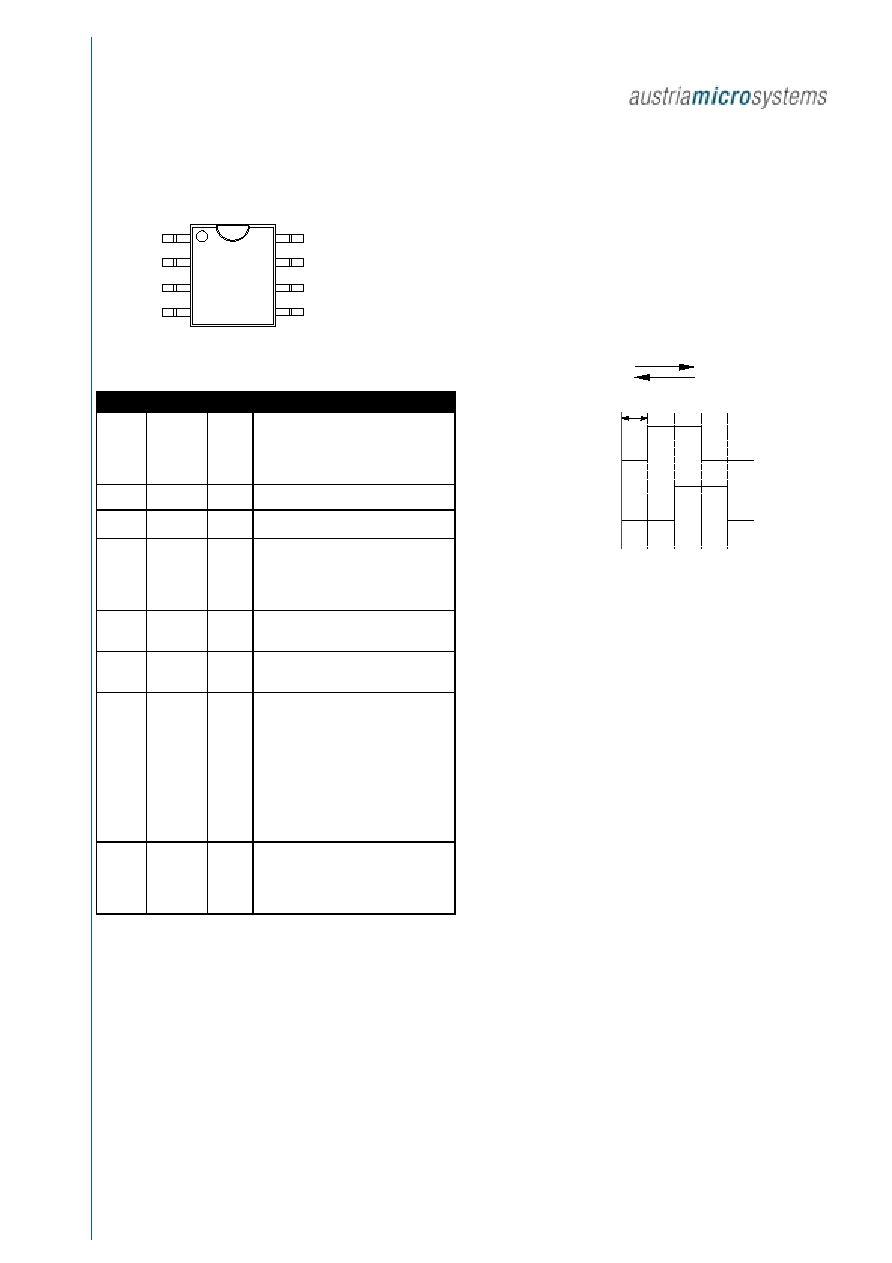

Pin Configuration

A

B

N.C.

N.C.

CSn/ Index

PROG

VSS

VDD

Pin Description

Pin #

Symbol

Type

Description

1

B

DO

This pin represents signal B of quad

A/B outputs. Signal B changes the

state every 11.25° and is shifted

5.625° relative to signal A.

2

V

DD

AI

Positive Supply Voltage.

3

V

S S

AI

Negative Supply Voltage (GND).

4

PROG

DI

PROGramming Input

This pin is used to program the index

position into a non-volatile memory

(One Time Programmable).

5

N.C.

AI

Not Connected during operation. This

pin is for manufacturers use only

6

N.C.

AI

Not Connected during operation. This

pin is for manufacturer's use only.

