FEATURES

D

USER-SELECTABLE: Voltage or Current

Output

D

+40V SUPPLY VOLTAGE

D

V

OUT

:

±

10V (up to

±

17.5V at

±

20V supply)

D

I

OUT

:

±

20mA (linear up to

±

24mA)

D

SHORT- OR OPEN-CIRCUIT FAULT

INDICATOR PIN

D

NO CURRENT SHUNT REQUIRED

D

OUTPUT DISABLE FOR SINGLE INPUT MODE

D

THERMAL PROTECTION

D

OVER-CURRENT PROTECTION

D

SEPARATE DRIVER AND RECEIVER

CHANNELS

D

DESIGNED FOR TESTABILITY

IA

Current Copy

OPA

R

GAIN

RG

1

RG

2

I

COPY

C

C

I

DRV

I

IA

IA

IN+

IA

IN

-

Load

DRV

IA

OUT

V

IN

SET

I

MON

V

-

DGND

V+

XTR300

Digital

Control

OD

M2

M1

Error

Flags

EF

CM

EF

LD

EF

OT

(Optional)

Input Signal

V

REF

R

IA

1k

R

SET

GND1

GND3

R

OS

R

IMON

1k

GND2

Figure 1. XTR300 Basic Diagram

APPLICATIONS

D

PLC OUTPUT PROGRAMMABLE DRIVER

D

INDUSTRIAL CROSS-CONNECTORS

D

INDUSTRIAL HIGH-VOLTAGE I/O

D

3-WIRE-SENSOR CURRENT OR VOLTAGE

OUTPUT

D

±

10V 2- AND 4-WIRE VOLTAGE OUTPUT

Patents Pending

DESCRIPTION

The XTR300 is a complete output driver for industrial and

process control applications. The output can be configured

as current or voltage by the digital I/V select pin. No

external shunt resistor is required. Only external

gain-setting resistors and a loop compensation capacitor

are required.

The separate driver and receiver channels provide

flexibility. The Instrumentation Amplifier (IA) can be used

for remote voltage sense or as a high-voltage, high-

impedance measurement channel. In voltage output

mode, a copy of the output current is provided, allowing

calculation of load resistance.

The digital output selection capability, together with the

error flags and monitor pins, make remote configuration

and troubleshooting possible. Fault conditions on the

output and on the IA input as well as over-temperature

conditions are indicated by the error flags. The monitoring

pins provide continuous feedback about load power or

impedance. For additional protection, the maximum output

current is limited and thermal protection is provided.

Digital communication like HART

can be modulated onto

the input signal. The receive signal applied to the output

can be detected at the monitor pins in both current and

voltage output modes. In addition to HART

communication, the device offers system or sensor

configuration through the signal connector.

The XTR300 is specified over the -40

∞

C to +85

∞

C

industrial temperature range and for supply voltage up to

40V.

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

Industrial Analog Current/Voltage

OUTPUT DRIVER

PRODUCTION DATA information is current as of publication date. Products

conform to specifications per the terms of Texas Instruments standard warranty.

Production processing does not necessarily include testing of all parameters.

www.ti.com

Copyright

2005-2006, Texas Instruments Incorporated

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

semiconductor products and disclaimers thereto appears at the end of this data sheet.

HART is a registered trademark of the HART Communication Foundation.

All other trademarks are the property of their respective owners.

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

2

ABSOLUTE MAXIMUM RATINGS

(1)

Supply Voltage

+44V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Input Terminals

Voltage

(2)

(V-) - 0.5V to (V+) + 0.5V

. . . . . . . . . . . . . . . . . . . . . .

Current

(2)

±

25mA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DGND

±

25mA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Short Circuit

(3)

Continuous

. . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Temperature

-55

∞

C to +125

∞

C

. . . . . . . . . . . . . . . . . . . . .

Storage Temperature

-55

∞

C to +125

∞

C

. . . . . . . . . . . . . . . . . . . . . . .

Junction Temperature

+150

∞

C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD Rating

Human Body Model

2000V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charged Device Model

1000V

. . . . . . . . . . . . . . . . . . . . . . . . . . .

(1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only, and

functional operation of the device at these or any other conditions

beyond those specified is not supported.

(2) Input terminals are diode-clamped to the power-supply rails.

Input signals that can swing more than 0.5V beyond the supply

rails should be current limited.

(3) See the Driver Output Disable section in Application Information

section for thermal protection.

PIN CONFIGURATION

Top View

QFN

M2

M1

V

IN

SET

I

MON

Pad

V+

NC

DRV

NC

V

-

1

2

3

4

5

15

14

13

12

11

IA

OU

T

IA

IN

-

IA

IN

+

RG

1

RG

2

OD

EF

OT

EF

LD

EF

CM

DG

N

D

Exposed

Thermal

Die Pad

on

Underside.

(Must be

connected

to V

-

)

6

7

8

9

10

20

19

18

17

16

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could

cause the device not to meet its published specifications.

ORDERING INFORMATION

(1)

PRODUCT

PACKAGE-LEAD

PACKAGE

DESIGNATOR

PACKAGE

MARKING

XTR300

QFN-20

(5mm x 5mm)

RGW

XTR300

(1) For the most current package and ordering information, see the

Package Option Addendum at the end of this document, or see

the TI web site at www.ti.com.

