| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: 16235STRD | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

PACIFIC DISPLAY DEVICES

LCD Component Data Sheet

Model Number: 16235

16 Character by 2 Line

Alphanumeric LCD Assembly

With Embedded Controller

CONTENTS

1. GENERAL

INFORMATION

1.1

Product

Overview

2

1.2 Part Numbering System

2

1.3

Absolute

Maximum

Ratings

3

1.4 Circuit Block Diagram

3

1.5

Mechanical

Characteristics

3

1.6 Input Signal Function

4

1.7 LCM Contrast Control and Bias

4

1.8

LCD

Dimensions

5

2.

ELECTRICAL / OPTICAL CHARACTERISTICS

2.1 DC Electrical Characteristics

6

2.2 AC Electrical Characteristics

6

2.3

Optical

Characteristics

8

2.4 LED Backlight Characteristics

10

2.5 EL Panel Backlight Characteristics

10

3.

OPERATING PRINCIPALS AND METHODS

3.1 LCD Controller Display and Control Functions

11

3.2 Display Data RAM Address Map

13

4. RELIABILITY

14

5.

PRECAUTIONS FOR USING LCD MODULES

15

516 N. Diamond Bar Blvd ≠ Suite 103 ≠ Diamond Bar, CA ≠ 91765

Tel: 909-396-5128 ≠ Fax: 909-396-1155 ≠ Web: www.pacificdisplay.com

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

2

1. GENERAL INFORMATION

1.1 Product Overview

∑ 16 Character x 2 line Alphanumeric Dot Matrix LCD Module

∑ LCD Controller: Embedded S6A0069 or equivalent alpha-numeric controller

∑ Multiplexing driving: 1/16 duty, 1/4 bias

∑ Operating Mode: Super Twisted Nematic (STN) technology

∑ LCD Module Service Life: 100,000 hours minimum

1.2 Part Numbering System

16235

-xx

-SL

-F

-ST

-LED

-GY

-12

Custom Option Designator

∑ (Can be left blank)

Operating Mode

∑ (-GR) Green

∑ (-SL) Silver

∑ (-BN) Blue Negative

Rear Polarizer Options:

∑ (-R) Reflective

∑ (-F) Transflective

∑ (-M) Transmissive

Operating Temperature

∑ (-ST) Standard (0 to +50 ∫C)

∑ (-ET) Extended (-20 to +70 ∫C)

Backlight Options:

∑ (-LED) LED Array Backlight

∑ (-ELP) EL Panel Backlight

Backlight Coloration Options:

∑ (-GY) LED - Green/Yellow

∑ (-AM) LED - Amber

∑ (-RD) LED - Red

∑ (-BG) ELP ≠ Blue Green

Viewing Angle

∑ (-6) 6 o'clock

∑ (-12) 12 0'clock

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

3

1.3 Absolute Maximum Ratings

Parameter Symbol

Min

Max

Unit

Supply voltage for logic

V

DD

-0.3

7.0

V

Supply voltage for LCD

V

DD

≠ V0

--

V

DD

+0.3

V

Input voltage

VI

-0.3

V

DD

+0.3

V

Standard Operating temperature

TOP (-ST)

0

50

∫C

Standard Storage temperature

TST (-ST)

-10

60

∫C

Extended Operating temperature

TOP (-ET)

-20

70

∫C

Extended Storage temperature

TST (-ET)

