FIND Vol.17 No.3

FIND

,

Vol. 17, No. 3, August 1999

N E W

P R O D U C T S

·

M B 8 1 x x 6 4 3 2 4 2 B

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

2M x 32-Bit

Synchronous DRAM for

Multimedia

&

Graphics:

MB81F643242B

MB811L643242B

The SDRAMs in a 32-bit I/O configuration can provide the effective

solution for a wide range of applications, including multimedia and

graphics applications. Also, these SDRAMs employ the new SCITT

technology, thereby reducing the test time and cost.

Features

·

64 M-bit SDRAM with a 32-bit I/O

configuration

·

High performance series or low power

consumption series

·

Introduction of a new test technology,

SCITT

·

Reduced test time and cost using SCITT

·

Also available as extended operating-

temperature components

·

JEDEC Standard 86-pin TSOP package

Photo 1.

MB81xx643242B Appearance

17-3-b2.fm Page 31 Saturday, August 28, 1999 9:57 PM

FIND

,

Vol. 17, No. 3, August 1999

N E W

P R O D U C T S

·

M B 8 1 x x 6 4 3 2 4 2 B

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Overview

Synchronous DRAMs (SDRAMs) have been rapidly

increasing in popularity since they were employed

as main memory for personal computers. They have

also been used not only for computer main memory,

but also for various other applications, including

communications equipment, consumer products,

multimedia, graphics, and mobile products. It is ex-

pected that the 64 M-bit SDRAM with a 32-bit I/O

configuration will be adopted as the preferred con-

figuration for many of these applications.

FUJITSU has now developed two series of SDRAM

with a 32-bit I/O configuration:

·

The MB81F643242B is a high-performance

version, operating at a maximum frequency of

143 MHz. This SDRAM is the second-

generation product, based on the current

mass-production 2M x 32-bit SDRAM.

·

The MB811L643242B is a low-voltage, low

power consumption version operating at 2.5V.

These products employ a new test technology, Stat-

ic Component Interconnection Test Technology

(SCITT), developed by a

FUJITSU/Philips (Nether-

lands) collaboration. SCITT

is a new XNOR circuit-

based technology that is

used for board-level inter-

connection testing. Using SCITT's simple method

reduces the test time and cost required for board-

level interconnection testing.

Product Features

The MB81F643242B and MB811L643242B are

SDRAMs in a "4 banks x 512K words x 32 bits" con-

figuration, operating at supply voltages of 3.3V and

2.5V, respectively. These SDRAMs support the fol-

lowing settings:

·

CAS latency: 2 or 3

·

Burst length: 1, 2, 4, 8, or full page

·

Burst type: Sequential or interleave

The package is an 86-pin TSOP with a pin pitch of

0.5 mm, fully conforming to JEDEC standards. The

MB81F643242B Series consists of three speed ver-

sions: 143-MHz, 125-MHz, and 100-MHz. The

MB811L643242B also consists of three speed ver-

sions: 100-MHz, 84-MHz, and 67-MHz. Also, a low

power version is available.

FUJITSU also provides support for the SCITT functions

and for optional, extended operating-temperature

products for use in special environments.

Examples of applications for these SDRAMs are:

·

High-speed model: Graphics card, digital TV,

game equipment, etc.

·

Low-voltage model: Portable video camera,

digital camera, PDA, mobile computer,

consumer product built-in device, etc.

·

Extended operating-temperature models:

Automotive equipment, such as a car

navigation system, application-specific

products, etc.

·

Other applications: Copier, communications

equipment, etc.