PIN ASSIGNMENTS

PIN

NAME

FUNCTION

1

M2

Mode Input

2

M1

Mode Input

3

V

IN

Noninverting Signal Input

4

SET

Input for Gain Setting; Inverting Input

5

I

MON

Current Monitor Output

6

IA

OUT

Instrumentation Amplifier Signal Output

7

IA

IN-

Instrumentation Amplifier Inverting Input

8

IA

IN+

Instrumentation Amplifier Noninverting Input

9

RG1

Instrumentation Amplifier Gain Resistor

10

RG2

Instrumentation Amplifier Gain Resistor

11

V-

Negative Power Supply

12

NC

No Internal Connection

13

DRV

Operational Amplifier Output

14

NC

No Internal Connection

15

V+

Positive Power Supply

16

DGND

Ground for Digital I/O

17

EF

CM

Error Flag for Common-Mode Over-Range,

Active Low

18

EF

LD

Error Flag for Load Error, Active Low

19

EF

OT

Error Flag for Over Temperature, Active Low

20

OD

Output Disable, Disabled Low

Pad

Pad

Exposed thermal pad must be connected to V-

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

3

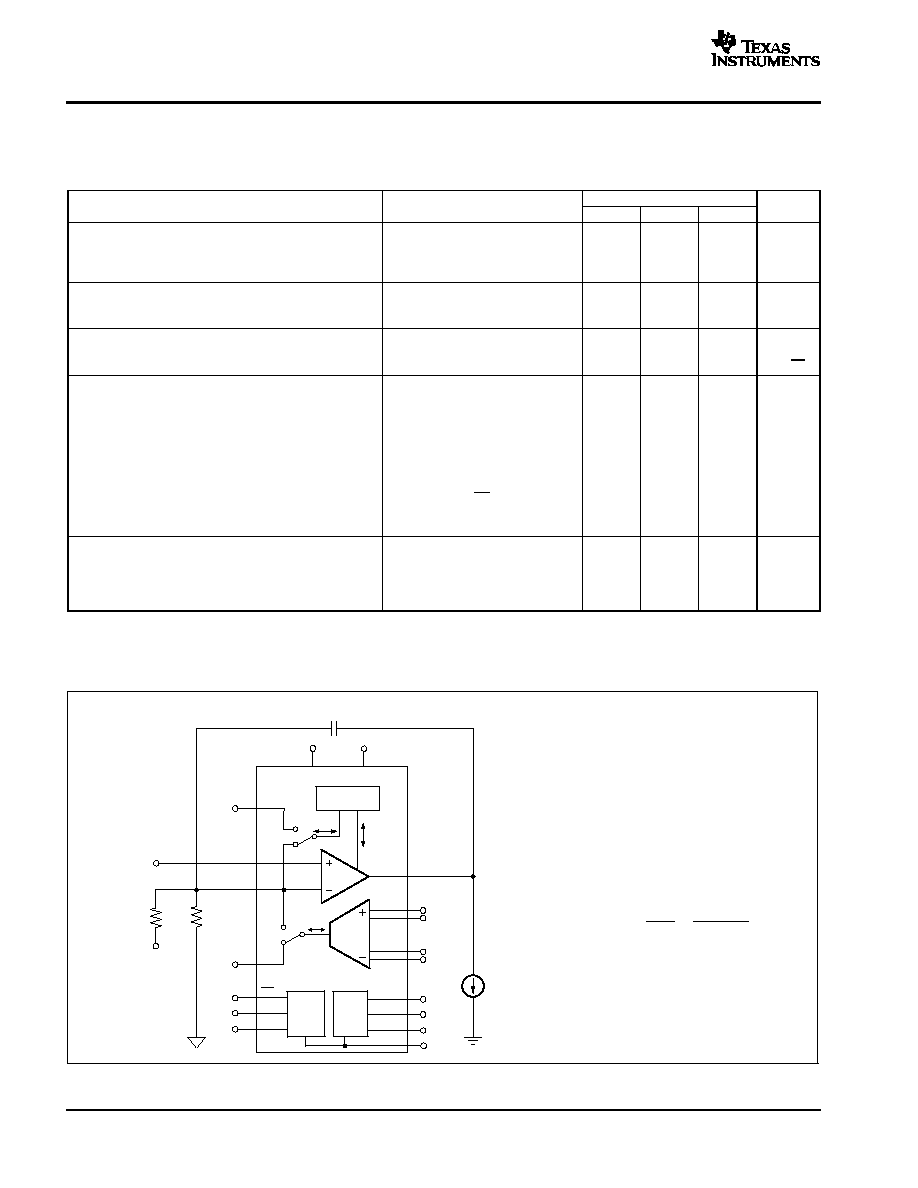

ELECTRICAL CHARACTERISTICS: VOLTAGE OUTPUT MODE

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, R

LOAD

= 800

, R

SET

= 2k

, R

OS

= 2k

, V

REF

= 4V, R

GAIN

= 10k

, Input Signal Span 0V to 4V, and C

C

= 100pF, unless

otherwise noted.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

Offset Voltage, RTI

V

OS

±

0.4

±

1.9

mV

vs Temperature

dV

OS/dT

±

1.6

±

6

µ

V/

∞

C

vs Power Supply

PSRR

V

S

=

±

5V to

±

22V

±

0.2

±

10

µ

V/V

INPUT VOLTAGE RANGE

Nominal Setup for

±

10V Output

See Figure 2

Input Voltage For Linear Operation

(V-) + 3V

(V+) - 3V

V

NOISE

Voltage Noise, f = 0.1Hz to 10Hz, RTI

3

µ

V

PP

Voltage Noise Density, f = 1kHz, RTI

e

n

40

nV/

Hz

OUTPUT

Voltage Output Swing from Rail

I

DRV

15mA

(V-) +3V

(V+) - 3

V

Gain Nonlinearity

±

0.01

±

0.1

%FS

vs Temperature

±

0.1

±

1

ppm/

∞

C

Gain Error

I

B

±

0.04

±

0.1

%FS

vs Temperature

±

0.2

±

1

ppm/

∞

C

Output Impedance, dV

DRV

/dI

DRV

7

m

Output Leakage Current While Output Disabled

Pin OD = L

(1)

30

nA

Short-Circuit Current

I

SC

±

15

±

20

±

24

mA

Capacitive Load Drive

C

LOAD

C

C

= 10nF, R

C

= 15

(2)

1

µ

F

Rejection of Voltage Difference between GND1 and GND2, RTO

130

dB

FREQUENCY RESPONSE

Bandwidth

-3dB

G = 5

300

kHz

Slew Rate

(2)

SR

1

V/

µ

s

SR

C

C

= 10nF, C

L

= 1

µ

F, R

C

= 15

0.015

V/

µ

s

Settling Time

(2)(3)

, 0.1%, Small Signal

V

DRV

=

±

1V

8

µ

s

Overload Recovery Time

50% Overdrive

12

µ

s

(1) Output leakage includes input bias current of INA.

(2) Refer to Driving Capacitive Loads section in Application Information.

(3) 8

µ

s plus number of chopping periods. See Application Information section, Internal Current Sources and Settling Time.

IA

Cu rrent C opy

OPA

R

GAIN

V

OUT

=

(

)

Transfer Function:

+

R

G

2

V

IN

R

SET

V

IN

-

V

REF

R

OS

R G

1

R G

2

I

COPY

C

C

I

DRV

I

IA

IA

IN+

IA

IN

-

Load

D RV

IA

OUT

V

IN

S ET

I

MON

V

-

D GN D

V +

X TR3 00

D igital

C ontro l

OD

M 2

M 1

H

L

L

E rr or

Flags

EF

CM

E F

LD

EF

OT

Input Sig nal

V

IN

= 0V to 4.0V

V

REF

= 4.0V

R

SET

GND 1

V

GND

GN D 2

R

OS

R

IMON

1k

GND 3

Figure 2. Standard Circuit for Voltage Output Mode

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

4

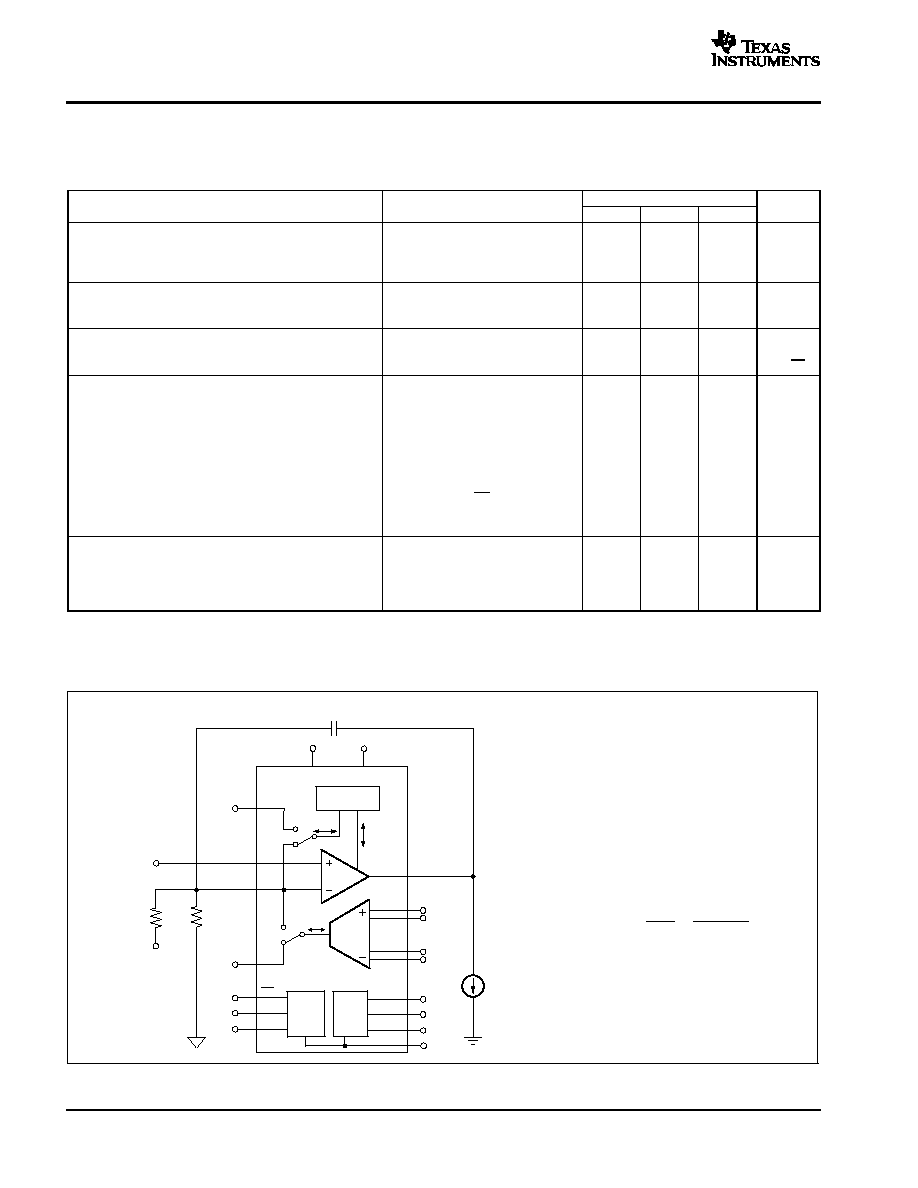

ELECTRICAL CHARACTERISTICS: CURRENT OUTPUT MODE

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, R

LOAD

= 800

, R

SET

= 2k

, R

OS

= 2k

, V

REF

= 4V, Input Signal Span 0 to 4V, and C

C

= 100pF, unless otherwise

noted.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

Input Offset Voltage

V

OS

Output Current < 1

µ

A

±

0.4

±

1.8

mV

vs Temperature

dV

OS

/dT

±

1.5

±

6

µ

V/

∞

C

vs Power Supply

PSRR

V

S

=

±

5V to

±

22V

±

0.2

±

10

µ

V/V

INPUT VOLTAGE RANGE

Nominal Setup for

±

20V Output

See Figure 3

Maximum Input Voltage For Linear Operation

(V-) + 3

(V+) - 3

V

NOISE

Voltage Noise, f = 0.1Hz to 10Hz, RTI

3

µ

V

PP

Voltage Noise Density, f = 1kHz, RTI

in

33

nV/

Hz

OUTPUT

Compliance Voltage Swing from Rail

I

DRV

=

±

24mA

(V-) +3

(V+) - 3

V

Output Conductance, (dI

DRV

/dV

DRV

)

dV

DRV

=

±

15V, dI

DRV

=

±

24mA

0.7

µ

A/V

Transconductance

See Transfer Function

Gain Error

I

DRV

=

±

24mA

±

0.04

±

0.12

%FS

vs Temperature

I

DRV

=

±

24mA

±

3.6

±

10

ppm/

∞

C

Linearity Error

I

B

I

DRV

=

±

24mA

±

0.01

±

0.1

%FS

vs Temperature

I

DRV

=

±

24mA

±

1.5

±

6

ppm/

∞

C

Output Leakage Current While Output Disabled

Pin OD = L

0.6

nA

Short-Circuit Current

I

SC

±

24.5

±

32

±

38.5

mA

Capacitive Load Drive

(1)(2)

C

LOAD

1

µ

F

FREQUENCY RESPONSE

Bandwidth

-3dB

160

kHz

Slew Rate

(2)

SR

1.3

mA/

µ

s

Settling Time

(2)(3)

, 0.1%, Small Signal

I

DRV

=

±

2mA

8

µ

s

Overload Recovery Time

C

LOAD

= 0, 50% Overdrive

1

µ

s

(1) Refer to Driving Capacitive Loads section in Application Information.

(2) With capacitive load, the slew rate can be limited by the short circuit current and the load error flag can trigger during slewing.

(3) 8

µ

s plus number of chopping periods. See Application Information section, Internal Current Sources and Settling Time.

