X

T

April 1999

Intel and Pentium are registered trademarks of Intel Corporation. I

2

C is a licensed trademark of Philips Electronics, N.V. American Microsystems, Inc. reserves the right to change the detail specifica-

tions as may be required to permit improvements in the design of its products.

4.5.99

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

1.0 Features

�

Generates up to eighteen low-skew, non-inverting

clocks from one clock input

�

Supports up to four SDRAM DIMMs

�

Uses either I

2

C

TM

-bus or SMBus serial interface with

Read and Write capability for individual clock output

control

�

Output enable pin tristates all clock outputs to facili-

tate board testing

�

Clock outputs skew-matched to less than 250ps

�

Less than 5ns propagation delay

�

Output impedance: 17

at 0.5V

DD

�

Serial interface I/O meet I

2

C specifications; all other

I/O are LVTTL/LVCMOS-compatible

�

Five differerent pin configurations available:

�

FS6050: 18 clock outputs in a 48-pin SSOP

�

FS6051: 10 clock outputs in a 28-pin SOIC, SSOP

�

FS6053: 13 clock outputs in a 28-pin SOIC

�

FS6054: 14 clock outputs in a 28-pin SOIC

Figure 1: Block Diagram (FS6050)

Serial

Interface

SDRAM_(0:1)

SCL

SDA

CLK_IN

OE

FS6050

SDRAM_(2:3)

SDRAM_(4:5)

SDRAM_(6:7)

SDRAM_(8:9)

SDRAM_(10:11)

SDRAM_(12:13)

SDRAM_(14:15)

SDRAM_16

VSS_I

2

C

VDD_I

2

C

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

VSS

VDD

SDRAM_17

VSS

VDD

18

2.0 Description

The FS6050 family of CMOS clock fanout buffer ICs are

designed for high-speed motherboard applications, such

as Intel Pentium

�

II PC100-based systems with 100MHz

SDRAM.

Up to eighteen buffered, non-inverting clock outputs are

fanned-out from one clock input. Individual clocks are

skew matched to less than 250ps at 100MHz. Multiple

power and ground supplies reduce the effects of supply

noise on device performance.

Under I

2

C-bus control, individual clock outputs may be

turned on or off. An active-low output enable is available

to force all the clock outputs to a tristate level for system

testing.

Figure 2: Pin Configuration (FS6050)

1

48

2

3

4

5

6

7

8

47

46

45

44

43

42

41

(

r

es

er

v

ed)

(

r

es

er

v

ed)

VD

D

S

DRA

M_

0

S

DRA

M_

1

VSS

VD

D

S

DRA

M_

2

VS

S

SD

R

A

M

_14

SD

R

A

M

_15

(

r

es

er

v

e

d)

VD

D

(

r

es

er

v

e

d)

9

10

11

12

13

14

15

16

S

DRA

M_

3

VSS

CL

K

_

I

N

VD

D

S

DRA

M_

4

S

DRA

M_

5

VSS

VD

D

17

18

19

20

21

22

23

S

DRA

M_

6

S

DRA

M_

7

VSS

VD

D

S

DRA

M_

1

6

VSS

V

DD_

I

2

C

40

39

38

37

36

35

34

33

SD

R

A

M

_10

SD

R

A

M

_11

VD

D

OE

SD

R

A

M

_13

SD

R

A

M

_12

VS

S

VD

D

32

31

30

29

28

27

26

VS

S_I

2

C

VS

S

SD

R

A

M

_17

VD

D

SD

R

A

M

_

9

SD

R

A

M

_

8

VS

S

24

SD

A

25

SC

L

VD

D

VS

S

FS6050

48-pin SSOP

Figure 3: Pin Configuration (FS6051)

1

2

3

4

5

6

7

8

VD

D

SD

R

A

M

_

0

SD

R

A

M

_

1

VSS

VD

D

SD

R

A

M

_

2

VS

S

S

DRA

M

_

1

4

S

DRA

M

_

1

5

VD

D

9

10

11

12

13

14

15

16

SD

R

A

M

_

3

VSS

CL

K

_

I

N

VD

D

17

18

19

20

21

22

23

S

DRA

M_

1

6

VSS

V

DD_

I

2

C

VD

D

OE

S

DRA

M

_

1

3

S

DRA

M

_

1

2

VS

S

VD

D

28

27

26

V

SS_I

2

C

VS

S

S

DRA

M

_

1

7

24

SD

A

25

SC

L

FS6051

28-pin SOIC, SSOP

Additional pin configurations are noted on Page 2.

