©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

HUF76113SK8

6.5A, 30V, 0.030 Ohm, N-Channel, Logic

Level UltraFET Power MOSFET

This N-Channel power MOSFET is

manufactured using the innovative

UltraFETTM process. This advanced

process technology achieves the

lowest possible on-resistance per silicon area, resulting in

outstanding performance. This device is capable of

withstanding high energy in the avalanche mode and the

diode exhibits very low reverse recovery time and stored

charge. It was designed for use in applications where power

efficiency is important, such as switching regulators, switching

converters, motor drivers, relay drivers, low-voltage bus

switches, and power management in portable and battery-

operated products.

Formerly developmental type TA76113.

Features

∑ Logic Level Gate Drive

∑ 6.5A, 30V

∑ Ultra Low On-Resistance, r

DS(ON)

= 0.030

∑ Temperature Compensating PSPICE

Æ

Model

∑ Temperature Compensating SABERTM Model

∑ Thermal Impedance SPICE Model

∑ Thermal Impedance SABER Model

∑ Peak Current vs Pulse Width Curve

∑ UIS Rating Curve

∑ Related Literature

- TB334, "Guidelines for Soldering Surface Mount

Components to PC Boards"

Symbol

Packaging

JEDEC MS-012AA

Ordering Information

PART NUMBER

PACKAGE

BRAND

HUF76113SK8

MS-012AA

76113SK8

NOTE: When ordering, use the entire part number. Add the suffix T

to obtain the variant in tape and reel, e.g., HUF76113SK8T.

SOURCE(2)

DRAIN(8)

NC(1)

DRAIN(7)

DRAIN(6)

DRAIN(5)

SOURCE(3)

GATE(4)

BRANDING DASH

1

2

3

4

5

Data Sheet

January 2003

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

Absolute Maximum Ratings

T

A

= 25

o

C, Unless Otherwise Specified

HUF76113SK8

UNITS

Drain to Source Voltage (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DSS

30

V

Drain to Gate Voltage (R

GS

= 20k

) (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DGR

30

V

Gate to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

GS

±

20

V

Drain Current

Continuous (T

A

= 25

o

C, V

GS

= 10V) (Figure 2) (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . I

D

Continuous (T

A

= 100

o

C, V

GS

= 5V) (Note 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

D

Continuous (T

A

= 100

o

C, V

GS

= 4.5V) (Note 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

D

Pulsed Drain Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

DM

6.5

2.0

2.0

Figure 4

A

A

A

Pulsed Avalanche Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E

ASB

Figure 6

Power Dissipation (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

D

Derate Above 25

o

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5

20

W

mW/

o

C

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

J

, T

STG

-55 to 150

o

C

Maximum Temperature for Soldering

Leads at 0.063in (1.6mm) from Case for 10s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

L

Package Body for 10s, See Techbrief 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

pkg

300

260

o

C

o

C

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. T

J

= 25

o

C to 125

o

C.

2. 50

o

C/W measured using FR-4 board with 0.76 in

2

footprint at 10 seconds.

3. 177

o

C/W measured using FR-4 board with 0.0115 in

2

footprint at 1000 seconds.

Electrical Specifications

T

A

= 25

o

C, Unless Otherwise Specified

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

OFF STATE SPECIFICATIONS

Drain to Source Breakdown Voltage

BV

DSS

I

D

= 250

µ

A, V

GS

= 0V (Figure 12)

30

-

-

V

Zero Gate Voltage Drain Current

I

DSS

V

DS

= 25V, V

GS

= 0V

-

-

1

µ

A

V

DS

= 25V, V

GS

= 0V, T

A

= 150

o

C

-

-

250

µ

A

Gate to Source Leakage Current

I

GSS

V

GS

=

±

20V

-

-

±

100

nA

ON STATE SPECIFICATIONS

Gate to Source Threshold Voltage

V

GS(TH)

V

GS

= V

DS

, I

D

= 250

µ

A (Figure 11)

1

-

3

V

Drain to Source On Resistance

r

DS(ON)

I

D

= 6.5A, V

GS

= 10V (Figures 9, 10)

-

0.025

0.030

I

D

= 2.0A, V

GS

= 5V (Figure 9)

-

0.031

0.038

I

D

= 2.0A, V

GS

= 4.5V (Figure 9)

-

0.033

0.041

THERMAL SPECIFICATIONS

Thermal Resistance Junction to Ambient

R

JA

Pad Area = 0.76 in

2

(Note 2)

-

-

50

o

C/W

Pad Area = 0.054 in

2

(See TB337)

-

-

143

o

C/W

Pad Area = 0.0115 in

2

(See TB337)

-

-

177

o

C/W

SWITCHING SPECIFICATIONS (V

GS

= 4.5V)

Turn-On Time

t

ON

V

DD

= 15V, I

D

2.0A, R

L

= 7.5

,

V

GS

=

4.5V, R

GS

= 15

(Figure 15)

-

-

100

ns

Turn-On Delay Time

t

d(ON)

-

16

-

ns

Rise Time

t

r

-

50

-

ns

Turn-Off Delay Time

t

d(OFF)

