| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: PWS750-4U | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Æ

PWS750

1

PWS750-3U

PWS750-2U

4

3

4

1

6

3

2

5

6

7

0.3µF

0.3µF

10

≠V

O

+V

O

S

D

G

S

D

G

2N7002

or

2N7008

2N7002

or

2N7008

0.3µF

Driver

Soft

Start

Oscillator

R

1

T

16

T

0.3µF

Comparator

Differential

Amplifier

+V

+V

IN

7

3

11

10µH

PWS750-1U

TTL

OUT

TTL

IN

Enable

V

D

Input

Gnd

12

14

10

(2)

(2)

(1)

10

(1)

10

(3)

10

(3)

Reference

S

(1)

Output

Ground

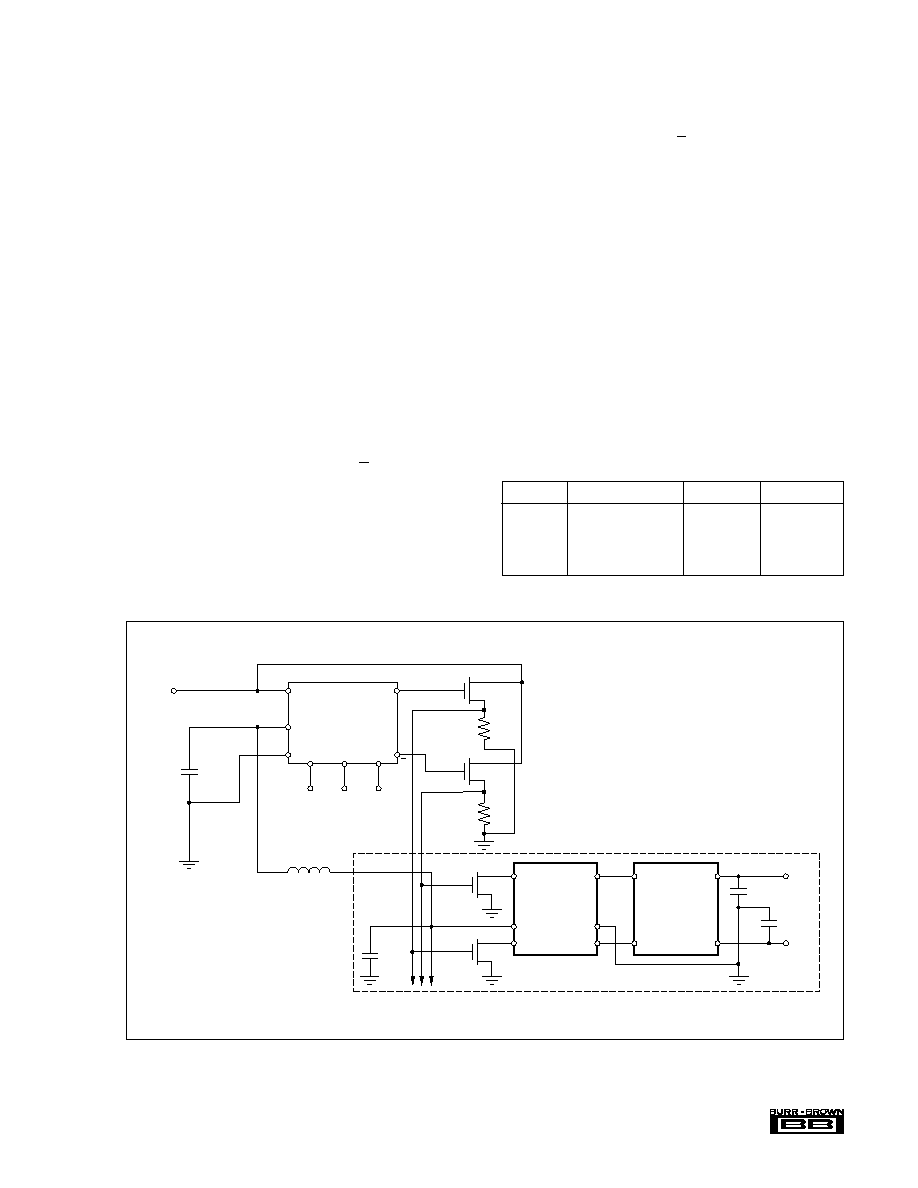

The PWS750-2U and PWS750-4U are split-bobbin

wound isolation transformers using a ferrite core.

They are encapsulated in plastic packages, allowing a

high isolation voltage rating.

The PWS750-3U is a high-speed monolithic diode

bridge in a plastic 8-pin SO package.

One PWS750-1U can be used to drive up to four

channels (15V nominal operation). One PWS750-2U

and PWS750-3U and two 2N7002 (surface mount) or

2N7008 (TO-92) MOSFETs made by Siliconix are

used per isolated channel. When a PWS750-4U is

used as the transformer (5V input), then two TN0604s

made by Supertex must be used, due to the higher

currents of the primary (lower RDS on) and the lower

V

GS

threshold. With 5V operation only one channel

can be directly driven by the PWS750-1U (a simple

FET booster circuit can be used for multichannel

operation; see Figure 3).

Isolated, Unregulated

DC/DC CONVERTER COMPONENTS

PWS750

DESCRIPTION

The PWS750 consists of three building blocks for

building a low cost DC/DC converter. With them you

can optimize DC/DC converter PC board layout or

build a multichannel isolated DC/DC converter. All

parts are surface mount, requiring minimal space to

build the converter. The modular design minimizes the

cost of isolated power.

The PWS750-1U is a high-frequency (800kHz nomi-

nal) driver that can drive N-channel MOSFETs up to

the size of a 1.3A 2N7010. The recommended

MOSFET for individual transformer drivers is the

2N7008. The PWS750-1U is supplied in a 16-pin

double-wide SO package.