-30

80

∫C

Soldering Temp

Tsolder

260

∫C

1.4 Circuit Block Diagram

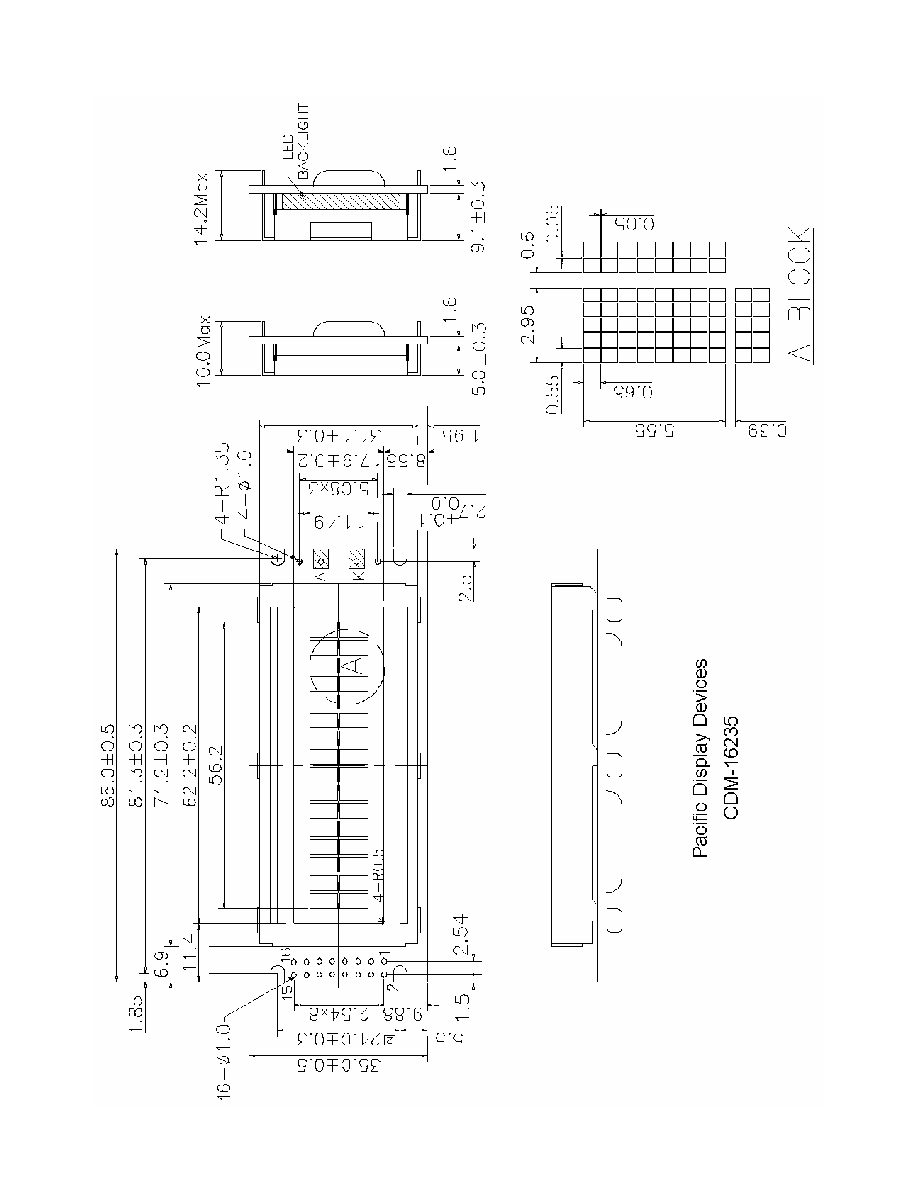

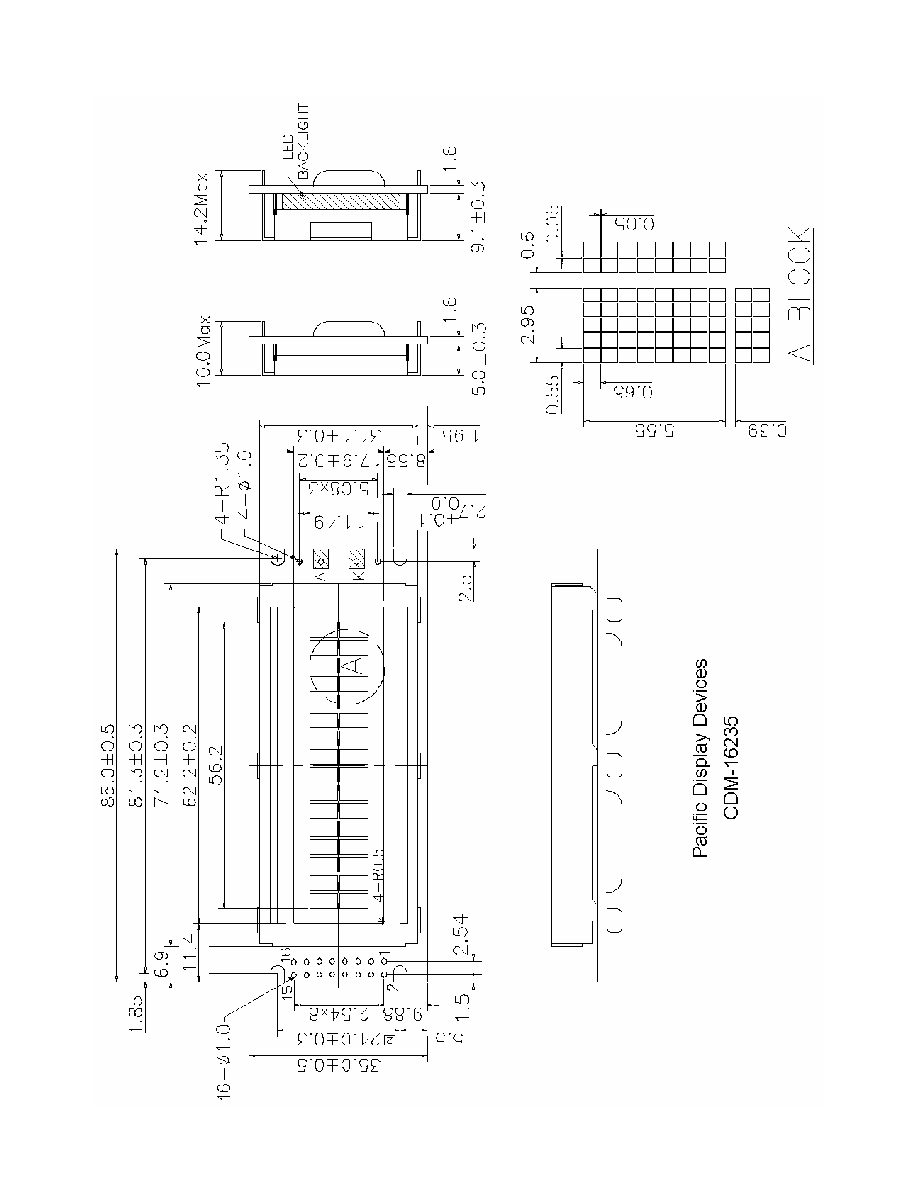

1.5 Mechanical Characteristics

Item Contents

Unit

Module size (W

◊H◊T)

85 x 35 x 14.2 Max (w/ LED Backlight)

85 x 35 x 10 Max (w/ ELP or No LED Backlight)

mm

Viewing area (W

◊H)

62.2 x 17.9

mm

Character matrix (W

◊H)

5 x 8

dots

Character size (W

◊H)

2.95 x 5.55

mm

Dot size (W

◊H)

0.55 x 0.65

mm

Dot pitch (W

◊H)

0.60 x 0.70

mm

CONTROLLER

IC

S6A0069

LCD PANEL

16 CHARACTERS x 2 LINES

V

O

V

DD

VSS

E

R/W

RS

DB0

~

DB7

EL / LED BACK LIGHT

BLA

BLK

Com16

Seg80

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

4

1.6 Input Signal Function

Pin NO.