7

CSn/

Index

DIO

Chip Select (active low)

CSn=0 activates the device and

enables measurement.

Index

After programming an user specific

index position this pin provides one

index pulse per revolution. A version

with pre-programmed index can be

delivered.

8

A

DO

This pin represents signal A of quad

A/B outputs. Signal A changes the

state every 11.25° and is shifted

5.625° relative to signal B.

DI:

Digital Input

AI:

Analogue Input

DO:

Digital Output

DIO:

Digital Input Output

Note:

Pins 4, 5 and 6 may be either left open or

connected together

Functional Description

A Hall sensor array is used to convert the magnetic field

distributed above the chip surface into a quadrature output

signal. Any angular change of 5.625° results in a change in

state of either A or B output.

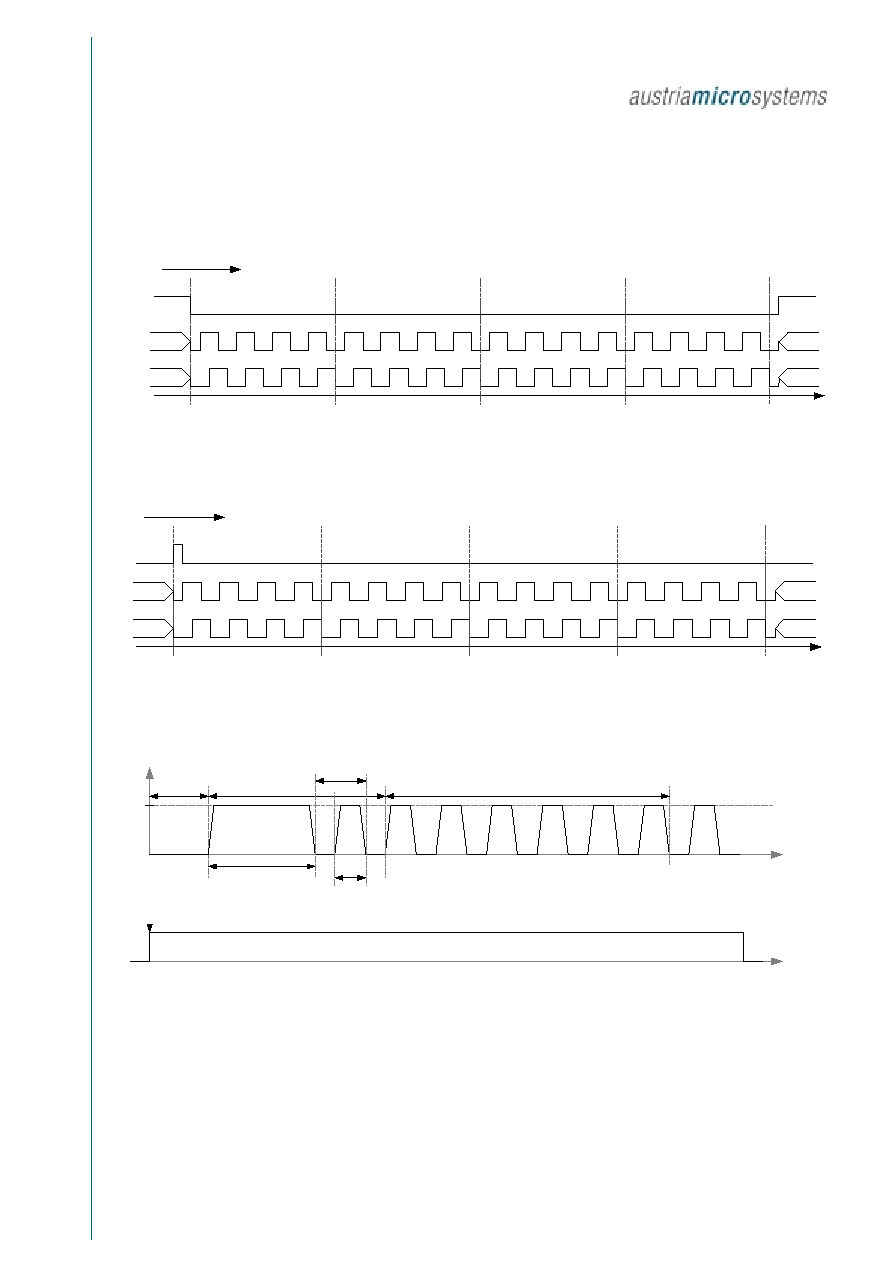

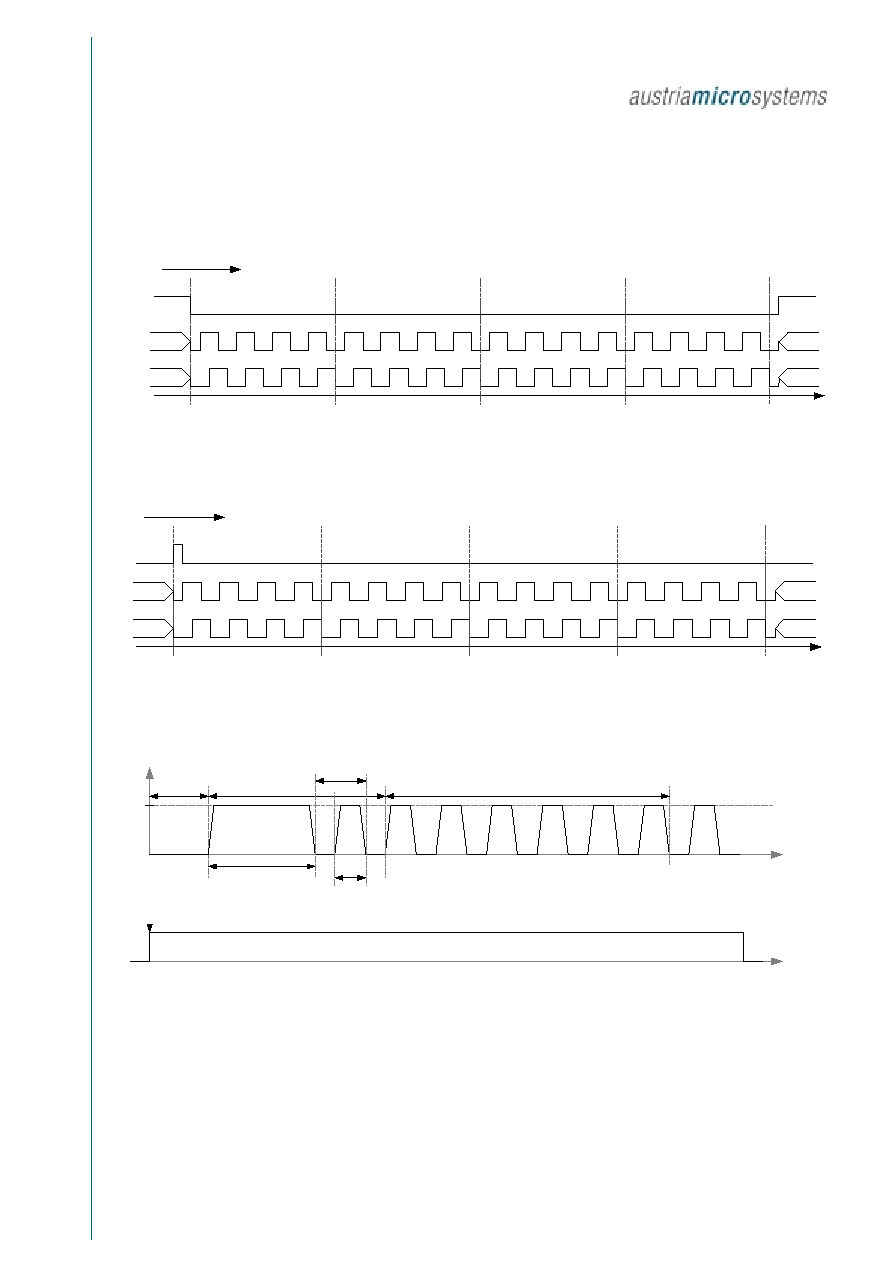

Figure 3 shows the changing of the quad A/B signal in

clockwise (CW) and counter-clockwise (CCW) direction.

A

0

C W

B

1

1

0

0

0

1

1

C C W

5 . 6 2 5

Figure 3

Quadrature A/B signal

Figure 4 shows the output signals A and B for one full 360°

rotation. 16 pulses per revolution, each interpolating 4

position changes, lead to a resolution of 64 increments over

360° with a maximum output frequency of 8,000 Hz.

Chip Select must be active low (CSn=0) to enable

measurement and to activate the output pin A and B

(pin 8 and 1).

