| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ISO124 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

Æ

ISO124

FEATURES

q

100% TESTED FOR HIGH-VOLTAGE

BREAKDOWN

q

RATED 1500Vrms

q

HIGH IMR: 140dB at 60Hz

q

0.010% max NONLINEARITY

q

BIPOLAR OPERATION: V

O

=

±

10V

q

16-PIN PLASTIC DIP AND 28-LEAD SOIC

q

EASE OF USE: Fixed Unity Gain

Configuration

q

±

4.5V to

±

18V SUPPLY RANGE

APPLICATIONS

q

INDUSTRIAL PROCESS CONTROL:

Transducer Isolator, Isolator for Thermo-

couples, RTDs, Pressure Bridges, and

Flow Meters, 4mA to 20mA Loop Isolation

q

GROUND LOOP ELIMINATION

q

MOTOR AND SCR CONTROL

q

POWER MONITORING

q

PC-BASED DATA ACQUISITION

q

TEST EQUIPMENT

ISO124

DESCRIPTION

The ISO124 is a precision isolation amplifier incor-

porating a novel duty cycle modulation-demodulation

technique. The signal is transmitted digitally across

a 2pF differential capacitive barrier. With digital modu-

lation the barrier characteristics do not affect signal

integrity, resulting in excellent reliability and good high

frequency transient immunity across the barrier. Both

barrier capacitors are imbedded in the plastic body of

the package.

The ISO124 is easy to use. No external components

are required for operation. The key specifications are

0.010% max nonlinearity, 50kHz signal bandwidth,

and 200

µ

V/

∞

C V

OS

drift. A power supply range of

±

4.5V to

±

18V and quiescent currents of

±

5.0mA on

V

S1

and

±

5.5mA on V

S2

make these amplifiers ideal

for a wide range of applications.

The ISO124 is available in 16-pin plastic DIP and 28-

lead plastic surface mount packages.

Æ

Precision Lowest Cost

ISOLATION AMPLIFIER

International Airport Industrial Park ∑ Mailing Address: PO Box 11400, Tucson, AZ 85734 ∑ Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 ∑ Tel: (520) 746-1111 ∑ Twx: 910-952-1111

Internet: http://www.burr-brown.com/ ∑ FAXLine: (800) 548-6133 (US/Canada Only) ∑ Cable: BBRCORP ∑ Telex: 066-6491 ∑ FAX: (520) 889-1510 ∑ Immediate Product Info: (800) 548-6132

©

1997 Burr-Brown Corporation

PDS-1405A

Printed in U.S.A. September, 1997

+V

S1

V

IN

V

OUT

≠V

S1

+V

S2

Gnd

≠V

S2

Gnd

ISO124

ISO124

2

Æ

ISO124

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

SPECIFICATIONS

At T

A

= +25

∞

C , V

S1

= V

S2

=

±

15V, and R

L

= 2k

, unless otherwise noted.

ISO124P, U

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

ISOLATION

Rated Voltage, continuous ac 60Hz

1500

Vac

100% Test

(1)

1s, 5pc PD

2400

Vac

Isolation Mode Rejection

60Hz

140

dB

Barrier Impedance

10

14

|| 2

|| pF

Leakage Current at 60Hz

V

ISO

= 240Vrms

0.18

0.5

µ

Arms

GAIN

V

O

=

±

10V

Nominal Gain

1

V/V

Gain Error

±

0.05

±

0.50

%FSR

Gain vs Temperature

±

10

ppm/

∞

C

Nonlinearity

(2)

±

0.005

±

0.010

%FSR

INPUT OFFSET VOLTAGE

Initial Offset

±

20

±

50

mV

vs Temperature

±

200

µ

V/

∞

C

vs Supply

±

2

mV/V

Noise

4

µ

V/

Hz

INPUT

Voltage Range

±

10

±

12.5

V

Resistance

200

k

OUTPUT

Voltage Range

±

10

±

12.5

V

Current Drive

±

5

±

15

mA

Capacitive Load Drive

0.1

µ

F

Ripple Voltage

(3)

