DS13015 Rev. B-2

1 of 2

MBRB1530CT-MBRB1545CT

MBRB1530CT - MBRB1545CT

15A SURFACE MOUNT SCHOTTKY BARRIER RECTIFIER

Features

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

Maximum Ratings and Electrical Characteristics

@ T

A

= 25∞C unless otherwise specified

∑

Case: D

2

PAK Molded Plastic

∑

Terminals: Solderable per MIL-STD-202,

Method 208

∑

Polarity: See Diagram

∑

Approx. Weight: 1.7 grams

∑

Mounting Position: Any

∑

Marking: Type Number

Mechanical Data

B

C

D

E

G

H

J

K

L

M

A

1

2

3

4

PIN 1

PIN 3

PIN 2 & 4

D

2

PAK

Dim

Min

Max

A

9.65

10.69

B

14.60

15.88

C

0.51

1.14

D

2.29

2.79

E

4.37

4.83

G

1.14

1.40

H

1.14

1.40

J

8.25

9.25

K

0.30

0.64

L

2.03

2.92

M

2.29

2.79

All Dimensions in mm

Characteristic

Symbol

MBRB

1530CT

MBRB

1535CT

MBRB

1540CT

MBRB

1545CT

Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

V

RRM

V

RWM

V

R

30

35

40

45

V

RMS Reverse Voltage

V

R(RMS)

21

24.5

28

31.5

V

Average Rectified Output Current

@ T

C

= 105∞C

I

O

15

A

Non-Repetitive Peak Forward Surge Current 8.3ms

single half sine-wave superimposed on rated load

(JEDEC Method)

I

FSM

150

A

Forward Voltage, per Element (Note 4)

@ I

F

= 7.5A

V

FM

0.7

V

Voltage Rate of Change

dv/dt

10,000

V/µs

Peak Reverse Current

@T

A

= 25∞C

at Rated DC Blocking Voltage

@ T

A

= 100∞C

I

RM

0.1

15

mA

Maximum Recovery Time (Note 3)

t

rr

30

ns

Typical Junction Capacitance (Note 2)

C

j

250

pF

Typical Thermal Resistance Junction to Terminal (Note 1)

R

qJT

3.0

K/W

Operating and Storage Temperature Range

T

j,

T

STG

-65 to +150

∞C

Notes:

1. Thermal resistance: junction to terminal, unit mounted on PC board with 5.0 mm

2

(0.013 mm thick) copper pad as heat sink.

2. Measured at 1.0 MHz and applied reverse voltage of 4.0V DC.

3. Reverse recovery test conditions: I

F

= 0.5A, I

R

= 1.0A, I

rr

= 0.25A (see figure 1).

4. 300µs pulse width, 2% duty cycle.

