| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: FMS2020 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Advanced Product Information

1.1

1

Preliminary specifications subject to change without notice

Filtronic Compound Semiconductors Ltd

Contact Details (UK): Tel: +44 (0) 1325 301111 Fax: +44 (0) 1325 306177 Email: sales@filcs.com

Contact Details (USA): Tel: +1 (408) 850 5790 Fax: +1 (408) 850 5766 Email:

sales@filcsi.com

Website: www.filcs.com

FMS2020

GaAs Multi-Purpose Wide Band SPDT Switch

Features:

Available in die form

Suitable for L and S-band digital

cellular, cordless telephony and WLAN

applications

High isolation, 30dB typ at 2.5GHz

Low insertion loss, 0.4dB typ at 2.5GHz

P0.1dB > 35dBm

Functional Schematic

Description and Applications:

The FMS2020 is a low loss, high power and linear single pole dual throw Gallium Arsenide antenna

switch. The die is fabricated using the Filtronic FL05 0.5

µm switch process technology which offers

leading edge performance optimised for switch applications. The FMS2020 is designed for use in L

and S band wireless applications.

Electrical Specifications:

(T

AMBIENT

= 25∞C,V

control

= 0V/2.5V, Z

IN

= Z

OUT

= 50

)

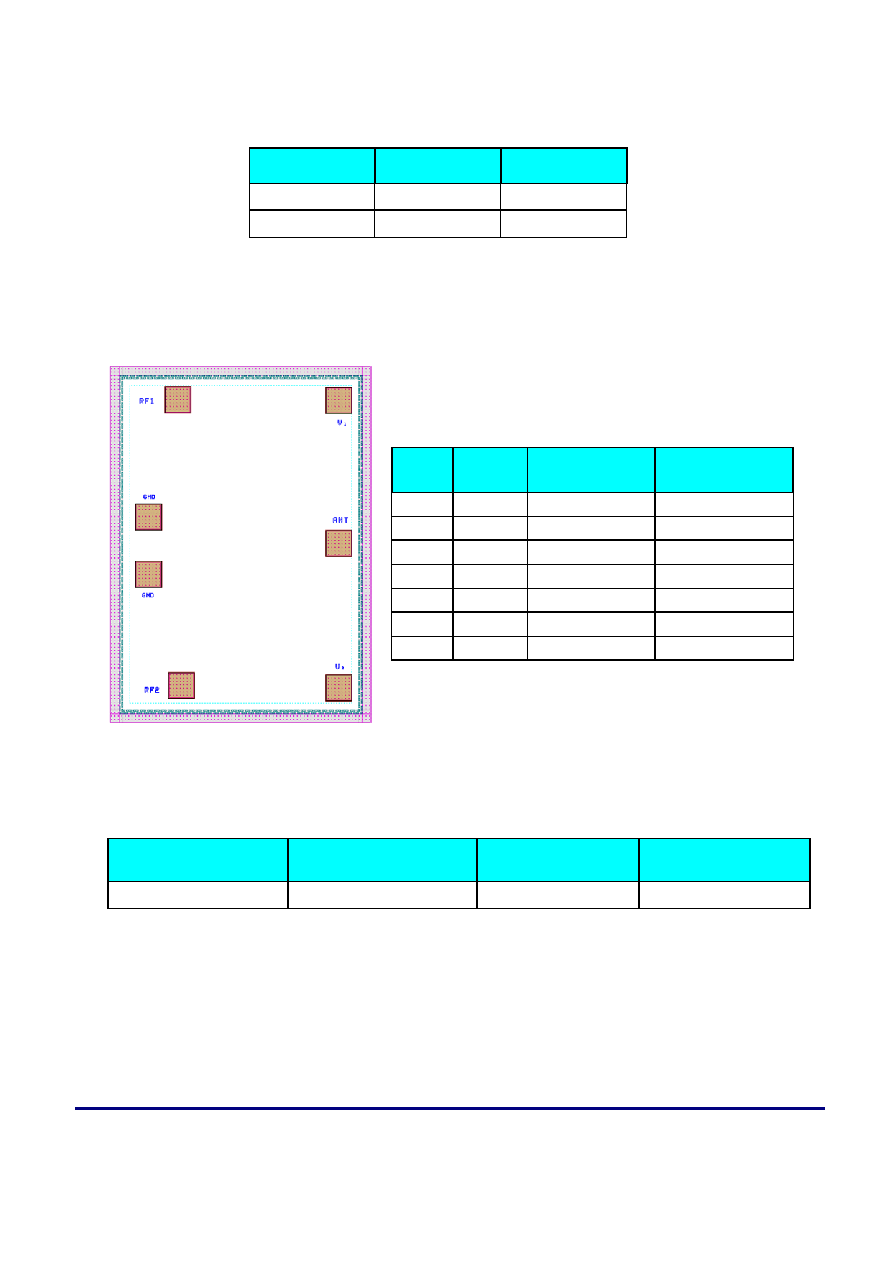

Parameter

Test Conditions

Min

Typ

Max

Units

Insertion Loss

0.5 ≠ 1.0 GHz

1.0 ≠ 2.5 GHz

0.4

0.4

dB

dB

Return Loss

0.5 ≠ 2.5 GHz

25

dB

Isolation

0.5 ≠ 1.0 GHz

1.0 ≠ 2.5 GHz

33

30

dB

dB

Input power at 0.1dB compression point

1GHz

36

2nd Harmonic Level

1 GHz, Pin = +35 dBm, 100% Duty Cycle

-75

dBc

3rd Harmonic Level

1 GHz, Pin = +35 dBm, 100% Duty Cycle

-75

dBc

Switching speed : Trise, Tfall

Ton, Toff

10% to 90% RF and 90% to 10% RF

50% control to 90% RF and 50% control to 10%

RF

<0.3

<1.0

µs

µs

Control

Current

1 µA

Note: External DC blocking capacitors are required on all RF ports (typ: 100pF)

ANT

V1

RF1

V2

RF2

Advanced Product Information

1.1

2

Preliminary specifications subject to change without notice

Filtronic Compound Semiconductors Ltd

Contact Details (UK): Tel: +44 (0) 1325 301111 Fax: +44 (0) 1325 306177 Email: sales@filcs.com

Contact Details (USA): Tel: +1 (408) 850 5790 Fax: +1 (408) 850 5766 Email:

sales@filcsi.com

Website: www.filcs.com

FMS2020

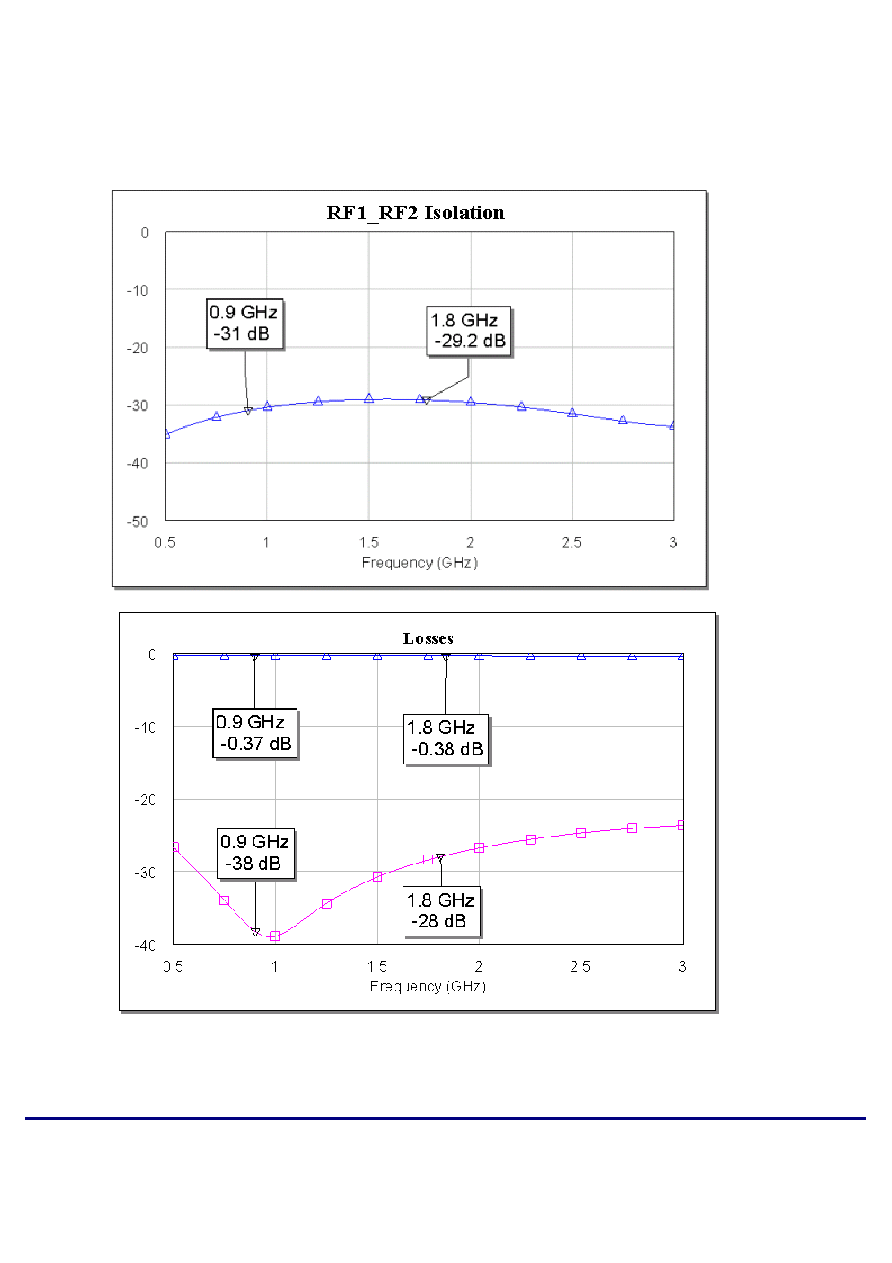

Truth Table:

V1

V2

PATH (ON)

High Low

RF1-ANT

Low High

RF2-ANT

Note:

`High' = +2.5V to +5V

`Low' = 0V to 0.2V

Pad and Die Layout:

Note: Co-ordinates are referenced from the bottom left hand corner of the die to the centre of the

bond pad opening

Die Size (

µm)

Die Thickness (

µm)

Min. Bond Pad

Pitch(

µm)

Min. Bond pad

opening (

µm)

930 x 1020(engineering mask)

100

166

70 x 70

Pad

Pad

Name

Description

Pin Coordinates

(µm)

A ANT

Antenna

732,

510

B RF1

RF1

Output

270,

920

C RF2

RF2 Output

280, 101

D

V1

RF1 Control Voltage

731, 918

E V2

RF2 Control Voltage

734, 98

F

GND T1

Ground 1

186, 885

G

GND T2

Ground 2

186, 420

A

B

G

F

E

D

C

Advanced Product Information

1.1

3

Preliminary specifications subject to change without notice

Filtronic Compound Semiconductors Ltd

Contact Details (UK): Tel: +44 (0) 1325 301111 Fax: +44 (0) 1325 306177 Email: sales@filcs.com

Contact Details (USA): Tel: +1 (408) 850 5790 Fax: +1 (408) 850 5766 Email:

sales@filss.com

Website: www.filcs.com

FMS2020

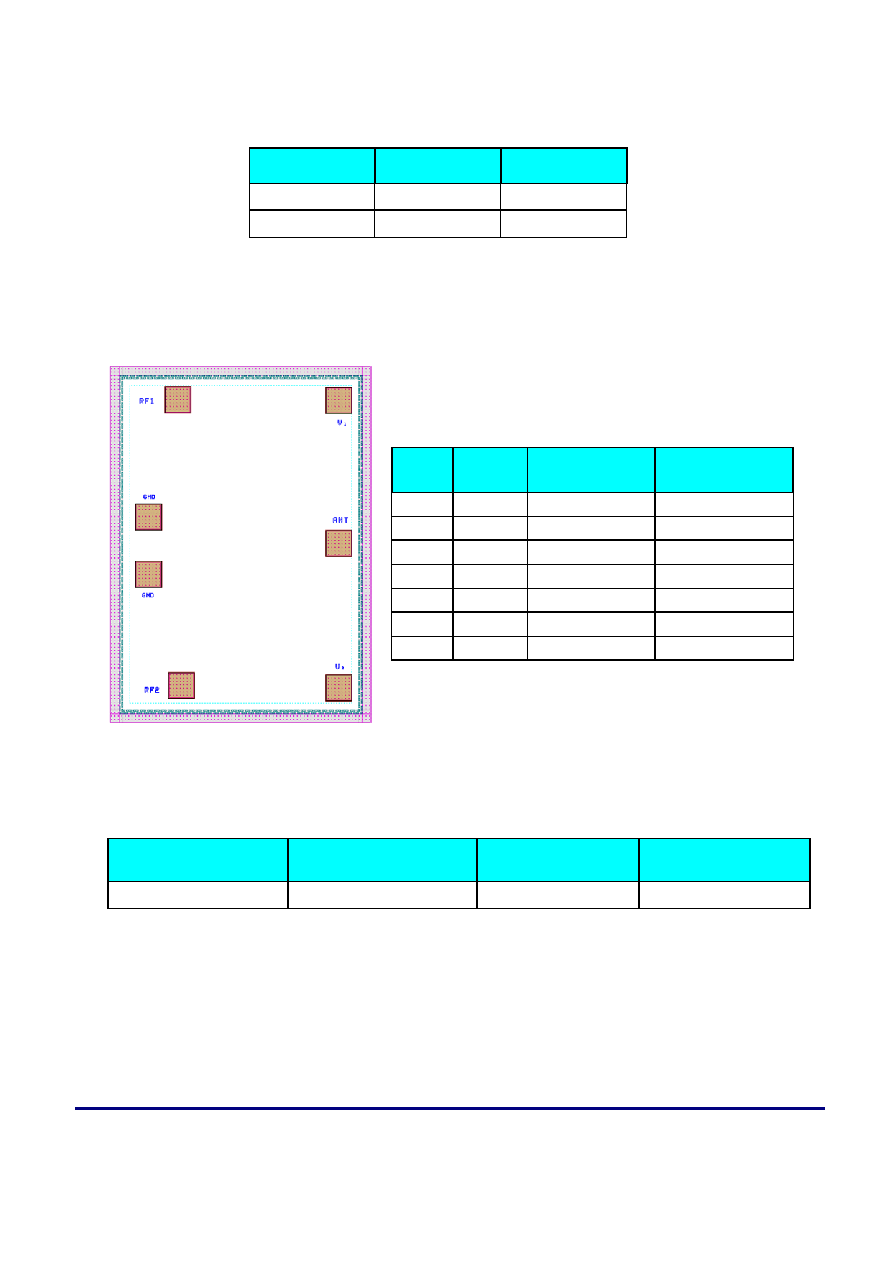

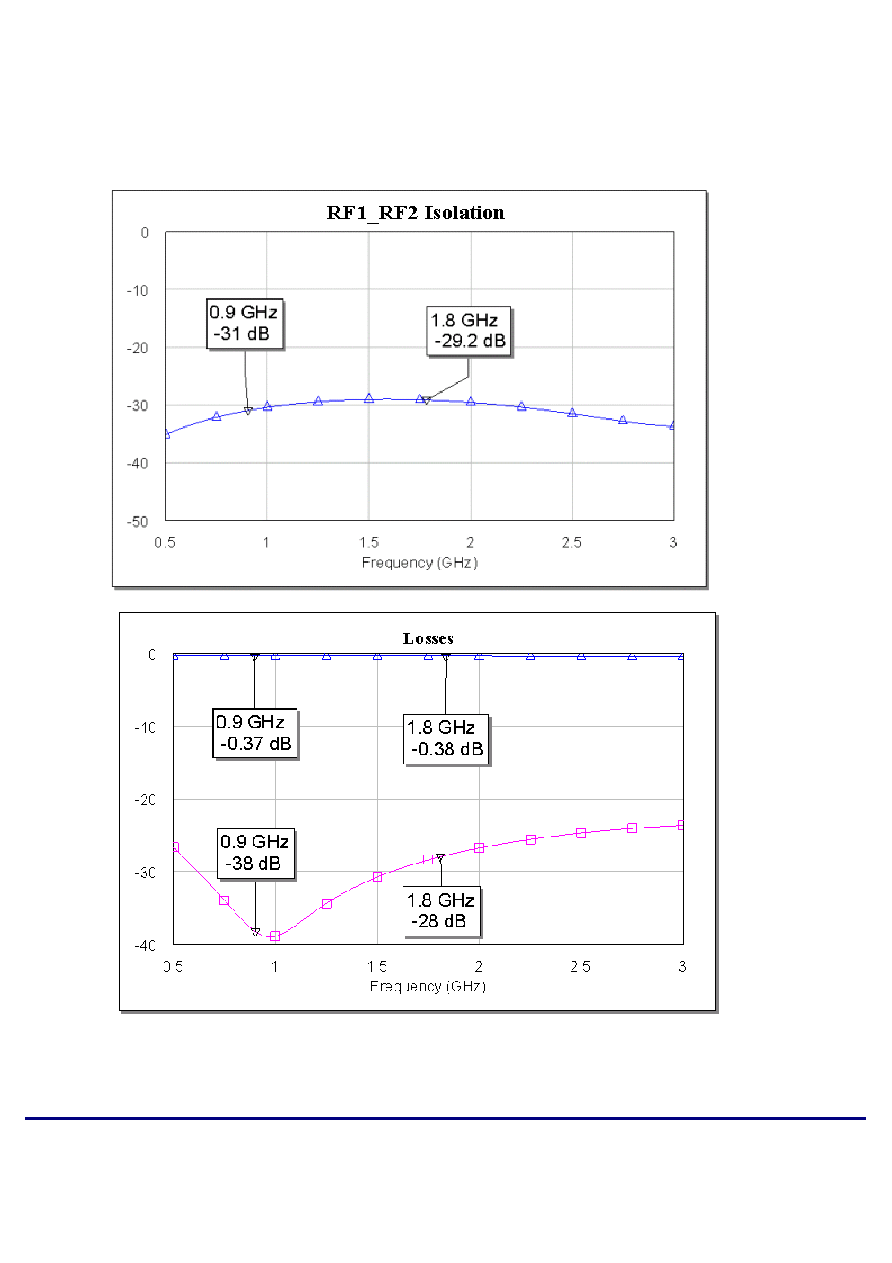

Simulated Performance:

Advanced Product Information

1.1

4

Preliminary specifications subject to change without notice

Filtronic Compound Semiconductors Ltd

Contact Details (UK): Tel: +44 (0) 1325 301111 Fax: +44 (0) 1325 306177 Email: sales@filcs.com

Contact Details (USA): Tel: +1 (408) 850 5790 Fax: +1 (408) 850 5766 Email:

sales@filss.com

Website: www.filcs.com

FMS2020

Preferred Assembly Instructions:

GaAs devices are fragile and should be handled with great care. Specially designed collets should be

used where possible.

The back of the die is not metallised and the recommended mounting method is by the use of

conductive epoxy. Epoxy should be applied to the attachment surface uniformly and sparingly to avoid

encroachment of epoxy on to the top face of the die and ideally should not exceed half the chip height.

For automated dispense Ablestick LMISR4 is recommended and for manual dispense Ablestick 84-1

LMI or 84-1 LMIT are recommended. These should be cured at a temperature of 150

∞C for 1 hour in

an oven especially set aside for epoxy curing only. If possible the curing oven should be flushed with

dry nitrogen.

This part has gold (Au) bond pads requiring the use of gold (99.99% pure) bondwire. It is

recommended that 25.4

µm diameter gold wire is used. Thermosonic ball bonding is preferred. A

nominal stage temperature of 150

∞C and a bonding force of 40g has been shown to give effective

results for 25

µm wire. Ultrasonic energy shall be kept to a minimum. For this bonding technique,

stage temperature should not be raised above 200

∞C and bond force should not be raised above 60g.

Thermosonic wedge bonding and thermocompression wedge bonding can also be used to achieve

good wire bonds.

Bonds should be made from the die first and then to the mounting substrate or package. The physical

length of the bondwires should be minimised especially when making RF or ground connections.

Handling Precautions:

To avoid damage to the devices care should be exercised during handling. Proper Electrostatic

Discharge (ESD) precautions should be observed at all stages of storage, handling, assembly, and

testing. These devices should be treated as Class 1A (0-500 V) as defined in JEDEC Standard No.

22-A114-B. Further information on ESD control measures can be found in MIL-STD-1686 and MIL-

HDBK-263.

Disclaimers:

This product is not designed for use in any space based or life sustaining/supporting equipment.