| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HMP8112 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

Semiconductor

March 1998

HMP8112

NTSC/PAL Video Decoder

Features

∑ Supports ITU-R BT.601 (CCIR601) and Square Pixel

∑ 3 Composite Analog Inputs with Sync Tip AGC, Black

Clamping and White Peak Control

∑ Patented Decoding Scheme with Improved 2-Line

Comb Filter, Y/C Separation

∑ NTSC M, N, and PAL (B, D, G, H, I, M, N, CN) Operation

∑ Composite or S-Video Input

∑ User-Selectable Color Trap and Low Pass Video

Filters

∑ User Selectable Hue, Saturation, Contrast, Sharpness,

and Brightness Controls

∑ User Selectable Data Transfer Output Modes

- 16-Bit 4:2:2 YCbCr

- 8-Bit 4:2:2 YCbCr

∑ User Selectable Clock Range from 20MHz - 30MHz

∑ I

2

C Interface

∑ VMI Compatible Video Data Bus

Applications

∑ Multimedia PCs

∑ Video Conferencing

∑ Video Editing

∑ Video Security Systems

∑ Settop Boxes (Cable, Satellite, and Telco)

∑ Digital VCRs

∑ Related Products

- NTSC/PAL Encoders: HMP8154, HMP8156,

HMP8171, HMP8173

- NTSC/PAL Decoders: HMP8115

Description

The HMP8112 is a high quality, digital video, color decoder with

internal A/D converters. The A/D function includes a 3:1 analog

input mux, Sync Tip AGC, Black clamping and two 8-bit A/D

Converters. The high quality A/D converters minimize pixel jitter

and crosstalk.

The decoder function is compatible with NTSC M, PAL B, D,

G, H, I, M, N and special combination PAL N video stan-

dards. Both composite (CVBS) and S-Video (Y/C) input for-

mats are supported. A 2 line comb filter plus a user

selectable Chrominance trap filter provide high quality Y/C

separation. Various adjustments are available to optimize

the image such as Brightness, Contrast, Saturation, Hue and

Sharpness controls. Video synchronization is achieved with

a 4xf

SC

chroma burst lock PLL for color demodulation and

line lock PLL for correct pixel alignment. A chrominance sub-

sampling 4:2:2 scheme is provided to reduce chrominance

bandwidth.

The HMP8112 is ideally suited as the analog video interface

to VCR's and camera's in any multimedia or video system.

The high quality Y/C separation, user flexibility and inte-

grated phase locked loops are ideal for use with today's pow-

erful compression processors. The HMP8112 operates from

a single 5V supply and is TTL/CMOS compatible.

Table of Contents

Page

Functional Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 2

Functional Operation Introduction. . . . . . . . . . . . . . . . . . . 6

Internal Register Description Tables . . . . . . . . . . . . . . . . . 14

Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC and DC Electrical Specifications . . . . . . . . . . . . . . . . . 24