IA

Current Copy

OPA

RG

1

RG

2

I

COPY

C

C

I

DRV

I

IA

IA

IN+

IA

IN

-

DRV

IA

O UT

V

IN

SET

I

MON

V

-

DGND

V+

XTR300

Digital

Control

OD

M2

H

L

H

M1

Error

Flags

EF

CM

I

O UT

EF

LD

EF

OT

Input Signal

V

IN

= 0V to 4.0V

V

REF

= 4.0V

R

SET

GND1

GND2

R

OS

I

OUT

= 10

(

)

Transfer Function:

+

V

IN

R

SET

V

IN

-

V

REF

R

OS

Figure 3. Standard Circuit for Current Output Mode

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

5

ELECTRICAL CHARACTERISTICS: OPERATIONAL AMPLIFIER (OPA)

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, R

LOAD

= 800

, unless otherwise noted.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

Offset Voltage, RTI

V

OS

I

DRV

= 0A

±

0.4

±

1.8

mV

Drift

dV

OS

/dT

±

1.5

µ

V/

∞

C

vs Power Supply

PSRR

V

S

=

±

5V to

±

22V

±

0.2

±

5

µ

V/V

INPUT VOLTAGE RANGE

Common-Mode Voltage Range

V

CM

(V-) + 3

(V+) - 3

V

Common-Mode Rejection Ratio

CMRR

(V-) + 3V < V

CM

< (V+) - 3V

100

126

dB

INPUT BIAS CURRENT

Input Bias Current

I

B

±

20

±

35

nA

Input Offset Current

I

OS

±

0.3

±

10

nA

INPUT IMPEDANCE

Differential

10

8

|| 5

|| pF

Common-Mode

10

8

|| 5

|| pF

OPEN-LOOP GAIN

Open-Loop Voltage Gain

A

OL

(V-) + 3V < V

DRV

< (V+) - 3V , I

DRV

=

±

24mA

100

126

dB

OUTPUT

Voltage Output Swing from Rail

I

DRV

=

±

24mA

(V-) + 3

(V+) - 3

V

Short-Circuit Current

I

LIMIT

M2 = High

±

25.5

±

32

±

38.5

mA

I

LIMIT

M2 = Low

±

16

±

20

±

24

mA

Output Leakage Current While Output Disabled

I

LEAK_DRV

Pin OD = L

10

pA

FREQUENCY RESPONSE

Gain-Bandwidth Product

GBW

G = 1

2

MHz

Slew Rate

SR

1

V/

µ

s

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

6

ELECTRICAL CHARACTERISTICS: INSTRUMENTATION AMPLIFIER (IA)

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, R

IA

= 2k

, and R

GAIN

= 2k

, unless otherwise noted. See Figure 4.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

Offset Voltage, RTI

VOS

IDRV = 0A

±

0.7

±

2.7

mV

vs Temperature

dVOS/dT

±

2.4

±

10

µ

V/

∞

C

vs Power Supply

PSRR

VS =

±

5V to

±

22V

±

0.8

±

10

µ

V/V

INPUT VOLTAGE RANGE

Common-Mode Voltage Range

VCM

(V-) + 3

(V+) - 3

V

Common-Mode Rejection Ratio

CMRR

RTI

100

130

dB

INPUT BIAS CURRENT

Input Bias Current

IB

±

20

±

35

nA

Input Offset Current

IOS

±

1

±

10

nA

INPUT IMPEDANCE

Differential

108 || 5

|| pF

Common-Mode

108 || 5

|| pF

TRANSCONDUCTANCE (Gain)

IA

OUT

= 2 (IA

IN+

- IA

IN-

)/R

GAIN

Transconductance Error

IA

OUT

=

±

2.4mA, (V-) + 3V < V

IAOUT

< (V+) - 3V

±

0.04

±

0.1

%FS

vs Temperature

±

0.2

ppm/

∞

C

Linearity Error

(V-) + 3V < V

IAOUT

< (V+) - 3V

±

0.01

±

0.1

%FS

Input Bias Current to G1, G2

±

20

nA

Input Offset Current to G1, G2

(1)

±

1

nA

OUTPUT

Output Swing to the Rail

IA

OUT

=

±

2.4mA

(V-) + 3

(V+) - 3

V

Output Impedance

IA

OUT

=

±

2.4mA

600

M

Short-Circuit Current

I

LIMIT

M2 = High

±

7.2

mA

I

LIMIT

M2 = Low

±

4.5

mA

FREQUENCY RESPONSE

Gain-Bandwidth Product

GBW

G = 1, R

GAIN

= 10k

, R

IA

= 5k

1

MHz

Slew Rate

SR

G = 1, R

GAIN

= 10k

, R

IA

= 5k

1

V/

µ

s

Settling Time

(2)

, 0.1%

IAOUT

=

±

40

µ

A, R

GAIN

= 10k

, R

IA

= 5k

,

C

L

= 100pF

6

µ

s

Overload Recovery Time, 50%

R

GAIN

= 10k

, R

IA

= 15k

, C

L

= 100pF

10

µ

s

(1)

See Typical Characteristics curve.

(2)

6

µ

s plus number of chopping periods. See Application Information section, Internal Current Sources and Settling Time.

ELECTRICAL CHARACTERISTICS: CURRENT MONITOR

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, unless otherwise noted. See Figure 4.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

OUTPUT

Offset Current

I

OS

I

DRV

= 0A

±

30

±

100

nA

vs Temperature

dI

OS

/dT

±

0.06

nA/

∞

C

vs Power Supply

PSRR

V

S

=

±

5V to

±

22V

±

0.1

±

10

nA/V

Monitor Output Swing to the Rail

I

MON

=

±

2.4mA

(V-) + 3

(V+) - 3

V

Monitor Output Impedance

I

MON

=

±

2.4mA

200

M

MONITOR CURRENT GAIN

I

MON

= I

DRV/10

Current Gain Error

I

DRV

=

±

24mA

±

0.04

±

0.12

%FS

vs Temperature

I

DRV

=

±

24mA

±

3.6

ppm/

∞

C

Linearity Error

I

DRV

=

±

24mA

±

0.01

±

0.1

%FS

vs Temperature

I

DRV

=

±

24mA

±

1.5

ppm/

∞

C

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

7

ELECTRICAL CHARACTERISTICS

Boldface limits apply over the temperature range, T

A

= -40

∞

C to +85

∞

C.

All specifications at T

A

= +25

∞

C, V

S

=

±

20V, unless otherwise noted. See Figure 4.

XTR300

PARAMETER

CONDITION

MIN

TYP

MAX

UNITS

POWER SUPPLY

Specified Voltage Range

V

S

±

5

±

20

V

Operating Voltage Range

±

5

±

22

V

Quiescent Current

I

Q

I

DRV

= IA

OUT

= 0A

1.8

2.3

mA

Over Temperature

2.8

mA

TEMPERATURE RANGE

Specified Temperature Range

-40

+85

∞

C

Operating Temperature Range

-55

+125

(1)

∞

C

Storage Temperature Range

-55

+125

∞

C

Thermal Resistance

Junction-to-Case

q

JC

6

∞

C/W

Junction-to-Ambient

q

JA

38

∞

C/W

THERMAL FLAG (EF

OT

) Output

Alarm (EF

OT

pin LOW)

140

∞

C

Return to Normal Operation (EF

OT

pin HIGH)

125

∞

C

DIGITAL INPUTS (M1, M2, OD)

V

IL

Low-Level Input Voltage

0.8

V

V

IH

High-Level Input Voltage

1.4

V

Input Current

±

1

µ

A

DIGITAL OUTPUTS (EF

LD

, EF

CM

, EF

OT

)

I

OH

High-Level Leakage Current (Open-Drain)

-1.2

µ

A

V

OL

Low-Level Output Voltage

I

OL

= 5mA

0.8

V

V

OL

Low-Level Output Voltage

I

OL

= 2.8mA

0.4

V

DIGITAL GROUND PIN

(V-)

DGND

(V+) - 7V

Current Input

M1 = M2 = L, OD = H, All Digital Outputs H

-25

µ

A

(1) EF

OT

not connected with OD.

IA

Current Copy

OPA

R

GAIN

RG

1

RG

2

I

COPY

I

DRV

I

IA

IA

IN+

IA

IN

-

Feedback

Network

DRV

IA

OUT

V

IN

SET

I

MON

V

-

DGND

V+

XTR300

Digital

Control

OD

M2

M1

H

Error

Flags

EF

CM

EF

LD

EF

OT

Input Signal

R

IA

GND3

GND3

GND1

R

SET

Figure 4. Standard Circuit for Current Output Mode

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

8

TYPICAL CHARACTERISTICS

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

-

50

-

25

Temperature (

_

C)

125

3.0

2.5

2.0

1.5

1.0

0.5

0

I

Q

(m

A

)

QUIESCENT CURRENT vs TEMPERATURE

0

25

50

75

100

10

15

Total Supply Voltage (V)

45

1.90

1.88

1.86

1.84

1.82

1.80

1.78

1.76

1.74

1.72

1.70

I

Q

(m

A

)

QUIESCENT CURRENT vs SUPPLY VOLTAGE

20

25

30

35

40

-

50

-

25

Temperature (

_

C)

125

0

-

5

-

10

-

15

-

20

-

25

-

30

I

B

(n

A

)

INPUT BIAS CURRENT vs TEMPERATURE

(V

IN

, SET, IA

IN+

, IA

IN

-

, RG1, RG2)

0

25

50

75

100

-

50

-

25

Temperature (

_

C)

125

2.2

2.0

1.8

1.6

1.4

1.2

1.0

V

S

-

V

OU

T

(V

)

OPA OUTPUT SWING TO RAIL vs TEMPERATURE

0

25

50

75

100

I

DRV

= +10mA

I

DRV

=

-

24mA

I

DRV

=

-

10mA

I

DRV

= +24mA

I

DRV

= +20mA

I

DRV

=

-

20mA

0.001

Frequency (Hz)

10M

180

160

140

120

100

80

60

40

20

0

-

20

Ga

i

n

(d

B

)

0

-

20

-

40

-

60

-

80

-

100

-

120

-

140

-

160

-

180

-

200

Ph

a

s

e

(

_

)

OPA GAIN AND PHASE vs FREQUENCY

0.1

0.01

10

1k

100k

1

100

10k

1M

Gain

Phase

1

Frequency (Hz)

