FEATURES

q

COMPLETE 12-BIT DATA ACQUISITION

SYSTEM IN A MINIATURE PACKAGE

q

INPUT RANGES SELECTABLE FOR

UNIPOLAR OR BIPOLAR OPERATION

q

THROUGHPUT RATES:

862/3

872/3

8-BIT ACCURACY:

45kHz

67kHz

12-BIT ACCURACY:

33kHz

50kHz

q

SELECTABLE GAINS OF 1, 10, AND 100

q

FULL MICROPROCESSOR COMPATIBLE

INTERFACE

q

GUARANTEED NO MISSING CODES OVER

TEMPERATURE

q

SURFACE-MOUNT OR PIN GRID ARRAY

PACKAGE OPTIONS

q

HIGH RELIABILITY SCREENED VERSIONS

AVAILABLE

q

FULL SPECIFICATION OVER THREE

TEMPERATURE RANGES:

0 to +70

�

C, �25 to +85

�

C, �55 to +125

�

C

q

EVERY UNIT SUPPLIED WITH

ELECTRICAL TEST DATA

APPLICATIONS

q

INDUSTRIAL PROCESS MONITORING

q

AIRBORNE SYSTEMS MONITORING

q

ENGINE MONITORING

FPO

43%

q

POWER PLANT MONITORING

q

SECURITY SYSTEMS MONITORING

q

AUTOMATIC TEST EQUIPMENT

DESCRIPTION

16 Single-Ended Inputs: SDM862

SDM872

8 Differential Inputs:

SDM863

SDM873

33kHz Throughput Rate: SDM862

SDM863

50kHz Throughput Rate: SDM872

SDM873

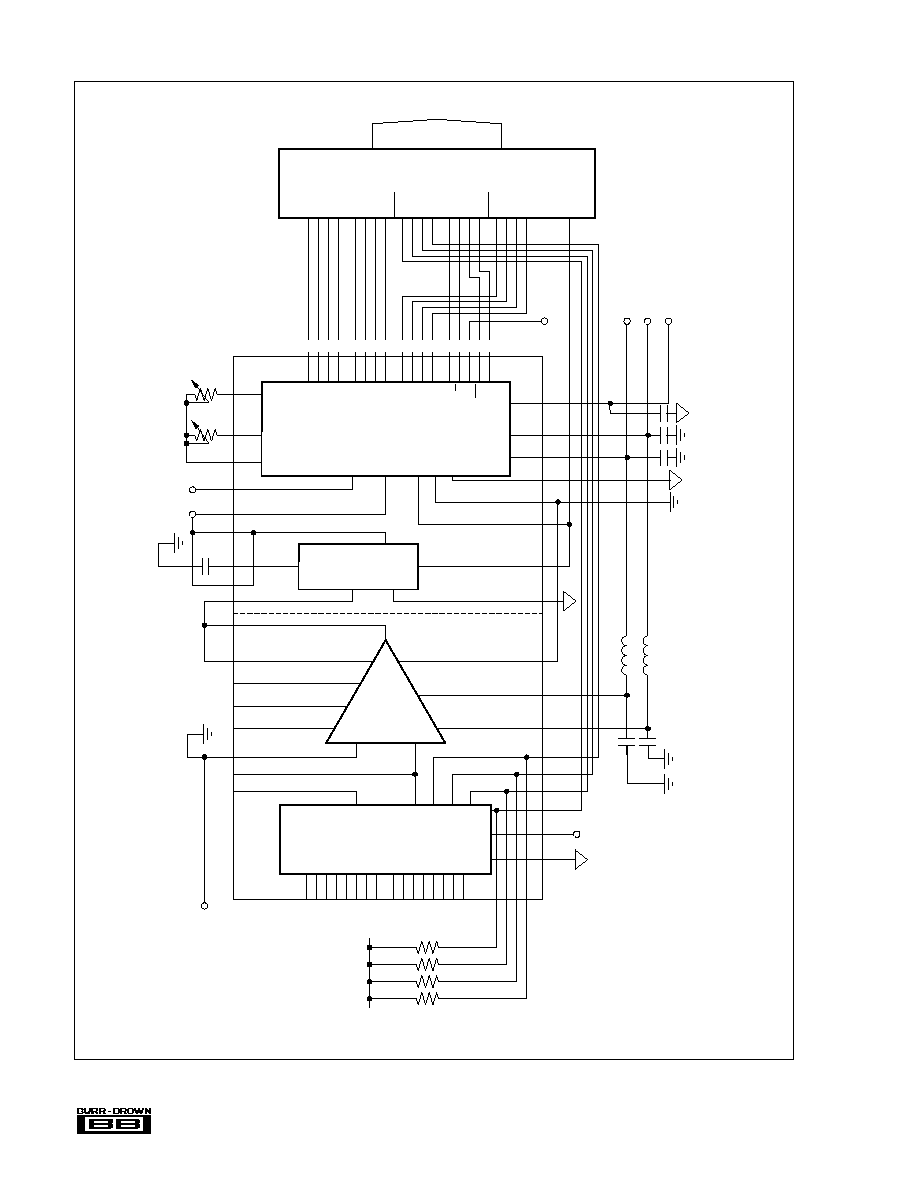

The SDM components are complete, pin-compatible,

data acquisition systems housed in a hermetically sealed

1"-square leadless chip carrier or a 1.1"-square pin grid

array. The small package outlines and low power con-

sumption provide an ideal data acquisition solution

when space is at a premium.

The devices comprise of an input multiplexer, instru-

mentation amplifier with selectable gains, sample/hold

amplifier and A/D converter with microprocessor inter-

face and three-state buffers.

The SDM family will accept unipolar or bipolar voltage

inputs in the range 0 to +10V,

�

5V and

�

10V. For low-

level signals, jumper-selectable gains of 10 or 100 can

be applied. The number of input channels can be ex-

panded by the addition of multiplexers. System integra-

tion is simplified by the microprocessor interface and

the facility of the sample/hold amplifier being con-

trolled directly by the A/D converter.

INA

16 CH

MUX

S/H

ADC

12 Bits

DIGITAL

ANALOG

862/872

863/873

8 CH

8 CH

FPO 46%

International Airport Industrial Park � Mailing Address: PO Box 11400 � Tucson, AZ 85734 � Street Address: 6730 S. Tucson Blvd. � Tucson, AZ 85706

Tel: (520) 746-1111 � Twx: 910-952-1111 � Cable: BBRCORP � Telex: 066-6491 � FAX: (520) 889-1510 � Immediate Product Info: (800) 548-6132

�

SDM862

SDM863

SDM872

SDM873

16 Single Ended/8 Differential Input

12-BIT DATA ACQUISITION SYSTEMS

� 1988 Burr-Brown Corporation

PDS-686F

Printed in U.S.A. August, 1993

�

SDM862/863/872/873

2

16 Single-Ended

or

8 Differential

Input

Multiplexer

Inst

Amp

S/H

Amp

12-Bit

A/D

Converter

Digital

Data

Outputs

CH0

+

�

CH7

CH

15

CH0

CH7

CH0

+ � �

+

�

*(Output MUX Minus)

Only on SDM863/873

Input

Channel

Select

Enable

S/H Control

Output MUX*

Input Amp

Gain

Select

Amp Output

S/H Input

S/H Output

Hold Capacitor

S/H Output

Input Range

Bipolar Offset

Reference In

Reference Out

S/H Common

Data Mode

Byte Select

Chip Select

Chip Enable

Read/Convert

Status

Reference

Sense

or

SDM863, SDM873

SDM862, SDM872

SPECIFICATIONS

ELECTRICAL

At +25

�

C, V

CC

=

�

15V, V

DD

= 5V, external sample/hold capacitor of 4700pF. All grades are burned-in at +125

�

C for 48 hours min.

�

5,

�

10

0-10

SDM862/863/872/873 J, A, R

SDM862/863/872/873 K, B, S

PARAMETER

MIN

TYP

MAX

MIN

TYP

MAX

UNITS

RESOLUTION

12

*

Bits

INPUT

ANALOG

Voltage Ranges: Bipolar

V

Unipolar

V

Input Impedance: On Channel

10

10

*

Off Channel

10

10

*

Input Capacitance: On Channel

20

*

pF

Off Channel

20

*

pF

CMRR (20VDC to 1kHz)

80

85

*

*

dB

Crosstalk (20Vp-p, 1kHz)

(1)

�85

�80

*

*

dB

Feedthrough (at 1kHz)

(1)

�85

�80

*

*

dB

Offset (channel to channel) G = 1

(2)

30

100

*

*

�

V

Input Bias Current/Channel

1

5

*

*

nA

Input Voltage Range

(3)

+10

+11

*

*

V

�10

�15

*

*

V

DIGITAL

(7, 8)

MUX Input Channel Select: Logic `1'

5

30

*

*

�

A

Logic `0'

5

30

*

*

�

A

MUX Input: Logic High

4.0

*

V

Logic Low

0.8

*

V

S/H Command: Logic `1'

0.2

*

nA

Logic `0'

5

30

*

*

�

A

ADC Section: Logic `1'

10

*

�

A

Logic `0'

10

*

�

A

TRANSFER CHARACTERISTICS

ACCURACY

Integral Linearity

(4)

�

0.024

�

0.012

%FSR

Differential Linearity

(4)

�

0.024

*

%FSR

No Missing Codes

Over Operating Temperature Range

Gain Error

(5)

: G = 1

0.5

*

%

G = 100

0.9

*

%

Unipolar Offset Error

(5)

16

*

mV

Bipolar Offset Error

(5)

50

*

mV

Noise Error

(Measured at S/H Output) G = 1

0.5

1

*

*

mVp-p

Droop Rate

50

500

*

*

�

V/ms

Temperature Coefficients:

Unipolar Offset

20

15

ppm of FSR/

�

C

Bipolar Offset

30

25

ppm of FSR/

�

C

Full-Scale Calibration

60

35

ppm of FSR/

�

C

�

SDM862/863/872/873

3

SPECIFICATIONS

ELECTRICAL

At +25

�

C, V

CC

=

�

15V, V

DD

= 5V, external sample/hold capacitor of 4700pF.

* Specification same as SDM862/863/872/873J, A, R grades.