-

28

-

ns

Fall Time

t

f

-

34

-

ns

Turn-Off Time

t

OFF

-

-

91

ns

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

SWITCHING SPECIFICATIONS (V

GS

= 10V)

Turn-On Time

t

ON

V

DD

= 15V, I

D

6.5A, R

L

= 2.31

,

V

GS

=

10V, R

GS

= 16

(Figure 16)

-

-

59

ns

Turn-On Delay Time

t

d(ON)

-

6.5

-

ns

Rise Time

t

r

-

33

-

ns

Turn-Off Delay Time

t

d(OFF)

-

45

-

ns

Fall Time

t

f

-

40

-

ns

Turn-Off Time

t

OFF

-

-

126

ns

GATE CHARGE SPECIFICATIONS

Total Gate Charge

Q

g(TOT)

V

GS

= 0V to 10V

V

DD

= 15V, I

D

2.0A,

R

L

= 7.5

I

g(REF)

= 1.0mA

(Figures 14)

-

17.5

21

nC

Gate Charge at 5V

Q

g(5)

V

GS

= 0V to 5V

-

10

12

nC

Threshold Gate Charge

Q

g(TH)

V

GS

= 0V to 1V

-

0.65

0.78

nC

Gate to Source Gate Charge

Q

gs

-

1.10

-

nC

Gate to Drain "Miller" Charge

Q

gd

-

5.40

-

nC

CAPACITANCE SPECIFICATIONS

Input Capacitance

C

ISS

V

DS

= 25V, V

GS

= 0V, f = 1MHz

(Figure 13)