X

T

April 1999

4.5.99

2

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

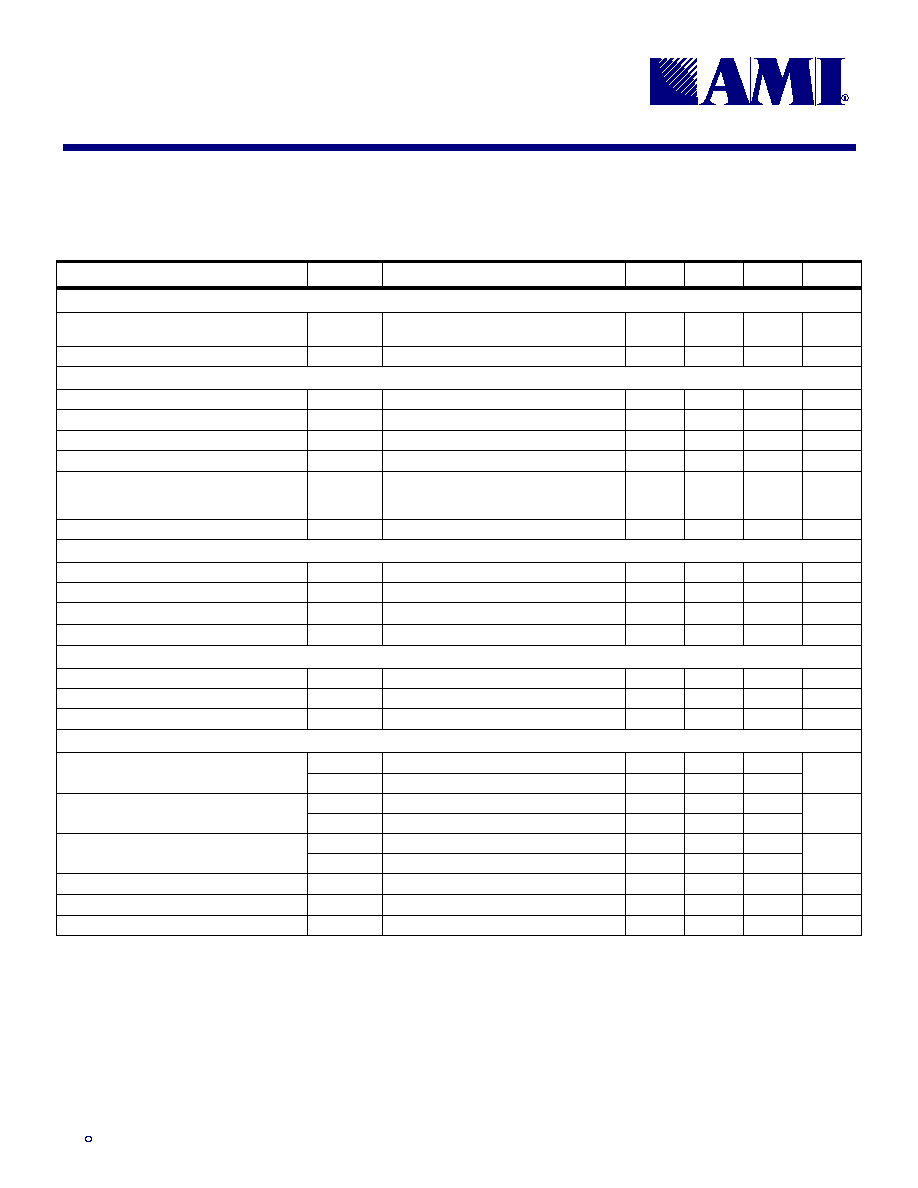

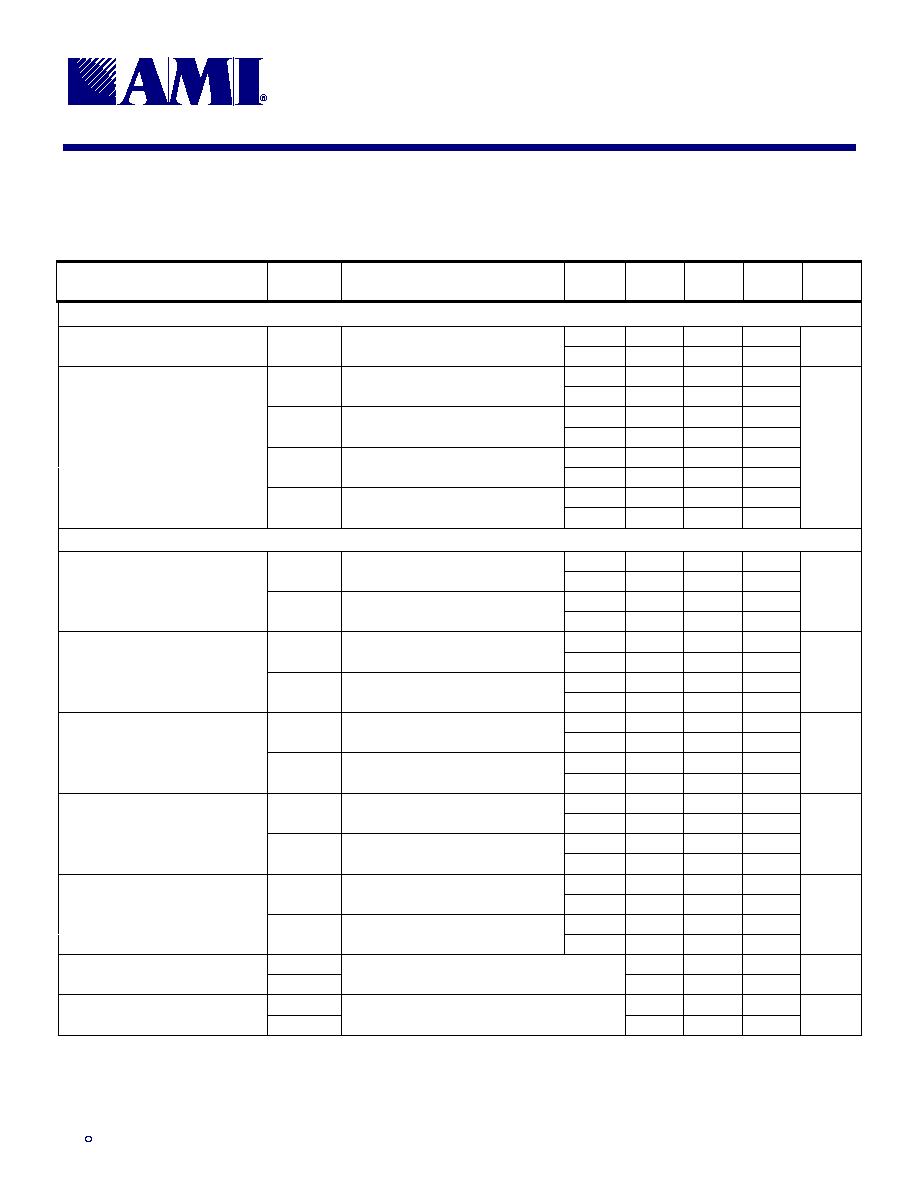

Table 1: Pin Descriptions

Key: AI = Analog Input; AO = Analog Output; DI = Digital Input; DI

U

= Input with Internal Pull-Up; DI

D

= Input with Internal Pull-Down; DIO = Digital Input/Output; DI-3 = Three-Level Digital Input,

DO = Digital Output; P = Power/Ground; # = Active Low pin

PIN (FS6050)

PIN (FS6051)

PIN (FS6053)

PIN (FS6054)

TYPE

NAME

DESCRIPTION

11

9

9

9

DI

CLK_IN

Clock input for SDRAM clock outputs

25

15

15

15

DI

U

SCL

Serial clock input

24

14

14

14

DI

U

O

SDA

Serial data input/output

4

2

2

2

DO

SDRAM_0

5

3

3

3

DO

SDRAM_1

8

6

6

6

DO

SDRAM_2

9

7

7

7

DO

SDRAM_3

13

-

-

-

DO

SDRAM_4

14

-

-

-

DO

SDRAM_5

17

-

10

10

DO

SDRAM_6

18

-

11

11

DO

SDRAM_7

SDRAM clock outputs (Byte 0)

31

-

18

18

DO

SDRAM_8

32

-

19

19

DO

SDRAM_9

35

-

-

-

DO

SDRAM_10

36

-

-

-

DO

SDRAM_11

40

22

22

22

DO

SDRAM_12

41

23

23

23

DO

SDRAM_13

44

26

26

26

DO

SDRAM_14

45

27

27

27

DO

SDRAM_15

SDRAM clock outputs (Byte 1)

21

11

12

12

DO

SDRAM_16

28

18

-

17

DO

SDRAM_17

SDRAM feedback clock outputs (Byte 2)

38

20

-

20

DI

U

OE

Output enable tristates all clock outputs when low

3, 7, 12, 16,

20, 29, 33, 37,

42, 46

1, 5, 10, 19,

24, 28

1, 5, 20, 24,

28

1, 5, 24, 28

P

VDD

3.3V � 5% power supply for SDRAM clock buffers

23

13

13

13

P

VDD_I

2

C

3.3V � 5% power supply for serial communications

6, 10, 15, 19,

22, 27, 30, 34,

39, 43

4, 8, 12, 17,

21, 25

4, 8, 17, 21,

25

4, 8, 21, 25

P

VSS

Ground for SDRAM clock buffers

26

16

16

16

P

VSS_I

2

C

Ground for serial communications

1, 2, 47, 48

-

-

-

-

(reserved)

Reserved

Figure 4: Pin Configuration (FS6053)

1

2

3

4

5

6

7

8

VD

D

SD

RAM

_

0

SD

RAM

_

1

VSS

VD

D

SD

RAM

_

2

VSS

S

DRA

M

_

1

4

S

DRA

M

_

1

5

VD

D

9

10

11

12

13

14

15

16

SD

RAM

_

3

VSS

CL

K_

I

N

SD

RAM

_

6

17

18

19

20

21

22

23

SD

RAM

_

7

S

D

R

A

M_16

V

DD_

I

2

C

S

DRA

M

_

9

VD

D

S

DRA

M

_

1

3

S

DRA

M

_

1

2

VSS

VD

D

28

27

26

VSS_

I

2

C

VSS

S

DRA

M

_

8

24

SD

A

25

SC

L

FS6053

Figure 5: Pin Configuration (FS6054)

1

2

3

4

5

6

7

8

VD

D

S

DRA

M

_

0

S

DRA

M

_

1

VS

S

VD

D

S

DRA

M

_

2

VSS

SD

RAM

_

1

4

SD

RAM

_

1

5

VD

D

9

10

11

12

13

14

15

16

S

DRA

M

_

3

VS

S

CL

K

_

I

N

S

DRA

M

_

6

17

18

19

20

21

22

23

S

DRA

M

_

7

S

DRA

M

_

1

6

VD

D_

I

2

C

SD

RAM

_

9

OE

SD

RAM

_

1

3

SD

RAM

_

1

2

VSS

VD

D

28

27

26

VSS_

I

2

C

SD

RAM

_

1

7

SD

RAM

_

8

24

SD

A

25

SC

L

FS6054

X

T

April 1999

4.5.99

3

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

3.0 Programming

Information

Table 2: Clock Enable

CONTROL INPUTS

CLOCK OUTPUTS (MHz)

OE

SDRAM_0:17

0

tristate

1

CLK_IN

3.1

Power-Up Initialization

All outputs are enabled and active upon power-up, and all

output control register bits are initialized to one.

The outputs must be configured at power-up and are not

expected to be configured during normal operation. Inac-

tive outputs are held low and are disabled from switching.

3.1.1

Unused Outputs

Outputs that are not used in versions of this device with a

reduced pinout are still operational internally. To reduce

power dissipation and crosstalk effects from the unloaded

outputs, it is recommended that these outputs be shut off

via the Control Registers.

3.2

Register Programming

A logic-one written to a valid bit location turns on the as-

signed output clock. Likewise, a logic-zero written to a

valid bit location turns off the assigned output clock.

Any unused or reserved register bits should be cleared to

zero.

Serial bits are written to this device in the order shown in

Table 3.