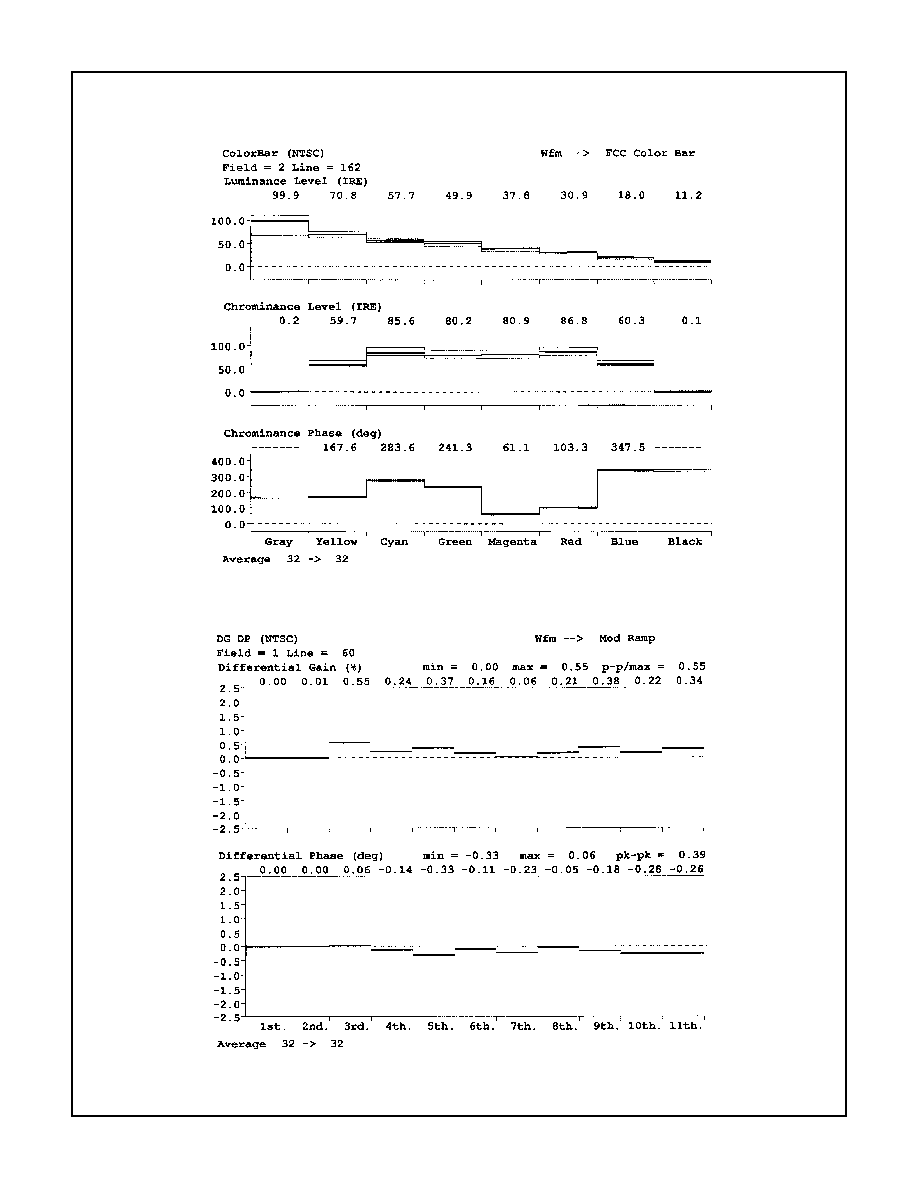

Typical Performance Curves . . . . . . . . . . . . . . . . . . . . . . . 27

Applications Information . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ordering Information

PART NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG.NO.

HMP8112CN

0 to 70

80 Ld PQFP

Q80.14x20

HMP8112EVAL2

PCI Reference Design (Includes Part)

HMP8156EVAL2

Frame Grabber Evaluation Board

(Includes Part)