APPLICATIONS

q

INDUSTRIAL PROCESS CONTROL

EQUIPMENT

q

GROUND-LOOP ELIMINATION

q

PC-BASED DATA ACQUISITION

q

VENDING MACHINES

FEATURES

q

100% TESTED FOR HIGH-VOLTAGE

BREAKDOWN

q

COMPACT-SURFACE MOUNT

q

MULTICHANNEL OPERATION

q

5V OR 15V INPUT OPTIONS

q

FLEXIBLE USE WITH PWS740/PWS745

COMPONENTS

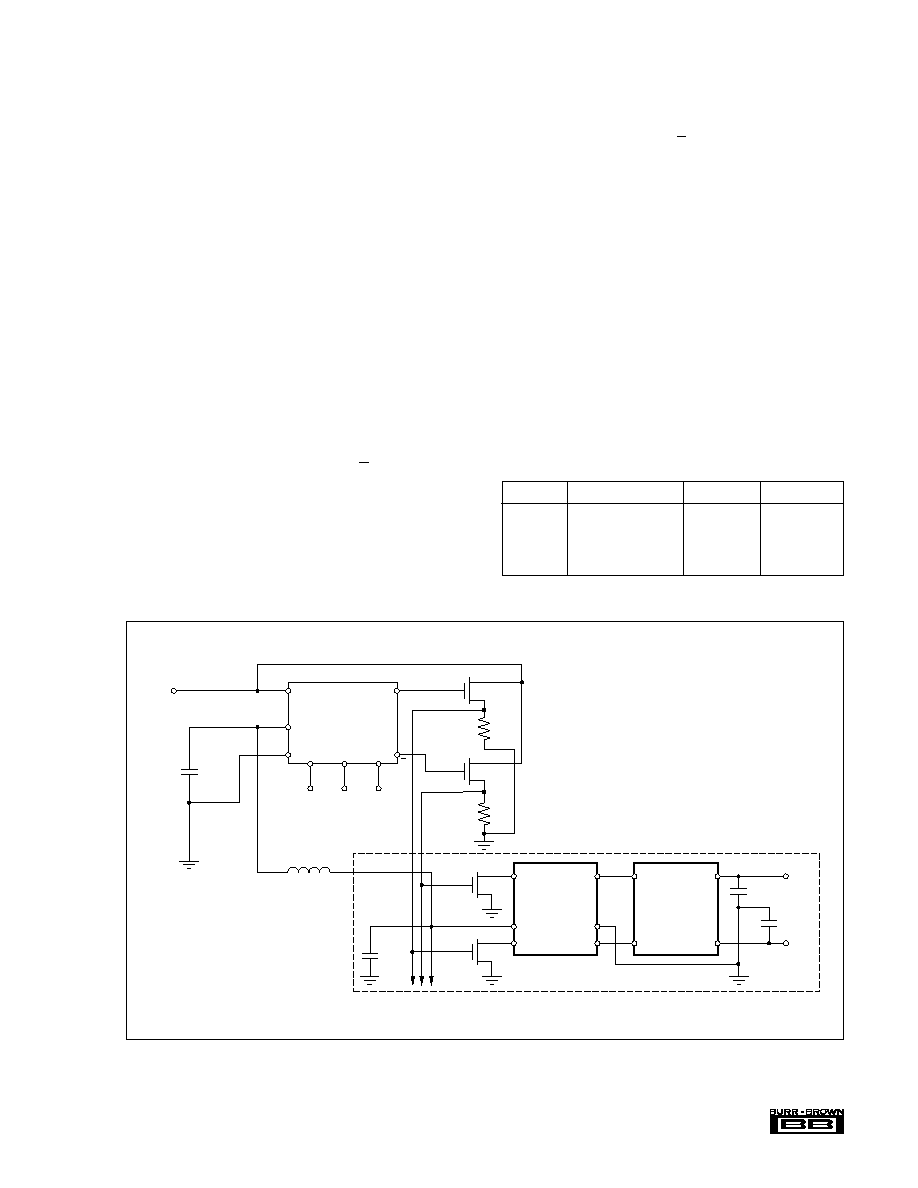

PWS750 SINGLE-CHANNEL CONNECTION

Typical Connection for

Internal Oscillator Operation

NOTES: (1) User option. (2) Use TN0604 for 5V to

±

15V operation. (3) Multichannel Operation.

Duplicate for multichannel

operation with PWS750-2U.

Æ

©

1988 Burr-Brown Corporation

PDS-838F

Printed in U.S.A. April, 1997

International Airport Industrial Park ∑ Mailing Address: PO Box 11400, Tucson, AZ 85734 ∑ Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 ∑ Tel: (520) 746-1111 ∑ Twx: 910-952-1111

Internet: http://www.burr-brown.com/ ∑ FAXLine: (800) 548-6133 (US/Canada Only) ∑ Cable: BBRCORP ∑ Telex: 066-6491 ∑ FAX: (520) 889-1510 ∑ Immediate Product Info: (800) 548-6132

2

Æ

PWS750

SPECIFICATIONS

ELECTRICAL

At T

A

= 25

∞

C; +V

IN

= +15V; and I

OUT

=

±

15mA balanced loads, unless otherwise noted.

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

PWS750-1U OSCILLATOR

Frequency: Internal OSC

TTL

IN

= 0V

725

800

875

kHz

External OSC

1

2.5

MHz

Supply: 15V Operation

10

15

18

V

5V Operation

4.5

5

5.5

V

T, T Drive Current

50

mApk

T, T Drive Voltage, High

3

7

V

Low

0.7

V

TTL

IN

, I

IH

10

nA

I

IL

≠1

µ

A

V

IH

2

V

V

IL

0.8

V

TTL

OUT

, I

OL

15

mA

PWS750-2U +V

IN

TO

±

V

OUT

ISOLATION TRANSFORMER

ISOLATION

Voltage Rated Continuous AC 60Hz

750

Vrms

100% Test

(1)

60Hz, 1s, <5pC PD

1200

Vrms

Barrier Impedance

10

12

|| 8

|| pF

Leakage Current at 60Hz

V

ISO

= 240Vrms

1

1.5

µ

Arms

Winding Ratio

Primary/Secondary

48/48

PWS750-3U DIODE BRIDGE

Reverse Recovery

I

F

= I

R

= 50mA

40

ns

Reverse Breakdown

I

R

= 100

µ

A

55

V

Reverse Current

V

R

= 40V

1.5

µ

A

Forward Voltage

I

F

= 100mA

1.8

V

PWS750-4U +5V

IN

to

±

15V

OUT

ISOLATION TRANSFORMER

ISOLATION

Voltage Rated Continuous AC 60Hz

750

Vrms

100% Test

(1)

60Hz, 1s, <5pC PD

1200

Vrms

Barrier Impedance

10

12

|| 8

|| pF

Leakage Current at 60Hz

V

ISO

= 240Vrms

1

1.5

µ

Arms

Winding Ratio

Primary/Secondary

24/70

TEMPERATURE RANGE

Specification

0

+70

∞

C

Operating

Derated performance

≠40

+85

∞

C

Storage

≠40

+85

∞

C

NOTES: (1) Tested at 1.6

x

rated, fail on 5pC partial discharge leakage current on five successive pulses at 60Hz.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