-

585

-

pF

Output Capacitance

C

OSS

-

327

-

pF

Reverse Transfer Capacitance

C

RSS

-

73

-

pF

Electrical Specifications

T

A

= 25

o

C, Unless Otherwise Specified

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

Source to Drain Diode Specifications

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

Source to Drain Diode Voltage

V

SD

I

SD

=6.5A

-

-

1.25

V

I

SD

= 2.0A

1.10

V

Reverse Recovery Time

t

rr

I

SD

= 2.0A, dI

SD

/dt = 100A/

µ

s

-

-

47

ns

Reverse Recovered Charge

Q

RR

I

SD

= 2.0A, dI

SD

/dt = 100A/

µ

s

-

-

52

nC

Typical Performance Curves

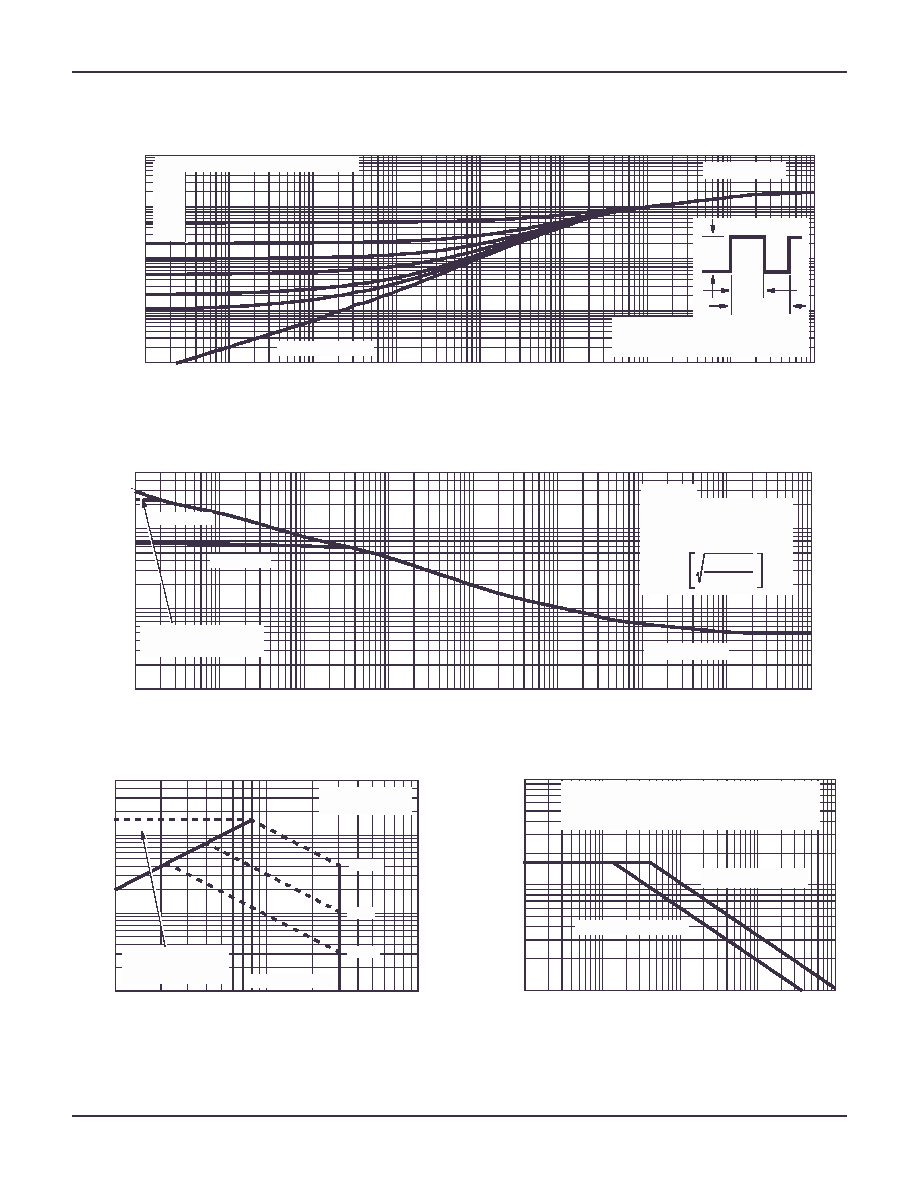

FIGURE 1. NORMALIZED POWER DISSIPATION vs AMBIENT

TEMPERATURE

FIGURE 2. MAXIMUM CONTINUOUS DRAIN CURRENT vs

AMBIENT TEMPERATURE

T

A

, AMBIENT TEMPERATURE (

o

C)

P

O

W

E

R DIS

S

IP

A

T

IO

N

M

U

L

T

IP

L

I

E

R

0

0

25

50

75

100

150

0.2

0.4

0.6

0.8

1.0

1.2

125

4

0

25

50

75

100

125

I

D

,

DRAIN CURRE

N

T

(

A

)

T

A

, AMBIENT TEMPERATURE (

o

C)

8

150

2

6

V

GS

= 4.5V, R

JA

= 177

o

C/W

V

GS

= 10V, R

JA

= 50

o

C/W

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

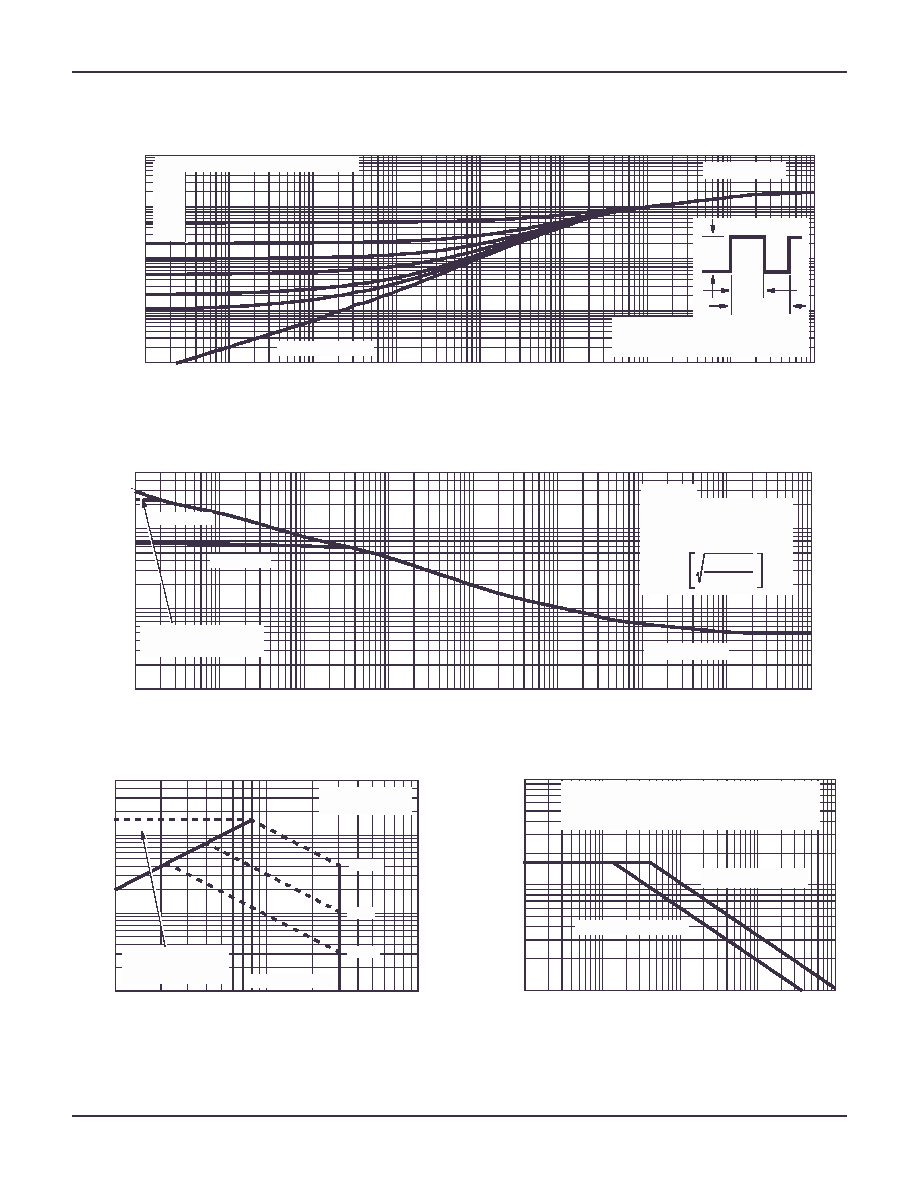

FIGURE 3. NORMALIZED MAXIMUM TRANSIENT THERMAL IMPEDANCE

FIGURE 4. PEAK CURRENT CAPABILITY

FIGURE 5. FORWARD BIAS SAFE OPERATING AREA

NOTE: Refer to Fairchild Application Notes AN9321 and AN9322.