20

mVp-p

FREQUENCY RESPONSE

Small Signal Bandwidth

50

kHz

Slew Rate

2

V/

µ

s

Settling Time

V

O

=

±

10V

0.1%

50

µ

s

0.01%

350

µ

s

Overload Recovery Time

150

µ

s

POWER SUPPLIES

Rated Voltage

±

15

V

Voltage Range

±

4.5

±

18

V

Quiescent Current: V

S1

±

5.0

±

7.0

mA

V

S2

±

5.5

±

7.0

mA

TEMPERATURE RANGE

Specification

≠25

+85

∞

C

Operating

≠25

+85

∞

C

Storage

≠40

+85

∞

C

Thermal Resistance,

JA

100

∞

C/W

JC

65

∞

C/W

NOTES: (1) Tested at 1.6 X rated, fail on 5pC partial discharge. (2) Nonlinearity is the peak deviation of the output voltage from the best-fit straight line. It is expressed

as the ratio of deviation to FSR. (3) Ripple frequency is at carrier frequency (500kHz).

3

Æ

ISO124

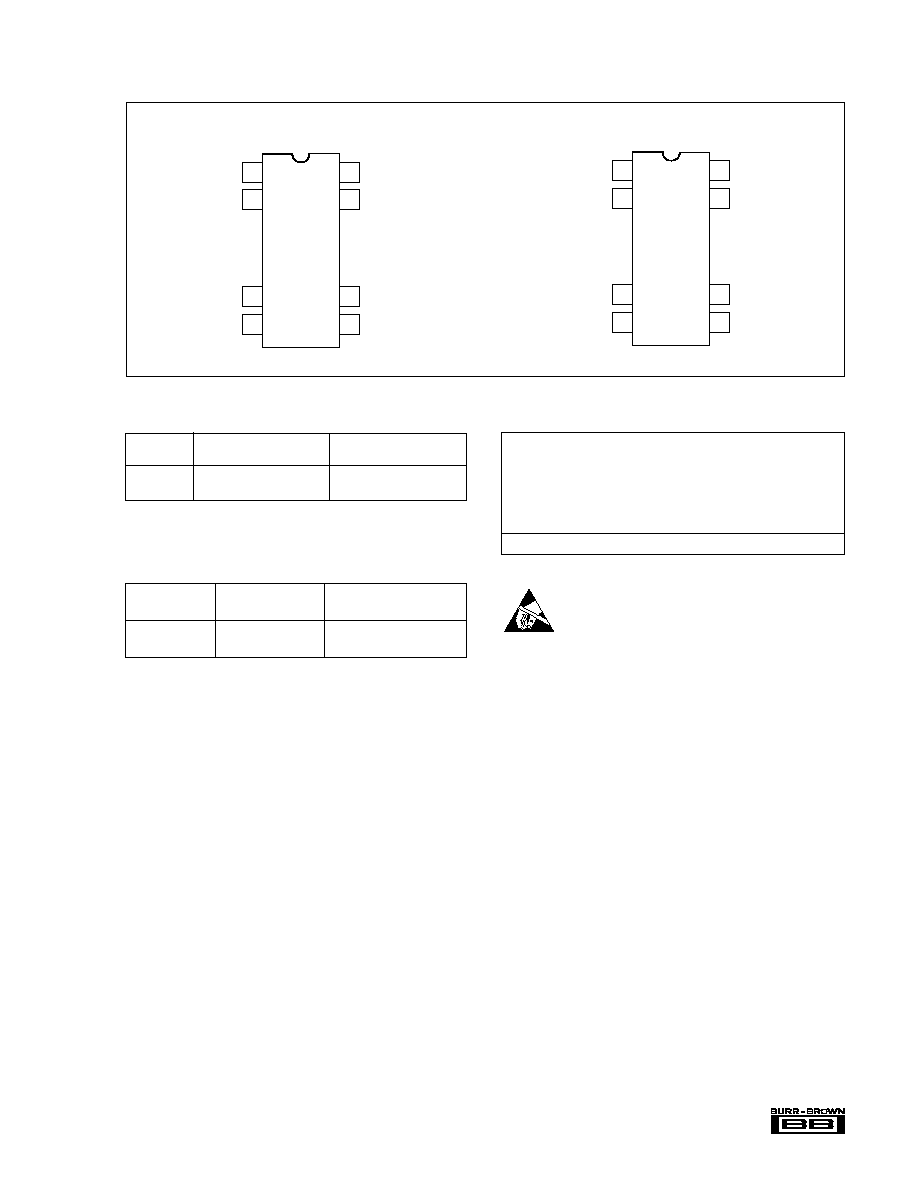

1

2

28

27

16

15

13

14

+V

S1

≠V

S1

V

OUT

Gnd

Gnd

V

IN

≠V

S2

+V

S2

Top View --P Package

Top View--U Package

CONNECTION DIAGRAM

ABSOLUTE MAXIMUM RATINGS

(1)

Supply Voltage ...................................................................................

