Chip Silicon Rectifier

FM4933 THRU FM4937

Fast recovery type

Features

Plastic package has Underwriters Laboratory

Flammability Classification 94V-O Utilizing Flame

Retardant Epoxy Molding Compound.

For surface mounted applications.

Exceeds environmental standards of MIL-S-19500 /

228

Low leakage current.

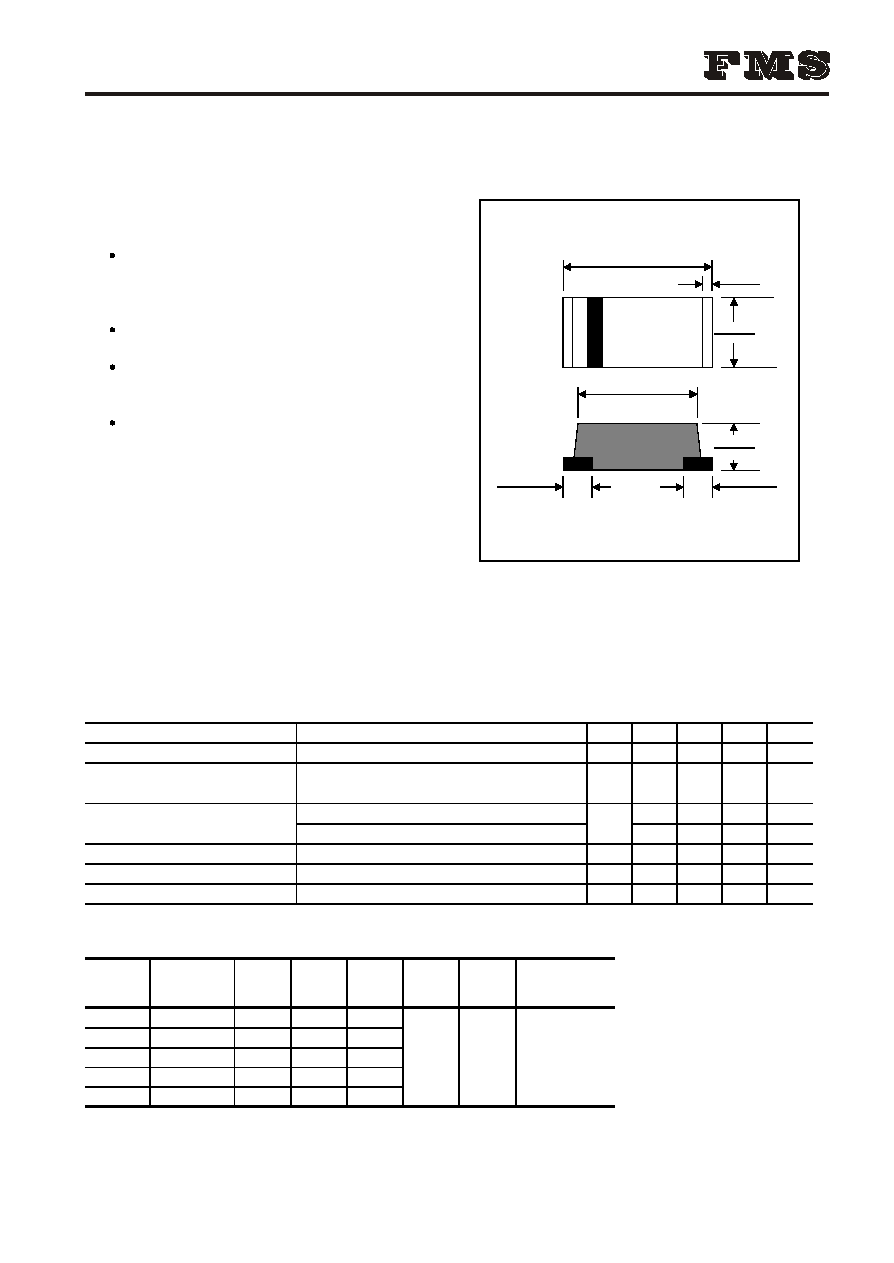

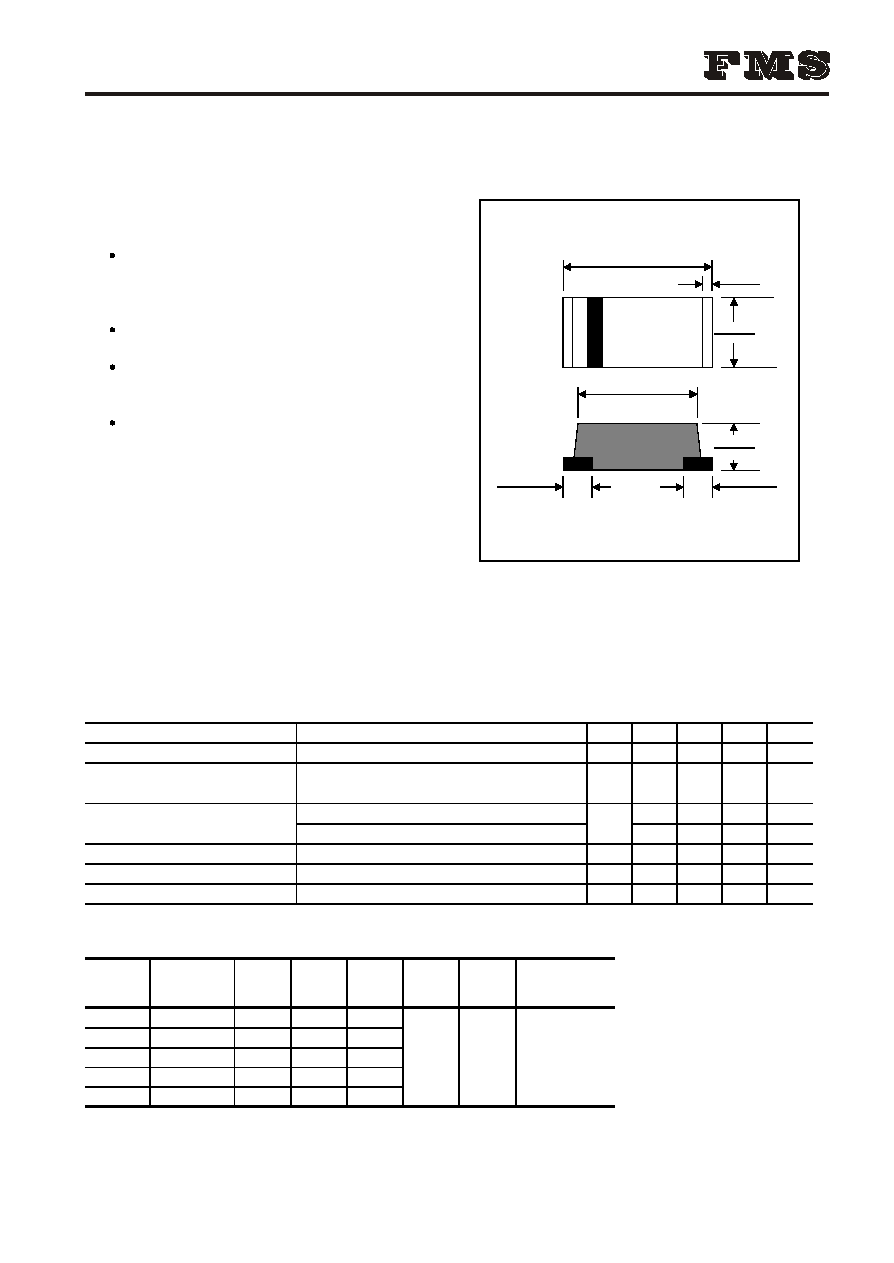

Mechanical data

Case : Molded plastic, JEDEC DO-214AC

Terminals : Solder plated, s olderable per MIL-STD-750,

Method 2026

Polarity : Indicated by cathode band

Mounting Position : Any

Weight : 0.0015 ounce, 0.05 gr am

(V)

(V)

(V)

(V)

(nS)

(

o

C)

FM4933

F93

50

35

50

FM4934

F94

100

70

100

FM4935

F95

200

140

200

FM4936

F96

400

280

400

FM4937

F97

600

420

600

SYMBOLS

MARKING

CODE

1.2

200

-55 to +150

Operating

temperature

V

RRM

*1

V

RMS

*2

V

R

*3

V

F

*4

T

RR

*5

MAXIMUM RATINGS

(AT T

A

=25

o

C unless otherwise noted)

PARAMETER

CONDITIONS

Symbol

MIN.