Table 3: Register Summary

SERIAL BIT

DATA BYTE

CLOCK OUTPUT

0

(MSB)

SDRAM_7

1

SDRAM_6

2

SDRAM_5

3

SDRAM_4

4

SDRAM_3

5

SDRAM_2

6

Byte 0

SDRAM Control Register 0

SDRAM_1

7

(LSB)

SDRAM_0

8

(MSB)

SDRAM_15

9

SDRAM_14

10

SDRAM_13

11

SDRAM_12

12

SDRAM_11

13

SDRAM_10

14

Byte 1

SDRAM Control Register 1

SDRAM_9

15

(LSB)

SDRAM_8

16

(MSB)

SDRAM_17

17

SDRAM_16

18

Reserved

19

Reserved

20

Reserved

21

Reserved

22

Byte 2

SDRAM Control Register 2

Reserved

23

(LSB)

Reserved

X

T

April 1999

4.5.99

4

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

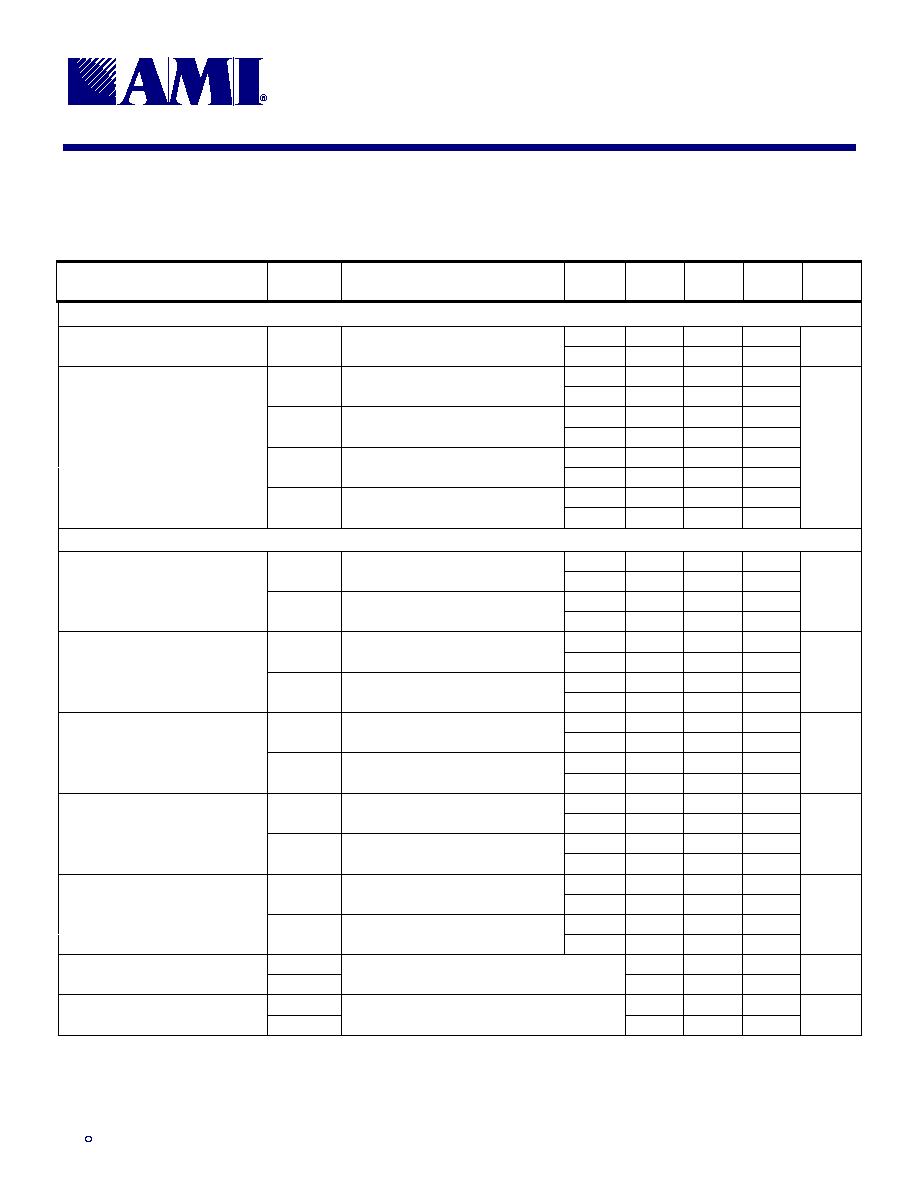

Table 4: Byte 0 - SDRAM Control Register 0

REGISTER

BIT

CLOCK

OUTPUT

DESCRIPTION

OUTPUT PIN

(FS6050)

OUTPUT PIN

(FS6051)

OUTPUT PIN

(FS6053)

OUTPUT PIN

(FS6054)

7

SDRAM_7

On (1) / Off (0)

Pin 18

-

Pin 11

Pin 11

6

SDRAM_6

On (1) / Off (0)

Pin 17

-

Pin 10

Pin 10

5

SDRAM_5

On (1) / Off (0)

Pin 14

-

-

-

4

SDRAM_4

On (1) / Off (0)

Pin 13

-

-

-

3

SDRAM_3

On (1) / Off (0)

Pin 9

Pin 7

Pin 7

Pin 7

2

SDRAM_2

On (1) / Off (0)

Pin 8

Pin 6

Pin 6

Pin 6

1

SDRAM_1

On (1) / Off (0)

Pin 5

Pin 3

Pin 3

Pin 3

0

SDRAM_0

On (1) / Off (0)

Pin 4

Pin 2

Pin 2

Pin 2

Table 5: Byte 1 - SDRAM Control Register 1

REGISTER

BIT

CLOCK

OUTPUT

DESCRIPTION

OUTPUT PIN

(FS6050)

OUTPUT PIN

(FS6051)

OUTPUT PIN

(FS6053)

OUTPUT PIN

(FS6054)

15

SDRAM_15

On (1) / Off (0)

Pin 45

Pin 27

Pin 27

Pin 27

14

SDRAM_14

On (1) / Off (0)

Pin 44

Pin 26

Pin 26

Pin 26

13

SDRAM_13

On (1) / Off (0)

Pin 41

Pin 23

Pin 23

Pin 23

12

SDRAM_12

On (1) / Off (0)

Pin 40

Pin 22

Pin 22

Pin 22

11

SDRAM_11

On (1) / Off (0)

Pin 36

-

-

-

10

SDRAM_10

On (1) / Off (0)

Pin 35

-

-

-

9

SDRAM_9

On (1) / Off (0)

Pin 32

-

Pin 19

Pin 19

8

SDRAM_8

On (1) / Off (0)

Pin 31

-

Pin 18

Pin 18

Table 6: Byte 2 - SDRAM Control Register 2

REGISTER

BIT

CLOCK

OUTPUT

DESCRIPTION

OUTPUT PIN

(FS6050)

OUTPUT PIN

(FS6051)

OUTPUT PIN

(FS6053)

OUTPUT PIN

(FS6054)

23

SDRAM_17

On (1) / Off (0)

Pin 28

Pin 18

-

Pin 17

22

SDRAM_16

On (1) / Off (0)

Pin 21

Pin 11

Pin 12

Pin 12

21

Reserved (set to 0)

-

-

-

-

20

Reserved (set to 0)

-

-

-

-

19

Reserved (set to 0)

-

-

-

-

18

Reserved (set to 0)

-

-

-

-

17

Reserved (set to 0)

-

-

-

-

16

Reserved (set to 0)

-

-

-

-

X

T

April 1999

4.5.99

5

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

4.0 Dual Serial Interface Control

This integrated circuit is a read/write slave device that

supports both the Inter IC Bus (I

2

C-bus) and the System

Management Bus (SMBus) two-wire serial interface pro-

tocols. The unique device address that is written to the

device determines whether the part expects to receive

SMBus commands or I

2

C commands. Since SMBus is

derived from the I

2

C-bus, the protocol for both bus types

is very similar.

In general, the bus has to be controlled by a master de-

vice that generates the serial clock SCL, controls bus

access, and generates the START and STOP conditions

while the device works as a slave. Both master and slave

can operate as a transmitter or receiver, but the master

device determines which mode is activated. A device that

sends data onto the bus is defined as the transmitter, and

a device receiving data as the receiver.

Bus logic levels and timing parameters noted herein fol-

low I

2

C-bus convention. Logic levels are based on a per-

centage of VDD. A logic-one corresponds to a nominal

voltage of VDD, while a logic-zero corresponds to ground

(VSS).

4.1 Bus

Conditions

Data transfer on the bus can only be initiated when the

bus is not busy. During the data transfer, the data line

(SDA) must remain stable whenever the clock line (SCL)

is high. Changes in the data line when the clock line is

high is interpreted by the device as a START or STOP

condition. Both I

2

C-bus and SMBus protocols define the

following conditions on the bus. Refer to Figure 12: Bus

Timing Data for more information.

4.1.1 Not

Busy

Both the data (SDA) and clock (SCL) lines remain high to

indicate the bus is not busy.

4.1.2

START Data Transfer

A high to low transition of the SDA line while the SCL in-

put is high indicates a START condition. All commands to

the device must be preceded by a START condition.

4.1.3

STOP Data Transfer

A low to high transition of the SDA line while SCL is held

high indicates a STOP condition. All commands to the

device must be followed by a STOP condition.

4.1.4

Data Valid

The state of the SDA line represents valid data if the SDA

line is stable for the duration of the high period of the SCL

line after a START condition occurs. The data on the

SDA line must be changed only during the low period of

the SCL signal. There is one clock pulse per data bit.

Each data transfer is initiated by a START condition and

terminated with a STOP condition. The number of data

bytes transferred between START and STOP conditions

is determined by the master device, and can continue

indefinitely. However, data that is overwritten to the de-

vice after the data registers are filled will overflow from

the last register into the first register, then the second,

and so on, in a first-in, first-overwritten fashion.

4.1.5 Acknowledge

When addressed, the receiving device is required to gen-

erate an Acknowledge after each byte is received. The

master device must generate an extra clock pulse to co-

incide with the Acknowledge bit. The acknowledging de-

vice must pull the SDA line low during the high period of

the master acknowledge clock pulse. Setup and hold

times must be taken into account.