Æ

PWS750

3

8

7

6

4

3

2

1

14

5

T

V

D

+V

IN

16

15

13

12

11

10

9

16-Pin SO Double-Wide

Surface Mount

Enable

Gnd

TTL

OUT

TTL

IN

T

PWS750-1U

PIN CONFIGURATIONS

AC

4

3

2

1

5

6

7

8

AC

+V

≠V

8-Pin SO

Surface Mount

PWS750-3U

5

PWS750-2U

PWS750-4U

8-Pin DIP

Surface Mount

6

8

7

1

2

3

4

NC

AC

Gnd

AC

NC

T

O

V

D

T

O

ABSOLUTE MAXIMUM RATINGS

Supply Voltage ..................................................................................... 18V

Junction Temperature ...................................................................... 150

∞

C

Storage Temperature ........................................................ ≠40

∞

C to +85

∞

C

Lead temperature (soldering, SOIC, 3s) ........................................ +260

∞

C

Max Load, Sum of Both Outputs (PWS750-2U, 4U) ......................... 60mA

PWS750-XU

Basic Model Number

Components

1U : High-Frequency Driver

2U, 4U : Isolation Transformer

3U : High-Speed Monolithic Diode Bridge

ORDERING INFORMATION

PACKAGE INFORMATION

PACKAGE DRAWING

PRODUCT

PACKAGE

NUMBER

(1)