10M

80

60

40

20

0

-

20

-

40

0

-

45

-

90

-

135

-

180

-

225

-

270

Ga

i

n

(

d

B

)

Ph

a

s

e

(

_

)

IA GAIN AND PHASE

vs FREQUENCY

10

100

1k

10k

100k

1M

R

GAIN

= 10k

R

IA

= 500k

R

IA

= 50k

R

IA

= 10k

R

IA

= 5k

R

IA

= 1k

Gain

Phase

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

9

TYPICAL CHARACTERISTICS

(continued)

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

1

PSRR

-

Frequency (Hz)

100k

160

140

120

100

80

60

40

20

0

CM

RR,

P

S

RR

(

d

B

)

OPA CMRR AND PSRR vs FREQUENCY

10

100

1k

10k

CMRR

PSRR+

1

PSRR

-

Frequency (Hz)

100k

140

120

100

80

60

40

20

0

CM

RR,

P

S

RR

(

d

B

)

IA CMRR AND PSRR vs FREQUENCY

10

100

1k

10k

CMRR

PSRR+

SMALL-SIGNAL STEP RESPONSE

CURRENT MODE

100

mV

/d

i

v

200

µ

s/div

I

OUT

=

±

200

µ

A

G = 8

C

L

= 100nF || R

L

= 800

C

C

= 4.7nF

R

SET

= 1k

R

G

= 10k

See Figure 3

LARGE-SIGNAL STEP RESPONSE

CURRENT MODE

10

V

/

di

v

200

µ

s/div

I

OUT

=

±

20mA

G = 8

C

L

= 100nF || R

L

= 800

C

C

= 4.7nF

R

SET

= 1k

R

G

= 10k

See Figure 3

SMALL-SIGNAL STEP RESPONSE

VOLTAGE MODE

50m

V

/

di

v

200

µ

s/div

G = 5

C

L

= 100nF || R

L

= 800

C

C

= 4.7nF

R

SET

= 1k

R

G

= 10k

See Figure 2

LARGE-SIGNAL STEP RESPONSE

VOLTAGE MODE

5V

/

d

i

v

200

µ

s/div

G = 5

C

L

= 100nF || R

L

= 800

C

C

= 4.7nF

R

SET

= 1k

R

G

= 10k

See Figure 2

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

10

TYPICAL CHARACTERISTICS

(continued)

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

1

G = 5

Frequency (Hz)

100k

1M

100k

10k

1k

100

10

1

No

i

s

e

(

n

V

/

Hz

)

INPUT-REFERRED NOISE SPECTRUM

VOLTAGE OUTPUT MODE

10

100

1k

10k

INPUT-REFERRED 0.1Hz to 10Hz NOISE

VOLTAGE OUTPUT MODE

1

µ

V/

d

i

v

1s/div

1

G = 10

Frequency (Hz)

100k

1M

100k

10k

1k

100

10

1

In

p

u

t

-

Re

fe

r

r

e

d

No

i

s

e

(

n

V

/

Hz

)

INPUT-REFERRED NOISE SPECTRUM

CURRENT OUTPUT MODE

10

100

1k

10k

INPUT-REFERRED 0.1Hz to 10Hz NOISE

CURRENT OUTPUT MODE

1

µ

V/

d

i

v

1s/div

1

G = 20

Frequency (Hz)

100k

1M

100k

10k

1k

100

10

1

I

nput

-

R

e

f

er

r

e

d

N

oi

s

e

(

n

V

/

Hz

)

IA INPUT-REFERRED NOISE SPECTRUM

10

100

1k

10k

IA INPUT-REFERRED 0.1Hz to 10Hz NOISE

1

µ

V/

d

i

v

1s/div

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

11

TYPICAL CHARACTERISTICS

(continued)

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

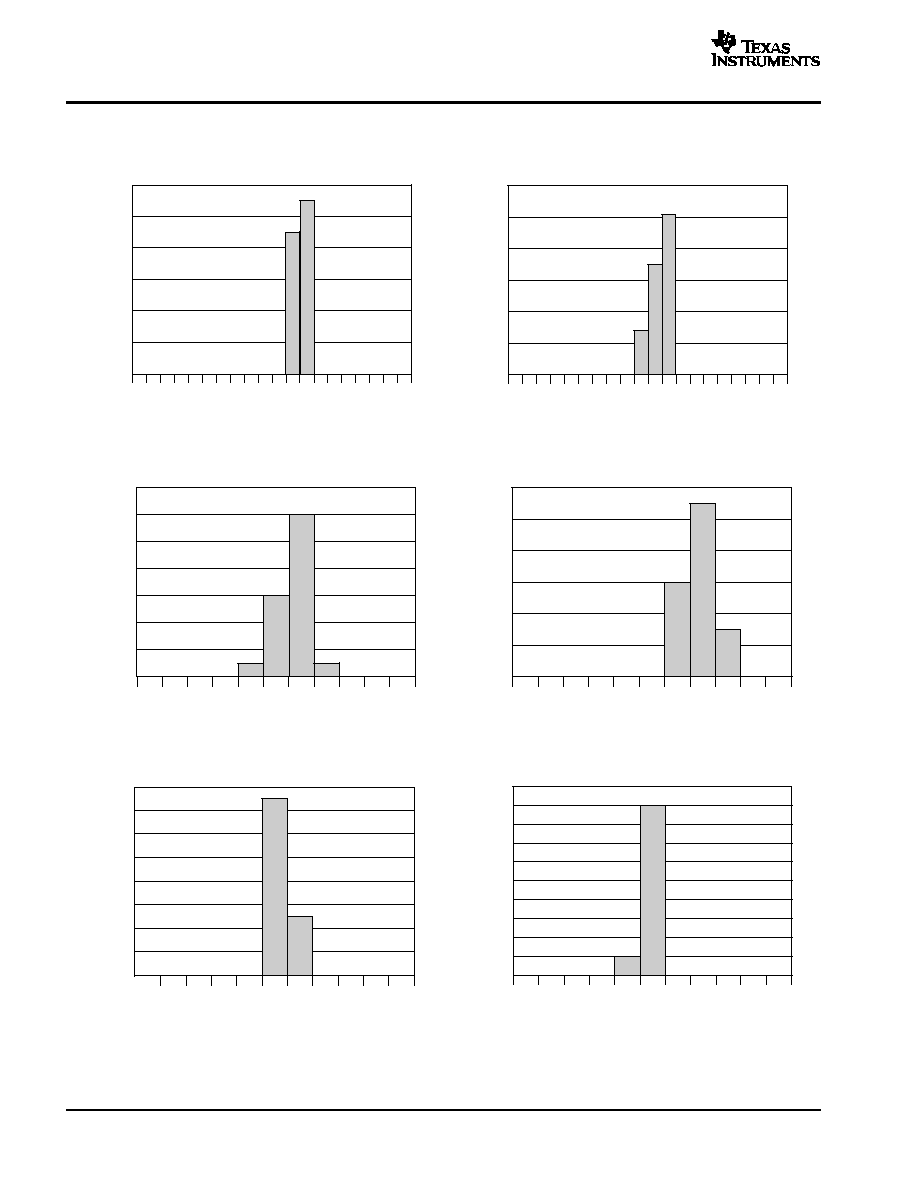

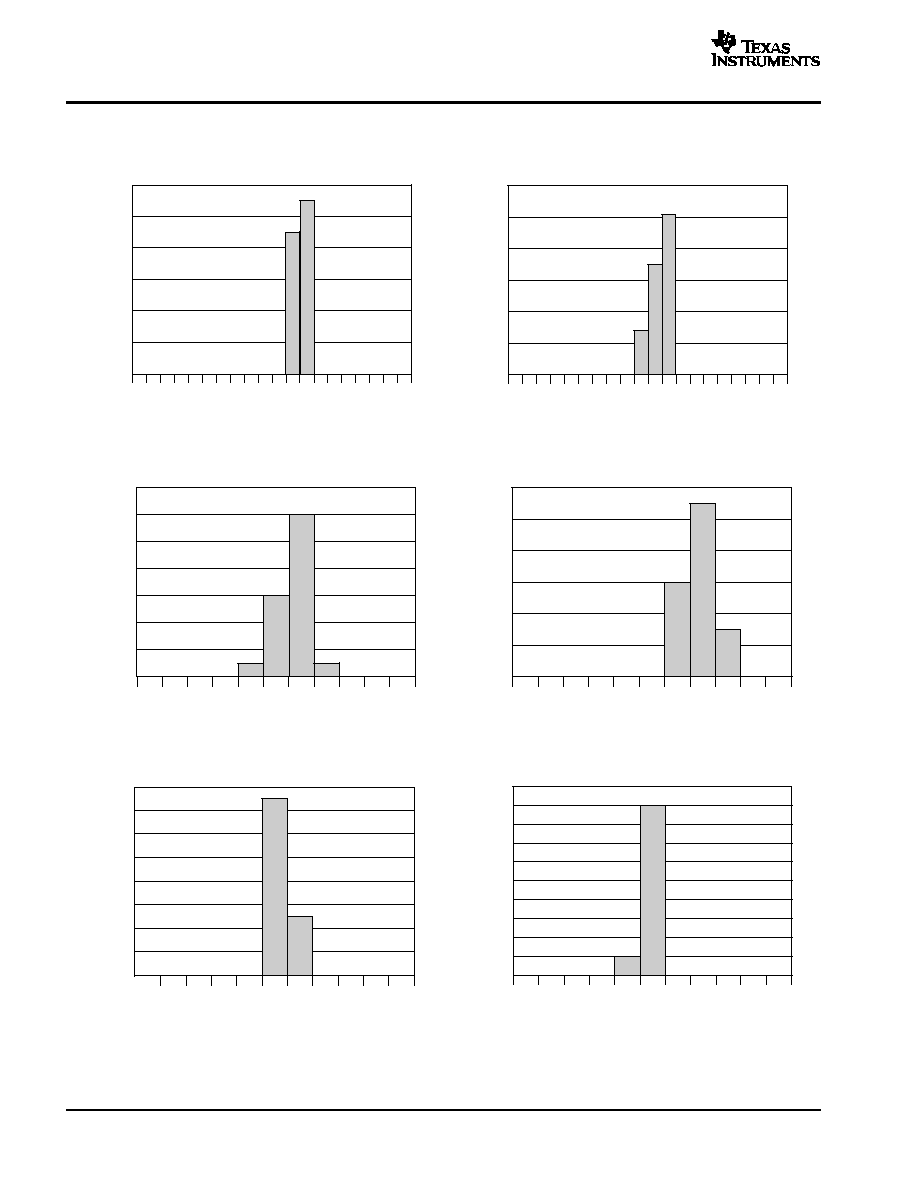

OPA OFFSET VOLTAGE DISTRIBUTION

P

e

r

c

e

n

to

fP

o

p

u

l

a

t

i

o

n(

%

)

Offset Voltage (mV)

18

16

14

12

10

8

6

4

2

0

-

2.