FIGURE 6. UNCLAMPED INDUCTIVE SWITCHING

CAPABILITY

Typical Performance Curves

(Continued)

t, RECTANGULAR PULSE DURATION (s)

10

-5

10

-1

10

0

10

0.01

1

10

-2

Z

JA

, NO

RM

A

L

IZ

E

D

T

H

E

R

M

A

L

IM

P

E

D

ANCE

0.001

10

-4

10

-3

SINGLE PULSE

NOTES:

DUTY FACTOR: D = t

1

/t

2

PEAK T

J

= P

DM

x Z

JA

x R

JA

+ T

A

P

DM

t

1

t

2

10

1

DUTY CYCLE - DESCENDING ORDER

0.5

0.2

0.1

0.05

0.01

0.02

0.1

10

2

10

3

R

JA

= 50

o

C/W

T

C

= 25

o

C

I

=

I

25

150 - T

A

125

FOR TEMPERATURES

ABOVE 25

o

C DERATE PEAK

CURRENT AS FOLLOWS:

V

GS

= 10V

TRANSCONDUCTANCE

MAY LIMIT CURRENT

IN THIS REGION

I

DM

, P

E

AK CURRE

NT

(

A

)

500

1

10

-5

10

-4

10

-3

10

-2

10

-1

10

0

10

3

t, PULSE WIDTH (s)

10

V

GS

= 5V

R

JA

= 50

o

C/W

100

10

2

10

1

T

J

= MAX RATED

T

A

= 25

o

C

100

µ

s

10ms

1ms

V

DSS(MAX)

= 30V

LIMITED BY r

DS(ON)

AREA MAY BE

OPERATION IN THIS

100

1

V

DS

, DRAIN TO SOURCE VOLTAGE (V)

1

100

500

10

I

D

, DRA

IN CURRE

NT

(

A

)

10

1

10

100

100

1

I

AS

, A

V

AL

ANCHE

CURRE

NT

(

A

)

t

AV

, TIME IN AVALANCHE (ms)

t

AV

= (L)(I

AS

)/(1.3*RATED BV

DSS

- V

DD

)

If R = 0

If R

0

t

AV

= (L/R)ln[(I

AS

*R)/(1.3*RATED BV

DSS

- V

DD

) +1]

STARTING T

J

= 25

o

C

STARTING T

J

= 150

o

C

0.1

10

0.01

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

FIGURE 7. TRANSFER CHARACTERISTICS

FIGURE 8. SATURATION CHARACTERISTICS

FIGURE 9. DRAIN TO SOURCE ON RESISTANCE vs GATE

VOLTAGE AND DRAIN CURRENT

FIGURE 10. NORMALIZED DRAIN TO SOURCE ON

RESISTANCE vs JUNCTION TEMPERATURE

FIGURE 11. NORMALIZED GATE THRESHOLD VOLTAGE vs

JUNCTION TEMPERATURE

FIGURE 12. NORMALIZED DRAIN TO SOURCE BREAKDOWN

VOLTAGE vs JUNCTION TEMPERATURE

Typical Performance Curves

(Continued)

0

2

3

4

5

1

0

10

20

25

I

D,

DRAIN

CURRE

NT

(

A

)

V

GS

, GATE TO SOURCE VOLTAGE (V)

150

o

C

-55

o

C

25

o

C

PULSE DURATION = 80

µ

s

DUTY CYCLE = 0.5% MAX

V

DD

= 15V

30

15

5

0

10

0

1

2

3

20

I

D

, DRAIN

CURRE

NT

(

A

)

V

DS

, DRAIN TO SOURCE VOLTAGE (V)

30

5

15

4

I

D

, DRAIN

CURRE

NT

(

A

)

V

DS

, DRAIN TO SOURCE VOLTAGE (V)

PULSE DURATION = 80

µ

s

T

C

= 25

o

C

25

V

GS

= 3V

V

GS

= 3.5V

V

GS

= 4V

V

GS

= 5V

V

GS

= 4.5V

V

GS

= 10V

DUTY CYCLE = 0.5% MAX

50

100

150

0

4

V

GS

, GATE TO SOURCE VOLTAGE (V)

0

6

10

8

PULSE DURATION = 250

µ

s

r

DS

(

O

N)

, DRA

IN T

O

S

O

URCE

O

N

RE

S

I

S

T

ANCE

(

m

)

2

I

D

= 0.5A

I

D

= 2A

I

D

= 6.5A

DUTY CYCLE = 0.5% MAX

0.5

1.0

1.5

2.0

-80

-40

0

40

80

120

NO

RM

AL

IZ

E

D

DRAIN T

O

S

O

UR

CE

T

J

, JUNCTION TEMPERATURE (

o

C)