Symbol

Level

Description

1 VSS 0V Ground

2

VDD

5.0V

Supply voltage for logic

3

VO

---

Input voltage for LCD

4

RS

H/L

H : Data signal, L : Instruction signal

5

R/W

H/L

H : Read mode, L : Write mode

6 E

H,

H

L

Chip enable signal

7

DB0

H/L

Data bit 0

8

DB1

H/L

Data bit 1

9

DB2

H/L

Data bit 2

10

DB3

H/L

Data bit 3

11

DB4

H/L

Data bit 4

12

DB5

H/L

Data bit 5

13

DB6

H/L

Data bit 6

14

DB7

H/L

Data bit 7

15 BLA 4.2V Back

light

anode

16 BLK 0V Back

light

cathode

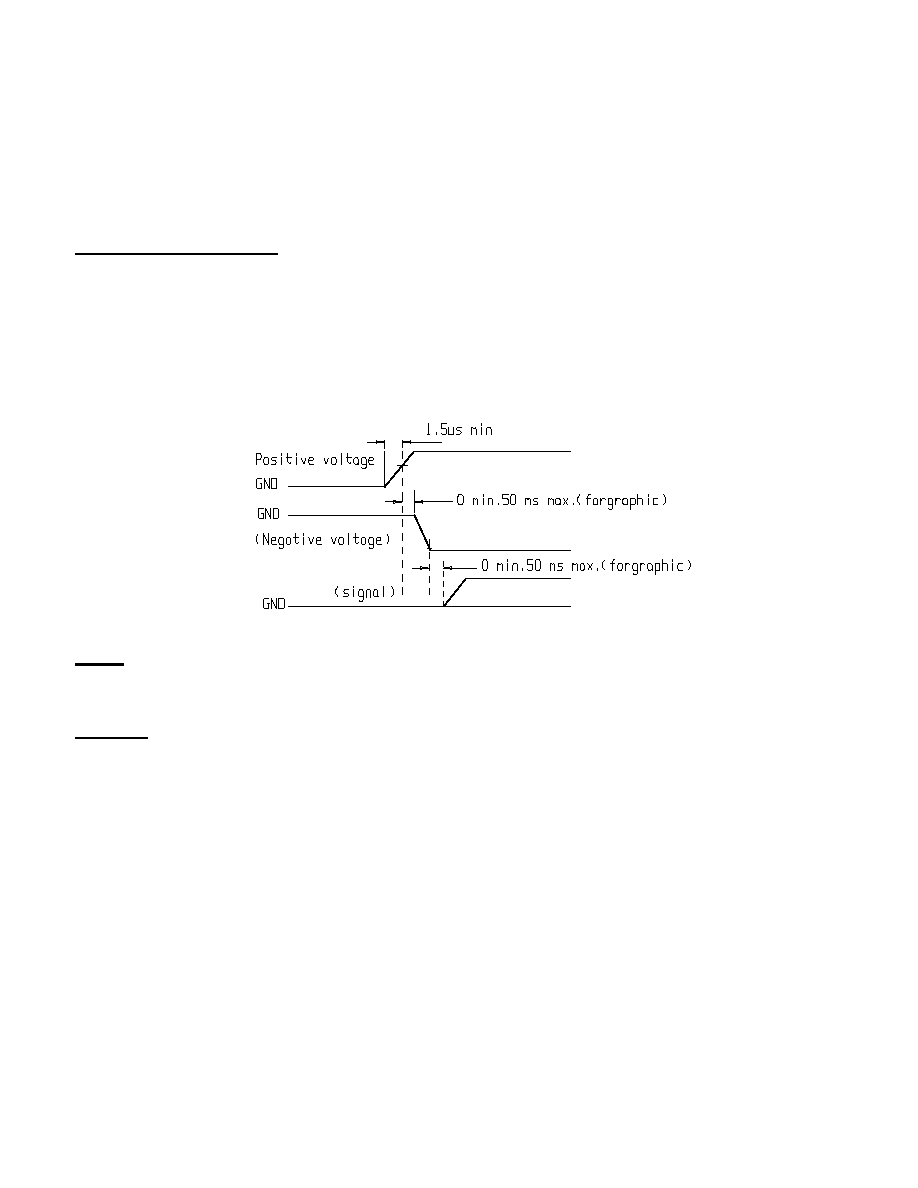

1.7 LCM Contrast Control and Bias

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

5

1.7 LCM Dimensions

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

6

2. ELECTRICAL / OPTICAL CHARACTERISTICS

2.1 DC Electrical Characteristics (V

DD

= +5V

±10% , V

SS

= 0V, Ta = 25∞C )

Parameter Symbol

Condition

Min Typ Max

Unit

Supply voltage for logic

V

DD

--- 4.5 5.0 5.5

V

Supply current for logic

I

DD

--- --- 1.38 3

mA

0∞C 4.7 5.0 5.3

V

25∞C 4.4 4.7 5.0

V

Operating voltage for LCD*

V

DD

-V

O

50∞C 4.2 4.5 4.8

V

Input voltage ' H ' level

V

IH

--- 2.2 --- VDD

V

Input voltage ' L ' level

V

IL

--- -0.3 --- 0.6

V

*Note: -ET temp range will require up to 8V biasing and require a minimum external voltage supply of -3V @-20∞C.

2.2 AC Electrical Characteristics

∑ Write Mode

Characteristic Symbol

Min. Typ. Max. Unit Test

pin

E cycle time

t

C

500

--- --- ns E

E rise time

t

r

---

---

25

ns E

E fall time

t

f

---

---

25

ns E

E pulse width (High, Low)