Pin A and pin B change the state every 11.25° . The 90

degree phase shift between channel A and B indicates the

direction of the magnet's movement. Channel A leads

channel B by 5.625 degree for a clockwise rotation of the

rotor viewed from the encoder cover. Channel B leads

channel A for a counter clockwise rotation of the rotor.

With Chip Select at logic high, the device returns to the

power down state. A and B becomes high ohmic (e.g. for use

in bus systems).

The AS5021 is extremely tolerant tof magnetic misalignment

and to environmental influences due to the design adopted

for the ratiometric measurement and Hall sensor conditioning

circuitry.

Due to the very high level of system integration, the AS5021

allows for easy implementation of an angular measurement

system. Only two external components, a magnetic field

source and a de-coupling capacitor, are required.

AS5021 - INCREMENTAL ROTARY ENCODER

Revision December 2002

Page 3 of 8

Timing Diagrams

A

CSn

360°

0°

clockwise movement of magnet

high Z

high Z

high Z

high Z

B

270°

180°

90°

Figure 4

Output signals A and B for one full 360° rotation in standard mode

A

Index

360°

0°

clockwise movement of magnet

high Z

high Z

high Z

high Z

B

270°

180°

90°

programmable default 0°

Figure 5

Output signals A, B and index for one full 360° rotation in continuous read out mode