±

18V

V

IN

......................................................................................................

±

100V

Continuous Isolation Voltage ..................................................... 1500Vrms

Junction Temperature .................................................................... +150

∞

C

Storage Temperature ....................................................................... +85

∞

C

Lead Temperature (soldering, 10s) ................................................ +300

∞

C

Output Short to Common ......................................................... Continuous

NOTE: (1) Stresses above these ratings may cause permanent damage.

PACKAGE INFORMATION

PACKAGE DRAWING

PRODUCT

PACKAGE

NUMBER

(1)

ISO124P

16-Pin Plastic DIP

238

ISO124U

28-Lead Plastic SOIC

217-1

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

1

2

16

15

10

9

7

8

+V

S1

≠V

S1

V

OUT

Gnd

Gnd

V

IN

≠V

S2

+V

S2

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degrada-

tion to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

NONLINEARITY

PRODUCT

PACKAGE

MAX %FSR

ISO124P

16-Pin Plastic DIP

±

0.010

ISO124U

28-Lead Plastic SOIC

±

0.010

ORDERING INFORMATION

4

Æ

ISO124

Time (

µ

s)

Time (

µ

s)

+10

0

≠10

0

STEP RESPONSE

500

1000

TYPICAL PERFORMANCE CURVES

At T

A

= +25

∞

C, and V

S

=

±

15V, unless otherwise noted.

+10

0

≠10

0

SINE RESPONSE

(f = 2kHz)

Output Voltage (V)

Output Voltage (V)

SINE RESPONSE

(f = 20kHz)

Time (

µ

s)

+10

0

≠10

0

100

50

Output Voltage (V)

Time (

µ

s)

+10

0

≠10

0

STEP RESPONSE

100

50

Output Voltage (V)

1000

500

ISOLATION VOLTAGE

vs FREQUENCY

Frequency (Hz)

Peak Isolation Voltage

100

1k

10k

100k

1M

10M

100M

1k

100

0

2.1k

Degraded

Performance

Typical

Performance

Max DC Rating

IMR vs FREQUENCY

Frequency (Hz)

IMR (dB)

160

140

120

100

80

60

40

1

10

100

1k

10k

100k

1M

5

Æ

ISO124

TYPICAL PERFORMANCE CURVES

(CONT)

At T

A

= +25

∞

C, and V

S

=

±

15V, unless otherwise noted.

60

40

20

0

54

1

10

100

1k

10k

100k

1M

PSRR vs FREQUENCY

Frequency (Hz)

PSRR (dB)

≠V

S1

, ≠V

S2

+V

S1

, +V

S2

100mA

10mA

1mA

100µA

10µA

1µA

0.1µA

1

10

100

1k

10k

100k

1M

ISOLATION LEAKAGE CURRENT vs FREQUENCY

Frequency (Hz)

Leakage Current (rms)

1500Vrms

240Vrms

0

≠10

≠20

≠30

≠40

250

200

150

100

50

0

500k

1M

1.5M

SIGNAL RESPONSE TO

INPUTS GREATER THAN 250kHz

Input Frequency (Hz)

V

OUT

/V

IN

(dBm)

Frequency Out

(NOTE: Shaded area shows aliasing frequencies that

cannot be removed by a low-pass filter at the output.)

V

OUT

/V

IN

100kHz

Frequency

Out

6

Æ

ISO124

THEORY OF OPERATION

The ISO124 isolation amplifier uses an input and an output

section galvanically isolated by matched 1pF isolating ca-

pacitors built into the plastic package. The input is duty-

cycle modulated and transmitted digitally across the barrier.

The output section receives the modulated signal, converts it

back to an analog voltage and removes the ripple component

inherent in the demodulation. Input and output sections are

fabricated, then laser trimmed for exceptional circuitry match-

ing common to both input and output sections. The sections

are then mounted on opposite ends of the package with the

isolating capacitors mounted between the two sections. The

transistor count of the ISO124 is 250 transistors.