NOTES: (1) Measured at the same and hold output. (2) Measured with all input channels grounded. (3) The range of voltage on any input with respect to common over

which accuracy and leakage current is guaranteed. (4) Applicable over full operating temperature range. NO MISSING CODES GUARANTEED OVER TEMPERATURE

RANGE. (5) Adjustable to zero using external potentiometer or select-on-test resistor. (6) Specifications are at +25

�

C and measured at 50% level of transition. (7) When

using TTL drivers a 1k

pull-up resistor should be used. (8) Muxes operate in a break-before-make manner.

Unipolar Straight Binary (USB)

Bipolar Offset Binary (BOB)

SDM862/863/872/873 J, A, R

SDM862/863/872/873 K, B, S

PARAMETERS

MIN

TYP

MAX

MIN

TYP

MAX

UNITS

SYSTEM TIMINGS

ADC Conversion Time: SDM862/SDM863

9

20

25

*

*

*

�

s

SDM872/SDM873

9

12

15

*

*

*

�

s

S/H Aperture Delay

50

*

ns

S/H Aperture Uncertainty

2

*

ns

TIMING

Throughput (Serial Mode)

SDM862/SDM863

22

*

kHz

SDM872/SDM873

28

*

kHz

(Overlap Mode):

SDM862/SDM863

33

*

kHz

SDM872/SDM873

50

*

kHz

MULTIPLEXER

(6)

Switching Time (between channels)

+1.5

*

�

s

Settling Time (10V step to 0.02%)

2.5

*

�

s

Enable Time `ON'

1

2

*

*

�

s

`OFF'

0.25

0.5

*

*

�

s

INSTRUMENTATION AMPLIFIER

(6)

Settling Time (20V step to 0.01%)

G = 1

5

12.5

*

*

�

s

G = 10

3

7.5

*

*

�

s

G = 100

4

7.5

*

*

�

s

Slew Rate

12

17

*

*

V/

�

s

S/H AMPLIFIER

(6)

Acquisition (10V step to 0.01%)

5

*

�

s

Aperture Delay

50

*

ns

Hold Mode Settling Time

1.5

*

�

s

Slew Rate

10

*

V/

�

s

OUTPUT

DIGITAL DATA

Output Codes: Unipolar

Bipolar

Logic Levels: Logic 0 (Sink = 1.6mA)

+0.4

*

V

Logic 1 (Source = 500

�

A)

+2.4

*

V

Leakage (Data Bits Only), High-Z State

�5

0.1

+5

*

*

*

�

A

POWER SUPPLY REQUIREMENTS

Rated Voltage: Analog (

�

V

CC

)

14.25

15

15.75

*

*

*

VDC

Digital (V

DD

)

4.5

5

5.5

*

*

*

VDC

Supply Drain: +15V

13

22

*

*

mA

�15V

22

30

*

*

mA

+5V

11

15

*

*

mA

Power Dissipation

580

855

*

*

mW

TEMPERATURE RANGE

Operating Temperature Range

JH, KH/JL, KL

0

70

*

*

�

C

AH, BH/AL, BL

�25

+85

*

*

�

C

RH, SH/RL, SL

�55

+125

*

*

�

C

Storage Temperature Range

�65

+150

*

*

�

C

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user's own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

�

SDM862/863/872/873

4

DIGITAL TIMING

CONVERSION CYCLE TIMING

SYMBOL

PARAMETER

MIN

TYP

MAX

UNITS

CONVERT MODE

tdsc

Status Delay from CE

100

200

ns

thec

CE Pulse Width

50

30

ns

tssc

CS to CE Setup

50

20

ns

thsc

CS Low During CE High

50

20

ns

tsrc

R/C to CE Setup

50

0

ns

thrc

R/C Low During CE High

50

20

ns

tsac

Byte Select to CE Setup

0

0

ns

thac

Byte Selected Valid During CE High 50

20

ns

tc 86X

Conversion Time: 12 Bit Cycle

9

20

25

�

s

8 Bit Cycle

6

13

17

�

s

tc 87X

Conversion Time: 12 Bit Cycle

9

12

15

�

s

8 Bit Cycle

6

8

10

�

s

READ MODE

tdd

Access Time from CE

75

150

ns

thd

Data Valid after CE Low

25

35

ns

thl

Output Float Delay

100

150

ns

tssr

CS to CE Setup

50

0

ns

tsrr

R/C to CE Setup

0

0

ns

tsar

Byte Select to CE Setup

50

25

ns

thsr

CS Valid after CE Low

0

0

ns

thrr

R/C High after CE Low

0

0

ns

thar

Byte Select Valid after CE Low

50

25

ns

ths 86X

Status Delay after Data Valid

100

500

1000

ns

ths 87X

Status Delay after Data Valid

100

300

600

ns

ABSOLUTE MAXIMUM RATINGS

(1)

+V

CC

to ACOM .................................................................... �0.5V to +16V

�V

CC

to ACOM ....................................................................... +0.5 to �16V

+V

DD

to DCOM ................................................................... �0.5V to +7.0V

Analog Input Signal Range ................................ +V

CC

+20V to �V

CC

�20V

Digital Input Signal ............................................................... �0.5V to +V

DD

ACOM to DCOM ..................................................................................

�

1V

DBO

CE

t

HEC

t

SSC

t

SRC

t

HSC

t

HRC

t

HAC

t

SAC

t

DSC

t

C

High Impedance

CS

R/C

STS

DB11�

Byte

Select

NOTE: (1) Absolute maximum ratings are limiting values applied individually,

beyond which the serviceability of the circuit may be impaired. Functions

operation under any of these conditions is not necessarily implied.

/QM HIGH RELIABILITY SCREENING

High Power Internal

Visual Inspection .......................................... Burr-Brown Spec. QC2010

Stabilization Bake ............................................................. 24Hr at +150

�

C

Temperature Cycling ...................................... 10 Cycles �65

�

C to +150

�

C

Constant Acceleration .......................................................... 30kG, Y1 axis

Hermeticity Fine Leak ................................................. Helium 5

x

10

�8

cc/s

Hermeticity Gross Leak ......................................................... Fluorocarbon

Burn-In ............................................................................ 160Hr at +125

�

C

READ CYCLE TIMING

CE

t

SSR

t

SRR

t

HRR

t

HS

t

HD

High-Z

CS

R/C

t

HSR

t

HAR

t

SAR

Data Valid

t

HL

t

DD

STS

Byte

Select

DB11�

DBO

�

SDM862/863/872/873

5

NOTE: (1) 16 single-ended inputs, LCC package, with accuracy of 0.24% FSR. Temp Range of 0

�

C to +70

�

C and throughput of 33kHz = SDM862JL.

LCC, PGA

Accuracy

Temperature

LCC, PGA

Accuracy

Temperature

Product

Input

Package

(% FSR)

Throughput

Range (

�

C)

Product

Input

Package

(% FSR)

Throughput

Range (

�

C)

SDM862J

16SE

L,H

�

0.024

33kHz

0 to +70

SDM863J

8DIF

L, H

�

0.024

33kHz

0 to +70

SDM862K

16SE

L,H

�

0.012

33kHz

0 to +70

SDM863K

8DIF

L, H

�

0.012

33kHz

0 to +70

SDM862A

16SE

L,H

�

0.024

33kHz

�25 to +85

SDM863A

8DIF

L, H

�

0.024

33kHz

�25 to +85

SDM862B

16SE

L,H

�

0.012

33kHz

�25 to +85

SDM863B

8DIF

L, H

�

0.012

33kHz

�25 to +85

SDM862R

16SE

L,H

�

0.024

33kHz

�55 to +125

SDM863R

8DIF

L, H

�

0.024

33kHz

�55 to +125

SDM862S

16SE

L,H

�

0.012

33kHz

�55 to +125

SDM863S

8DIF

L, H

�

0.012

33kHz

�55 to +125

SDM872J

16SE

L,H

�

0.024

50kHz

0 to +70

SDM873J

8DIF

L,H

�

0.024

50kHz

0 to +70

SDM872K

16SE

L,H

�

0.012

50kHz

0 to +70

SDM873K

8DIF

L,H

�

0.012

50kHz

0 to +70

SDM872A

16SE

L,H

�

0.024

50kHz

�25 to +85

SDM873A

8DIF

L,H

�

0.024

50kHz

�25 to +85

SDM872B

16SE

L,H

�

0.012

50kHz

�25 to +85

SDM873B

8DIF

L,H

�

0.012

50kHz

�25 to +85

SDM872R

16SE

L,H

�

0.024

50kHz

�55 to +125

SDM873R

8DIF

L,H

�

0.024

50kHz

�55 to +125

SDM872S

16SE

L,H

�

0.012

50kHz

�55 to +125

SDM873S

8DIF

L,H

�

0.012

50kHz

�55 to +125

ORDERING INFORMATION

(1)

PACKAGE DRAWING

PRODUCT

DESCRIPTION

NUMBER

(1)

PC862/863-1

LCC (Socketed) Evaluation PCB

(2)

907

PC862/863-2

PGA Evaluation PCB

906

PACKAGE INFORMATION

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book. (2) Socket is MC0068-1.

�

SDM862/863/872/873

6

PIN CONFIGURATIONS

51

34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

AMP OUT

AMP REF

+15V (1)

�15V (1)

+5V (2)

STATUS

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

MUX ADD2

MUX ADD1

MUX ADD0

MUX ENABLE

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

S/H IN

NC

S/H OUT

HOLD CAP

S/H OUT

MUX ADD3

DCOM (1)

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

RG

G10

G100

MUX OUT +/AMP IN+

AMP IN�

NC

AMP SENSE

S/H COM (2)

S/H CONT

BYTE SELECT

CS

DATA MODE

R/C

CE

+15V (2)

REF OUT

ACOM (2)

REF IN

BIP OFF

ADC IN (10V)

ADC IN (20V)

�15V (2)

DCOM (2)

D0

MUX

INA

A/D

DOTTED

LINE

SHOWS

SUPPLY

SEPARATION

PIN

GROUPING

BY

FUNCTION

S/H

51

34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

AMP OUT

AMP REF

+15V (1)

�15V (1)

+5V (2)

STATUS

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

MUX ADD2

MUX ADD1

MUX ADD0

MUX ENABLE

CH0+

CH1+

CH2+

CH3+

CH4+

CH5+

CH6+

CH7+

S/H IN

NC

S/H OUT

HOLD CAP

S/H OUT

S/H COM (2)

S/H CONT

BYTE SELECT

CS

DATA MODE

R/C

CE

+15V (2)

REF OUT

ACOM (2)

REF IN

BIP OFF

ADC IN (10V)

ADC IN (20V)

�15V (2)

DCOM (2)

D0

MUX

INA

A/D

DOTTED

LINE

SHOWS

SUPPLY

SEPARATION

PIN

GROUPING

BY

FUNCTION

S/H

NC

DCOM (1)

CH0�

CH1�

CH2�

CH3�

CH4�

CH5�

CH6�

CH7�

RG

G10

G100

MUX OUT +/AMP IN+

AMP IN�

MUX OUT�

AMP SENSE

TOP VIEW

SDM863/SDM873

TOP VIEW

SDM862/SDM872

�

SDM862/863/872/873

7

PIN DESIGNATION

DEFINITION

COMMENTS

SDM8X2 = SDM862 OR SDM872

CH0 to CH15

Channel Inputs

Analog Inputs (Total 16) for single-ended and differential operation. Unused

CH0 to CH7 (+, �)

inputs must be connected to analog common.

