DATA SHEET

Position Sensor C7339

(For Laser Beam Alignment)

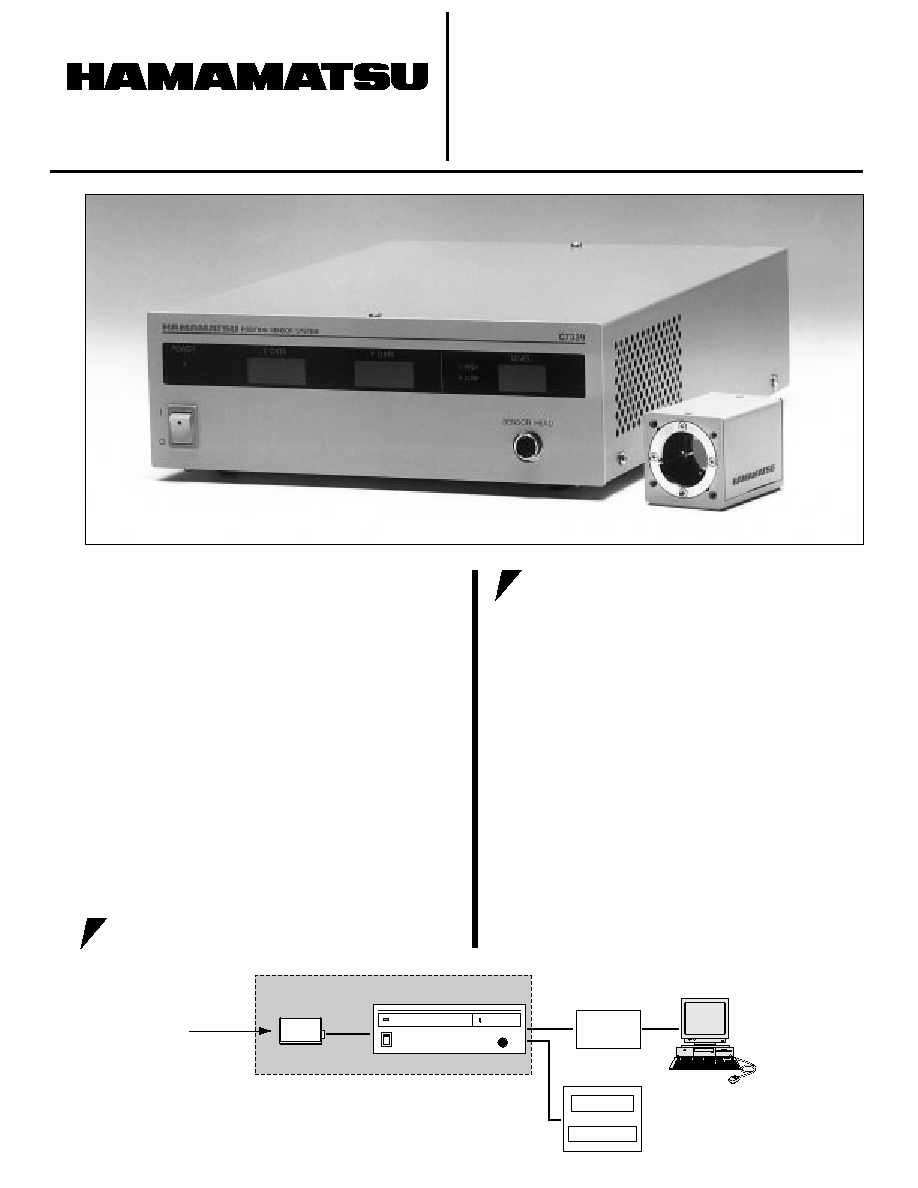

The C7339 Position Sensor is an opto-electric position-

sensing unit which measures the position of a single

point of light spot-focused onto the sensor head.

The use of hybrid circuitry allows for a compact, light-

weight design and a divided configuration with a light,

compact sensor head and a controller equipped with a

light level indicator and data displays for ease of opera-

tion. The measured position is displayed digitally in terms

of X- and Y-coordinate voltages on the front panel of the

controller and may be simultaneously output to a re-

corder.

The C7339 does not possess a background-light cancel-

lation function and is suited for use in locations where the

signal light is distinct from the background such as in the

detection of laser beams.

FEATURES

∑ Quick Response

The response time of less than 20

µ

s enables accurate mea-

surement of the spot, even while it is moving at high speeds.

∑ Stable Measurement

The position data (X-Y coordinate voltages) of a light spot is

obtained without being affected by signal current fluctua-

tions from the PSD, enabling accurate position measurement

regardless of fluctuations in the light intensity.

∑ Broad Spectral Response

The C7339 has a broad spectral range, from 300 to 1100 nm,

enabling the detection of a variety of light sources, including

lasers.

∑ High Resolution

The PSD employed in the sensor head is of the non-discrete

type, which, contrary to a discrete-type sensor, has no insen-

sitive area. This enables continuous measurement at a high

resolution of 1/5000 (when using a recorder).