PWS750-1U

16-Pin SOIC

211

PWS750-2U

8-Pin Plastic

226

PWS750-3U

8-Pin SO

182

PWS750-4U

8-Pin Plastic

226

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

4

Æ

PWS750

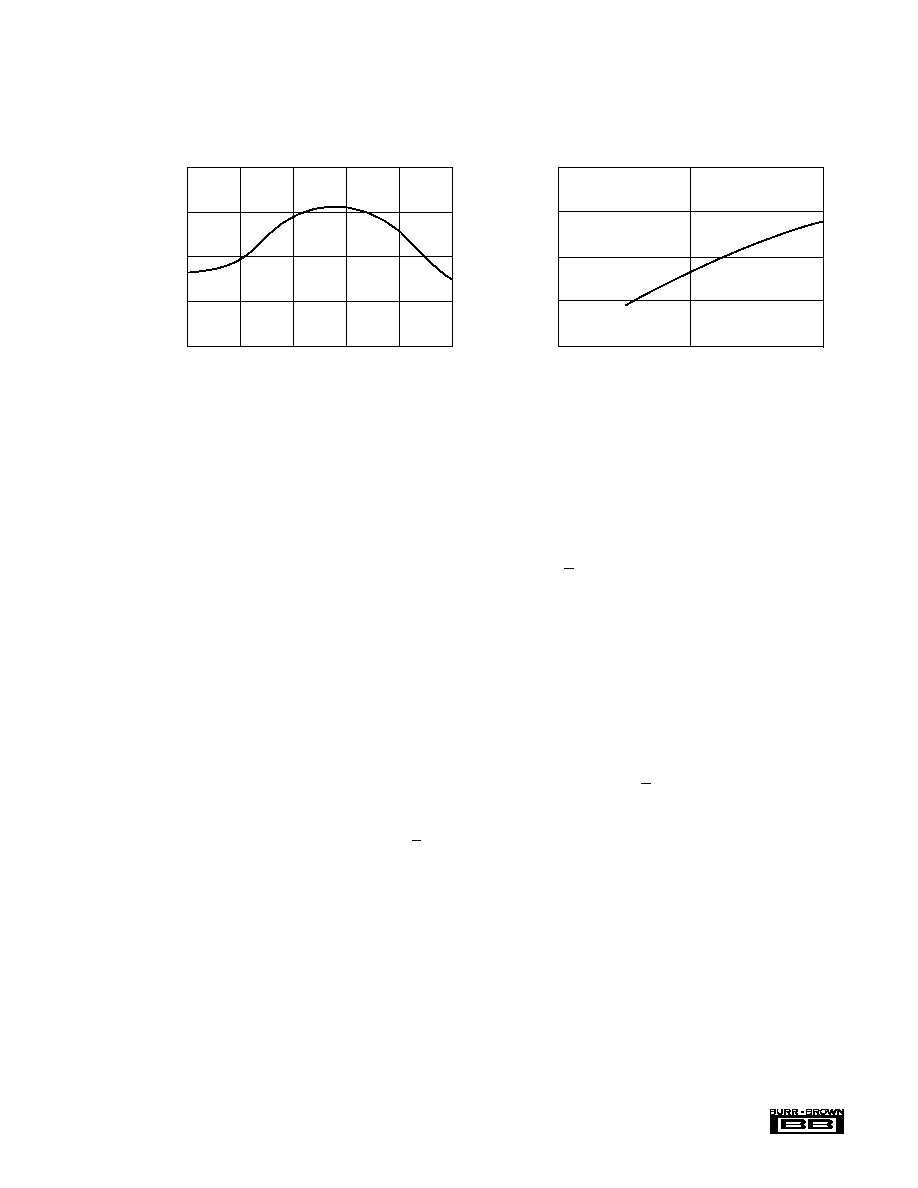

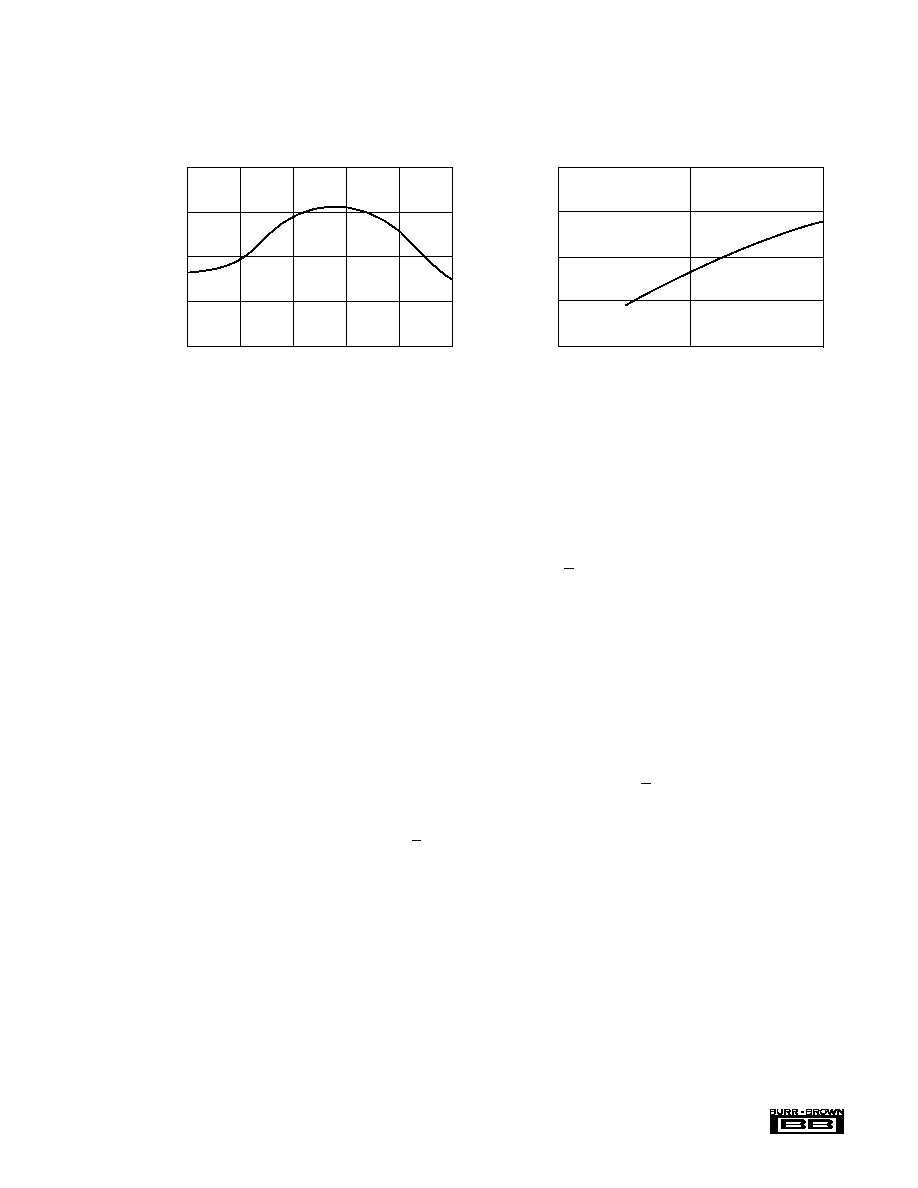

TYPICAL PERFORMANCE CURVES

T

A

= +25

∞

C, V

IN

= 15VDC, I

LOAD

=

±

15mA unless otherwise noted.

PWS750-4U LINE REGULATION

5.3

5.2

5.1

5

4.9

4.8

4.7

14

15

16

17

±V (V)

OUT

Input (V)

4.6

5.4

13

18

PWR750-2U LINE REGULATION

16

14

12

10

10

12

14

16

±V (V)

OUT

Input (V)

18

18

PWR750-2U AND PWS70-4U LOAD LINES

10

15

20

0

5

10

15

20

25

30

±V (V)

OUT

Load (mA)

PWS750-2U

PWS750-4U

OUTPUT RIPPLE VOLTAGE

50

40

30

20

10

0

0.2

0.4

0.6

0.8

1

Filter Capacitance (µF)

Ripple Voltage (mVp-p)

Ripple Frequency =

Oscillator Frequency

0.1

EFFICIENCY/LOAD CURVE

80

70

60

50

40

30

0

5

10

15

20

25

30

Efficiency (%)

PWS750-4U

4 Channel

PWS750-1U

PWS750-2U

Load Current (±mA)

TTL SIGNAL DUTY CYCLE

IN

100

75

50

25

0

% Duty Cycle

1

1.5

2

2.5

Synchronization Frequency (MHz)

(= Twice the FET Drive Frequency)

DC = %

t

H

t + t

H L

t

H

t

L

Acceptable

Duty

Cycle

Nominal Operating

Frequency

Synchronization Frequency (MHz)

(= Twice the FET Drive Frequency)

Æ

PWS750

5

THEORY OF OPERATION

The PWS750 components are basic building blocks to be

used with other standard components to build an isolated

push-pull DC/DC converter. The oscillator runs at 800kHz

nominal, making it possible to reduce the size of the trans-

former and lower the output ripple voltage.

PWS750-1U OSCILLATOR PIN FUNCTIONS

TTL

IN

is used to control the driver frequency with an

external TTL level frequency source. The input frequency

must be twice the desired driver frequency, since there is an

internal divide-by-2 circuit to produce a 50% duty cycle

output. The input duty cycle can vary from 12% to 95% (see

Typical Performance Curves). When in the free running

mode, the TTL