(PINS 40 to 47, 54 to 61)

MUX OUT+/AMP IN+

MULTIPLEXER "HI" OUTPUT

On the SDM8X2 this is the multiplexer output. On the SDM8X3 it is the

output of the positive selected inputs. It is connected internally to the

(PIN 65)

positive input of the instrumentation amplifier.

MUXOUT (Pin 67)

MULTIPLEXER "LO" OUTPUT

This pin is used on the SDM8X3 only. It should be connected to the negative

input of the instrumentation amplifier.

AMP IN (Pin 66)

Negative input of instrumentation

On the SDM8X2 this should be connected to analog common. On the

amplifier

SDM8X3 it should be connected to Muxout--(Pin 67).

AMP OUT (Pin 1)

Output of instrumentation amplifier

This pin should be connected to the input of the S/H amplifier (Pin 39).

AMP SENSE (Pin 68)

Output sense line of instrumentation

This pin will normally be connected direct to AMP OUT (Pin 1).

amplifier

AMP REF (Pin 2)

Reference for amplifier output

This pin will normally be connected to analog common. Care should be

taken to minimize tracking and contact resistance to analog common to

optimize system accuracy.

S/H OUT (Pins 35/37)

Output of sample/hold amplifier

Two pins are provided to facilitate a guard ring around the hold capacitor

pin. These pins should be connected to either ADC in (20V) or ADC in (10V)

depending on the desired range.

HOLD CAP (Pin 36)

Connection for hold capacitor on

The tracking to the hold capacitor should be as short as possible and a

S/H amplifier

guard ring employed using Pins 35 and 37.

ADC IN (20V); ADC IN (10V)

Inputs to A/D converter

Connect to S/H amplifier output. Use appropriate pin for desired range.

(Pins 21, 22)

RG, G10, G100

Gain settling pins on instrumentation

For Gain = 1, no connections. For Gain = 10, connect G10 to RG.

(Pins 62, 63, 64)

amplifier

For Gain = 100, connect G100 to RG.

REF OUT (PIN 26)

10V Reference voltage

This is the reference voltage for the A/D converter.

REF IN, BIP OFF

Reference input and offset input to

Connect trim potentiometers (or select-on-test resistors) to these pins for

(Pins 24, 23)

A/D converter

unipolar or bipolar operation as shown in Figures 12, 13.

S/H IN (Pin 39)

Input to sample/hold amplifier

Connect to amp out (Pin 1).

MUX ENABLE (Pin 48)

Multiplex enable/disable

Logic `1' on this pin will enable a selected channel on the internal

multiplexer. Logic `0' de-selects all channels.

MUX ADD0 to MUX ADD3

Address inputs for channel selection

These address lines select a particular channel as specified in Figure 24.

(Pins 49 to 52)

S/H CONT (Pin 33)

Track/Hold control on S/H amplifier

Logic `1' holds an analog value for conversion by the A/D converter. This line

may be controlled by the status (Pin 6) of the converter to simplify external

timing control.

S/H COM (Pin 34)

Reference for S/H logic control

Connect to digital common.

D0 to D11 (Pins 7 to 18)

3-state digital outputs

The 12- or 8-bit result of a conversion is available as output on these pins

(D0-LSB, D11-MSB).

STATUS (Pin 6)

Status of A/D conversion

This output is at logic `1' while the internal A/D converter is carrying out a

conversion. This pin may be used to directly control the S/H amplifier.

CE (Pin 28)

Chip enable

This input must be at logic `1' to either initiate a conversion or read output

data (see Figures 10, 17, 18, 19, 20).

CS (Pin 31)

Chip select

This input must be at logic `0' to either initiate a conversion or read output

data (see Figures 10, 17, 18, 19, 20).

R/C (Pin 29)

Read/convert

Data can be read when this pin is logic `1' or a conversion can be initiated

when this pin is logic `0'. This pin is typically connected to the R/W control

line of a microprocessor-based system (see Figures 10, 17, 18, 19, 20).

DATA MODE (Pin 30)

Select 12- or 8-Bit Data

When data mode is at logic `1' all 12 output data bits are enabled

simultaneously. When data mode is at logic `0' MSBs and LSBs are

controlled by byte select (Pin 32).

BYTE SELECT (Pin 32)

Byte address, short cycle

When reading output data, byte select at logic `0' enables the 8 MSBs. Byte

select at logic `1' enables the 4 LSBs. The 4 LSBs can therefore be connected

to four of the MSB lines for inter-connection to an 8-bit bus. In start convert

mode, logic `0' enables a 12-bit conversion while logic `1' will short cycle the

conversion to 8 bits (see Figure 10).

+15V(1), +15V(2)(Pins 3, 27)

Power Supply

Connect to +15V supply using decoupling as indicated in Figures 15, 16.

�15V(1), �15V(2)(Pins 4, 20)

Power Supply

Connect to �15V supply using decoupling as indicated in Figures 15, 16.

ACOM(2) (Pin 25)

Analog Common

Analog common connection. Note that a common (including digital

common) should be connected together at one point close to the device.

DCOM (1) (Pin 53)

Reference for MUX logic control.

Connect to digital common.

+5V (Pin 5)

Logic power supply

Connect to +5V digital supply line with decoupling as in Figures 15, 16.

DCOM(2) (Pin 19)

Reference for A/D converter control

Connect to S/H common at one point close to device.

lines

NC (Pin 38)

No internal connection

�

SDM862/863/872/873

8

All data acquisition systems using a MUX require consider-

ation of the errors that may be introduced by MUX output

capacitance. The applications information explains this more

fully in the input filtering section.

Shown in Figure 3 is an application that demonstrates the

flexibility of signal conditioning and gives the opportunity

to use a higher bandwidth filter. Diodes shown are low

leakage types (1na). The low output impedance of the

amplifiers reduces the time taken to charge MUX capaci-

tance C

M

.

INSTRUMENT AMPLIFIER

The instrument amplifier (INA) presents a very high input

impedance to the signal source, eliminating gain errors

introduced by voltage divider action between the source

output impedance and SDM input impedance. Where the

differential models are used, the INA performs the differen-

tial to single-ended conversion required to drive the sample/

hold amplifier. Gains may be set by using external jumpers,

to values of 1 (no jumper), 10 and 100. For gains other than

these presets, the following formula may be used to find an

external resistor value to add in series with the G = 10 or G

= 100 jumpers.

40k

Where Ri = 4444

, G = 10 input.

G � 1

404

, G = 100 input.

It should be noted that the internal gain set resistors have a

�

20% tolerance and

�

20ppm/

�

C drift.

to ensure that neither of the differential inputs exceed the

maximum input range. Otherwise, signal distortion will

result. A return path for the input bias currents must always

be provided. This prevents the charging of stray capaci-

tances in applications using floating sources, such as trans-

formers and thermocouples. Multiplexer inputs are protected

from overvoltage, as indicated in the electrical specifica-

tions, and should be current limited to 20mA.

Where high-speed operation is required and channels require

rapid sampling, then it is important to buffer the inputs

against the effect of current sharing between the MUX

output capacitance and the input filter capacitance. See

Figure 2.

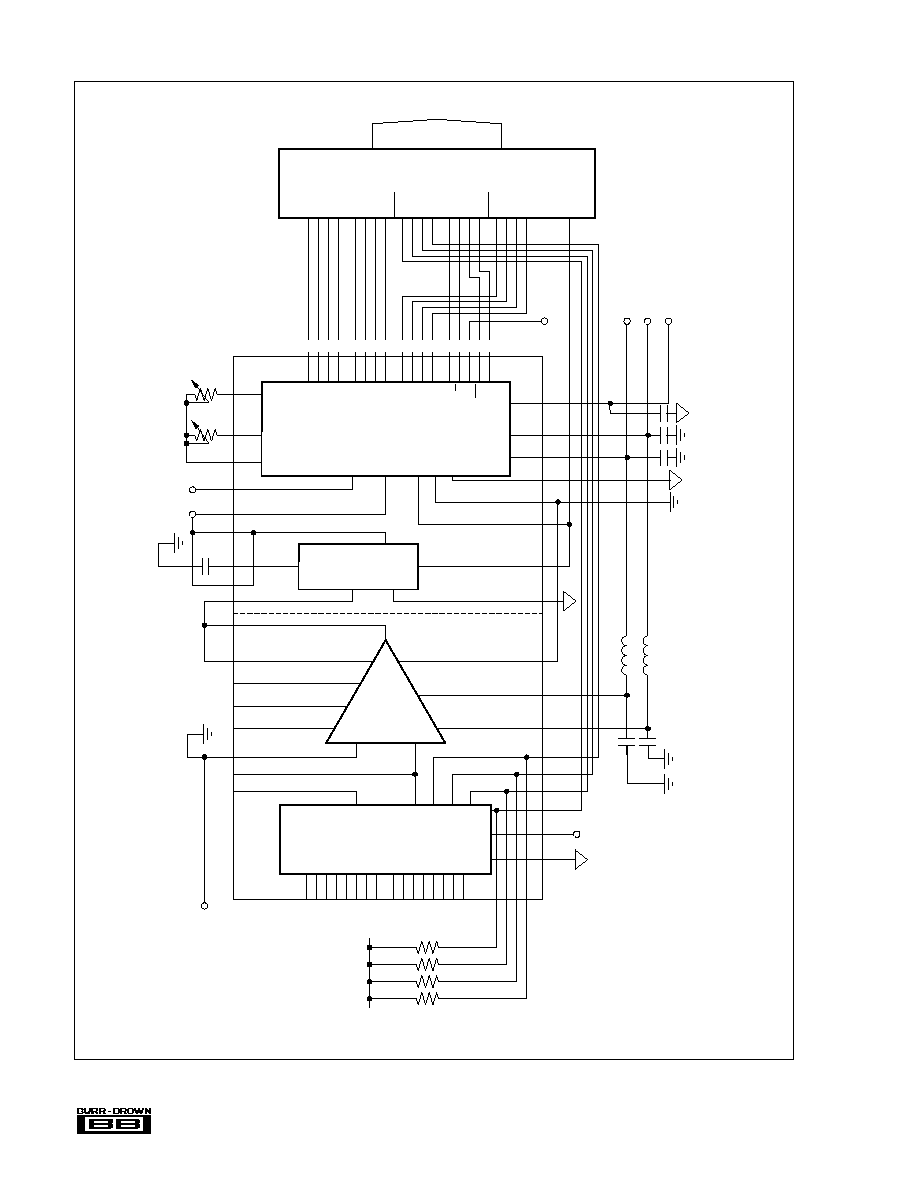

SYSTEM DESCRIPTION

The SDM comprises four circuit elements--an input-pro-

tected multiplexer, an instrumentation amplifier, a sample/

hold amplifier, and an analog-to-digital converter.