0

-

1.

6

-

1.

2

-

0.

8

-

0.

4

0

0.4

0.8

1.2

1.6

2.0

IA OFFSET VOLTAGE DISTRIBUTION

P

e

r

c

e

n

t

o

f

P

o

pul

ati

o

n

(

%

)

Offset Voltage (mV)

30

25

20

15

10

5

0

-

3.

0

-

2.

4

-

1.

8

-

1.

2

-

0.

6

0

0.

6

1.

2

1.

8

2.

4

3.

0

OPA OFFSET VOLTAGE DRIFT DISTRIBUTION

P

e

r

c

ent

of

P

opu

l

a

ti

on

(

%

)

Offset Voltage Drift (

µ

V/

_

C)

60

50

40

30

20

10

0

-

10

-

8

-

6

-

4

-

2

0

2

4

6

8

10

IA OFFSET VOLTAGE DRIFT DISTRIBUTION

P

e

r

c

en

t

o

f

P

o

pul

ati

o

n

(

%

)

Offset Voltage Drift (

µ

V/

_

C)

40

35

30

25

20

15

10

5

0

-

10

-

8

-

6

-

4

-

2

0

2

4

6

8

10

VOLTAGE MODE GAIN ERROR DISTRIBUTION

P

e

r

c

en

t

o

f

P

o

pul

a

t

i

o

n

(

%

)

Gain Error (ppm)

40

35

30

25

20

15

10

5

0

-

10

00

-

80

0

-

60

0

-

40

0

-

20

0

0

20

0

40

0

60

0

80

0

100

0

CURRENT MODE GAIN ERROR DISTRIBUTION

P

e

r

c

en

t

o

f

P

o

pul

a

t

i

o

n

(

%

)

Gain Error (ppm)

30

25

20

15

10

5

0

-

10

00

-

80

0

-

60

0

-

40

0

-

20

0

0

20

0

40

0

60

0

80

0

100

0

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

12

TYPICAL CHARACTERISTICS

(continued)

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

VOLTAGE MODE NONLINEARITY DISTRIBUTION

P

e

r

c

ent

of

P

opu

l

a

t

i

on

(

%

)

Nonlinearity (ppm)

60

50

40

30

20

10

0

-

100

0

-

80

0

-

60

0

-

40

0

-

20

0

0

200

400

600

800

1

000

CURRENT MODE NONLINEARITY DISTRIBUTION

P

e

r

c

ent

of

P

opul

a

t

i

o

n

(

%

)

Nonlinearity (ppm)

60

50

40

30

20

10

0

-

10

0

0

-

80

0

-

60

0

-

40

0

-

20

0

0

200

400

600

800

1000

VOLTAGE MODE GAIN

ERROR DRIFT DISTRIBUTION

P

e

r

c

en

t

o

f

P

op

ul

a

t

i

o

n

(

%

)

Gain Error Drift (ppm/

_

C)

70

60

50

40

30

20

10

0

-

1.

0

-

0.

8

-

0.

6

-

0.

4

-

0.

2

0

0.

2

0.

4

0.

6

0.

8

1.

0

CURRENT MODE GAIN

ERROR DRIFT DISTRIBUTION

P

e

r

c

en

t

o

f

P

op

ul

a

t

i

o

n

(

%

)

Gain Error Drift (ppm/

_

C)

60

50

40

30

20

10

0

-

10

-

8

-

6

-

4

-

2

0

2

4

6

8

10

VOLTAGE MODE

NONLINEARITY DRIFT DISTRIBUTION

P

e

r

c

e

n

to

fP

o

p

u

l

a

t

i

o

n(

%

)

Nonlinearity Drift (ppm/

_

C)

80

70

60

50

40

30

20

10

0

-

1.

0

-

0.

8

-

0.

6

-

0.

4

-

0.

2

0

0.2

0.4

0.6

0.8

1.0

CURRENT MODE

NONLINEARITY DRIFT DISTRIBUTION

P

e

r

c

ent

of

P

o

p

u

l

a

ti

o

n

(

%

)

Nonlinearity Drift (ppm/

_

C)

100

90

80

70

60

50

40

30

20

10

0

-

10

-

8

-

6

-

4

-

2

0

2

4

6

8

10

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

13

TYPICAL CHARACTERISTICS

(continued)

At T

A

= +25

∞

C and V+ =

±

20V, unless otherwise noted.

-

50

-

25

Temperature (

_

C)

125

36

34

32

30

28

26

24

22

20

18

16

I

LI

M

I

T

(m

A

)

POSITIVE CURRENT LIMIT vs TEMPERATURE

0

Voltage Mode

25

50

75

100

Current Mode

-

50

-

25

Temperature (

_

C)

125

-

16

-

18

-

20

-

22

-

24

-

26

-

28

-

30

-

32

-

34

-

36

I

LI

M

I

T

(m

A

)

NEGATIVE CURRENT LIMIT vs TEMPERATURE

0

Current Mode

25

50

75

100

Voltage Mode

-

24

-

20

Output Current (mA)

24

0.025

0

-

0.025

-

0.050

-

0.075

-

0.10

N

o

n

lin

e

a

r

i

t

y

(

%

)

NONLINEARITY vs OUTPUT CURRENT

(

±

24mA End Point Calibration)

-

16

-

12

-

8

-

4

0

4

8

12

16

20

-

55

_

C

+25

_

C

+85

_

C

+125

_

C

-

24

-

20

Output Current (mA)

24

NONLINEARITY vs OUTPUT CURRENT

(

±

20mA End Point Calibration)

-

16

-

12

-

8

-

4

0

4

8

12

16

20

-

55

_

C

+25

_

C

+85

_

C

+125

_

C

0.025

0

-

0.025

-

0.050

-

0.075

-

0.10

N

o

n

lin

e

a

r

it

y

(

%

)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

14

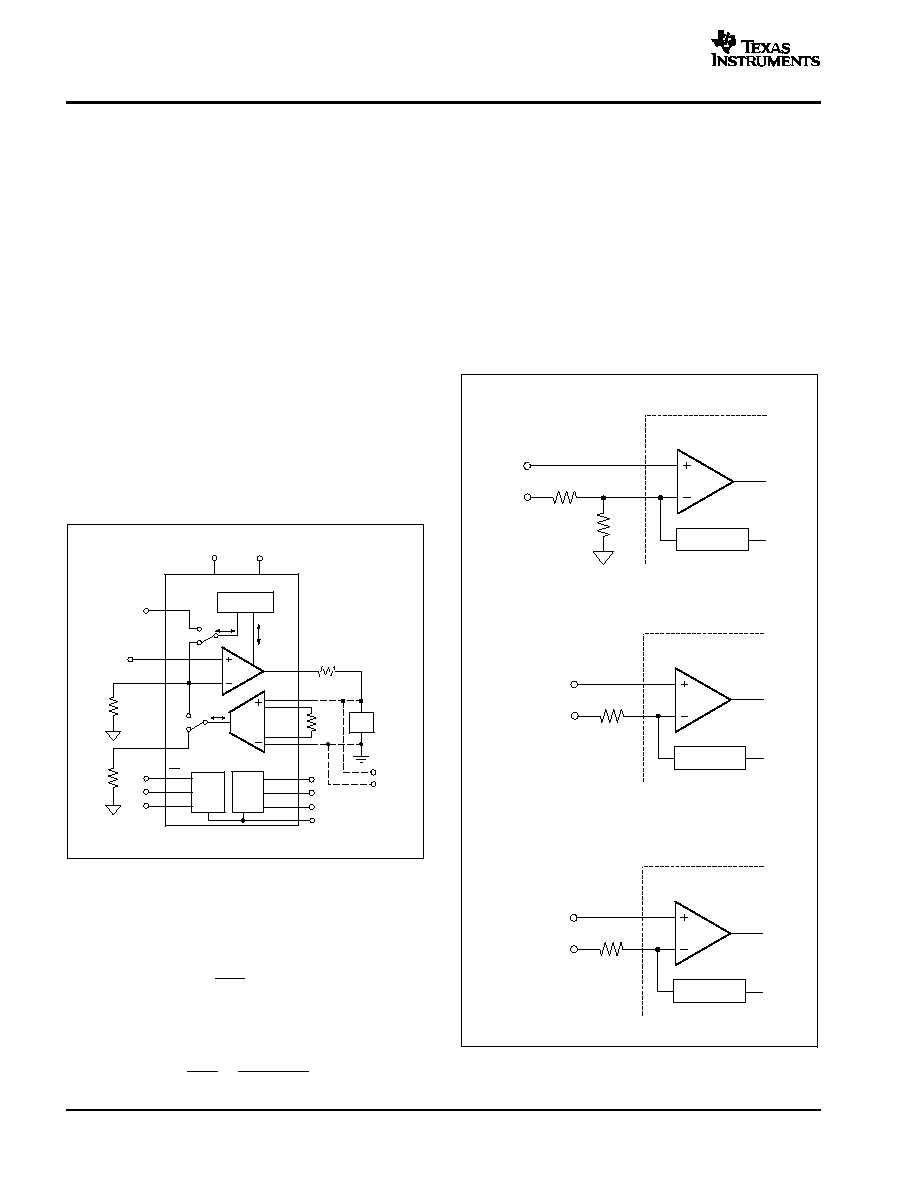

APPLICATION INFORMATION

Figure 5. Standard Circuit Configuration

D

Recommended bypassing: 100nF or more for

supply bypassing at each supply.