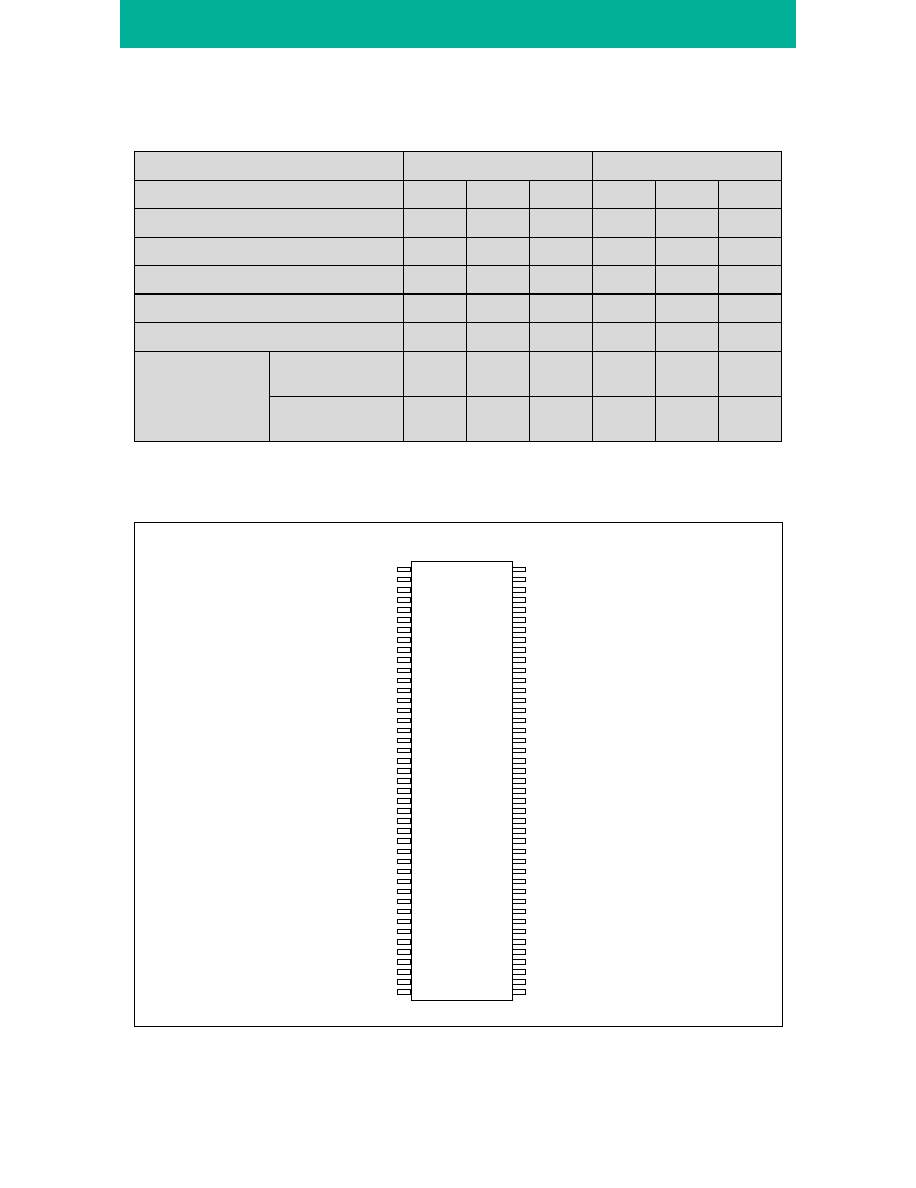

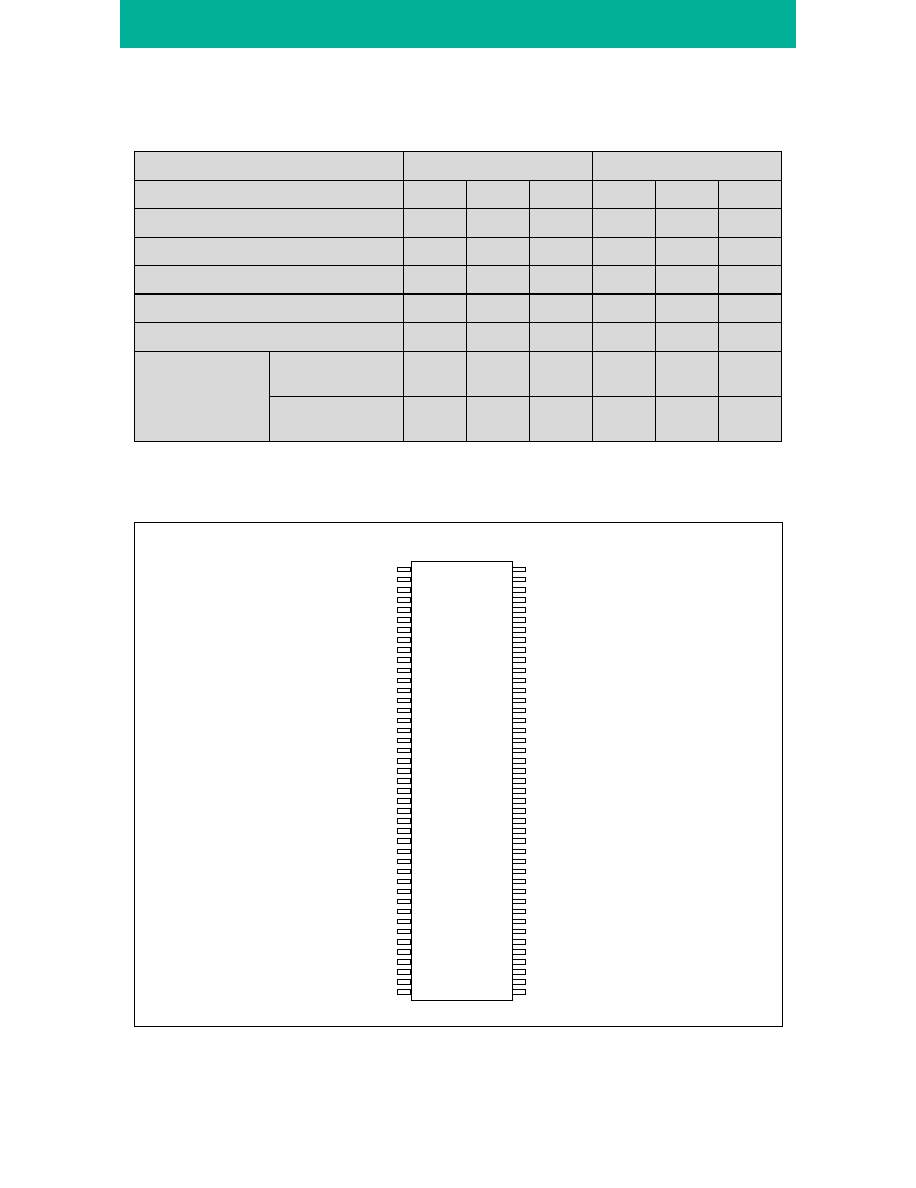

Table 1 lists the major characteristics of these

SDRAMs and Figure 1 shows their pin assignments.

". . . reduces the test time and

cost required for board-level

interconnection testing."

17-3-b2.fm Page 32 Saturday, August 28, 1999 9:57 PM

FIND

,

Vol. 17, No. 3, August 1999

N E W

P R O D U C T S

·

M B 8 1 x x 6 4 3 2 4 2 B

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Figure 1.

MB81F643242B/MB811L643242B Pin Assignments

Table 1.

MB81F643242B/MB811L643242B Major Characteristics

Part Number

MB81F643232B

MB811L643242B

Speed Version

70/70L

80/80L

10/10L

10/10L

12/12L

15/15L

Clock Frequency

MHz

143

125

100

100

84

67

Clock Cycle Time

t

CK

(min.)

ns

7

8

10

10

12

15

RAS Cycle Time

t

RC

(min.)

ns

63

72

90

90

100

110

RAS-CAS Delay Time t

RCD

(min.)

ns

21

24

30

30

30

30

RAS Precharge Time

t

RP

(min.)

