CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 1 OF 7

TBF-2520-245-A1 SERIES THIN FILM BAND PASS FILTER

1. Feature:

1. 2.45GHz Thin Film Band Pass Filter

2. For ISM Band applications like Wireless LAN & Bluetooth.

3. Lead Free

2. Part Number

TBF -- 2520 -- 245 --A1

--

XX

(1) (2) (3)

(4) (5)

Where

(1) TBF : Thin Film Band Pass Filter

(2)

Size

:

4 digits of number ≠≠2520 = 2.50◊2.00 mm

(3) Center Frequency :

245 = 2.45 GHz

(4)

Type

Refer to Table 3-1

(5)

XX

Internal Code

3. Ratings

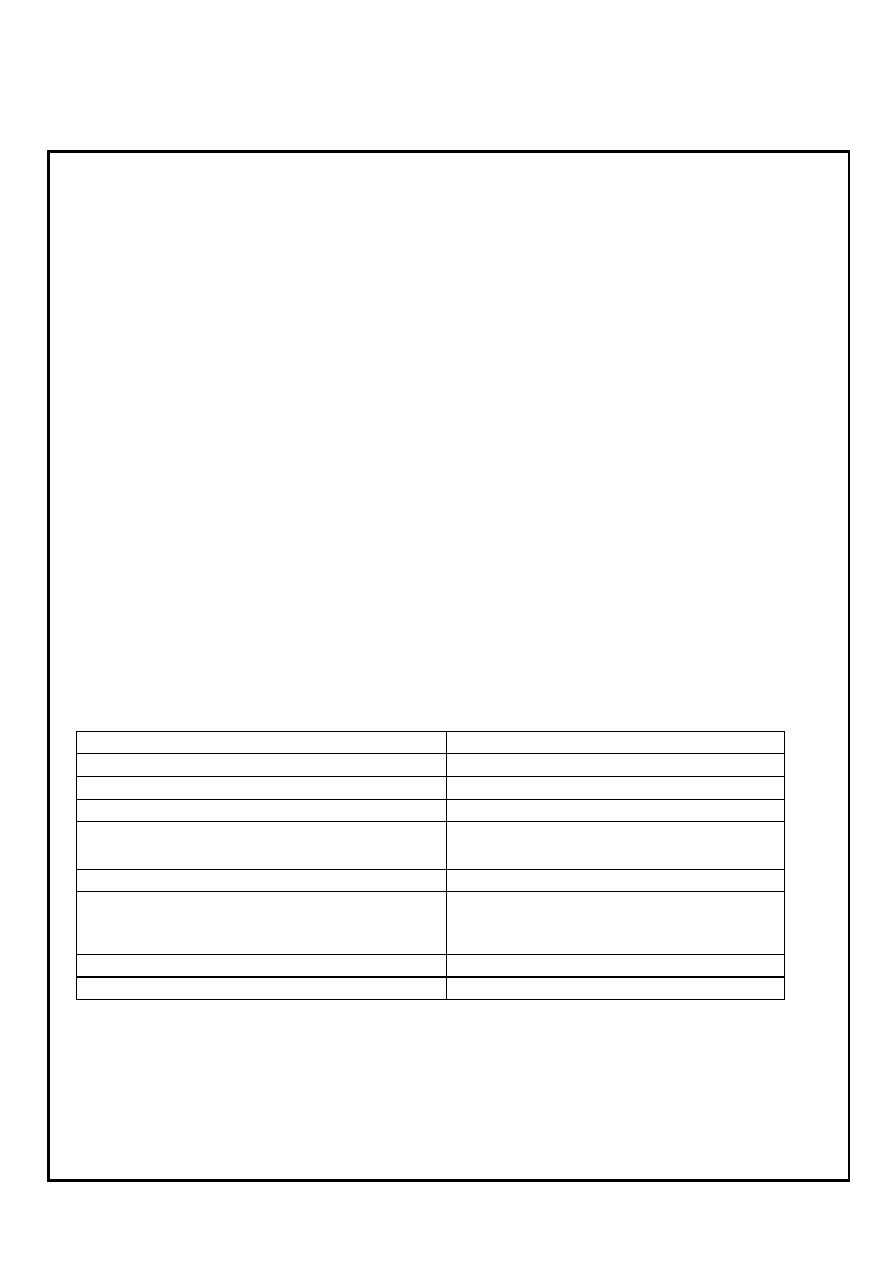

3-1 Specifications

Part Number

TBF-2520-245-A1

Nominal Characteristics Impedance

50

Nominal Center Frequency

2450MHz

Bandwidth

2400 ~ 2500MHz

Insertion Loss

1.7 dB Max. at +25

1.9 dB max. at ≠40 ~ +85

Ripple in BW

0.5dB max.