The master must signal an end of data to the slave by not

generating an acknowledge bit on the last byte that has

been read (clocked) out of the slave. In this case, the

slave must leave the SDA line high to allow the master to

generate a STOP condition.

4.2

Bus Operation and Commands

All programmable registers can be accessed via the bi-

directional two wire digital interface. The device accepts

the Random Register Read/Write and the Sequential

Register Read/Write I

2

C commands. The device also

supports the Block Read/Write SMBus commands.

4.2.1 I

2

C-bus and SMBus Device Addressing

After generating a START condition, the bus master

broadcasts a seven-bit device address followed by a R/W

bit. Note that every device on an I

2

C-bus or SMBus must

have a unique address to avoid bus conflicts.

For an SMBus interface, the address of the device is:

A6

A5

A4

A3

A2

A1

A0

1

1

0

1

0

0

1

X

T

April 1999

4.5.99

6

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

For an I

2

C-bus interface, the device can support two de-

vice addresses to permit multiple devices on one I

2

C-bus.

The A2 address bit is ignored and can be set to either a

one or a zero.

Therefore, for an I

2

C-bus interface the device address is:

A6

A5

A4

A3

A2

A1

A0

1

0

1

1

X

0

0

4.2.2 I

2

C-bus: Random Register Write Procedure

Random write operations, as shown in Figure

6, allow the master to directly write to any

register. To initiate a write procedure, the R/W

bit that is transmitted after the seven-bit I

2

C

device address is a logic-low. This indicates to the ad-

dressed slave device that a register address will follow

after the slave device acknowledges its device address.

The register address is written into the slave's address

pointer. Following an acknowledge by the slave, the

master is allowed to write eight bits of data into the ad-

dressed register. A final acknowledge is returned by the

device, and the master generates a STOP condition.

If either a STOP or a repeated START condition occurs

during a Register Write, the data that has been trans-

ferred is ignored.

4.2.3 I

2

C-bus: Random Register Read Procedure

Random read operations allow the master to directly read

from any register. To perform a read procedure, as

shown in Figure 7, the R/W bit that is transmitted after the

seven-bit I

2

C address is a logic-low, as in the Register

Write procedure. This indicates to the addressed slave

device that a register address will follow after the slave

device acknowledges its device address. The register

address is then written into the slave's address pointer.

Following an acknowledge by the slave, the master gen-

erates a repeated START condition. The repeated

START terminates the write procedure, but not until after

the slave's address pointer is set. The slave address is

then resent, with the R/W bit set this time to a logic-high,

indicating to the slave that data will be read. The slave

will acknowledge the device address, and then transmits

the eight-bit word. The master does not acknowledge the

transfer but does generate a STOP condition.

4.2.4 I

2

C-bus: Sequential Register Write Procedure

Sequential write operations, as shown in Figure 8, allow

the master to write to each register in order. The register

pointer is automatically incremented after each write. This

procedure is more efficient than the Random Register

Write if several registers must be written.

To initiate a write procedure, the R/W bit that is transmit-

ted after the seven-bit I

2

C device address is a logic-low.

This indicates to the addressed slave device that a reg-

ister address will follow after the slave device acknowl-

edges its device address. The register address is written

into the slave's address pointer. Following an acknowl-

edge by the slave, the master is allowed to write data up

to the last addressed register before the register address

pointer overflows back to the beginning address. An ac-

knowledge by the device between each byte of data must

occur before the next data byte is sent.

Registers are updated every time the device sends an

acknowledge to the host. The register update does not

wait for the STOP condition to occur. Registers are

therefore updated at different times during a Sequential

Register Write.

4.2.5 I

2

C-bus: Sequential Register Read Procedure

Sequential read operations allow the master to read from

each register in order. The register pointer is automati-

cally incremented by one after each read. This proce-

dure, as shown in Figure 9, is more efficient than the

Random Register Read if several registers must be read

from.

To perform a read procedure, the R/W bit that is trans-

mitted after the seven-bit I

2

C address is a logic-low, as in

the Register Write procedure. This indicates to the ad-

dressed slave device that a register address will follow

after the slave device acknowledges its device address.

The register address is then written into the slave's ad-

dress pointer.

Following an acknowledge by the slave, the master gen-

erates a repeated START condition. The repeated

START terminates the write procedure, but not until after

the slave's address pointer is set. The slave address is

then resent, with the R/W bit set this time to a logic-high,

indicating to the slave that data will be read. The slave

will acknowledge the device address, and then transmits

all data starting with the initial addressed register. The

register address pointer will overflow if the initial register

address is larger than zero. After the last byte of data, the

master does not acknowledge the transfer but does gen-

erate a STOP condition.

X

T

April 1999

4.5.99

7

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Figure 6: Random Register Write Procedure (I

2

C-bus)

A

A

DATA

W A

From bus host

to device

S

REGISTER ADDRESS

P

From device

to bus host

DEVICE ADDRESS

Register Address

Acknowledge

STOP Condition

Data

Acknowledge

Acknowledge

START

Command

WRITE Command

7-bit Receive

Device Address

Figure 7: Random Register Read Procedure (I

2

C-bus)

A

R

A

A

A

W

S

REGISTER ADDRESS

P

S

DEVICE ADDRESS

START

Command

WRITE Command

Acknowledge

Register Address

Acknowledge

READ Command

Acknowledge

Data

NO Acknowledge

STOP Condition

From bus host

to device

From device

to bus host

7-bit Receive

Device Address

7-bit Receive

Device Address

DEVICE ADDRESS

DATA

Repeat START

Figure 8: Sequential Register Write Procedure (I

2

C-bus)

A

A

A

W

S

P

START

Command

WRITE Command

Acknowledge

Register Address

Acknowledge

Data

Data

Acknowledge

Data

STOP Command

Acknowledge

Acknowledge

From bus host

to device

From device

to bus host

7-bit Receive

Device Address

DEVICE ADDRESS

A

A

REGISTER ADDRESS

DATA

DATA

DATA

Figure 9: Sequential Register Read Procedure (I

2

C-bus)

A

W

S

START

Command

WRITE Command

Acknowledge

Register Address

Acknowledge

Data

Acknowledge

Data

STOP Command

Acknowledge

READ Command

NO Acknowledge

From bus host

to device

From device

to bus host

7-bit Receive

Device Address

7-bit Receive

Device Address

DEVICE ADDRESS

A

A

REGISTER ADDRESS

A

R

A P

S

DEVICE ADDRESS

DATA

DATA

Repeat START

X

T

April 1999

4.5.99

8

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

SMBus

4.2.6

SMBus: Block Write

The Block Write command permits the

master to write several bytes of data to

sequential registers, starting by default at Register 0. The

Block Write command, as noted in Figure 10, begins with

the seven-bit SMBus device address followed by a logic-

low R/W bit to begin a Write command. Following an ac-

knowledge of the SMBus address and R/W bit by the

slave device, a command code is written.

It is defined

that all eight bits of the command code must be zero (0).

After the command code of zero and an acknowledge,

the host then issues a byte count that describes the

number of data bytes to be written. According to SMBus

convention, the byte count should be a value between 0

and 32; however this slave device ignores the byte count

value.

Following an acknowledge of the byte count, data bytes

may be written starting with Register 0 and incrementing

sequentially. An acknowledge by the device between

each byte of data must occur before the next data byte is

sent.

4.2.7

SMBus: Block Read

The Block Read command, shown in Figure 11, permits

the master to read several bytes of data from sequential

registers, starting by default at Register 0. To perform a

Block Read procedure the R/W bit that is transmitted af-

ter the seven-bit SMBus address is a logic-low, as in the

Block Write procedure. The write bit resets the register

address pointer to zero. Following an acknowledge of the

SMBus address and R/W bit by the slave device, a com-

mand code is written.

It is defined that all eight bits of the

command code must be zero (0).

Following an acknowledge by the slave, the master gen-

erates a repeated START condition. The repeated

START terminates the write procedure, but not until after

the slave's address pointer is set. The slave SMBus ad-

dress is then resent, with the R/W bit set this time to a

logic-high, indicating to the slave that data will be read.

The slave will acknowledge the device address, and then

will expect a byte count value (which will be ignored).

Following the byte count value, the device will take com-

mand of the bus and will transmit all the data beginning

with Register 0. After the last byte of data, the master

does not acknowledge the transfer but does generate a

STOP condition.

If the master does not want to receive all the data, the

master can not acknowledge the last data byte and then

can issue a STOP condition of the next clock.