ns

17

20

30

30

35

40

Clock Access Time

tAC

(CL=2)

ns

6

6

7

8

8

8

tAC

(CL=3)

ns

6

6

7

8

8

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

V

CC

DQ

0

V

CCQ

DQ

1

DQ

2

V

SSQ

DQ

3

DQ

4

V

CCQ

DQ

5

DQ

6

V

SSQ

DQ

7

NC

V

CC

DQM

0

/WE

/CAS

/RAS

/CS

NC

A

12

A

11

A

10

/AP

A

0

A

1

A

2

DQM

2

V

CC

NC

DQ

16

V

SSQ

DQ

17

DQ

18

V

CCQ

DQ

19

DQ

20

V

SSQ

DQ

21

DQ

22

V

CCQ

DQ

23

V

CC

V

SS

DQ

15

V

SSQ

DQ

14

DQ

13

V

CCQ

DQ

12

DQ

11

V

SSQ

DQ

10

DQ

9

V

CCQ

DQ

8

NC

V

SS

DQM

1

NC

NC

CLK

CKE

A

9

A

8

A

7

A

6

A

5

A

4

A

3

DQM

3

V

SS

NC

DQ

31

V

CCQ

DQ

30

DQ

29

V

SSQ

DQ

28

DQ

27

V

CCQ

DQ

26

DQ

25

V

SSQ

DQ

24

V

SS

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

Pin No.

Pin No.

Pin Symbol

Pin Symbol

Top View

400 mil x 875 mil

86-Pin TSOP

Pin Pitch

= 0.5 mm

Low Addresses:

A

0

to A

10

Bank Addresses:

A

11

, A

12

Column Addresses:

A

0

to A

7

Auto-Precharge:

A

10

spacer

17-3-b2.fm Page 33 Saturday, August 28, 1999 9:57 PM

FIND

,

Vol. 17, No. 3, August 1999

N E W

P R O D U C T S

·

M B 8 1 x x 6 4 3 2 4 2 B

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

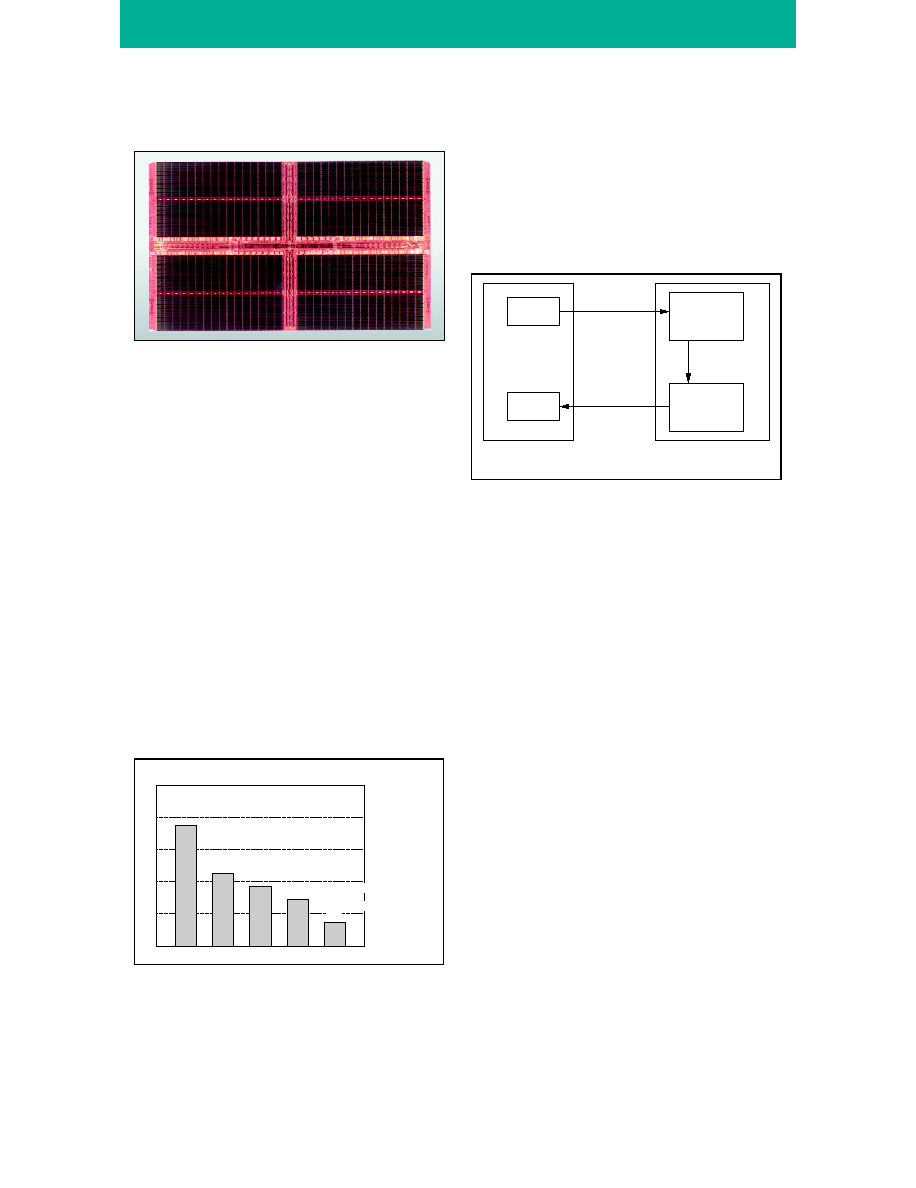

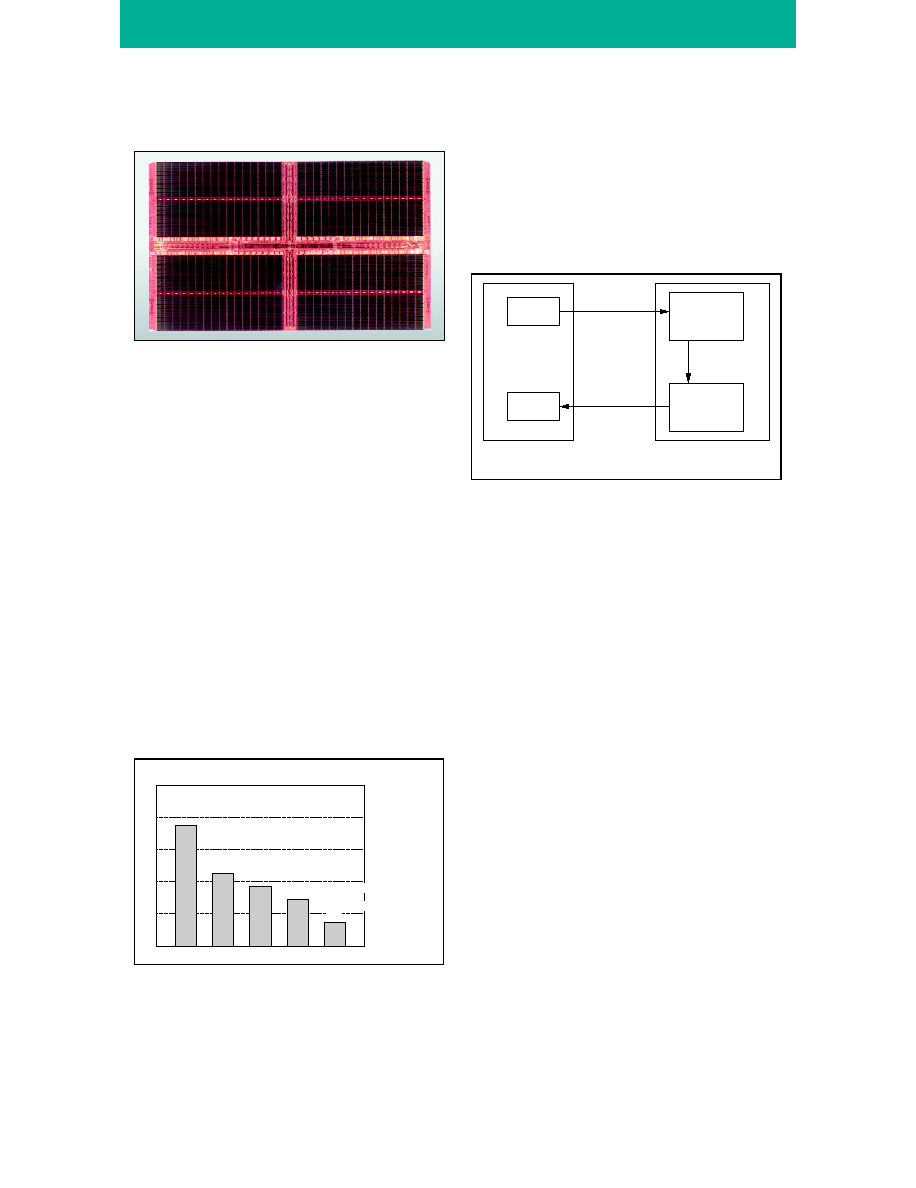

Photo 2.