Attenuation

25.0dB min. at 1750MHz

25.0dB min. at 2000 ~ 2100MHz

22.0dB min at 4800 ~ 5000MHz

VSWR in BW

2.0 Max.

Power Capacity

500mW Max.

3-2 Operation Temperature:

-40 to +85

3-3 Storage Temperature: +15 to +35

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 2 OF 7

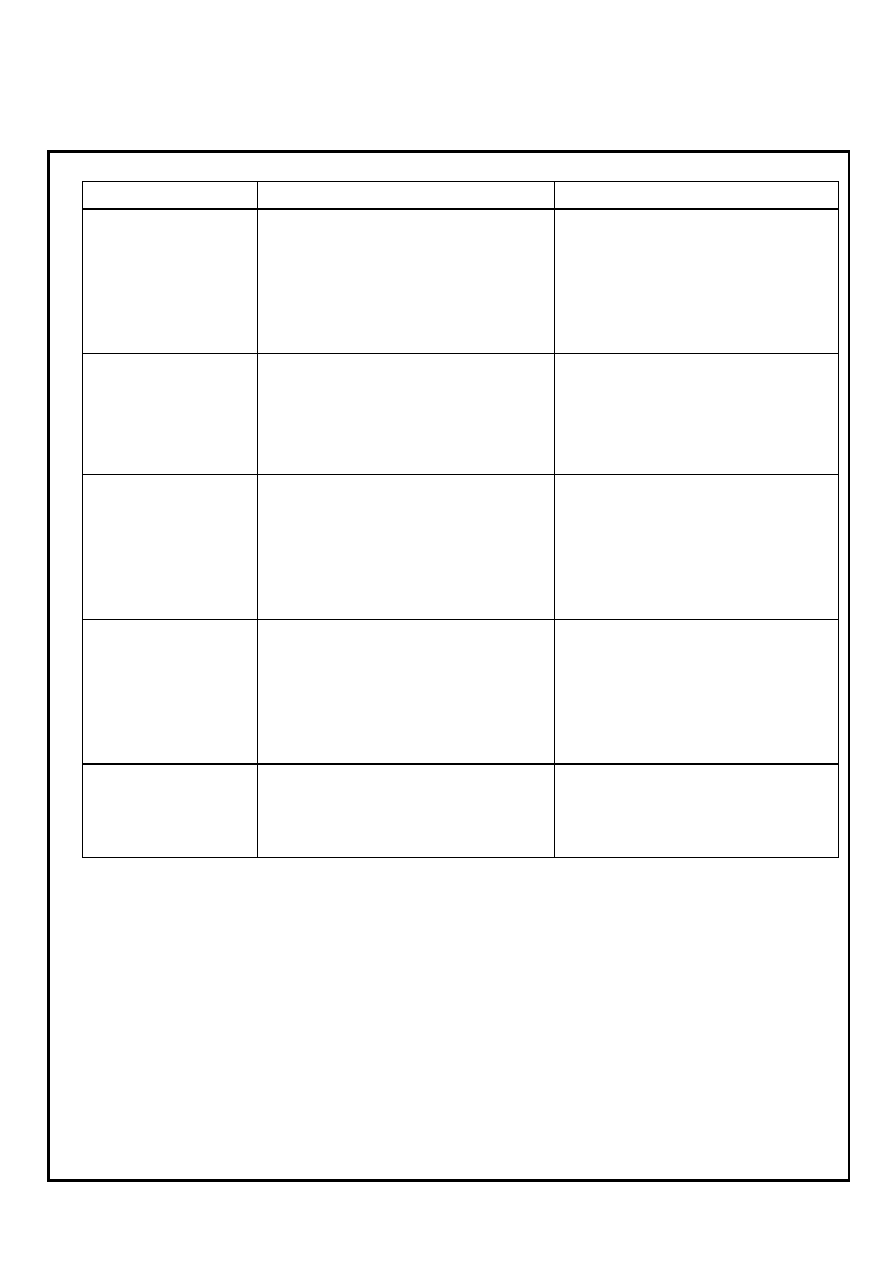

4. Outline Dimension

5. Electrical Performance

Code

Dimension Code Dimension

L 2.5

± 0.2

L1

2.0

± 0.1

W 2.0

± 0.2

Lt

1.2

± 0.1

T 0.5

± 0.1

Lw

0.2

± 0.1

W1

0.8

± 0.1

Wt

0.4

± 0.1

Ww

0.2

± 0.1

Unit : mm

Terminal Configuration:

Terminal No.