IN

pin must be tied to ground.

TTL

OUT

is used when it is desired to synchronize the outputs

of multiple PWS750-1Us to minimize beat frequency prob-

lems. A standard open collector output is provided, therefore

a 330

to 3.3k

pull-up resistor will be necessary depend-

ing on stray capacitance on the sync line. A maximum of

eight PWS750-1Us can be connected without the use of an

external TTL buffer.

An Enable pin is provided so that the driver (T, T) can be

shut down to minimize power use if required. A TTL low

applied to the pin will shut down the driver within one cycle.

A TTL high will enable the driver within one cycle. The

TTL

OUT

will still have an 800kHz signal when a master

driver is disabled, so other synchronized drivers will not be

shut down. The pin can be left open for normal operation.

The +V

IN

pin supplies power to the oscillator. The V

D

pin

connects the power to the transformer through the internal

overcurrent sense resistor. The other end of the overcurrent

sense resistor is tied to +V

IN

. A 0.3

µ

F bypass capacitor must

be connected to the V

D

pin to reduce the ripple current

through the shunt resistor; otherwise false current limit

conditions can occur due to ripple voltage peaks.

TYPICAL PERFORMANCE CURVES

(CONT)

T

A

= +25

∞

C, V

IN

= 15VDC, I

LOAD

=

±

15mA unless otherwise noted.

During overload conditions the output drive shuts off for

approximately 80

µ

s, then turns back on for 20

µ

s, resulting

in a 25% power up duty cycle. If the overload condition still

exists, then the output will shut off again. When the fault or

the excessive load is removed, the converter resumes normal

operation.

The T and T pins are the complementary FET drive outputs

and are tied directly to the corresponding FET gate. The

connection must be as short as possible. For multiple chan-

nel operation they cannot be located above any ground or

power planes, because capacitive loading will not allow fast

enough charging of the FET gate.