t

W

220 --- --- ns E

R/W and RS set-up time

t

SU1

40 --- --- ns

R/W,

RS

R/W and RS hold time

t

h1

10 --- --- ns

R/W,

RS

Data set-up time

t

SU2

60 --- --- ns

DB

0

~ DB

7

Data hold time

t

h2

10 --- --- ns

DB

0

~ DB

7

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

7

∑ Read Mode

Characteristic Symbol

Min. Typ. Max. Unit Test

pin

E cycle time

t

C

500

--- --- ns

E

E rise time

t

r

---

---

25 ns

E

E fall time

t

f

---

---

25

ns E

E pulse width

t

W

220 --- --- ns

E

R/W and RS set-up

time

t

SU

40 --- --- ns R/W,

RS

R/W and RS hold time

t

h

10

---

---

ns R/W,

RS

Data output delay time

t

D

---

---

120 ns DB

0

~ DB

7

Data hold time

t

DH

20 --- --- ns

DB

0

~ DB

7

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

8

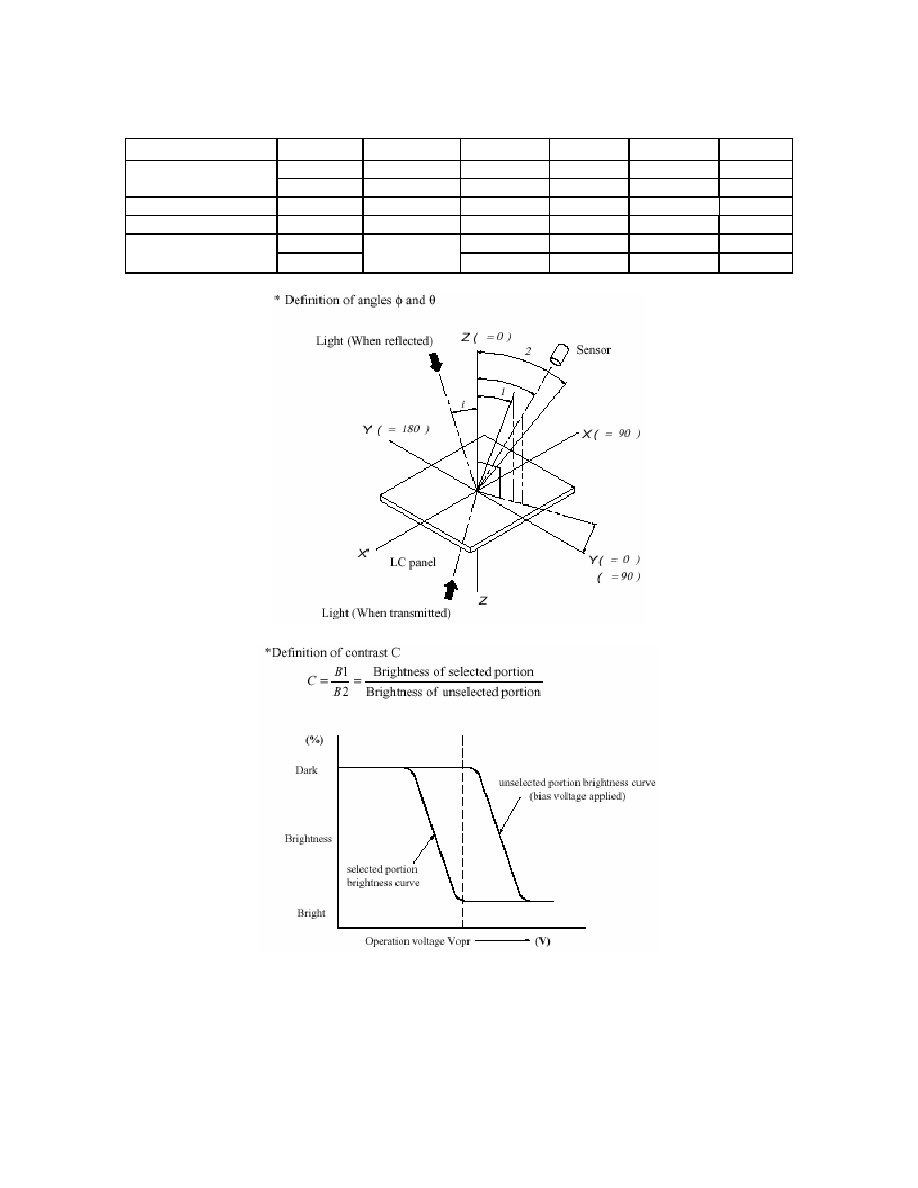

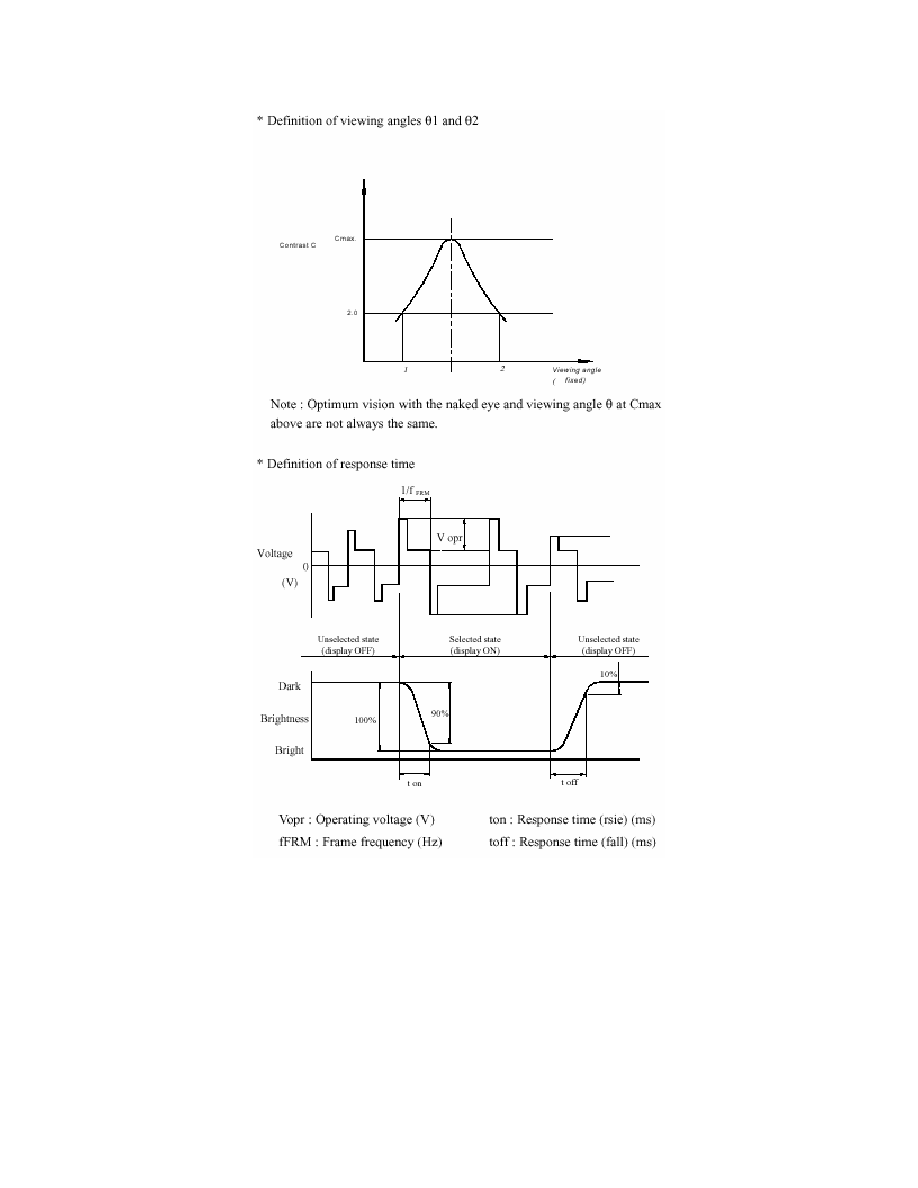

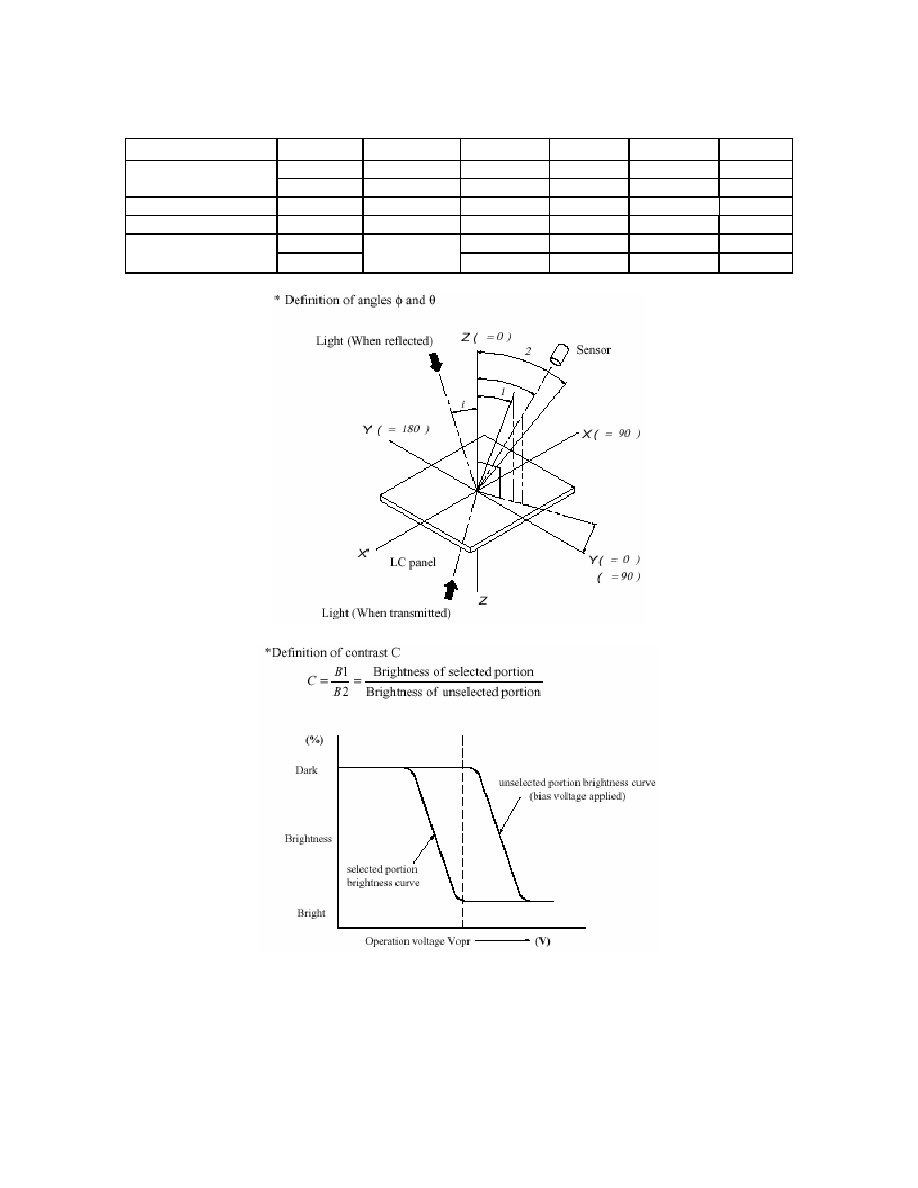

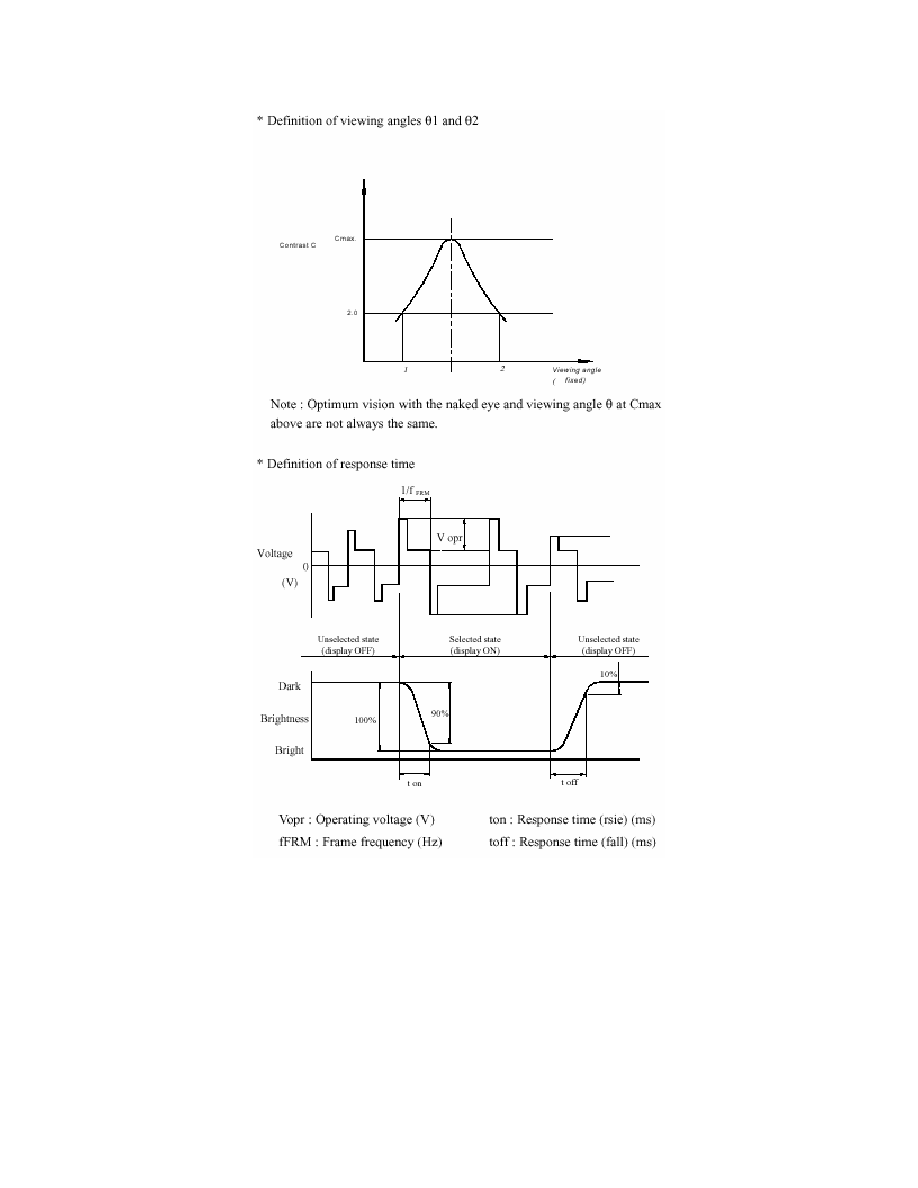

2.3 Optical Characteristics

(V

OP

= 4.7V, Ta = 25∞C )

Item Symbol

Condition

Min

Typ

Max

Unit

Response time

Tr

---

---

250

380

ms

Tf

---

---

200

300

ms

Frame Frequency

fFRM

---

---

64

---

Hz

Contrast

ratio

Cr --- 3 4 7 ---

1

-40 -- 40 Deg

Viewing angle range

2

25

∞ C

-40 -- -40

Deg

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

9

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

10

2.4 LED Backlight Characteristics

Yellow-Green LED Operating Characteristics (5V - Array Lit)

Standard

Item Symbol

Conditions

Min. Typ. Max.

Unit

Forward Voltage

V

f

Ta=

25

∞C ---

4.2

4.6 VDC

Forward Current

I

F

Ta=

25

∞C ---

120 220

mA

Reverse Voltage

V

R

Ta=

25

∞C ---

8

---

V

Life (Array or Edge Lit)

Standard

Item Conditions

Min. Max.

Unit

Life Ta=

25

∞C

100,000

---

hrs

2.5 EL Panel Backlight Characteristics

Blue-Green EL Panel Operating Characteristics:

Standard

Item Conditions

Min. Typ. Max.

Unit

Current Consumption

100VAC RMS, 400Hz

Ta: 25∞C

--- 1.8 3.1 mA

EL Drive Voltage

---

---

100

150

VAC RMS

EL Drive Frequency

---

---

400

1000

Hz

Operating Temperature