Terminal Name

(1) GND

(2) Output

(3) GND

(4) Input

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 3 OF 7

6. Recommended Land Pattern

Line Width be designed to match 50ohm characteristic impedance, depending on PCB material

and thickness

Notes : All the technical data and information contained herein are subject to change without prior

notice

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 4 OF 7

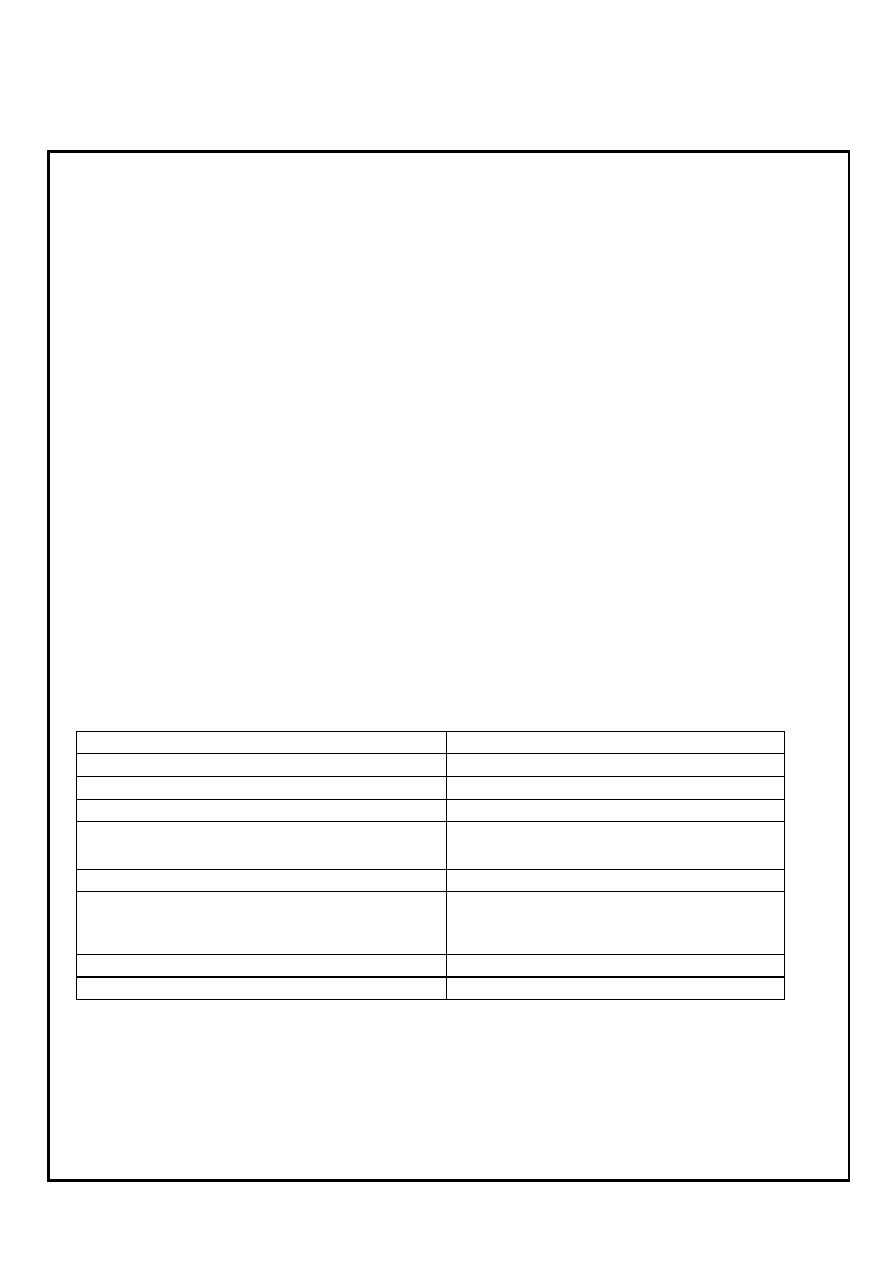

7. Reliability Test

7-1 Electrical

ITEM

Specification and Requirement

Test Method

Temperature

Characteristics

Satisfy electrical characteristics

Solder the sample on PCB.