∑

Light Level Indicator

The input light level is i

ndicated in digits on the front panel

of the control unit (0.00 to 10.0) so as to make it easy to adjust

the lens iris and select an ND filter.

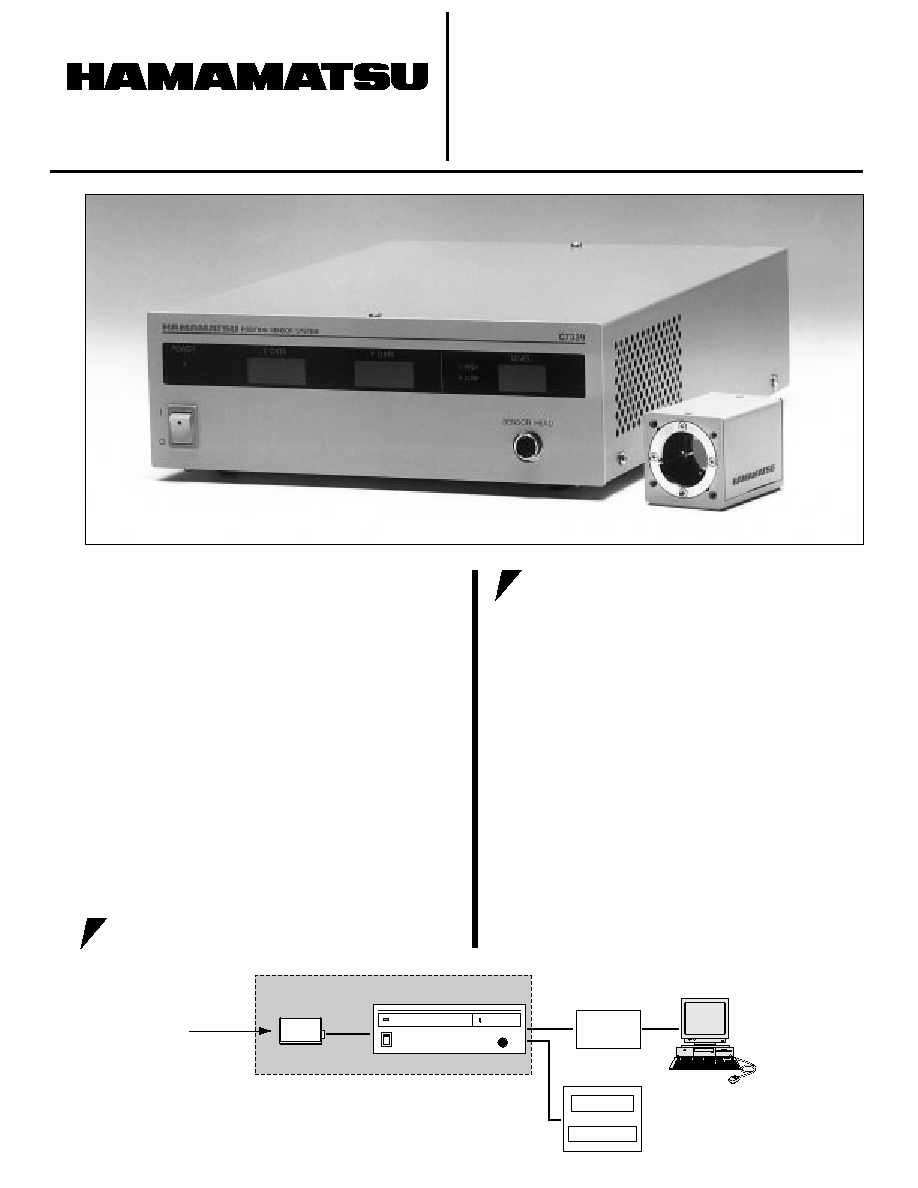

Power Macintosh

6100/60

Power PC

AD convertor

Laser beam

Sensor head

Standard configuration

Controller

X-Y Recorder

Oscilloscope

Computer

Analog

OUT

Analog

OUT

H A M A M A T S U

POSITION SENSOR SYSTEM

C7339

POWER

HIGH

LEVEL

SENSOR HEAD

LOW

X D A T A

POWER

1 . 1 1

Y D A T A

1 . 1 1

5 . 5

HAMAMATSU

SYSTEM CONFIGURATION EXAMPLE

Laser beam alignment system

∑

Subject to local technical requirements and regulations, availability of products included in this promotional material may vary.

Please consult with our sales office.

∑

Information furnished by HAMAMATSU is believed to be reliable. However, no responsibility is assumed for possible inaccuracies

or omissions. Specifications and external appearance are subject to change without notice.

© 1999 Hamamatsu Photonics K.K.