PWS750-2U AND PWS750-4U

TRANSFORMER PIN FUNCTIONS

On the primary side the V

D

pin of the PWS750-2U is tied

directly to the V

D

pin of the PWS750-1U. Remember to

place a 0.1

µ

F capacitor as close to the PWS750-2U V

D

pin

as possible. The T

O

and T

O

pins are connected to the drains

of the corresponding FETs, whose sources are connected to

ground. On the secondary side of the transformer, the Gnd

pin is tied directly to the isolated ground. AC pins are

800kHz square wave signals at twice the output voltage, and

are connected directly to the corresponding pin on the

PWS750-3U. Pins 2 and 4 can be interchanged for ease of

hook up. The connection to the diode bridge must be as

direct as possible to minimize radiated noise.

The winding ratio for the PWS750-2U is 1:1. This means

that the output would normally be less than the input due to

voltage drops in the FETs, transformer and diode bridge.

Since the DC/DC converter is operating at 800kHz, the

transformer is starting to operate close to the resonant

frequency, which causes the output to increase in magni-

tude.

OUTPUT VOLTAGE DRIFT WITH A ±15mA LOAD

15.5

15.25

15

14.75

14.5

≠25

0

25

50

75

100

Temperature (∞C)

V (V)

OUT

TTL

IN

Frequency (MHz)

1.5

1.6

2

1

16

15

±V

OUT

(V)

THE OUTPUT VOLTAGE CAN BE ADJUSTED

±3% BY VARYING THE DRIVER FREQUENCY

14

15.5

14.5

6

Æ

PWS750

+V

IN

FIGURE 1. Sample PC Board Layout, 4:1.

Æ

PWS750

7

6

5

7

PWS750-2U

2

3

4

3

6

PWS750-3U

4

1

Output

Gnd

0.3µF

≠V

O

+V

O

Duplicate for Up to 8 Channels

User Option

10µH

0.3µF

Input

Gnd

14

12

10

EN

TTL

IN

TTL

OUT

PWS750-1U

1

G

16

D

S

56

2N7002

T

T

3

7

11

V

D

IN

+V

+V

G

D

S

56

2N7002

G

D

S

2N7002

G

D

S

2N7002

0.3µF

0.3µF

PWS750-3U HIGH SPEED

DIODE BRIDGE PIN FUNCTIONS

The AC pins are tied directly to the AC pins of the PWS750-

2U. The +V and ≠V pins are rectified output voltages. The

filter capacitors must be located as close as possible to these

pins to minimize series inductance and therefore noise.

Bypass capacitors will be needed at each device in the

circuit.

BASIC OPERATION

SINGLE CHANNEL OPERATION,

PC BOARD LAYOUT CONSIDERATIONS

A simple two-layer board can be used on single channel

applications to create a DC/DC converter with low radiated

noise. A ground plane should be located directly under both

the input and the output components for optimum ground

return paths. The surface mount components make it easy to

design with a ground plane. The output filter capacitors

should be located as close to the PWS750-3U as possible. A

sample layout is shown in Figure 1.

For multiple channel applications, T and T traces must have

minimum capacitive loading. Therefore, there should be no

ground plane (or power plane) under these two traces. The

driver signal is a 4-6V low current 800kHz signal, which

will generate little radiated noise if the traces are kept short.

MULTIPLE CHANNEL OPERATION

The oscillator can drive up to four-channels (eight FETs)

directly when operating at 10-18V. A 10

resistor must be

placed in series with T and T to stabilize the FET gate

charging. For more than four-channel operation, or 5V-

multiple-channel operation, the driver circuit needs a FET

booster circuit, as shown in Figure 2. Large gate drive surge

currents (>100mA) are needed to turn on the gates.

If the total output current drawn by all the channels exceeds

250mA, then it will be necessary to circumvent the current

limit circuit by leaving the V

D

pin of the PWS750-1U open,

and connect the V

D

pin of the PWS750-2U directly to the

supply.

5V OPERATION

With 5V operation, the transformer winding current ratio is

3:1, therefore generating much greater currents in the pri-

mary. The input ripple voltage will be larger, so an input pi

filter will be necessary to isolate the converter noise from the

rest of the circuit. For example, when the output is

±

15mA

the input current will be at least 120mA.

MOSFET

MAX DRIVE CURRENT

PACKAGE

BREAKDOWN

TN0604

4A

TO-92

40V

2N7002

115mA

SO-T23

60V

2N7008

500mA

TO-92

60V

2N7010

1.3A

TO-237

60V

2N7012

1.2A

4-Pin DIP

60V

TABLE I. MOSFET Selector Guide.

FIGURE 2. MOSFET Driver Booster Circuits.

8

Æ

PWS750

2N7008, 8ea.

PWS750-2U

PWS750-2U

ISO122P

PWS750-3U

2

3

4

7

6

5

3

6

1

4

2

1

10

9

7

8

V

OUT

1µF

16

0.33 F

µ

10µH

+V

IN

+V

IN

15

7

3

1

16

2

1

10

9

8

V

OUT

16

+V

IN

15

1

4

1

4

2

1

10

9

7

7

10

9

2

1

8

16

15

8

16

15

V

OUT

+V

IN

PWS750-1U

+V

IN

V

OUT

11

14

ISO122P

ISO122P

ISO122P

7

1

4

3

6

2

3

4

7

6

5

PWS750-3U

PWS750-2U

PWS750-2U

PWS750-3U

2

3

4

7

6

5

3

6

1

4

1

4

3

6

2

3

4

7

6

5

PWS750-3U

1µF

OUTPUT CURRENT RATING

The PWS750-1U oscillator contains soft start circuitry to

protect the FETs from high inrush currents during turn on.

The internal input current limit is 250mA peak to prevent

thermal overload of the MOSFETs. The maximum output

rating is

±

30mA. Total current, which can be drawn from

each isolation channel, is the total of the power being drawn

from both the +V and ≠V outputs. For example, if one output

is not used, then maximum current can be drawn from the

other output. In all cases the maximum current that can be

drawn from any individual channel is:

|+I

OUT

| + |≠I

OUT

| < 60mA

It should be noted that many analog circuit functions do not

simultaneously draw equal current from both the positive

and negative supplies.

When multiple channel operation is used, the maximum

current of all channels must be reduced to prevent the

overcurrent limit to trip. Alternately, bypass the overcurrent

by leaving the V

D

pin of the PWS750-1U open and connect-

ing the V

D

pin of the PWS750-2U directly to the supply.