O

N

RE

S

I

S

T

ANCE

160

PULSE DURATION = 80

µ

s

V

GS

= 10V, I

D

= 6.5A

DUTY CYCLE = 0.5% MAX

-80

-40

0

40

80

120

0.6

0.7

0.8

1.0

1.2

NO

RM

AL

IZ

E

D

G

A

T

E

T

J

, JUNCTION TEMPERATURE (

o

C)

T

HRE

S

H

O

L

D V

O

L

T

A

G

E

V

GS

= V

DS

, I

D

= 250

µ

A

160

0.9

1.0

1.2

1.1

1.0

0.9

-80

-40

0

40

80

120

T

J

, JUNCTION TEMPERATURE (

o

C)

NO

RM

AL

IZ

E

D

DRAIN T

O

S

O

URCE

BRE

AKDO

W

N

V

O

L

T

A

G

E

I

D

= 250

µ

A

160

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

FIGURE 13. CAPACITANCE vs DRAIN TO SOURCE VOLTAGE

NOTE: Refer to Fairchild Application Notes AN7254 and AN7260.

FIGURE 14. GATE CHARGE WAVEFORMS FOR CONSTANT

GATE CURRENT

FIGURE 15. SWITCHING TIME vs GATE RESISTANCE

FIGURE 16. SWITCHING TIME vs GATE RESISTANCE

Test Circuits and Waveforms

FIGURE 17. UNCLAMPED ENERGY TEST CIRCUIT

FIGURE 18. UNCLAMPED ENERGY WAVEFORM

Typical Performance Curves

(Continued)

C

OSS

1200

800

0

0

5

15

25

C, CAP

A

C

IT

ANCE

(

p

F

)

1000

V

DS

, DRAIN TO SOURCE VOLTAGE (V)

600

30

400

C

ISS

C

RSS

10

20

200

V

GS

= 0V, f = 1MHz

C

ISS

= C

GS

+ C

GD

C

RSS

= C

GD

C

OSS

= C

DS

+ C

GD

10

8

6

4

0

V

GS

,

G

A

T

E

T

O

SO

U

R

C

E

V

O

L

T

A

G

E (

V

)

V

DD

= 15V

2

15

20

0

Q

g

, GATE CHARGE (nC)

5

I

D

= 6.5A

I

D

= 2.0A

I

D

= 0.5A

WAVEFORMS IN

DESCENDING ORDER:

10

30

20

30

40

50

0

120

90

60

0

10

S

W

IT

CHING

T

I

M

E

(

n

s

)

R

GS

, GATE TO SOURCE RESISTANCE (

)

t

d(OFF)

t

d(ON)

t

r

t

f

V

GS

= 4.5V, V

DD

= 15V, I

D

= 2A, R

L

= 7.5

60

20

30

40

50

0

150

120

90

0

10

S

W

IT

CHING

T

I

M

E

(

n

s

)

R

GS

, GATE TO SOURCE RESISTANCE (

)

t

d(OFF)

t

d(ON)

t

r

t

f

V

GS

= 10V, V

DD

= 15V, I

D

= 6.5A, R

L

= 2.31

30

t

P

V

GS

0.01

L

I

AS

+

-

V

DS

V

DD

R

G

DUT

VARY t

P

TO OBTAIN

REQUIRED PEAK I

AS

0V

V

DD

V

DS

BV

DSS

t

P

I

AS

t

AV

0

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

Thermal Resistance vs. Mounting Pad Area

The maximum rated junction temperature, T

J(MAX)

, and the

thermal resistance of the heat dissipating path determines

the maximum allowable device power dissipation, P

D(MAX)

,

in an application. Therefore the application's ambient

temperature, T

A

(

o

C), and thermal resistance R

JA

(

o

C/W)

must be reviewed to ensure that T

J(MAX)

is never exceeded.

Equation 1 mathematically represents the relationship and

serves as the basis for establishing the rating of the part.

In using surface mount devices such as the SO-8 package,

the environment in which it is applied will have a significant

influence on the part's current and maximum power

dissipation ratings. Precise determination of the P

D(MAX)

is

complex and influenced by many factors:

1. Mounting pad area onto which the device is attached and

whether there is copper on one side or both sides of the

board

2. The number of copper layers and the thickness of the

board

3. The use of external heat sinks

4. The use of thermal vias

5. Air flow and board orientation

6. For non steady state applications, the pulse width, the

duty cycle and the transient thermal response of the part,

the board and the environment they are in.

Fairchild provides thermal information to assist the

designer's preliminary application evaluation. Figure 23

defines the R

JA

for the device as a function of the top

copper (component side) area. This is for a horizontally

FIGURE 19. GATE CHARGE TEST CIRCUIT

FIGURE 20. GATE CHARGE WAVEFORMS

FIGURE 21. SWITCHING TIME TEST CIRCUIT

FIGURE 22. SWITCHING TIME WAVEFORMS

Test Circuits and Waveforms

(Continued)

R

L

V

GS

+

-

V

DS

V

DD

DUT

I

g(REF)

V

DD

Q

g(TH)

V

GS

= 1V

Q

g(5)

V

GS

= 5V

Q

g(TOT)

V

GS

= 10

V

DS

V

GS

I

g(REF)

0

0

V

GS

R

L

R

GS

DUT

+

-

V

DD

V

DS

V

GS

t

ON

t

d(ON)

t

r

90%

10%

V

DS

90%

10%

t

f

t

d(OFF)

t

OFF

90%

50%

50%

10%

PULSE WIDTH

V

GS

0

0

(EQ. 1)

P

DMAX

T

JM AX

T

A

≠

(

)

Z

JA

----------------------------------------

=

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

positioned FR-4 board with 1oz copper after 1000 seconds

of steady state power with no air flow. This graph provides

the necessary information for calculation of the steady state

junction temperature or power dissipation. Pulse applications

can be evaluated using the Fairchild device Spice thermal

model or manually utilizing the normalized maximum

transient thermal impedance curve.