TYP.

MAX.

UNIT

Forward rectified current

Ambient temperature = 55

o

C

I

O

1.0

A

Forward surge current

8.3ms single half sine-wave superimposed on

rate load (JEDEC methode)

I

FSM

30

A

V

R

= V

RRM

T

A

= 25

o

C

5.0

uA

V

R

= V

RRM

T

A

= 100

o

C

100

uA

Thermal resistance

Junction to ambient

R

q

JA

75

o

C / w

Diode junction capacitance

f=1MHz and applied 4vDC reverse voltage

C

J

15

pF

Storage temperature

T

J

-55

+150

o

C

Reverse current

I

R

*1 Repetitive peak reverse voltage

*2 RMS voltage

*3 Continuous reverse voltage

*4 Maximum forward voltage

*5 Reverse recovery time

Test condition : I

F

=1.0A, V

R

=30V

PATENT PUBLICATION NO. 37116

0.185(4.8)

0.177(4.4)

0.012(0.3) Typ.

0.110(2.8)

0.094(2.4)

0.165(4.2)

0.150(3.8)

0.067(1.7)

0.060(1.5)

0.040 (1.0) Typ.

0.040(1.0) Typ.

Dimensions in inches and (millimeters)

SMA

0.1

1.0

.01

10

50

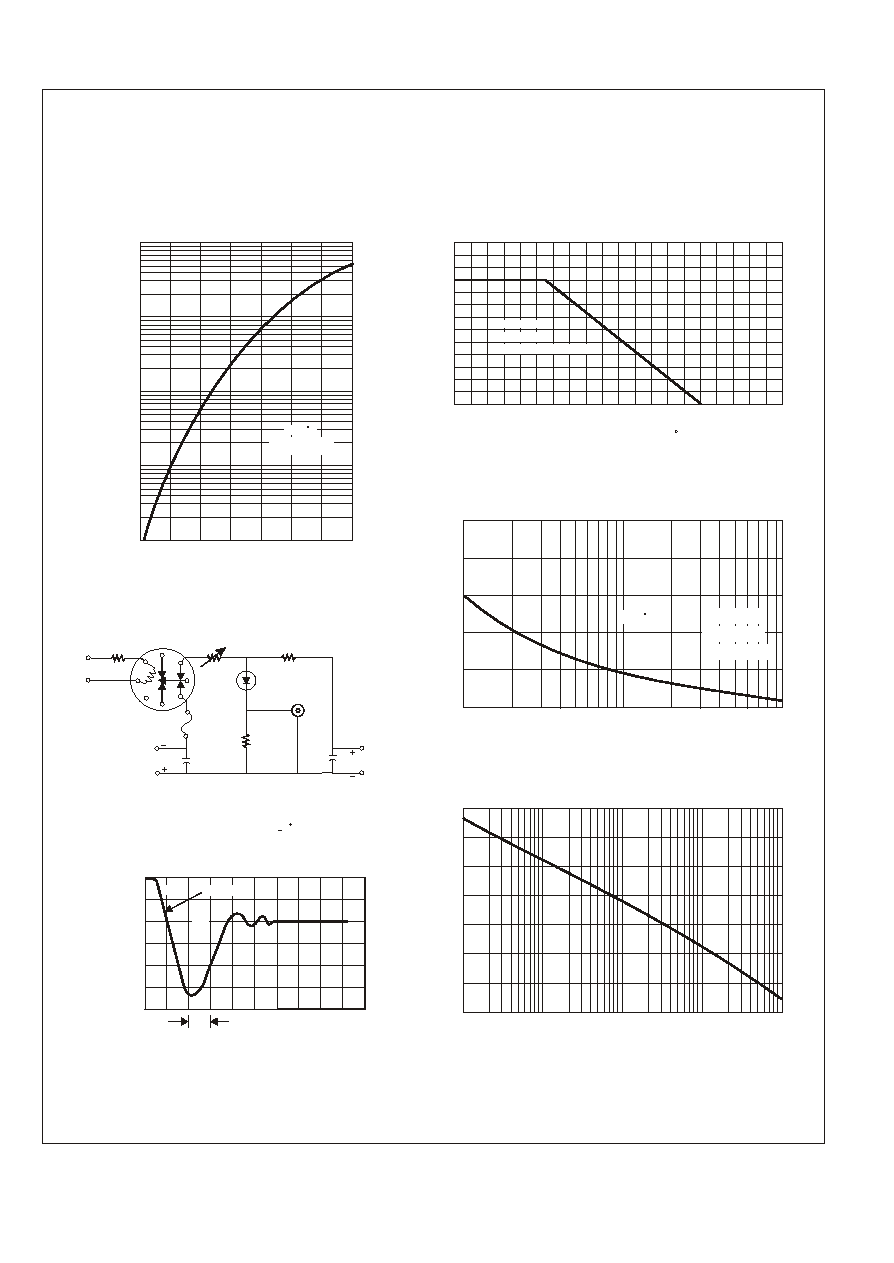