PQFP is also known as QFP and MQFP

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

©

Harris Corporation 1998

File Number

4221.3

NOT RECOMMENDED FOR NEW DESIGNS

See HMP8115

2

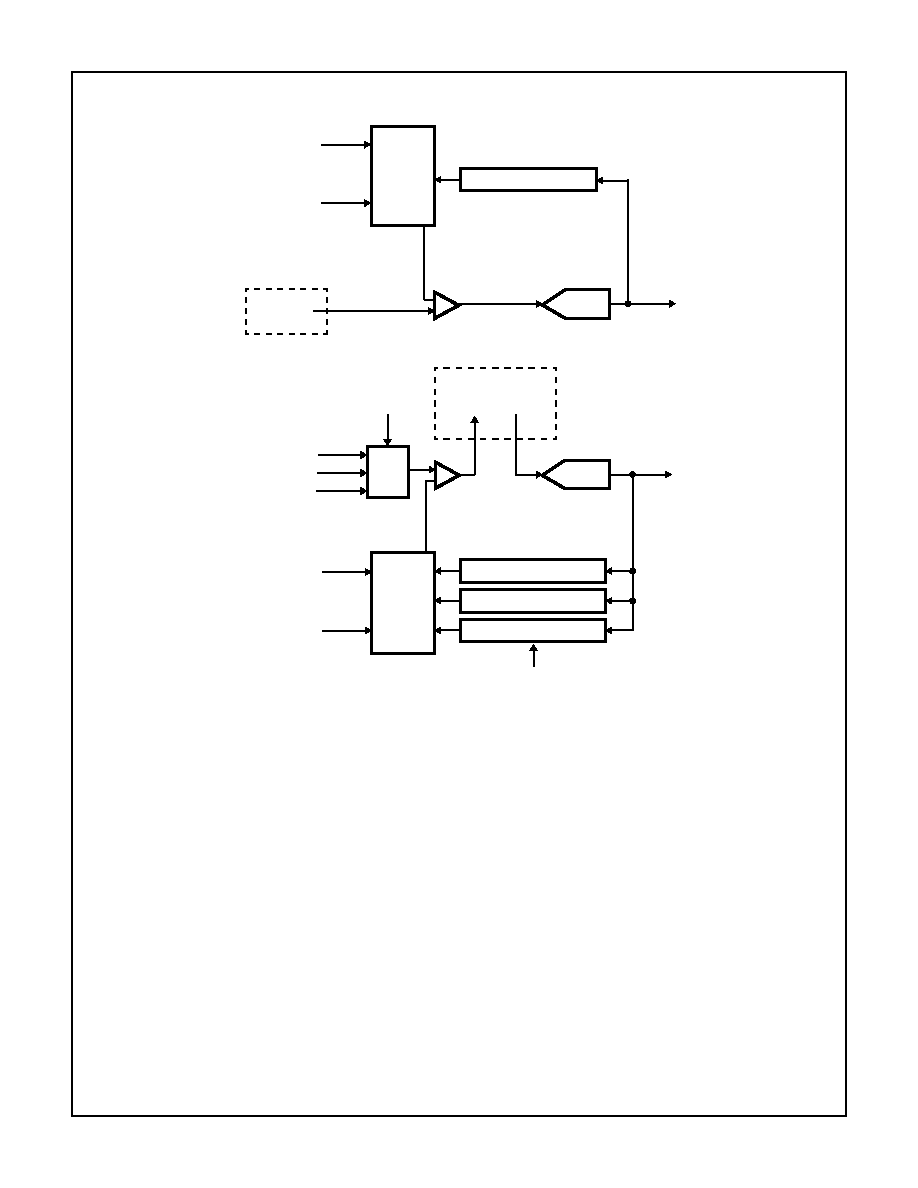

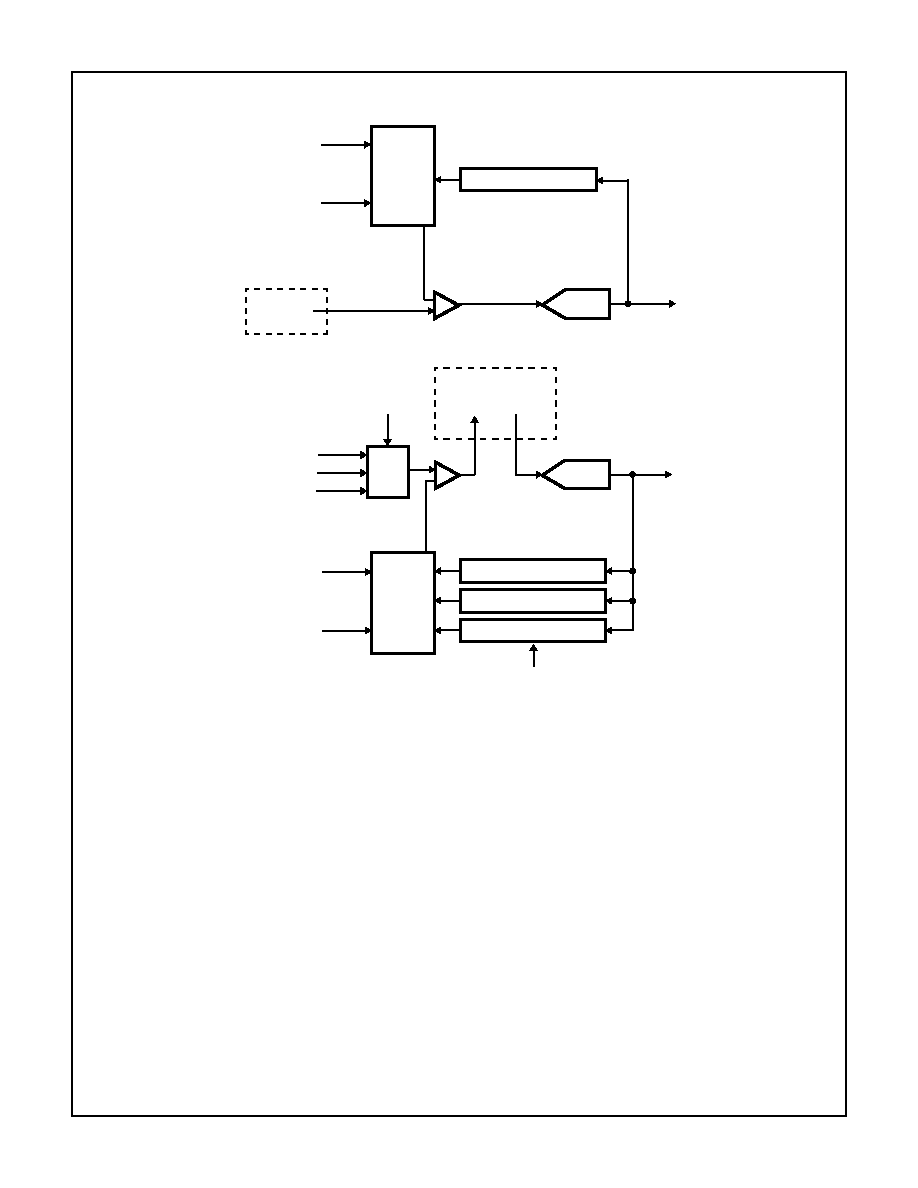

Functional Block Diagrams

CbCr[7:0]

Y[7:0]

A

CTIVE

FIELD

D

VLD

USER

ADJUST

.

COLOR

TRAP

OUTPUT

SAMPLE

RA

TE

CONVER

TER

STD_ERR

LOCKED

INPUT

MUX

WHITE PEAK LEVEL

DIGIT

AL COMP

ARA

T

ORS

BLA

CK LEVEL

SYNC LEVEL

8-BIT

ADC

AG

C

CLAMP

AND

VID_IN0

VID_IN1

VID_IN2/Y

CLAMP_CAP

A

GC_CAP

COMP_FIL

TER

COMP_A/D_IN

+ -

CLAMP

DIGIT

AL COMP

ARA

T

O

R

8-BIT

ADC

CLAMP

CHR

OMA_IN

CR_CLAMP_CAP

GAIN_CTRL

+

-

SD

A

SCL

RESET

GAIN

CONTR

OL

LOGIC

AND

LINE

PLL

VSYNC