Displayed on the curve are the three R

JA

values listed in

the Electrical Specifications table. The three points where

chosen to depict the compromise between the copper board

area, the thermal resistance and ultimately the power

dissipation, P

D(MAX)

. Thermal resistances corresponding to

other component side copper areas can be obtained from

Figure 23 or by calculation using Equation 2. The area, in

square inches is the top copper area including the gate and

source pads.

R

JA

(

o

C/W

)

50

100

150

200

AREA, TOP COPPER AREA (in

2

)

0.01

0.1

1.0

R

JA

= 79.3 - 21.8

*

ln(AREA)

143

o

C/W - 0.054in

2

177

o

C/W - 0.0115in

2

FIGURE 23. THERMAL RESISTANCE vs MOUNTING PAD AREA

0.001

250

(EQ. 2)

R

JA

79.3

21.8

Area

(

)

ln

◊

≠

=

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

PSPICE Electrical Model

SUBCKT HUF76113SK8 2 1 3 ;

REV 4 June 1998

CA 12 8 9.60-10

CB 15 14 9.95e-10

CIN 6 8 5.01e-10

DBODY 7 5 DBODYMOD

DBREAK 5 11 DBREAKMOD

DPLCAP 10 5 DPLCAPMOD

EBREAK 11 7 17 18 32.3

EDS 14 8 5 8 1

EGS 13 8 6 8 1

ESG 6 10 6 8 1

EVTHRES 6 21 19 8 1

EVTEMP 20 6 18 22 1

IT 8 17 1

LDRAIN 2 5 1.00e-9

LGATE 1 9 1.00e-9

LSOURCE 3 7 2.27e-10

MMED 16 6 8 8 MMEDMOD

MSTRO 16 6 8 8 MSTROMOD

MWEAK 16 21 8 8 MWEAKMOD

RBREAK 17 18 RBREAKMOD 1

RDRAIN 50 16 RDRAINMOD 2.01e-3

RGATE 9 20 2.94

RLDRAIN 2 5 10

RLGATE 1 9 10

RLSOURCE 3 7 2.27

RSLC1 5 51 RSLCMOD 1e-6

RSLC2 5 50 1e3

RSOURCE 8 7 RSOURCEMOD 17.50e-3

RVTHRES 22 8 RVTHRESMOD 1

RVTEMP 18 19 RVTEMPMOD 1

S1A 6 12 13 8 S1AMOD

S1B 13 12 13 8 S1BMOD

S2A 6 15 14 13 S2AMOD

S2B 13 15 14 13 S2BMOD

VBAT 22 19 DC 1

ESLC 51 50 VALUE={(V(5,51)/ABS(V(5,51)))*(PWR(V(5,51)/(1e-6*180),2.5))}

.MODEL DBODYMOD D (IS = 9.35e-13 RS = 1.39e-2 TRS1 = 1.12e-6 TRS2 = 1.05e-6 CJO = 9.85e-10 TT = 2.82e-8 M = 0.42 )

.MODEL DBREAKMOD D (RS = 1.91e-1 TRS1 = 3.51e-3 TRS2 = 1.21e-6 )

.MODEL DPLCAPMOD D (CJO = 5.51e-10 IS = 1e-30 N = 10 M = 0.60 )

.MODEL MMEDMOD NMOS (VTO = 1.76 KP = 3.55 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u RG = 2.94)

.MODEL MSTROMOD NMOS (VTO = 2.08 KP = 37 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u)

.MODEL MWEAKMOD NMOS (VTO = 1.48 KP = 0.095 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u RG = 29.4 RS=0.1)

.MODEL RBREAKMOD RES (TC1 = 1.02e-3 TC2 = 1.10e-7)

.MODEL RDRAINMOD RES (TC1 = 4.05e-2 TC2 = 1.12e-4)

.MODEL RSLCMOD RES (TC1 = 9.92e-3 TC2 = -2.06e-5)

.MODEL RSOURCEMOD RES (TC1 = 0 TC2 = 0)

.MODEL RVTHRESMOD RES (TC1 = -1.87e-3 TC2 = -5.42e-6)

.MODEL RVTEMPMOD RES (TC1 = -1.12e-3 TC2 = 1.12e-6)

.MODEL S1AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -7.00 VOFF= -1.55)

.MODEL S1BMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -1.55 VOFF= -7.00)

.MODEL S2AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 0.00 VOFF= 1.05)

.MODEL S2BMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 1.05 VOFF= 0.00)

.ENDS

NOTE: For further discussion of the PSPICE model, consult A New PSPICE Sub-Circuit for the Power MOSFET Featuring Global

Temperature Options; IEEE Power Electronics Specialist Conference Records, 1991, written by William J. Hepp and C. Frank Wheatley.