MODULATOR

An input amplifier (A1, Figure 1) integrates the difference

between the input current (V

IN

/200k

) and a switched

±

100

µ

A current source. This current source is implemented

by a switchable 200

µ

A source and a fixed 100

µ

A current

sink. To understand the basic operation of the modulator,

assume that V

IN

= 0.0V. The integrator will ramp in one

direction until the comparator threshold is exceeded. The

comparator and sense amp will force the current source to

switch; the resultant signal is a triangular waveform with a

50% duty cycle. The internal oscillator forces the current

source to switch at 500kHz. The resultant capacitor drive is

a complementary duty-cycle modulation square wave.

DEMODULATOR

The sense amplifier detects the signal transitions across the

capacitive barrier and drives a switched current source into

integrator A2. The output stage balances the duty-cycle

FIGURE 1. Block Diagram.

modulated current against the feedback current through the

200k

feedback resistor, resulting in an average value at the

V

OUT

pin equal to V

IN

. The sample and hold amplifiers in the

output feedback loop serve to remove undesired ripple

voltages inherent in the demodulation process.

BASIC OPERATION

SIGNAL AND SUPPLY CONNECTIONS

Each power supply pin should be bypassed with 1

µ

F tantalum

capacitors located as close to the amplifier as possible. The

internal frequency of the modulator/demodulator is set at

500kHz by an internal oscillator. Therefore, if it is desired to

minimize any feedthrough noise (beat frequencies) from a

DC/DC converter, use a

filter on the supplies (see Figure 4).

ISO124 output has a 500kHz ripple of 20mV, which can be

removed with a simple two pole low-pass filter with a

100kHz cutoff using a low cost op amp (see Figure 4).

The input to the modulator is a current (set by the 200k

integrator input resistor) that makes it possible to have an

input voltage greater than the input supplies, as long as the

output supply is at least

±

15V. It is therefore possible when

using an unregulated DC/DC converter to minimize PSR

related output errors with

±

5V voltage regulators on the

isolated side and still get the full

±

10V input and output

swing. An example of this application is shown in Figure 9.

CARRIER FREQUENCY CONSIDERATIONS

The ISO124 amplifier transmits the signal across the isola-

tion barrier by a 500kHz duty cycle modulation technique.

For input signals having frequencies below 250kHz, this

system works like any linear amplifier. But for frequencies

200k

1pF

1pF

1pF

1pF

150pF

Osc

200µA

100µA

Sense

200µA

100µA

200k

150pF

S/H

G = 1

S/H

G = 6

Sense

A2

A1

+V

S2

Gnd 2

≠V

S2

+V

S1

Gnd 1

≠V

S1

V

IN

V

OUT

Isolation Barrier

7

Æ

ISO124

1

2

7

9

10

8

PGA102

ISO124

ISO150

1

2

3

16

4

6

7

8

5

15

15

+15V ≠15V

+15V ≠15V

V

IN

V

OUT

A

0

A

1

above 250kHz, the behavior is similar to that of a sampling

amplifier. The signal response to inputs greater than 250kHz

performance curve shows this behavior graphically; at input

frequencies above 250kHz the device generates an output

signal component of reduced magnitude at a frequency

below 250kHz. This is the aliasing effect of sampling at

frequencies less than 2 times the signal frequency (the

Nyquist frequency). Note that at the carrier frequency and its

harmonics, both the frequency and amplitude of the aliasing

go to zero.

ISOLATION MODE VOLTAGE INDUCED ERRORS

IMV can induce errors at the output as indicated by the plots of

IMV vs Frequency. It should be noted that if the IMV frequency

exceeds 250kHz, the output also will display spurious outputs

(aliasing) in a manner similar to that for V

IN

>250kHz and the

amplifier response will be identical to that shown in the "Signal

Response to Inputs Greater Than 250kHz" typical performance

curve. This occurs because IMV-induced errors behave like input-

referred error signals. To predict the total error, divide the isolation

voltage by the IMR shown in the "IMR versus Frequency" typical

performance curve and compute the amplifier response to this

input-referred error signal from the data given in the "Signal

Response to Inputs Greater Than 250kHz" typical performance

curve. For example, if a 800kHz 1000Vrms IMR is present, then

a total of [(≠60dB) + (≠30dB)]

x

(1000V) = 32mV error signal at

200kHz plus a 1V, 800kHz error signal will be present at the

output.

HIGH IMV dV/dt ERRORS

As the IMV frequency increases and the dV/dt exceeds

1000V/

µ

s, the sense amp may start to false trigger, and the

output will display spurious errors. The common-mode

current being sent across the barrier by the high slew rate is

the cause of the false triggering of the sense amplifier.