Dummy

2

3

4

5

6

7

8

9

1

Enable

Programming

8

0

PROG

Initialization

t

wait

Index Position Programming

t

Enable Index

Bit0

Bit5

Bit4

Bit3

Bit2

Bit1

Measurement

Enable

CSn

Calibration Position

Latched

t

ProgEN

t

Zap

t

Prog

Figure 6

Programming sequence

AS5021 - INCREMENTAL ROTARY ENCODER

Revision December 2002

Page 4 of 8

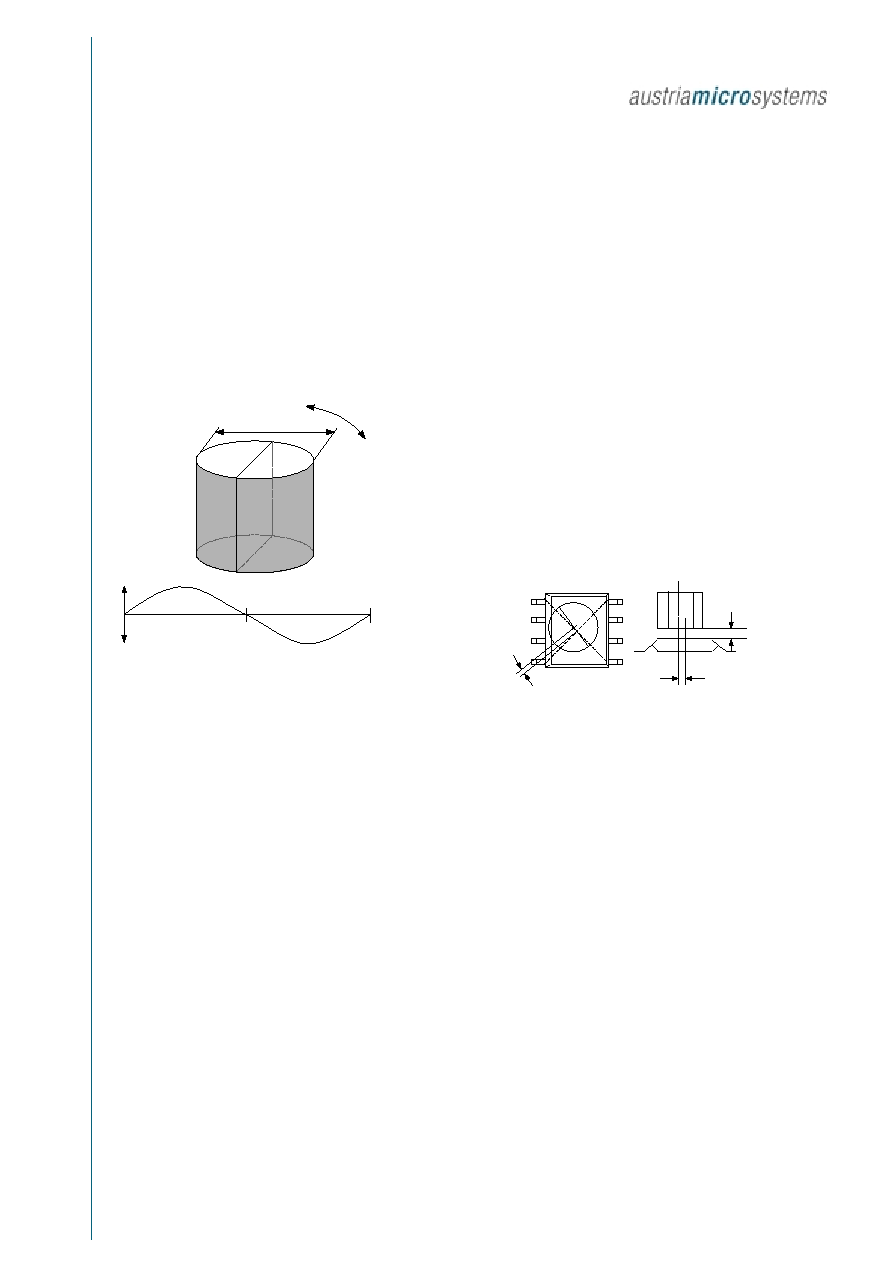

As illustrated in figure 7, a simple two-pole permanent

magnet may be used as the magnetic field source.

The magnet may be a diametrically magnetized, cylindrical

standard magnet. Magnetic materials such as rare earth

AlNiCo / SmCo5 or NdFeB are recommended. Typically, the

magnet size should be 3 to 6mm in diameter and 2 to 3mm in

height. The typical distance between the magnet and the

device is 0.5 to 1.5 mm.

A magnetic field strength of typically

±40mT is required at

the package surface and a diameter of 1.6 mm.

3 - 6mm

S

N

40

-40

S

N

180°

360°

/ °

B/mT

Figure 7

Typical magnet and magnetic field at the diameter of 1.5mm

Programming of Index Pulse

The possibility to program the optional 3rd channel index

pulse at a user specific position gives many advantages (e.g.

it simplifies the assembly at the production line, as the

orientation of the magnet does not need to be considered).

Figure 6 shows the timing diagram for programming the user

specific index pulse (one pulse per revolution). The typical

values are shown in the table on page 5.

Before programming the user specific index position the

magnet must be adjusted in measurement mode (CSn=0).

The rising edge of CSn measures the actual position between

the device and the magnetic source and stores it internally

for the permanent programming CSn must be high during the

whole programming sequence.

The first 8V pulse after the minimum waiting time t

w ait

sets the

device into programming mode. It is important that this first

pulse has a minimum duration of t

p r og E N

= 200 µ s. The

following 7 pulses with 8V/5

µs select the latched position

information and permanently write the reference value into

the OTP ROM. The 9th pulse enables the index.

The index pulse at pin 7 will be available after switching the

power off and on again.

Physical Placement of the Magnet

The magnet may be placed above or below the device. The

distance must be within the specified range and the rotation

axis should be aligned to the device center.

The recommended axis point is given by the crossing of the

diagonals with respect to the leadframe.

Accurate placement is important to achieve the specified

accuracy with respect to the temperature and the voltage

ranges. Figure 8 shows the maximum allowed misalignment

of the magnet with respect to the device, the typical values

are shown in the table on page 6.

Referenced to pins

R

Disp

R

Disp

Z

Dist

Figure 8

Maximum allowed misalignment of magnet with respect to

the device

If placement tolerances are larger than specified, the device

continues to operate at a reduced linearity performance.