INSTALLATION

MULTIPLEXER

The SDM family has a choice of input multiplexers (MUX).

SDM862 and SDM872:

16 single-ended inputs

SDM863 and SDM873:

8 differential inputs

On all models, the analog inputs may be expanded using the

enable control. See Figure 1. When the enable is at a logic

"0," the internal MUX is disabled, allowing additional

multiplexers to be connected in parallel. The limiting factor

for the number of additional multiplexers is the cumulative

effect of leakage current flowing in the signal source imped-

ance, causing offset errors.

Differential inputs will generally eliminate the noise associ-

ated with common system grounds, but care must be taken

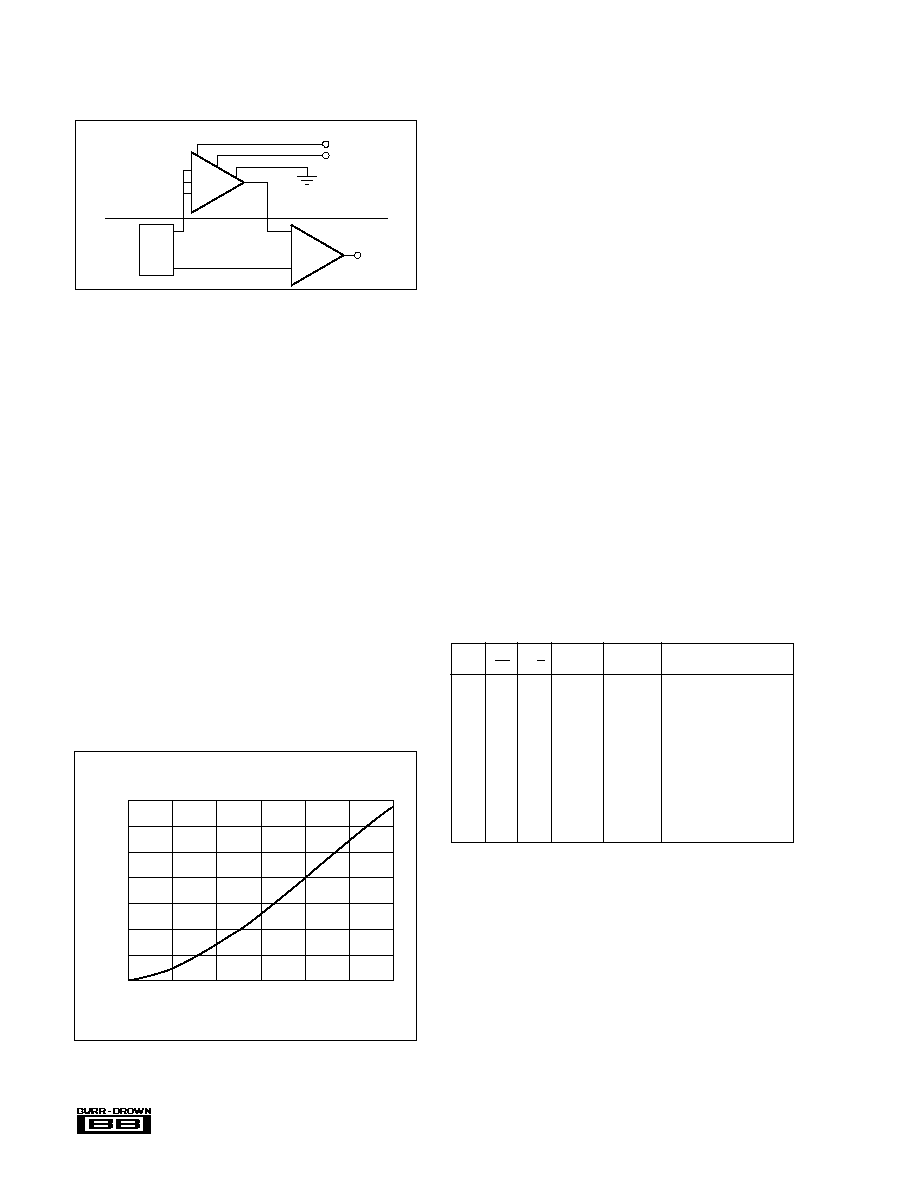

FIGURE 1. External Multiplexer Connections for Differen-

tial and Single-Ended Operation.

FIGURE 2. Filter and MUX Capacitance

.

� Ri

R

ext

=

C

f

C

M

C

f

MUX

A3

A2

A1

A0

Out

A3

A2

A1

A0

Out

A2

A1

A0

� Out

+Out

D-Com

EN

D-Com

EN

D-Com

EN

49 50 51 52 48 65

66

53

SDM8X2

66

A2

A1

A0

�Out

+Out

D-Com

EN

A0

A1

A2

A3

MUX

Extern

49 50 51 48

65

53

SDM8X3

67

A0

A1

A2

A3

INA

INA

A4

MUX

Intern

MUX

Intern

MUX

Extern

�

SDM862/863/872/873

9

Matching of R

1

and R

3

is required to maintain high

common-mode rejection (CMR), R

2

sets the gain and may

be varied without effect on CMR.

To ensure that the effects of temperature are minimized

when altering the gain with external components, it is very

important to use low tempco resistors. When connecting the

output sense, ensure that series resistance is minimized

because resistance present will degrade CMR.

FIGURE 5. Increasing Output Amplifier Gain.

20k

20k

4.44k

404

FET Input

10k

10k

10k

10k

FET Input

A1

A3

A2

R

1

R

2

R

3

FIGURE 4. Use External Gain Set Resistor.

�

+

�

+

+

�

+

�

C

f

+

�

R

f

MUX

C

M

�V

+V

C

f

C

f

R

f

C

f

R

f

C

f

10V

10V

R

f

R

i

R

f

R

f

FIGURE 3. Example Application Illustrating Flexible Signal

Conditioning.

Output

20k

20k

X10

X100

4.44k

404

FET Input

10k

10k

10k

10k

FET Input

+In

R

G

R

EXT

�In

A1

A3

A2

Sense

Ref

Where it is necessary to keep the input amplifiers from

saturating or increasing the overall gain, then the gain of the

output amplifier can be increased from unity by using the

circuit in Figure 5.

The values of the resistors in Figure 5 are in the following

table.

O/P GAIN

R

1

and R

3

R

2

2

1200

2740

5

1000

511

10

1500

340

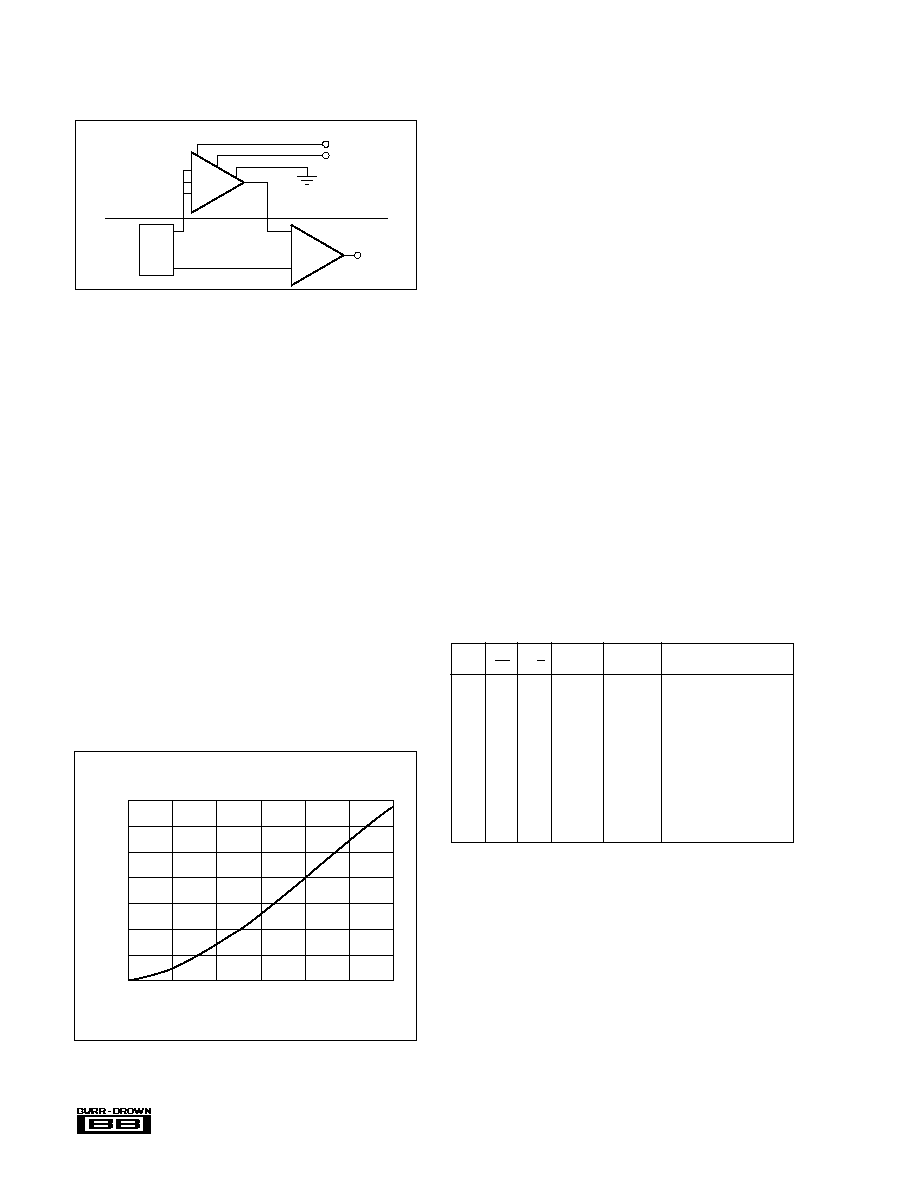

FIGURE 6. Typical INA Settling Time and CMR.