Figure 10: Block Write (SMBus)

A

A

A

DATA BYTE 1

WRITE Command

Acknowledge

Command Code

Acknowledge

Data

Acknowledge

Data

STOP Command

DATA BYTE N

Acknowledge

Byte Count

Acknowledge

START

Command

From bus host

to device

From device

to bus host

7-bit Receive

Device Address

W

S

DEVICE ADDRESS

A

A

BYTE COUNT = N

P

Figure 11: Block Read (SMBus)

A

W

A

R

A

A

START

Command

WRITE Command

Acknowledge

Command Code

Acknowledge

Data

Acknowledge

Data

STOP Command

Acknowledge

Byte Count

NO Acknowledge

Repeat START

READ Command

Acknowledge

From bus host

to device

From device

to bus host

7-bit Receive

Device Address

7-bit Receive

Device Address

S

DEVICE ADDRESS

A S

DEVICE ADDRESS

BYTE COUNT = N

A

DATA BYTE 1

DATA BYTE N

P

X

T

April 1999

4.5.99

9

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

5.0 Electrical Specifications

Table 7: Absolute Maximum Ratings

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. These conditions represent a stress rating only, and functional operation of the device at

these or any other conditions above the operational limits noted in this specification is not implied. Exposure to maximum rating conditions for extended conditions may affect device performance,

functionality, and reliability.

PARAMETER

SYMBOL

MIN.

MAX.

UNITS

Supply Voltage, dc, Clock Buffers (V

SS

= ground)

V

DD

V

SS

-0.5

7

V

Supply Voltage, dc, Serial Communications

V

DD_I2C

V

SS

-0.5

7

V

Input Voltage, dc

V

I

V

SS

-0.5

V

DD

+0.5

V

Output Voltage, dc

V

O

V

SS

-0.5

V

DD

+0.5

V

Input Clamp Current, dc (V

I

< 0 or V

I

> V

DD

)

I

IK

-50

50

mA

Output Clamp Current, dc (V

I

< 0 or V

I

> V

DD

)

I

OK

-50

50

mA

Storage Temperature Range (non-condensing)

T

S

-65

150

�C

Ambient Temperature Range, Under Bias

T

A

-55

125

�C

Junction Temperature

T

J

125

�C

Lead Temperature (soldering, 10s)

260

�C

Static Discharge Voltage Protection (MIL-STD 883E, Method 3015.7)

2

kV

CAUTION: ELECTROSTATIC SENSITIVE DEVICE

Permanent damage resulting in a loss of functionality or performance may occur if this device is subjected to a high-energy elec-

trostatic discharge.

Table 8: Operating Conditions

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

MIN.

TYP.

MAX.

UNITS

Supply Voltage, Clock Buffers

V

DD

3.3V � 5%

3.135

3.3

3.465

V

Supply Voltage, Serial Communications

V

DD_I2C

3.3V � 5%

3.135

3.3

3.465

V

Ambient Operating Temperature Range

T

A

0

70

�C

Input Frequency

f

CLK

0

133

MHz

Output Load Capacitance

C

L

30

pF

Serial Data Transfer Rate

Standard mode

10

100

400

kb/s

X

T

April 1999

4.5.99

10

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

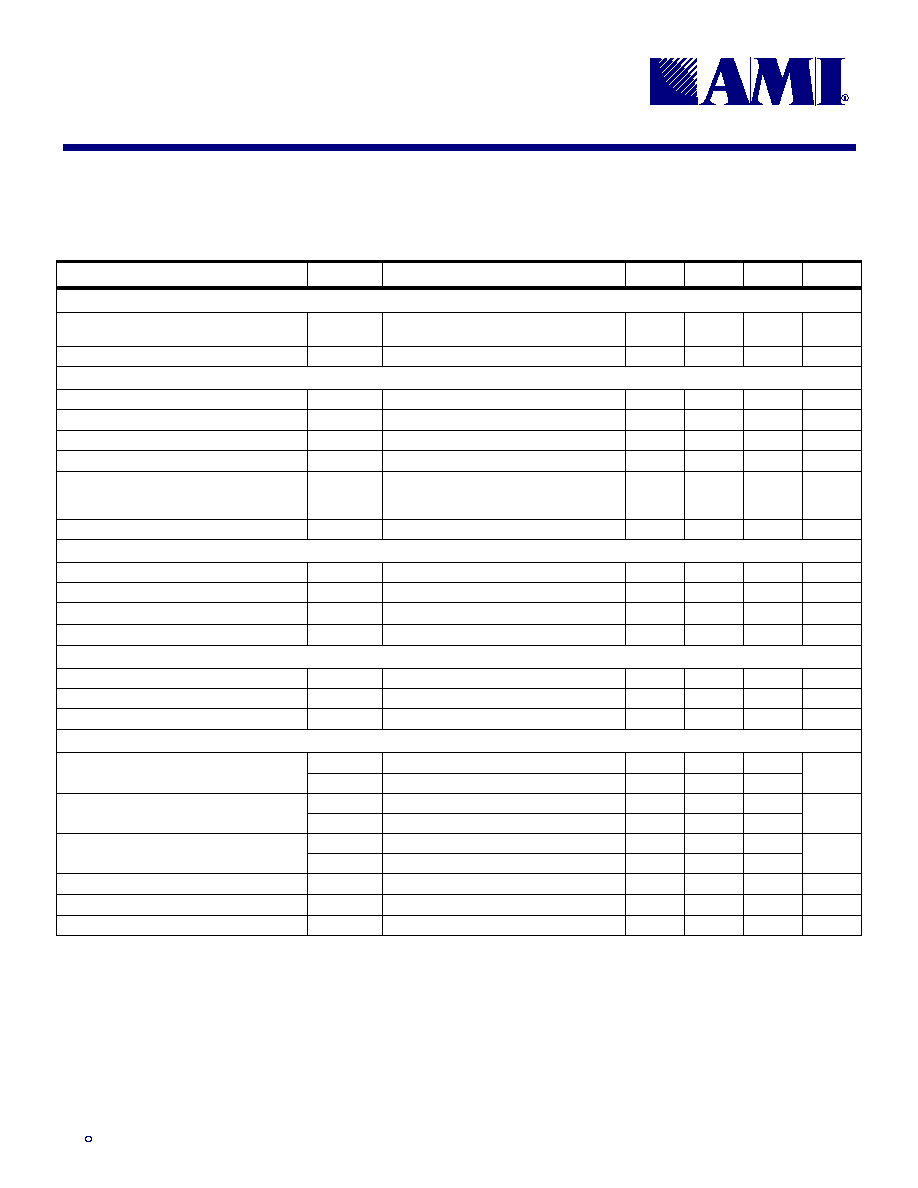

Table 9: DC Electrical Specifications

Unless otherwise stated, all power supplies = 3.3V � 5%, no load on any output, and ambient temperature range T

A

= 0�C to 70�C. Parameters denoted with an asterisk ( * ) represent nominal

characterization data and are not currently production tested to any specific limits. MIN and MAX characterization data are

�

3

from typical. Negative currents indicate current flows out of the device.

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

MIN.

TYP.

MAX.

UNITS

Overall (FS6050)

Supply Current, Dynamic, with Loaded

Outputs

I

DD

f

CLK

= 100MHz; V

DD

= 3.47V

180

360

mA

Supply Current, Static

I

DDL

Outputs low; V

DD

= 3.47V

0.75

3

mA

Serial Communication Inputs/Output (SDA, SCL)

High-Level Input Voltage

V

IH

Outputs low

2.31

V

DD

+0.3

V

Low-Level Input Voltage

V

IL

Outputs low

V

SS

-0.3

0.9

V

Hysteresis Voltage *

V

hys

Outputs low

1.0

V

High-Level Input Current

I

IH

-1

1

�

A

Low-Level Input Current (pull-up)

I

IL

Outputs low; V

IH

= 0.4V, V

DD

= 3.47V.

Note: SDA requires an external pull-up to

drive the data bus.

5

11

15

�

A

Low-Level Output Sink Current (SDA)

I

OL

V

OL

= 0.4V

10

25

mA

Output Enable Input (OE)

High-Level Input Voltage

V

IH

2.0

V

DD

+0.3

V

Low-Level Input Voltage

V

IL

V

SS

-0.3

0.8

V

High-Level Input Current

I

IH

-1

1

�

A

Low-Level Input Current (pull-up)

I

IL

V

IH

= 0.4V; V

DD

= 3.47V

10

22

30

�

A

Clock Input (CLK_IN)

High-Level Input Voltage

V

IH

2.0

V

DD

+0.3

V

Low-Level Input Voltage

V

IL

V

SS

-0.3

0.8

V

Input Leakage Current

I

I

-1

1

�

A

Clock Outputs (SDRAM_0:17 3.3V Type 4 Clock Buffer)

I

OH min

V

DD

= 3.135V, V

O

= 2.0V

-54

-65

High-Level Output Source Current

I

OH max

V

DD

= 3.465V, V

O

= 3.135V

-28

-46

mA

I

OL min

V

DD

= 3.135V, V

O

= 1.0V

54

69

Low-Level Output Sink Current

I

OL max

V

DD

= 3.465V, V

O

= 0.4V

33

53

mA

z

OH

V

O

= 0.5V

DD

; output driving high

10

17.9

24

Output Impedance

z

OL

V

O

= 0.5V

DD

; output driving low

10

16.3

24

Tristate Output Current

I

OZ

-5

5

�

A

Short Circuit Source Current *

I

OSH

V

O

= 0V; shorted for 30s, max.