---

-35∞C

---

+50∞C

∞C

Storage Temperature

---

-40∞C

---

+60∞C

∞C

Luminance 40

50

---

cd/m

2

Luminance Half-Life

100VAC RMS, 400Hz

Ta: 25∞C

3500 --- --- Hrs

*Note: half life is defined as Luminance being reduced by 50%

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

11

3. OPERATING PRINCIPALS AND METHODES

∑ Control and Display Command

Command

RS

R/W

DB

7

DB

6

DB

5

DB

4

DB

3

DB

2

DB

1

DB

0

Exe Time

f=250khz

Remark

Display

Clear

L L L L L L L L L H 1.64ms

Return

Home

L L L L L L L L H X 1.64ms Cursor

move

to

first

digit

Entry

Mode

Set

L L L L L L L H I/D

SH 42

µs

∑ I/D : Set cursor move direction

∑ SH : Specifies shift of display

Display

On/Off

L L L L L L H D C B 42

µs

∑ Display

∑ Cursor

∑ Blinking

Shift

L L L L L H S/C

R/L X X 42

µs

Set

Function

L L L L H DL N F X X 42

µs

Set Cg Ram Address

L

L

L

H

CG RAM address

(corresponds to cursor address)

42

µs

CG RAM Data is sent and

received after this setting

Set Dd Ram

Address

L

L

H

DD RAM address

42

µs

DD RAM Data is sent and

received after this setting

Read Busy Flag &

Address

L

H

BF

Address Counter used for

both DD & CG RAM address

0

µs

- Reads BF indication internal

operating is being performed

- Reads addr counter contents

Write Data

H

L

Write Data

46

µs

Write data into DD or CG RAM

Read Data

H

H

Read Data

46

µs

Read data from DD or CG RAM

X : Don't care

H

Busy

BF

L

Ready

H 5 X 10 dots

F

L 5 X 7 dots

H 2 line display

N

L 1 line display

H 8 bits interface

DL

L 4 bits interface

H

Display

shift

S/C

L

Cursor

move

H

Right

shift

R/L

L

Left

shift

H

Blinking

on

B

L

Blinking

off

H

Cursor

on

C

L

Cursor

off

H

Display

on

D

L

Display

off

H

Increase

I/D

L

Decrease

H Display is shifted

SH

L Display is not

shifted

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

12

∑ Initializing by Instruction

Power On

|

Wait for more than 15ms after VDD rises to 4.5V

|

RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 1 1 * * * *

BF cannot be checked before this instruction.