10

100

1

1k

10k

100k

1M

120

100

80

60

40

20

0

Common-Mode Rejection (dB)

Frequency (Hz)

Gain (V/V)

Settling Time (�s)

1

10

100

10

5

0

CMR vs FREQUENCY

SETTLING TIME vs GAIN

(0.01%, 20V Step)

Gain = 1

Gain = 10

Gain = 100

�

SDM862/863/872/873

10

acquisition time and droop rate, as the hold capacitor is

increased in value it takes longer to charge, and hence there

is a corresponding increase in acquisition time and reduction

in droop rate. The droop rate is determined by the amount of

leakage present in the SDM, board leakage and the dielectric

absorption of the hold capacitance. The hold capacitor is

also a compensation element for the S/H and should not be

reduced below 2nf for good stability. The offset error in

sample mode is not affected by the hold capacitor. However,

during the transition to hold mode there is approximately

5pC of charge injected into the hold capacitor, causing an

offset error that has been nulled for use with a 5nf hold

capacitor. Any other value for the hold capacitor will cause

a minor but fixed hold mode offset to be introduced, and is

proportional to the change in value from 5nf. Therefore, the

SDM should be offset nulled with the S/H in hold mode.

ANALOG-TO-DIGITAL CONVERTER

This circuit element converts the analog voltage presented

by the sample/hold amplifier to a digital number in binary

format under control of the digital signals detailed in Figure

9. The converter can convert unipolar and bipolar signals in

the range 10V and 20V. It can be calibrated to remove gain

and offset errors from the entire system. The converter

contains its own clock, voltage reference, and microproces-

sor interface with 3-state outputs. The converter will nor-

mally be used to digitize signals to 12-bit resolution, but it

can be short-cycled to provide 8-bit resolution at higher

speed. The digital output is compatible with 8- or 16-bit data

buses, the data format being selected by control signals as

detailed in Figure 9.

SAMPLE/HOLD AMPLIFIER

The Sample/Hold amplifier (S/H) is used to track the incom-

ing signal and "hold" the required instantaneous value so

that it does not change while the ADC is carrying out its

conversion. Timing for the S/H may be derived from the

STATUS output of the ADC, with care being taken to

comply with the SDM timing considerations.

Capacitors with high insulation resistance and low dielectric

absorption such as TeflonTM, polystyrene or polypropylene

should be used as storage elements. (Polystyrene should not

be used above +80

�

C.) TeflonTM is recommended for high

temperature operation. Care should be taken in the printed

circuit layout to minimize stray capacitance and leakage

currents from the capacitor to minimize charge offset and

droop errors. The use of a guard ring driven by the S/H

output around the pin connecting to the hold capacitor is

recommended. (Refer to the application board layout for an

example of this.)

The value of the external hold capacitor determines the

droop rate, charge offset and acquisition time of the S/H,

Figure 8. Droop rate for the SDM is specified with a hold

capacitor value of 4700pf. There is a trade-off between

FIGURE 7. Setting Programmable Gains.

Some applications may require programmable gains. This

may be realized with Figure 7.

1

2

3

15

66

6

7

8

67

SDM8X3

MUX

INA

Gain Sel

TTL/CMOS

1-10-100

PGA

102

FIGURE 8. Acquisition Time vs Hold Capacitance for a 10V

Step Settling to

�

10mV of Final Value.

DATA

BYTE

CE

CS

R/C

MODE

SELECT

OPERATION

0

X

X

X

X

None

X

1

X

X

X

None

0

0

X

0

Initiate 12-bit conversion

0

0

X

1

Initiate 8-bit conversion

1

0

X

0

Initiate 12-bit conversion

1

0

X

1

Initiate 8-bit conversion

1

0

X

0

Initiate 12-bit conversion

1

0

X

1

Initiate 8-bit conversion

1

0

1

1

X

Enable 12-bit output

1

0

1

0

0

Enable 8 MSBs only

1

0

1

0

1

Enable 4 LSBs plus 4

trailing zeros

FIGURE 9. Control Input Truth Table.

LINEARITY ERROR

Linearity error is defined as the deviation of actual code

transition values from the ideal transition values. Ideal

transition values lie on a line drawn through zero (or minus

full scale for bipolar operation) and plus full scale. The zero

value is located at an analog input value 1/2LSB before the

first code transition (000

H

to 001

H

). The full-scale value is

located at an analog value 3/2LSB beyond the last code

transition (FFE

H

to FFF

H

) (see Figure). Thus, with the SDM

connected for bipolar operation and with a full-scale range

(or span) of 20V (

�

10V), the zero value of �10V is 2.44mV

6

10

9

8

7

6

5

4

3

8

4

10

12

14

16

Acquisition Time (�s)

Hold Capacitance (nF)

ACQUISITION TIME vs HOLD CAPACITANCE

For a 10V Step to �10mV of Final Value

�

SDM862/863/872/873

11

below the first code transition (000

H

to 001

H

at �9.99756V)

and the plus full-scale value of +10V is 7.32mV above the

last code transition (FFE

H

to FFF

H

at +9.99268) (see Figure

13).

NO MISSING CODES

(DIFFERENTIAL LINEARITY ERROR)

A specification which guarantees no missing codes requires

that every code combination appear in a monotonically-

increasing sequence as the analog input is increased through-

out the range. Thus, every input code width (quantum) must

have a finite width. If an input quantum has a value of zero

(a differential linearity error of �1LSB), a missing code will

occur.

The SDM is guaranteed to have no missing codes to 12-bit

resolution over it's respective specification temperature

ranges.

UNIPOLAR OFFSET ERROR

An SDM connected for unipolar operation has an analog

input range of 0V to plus full scale. The first output code

transition should occur at an analog input value 1/2LSB

above 0V. Unipolar offset error is defined as the deviation of

the actual transition value from the ideal value. The unipolar

offset temperature coefficient specifies the change of this

transition value versus a change in ambient temperature.

BIPOLAR OFFSET ERROR

A/D converter specifications have historically defined bipo-

lar offset as the first transition value above the minus full-

scale value. The SDM specification, however, follows the

terminology defined for the 574 converter several years ago.

Thus, bipolar offset is located near the midscale value of 0V

(bipolar zero) at the output code transition 7FFH to 800H.

Bipolar offset error for the SDM is defined as the deviation

of the actual transition value from the ideal transition value

located 1/2LSB below 0V. The bipolar offset temperature

coefficient specifies the maximum change of the code tran-

sition value versus a change in ambient temperature.

FULL SCALE CALIBRATION ERROR

The last output code transition (FFE

H

to FFF

H

) occurs for an

analog input value 3/2LSB below the nominal full-scale

value. The full-scale calibration error is the deviation of the

actual analog value at the last transition point from the ideal

value. The full-scale calibration temperature coefficient speci-

fies the maximum change of the code transition value versus

a change in ambient temperature.

OPERATING INSTRUCTIONS

OPERATING MODES

The SDM can operate in one of two modes, namely serial

and overlap, as shown in Figure 10. In serial mode, control

of the device is such that a multiplexer channel X is first

selected, time is then allowed for the instrumentation ampli-

fier to settle, the sample/hold amplifier is set to HOLD mode

and finally a conversion is carried out. This procedure is

then repeated for channel Y. Faster throughput can be

obtained using overlap mode. While a conversion is being

Conversion

Signal Acquisition

SERIAL MODE

Time

Signal Acquisition

Signal Acquisition

Conversion

Time

MUX

Selection

(X)

Instrumentation

Amp

Settling

Sample/

Hold

Acquisition

A/D

Conversion

Data

Valid

MUX

Selection

(Y)

MUX

Selection

(X)

Instrumentation

Amp

Settling

Sample/

Hold

Acquisition

MUX

Selection

(Y)

Instrumentation

Amp

Settling

Sample/

Hold

Acquisition

MUX

Selection

(Z)

A/D

Conversion on

Channel (X)

Data Valid

A/D

Conversion on

Channel (Y)

OVERLAP MODE

FIGURE 10. Serial and Overlap Modes of Operation.

�

SDM862/863/872/873

12

carried out by the ADC on a voltage from channel X held on

the sample/hold, channel Y is selected and the multiplexer

and instrumentation amplifier allowed to settle. In this way,

the total throughput time is limited only by the sum of the

sample/hold acquisition time and the ADC conversion time.

CALIBRATION � UNIPOLAR

If adjustment of unipolar offset and gain are not required,

then the gain set potentiometer in Figure 11 (Unipolar

operation) may be replaced with a 50

, 1% metal film

resistor, and the offset network replaced with a connection

from pin 23 to ground.

FIGURE 11. Unipolar Calibration.

CALIBRATION - BIPOLAR

If adjustment of bipolar offset and gain are not required then

the gain set and offset potentiometers in Figure 12 (Bipolar

operation) may both be replaced with 50

, 1% metal film

resistors.

FIGURE 12. Bipolar Calibration.

21

22

23

24

26

20V

Span

10V

Span

Inputs

SDM

(Gain)

100

(Offset)

100

CALIBRATION - GENERAL

The input voltage ranges of the ADC are 0-10V,

�

5V and

�

10V. Calibration in all ranges is achieved by adjusting the

offset and gain potentiometers (indicated in Figures 11 and

12) such that the 000 to 001 code transition takes place at

+1/2LSB from full-scale negative (�FS) and the FFE to FFF

transition takes place at �3/2LSB from full-scale positive

(+FS). The procedure is therefore to select the required range

from Figure 13, apply the specified (�FS+1/2LSB) voltage

to any selected input channel and adjust the offset potenti-

ometer for the 000 to 001 transition. The (+FS�3/2LSB)

voltage should then be applied to the same channel and the

gain potentiometer adjusted for the FFE to FFF transition.