-106

mA

Short Circuit Sink Current *

I

OSL

V

O

= 3.3V; shorted for 30s, max.

107

mA

X

T

April 1999

4.5.99

11

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Table 10: AC Timing Specifications

Unless otherwise stated, all power supplies = 3.3V � 5%, no load on any output, and ambient temperature range T

A

= 0�C to 70�C. Parameters denoted with an asterisk ( * ) represent nominal

characterization data and are not currently production tested to any specific limits. MIN and MAX characterization data are

�

3

from typical.

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

CLOCK

(MHz)

MIN.

TYP.

MAX.

UNITS

Overall

66.67

182

Clock Skew, Maximum;

SDRAM_0 to any SDRAM pin *

t

skw

Measured on the rising edge at 1.5V;

C

L

= 20pF

100

228

ps

66.67

3.7

t

PLH(min)

Measured on the rising edge at 1.5V;

C

L

= 20pF

100

3.8

66.67

3.7

t

PLH(max)

Measured on the rising edge at 1.5V;

C

L

= 30pF

100

4.0

66.67

3.9

t

PHL(min)

Measured on the rising edge at 1.5V;

C

L

= 20pF

100

3.8

66.67

4.2

Propagation Delay, Average;

CLK_IN to any SDRAM pin *

t

PHL(max)

Measured on the rising edge at 1.5V;

C

L

= 30pF

100

4.0

ns

Clock Outputs (SDRAM_0:17 3.3V Type 4 Clock Buffer)

66.67

1.0

t

r(min)

V

O

= 0.4V to 2.4V; C

L

= 20pF

100

0.9

66.67

1.2

Rise Time *

t

r(max)

V

O

= 0.4V to 2.4V; C

L

= 30pF

100

1.0

ns

66.67

1.0

t

f(min)

V

O

= 2.4V to 0.4V; C

L

= 20pF

100

0.7

66.67

1.1

Fall Time *

t

f(max)

V

O

= 2.4V to 0.4V; C

L

= 30pF

100

0.8

ns

66.67

6.5

t

KH(min)

V

O

= 2.4V; C

L

= 20pF

100

3.8

66.67

6.5

Clock High Time *

t

KH(max)

V

O

= 2.4V; C

L

= 30pF

100

3.8

ns

66.67

6.5

t

KL(min)

V

O

= 0.4V; C

L

= 20pF

100

4.6

66.67

6.3

Clock Low Time *

t

KL(max)

V

O

= 0.4V; C

L

= 30pF

100

4.5

ns

66.67

49

From rising edge to rising edge at

1.5V; C

L

= 20pF

100

45

66.67

50

Duty Cycle *

From rising edge to rising edge at

1.5V; C

L

= 30pF

100

46

%

t

PZL

4.7

Tristate Enable Delay *

t

PZH

Output tristated to output active; C

L

= 20pF

4.6

ns

t

PLZ

6.3

Tristate Disable Delay *

t

PHZ

Output active to output tristated; C

L

= 20pF

7.9

ns

X

T

April 1999

4.5.99

12

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Table 11: Serial Interface Timing Specifications

Unless otherwise stated, all power supplies = 3.3V � 5%, no load on any output, and ambient temperature range T

A

= 0�C to 70�C. Parameters denoted with an asterisk ( * ) represent nominal

characterization data and are not currently production tested to any specific limits. MIN and MAX characterization data are

�

3

from typical.

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

MIN.

MAX.

UNITS

Clock frequency

f

SCL

SCL

10

400

kHz

Bus free time between STOP and START

t

BUF

4.7

�

s

Set up time, START (repeated)

t

su:STA

4.7

�

s

Hold time, START

t

hd:STA

4.0

�

s

Set up time, data input

t

su:DAT

SDA

250

ns

Hold time, data input

t

hd:DAT

SDA

300

ns

Output data valid from clock

t

AA

Minimum delay to bridge undefined region of the fall-

ing edge of SCL to avoid unintended START or STOP

3.5

�

s

Rise time, data and clock

t

r

SDA, SCL

1000

ns

Fall time, data and clock

t

f

SDA, SCL

300

ns

High time, clock

t

H

SCL

4.0

�

s

Low time, clock

t

L

SCL

4.7

�

s

Set up time, STOP

t

su:STO

4.0

�

s

Figure 12: Bus Timing Data

SCL

SDA

~ ~

~ ~

~ ~

STOP

t

su:STO

t

hd:STA

START

t

su:STA

ADDRESS OR

DATA VALID

DATA CAN

CHANGE

Figure 13: Data Transfer Sequence

SCL

SDA

IN

t

hd:DAT

~ ~

t

hd:STA

t

su:STA

t

su:STO

t

L

t

H

SDA

OUT

t

su:DAT

~ ~

~ ~

t

BUF

t

r

t

f

t

AA

t

AA

X

T

April 1999

4.5.99

13

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Figure 14: SDRAM_0:17 Clock Output (3.3V Type 4 Clock Buffer)

Low Drive Current (mA)

High Drive Current (mA)

Voltage

(V)

MIN.

TYP.

MAX.

Voltage

(V)

MIN.

TYP.

MAX.

0

0

0

0

0

-72

-116

-198

0.4

23

34

53

1

-72

-116

-198

0.65

35

52

83

1.4

-68

-110

-188

0.85

43

65

104

1.5

-67

-107

-184

1

49

74

118

1.65

-64

-103

-177

1.4

61

93

152

1.8

-60

-98

-170

1.5

64

98

159

2

-54

-90

-157

1.65

67

103

168

2.4

-39

-69

-126

1.8

70

108

177

2.6

-30

-56

-107

1.95

72

112

184

3.135

0

-15

-46

3.135

72

112

204

3.3

0

-23

3.6

112

204

3.465

0

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

0

0.5

1

1.5

2

2.5

3

3.5

4

P�Wyhtr�W

P

�

8

r

�

6

MIN.

TYP.

MAX.

30

50

90

Figure 15: DC Measurement Points

V

IH 3.3

= 2.0V

V

IL 3.3

= 0.8V

V

OL 3.3

= 0.4V

V

OH 3.3

= 2.4V

1.5V

3.3V

(device

interface)

(system

interface)

Figure 16: Clock Skew Measurement Point

t

skw

3.3V

3.3V

1.5V

1.5V

Figure 17: Timing Measurement Points

t

KH

t

r

Duty Cycle

t

KL

KP

2.4V

1.5V

0.4V

t

f

t

PLZ

V

OL

V

OH

V

SS

V

DD

10%

90%

t

PHZ

50%

50%

50%

50%

t

PZL

t

PHZ

X

T

April 1999

4.5.99

14

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

6.0 Package

Information

Table 12: 48-pin SSOP (7.5mm/0.300") Package Dimensions

DIMENSIONS

INCHES

MILLIMETERS

MIN.

MAX.

MIN.

MAX.

A

0.095

0.110

2.41

2.79

A

1

0.008

0.016

0.203

0.406

A

2

0.088

0.092

2.24

2.34

B

0.008

0.0135

0.203

0.343

C

0.005

0.010

0.127

0.254

D

0.620

0.630

15.75

16.00

E

0.292

0.299

7.42

7.59

e

0.025 BSC

0.64 BSC

H

0.400

0.410

10.16

10.41

h

0.010

0.016

0.254

0.410

L

0.024

0.040

0.610

1.02

0

�

8

�

0

�

8

�

B

e

D

A

1

SEATING PLANE

H

E

48

1

ALL RADII:

0.005" TO 0.01"

BASE PLANE

A

2

��"����"#)#$�#��

C

L

7� typ.

A

Table 13: 48-pin SSOP (7.5mm/0.300") Package Characteristics

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

TYP.

UNITS

Thermal Impedance, Junction to Free-Air

JA

Air flow = 0 m/s

93

�C/W

Lead Inductance, Self

L

11

Center lead

3.3

nH

Lead Inductance, Mutual

L

12

Center lead to any adjacent lead

1.6

nH

Lead Capacitance, Bulk

C

11

Center lead to V

SS

0.6

pF

Lead Capacitance, Mutual

C

12

Center lead to any adjacent lead

0.2

pF

X

T

April 1999

4.5.99

15

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Table 14: 28-pin SOIC (7.5mm/0.300") Package Dimensions

DIMENSIONS

INCHES

MILLIMETERS

MIN.

MAX.

MIN.

MAX.

A

0.093

0.104

2.35

2.65

A

1

0.004

0.012

0.10

0.30

A

2

0.08

0.100

2.05

2.55

B

0.013

0.013

0.33

0.51

C

0.009

0.009

0.23

0.32

D

0.697

0.713

17.70

18.10

E

0.291

0.299

7.40

7.60

e

0.05 BSC

1.27 BSC

H

0.393

0.419

10.00

10.65

h

0.010

0.030

0.25

0.75

L

0.016

0.05

0.40

1.27

0

�

8

�

0

�

8

�

B

e

D

A

1

SEATING PLANE

H

E

28

1

ALL RADII:

0.005" TO 0.01"

BASE PLANE

A

2

��"����"#)#$�#��

C

L

7� typ.