DETECT

MICR

OPR

OCESSOR

INTERF

A

CE AND

CONTR

OL

HSYNC

VSYNC

LOGIC

COLOR

DEMODULA

TION

Y/C

SEP

ARA

TION

INPUT

SAMPLE

RA

TE

CONVER

TER

CHR

OMA

PLL

HSYNC

DETECT

LOCK

COLOR

ADJUST

HMP8112

3

VIDEO INPUT

Functional Block Diagrams

(Continued)

INPUT

MUX

WHITE PEAK LEVEL

DIGITAL COMPARATORS

BLACK LEVEL

SYNC LEVEL

8-BIT

ADC

AGC

CLAMP

AND

LIN0

LIN1

LIN2

LCLAMP_CAP

LAGC_CAP

L_OUT

L_ADIN

+

-

CLAMP

DIGITAL COMPARATOR

8-BIT

ADC

CLAMP

CIN3

CCLAMP_CAP

GAIN_CTRL

+

-

GAIN

CONTROL

LOGIC

AND

LOGIC

EXTERNAL

ANTIALIASING

FILTER

EXTERNAL

ANTIALIASING

FILTER

SOURCE

SELECT

WHITE

PEAK

ENABLE

(WPE)

C

CR[7:0]

Y, CVBS

L[7:0]

HMP8112

4

VIDEO DECODER

Functional Block Diagrams

(Continued)

Y

,CVBS

C

CR[7:0]

L[7:0]