The offset should always be made before the gain adjustment.

FULL-SCALE

000 TO 001

FFE TO FFF

1LSB

RANGE

TRANSITION VOLT.

TRANSITION VOLT.

EQUALS

0�10V

+0.0012V

+9.9963V

2.44mV

�

5V

�4.9988V

+4.9963V

2.44mV

�

10V

�9.9976V

+9.9927V

4.88mV

FIGURE 13. Code Transition Ranges.

Full-Scale

Calibration

Error

Rotates

The

Line

Offset

Error

Shifts

The Line

(Bipolar

Offset

Transaction)

Midscale

(Bipolar

Zero)

FFF

H

FFE

H

FFD

H

802

H

801

H

800

H

7FF

H

7FE

H

001

H

000

H

002

H

Digital Output

1/2LSB

Zero

(�Full Scale)

Zero

(�Full-Scale

Calibration

Transition)

1/2LSB

3/2LSB

+Full-Scale

Calibration

Transition

+Full

Scale

Analog Input

FIGURE 14. SDM Transfer Characteristic Terminology.

GROUNDING, DECOUPLING

AND LAYOUT CONSIDERATIONS

It should be noted that the multiplexer/instrumentation am-

plifier section and sample/hold plus ADC section of the

SDM have separate power connections. This is to enable

more flexible grounding techniques to be implemented,

Figures 15, 16. It also facilitates the use of independent

decoupling of the analog front-end power supply, and the

ADC plus associated digital circuitry power supply if de-

sired. In this way, a separately decoupled analog front-end

can be made to be substantially more immune to power

supply noise generated by the ADC circuitry than if the

20V

Span

10V

Span

Inputs

(Gain)

SDM

+15V

�15V

21

22

23

24

26

160

100

100k

(Offset)

100k

�

SDM862/863/872/873

13

power supplies to the two sections were directly connected.

This feature is important where low-level signals are in use

or high input signal noise immunity is desired.

The output section has three grounds:

Pin 25 Analog Common, A/D Converter

Pin 34 S/H Amp Digital Input Reference

Pin 19 Digital Common, A/D Converter

The input section has one ground:

Pin 53 Common for digital MUX-inputs and power

supply decoupling.

All grounds have to be interconnected externally to the

SDM, and it is recommended that all grounds are connected

via one track to a single point as close as possible to the

SDM. To check that the grounding structure is correct, the

ground tracking should be sketched and a grounding "tree"

should result whereby all grounds route to a central point.

In general, layout should be such that analog and digital

tracks are separated as much as possible with coupling

between analog and digital lines minimized by careful lay-

out. For instance, if the lines must cross they should do so

at right angles to each other. Parallel analog and digital lines

should be separated from each other by a pattern connected

to common.

Signal-Ref (Single-Ended)

DCOM (1)

�V

+V

Output-Ref

SHC GND

ACOM (2)

DCOM (2)

+15V

�15V

+5V

66

53

4

3

2

34

25

19

27

20

5

100�H

100�H

+5V

�15V

+15V

Signal-Ref

NOTE: (1) 10�F tantalum in parallel with 100nF ceramic.

(1)

(1)

(1)

(1)

(1)

FIGURE 15. Recommended Decoupling of Power Supplies.

�V

0

+V

0

+5V

�V

0

+V

4

53

3

20

27

25

19

5

5V

+5V

1/2 SDM

ISO100

4 Opto-Couplers

MUX-Address

MUX-Address

+5V

INA

1/2 SDM

PWR305

1

2

39

100�H

100�H

100�H

100�H

100�H

FIGURE 16. Galvanic Isolation Between Analog and Digital Signals.

�

SDM862/863/872/873

14

FIGURE 17. The SDM Connected to an Input/Output Port.

RG

�In

G10

G100

Sense

INA

Out

+In

Ref

V

EE

V

CC

Analog-Ref

67

65

66

62

63

64

68

1

39

35

36

44.7nF

37

21

22

26

24

23

B0

B1

B2

B3

B4

B5

B6

B7

C0

C1

C2

C3

C4

C5

C6

C7

A0

A1

A2

A3

A4

A5

A6

A7

47

46

45

44

43

42

41

40

54

55

56

57

58

59

60

61

CH0

1

2

3

4

5

6

7

8(0)

9(1)

10(2)

11(3)

12(4)

13(5)

14(6)

15(7)

MUX

(Out)

Out

A3

A2

A1

A0

DCOM

EN

53

48

49

50

51

52

4

3

2

+5V

34

33

6

25

19

27

20

5

+5V

(12 Bit)

+15V

�15V

+5V

Ref

Out

Ref

In

Bip

Off

ADC

In(10V)

In(20V)

Status

AGND

DGND

LSB D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

Data M.

CS

Byte S.

Hold

Cap

In

Out

SHC

Gnd

Cont

8255 Port

R

100

+15V

�15V

+5V

S/H

R

100

+5V

1k

17

18

32

31

30

29

28

7

8

9

10

11

12

13

14

15

16

�

SDM862/863/872/873

15

D0

D1

D2

D3

D4

Hold

Cap

In

Out

SHC

Gnd

Cont

Ref

Out

Ref

In

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

Data M.

CS

Byte S.

+15V

�5V

+5V

In (10V

In (20V)

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D0

D1

D2

D3

D4

D5

D6

D7

A0

A1

A2

A3

+15V (12 Bit)

34

33

6

25

19

27

20

5

37

21

22

26

24

23

36

35

39

Status

AGND

DGND

.47nF

R

50

74244

74244

1G

2G

1G

2G

G

OC

D

Q

18

17

16

15

14

13

12

11

10

9

8

7

28

29

30

31

32

D15

CS

RD

WR

CS

74373

MUX

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

Data M.

CS

Byte S.

+5V

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

A0

A1

A2

A3

+15V (12 Bit)

5

23

74244

74244

1G

2G

1G

2G

G

OC

D

Q

18

17

16

15

14

13

12

11

10

9

8

7

D15

CS

RD

WR

CS

74373

MUX

WR

CS

Status

S/H Cont

Fully Controlled Mode

Stand Alone Mode

ADC

S/H

R

50

28

29

30

31

32

FIGURE 18. The SDM Connected to a 16-Bit-BUS.

�

SDM862/863/872/873

16

FIGURE 19b. 68000/SDM Interface.

FIGURE 19a. SDM on the Z80 Interface.

R

100

4.7nF

R

100

Address

Decode

Z80

ADC

S/H

34

19

25

6

27

20

5

In

Hold

Cap

Out

SHC

Gnd

Cont

Ref

Out

Ref

In

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

DATAM.

CS

Bytes

+5V

�15V

+15V

DGND

AGND

Status

In (20V)

In (10V)

D0

D1

D2

D3

A0

A1

A2

A3

74LS175

Reset

A1 � A7

AO

RD

WR

D7

D6

D5

D4

D3

D2

D1

D0

39

35

36

37

21

22

26

24

23

33

18

17

16

15

14

13

12

11

10

9

8

7

28

29

30

31

32

IORQ

MUX

4.7nF

R

100

ADC

S/H

34

19

25

6

27

20

5

In

Hold

Cap

Out

SHC

Gnd

Cont

Ref

Out

Ref

In

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

DATAM

CS

Bytes

+5V

�15V

+15V

DGND

AGND

Status

In (20V)

In (10V)

39

35

36

37

21

22

26

24

23

33

18

17

16

15

14

13

12

11

10

9

8

7

28

29

30

31

32

Data Bus

LS

374

SDM

Status

Pin 6

SDM

Status

Address

Bus

Address

Decode

68000

R/W

UDS

DTACK

LOS

+5V

LS

374

R

100

�

SDM862/863/872/873

17

FIGURE 19c. IBM PC SDM Interface.

R

100

4.7nF

R

100

Adress

Decode

IBM PC or XT

Card Slot

ADC

S/H

34

19

25

6

27

20

5

In

Hold

Cap

Out

SHC

Gnd

Cont

Ref

Out

Ref

In

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

DATAM

CS

Bytes

+5V

�15V

+15V

DGND

AGND

Status

In (20V)

In (10V)

D0

D1

D2

D3

A0

A1

A2

A3

Reset

A1 - A9

AO

IOR

IOW

D7

D6

D5

D4

D3

D2

D1

D0

39

35

36

37

21

22

26

24

23

33

18

17

16

15

14

13

12

11

10

9

8

7

28

29

30

31

32

MUX

AEN

FIGURE 20. SDM on the 6502 BUS.

4.7nF

R

100

ADC

S/H

34

19

25

6

27

20

5

In

Out

SHC

GND

Cont

Ref

Out

Ref

In

Bip

Off

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

MSB D11

CE

R/C

DATAM

CS

Bytes

+5V

�15V

+15V

DGND

AGND

Status

In (20V)

In (10V)

39

35

36

37

21

22

26

24

23

33

18

17

16

15

14

13

12

11

10

9

8

7

28

29

30

31

32

D0

D1

D2

D3

A0

A1

A2

A3

74LS 175

Reset

A4

Select

8 Bit

D0

D1

D2

D3

D4

D5

D6

�2

D7

R/W

A0

BUS

Hold

Cap

R

100

�

SDM862/863/872/873

18

CONTROLLING THE SDM

The Burr-Brown SDM family can be easily interfaced to

most microprocessor systems, as shown in Figures 17-20.

The microprocessor may control each conversion, or the

converter may operate in a stand-alone mode controlled only

by the R/C input.

STAND-ALONE OPERATION

The stand-alone mode is used in systems containing dedi-

cated input ports which do not require full bus interface

capability.

Control of the converter is accomplished by a single control

line connected to R/C. In this mode CS and BYTE SELECT

are connected to LOW and CE and DATA MODE are

connected to HIGH. The output data are presented as 12-bit

words.

Conversion is initiated by a High-to-Low transition of R/C.

The three-state data output buffers are enabled when R/C is

high and STATUS is low. Thus, there are two possible

modes of operation; conversion can be initiated with either

positive or negative pulses. In each case the R/C pulse must

remain low for a minimum of 50ns.