A

h x 45�

Table 15: 28-pin SOIC (7.5mm/0.300") Package Characteristics

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

TYP.

UNITS

Thermal Impedance, Junction to Free-Air

JA

Air flow = 0 m/s

80

�C/W

Lead Inductance, Self

L

11

Center lead

2.5

nH

Lead Inductance, Mutual

L

12

Center lead to any adjacent lead

0.85

nH

Lead Capacitance, Bulk

C

11

Center lead to V

SS

0.42

pF

Lead Capacitance, Mutual

C

12

Center lead to any adjacent lead

0.08

pF

X

T

April 1999

4.5.99

16

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Table 16: 28-pin SSOP (5.3mm/0.209") Package Dimensions

DIMENSIONS

INCHES

MILLIMETERS

MIN.

MAX.

MIN.

MAX.

A

0.068

0.078

1.73

2.00

A

1

0.002

0.008

0.05

0.21

A

2

0.066

0.07

1.68

1.78

B

0.01

0.015

0.25

0.38

C

0.005

0.008

0.13

0.20

D

0.396

0.407

10.07

10.33

E

0.205

0.212

5.20

5.38

e

0.028 BSC

0.65 BSC

H

0.301

0.311

7.65

7.90

L

0.022

0.037

0.55

0.95

0

�

8

�

0

�

8

�

H

E

ALL RADII:

0.005" TO 0.01"

��"����"#)#$�#��

1

28

B

e

D

A

1

SEATING PLANE

BASE PLANE

A

2

A

C

L

7� typ.

Table 17: 28-pin SSOP (5.3mm/0.209") Package Characteristics

PARAMETER

SYMBOL

CONDITIONS/DESCRIPTION

TYP.

UNITS

Thermal Impedance, Junction to Free-Air

JA

Air flow = 0 m/s

97

�C/W

Lead Inductance, Self

L

11

Center lead

2.24

nH

Lead Inductance, Mutual

L

12

Center lead to any adjacent lead

0.95

nH

Lead Capacitance, Bulk

C

11

Center lead to V

SS

0.25

pF

Lead Capacitance, Mutual

C

12

Center lead to any adjacent lead

0.07

pF

X

T

April 1999

4.5.99

17

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

7.0 Ordering Information

DEVICE

NUMBER

ORDERING

CODE

PACKAGE TYPE

OPERATING

TEMPERATURE RANGE

SHIPPING CONFIGURATION

11257-801

48-pin (7.5mm/0.300") SSOP

0

�

C to 70

�

C (Commercial)

Tape and Reel

FS6050

11257-811

48-pin (7.5mm/0.300") SSOP

0

�

C to 70

�

C (Commercial)

Tube

11257-802

28-pin (7.5mm/0.300") SOIC

0

�

C to 70

�

C (Commercial)

Tape and Reel

11257-812

28-pin (7.5mm/0.209") SOIC

0

�

C to 70

�

C (Commercial)

Tube

11257-806

28-pin (5.3mm/0.209") SSOP

0

�

C to 70

�

C (Commercial)

Tape and Reel

FS6051

11257-816

28-pin (5.3mm/0.209") SSOP

0

�

C to 70

�

C (Commercial)

Tube

11257-803

28-pin (7.5mm/0.300") SOIC

0

�

C to 70

�

C (Commercial)

Tape and Reel

FS6053

11257-813

28-pin (7.5mm/0.300") SOIC

0

�

C to 70

�

C (Commercial)

Tube

11257-804

28-pin (7.5mm/0.300") SOIC

0

�

C to 70

�

C (Commercial)

Tape and Reel

FS6054

11257-814

28-pin (7.5mm/0.300") SOIC

0

�

C to 70

�

C (Commercial)

Tube

Purchase of I

2

C components of American Microsystems, Inc., or one of its sublicensed Associated Companies conveys

a license under Philips I

2

C Patent Rights to use these components in an I

2

C system, provided that the system conforms

to the I

2

C Standard Specification as defined by Philips.

Copyright � 1998 American Microsystems, Inc.

Devices sold by AMI are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. AMI

makes no warranty, express, statutory implied or by description, regarding the information set forth herein or regarding the freedom

of the described devices from patent infringement. AMI makes no warranty of merchantability or fitness for any purposes. AMI re-

serves the right to discontinue production and change specifications and prices at any time and without notice. AMI's products are

intended for use in commercial applications. Applications requiring extended temperature range, unusual environmental require-

ments, or high reliability applications, such as military, medical life-support or life-sustaining equipment, are specifically not recom-

mended without additional processing by AMI for such applications.

American Microsystems, Inc., 2300 Buckskin Rd., Pocatello, ID 83201, (208) 233-4690, FAX (208) 234-6796,

WWW Address:

http://www.amis.com

E-mail:

tgp@amis.com

X

T

April 1999

4.5.99

18

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

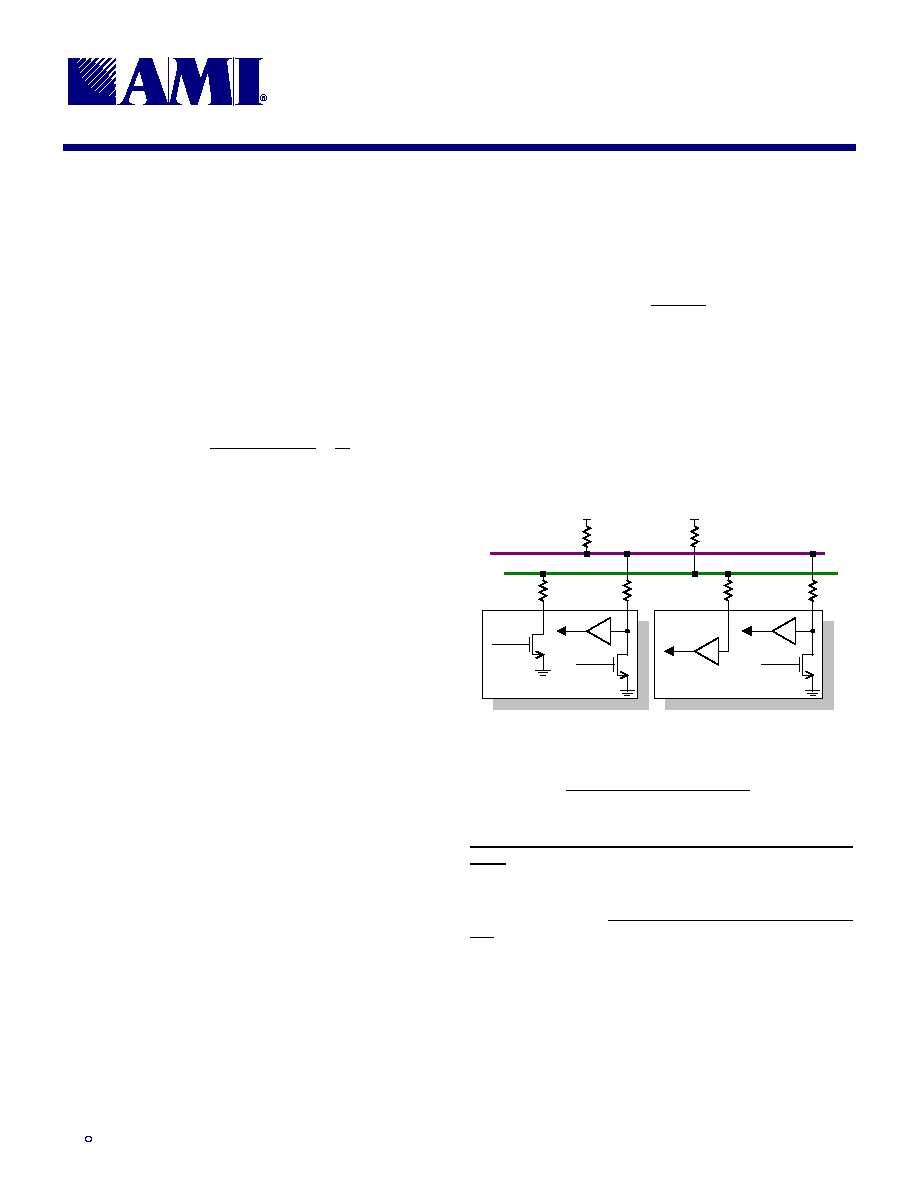

8.0 Application

Information

8.1

Reduction of EMI

The primary concern when designing the board layout for

this device is the reduction of electromagnetic interfer-

ence (EMI) generated by the 18 copies of the 100MHz

SDRAM clock. It is assumed the reader is familiar with

basic transmission line theory.

8.1.1

Layout Guidelines

To obtain the best performance, noise should be mini-

mized on the power and ground supplies to the IC. Ob-

serve good high-speed board design practices, such as:

Use multi-layer circuit boards with dedicated low im-

pedance power and ground planes for the device

(denoted as CLK VDD and CLK GND in Figure 18).