HIGH VOLTAGE TESTING

Burr-Brown Corporation has adopted a partial discharge test

criterion that conforms to the German VDE0884 optocou-

pler standard. This method requires that less than 5pC partial

discharge crosses the isolation barrier with 1200Vrms 60Hz

applied. This criterion confirms transient overvoltage (1.5

x

750Vrms) protection without damage to the PWS750-2U or

PWS750-4U. Life test results verify the absence of high

voltage breakdown under continuous rated voltage and maxi-

mum temperature.

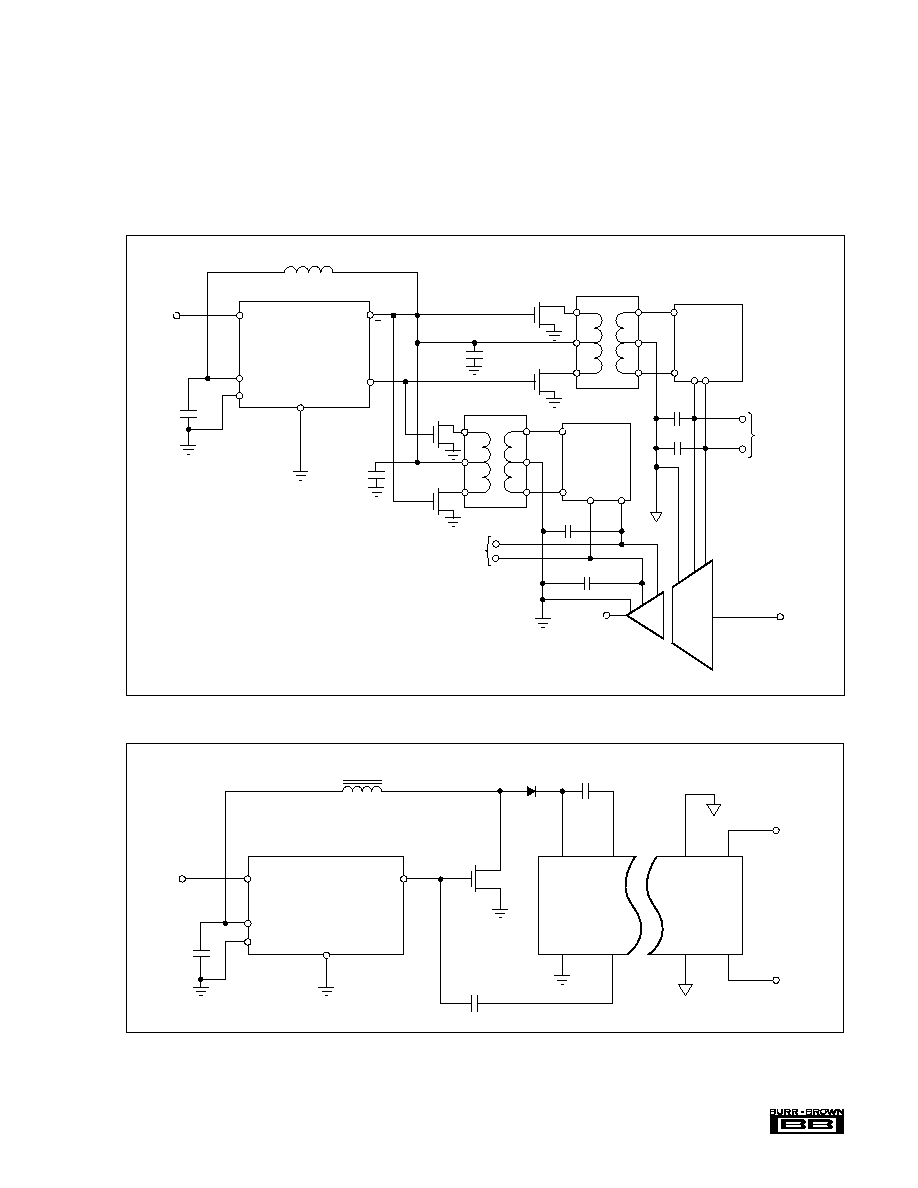

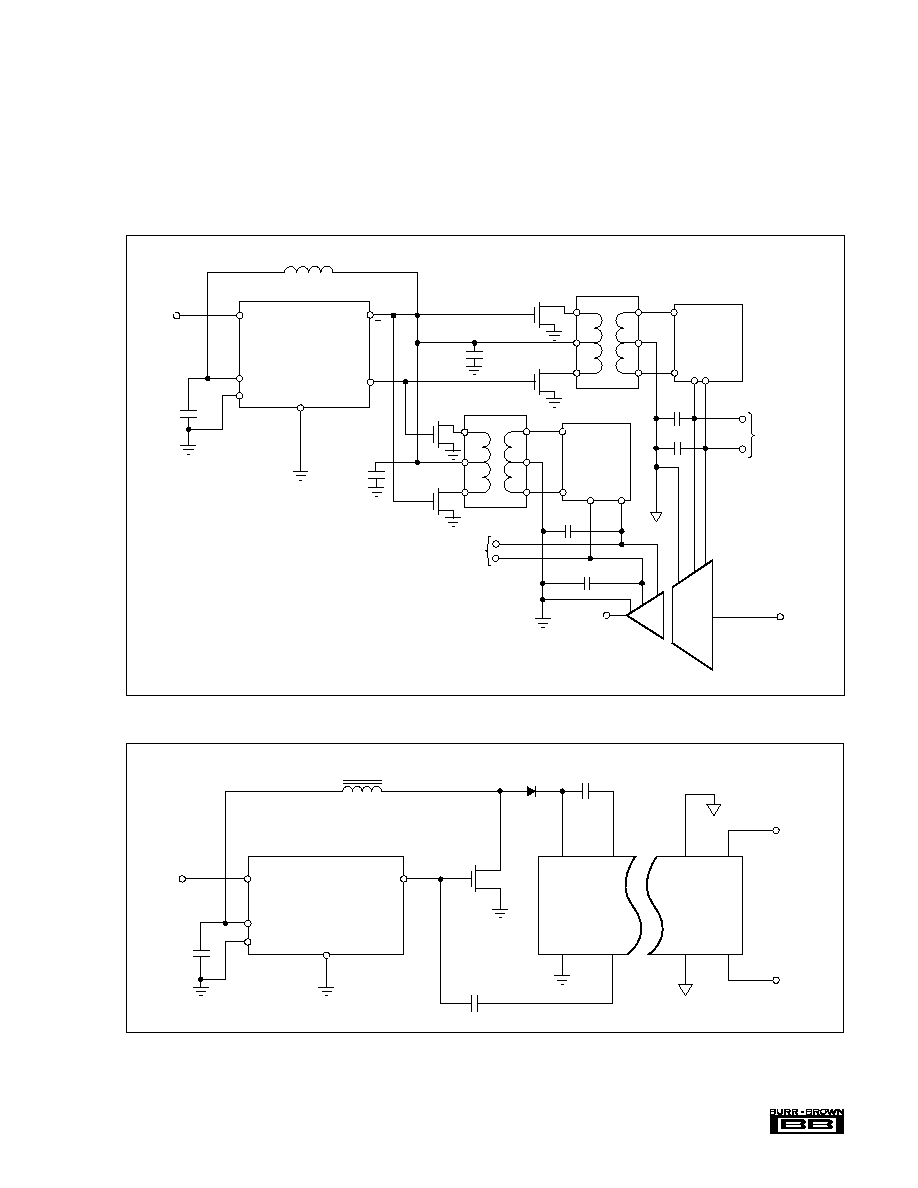

FIGURE 3. Four-Channels of

±

10V Signal Isolation with Channel-to-Channel Isolation.

Æ

PWS750

9

V ±10V

IN

15

1

2

16

Power for

input signal

conditioning

circuitry

0.3µF

0.3µF

4

1

6

8

10

9

V

±10V

OUT

0.3µF

Power for

output

circuitry

0.3µF

1

4

ISO122P

7

D

PWS750-3U

S

5

6

7

4

D

S

3

2

TNO604

10µH

PWS750-1U

+V

IN

V

D

7

3

11

Input

Gnd

14

16

T

0.3µF

0.3µF

D

PWS750-3U

S

5

6

7

4

D

S

3

2

PWS750-4U

3

6

3

5V

TNO604

TN0604

TN0604

PWS750-4U

1

T

180mA

3 Turns

PWS750-1U

7

3

11

14

1

TNO604

D

S

G

47pF

Gnd

0.3µF

+5V

1µF

16

19

15

14

PWS726

4

1

30

32

≠V

O

+V

O

V

D

TTL In

≠

T

H7F

TO7-14-3.5

The minimum AC barrier voltage that initiates partial dis-

charge above 5pC is defined as the "inception voltage."

Decreasing the barrier voltage to a lower level is required

before partial discharge ceases; this is known as "extinction

voltage." We have developed a package insulation system to

yield an inception voltage greater than 1200Vrms so that

transient voltages below this level will not damage the

isolation barrier. The extinction voltage is above 750Vrms

so that even overvoltage-induced partial discharge will cease

once the barrier voltage is reduced to the rated value.

Previous high voltage test methods relied on applying a

large enough overvoltage (above rating) to break down

marginal units, but not so high as to permanently damage

good ones. Our partial discharge testing gives us more

confidence in barrier reliability than breakdown/no break-

down criteria.

FIGURE 5. A PWS750 Driver Can Be Used to Boost the Input Voltage to 15V to Power a PWS726 From a 5V Supply.

FIGURE 4. A Complete

±

10V Signal Acquisition System Operating From a Single 5V Supply.