Homepage Address http://www.hamamatsu.com

HAMAMATSU PHOTONICS K.K., Systems Division

812 Joko-cho, Hamamatsu City, 431-3196, Japan, Telephone: (81)53-431-0124, Fax: (81)53-435-1574, E-mail:export@sys.hpk.co.jp

U.S.A. and Canada: Hamamatsu Photonic Systems: 360 Foothill Road, Bridgewater, N.J. 08807-0910, U.S.A., Telephone: (1)908-231-1116, Fax: (1)908-231-0852

Germany: Hamamatsu Photonics Deutschland GmbH: Arzbergerstr. 10, D-82211 Herrsching am Ammersee, Germany, Telephone: (49)8152-375-0, Fax: (49)8152-2658

France: Hamamatsu Photonics France S.A.R.L.: 8, Rue du Saule Trapu, Parc du Moulin de Massy, 91882 Massy Cedex, France, Telephone: (33)1 69 53 71 00, Fax: (33)1 69 53 71 10

United Kingdom: Hamamatsu Photonics UK Limited: Lough Point, 2 Gladbeck Way, Windmill Hill, Enfield, Middlesex EN2 7JA, United Kingdom, Telephone: (44)181-367-3560, Fax: (44)181-367-6384

North Europe: Hamamatsu Photonics Norden AB: Smidesv‰gen 12, SE-171-41 Solna, Sweden, Telephone: (46)8-509-031-00, Fax: (46)8-509-031-01

Italy: Hamamatsu Photonics Italia S.R.L.: Strada della Moia, 1/E 20020 Arese (Milano), Italy, Telephone: (39)02-935 81 733, Fax: (39)02-935 81 741

Cat. No. SIMS1004E01

FEB/99 CR

Created in Japan (PDF)

OTHER APPLICATIONS

∑ Surface Flatness Measurement

∑ Solar Tracking Systems

CONFIGURATION

Sensor head (C7339-01) ....................... 1

Controller (C7339-0X*) .......................... 1

AC cable (2m) ........................................ 1

Head connecting cable (5m) .................. 1

Signal cables (BNC-BNC, 3m) .............. 2

Fuses (1A) ............................................. 3

Line voltage * X = 2 ......................... 100V

3 .......................... 117V

4 .......................... 220V

5 .......................... 240V

OPTIONAL

Metal interference filters

Filter adapter

SPECIFICATIONS

Detector

Non-discrete position-sensitive detector

(Hamamatsu S1880-03)

Useful sensitive area (Fig.1)

10

◊

10mm

Lens mount

C mount

Output voltage: X-axis

≠ 5 to + 5V

Y-axis

≠ 5 to + 5V

Output impedance

500

±

10%

Response speed (Fig.2)

Within 20

µ

s

Recommended measurement light level

Light level (

) = 8 (Displayed on a level indicator)

Position detection error

Zone A (refer to figure below)

±

1.0%, Zone B

±

2.0%

Error due to light intensity variations

±

1% (Light level (

) = 8

4)

Resolution (when using a recorder)

1/5000

Jitter

±

1.5/1000

Drift

±

0.5%/day (after the first 30 minutes)

Operating temperature

0 to +40

∞

C

Storage temperature

≠10 to +50

∞

C

Operating/storage humidity

Less than 90% (with no condensation)

Line voltage

100/117/220/240VAC

±

10%, 50/60Hz

Power consumption

Approx. 30VA

ZONE A

ZONE B

10mm

10mm

5mm

INPUT

LIGHT

OUTPUT

VOLTAGE

RISE TIME

FALL TIME

20

µ

s

20

µ

s

10%

90%

RESPONSE

FREQUENCY

OUTPUT

0

100H

Z

2kH

Z

-3dB

Fig.1 Useful Sensitive Area

and Zones A and B

Fig.2 Rise and fall time of the output voltage when a pulsed light is applied to the center

of the sensitive area.

The rise time is the period of time required for the output voltage to rise from 10%

to 90% of its full level.

The fall time is the period required for the output voltage to return from 90% to 10%.

Fig.3 Response frequency of the output

voltage when a spot light is moved

right and left repeatedly while it is

being applied to the sensitive area.

When light with the value on the table at the left is input, "8" appears on the

display indicating the volume of incident light. If strong laser light is used, an

ND filter or similar means should be used to reduce the volume of laser light

to the optimum volume before beginning measurement.

Laser

Wavelength

Input Laser Power

He-Ne Laser

632nm

Approx. 23

µ

W

Ar Laser

514nm

Approx. 27

µ

W

40

64

42

HAMAMATSU

H A M A M A T S U

POSITION SENSOR SYSTEM

C7339

POWER

HIGH

LEVEL

SENSOR HEAD

SIGNAL OUT

X DATA

Y DATA

LOW

X D A T A

POWER

1 . 1 1

Y D A T A

1 . 1 1

5 . 5

LINE

232

74

227

69.6

DIMENTIONAL OUTLINE (UNIT:mm)

∑ Sensor head

(Weight: Approx. 140g)

∑ Controller

(Weight: Approx. 3.87kg)

OPTIMUM INPUT LASER POWER

ISO 9001/ISO 13485

EN 46001

Certificate: 09 105 79045