∑

Schottky Barrier Chip

∑

Guard Ring Die Construction for

Transient Protection

∑

Low Power Loss, High Efficiency

∑

High Surge Capability

∑

High Current Capability and Low Forward

Voltage Drop

∑

Surge Overload Rating to 150A Peak

∑

For Use in Low Voltage, High Frequency

Inverters, Free Wheeling, and Polarity

Protection Applications

∑

Plastic Material - UL Flammability

Classification 94V-0

DS13015 Rev. B-2

2 of 2

MBRB1530CT-MBRB1545CT

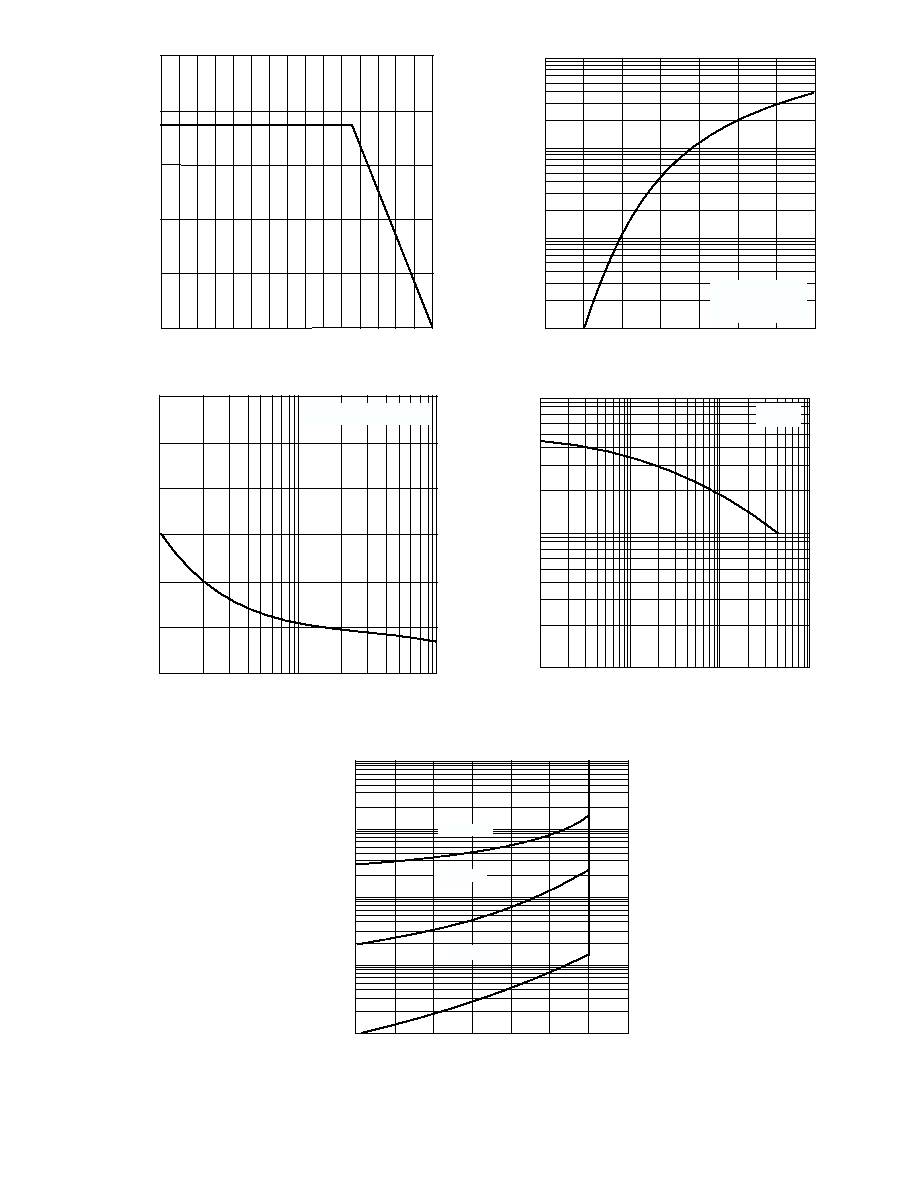

50

100

150

0

200

250

300

1

10

100

I

,

PEAK

FOR

W

ARD

SURGE

CURRENT

(A)