D

R

IMON

can be in the k

-range or short-circuited if not

used. Do not leave this current output

unconnected--it would saturate the internal current

source. The current at this I

MON

output is I

DRV

/10.

Therefore, V

IMON

= R

IMON

(I

DRV

/10).

D

R

3

is not required but can match R

SET

(or R

SET

||R

OS

)

to compensate for the bias current.

D

R

IA

can be short-circuited if not used. Do not leave

this current output unconnected. R

GAIN

is selected to

10k

to match the output of 10V with 20mA for the

equal input signal.

D

R

C

ensures stability for unknown load conditions

and limits the current into the internal protection

diodes. C

4

helps protect the device. Over-voltage

clamp diodes (standard 1N4002) might be

necessary to protect the output.

D

R

6

, R

7

, and C

5

protect the IA.

D

R

LOAD

and C

LOAD

represent the load resistance and

load capacitance.

D

R

SET

defines the transfer gain. It can be split to allow

a signal offset and, therefore, allow a 5V single-

supply digital-to-analog converter (DAC) to control a

±

10V or

±

20mA output signal.

The XTR300 can be used with asymmetric supply voltages;

however, the minimum negative supply voltage should be

equal to or more negative than -3V (typically -5V). This sup-

ply value ensures proper control of 0V and 0mA with wire re-

sistance, ground offsets, and noise added to the output. For

positive output signals, the current requirement from this

negative voltage source is less than 5mA.

GND1 through GND4 must be selected to fulfill speci-

fied operating ranges. DGND must be in the range of

(V-)

DGND

(V+) -7V.

The following information should be considered during XTR300 circuit configuration:

S-IN

IA-O

SG

OS

I-MON

IA

Current Copy

OPA

R

GAIN

10k

RG

1

RG

2

I

COPY

I

DRV

I

IA

IA

IN+

IA

IN

-

DRV

IA

OUT

V

IN

C

C

47nF

C

2

100nF

C

3

100nF

R

3

1k

R

IA

1k

NOTE: (1) See the Electrical Characteristics and Digital Input and Output section for operating limits of DGND.

(2) Connect thermal pad to V

-

.

R

OS

2k

SET

I

MON

V

-

Thermal

Pad

DGND

(1)

(2)

V+

V

-

GND

V+

XTR300

Digital

Control

OD

M2

M1

Error

Flags

EF

CM

EF

LD

EF

OT

R

SET

GND1

GND3

GND4

R

IMON

1k

R

C

15

C

4

100nF

C

5

10nF

C

LOAD

External Load

Logic Supply

(+2.7V to +5V)

Pull-up Resistors

(10k

)

R

LOAD

R

6

2.2k

R

7

2.2k

GND1

GND1

GND2

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

15

Built on a robust high-voltage BI-CMOS process, the

XTR300 is designed to interface the 5V or 3V supply do-

main used for processors, signal converters, and amplifi-

ers to the high-voltage and high-current industrial signal

environment. It is specified for up to

±

20V supply, but can

also be powered asymmetrically (for example, +24V and

-5V). It is designed to allow insertion of external circuit

protection elements and drive large capacitive loads.

FUNCTIONAL FEATURES

The XTR300 provides two basic functional blocks: an in-

strumentation amplifier (IA) and a driver that is a unique

operational amplifier (OPA) for current or voltage output.

This combination represents an analog output stage which

can be digitally configured to provide either current or volt-

age output to the same terminal pin. Alternatively, it can be

configured for independent measurment channels.

Three open collector error signals are provided to indicate

output related errors such as over-current or open-load

(EF

LD

) or exceeding the common-mode input range at the

IA inputs (EF

CM

). An over-temperature flag (EF

OT

) can be

used to control output disable to protect the circuit. The

monitor outputs (I

MON

and IA

OUT

) and the error flags offer

optimal testability during operation and configuration. The

I

MON

output represents the current flowing into the load in

voltage output mode, while the IA

OUT

represents the volt-

age across the connectors in current output mode. Both

monitor outputs can be connected together when used in

current or voltage output mode because the monitor sig-

nals are multiplexed accordingly.

VOLTAGE OUTPUT MODE

In voltage output mode (M1 and M2 are connected low or

left unconnected), the feedback loop through the IA pro-

vides high impedance remote sensing of the voltage at the

destination, compensating the resistance of a protection

circuit, switches, wiring, and connector resistance. The

output of the IA is a current that is proportional to the input

voltage. This current is internally routed to the OPA sum-

ming junction through a multiplexer, as shown in Figure 6.

A 1:10 copy of the output current of the OPA can be moni-

tored at the I

MON

pin. This output current and the known

output voltage can be used to calculate the load resistance

or load power.

During an output short-circuit or an over-current condition

the XTR300 output current is limited and EF

LD

(load error,

active low) flag is activated.

IA

Current Copy

OPA

R

GAIN

RG

1

RG

2

I

COPY

C

C

I

DRV

I

IA

IA

IN+

IA

IN

-

Load

GN D2

DRV

IA

OUT

V

IN

SET

I

MON

V

-

DGND

V +

XTR300

Digital

Control

OD

M2

M1

L

L

Error

Flags

EF

CM

EF

LD

EF

OT

Input Signal

R

SET

R

IMON

GND1

GND 3

Figure 6. Simplified Voltage Output Mode

Configuration

Applications not requiring the remote sense feature can

use the OPA in stand-alone operation (M1 = high). In this

case, the IA is available as a separate input channel.

The IA gain can be set by two resistors, R

GAIN

and R

SET

:

V

OUT

+

R

GAIN

2R

SET

V

IN

or when adding an offset, V

REF

, to get bidirectional output

with a single-ended input:

V

OUT

+

R

GAIN

2

V

IN

R

SET

)

V

IN

*

V

REF

R

OS

The R

SET

resistor is also used in current output mode.

Therefore, it is useful to define R

SET

for the current mode,

then set the ratio between current and voltage span with

R

GAIN

.

(1)

(2)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

16

CURRENT OUTPUT MODE

The XTR300 does not require a shunt resistor for current

control because it uses a precise current mirror arrange-

ment.

In current output mode (M1 connected low, or left uncon-

nected and M2 connected high) a precise copy of 1/10th

of the output is internally routed back to the summing junc-

tion of the OPA through a multiplexer, closing the control

loop for the output current.

The OPA driver can deliver more than

±

24mA within a wide

output voltage range. An open-output condition or high-im-

pedance load that prevents the flow of the required current

activates the EF

LD

flag.

While in current output mode, a current (I

IA

) that is propor-

tional to the voltage at the IA input is routed to IA

OUT

and

can be used to monitor the load voltage. A resistor con-

verts this current into voltage. This arrangement makes

level shifting easy.

Alternatively, the IA can be used as an independent moni-

toring channel. If this output is not used, connect it to GND

to maintain proper function of the monitor stage, as shown

in Figure 7.

IA

Current Copy

OPA

R

GAIN

RG

1

RG

2

I

COPY

I

DRV

I

IA

IA

IN+

IA

IN

-

Load

GND2

DRV

IA

OUT

V

IN

SET

I

MON

V

-

DGND

V+

XTR300

Digital

Control

OD

M2

M1

H

L

Error

Flags

EF

CM

EF

LD

EF

OT

Input Signal

R

IA

R

SET

GND3

GND1

Figure 7. Simplified Current Output Mode

Configuration

The transconductance (gain) can be set by the resistor,

R

SET

, according to the equation:

I

OUT

+

10

R

SET

V

IN

or when adding an offset V

REF

to get bidirectional output

with a single-ended input:

I

OUT

+

10

V

IN

R

SET

)