10

Æ

PWS750

1

4

D

S

10µH

PWS750-1U

+V

IN

V

D

7

Input

Gnd

14

1

T

0.3µF

PWS750-3U

4

5

3

2

1

PWS740-2

0.3µF

6

3

G

6

2N7008

0.3µF

Output

Gnd

+V

O

O

≠V

D

S

16

G

2N7008

3

11

V ±10V

IN

≠V +V

Power for input signal

conditioning circuits

1

4

2

3

22

24

21

ISO103

12

16

14

10

V ±10V

OUT

0.3µF

1

4

D

S

5

6

7

2

D

S

4

3

TN0604

10µH

PWS750-1U

+V

IN

V

D

7

3

11

Input

Gnd

14

16

1

0.3µF

0.3µF

PWS750-3U

S

D

S

PWS750-4U

0.3µF

6

3

5V

TN0604

TN0604

TN0604

PWS750-4U

D

G

G

G

G

1

4

PWS750-3U

6

3

0.3µF

+V

O

≠V

O

11

6

7

2

4

3

5

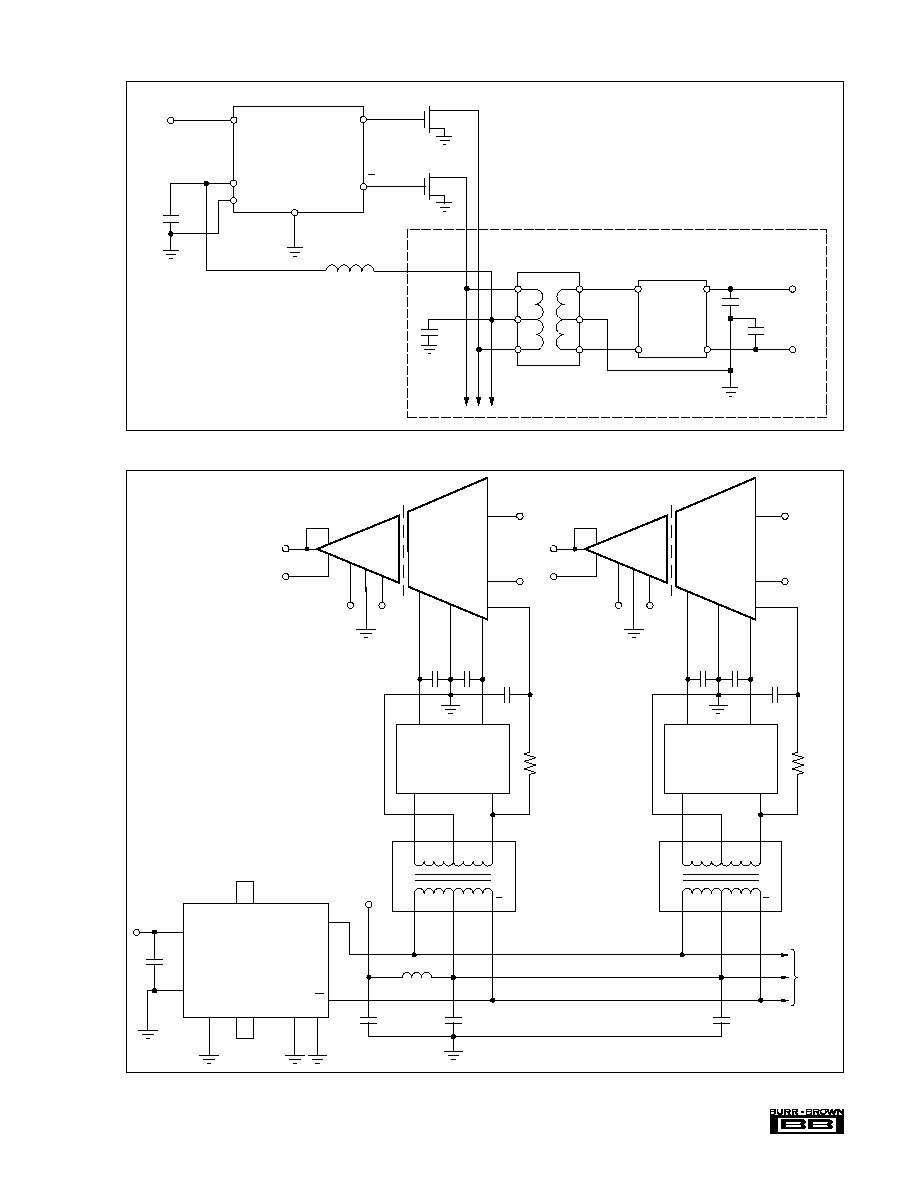

FIGURE 6. Powering the Internally Powered ISO103 Isolation Buffer From a Single 5V Supply. Two Power Channels Are

Necessary to Provide the 80mA Nominal for the +V of the ISO103.

FIGURE 7. 1500VAC Isolation Using PWS740-2 Transformer.

Æ

PWS750

11

TTL

6, 7

8

12

13

IN

4

5

T

T

PWS740-3

PWS750-3

0.3µF

V

IN

20µH

PWS745-1

5V

11

16

1

2, 3

14, 15

V

IN1

AC

GND

AC

3

6

PWS745-2

PWS740-2

PWS750-2

Gnd1

1

4

20k

20pF

+V

S1

≠V

S1

ISO120

23

21

V+

V≠

15

12

16

11

10

V

OUT1

9

22

Ext

Osc

4

24

3

0.3µF

PWS740-3

PWS750-3

V

IN2

AC

GND

AC

3

6

PWS745-2

PWS740-2

PWS750-2

Gnd2

1

4

20k

20pF

+V

S2

T

O

ISO120

23

21

22

Ext

Osc

4

24

3

0.3µF

10µF

V+

Up to 6

more

channels

V+

V≠

15

12

16

11

10

V

OUT2

9

V

D

T

O

T

O

V

D

T

O

0.3µF 0.3µF

0.3µF 0.3µF

V≠

V+

AC

AC

V≠

V+

AC

AC

1

4

D

S

D

S

10µH

PWS750-1U

+V

IN

V

D

7

3

11

Input

Gnd

14

T

1

T

16

0.3µF

PWS750-3U

5

6

4

3

2

PWS750-2U

0.3µF

6

3

G

G

7

2N7010

0.3µF

Output

Gnd

+V

O

O

≠V

Duplicate for up to 8 Channels

2N7010

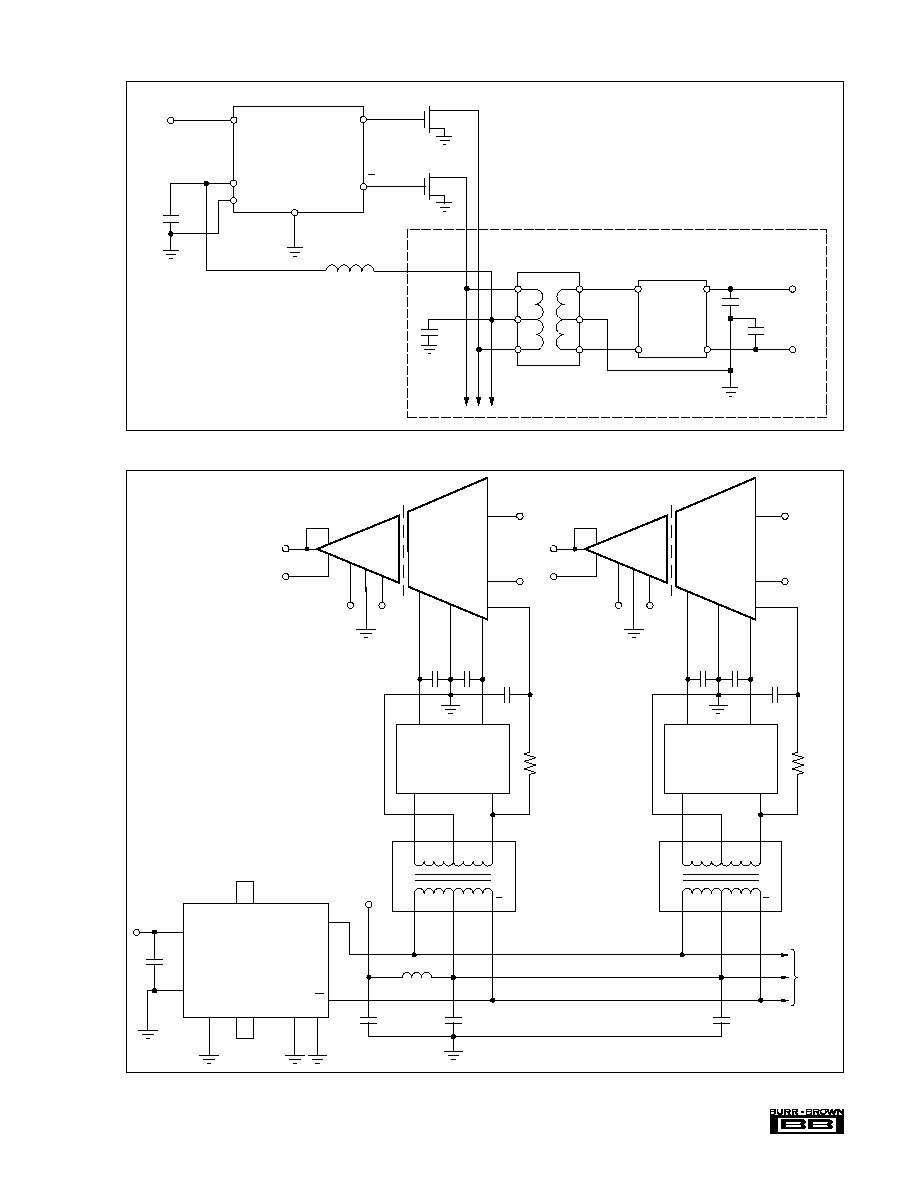

FIGURE 8. FET Pair Driving Up to Eight-Channels.

FIGURE 9. Synchronized-Multichannel Isolation System.