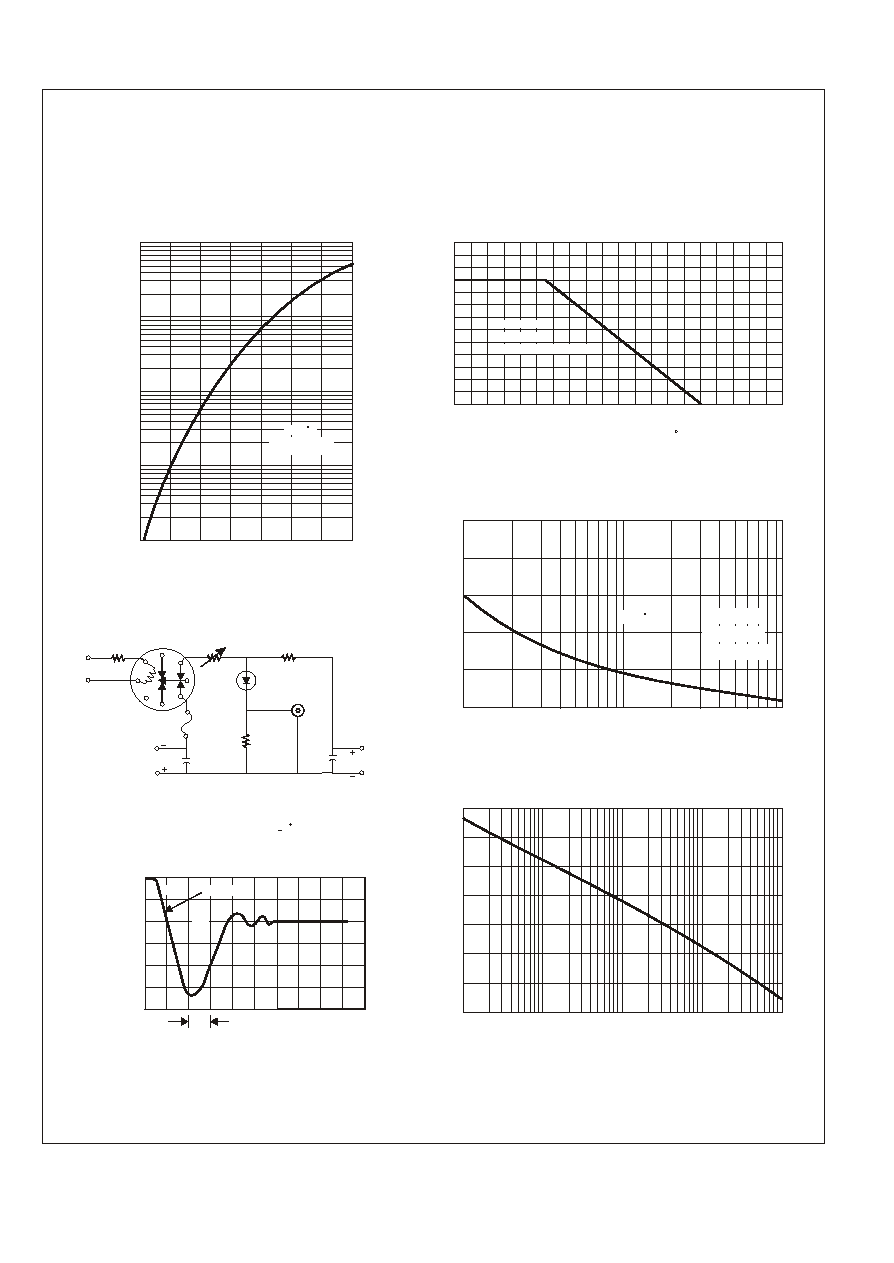

RATING AND CHARACTERISTIC CURVES (FM4933 THRU FM4937)

CHARACTERISTICS

FIG.2-TYPICAL FORWARD CURRENT DERATING CURVE

A

V

E

R

A

G

E

F

O

R

W

A

R

D

C

U

R

R

E

N

T

,

(

A

)

FIG.5-TYPICAL JUNCTION CAPACITANCE

REVERSE VOLTAGE,(V)

J

U

N

C

T

I

O

N

C

A

P

A

C

I

T

A

N

C

E

,

(

p

F

)

I

N

S

T

A

N

T

A

N

E

O

U

S

F

O

R

W

A

R

D

C

U

R

R

E

N

T

,

(

A

)

FORWARD VOLTAGE,(V)

Pulse Width 300us

1% Duty Cycle

0.2

0

0.4

0.6

0.8

1.0

1.2

35

30

25

20

15

10

5

0

IFM 1.0

0

IRM(REC) 2.0

1cm

SET TIME BASE FOR

50 / 100ns / cm

.01 .05 .1 .5 1 5 10 50 100

.6 .8 1.0 1.2 1.4 1.6 1.8 2.0

3.0

FIG.3- TEST CIRCUIT DIAGRAM AND REVERSE

RECOVERY TIME CHARACTERISTICS

W

W

W

W

Tj=25 C

FIG.4-MAXIMUM NON-REPETITIVE FORWARD

SURGE CURRENT

10

0

20

30

40

50

NUMBER OF CYCLES AT 60Hz

1

10

5

50

100

Tj=25 C

8.3ms Single Half