Function Set

|

Wait for more than 4.1ms

|

RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 1 1 * * * *

BF cannot be checked before this instruction.

Function Set

|

Wait for more than 100

µs

|

RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 1 1 * * * *

BF cannot be checked before this instruction.

Function Set

|

|

|

|

|

BF can be checked after following

instruction.

When BF is not checked, the waiting time

between instructions is longer than execution

instruction time.

|

RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

0 0 0 0 1 1 N F * *

Function Set (Specify the number of display

lines and character font.) The number of

display lines and character font cannot be

changed afterwards.

0 0 0 0 0 0 1 0 0 0

Display Off

0 0 0 0 0 0 0 0 0 1

Display Clear

0 0 0 0 0 0 0 1 I/D S

Entry Mode Set

|

|

Initialization ends

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

13

3.2 Display Data RAM Address Map

LCD Character Location map

Characters 1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16

First line

00H 01H 02H 03H 04H 05H 06H 07H 08H 09H 0AH 0BH 0CH 0DH 0EH 0FH

Second line 40H 41H 42H 43H 44H 45H 46H 47H 48H 49H 4AH 4BH 4CH 4DH 4EH 4FH

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

14

4. RELIABILITY

Environmental Test

No

.

Test Item

Content of Test Test

Condition

Applicable

Standard

1 High

temperature

storage

Endurance test applying the high storage

temperature for a long time.

80

∞C

200 hrs

------

2 Low

temperature

storage

Endurance test applying the low storage

temperature for a long time.

-30

∞C

200 hrs

------

3 High

temperature

operation

Endurance test applying the electric stress

(Voltage & Current) and the thermal stress to

the element for a long time.

70

∞C

200 hrs

------

4 Low

temperature

operation

Endurance test applying the electric stress

under low temperature for a long time.

-20

∞C

200 hrs

------

5

High temperature

/

Humidity storage

Endurance test applying the high temperature

and high humidity storage for a long time.

80

∞C , 90 %RH

96 hrs

MIL-202E-103B

JIS-C5023

6

High temperature

/

Humidity operation

Endurance test applying the electric stress

(Voltage & Current) and temperature

/ humidity

stress to the element for a long time.

70

∞C , 90 %RH

96 hrs

MIL-202E-103B

JIS-C5023

7

Temperature cycle

Endurance test applying the low and high

temperature cycle.

-20

∞C / 70∞C

10 cycles

------

Mechanical Test

8

Vibration test

Endurance test applying the vibration during

transportation and using.

10

22Hz 1.5mmp-p

22

500Hz 1.5G

Total 0.5hrs

MIL-202E-201A

JIS-C5025

JIS-C7022-A-10

9

Shock test

Constructional and mechanical endurance test

applying the shock during transportation.

50G Half sign

wave 1l msedc

3 times of each direction

MIL-202E-213B

10 Atmospheric

pressure test

Endurance test applying the atmospheric

pressure during transportation by air.

115 mbar

40 hrs

MIL-202E-105C

Others

11

Static electricity test

Endurance test applying the electric stress to the

terminal.

VS=800V , RS=1.5 k

CS=100 pF

1 time

MIL-883B-

3015.1

Supply voltage for logic system = VDD. Supply voltage for LCD system = Operating voltage at 25∞C

LCD Panel Service Life

Definition of panel service life

∑ 100,000 hours minimum at 25∞ C ±10%

∑ Contrast becomes 30% of initial value

∑ Current consumption becomes three times higher than initial value

∑ Remarkable alignment deterioration occurs in LCD cell layer

∑ Unusual operation occurs in display functions

25

∞C

5min.

1

70

∞C

30min.

-20

∞C

30min.