MB81xx643242B Chip

SCITT Functions

Most of the failures occurring after mounting LSIs on

the board are attributable to open-circuit, mounting,

or short-circuit faults. In addition, new packaging

technologies make the post-mounting test more

complicated. Considering these factors, FUJITSU,

in collaboration with Philips, planned and developed

the method for simply testing the mutual connection

between LSIs mounted on the board.

Figure 2 shows post-mounting fault ratios. Figure 3

illustrates the basic concept of SCITT technology,

developed for detecting connection faults.

Figure 2. Post-Mounting Fault Ratios

The host controller outputs a test pattern on the ad-

dress and control pins to memory. This test pattern

had been stored in ROM in the host controller during

controller design. The memory outputs a correspond-

ing test pattern to the host controller via the I/O pins.

The host side then checks the output pattern from the

memory and compares the expected value and actu-

al output value to detect open-circuit faults, short-

circuit faults, missing LSIs, and mounting errors.

Figure 3. SCITT Technology Basic Concept

SCITT Advantages

The following features of SCITT can be listed as its

advantages over the boundary scan method.

·

No need for dedicated pins

·

Short test time: 1/1,000 of the current test

time or less

·

Fault reject ratio: almost 100%

·

Insignificant increase in chip size

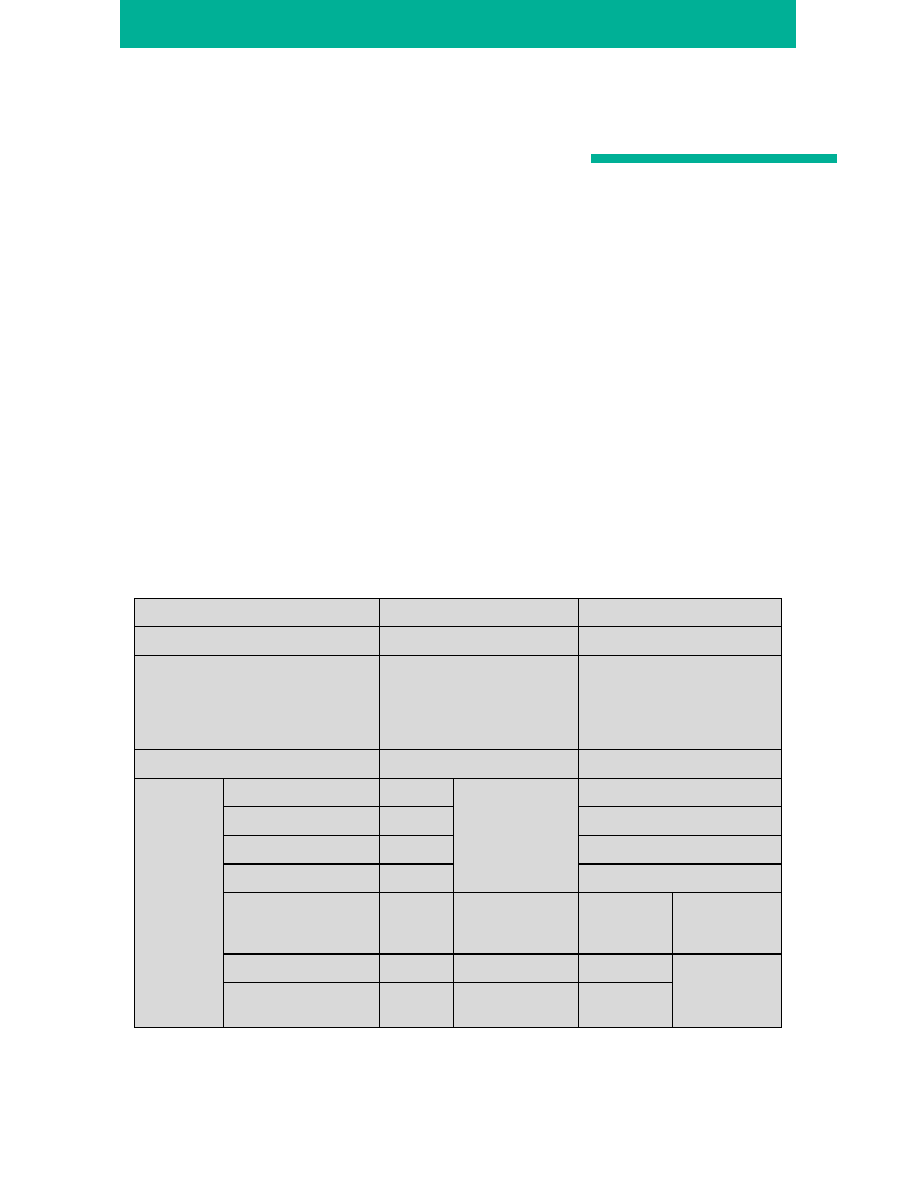

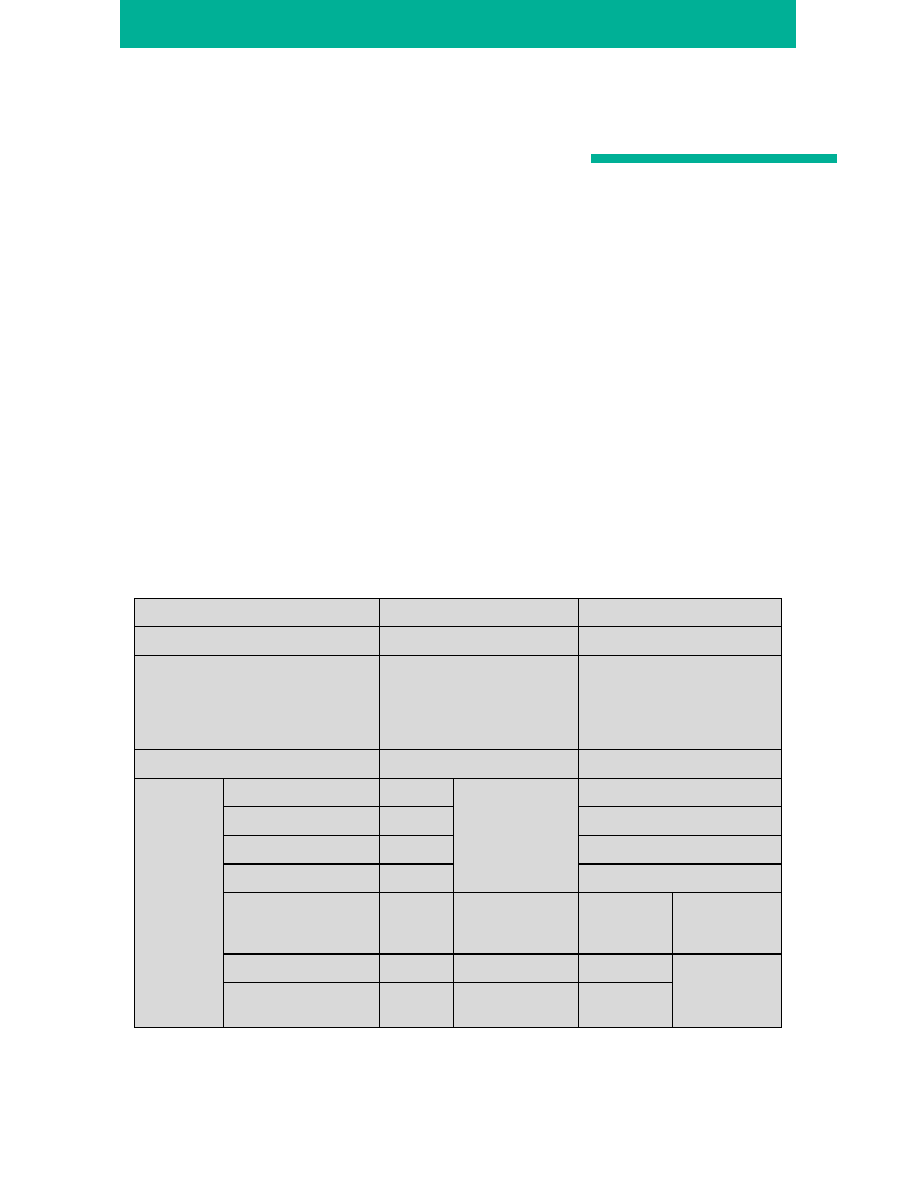

Table 2 compares the interconnection tests by the