18

22

+

-

6

8

+

-

5

51

+

-

19

8

+

-

17

18

6

8

+

-

5

8

+

-

RBREAK

RVTEMP

VBAT

RVTHRES

IT

17

18

19

22

12

13

15

S1A

S1B

S2A

S2B

CA

CB

EGS

EDS

14

8

13

8

14

13

MWEAK

EBREAK

DBODY

RSOURCE

SOURCE

11

7

3

LSOURCE

RLSOURCE

CIN

RDRAIN

EVTHRES

16

21

8

MMED

MSTRO

DRAIN

2

LDRAIN

RLDRAIN

DBREAK

DPLCAP

ESLC

RSLC1

10

5

51

50

RSLC2

1

GATE

RGATE

EVTEMP

9

ESG

LGATE

RLGATE

20

+

-

+

-

+

-

6

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

SABER Electrical Model

nom temp=25 deg c HUF76113SK8 Ultrafet

REV 4 June 98

template huf76113sk8 n2,n1,n3

electrical n2,n1,n3

{

var i iscl

d..model dbodymod = (is=9.35e-13, cjo= 9.85e-10,tt=2.82e-8, m=0.42)

d..model dbreakmod = ()

d..model dplcapmod = (cjo=5.51e-10,is=1e-30,n=10,m=0.60)

m..model mmedmod = (type=_n,vto=1.76,kp=3.55,is=1e-30, tox=1)

m..model mstrongmod = (type=_n,vto=2.08,kp=37,is=1e-30, tox=1)

m..model mweakmod = (type=_n,vto=1.48,kp=0.095,is=1e-30, tox=1)

sw_vcsp..model s1amod = (ron=1e-5,roff=0.1,von=-7.00,voff=-1.55)

sw_vcsp..model s1bmod = (ron=1e-5,roff=0.1,von=-1.55,voff=-7.00)

sw_vcsp..model s2amod = (ron=1e-5,roff=0.1,von=0,voff=1.05)

sw_vcsp..model s2bmod = (ron=1e-5,roff=0.1,von=1.05,voff=0)

c.ca n12 n8 = 9.60e-10

c.cb n15 n14 = 9.95e-10

c.cin n6 n8 = 5.01e-10

d.dbody n7 n71 = model=dbodymod

d.dbreak n72 n11 = model=dbreakmod

d.dplcap n10 n5 = model=dplcapmod

i.it n8 n17 = 1

l.ldrain n2 n5 = 1e-9

l.lgate n1 n9 = 1e-9

l.lsource n3 n7 = 2.27e-10

m.mmed n16 n6 n8 n8 = model=mmedmod, l=1u, w=1u

m.mstrong n16 n6 n8 n8 = model=mstrongmod, l=1u, w=1u

m.mweak n16 n21 n8 n8 = model=mweakmod, l=1u, w=1u

res.rbreak n17 n18 = 1, tc1=1.02e-3,tc2=1.10e-7

res.rdbody n71 n5 =1.39e-2, tc1=1.12e-6, tc2=1.05e-6

res.rdbreak n72 n5 =1.91e-1, tc1=3.51e-3, tc2=1.21e-6

res.rdrain n50 n16 = 2.01e-3, tc1=4.05e-2,tc2=1.12e-4

res.rgate n9 n20 = 2.94

res.rldrain n2 n5 = 10

res.rlgate n1 n9 = 10

res.rlsource n3 n7 = 2.27

res.rslc1 n5 n51 = 1e-6, tc1=-9.92e-3,tc2=-2.06e-5

res.rslc2 n5 n50 = 1e3

res.rsource n8 n7 = 17.5e-3, tc1=0,tc2=0

res.rvtemp n18 n19 = 1, tc1=-1.12e-3,tc2=1.12e-6

res.rvthres n22 n8 = 1, tc1=-1.87e-3,tc2=-5.42e-6

spe.ebreak n11 n7 n17 n18 = 32.3

spe.eds n14 n8 n5 n8 = 1

spe.egs n13 n8 n6 n8 = 1

spe.esg n6 n10 n6 n8 = 1

spe.evtemp n20 n6 n18 n22 = 1

spe.evthres n6 n21 n19 n8 = 1

sw_vcsp.s1a n6 n12 n13 n8 = model=s1amod

sw_vcsp.s1b n13 n12 n13 n8 = model=s1bmod

sw_vcsp.s2a n6 n15 n14 n13 = model=s2amod

sw_vcsp.s2b n13 n15 n14 n13 = model=s2bmod

v.vbat n22 n19 = dc=1

equations {

i (n51->n50) +=iscl

iscl: v(n51,n50) = ((v(n5,n51)/(1e-9+abs(v(n5,n51))))*((abs(v(n5,n51)*1e6/180))** 2.5 ))