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

15

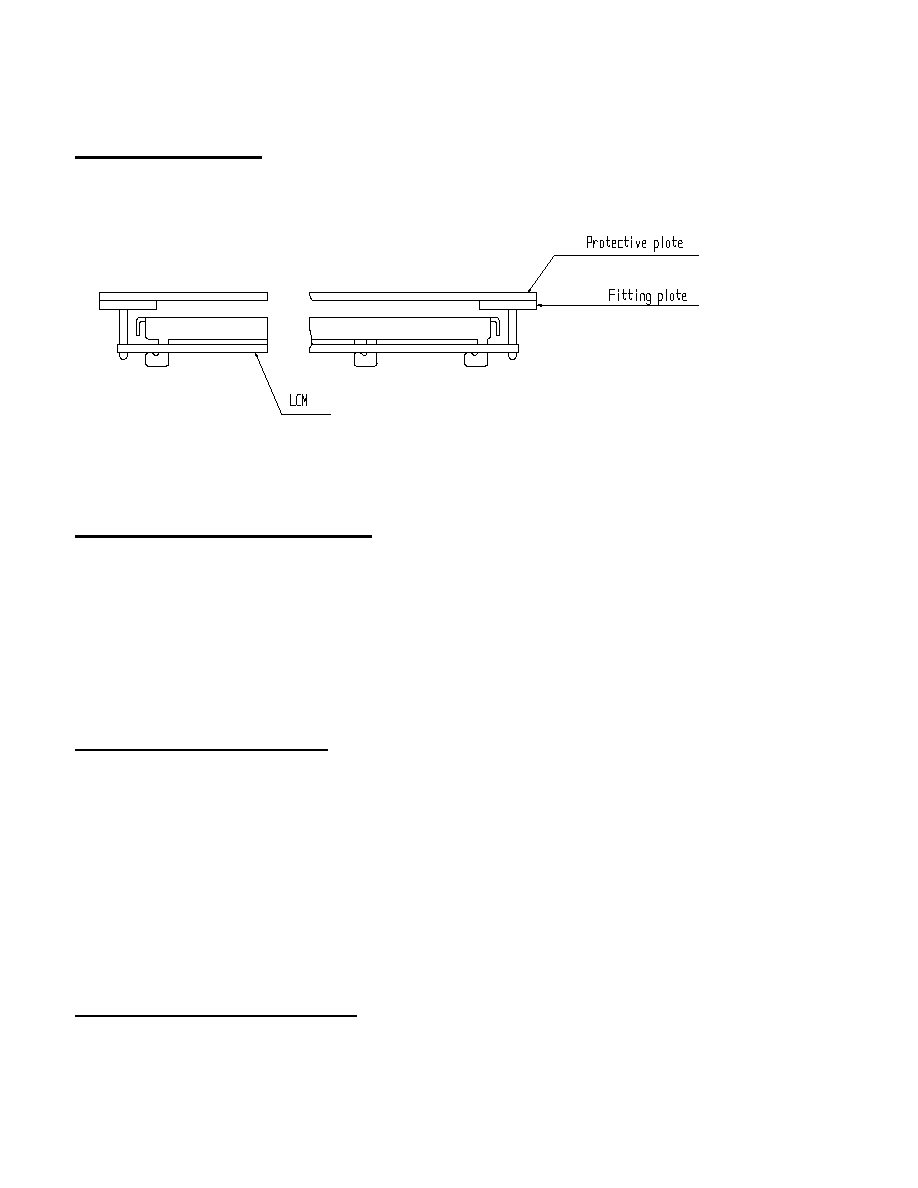

5. PRECAUTIONS FOR USING LCD MODULES

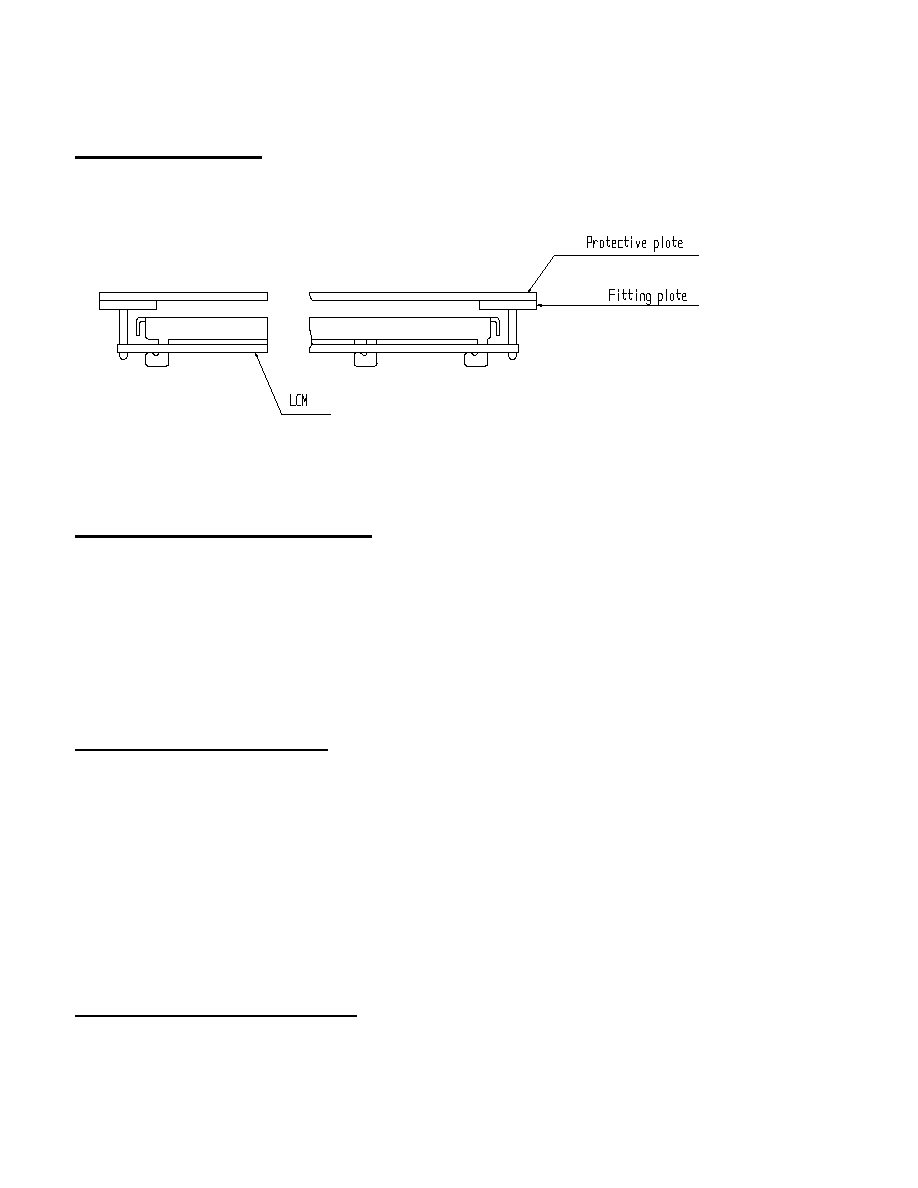

Installing LCD Modules

The hole in the printed circuit board is used to fix LCM as shown in the picture below. Attend to the following items when

installing the LCM.

1) Cover the surface with a transparent protective plate to protect the polarizer and LC cell.

2) When assembling the LCM into other equipment, the spacer to the bit between the LCM and the fitting plate

should have enough height to avoid causing stress to the module surface, refer to the individual specifications for

measurements. The measurement tolerance should be

±0.1mm.

Precaution for Handing LCD Modules

Since LCM has been assembled and adjusted with a high degree of precision, avoid applying excessive shocks to the module or

making any alterations or modifications to it.

1) Cover the surface with a transparent protective plate to protect the polarizer and LC cell.

2) Do not alter, modify or change the shape of the tab on the metal frame.

3) Do not make extra holes on the printed circuit board, modify its shape or change the positions of components to

be attached.

4) Do not damage or modify the pattern writing on the printed circuit board.

5) Absolutely do not modify the zebra rubber strip (conductive rubber) or heat seal connector.

6) Except for soldering the interface, do not make any alterations or modifications with a soldering iron.

7) Do not drop, bend or twist LCM.

Electro-Static Discharge Control

Since this module uses a CMOS LSI, the same careful attention should be paid to electrostatic discharge as for an ordinary

CMOS IC.

1) Make certain that you are grounded when handing LCM.

2) Before remove LCM from its packing case or incorporating it into a set, be sure the module and your body have

the same electric potential.

3) When soldering the terminal of LCM, make certain the AC power source for the soldering iron does not leak.

4) When using an electric screwdriver to attach LCM, the screwdriver should be of ground potentiality to minimize

as much as possible any transmission of electromagnetic waves produced sparks coming from the commutator of

the motor.

5) As far as possible make the electric potential of your work clothes and that of the work bench the ground

potential.

6) To reduce the generation of static electricity be careful that the air in the work is not too dried. A relative

humidity of 50%-60% is recommended.

Precaution for soldering to the LCM

1) Observe the following when soldering lead wire, connector cable and etc. to the LCM.

a) Soldering iron temperature : 280

∞C ± 10∞C.

b) Soldering time : 3-4 sec.

2) Solder : eutectic solder.

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

16

3) If soldering flux is used, be sure to remove any remaining flux after finishing to soldering operation. (This does

not apply in the case of a non-halogen type of flux.) It is recommended that you protect the LCD surface with a

cover during soldering to prevent any damage due to flux spatters.

4) When soldering the electroluminescent panel and PC board, the panel and board should not be detached more

than three times. This maximum number is determined by the temperature and time conditions mentioned above,

though there may be some variance depending on the temperature of the soldering iron.

5) When remove the electroluminescent panel from the PC board, be sure the solder has completely melted, the

soldered pad on the PC board could be damaged.