AS5021 - INCREMENTAL ROTARY ENCODER

Revision December 2002

Page 5 of 8

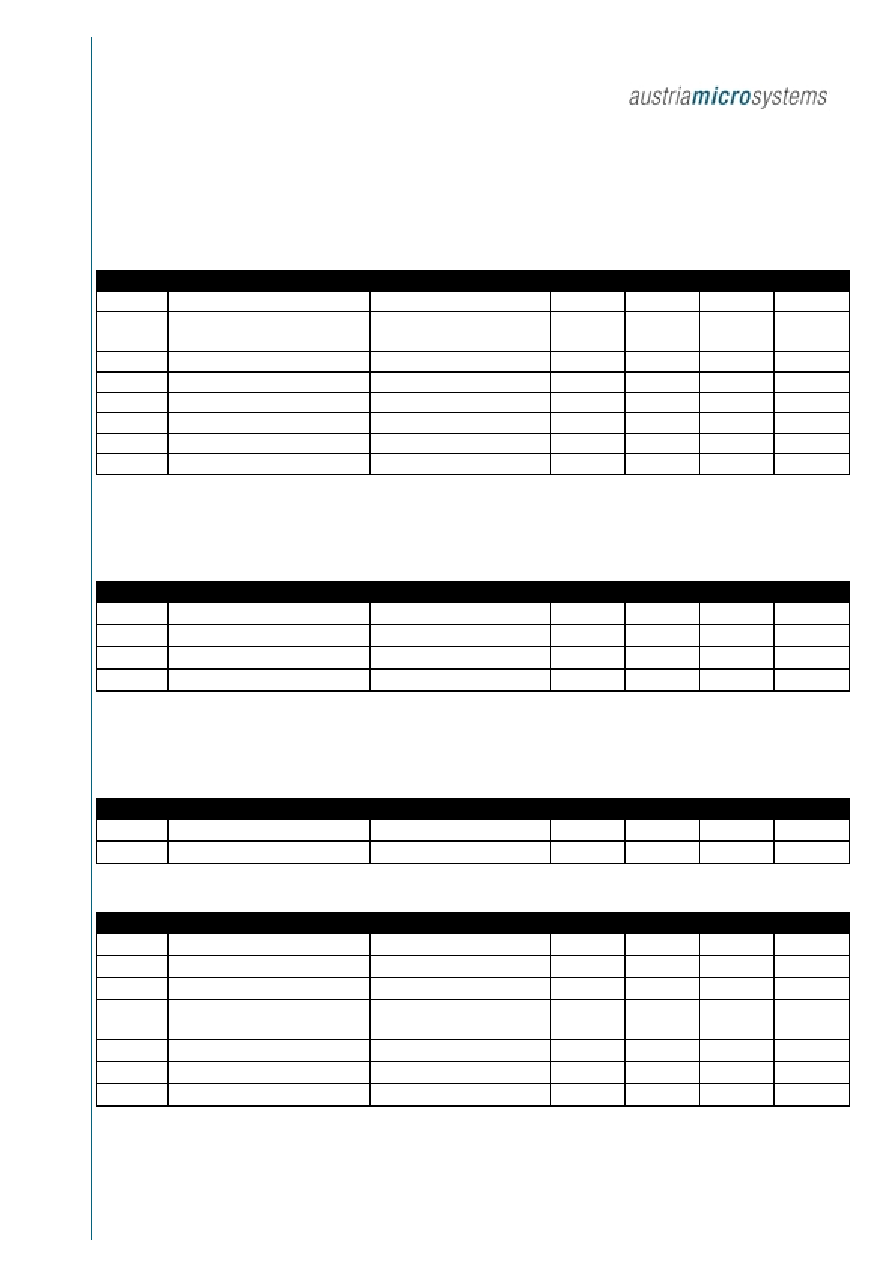

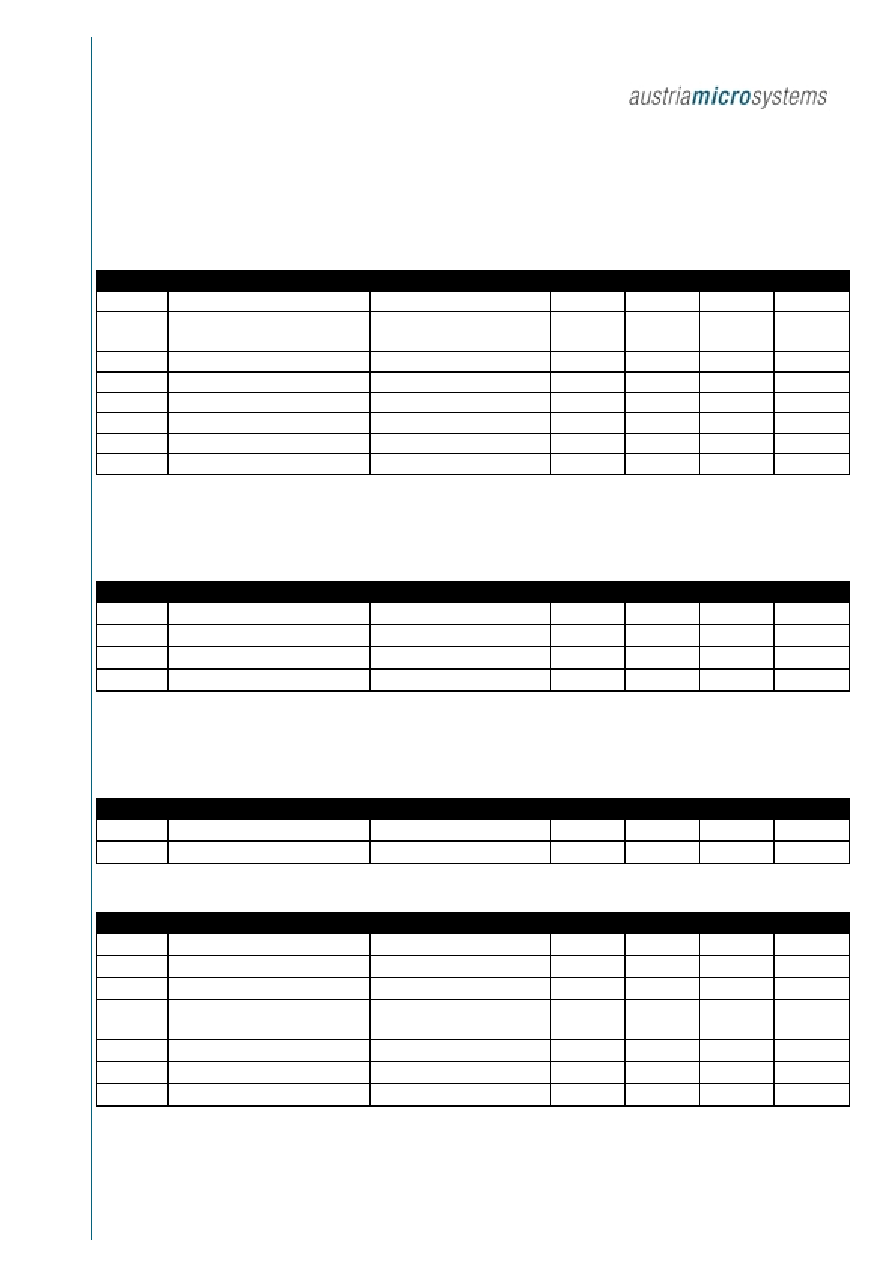

Electrical Characteristics

Absolute Maximum Ratings

Symbol

Parameter

Remarks

Min

Typ

Max

Unit

V

DD

Max. Supply Voltage

-0.3

7

V

I

L UI

Max. Input Current

Latch-up immunity /

Norm JEDEC 17

25

mA

V

I N

Max. Digital Input Voltage

-0.3

V

DD

+ 0.3

V

ESD

Electrostatic Discharge

Norm MIL883E method 3015

-1000

+1000

V

T

S to re

Storage Temperature Range

-50

+125

° C

P

t ot

Total Power Dissipation

150

mW

H

Humidity non-condensing

5

85

%

Soldering Conditions

Norm: IEC 6170-1

0.7 V

DD

V

DD

V

Stresses beyond those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. These are stress

ratings only. Functional operation of the device at these or any other conditions beyond those indicated under "Operating

Conditions" is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Operating Conditions

Symbol

Parameter

Conditions

Min

Typ*

Max

Unit

V

DD

Supply Voltage

Measurement mode, V