FSM

NUMBER OF CYCLES AT 60 Hz

Fig. 3 Max Non-Repetitive Surge Current

8.3 ms single half-sine-wave

JEDEC method

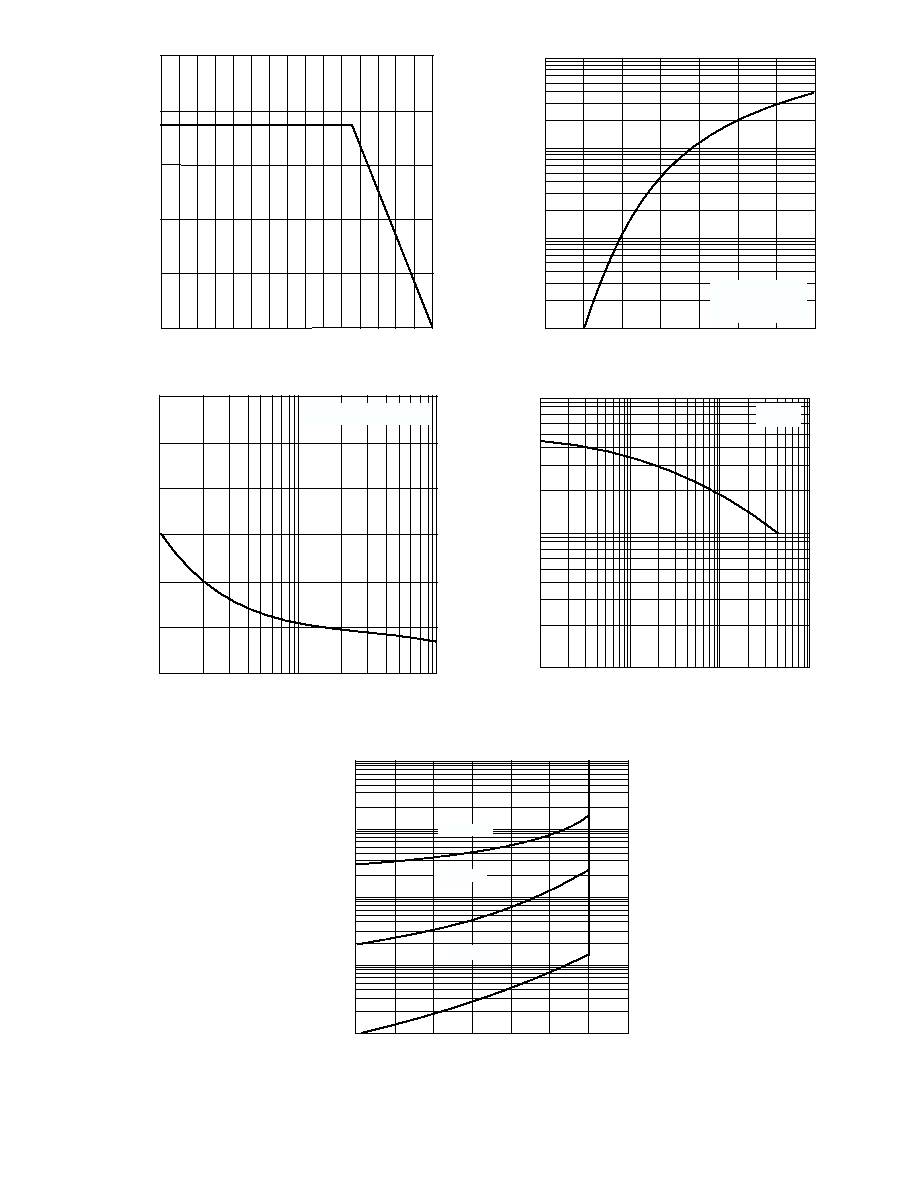

0.01

0.1

1.0

10

100

0

40

80

120

I

,

INST

ANT

ANEOUS

REVERSE

CURRENT

(mA)

R

PERCENT OF RATED PEAK REVERSE VOLTAGE (%)

Fig. 5 Typical Reverse Characteristics, per element

T = 100∞C

j

T = 75∞C

j

T = 25∞C

j

0

4

8

12

16

20

0

50

100

150

I

,

A

VERAGE

FOR

W

ARD

CURRENT

(A)

(A

V)

T , CASE TEMPERATURE (∞C)

Fig. 1 Fwd Current Derating Curve

C

0.1

1.0

10

100

0.2

0.4

0.6

0.8

I

,

INST

ANT

ANEOUS

FOR

W

ARD

CURRENT

(A)

F

V , INSTANTANEOUS FORWARD VOLTAGE (V)

Fig. 2 Typical Fwd Characteristics per Element

F

T = 25∞C

Pulse width = 300 µs

2% duty cycle

j

10

100

1000

0.1

1.0

10

100

C

,

JUNCTION

CAP

ACIT

ANCE

(pF)

j

V , REVERSE VOLTAGE (V)

Fig. 4 Typical Junction Capacitance

R

T = 25∞C

f = 1MHz

j