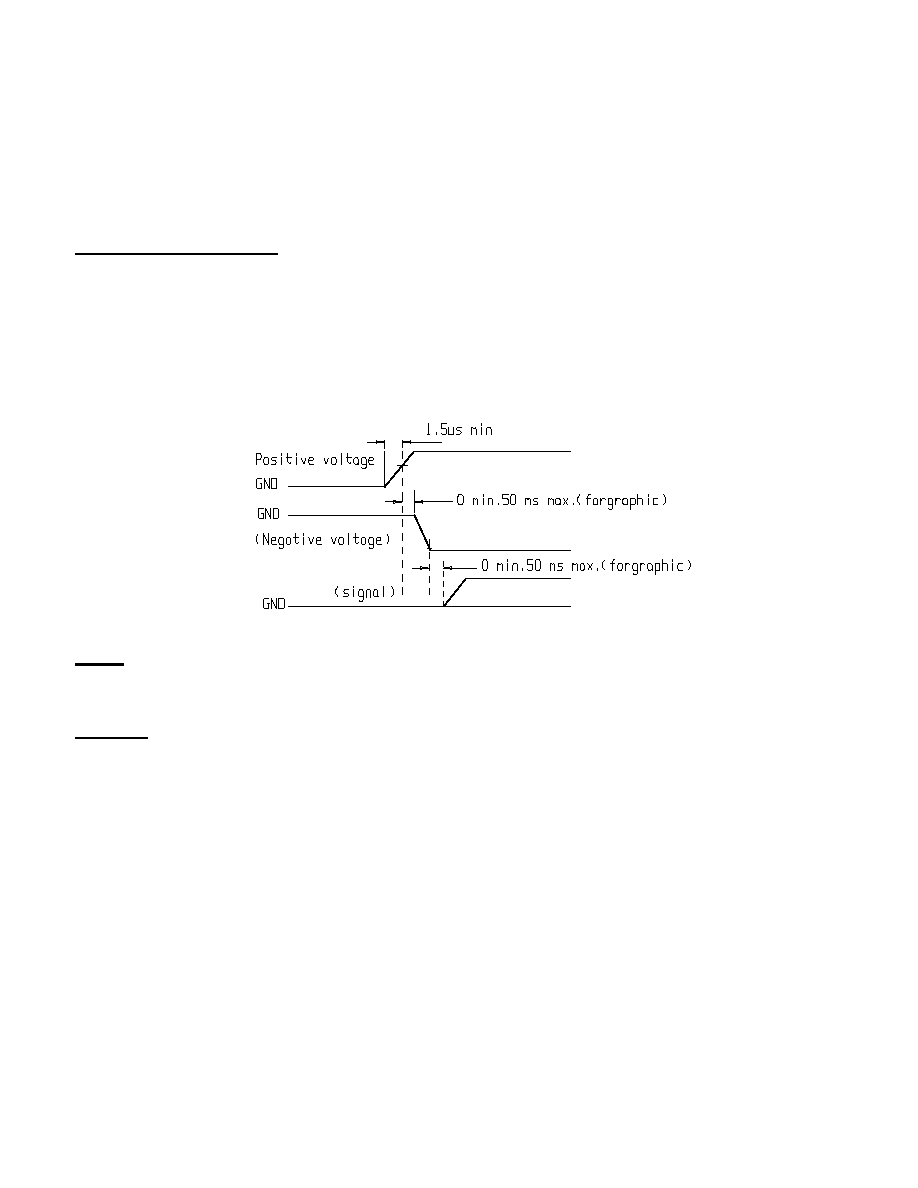

Precautions for Operation

1) Viewing angle varies with the change of liquid crystal driving voltage (VO). Adjust VO to show the best contrast.

2) Driving the LCD in the voltage above the limit shortens its life.

3) Response time is greatly delayed at temperature below the operating temperature range. However, this does not

mean the LCD will be out of the order. It will recover when it returns to the specified temperature range.

4) If the display area is pushed hard during operation, the display will become abnormal. However, it will return to

normal if it is turned off and then back on.

5) Condensation on terminals can cause an electrochemical reaction disrupting the terminal circuit. Therefore, it

must be used under the relative condition of 40

∞C , 50% RH.

6) When turning the power on, input each signal after the positive/negative voltage becomes stable.

Safety

∑ If the LCD panel breaks, be careful not to get the liquid crystal in your mouth. If the liquid crystal touches your skin

or clothes, wash it off immediately using soap and plenty of water.

Handling

∑ The display panel is made of glass. Do not subject it to a mechanical shock by dropping it or impact.

∑ If the display panel is damaged and the liquid crystal substance leaks out, be sure not to get any in your mouth. If the

substance contacts your skin or clothes, wash it off using soap and water.

∑ Do not apply excessive force to the display surface or the adjoining areas since this may cause the color tone to vary.

∑ The polarizer covering the display surface of the LCD module is soft and easily scratched. Handle this polarizer

carefully.

∑ If the display surface becomes contaminated, breathe on the surface and gently wipe it with a soft dry cloth. If it is

heavily contaminated, moisten cloth with one of the following solvents :

o Isopropyl alcohol

o Ethyl alcohol

∑ Solvents other than those above-mentioned may damage the polarizer. Especially, do not use the following.

o Water

o Ketone

o Aromatic solvents

∑ Exercise care to minimize corrosion of the electrode. Corrosion of the electrodes is accelerated by water droplets,

moisture condensation or a current flow in a high-humidity environment.

∑ Install the LCD Module by using the mounting holes. When mounting the LCD module make sure it is free of

twisting, warping and distortion. In particular, do not forcibly pull or bend the I

/O cable or the backlight cable.

∑ Do not attempt to disassemble or process the LCD module.

∑ NC terminal should be open. Do not connect anything.

∑ If the logic circuit power is off, do not apply the input signals.

SPECIFICATIONS FOR LIQUID CRYSTAL DISPLAY MODULE

MODEL NO: 16235

PACIFIC DISPLAY DEVICES

07.01.2003

17

∑ To prevent destruction of the elements by static electricity, be careful to maintain an optimum work environment.

o Be sure to ground the body when handling the LCD modules.

o Tools required for assembling, such as soldering irons, must be properly grounded.

o To reduce the amount of static electricity generated, do not conduct assembling and other work under dry

conditions.

o The LCD module is coated with a film to protect the display surface. Exercise care when peeling off this

protective film since static electricity may be generated.

Storage

∑ When storing the LCD modules, avoid exposure to direct sunlight or to the light of fluorescent lamps

∑ Store the module in a dark place where the temperature is 25

o

C ±10

o

C and the humidity below 65% RH.

∑ Do not store the module near organic solvents or corrosive gases.

∑ Do not crush, shake, or jolt the module (including accessories).

Cleaning

∑ Do not wipe the polarizing plate with a dry cloth, as it may scratch the surface.

∑ Wipe the module gently with soft cloth soaked with a petroleum benzene.

∑ Do not use ketonic solvents (ketone and acetone) or aromatic solvents (toluene and xylene), as they may damage the

polarizing plate.

Others:

∑ Liquid crystals solidify under low temperature (below the storage temperature range) leading to defective orientation

or the generation of air bubbles (black or white). Air bubbles may also be generated if the module is subject to a low

temperature.

∑ If the LCD modules have been operating for a long time showing the same display patterns, the display patterns may

remain on the screen as ghost images and a slight contrast irregularity may also appear. A normal operating status can

be regained by suspending use for some time. It should be noted that this phenomenon does not adversely affect

performance reliability.

∑ To minimize the performance degradation of the LCD modules resulting from destruction caused by static electricity

etc., exercise care to avoid holding the following sections when handling the modules.

-

Exposed area of the printed circuit board.

-

Terminal electrode sections.