Exposure at each temperature,

-40, -20, 0, +25, +50,

+85 for 30minutes

7-2 Mechanical

ITEM

Specification and Requirement

Test Method

Solderability

The Surface of terminal immersed shall

be minimum of 95% covered with a

new coating of solder

Solder bath :

After immersing in flux, dip in

245

± 5 molten solder bath

for 2

± 0.5 seconds

Resistance to solder

Heat

Satisfy electrical characteristics without

distinct deformation in appearance

(1) Pre-heat : 100 ~ 110 for

30 seconds

(2) Immersed at solder bath of

270

± 5 for 20 ± 1 seconds

Vibration

Satisfy electrical characteristics without

Mechanical damage such as break

Vibrate as apply 20 to 2,000Hz,

186m/s

2

(19G) acceleration 1.5mm

amplitude for 2 hours in each of three

(X, Y, Z) axis (total 6 hours).

Shock

Satisfy electrical characteristics without

mechanical damaged such as break

(1) Break value : 490 N

(2) Duration of pulse : 11ms

(3) 3 times in each positive and

negative direction of 3 mutual

perpendicular directions.

Bending Test

Satisfy electrical characteristics without

mechanical damage such as break

Bending value : 3mm for

30

± 1 seconds

Solvent Resistant

Marking should be legible without

mechanical and distinct damage in

appearance

(1)

Solvent : Trichloroethane or

Isopropyl alcohol.