V

IN

*

V

REF

R

OS

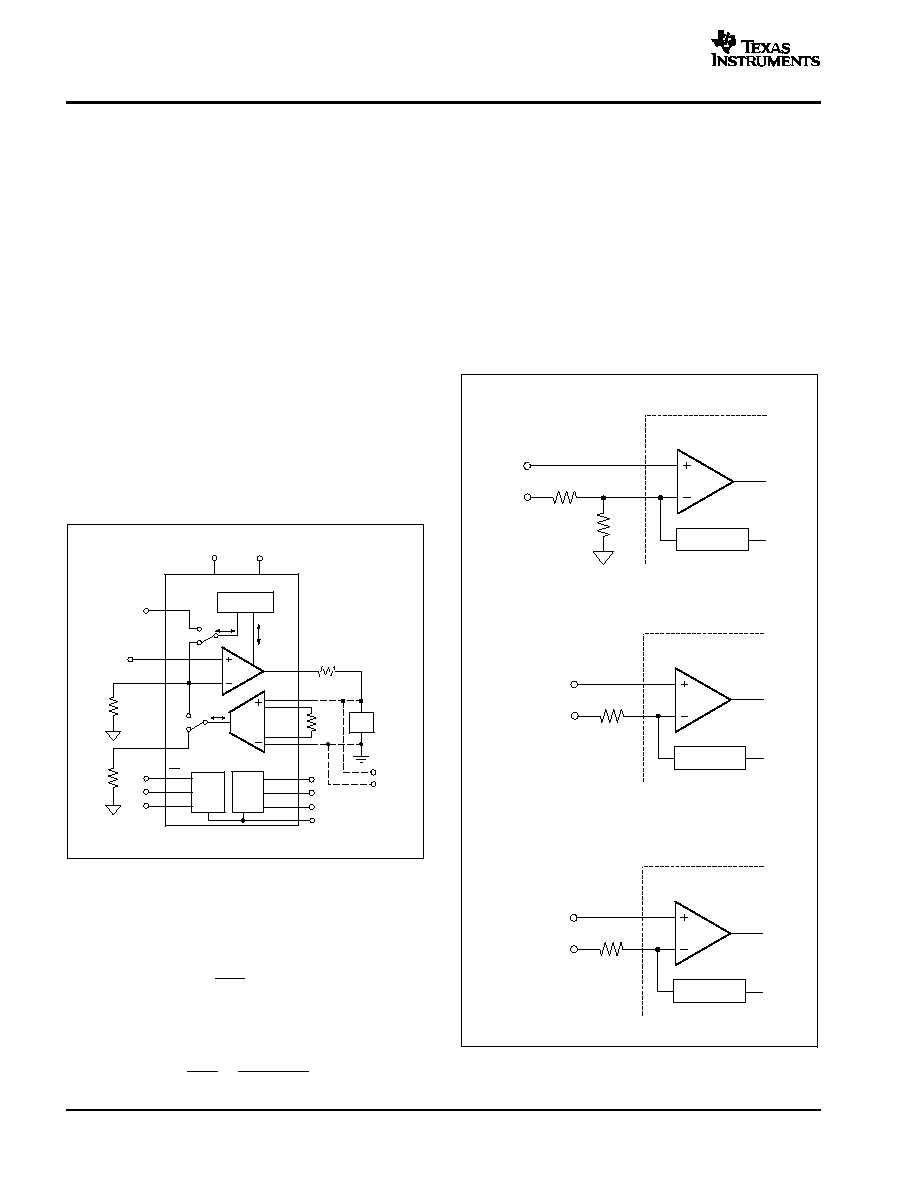

INPUT SIGNAL CONNECTION

It is possible to drive the XTR300 with a unidirectional input

signal and still get a bidirectional output by adding an addi-

tional resistor, R

OS

, and an offset voltage signal, V

REF

. It

can be a mid-point voltage or a signal to shift the output

voltage to a desired value.

This design is illustrated in Figure 8a, Figure 8b, and

Figure 8c. As with a normal operational amplifier, there are

several options for offset-shift circuits. The input can be

connected for inverting or noninverting gain. Unlike many

op amp input circuits, however, this configuration uses cur-

rent feedback, which removes the voltage relationship be-

tween the noninverting input and output potential because

there is no feedback resistor.

V

IN

(

±

V

MIDSCALE

)

V

MIDSCALE

R

SET

1k

XTR300

OPA

I-Feedback

V

IN

(

±

V

OFFSET

)

V

REF

R

SET

1k

XTR300

OPA

I-Feedback

a) Noninverting Input

b) Noninverting Input

c) Inverting Input (V

REF

= V

OFFSET

)

V

IN

(0 to V

OFFSET

)

V

REF

R

OS

2k

R

SET

2k

XTR300

OPA

I-Feedback

Figure 8. Circuit Options for Op Amp Output

Level-Shifting

(3)

(4)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

17

The input bias current effect on the offset voltage can be

reduced by connecting a resistor in series with the positive

input that matches the approximate resistance at the neg-

ative input. This resistor placed close to the input pin acts

as a damping element and makes the design less sensitive

to RF noise. See R

3

in Figure 5.

EXTERNALLY-CONFIGURED MODE:

OPA AND IA

It is possible to use the precision of the operational amplifi-

er (OPA) and instrumentation amplifier (IA) independently

from each other by configuring the digital control pins (M1

high). In this mode, the IA output current is routed to IA

OUT

and the copy of the OPA output current is routed to I

MON

,

as shown in Figure 4.

This mode allows external configuration of the analog sig-

nal routing and feedback loop.

The current output IA has high input impedance, low offset

voltage and drift, and very high common-mode rejection

ratio. An external resistor (R

IA

) can be used to convert the

output current of the IA (I

IA

) to an output voltage. The gain

is given by:

I

IA

+

2

R

GAIN

V

IN

or V

IA

+

2R

IA

R

GAIN

V

IN

The OPA provides low drift and high voltage output swing

that can be used like a common operational amplifier by

connecting a feedback network around it. In this mode, the

copy of the output current is available at the I

MON

pin (it in-

cludes the current into the feedback network). It provides

an output current limit for protection, which can be set be-

tween two ranges by M2. The error flag indicates an over-

current condition, as well as indicating driving the output

into the supply rails.

Alternatively, the feedback can be closed through the I

MON

pin to create a precise voltage-to-current converter.

DRIVER OUTPUT DISABLE

The OPA output (DRV) can be switched to a high-imped-

ance mode by driving the OD control pin low. This input can

be connected to the over-temperature flag, EF

OT

, and a

pull-up resistor to protect the IC from over-temperature by

disconnecting the load.

The output disable mode can be used to sense and mea-

sure the voltage at the IA input pins without loading from

the DRV output. This mode allows testing of any voltage

present at the I/O connector. However, consider the bias

current of the IA input pins.

The digital control inputs, M1 and M2, set the four opera-

tion modes of the XTR300 as shown in Table 1. When M1

is asserted low, M2 determines voltage or current mode

and the corresponding appropriate current limit (I

SC

) set-

ting. When M1 is high, the internal feedback connections

are opened; IA

OUT

and I

MON

are both connected to the out-

put pins; and M2 only determines the current limit (I

SC

) set-

ting.

SUMMARY OF CONFIGURATION MODES

(1)

M1

M2

MODE

DESCRIPTION

L

L

V

OUT

Voltage Output Mode, I

SC

= 20mA

L

H

I

OUT

Current Output Mode, I

SC

= 32mA

H

L

Ext

IA and I

MON

on ext. pins, I

SC

= 20mA

H

H

Ext

IA and I

MON

on ext. pins, I

SC

= 32mA

(1) OD is a control pin independent of M1 or M2. See the Driver

Output Disable section.

Table 1. Mode Configuration

M1 and M2 are pulled low internally with 1

µ

A. Terminate

these two pins to avoid noise coupling.

Output disable (OD) is internally pulled high with approxi-

mately 1

µ

A.

DRIVING CAPACITIVE LOADS AND LOOP

COMPENSATION

For normal operation, the driver OPA and the IA are con-

nected in a closed loop for voltage output. In current output

mode, the current copy closes the loop directly.

In current output mode, loop compensation is not critical,

even for large capacitive loads. However, in voltage output

mode, the capacitive load, together with the source imped-

ance and the impedance of the protection circuit, gener-

ates additional phase lag. The IA input might also be pro-

tected by a low-pass filter that influences phase in the

closed loop.

The loop compensation low-pass filter consists of C

C

and

the parallel resistance of R

OS

and R

SET

. For loop stability

with large capacitive load, the external phase shift has to

be added to the OPA phase. With C

C

, the voltage gain of

the OPA has to approach zero at the frequency where the

total phase approaches 180

∞

+ 135

∞

.

The best stability for large capacitive loads is provided by

adding a small resistor, R

C

(15

). See the Output Protec-

tion section.

An empirical method of evaluation is using a square wave

input signal and observing the settling after transients. Use

small signal amplitudes only--steep signal edges cause

excessive current to flow into the capacitive load and may

activate the current limit, which hides or prevents oscilla-

tion. A small-signal oscillation can be hidden from large ca-

pacitive loads, but observing the I

MON

output on an ap-

propriate resistor (use a similar value like R

SET

||R

OS

) would

indicate stability issues. Note that noise pulses at I

MON

dur-

(5)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

18

ing overload (EF

LD

active) are normal and are caused by

cycling of the current mirror.

The voltage output mode includes the IA in the loop. An

additional low-pass filter in the input reverses the phase

and therefore increases the signal bandwidth of the loop,

but also increases the delay. Again, loop stability has to be

observed. Overloading the IA disconnects the closed loop

and the output voltage rails.

INTERNAL CURRENT SOURCES,

SWITCHING NOISE, AND SETTLING TIME

The accuracy of the current output mode and the DC per-

formance of the IA rely on dynamically-matched current

mirrors.

Identical current sources are rotated to average out mis-

match errors. It can take several clock cycles of the internal

100kHz ocsillator (or a submultiple of that frequency) to

reach full accuracy. This may dominate the settling time to

the 0.1% accuracy level and can be as much as 100

µ

s in

current output mode or 40

µ

s in voltage output mode.

A small portion of the switching glitches appear at the DRV

output, and also at the I

MON

and IA

MON

outputs. The stan-

dard circuit configuration, with R

C

, C

4

, and C

C

, which are

required for loop compensation and output protection, also

helps reduce the noise to negligible levels at the signal out-

put. If necessary, the monitor outputs can be filtered with

a shunt capacitor.

IA STRUCTURE, VOLTAGE MONITOR

The instrumentation amplifier has high-impedance NPN

transistor inputs that do not load the output signal, which

is especially important in current output mode. The output

signal is a controlled current that is multiplexed either to

the SET pin (to close the voltage output loop) or to IA

OUT

(for external access).

The principal circuit is shown in Figure 9. The two input

buffer amplifiers reproduce the input difference voltage

across R

GAIN

. The resulting current through this resistor is

bidirectionally mirrored to the output. That mirroring results

in the ideal transfer function of:

I

IA

+

IA

OUT

+

2 (IA

IN

)

*

IA

IN

*

) R

GAIN

The accuracy and drift of R

GAIN

defines the accuracy of the

voltage to current conversion. The high accuracy and sta-

bility of the current mirrors result from a cycling chopper

technique.