Lowering the power supply voltages below

±

15V may

decrease the dV/dt to 500V/

µ

s for typical performance.

HIGH VOLTAGE TESTING

Burr-Brown Corporation has adopted a partial discharge test

criterion that conforms to the German VDE0884 Optocou-

pler Standards. This method requires the measurement of

minute current pulses (<5pC) while applying 2400Vrms,

60Hz high voltage stress across every ISO124 isolation

barrier. No partial discharge may be initiated to pass

this test. This criterion confirms transient overvoltage

(1.6

x

1500Vrms) protection without damage to the ISO124.

Lifetest results verify the absence of failure under continu-

ous rated voltage and maximum temperature.

This new test method represents the "state-of-the art" for

non-destructive high voltage reliability testing. It is based on

the effects of non-uniform fields that exist in heterogeneous

dielectric material during barrier degradation. In the case of

void non-uniformities, electric field stress begins to ionize

the void region before bridging the entire high voltage

barrier. The transient conduction of charge during and after

the ionization can be detected externally as a burst of 0.01-

0.1

µ

s current pulses that repeat on each ac voltage cycle.

The minimum ac barrier voltage that initiates partial dis-

charge is defined as the "inception voltage." Decreasing the

barrier voltage to a lower level is required before partial

discharge ceases and is defined as the "extinction voltage."

We have characterized and developed the package insulation

processes to yield an inception voltage in excess of 2400Vrms

so that transient overvoltages below this level will not

damage the ISO124. The extinction voltage is above

1500Vrms so that even overvoltage induced partial dis-

charge will cease once the barrier voltage is reduced to the

1500Vrms (rated) level. Older high voltage test methods

relied on applying a large enough overvoltage (above rating)

to break down marginal parts, but not so high as to damage

good ones. Our new partial discharge testing gives us more

confidence in barrier reliability than breakdown/no break-

down criteria.

FIGURE 3. Programmable-Gain Isolation Channel with

Gains of 1, 10, and 100.

FIGURE 2. Basic Signal and Power Connections.

+V

S1

+V

S2

Gnd

Gnd

V

IN

V

OUT

≠V

S1

±V

S1

±V

S2

≠V

S2

1µF

1µF 1µF

1µF

Isolation Barrier

ISO124

8

Æ

ISO124

FIGURE 5. Battery Monitor for a 600V Battery Power System. (Derives input power from the battery.)

FIGURE 4. Optional

Filter to Minimize Power Supply Feedthrough Noise; Output Filter to Remove 500kHz Carrier Ripple.

For more information concerning output filter refer to AB-023 and AB-034.

V

IN

V

OUT

= V

IN

Isolation Barrier

ISO124

+V

S2

+V

S1

≠V

S1

±V

S1

≠V

S2

Gnd2

Gnd1

R

1

4.75k

R

2

9.76k

1µF

1µF

1µF

1µF

10µH

10µH

±V

S2

10µH

10µH

1µF

1µF

1µF 1µF

C

1

220pF

C

2

1000pF

OPA237

15

1

9

10

7

2

e

50

= 12V

8

≠V

16

+V

15

1

9

10

7

2

10k

8

≠V

16

+V

10k

e

49

= 12V

e

2

= 12V

e

1

= 12V

10k

10k

Charge/Discharge Control

INA105

25k

25k

25k

25k

2

3

1

e

50

V =

2

+V ≠V

7

4

5

6

e

1

V =

2

Multiplexer

Control

Section

ISO124

This Section Repeated 49 Times.

ISO124

9

Æ

ISO124

FIGURE 6. Thermocouple Amplifier with Ground Loop Elimination, Cold Junction Compensation, and Up-scale Burn-out.

FIGURE 7. Isolated 4-20mA Instrument Loop. (RTD shown.)

R

CM

1k

RCV420

XTR105

R

G

R

Z

(1)

13

3

4

2

6

7

10

14

1

0.01µF

4-20mA

RTD

(PT100)

0.8mA

0.8mA

1.6mA

14

15

16

3

2

10

4

12

11

5, 13

15

16

2

1

Gnd

≠V

S

= ≠15V

on PWS740

+V

S

= 15V on PWS740

9

10

7

8

≠V

+V

ISO124

V

OUT

0V - 5V

NOTE: (1) R

Z

= RTD resistance at minimum measured temperature.