Figure 21 illustrates timing when conversion is initiated by

an R/C pulse which goes low and returns to the high state

during the conversion. In this case, the three-state outputs go

to the high-impedance state in response to the falling edge of

R/C and are enabled for external access of the data after

completion of the conversion. Figure 22 illustrates the tim-

ing when conversion is initiated by a positive R/C pulse. In

this mode the output data from the previous conversion is

enabled during the positive portion of R/C. A new conver-

sion is started on the falling edge of R/C, and the three-state

outputs return to the high impedance state until the next

occurrence of a high R/C pulse. Table I lists timing specifi-

cations for stand-alone operation.

FULLY CONTROLLED OPERATION

Conversion Length

Conversion length (8-bit or 12-bit) is determined by the state

of the BYTE SELECT input, which is latched upon receipt

of a conversion start transition. BYTE SELECT is latched

because it is also involved in enabling the output buffers. No

other control inputs are latched. If BYTE SELECT is latched

high, the conversion continues for 8 bits. The full 12-bit

conversion will occur if BYTE SELECT is low. If all 12 bits

are read following an 8-bit conversion, the 3LSBs (DB0-

DB2) will be low (logic 0) and DB3 will be high (logic 1).

Word 1

Word 2

Processor

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

SDM

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

0

0

0

0

FIGURE 23. 12-Bit Data Format for 8-Bit Systems (connected as Figures 18 and 19).

Conversion Start

A conversion is initiated by a transition on any of three logic

inputs (CE, CS, and R/C)--refer to Figure 9. The last of the

three to reach the required state start the conversion and thus

all three may be dynamically controlled. If necessary, they

may change state simultaneously, and the nominal delay

time is independent of which input actually starts the con-

version. If it is desired that a particular input establish the

actual start of conversion, the other two should be stable a

minimum of 50ns prior to the transition of that input. Timing

relationships for start of conversion timing are illustrated in

Conversion Cycle Timing of the Digital Specifications.

SYMBOL

PARAMETER

MIN

TYP

MAX UNITS

t

HRL

Low R/C Pulse Width

50

ns

t

DS

STS Delay from R/C

200

ns

t

HDR

Data Valid After R/C Low

25

ns

t

HS

86X

STS Delay After Data Valid

300

500

1000

ns

t

HS

87X

100

300

600

ns

t

HRH

High R/C Pulse Width

150

ns

t

DDR

Data Access Time

150

ns

FIGURE 22. R/C Pulse High--Outputs Enabled Only Where

R/C is High.

R/C

Status

DB11�

DB0

Data Valid

High-Z State

t

HRH

t

DS

t

DDR

t

C

t

HDR

High-Z

FIGURE 21. R/C Pulse Low--Outputs Enabled After Con-

version.

R/C

Status

DB11�DB0

Data Valid

Data Valid

High-Z State

t

HRL

t

DS

t

HDR

t

HS

t

C

TABLE I. Stand-Alone Mode Timing.

�

SDM862/863/872/873

19

The STATUS output indicates the state of the converter by

being high only during a conversion. During this time the

three-state output buffers remain in a high-impedance state,

and therefore, data is not valid. During this period additional

transitions of the three control inputs will be ignored, so that

conversion cannot be prematurely terminated or restarted.

However, if BYTE SELECT changes state after the begin-

ning of conversion, any additional start conversion transition

will latch the new state of BYTE SELECT, possibly result-

ing in an incorrect conversion length (8 bit versus 12 bits)

for that conversion.

READING OUTPUT DATA

After conversion is initiated, the output data buffers remain

in a high-impedance state until the following four conditions

are met: R/C high, STATUS low, CE high, and CS low. In

this condition the data lines are enabled according to the

state of the inputs DATA MODE and BYTE SELECT. See

Read Cycle Timing for timing relationships and specifica-

tion.

In most applications the DATA MODE input will be

hardwired in either the high or low condition, although it is

fully TTL- and CMOS-compatible and may be actively

driven if desired. When DATA MODE is high, all 12

outputs lines (DB0-DB11 ) are enabled simultaneously for

full data word transfer to a 12-bit or 16-bit bus and the state

of the BYTE SELECT is ignored.

When DATA MODE is low, the data is presented in the

form of two 8-bit bytes, with selection of each byte by the

state of BYTE SELECT during the read cycle.

The BYTE SELECT input is usually driven by the least

significant bit of the address bus, allowing storage of the

output data word in two consecutive memory locations.

When BYTE SELECT is low, the byte addressed contains

the 8MSBs. When BYTE SELECT is high, the byte ad-

dressed contains the 4LSBs from the conversion followed by

four zeros that have been forced by the control logic. The

left-justified formats of the two 8-bit bytes are shown in

Figure 23. The design of the SDM guarantees that the BYTE

SELECT input may be toggled at any time without damage

to the output buffers occurring.

In the majority of applications, the read operation will be

attempted only after the conversion is complete and the

status output has gone low. In those situations requiring the

fastest possible access to the data, the read may be started as

much as (t

DD

max + t

HS

max) before STATUS goes low.

Refer to Read Cycle Timing for these timing relationships.

APPLICATIONS INFORMATION

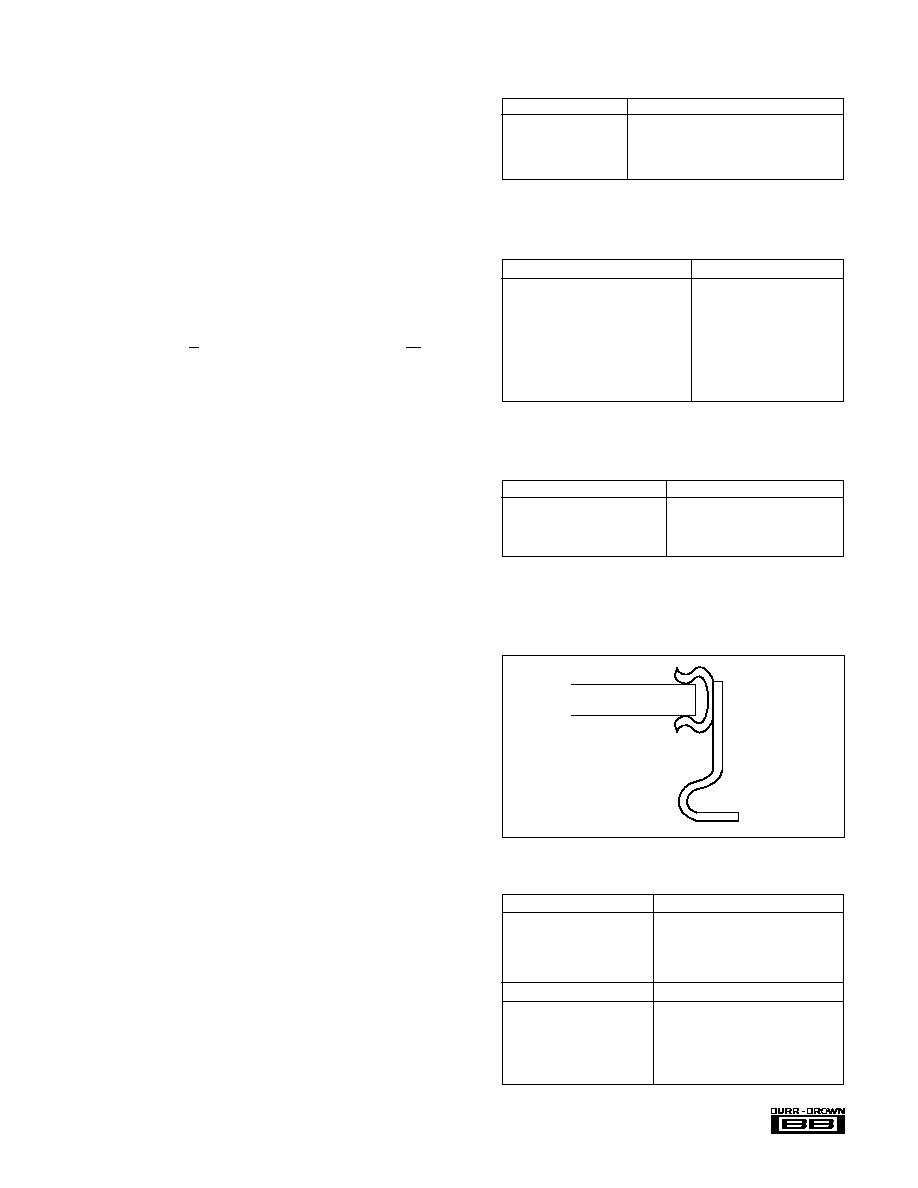

ASSEMBLY OF SURFACE MOUNT PACKAGES

There are several assembly methods for the LCC versions of

the SDM8XX. The associated advantages and disadvantages

of three methods are outlined below.

1. DIRECT SURFACE MOUNT ONTO PCB

ADVANTAGES

DISADVANTAGES

Ease of assembly

Difficult to inspect solder joints

Low cost

Difficult to clean

Low weight

Choice of board material important in

Small footprint size

wide temperature range applications

In wide temperature applications it is important to match the

coefficients of thermal expansion of the board and the

SDM8XXL. Below is a list of materials and their approxi-

mate coefficients of linear thermal expansion.

MATERIAL

(ppm/

�

C)

Alumina (96%) - SDM Package

6-7

Copper-clad-Invar (50% Cu)

9

(30% Cu)

6

(10% Cu)

3

Epoxy-Kevlar (60% Kevlar)

6

Polyimide-Kevlar (40% Kevlar)

6

Beryllia

5

Polyimide-glass (x-axis)

12

(y-axis)

14

KevlarTM E.I. du Pont de Nemours & Co.