SCITT and boundary scan methods.

SCITT Specifications for SDRAM

The SDRAM with SCITT functions has the following

SCITT specifications.

Figure 4 shows the state diagram of SCITT mode. As

shown in the figure, the SCITT functions are execut-

ed only before initialization after the supply voltage

is applied. The SCITT functions are optional; the ex-

ecution is not required.

50

40

30

20

10

0

37%

22%

19%

14%

Open-Circuit Failure

Mounting Failure

Analog Failure

7%

(%)

LSI Function Failure

Short-Circuit Failure

ROM

ROM &

Decoder

Output

Buffer

Evaluation

Memory

Controller

Memory

x Address

Data Bus

x Address: Address + Control Line

17-3-b2.fm Page 34 Saturday, August 28, 1999 9:57 PM

FIND

,

Vol. 17, No. 3, August 1999

N E W

P R O D U C T S

·

M B 8 1 x x 6 4 3 2 4 2 B

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

The SCITT mode is controlled by the inputs from

three pins: /CAS, /CS, and CKE. Each pin has the

following functions:

·

/CAS: For test mode entry/exit control

·

/CS: For chip select control

·

CKE: For test mode select control

Table 3 is the SCITT function table. Figure 5 shows

the timings for entry to and exit from the SCITT

mode. Figures 6 and 7 show test timings. Table 4

lists AC timing values.

Figures 8 and 9 show test patterns to be applied to

2M x 32-bit SDRAM. The applied test patterns con-

sist of "walking-0," "walking-1," "all-0," and "all-1."

Using these simple test patterns contributes to the

significant reduction in test time.

Details on SCITT technology will be presented in