2

6

10.0V

4

REF102

INA114

or

INA128

+In

7

4

3

8

1

2

5

16

15

8

10

ISO124

7

V

OUT

9

6

≠In

+15V

+15V

≠15V

+15V ≠15V

ISA

TYPE

E

J

K

T

MATERIAL

Chromel

Constantan

Iron

Constantan

Chromel

Alumel

Copper

Constantan

SEEBACK

COEFFICIENT

(µV/∞C)

58.5

50.2

39.4

38.0

R

2

(R

3

= 100

)

3.48k

4.12k

5.23k

5.49k

R

4

(R

5

+ R

6

= 100

)

56.2k

64.9k

80.6k

84.5k

+15V ≠15V

R

3

100

Ground Loop Through Conduit

NOTE: (1) ≠2.1mV/∞C at 2.00µA.

R

1

27k

Isothermal

Block with

1N4148

(1)

R

2

1M

R

5

50

R

G

R

4

R

6

100

Zero Adj

Thermocouple

2

1

10

Æ

ISO124

FIGURE 8. Isolated Power Line Monitor.

15

V≠

V+

10

7

9

8

ISO124

1

2

16

15

16

V≠

V+

10

7

9

8

ISO124

1

2

0.47µF

0.47µF

0.47µF

0.47µF

0.47µF

0.47µF

R

S

R

D1

I

L

Load

R

D2

V

L

Y

X

XY

10

P

L

= V

2

(R

D1

+ R

D2

)

R

S

R

D2

(V

2

)

MPY634

I

L

=

V

1

10R

S

(V

1

)

10k

2k

2k

0.01µF

V

L

= V

3

(R

D1

+ R

D2

)

R

D2

(V

3

)

OPA237

6

2

3

12

DCP011515

5

6

7

12

DCP011515

5

6

7

11

Æ

ISO124

FIGURE 10. Single Supply Operation of the ISO124 Isolation Amplifier. For additional information refer to AB-009.

R

1

R

2

R

4

INA105

Difference Amp

R

3

R

S

2

3

4

IN4689

5.1V

Reference

5

7

6

1

V

IN

Signal Source

+

NOTE: (1) Select to match R .

NOTE: Since the amplifier is unity gain, the input

range is also the output range. The output can go

to ≠2V since the output section of the ISO amp

operates from dual supplies.

S

10k

15

≠V

S2

(≠15V)

+V

S2

(+15V)

V

S1

(+15V)

16

≠V

S1

Com 2

10

In

Gnd

R

C

(1)

V

S

(V)

20+

15

12

INPUT RANGE

(V)

(1)

≠2 to +10

≠2 to +5

≠2 to +2

7

9

8

ISO124

2

1

V

OUT

= V

IN

FIGURE 9. Improved PSR Using External Regulator.

NOTE: The input supplies can be subregulated to ±5V to reduce

PSR related errors without reducing the ±10V input range.

10

7

9

8

2

V

OUT

+15V

≠15V

V

IN

, up to

±10V Swing

+5V

Regulator

MC78L05

≠5V

Regulator

MC79L05

0.47µF 0.47µF

0.1µF

1

2

3

0.1µF

0.47µF

ISO124

3

1

2

16

1

DCP011515

7

6

5

2

1

12

Æ

ISO124

FIGURE 12. Powered ISO Amp with Three-Port Isolation.

FIGURE 11. Input-Side Powered ISO Amp.

16

Gnd

V

IN

V≠

V+

V+

V≠

V

O

Gnd

15

1

2

1

2

10

9

7

8

DCP011515

INPUT

SECTION

OUTPUT

SECTION

5

6

7

V

IN

Input

Gnd

+15V

≠15V

≠15V, 20mA

+15V, 20mA

Auxiliary

Isolated

Power

Output

Output

Gnd

V

O

ISO124

0.47µF

0.47µF

0.47µF

16

Gnd

V

IN

V≠

V+

V+

V≠

V

O

Gnd

15

1

2

1

2

10

9

7

8

DCP011515

INPUT

SECTION

OUTPUT

SECTION

5

6

7

+15V Gnd

DCP011515

7

6

5

2

1

V

IN

Input

Gnd

+15V, 20mA

≠15V, 20mA

≠15V, 20mA

+15V, 20mA

Auxiliary

Isolated

Power

Output

Auxiliary

Isolated

Power

Output

Output

Gnd

V

O

ISO124

0.47µF

0.47µF

0.47µF

0.47µF

0.47µF