Sine Wave

JEDEC method

0 20 40 60 80 100 120 140 160 180 200

Single Phase

Half Wave 60Hz

Resistive Or Inductive Load

10K

2W

115Va

60Hz

1

2

3

4

8

7

6

5

C P CLARE

HPG1002

30Vdc

CONSTANT VOLTAGE

SUPPLY

C1

1.0

m

F

300V

C1

1.0

m

F

300V

1.0Adc FROM

CONSTANT

VOLTAGE SUPPLY

RIPPLE=3mVrms MAX.

1 AMP

SLO-BLO

FUSE

R1

3

25W

R2

1 /10W

NON-

INDUCTIVE

UNIT

UNDER TEST

30 /50W

NON-INDUCTIVE

Zout 1 / MAX.

DC To 2KHz

1

2

MINIMIZE ALL LEAD LENGTHS

A

A-TEKTRONIX 545A. K PLUG IN R2- TEN 1W 10 1% CARBON CORE

PRE AMP P6000 PROBE OR EQUIVALENT IN PARALLEL

R1- ADJUSTED FOR 14 BETWEEN

POINT 2 OF RELAY AND RECTIFIER TA= 25 C FOR RECTIFIER

INDUCTIVE=3.8

m

H

trr

i(t)

di/dt=50A/

m

S

AMBIENT TEMPERATURE,( C)

FIG.1-TYPICAL FORWARD

P

E

A

K

F

O

R

W

A

R

D

S

U

R

G

E

C

U

R

R

E

N

T

,

(

A

)

P

E

A

K

F

O

R

W

A

R

D

S

U

R

G

E

C

U

R

R

E

N

T

,

(

A

)

W

+10

0