The device power and ground planes should be

completely isolated from the motherboard power and

ground planes by a void in the power planes.

Several low-pass filters using low impedance ferrite

EHDGV DW 0+]� DUH UHFRPPHQGHG WR GHFR

u-

ple the device power and ground planes from the

motherboard power and ground planes (MB VDD and

MB GND). The beads should span the gap between

the power and ground planes. Seven beads for

power and seven beads for ground are suggested

(14 total) so that the clock rise times (1V/ns) can be

maintained.

Place 1000pF bypass capacitors as close as possible

to the power pins of the IC. Use RF-quality low-

inductance multi-layer ceramic chip capacitors. Six

capacitors is optimal, one on each power/ground

grouping as shown in Figure 18.

Load similar clock outputs equally, and keep output

loading as light as possible to help reduce clock skew

and power dissipation.

Use equal-length clock traces that are as short as

possible. Rounded trace corners help reduce reflec-

tions and ringing in the clock signal.

The clock traces must never cross the void area be-

tween power/ground planes. Each trace must have a

complete plane (either VDD or GND) under the com-

plete length of the trace.

Figure 18: Board Layout

1

2

4

5

8

9

11

13

14

17

18

21

48

45

41

40

36

28

25

47

MB GND

MB VDD

31

32

44

35

38

24

CLK GND

CLK VDD

VOID

R

S

1000pF

1000pF

1000pF

1000pF

1000pF

1000pF

CLK GND

CLK VDD

MB GND

MB GND

MB VDD

MB VDD

Signal Layer

Component

Layer

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

R

S

8.1.2

Output Driver Termination

A signal reflection will occur at any point on a PC-board

trace where impedance mismatches exist. Reflections

cause several undesirable effects in high-speed applica-

tions, such as an increase in clock jitter and a rise in

electromagnetic emissions from the board. Using a prop-

erly designed series termination on each high-speed line

can alleviate these problems by eliminating signal reflec-

tions.

Figure 19: Series Termination

R

S

z

L

z

O

DRIVER

RECEIVE

LINE

X

T

April 1999

4.5.99

19

)6)6)6)6

/RZ6NHZ &ORFN )DQRXW %XIIHU ,&V

,62

Series termination adds no dc loading to the driver, and

requires less power than other resistive termination

methods. Further, no extra impedance exists from the

signal line to a reference voltage, such as ground.

As shown in Figure 19, the sum of the driver's output im-

pedance (z

O

) and the series termination resistance (R

S

)

must equal the line impedance (z

L

). That is,

O

L

S

z

z

R

-

=

.

Note that when the source impedance (z

O

+R

S

) is

matched to the line impedance, then by voltage division

the incident wave amplitude is one-half of the full signal

amplitude.

2

)

(

)

(

V

z

R

z

R

z

V

V

L

S

O

S

O

i

=

+

+

+

=

The full signal amplitude may take up to twice as long as

the propagation delay of the line to develop, reducing

noise immunity during the half-amplitude period. Note

also that the voltage at the receive end must add up to a

signal amplitude that meets the receiver switching

thresholds. The slew rate of the signal is also reduced

due to the additional RC delay of the load capacitance

and the line impedance. Also note that the output driver

impedance will vary slightly with the output logic state

(high or low).

8.2

Dynamic Power Dissipation

High-speed clock drivers require careful attention to

power dissipation. Transient power (P

T

) consumption can

be derived from

SW

CLK

load

DD

T

N

f

C

V

P

�

�

�

=

2

where C

load

is the load capacitance, V

DD

is the supply

voltage, f

CLK

is the clock frequency, and N

sw

is the

number of switching outputs.

The internal heat (junction temperature, T

J

) generated by

the power dissipation can be calculated from

A

T

JA

J

T

P

T

+

�

=

where

JA

is the package thermal resistance, T

A

is the

ambient temperature, and P

T

is derived above.

8.3

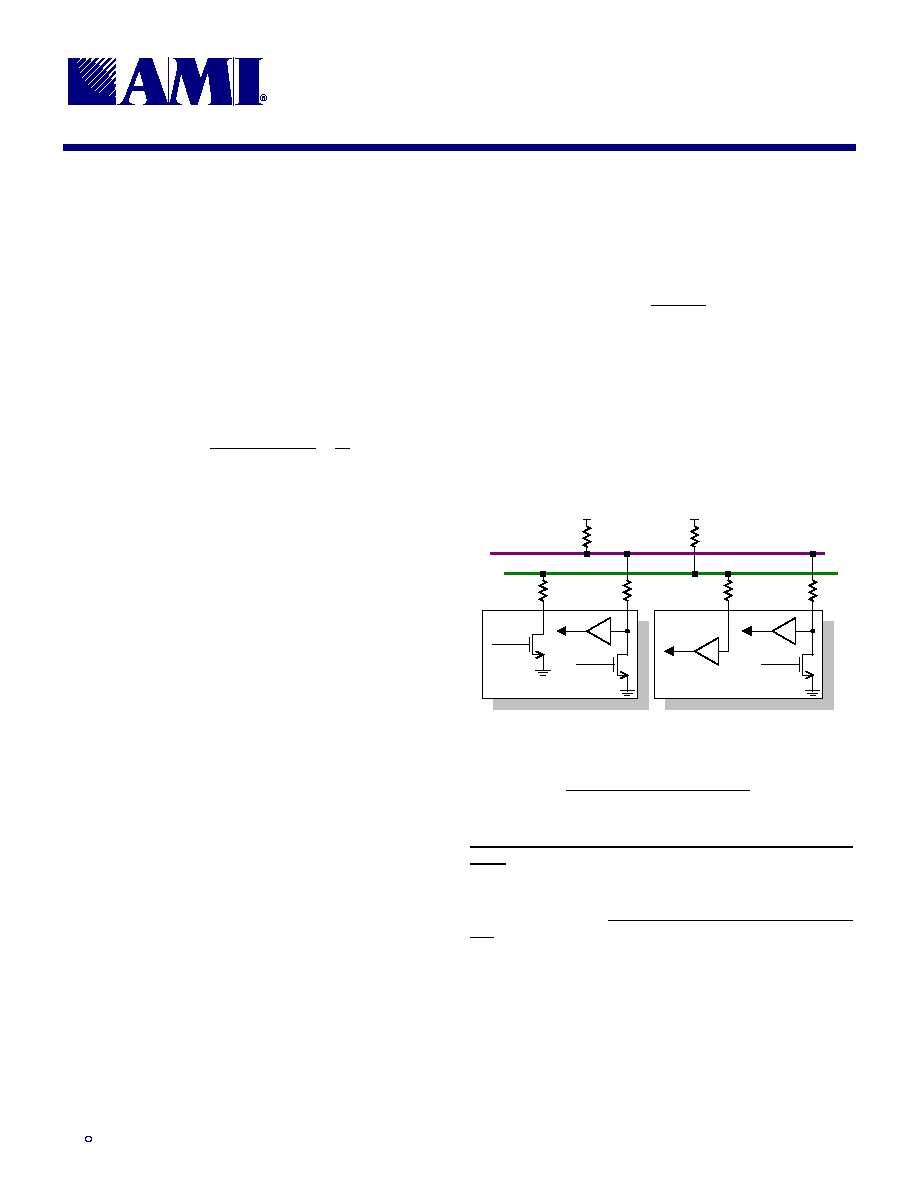

Serial Communications

Connection of devices to a standard-mode implementa-

tion of either the I

2

C-bus or the SMBus is similar to that

shown in Figure 20. Selection of the pull-up resistors (R

P

)

and the optional series resistors (R

S

) on the SDA and

SCL lines depends on the supply voltage, the bus ca-

pacitance, and the number of connected devices with

their associated input currents.

Control of the clock and data lines is done through open

drain/collector current-sink outputs, and thus requires

external pull-up resistors on both lines. A guideline is

bus

r

P

C

t

R

�

<

2

,

where t

r

is the maximum rise time (minus some margin)

and C

bus

is the total bus capacitance. Assuming an I

2

C

device on each DIMM, an I

2

C controller, the clock buffer,

and two other bus devices results in values in the 5k

to

7k

range. Use of a series resistor to provide protection

against high voltage spikes on the bus will alter the val-

ues for R

P

.

Figure 20: Connections to the Serial Bus

R

P

SDA

SCL

Data In

Data Out

Clock Out

TRANSMITTER

Data In

Data Out

RECEIVER

Clock In

R

P

R

S

(optional)

R

S

(optional)

R

S

(optional)

R

S

(optional)

8.3.1

For More Information

More detailed information on serial bus design can be

obtained from SMBus and I

2

C Bus Design

,

available from

the Intel Corporation at

http://www.intel.com.

Information on the I

2

C-bus can be found in the document

The I

2

C-bus And How To Use It (Including Specifica-

tions), available from Philips Semiconductors at

http://www-us2.semiconductors.philips.com.

Additional information on the System Management Bus

can be found in the System Management Bus Specifica-

tion, available from the Smart Battery System

Implementers' Forum at

http://www.sbs-forum.org.