S S

=0V

4.75

5.0

5.25

V

T

A MB

Ambient Operating Temp. Range

-40

+125

° C

V

I L

Input Low Voltage

V

S S

0.3 V

DD

V

V

I H

Input High Voltage**

0.7 V

DD

V

DD

V

Note: External Buffer Capacitance is needed: e.g. 4.7µ F between the supply pins

* typical figures at 25° C are for design aid only; not guaranteed and not subjected to production testing.

** At pin PROG a higher voltage (up to 8.5V) is defined for the zero position programming routine.

DC Characteristics

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

I

DD

Operating Supply Current

CSn=0, Continuous Mode

15

24

mA

I

O

Digital Output Current Capability

4

mA

Programming Input

(see Figure 6)

Symbol

Parameter

Conditions

Min

Typ*

Max

Unit

V

P ROG

Programming Voltage

Measurement mode, V

S S

=0V

8

8.5

V

t

Zap

Zap Pulse Duration

4.5

5

5.5

µ s

t

P ro g

Programming Period

9

10

11

µ s

t

Wa it

Minimum Waiting Time after

Rising Edge of CSn

0.5

µ s

t

P ro gE N

Delay after CSn=1

200

µ s

T

L H

Pulse Slew Rate

2

V/µ s

I

P ROG

Programming Current

100

mA