(2) Immersed in solvent at room

temperature for 90 seconds

Drop Test

Satisfy electrical characteristics without

mechanical damage

Drop the sample from a height of 1m

to concrete ground for 10 times

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 5 OF 7

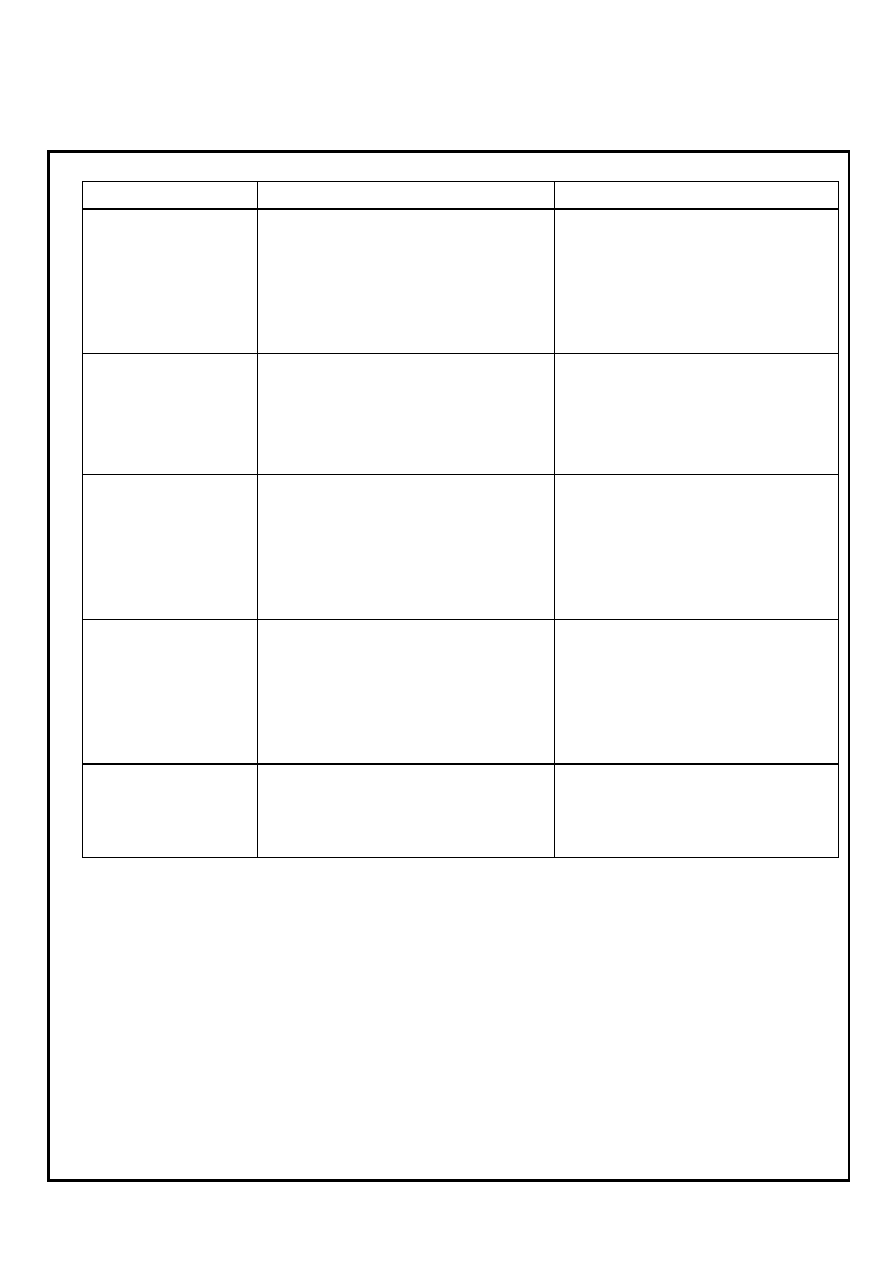

7-3 Load Life

ITEM

Specification and Requirement

Test Method

Rapid change of

temperature

Satisfy Electrical Characteristics.

Without distinct damage.

Perform 5 cycles as follows :

-55 for 30minutes room

temperature for 3 minutes

+125 for 30minutes room

temperature for 3 minutes.

(Dwell time : 5 to 8 minutes)

Humidity Resistance

Test

Satisfy Electrical Characteristics.

Without distinct damage.

Precondition at +25 for 1hour.

Let stand at temperature +40

± 3,

90~95% relative humidity for 1,000

hours before taking final

measurements.

Low Temperature

Store

Satisfy Electrical Characteristics.

Without distinct damage.

Solder the sample on PCB.

Exposure at

-55 ± 3 for 1,000

hours.

1~2 hours exposure at room

temperature and humidity, prior to

measurement.

High Temperature

Store

Satisfy Electrical Characteristics.

Without distinct damage.

Solder the sample on PCB.

Exposure at +85

± 3 for 1,000

hours.

1~2 hours exposure at room

temperature and humidity, prior to

measurement.

Load Life

Satisfy Electrical Characteristics.

Without distinct damage.

Apply 16 Volt voltage at 70

± 2

ambient

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 6 OF 7

8. Packaging

8-1 Material : Paper Carrier Tape

8-2 Dimensions

8-2-1 Tape packaging dimensions

Direction mark

Carries cavity

A

0.65 ± 0.10

B

A = 2.28 ± 0.10

B = 2.74 ± 0.10

P(PITCH) = 4.00 ± 0.10

+

1.5

-

P

1.75 ± 0.10

8.00 ± 0.30

P

Unit : mm

Sprocket hole

0.60 ± 0.10

2.00 ± 0.10

3.50 ± 0.10

0.1

8-2-2 Setting Direction

8-2-3 Reel dimensions

Unit : mm

10.0 ± 1.5

0.8 ± 0.2

2.0 ± 0.5

21 ± 0.8

13

.0 ± 0.

5

60

±

5.0

1

78 ± 2

CYNTEC CO., LTD.

DOCUMENT : TBF2520245A1

REVISION : A0

PAGE : 7 OF 7

8-3 Peel force of top cover tape

The peel speed shall be about 300 mm/minute

The peel force of top cover tape shall be between 10 to 70g

8-4 Numbers of taping

4,000 pieces/reel

8-5 Label marking

The following items shall be marked on the production and shipping

Label on the reel.

8-5-1 Production Label

(1) Part No.

(2) Description

(3) Quantity

(4) Taping No.

8-5-2 Shipping Label

(1) *Customer's name

(2) *Customer's part No.

(3) Manufacturer's part No.

(4) Manufacturer's name

(5) Manufacturer's country

*Note : Item (1) and (2) are listed by request