Current Mirror

Current Mirror

Current Mirror

Current Mirror

IA

IN+

IA

IN

-

R

GAIN

I

R

I

R

I

R

I

R

2I

R

2I

R

2I

R

2I

R

A1

A2

I

IA

Figure 9. IA Block Diagram

The output current, IA

OUT

, of the instrumentation amplifier

is limited to protect the internal circuitry. This current limit

has two settings controlled by the state of M2 (see Electri-

cal Characteristics, Short-Circuit Current specification).

Note that if R

SET

is too small, the current output limitation

of the instrumentation amplifier can disrupt the closed loop

of the XTR300 in voltage output mode. With M2 = low, the

nominal R

GAIN

of 10k

allows an input voltage of 20V

PP

,

which produces an output current of 4mA

PP

. When using

lower resistors for R

GAIN

that can allow higher currents, the

IA output current limitation must be taken into account.

CURRENT MONITOR

In current output mode (M2 = high), the XTR300 provides

high output impedance. A precision current mirror gener-

ates an exact 1/10th copy of the output current and this cur-

rent is either routed to the summing junction of the OPA to

close the feedback loop (in the current output mode) or to

the I

MON

pin for output current monitoring in other operating

modes.

(6)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

19

The high accuracy and stability of this current split results

from a cycling chopper technique. This design eliminates

the need for a precise shunt resistor or a precise shunt-

voltage measurement, which would require high common-

mode rejection performance.

During a saturation condition of the DRV output (the error

flag is active), the monitor output (I

MON

) shows a current

peak because the loop opens. Glitches from the current

mirror chopper appear during this time in the monitor sig-

nal. This part of the signal cannot be used for measure-

ment.

ERROR FLAGS

The XTR300 is designed for testability of its proper func-

tion and allows observation of the conditions at the load

connection without disrupting service.

If the output signal is not in accordance to the transfer func-

tion, an error flag is activated (limited by the dynamic re-

sponse capabilities). These error flags are in addition to

the monitor outputs, I

MON

and IA

OUT

, which allow the mo-

mentary output current (in voltage mode) or output voltage

(in current mode) to be read back.

This combination of error flag and monitor signal allows

easy observation of the XTR300 for function and working

condition, providing the basis for not only remote control,

but also for remote diagnosis.

All error flags of the XTR300 have open collector outputs

with a weak pull-up of approximately 1

µ

A to an internal 5V.

External pull-up resistors to the logic voltage are required

when driving 3V or 5V logic.

The output sink current should not exceed 5mA. This is just

enough to directly drive optical-couplers, but a current-lim-

iting resistor is required.

There are three error flags:

D

IA Common-Mode Over-Range (EF

CM

)--goes low

as soon as the inputs of the IA reach the limits of the

linear operation for the input voltage.

This flag shows noise from the saturated current

mirrors which can be filtered with a capacitor to GND.

D

Load Error (EF

LD

)--indicates fault conditions driving

voltage or current into the load. In voltage output mode

it monitors the voltage limits of the output swing and

the current limit condition caused from short or low

load resistance. In current output mode it indicates a

saturation into the supply rails from a high load

resistance or open load.

D

Over-Temperature Flag (EF

OT

)--is a digital output

that goes low if the chip temperature reaches a

temperature of +140

∞

C and resets as soon as it cools

down to +125

∞

C. It does not automatically shut down

the output; it allows the user system to take action on

the situation. If desired, this output can be connected

to output disable (OD) which disables the output and

therefore removes the source of power. This

connection acts like an automatic shut down, but

requires an external pull-up resistor to safely override

the internal current sources. The IA channel is not

affected, which allows continuous observation of the

voltage at the output.

DIGITAL COMMUNICATION: HART

The bandwidth and drive capability of the XTR300 are

sufficient to transmit communication signals such as

HART. The combination of current monitor and voltage

sense with the IA circuit enables communication signal

transmission from the signal output connector to the

monitor pins in both current or voltage output mode. In

current output mode, the signal arrives at IA

OUT

; in voltage

output mode the communication signal modulates the

DRV current and arrives at I

MON

. Both IA

OUT

and I

MON

can

be connected together because they are internally

multiplexed according to the output mode (while M1 = low).

Driving a communication signal through the output

connector back into the system or sensor, regardless of

the output mode, enables easy configuration, calibration,

diagnosis, and universal communication.

DIGITAL I/O AND GROUND

CONSIDERATIONS

The XTR300 offers voltage output mode, current output

mode, external configuration, and instrumentation mode

(voltage input). In addition, the internal feedback mode can

be disconnected and external loop connections can be

made. These modes are controlled by M1 and M2 (see the

function table). The OD input pin controls enable or disable

of the output stage (OD is active low).

The digital I/O is referenced to DGND and signals on this

pin should remain within 5V of the DGND potential. This

DGND pin carries the output low-current (sink current) of

the logic outputs. DGND can be connected to a potential

within the supply voltage but needs to be 8V below the

positive supply. Proper connection avoids current from the

digital outputs flowing into the analog ground.

It is important to note that DGND has normally reverse-

biased diodes connected to the supply. Therefore, high

and destructive currents could flow if DGND is driven

beyond the supply rails by more than a diode forward

voltage. Avoid this condition during power-on and

power-off!

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

20

OUTPUT PROTECTION

The XTR300 is intended to operate in a harsh industrial

environment. Therefore, a robust semiconductor process

was chosen for this design. However, some external

protection is still required.

The instrumentation amplifier inputs can be protected by

external resistors that limit current into the protection cell

behind the IC-pins, as shown in Figure 10. This cell

conducts to the power-supply connection through a diode

as soon as the input voltage exceeds the supply voltage.

The circuit configuration example shows how to arrange

these two external resistors.

The bias current is best cancelled if both resistors are

equal. The additional capacitor reduces RF noise in the

input signal to the IA.

RG

1

RG

2

IA

IN+

IA

IN+

R

GAIN

R

6

2.2k

R

7

2.2k

C

5

10nF

V

SENSE+

V

SENSE

-

IA

Figure 10. Current Limiting Resistors

The load connection to the DRV output must be low

impedance; therefore, external protection diodes may be

necessary to handle excessive currents, as shown in

Figure 11. The internal protection diodes start to conduct

earlier than a normal external PN-type diode because they

are affected by the higher die temperature. Therefore,

either Schottky diodes are required, or an additional

resistor (R

C

) can be placed in series with the input. An

example of this protection is shown in Figure 11. Assuming

the standard diodes limit the voltage to 1.4V and the

internal diodes clamp at 0.7V, this resistor can limit the

current into the internal protection diodes to 50mA:

(1.4V

*

0.7V) 15

W +

47mA

R

C

is also part of the recommended loop compensation. C

4

helps protect the output against RFI and high-voltage

spikes.

OPA

XTR300

I/V OUT

V+

V

-

C

C

47nF

R

C

15

C

4

100nF

D

1N4002

D

1N4002

DRV

Figure 11. Example for DRV Output Protection

POWER ON/OFF GLITCH

When power is turned on or off, most analog amplifiers

generate some glitching of the output because of internal

circuit thresholds and capacitive charges. Characteristics

of the supply voltage, as well as its rise and fall time, also

directly influence output glitches. Load resistance and

capacitive load affect the amplitude as well.

The output disable control (OD) allows good control over

the output during power-on, power-off, and system down

time by providing a high impedance to the output.

Figure 12a, Figure 12b, and Figure 12c show the output

voltage with the output disabled during power on and

off--no glitch can be see on the output signal. Holding OD

low also prevents glitches in current output mode.

Figure 12c indicates no glitches when transitioning from

disable to enable.

All measurements are made with a load resistance of 1k

and tested in the circuit configuration of Figure 5. OD has

an internal pull-up of approximately 1

µ

A; therefore, a

100k

resistor provides safe pull-down during power

on--make sure the logic controlling the OD pin does not

glitch.

(7)

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

21

a) Power-on in voltage or current output mode.

CH 1 shows supply voltage; CH 2 output voltage across a 1k

load.

b) Power-off in voltage or current output mode.

CH 1 shows supply voltage; CH 2 output voltage across a 1k

load.

Power-Supply Voltage

5.0V/div

Output

0.5V/div

Time (10ms/div)

Power-Supply Voltage

5.0V/div

Output

0.5V/div

Time (10ms/div)

Time (10ms/div)

OD

2.0V/div

Output

0.5V/div

c) CH 2: Output signal during toggle of OD:

CH 1 voltage or current output mode across a 1k

load.

Figure 12. Output Signal with Output Disabled During Power On/Off

LAYOUT CONSIDERATIONS

Supply bypass capacitors should be close to the package

and connected with low-impedance conductors. Avoid

noise coupled into R

GAIN

, and observe wiring resistance.

For thermal management, see the Heat Sinking section.

Layout for the XTR300 is not critical; however, its internal

current chopping works best with good (low dynamic

impedance) supply decoupling. Therefore, avoid through-

hole contacts in the connection to the bypass capacitors

or use multiple through-hole contacts. Switching noise

from chopper-type power supplies should be filtered

enough to reduce influence on the circuit. Small resistors

(2

, for example) or damping inductors in series with the

supply connection (between the DC/DC converter and the

XTR circuit) act as a decoupling filter together with the

bypass capacitor, as shown in Figure 13.

V

-

V+

V

-

V+

C

B1

100nF

C

B3

1

µ

F

C

B4

1

µ

F

C

B2

100nF

L

1

10

µ

H

L

2

10

µ

H

XTR300

Figure 13. Suggested Supply Decoupling for

Noisy Chopper-Type Supplies

XTR300

SBOS336B - JUNE 2005 - REVISED MARCH 2006

www.ti.com

22

Resistors connected close to the input pins help dampen

environmental noise coupled into conductor traces.

Therefore, place the OPA input- and IA input-related

resistors close to the package. Also, avoid additional wire

resistance in series to R

SET

, R

OS

, and R

GAIN