collaboration with

Philips in the Inter-

national Test Con-

ference to be held

in October 1999.

The SCITT functions have been tested on actual ap-

plications and have verified the proof of concept

and effectiveness. These functions are applicable

not only to SDRAMs but also other devices. Follow-

ing the accelerated trend of implementing equip-

ment in digital form, multimedia products and

consumer products will increasingly incorporate a

mixture of Digital Signal Processors (DSPs), high-

speed DRAMs, and flash memory. If the host pro-

cessor can perform the SCITT type of interconnec-

tion test for each memory device, the efficiency of

the test will be dramatically improved.

<

Table 2.

SCITT and Boundary Scan Method Comparison

Item

Boundary Scan

SCITT Technology

Dedicated Pins Required

5 Pins

None

Components

Shift Register/Pin

TAP Controller

Instruction Register

Bypass Register

IDCODE Register

ROM (or decoder)

Comparator Circuit (controller

side)

Die Size Penalty

Yes

Negligible

Test Items

Open-Circuit Fault

Yes

EX Test Feature

Sample/Preload

Feature

Bypass Feature

Yes

Short-Circuit Fault

Yes

Yes

Missing IC

Yes

Yes

Mounting Error

Yes

Yes

Internal Logic

Inspection

Yes

Run Test Feature

IN Test Feature

No

Covered by

Component

Shipping Test

ID Code Check

Yes

ID Code Feature

No

Covered by

DIMM/SPD

Function

User Code Check

Yes

User Code

Feature

No

"Using these simple test patterns

contributes to the significant

reduction in test time."

17-3-b2.fm Page 35 Saturday, August 28, 1999 9:57 PM