2. ATTACHMENT OF

SURFACE MOUNT EDGE CLIPS

ADVANTAGES

DISADVANTAGES

Ease of Inspection

Extra cost

Easy cleaning

Extra assembly

Thermal expansion taken up by

the flexing of the edge clips

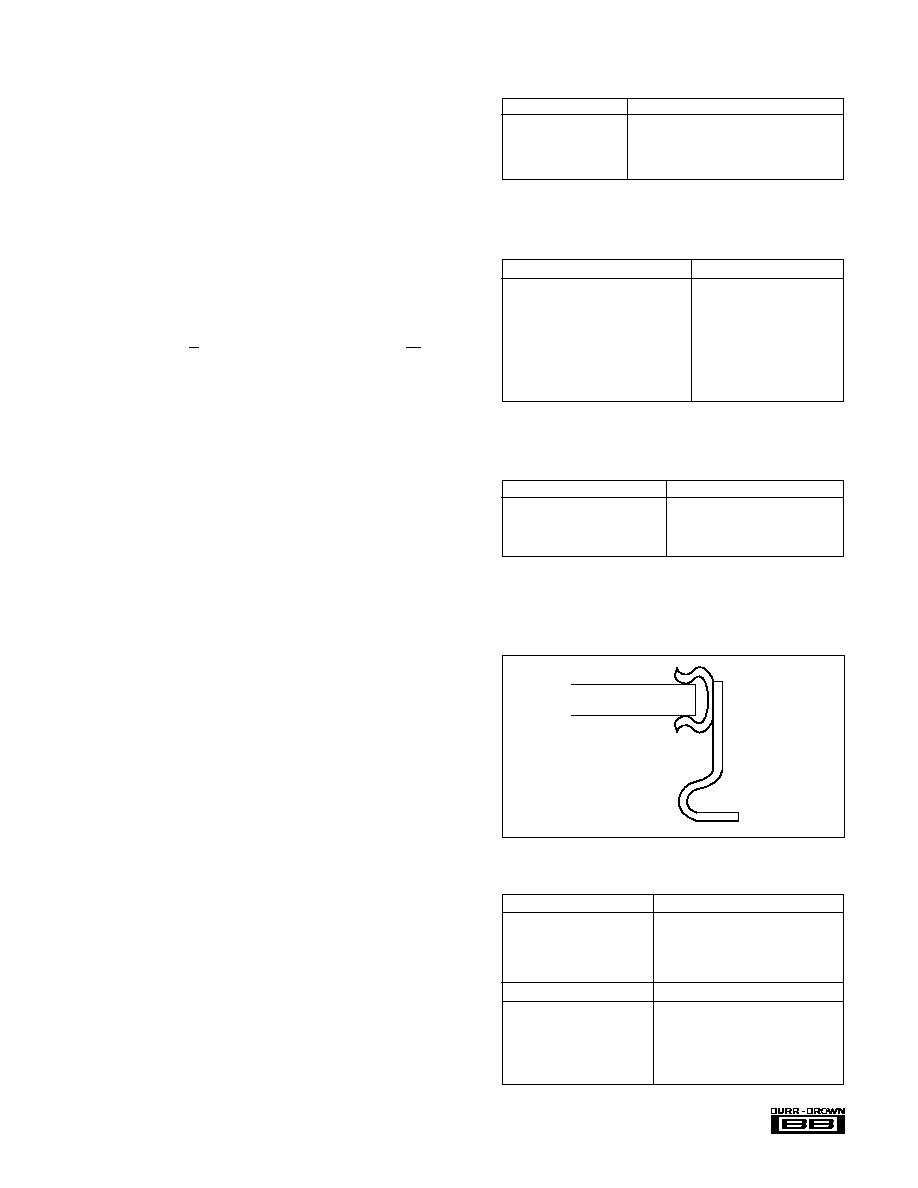

ASSEMBLY

The edge clips are attached to the edges of the SDM8XXL

as in Figure 24 before the device is mounted on to the board.

FIGURE 24. Edge Clip Assembly.

SDM

EDGE

CLIP

SUPPLIERS OF EDGE CLIPS

USA

USA

DIE-TECH INC.,

NAS Electronics,

R.D. 1, Sipe Road,

381 Park St.,

York Haven,

Hackensack,

PA 17370 USA

NJ 07602 USA

PHONE: (717) 938-6771

PHONE: (201) 343-3156

EUROPE

EUROPE

SEMI-DICE (UK) Ltd,

NASBRIT Ltd,

Buckingham House,

Wester Goudi Ind. Est.

Mineral Lane,

Dundee DD2 4UX

Chesham,

UK

Bucks. HP5 2AU UK

PHONE: 0382 622222

PHONE: 0494 771275

�

SDM862/863/872/873

20

3. SURFACE MOUNT SOCKET

ADVANTAGES

DISADVANTAGES

Board thermal expansion

Cost

not so critical

Extra height (if critical)

Ease of component

replacement

Below is the name and address of a supplier of a 68-pin surface mountable

socket.

The part number is:

Socket

212-068-012

Spring cover

CCS-004

USA

EUROPE

Methode Electronics INC,

Lucas Methode Connectors Ltd,

Interconnect Products Div.

Halifax Road

1700 Hick Road,

Ingrow Bridge,

Rolling Meadows, TX 75050

Keighley, Yorkshire BD21 5HR

USA

UK

PHONE: (312) 392-3500

PHONE: 0535 603282

General Comments

The advantages and disadvantages of all the methods men-

tioned above are for general use of surface mount compo-

nents. Every user will find that the importance of these

factors will depend on his application and situation.

EVALUATION BOARD

For the engineer who wishes to evaluate the SDM family,

Burr-Brown has designed printed circuit boards on a single

`Eurocard' (shown here for LCC only). These boards enable

the design engineer to experiment with various accuracy

improvement techniques which are described below. Special

consideration has been given to the grounding and circuit

layout techniques required when dealing with 12-bit analog

signals.

The printed circuit board has been designed so that the

solutions to several of the problems likely to be encountered

by the user can be examined.

It should not be thought that every user is required to adopt

all of the techniques used on the circuit board. In many

applications very few external components will be required.

However, in following the application guidelines illustrated

by the circuitry and accompanying notes, the designer will

be able to select and adapt the solutions most suited to their

won particular application or problem area.

Provisions for the following are made on the LCC PC board:

--68 pin LCC socket (Burr-Brown Part No. MC0068).

--8 differential or 16 single-ended inputs.

--Input filtering with overvoltage protection for each chan-

nel.

--Socket for quad D-type flip-flop 74175 (MUX address

latches).

--7 additional I.C. sockets for easy interfacing to various

BUS systems (connection by wire wrap techniques).

--2 voltage regulators (15V).

--LC power supply decoupling.

The layout pays particular attention to the requirements

when operating with precision analog signals. This requires

strict separation of the analog and digital areas. Analog and

digital commons are totally separated and connected to-

gether only at the commons of the supply voltage. All

common lines are low resistance and low inductance.

SUPPLY VOLTAGES

In order to avoid coupling between the external supply

voltage 15V supplies, 2 voltage regulators (78M15, 79L15)

are provided on the PC board. The unregulated supply

voltage may vary from

�

17V to

�

25V.

The MUX/INA section and SHC/ADC section of the SDM

have separate supply lines which can be inductively

decoupled. This is recommended in order to suppress the

high frequency noise which comes from the ADC during

conversion.

The power supply rejection of the instrumentation amplifier

reduces with increasing frequency. If high frequency noise

on the supplies is not decoupled it will be injected into the

signal path and cause errors. This effect can be particularly

pronounced when using the `overlap' mode since the instru-

FIGURE 25. Channel Select Truth Table.

SDM862/872

SDM863/873

Channel

MUX

MUX

MUX

MUX

MUX

Channel

MUX

MUX

MUX

MUX

Pair

ADD3

ADD2

ADD1

ADD0

Enable

Selected

ADD2

ADD1

ADD0

Enable

Selected

X

X

X

X

L

NONE

X

X

X

L

NONE

L

L

L

L

H

0

L

L

L

H

0

L

L

L

H

H

1

L

L

H

H

1

L

L

H

L

H

2

L

H

L

H

2

L

L

H

H

H

3

L

H

H

H

3

L

H

L

L

H

4

H

L

L

H

4

L

H

L

H

H

5

H

L

H

H

5

L

H

H

L

H

6

H

H

L

H

6

L

H

H

H

H

7

H

H

H

H

7

H

L

L

L

H

8

�

H

L

L

H

H

9

�

H

L

H

L

H

10

�

H

L

H

H

H

11

�

H

H

L

L

H

12

�

H

H

L

H

H

13

�

H

H

H

L

H

14

�

H

H

H

H

H

15

�

�

SDM862/863/872/873

21

mentation amplifier is settling to a new analog value while

the ADC is still carrying out the previous conversion.

The digital supply voltage is +5V and is also LC-filtered.

All supply lines are bypassed with a 10

�

F tantalum and a

100nF ceramic capacitor situated as close as possible to the

package.

If the voltage regulators for the

�

15V are not used, small

inductors for decoupling of the supply voltages are recom-

mended. If inductors are not fitted a dynamic ground loop

will be created from supply lines via bypass capacitors to

analog common.

INPUT PROTECTION

The multiplexer is protected up to an input voltage which

can exceed the supply voltage by a maximum of 20V. This

means, that with

�

15V supply voltage, the input voltage can

be

�

35V without damage. This is also the case when the

supply voltages are switched off (0V). The maximum input

voltage can then be

�

20V. For higher overvoltage protection

a series resistor has to be used. The current via the multi-

plexer should be limited to 20mA absolute maximum, 1mA

is preferred. For example, a 10k

series resistor would give

an additional 10V overprotection.

For much higher overvoltages (e.g. 100V), high value series

resistors cannot be used as offset errors would result. In

practice, a combination of series resistors and diodes is used.

The diodes are connected to

�

15V and will conduct when-

ever the input voltage exceeds the

�

15V supply voltage. The

diodes are selected by signal source impedance, as well as

filter resistance, as the diode leakage current across the

series resistor can cause offset and linearity errors. In this

circuit, IN4148 together with 10k

are used.

INPUT FILTER

Processor noise can be induced in the analog ground. Input

filtering is therefore recommended for analog data acquisi-

tion. Such high frequency noise signals can cause dynamic

overload of the instrumentation amplifier resulting in non-

linear behavior. This leads directly to digitizing errors.

The design of the filter takes into account the characteristics

of the SDM and of the signal source.

The following points have to be considered:

--The stray capacitance, output capacitance of the multi-

plexer and input capacitance of the instrument amplifier

(up to 80pf in some cases) has to be discharged in order

to minimize errors caused by `charge sharing.'

--The series resistor limits the current in the protection

diodes, but it also has to be selected for the required filter

time constant.

--The noise rejection of the filter has to be >80db in order

to satisfy a 12-bit A/D conversion.

As well as considering the above, different calculations

have to be carried out for single and differential input

signals.

Single-Ended Measurement

R

f

limits the maximum input current through the protection

diodes. In this case, R

f

has been chosen as 10k

and

together with the capacitor C

g

, forms the input filter time

constant (C

g

= 0.47

�

F). The time constant must be chosen

according to the requirements of the input signal bandwidth

and noise rejection. The multiplexer capacitance (C

m

) is

discharged mainly by C

g

. This means C

g

has to be suffi-