}

}

18

22

+

-

6

8

+

-

19

8

+

-

17

18

6

8

+

-

5

8

+

-

RBREAK

RVTEMP

VBAT

RVTHRES

IT

17

18

19

22

12

13

15

S1A

S1B

S2A

S2B

CA

CB

EGS

EDS

14

8

13

8

14

13

MWEAK

EBREAK

DBODY

RSOURCE

SOURCE

11

7

3

LSOURCE

RLSOURCE

CIN

RDRAIN

EVTHRES

16

21

8

MMED

MSTRO

DRAIN

2

LDRAIN

RLDRAIN

DBREAK

DPLCAP

ISCL

RSLC1

10

5

51

50

RSLC2

1

GATE

RGATE

EVTEMP

9

ESG

LGATE

RLGATE

20

+

-

+

-

+

-

6

RDBODY

RDBREAK

72

71

HUF76113SK8

©2003 Fairchild Semiconductor Corporation

HUF76113SK8 Rev. B1

SPICE Thermal Model

(0.76 in

2

footprint)

REV 3 June 1998

HUF76113SK8

CTHERM1 th 6 3.75e-4

CTHERM2 6 5 3.05e-3

CTHERM3 5 4 3.70e-2

CTHERM4 4 3 2.52e-2

CTHERM5 3 2 8.50e-2

CTHERM6 2 tl 7.95e-1

RTHERM1 th 6 3.95e-2

RTHERM2 6 5 2.50e-1

RTHERM3 5 4 4.00e-1

RTHERM4 4 3 6.35

RTHERM5 3 2 2.02e1

RTHERM6 2 tl 4.80e1

SABER Thermal Model

(0.76 in

2

footprint)

SABER thermal model HUF76113SK8

template thermal_model th tl

thermal_c th, tl

{

ctherm.ctherm1 th 6 = 3.75e-4

ctherm.ctherm2 6 5 = 3.05e-3

ctherm.ctherm3 5 4 = 3.70e-2

ctherm.ctherm4 4 3 = 2.52e-2

ctherm.ctherm5 3 2 = 8.50e-2

ctherm.ctherm6 2 tl = 7.95e-1

rtherm.rtherm1 th 6 = 3.95e-2

rtherm.rtherm2 6 5 = 2.50e-1

rtherm.rtherm3 5 4 = 4.00e-1

rtherm.rtherm4 4 3 = 6.35

rtherm.rtherm5 3 2 = 2.02e1

rtherm.rtherm6 2 tl = 4.80e1

}

RTHERM4

RTHERM6

RTHERM5

RTHERM3

RTHERM2

RTHERM1

CTHERM4

CTHERM6

CTHERM5

CTHERM3

CTHERM2

CTHERM1

tl

2

3

4

5

6

th

JUNCTION

CASE

HUF76113SK8

Rev. I2

TRADEMARKS

The following are registered and unregistered trademarks Fairchild Semiconductor owns or is authorized to use and is not

intended to be an exhaustive list of all such trademarks.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY

PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY

LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF FAIRCHILD SEMICONDUCTOR

CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, or (c) whose failure to perform

when properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to

result in significant injury to the user.

2. A critical component is any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

PRODUCT STATUS DEFINITIONS

Definition of Terms

ACExTM

ActiveArrayTM

BottomlessTM

CoolFETTM

CROSSVOLTTM

DOMETM

EcoSPARKTM

E

2

CMOSTM

EnSignaTM

FACTTM

FACT Quiet SeriesTM

FAST

Æ

FASTrTM

FRFETTM

GlobalOptoisolatorTM

GTOTM

HiSeCTM

I

2

CTM

ImpliedDisconnectTM

ISOPLANARTM

LittleFETTM

MicroFETTM

MicroPakTM

MICROWIRETM

MSXTM

MSXProTM

OCXTM

OCXProTM

OPTOLOGIC

Æ

OPTOPLANARTM

PACMANTM

POPTM

Power247TM

PowerTrench

Æ

QFETTM

QSTM

QT OptoelectronicsTM

Quiet SeriesTM

RapidConfigureTM

RapidConnectTM

SILENT SWITCHER

Æ

SMART STARTTM

SPMTM

StealthTM

SuperSOTTM-3

SuperSOTTM-6

SuperSOTTM-8

SyncFETTM

TinyLogic

Æ

TruTranslationTM

UHCTM

UltraFET

Æ

VCXTM

Across the board. Around the world.TM

The Power FranchiseTM

Programmable Active DroopTM

Datasheet Identification

Product Status

Definition

Advance Information

Formative or In

Design

This datasheet contains the design specifications for

product development. Specifications may change in

any manner without notice.

Preliminary

First Production

This datasheet contains preliminary data, and

supplementary data will be published at a later date.

Fairchild Semiconductor reserves the right to make

changes at any time without notice in order to improve

design.

No Identification Needed

Full Production

This datasheet contains final specifications. Fairchild

Semiconductor reserves the right to make changes at

any time without notice in order to improve design.

Obsolete

Not In Production

This datasheet contains specifications on a product

that has been discontinued by Fairchild semiconductor.

The datasheet is printed for reference information only.