M U X

ISL

CHR

OMA

LINE

COMB

C,CVBS

DA

T

A

Y D

A

T

A

CHR

OMA TRAP

ENABLE

Y D

A

T

A

CHR

OMA

DEMODULA

T

O

R

Y D

A

T

A

C,CVBS

DA

T

A

C D

A

T

A

Y D

A

T

A

UV

AG

C

U,

V

UV

SA

TURA

TION

ADJUST

SA

TURA

TION

ADJUST

SHARPNESS

ADJUST

ST

AND

ARD

SELECT

M U X

ISL

HSYNC

DETECT

CHR

OMA

PHASE

DETECT

OR

CHR

OMA

PLL NCO

4FSC

CLOCK

CLK

(20MHz - 30MHZ)

LINE LOCKED

PLL LOOP FIL

TER

HUE

ADJUST

AG

C

ADJUST

VSYNC DETECT

INPUT

RA

TE

CONVER

TER

SAMPLE

FIL

TER

DELA

Y

TRAP

CbCr

DA

T

A

Y

DA

T

A

CLK T

O

4FSC RA

TIO

LO

W P

ASS

FIL

TER ENABLE

HSYNC

VSYNC

ST

AND

ARD ERR

OR

LOCKED

FIELD

SYNC

& CONTRAST

ADJUST

BRIGHTNESS,

STRIPPER,

OUTPUT

RA

TE

CONVER

TER

SAMPLE

LINE LOCKED

NCO

LP FIL

TER

CHR

OMA

PLL LOOP

FIL

TER

HORIZONT

AL

AND VER

TICAL

SHARPNESS

ADJUST

U

,V T

O

CbCr

COLOR

CONVER

TER

AND COLOR

KILLER

SP

A

C

E

HMP8112

5

Schematic

I

2

C CONTROL INTERFACE

OUTPUT INTERFACE

Functional Block Diagrams

(Continued)

SERIAL SHIFT

ADDRESS

POINTER

CONTROL

REGISTERS

....

....

....

....

A0

CONTROL

ADDRESS

POINTER

REGISTER

SDA

SCL

0

1

.

.

.

.

25

DATA BUS

R

E

G

I

S

T

E

R

R

E

G

I

S

T

E

R

8

8

CbCr[7:0]

Y[7:0]

Y[7:0]

CbCr[7:0]

DVLD

OEN

M

U

X

8/16 OUTPUT

SELECT

ACTIVE

FIFO

32 X 16

DEEP

JP1

JUMPER

V

CC

R10

50

C13

15pF

R2

10K

27MHz

64

63

60

58

57

56

55

54

Y7

Y6

Y5

Y4

Y3

Y2

Y1

Y0

Y7

Y6

Y5

Y4

Y3

Y2

Y1

Y0

65

66

67

71

70

ACTIVE

DVLD

FIELD

HSYNC

VSYNC

WPE

RESET

SDA

SCL

CLK

CLK

TEST

L_OUT

L_ADIN

LAGC_CAP

LCLAMP_CAP

CCLAMP_CAP

GAIN_CNTL

DEC_T

DEC_L

LIN2

LIN1

LIN0

CIN

U1

CRCB7

CRCB6

CRCB5

CRCB4

CRCB3

CRCB2

CRCB1

CRCB0

CR_CB7

CR_CB6

CR_CB5

CR_CB4

CR_CB3

CR_CB2

CR_CB1

CR_CB0

51

50

49

48

47

45

43

42

Y10. .71

Y10. .71

CR_CB10. .71

CR_CB10. .71

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

R11

10K

R12

10K

R13

10K

R14

10K

R15

10K

R16

4K

R17

4K

V

CC

RESET

27MHz

SCL

27

34

40

41

38

13

36

5

6

7

19

9

8

77

76

29

28

78

30

SDA

ACTIVE

DVLD

FIELD

VDRIVE

HDRIVE

LOW PASS FILTER

R7

680

L1

82

µ

H

R8

5.62K

C1

15pF

C4

1.0

µ

F

C5

1.0

µ

F

C3

1.0

µ

F

R5

75

R4

75

R3

75

C6

1.0

µ

F

R6

75

LUMA0

LUMA1

LUMA2

CHROMA

C2

15pF

C9

0.22

µ

F

C8

0.01

µ

F

C7

0.01

µ

F

C12

0.1

µ

F

C11

0.1

µ

F

R9

5K

AV

CC

C10

0.1

µ

F

R1

1K

R18

10

HMP8112

6

Introduction

The HMP8112 is an NTSC/PAL compatible Video Decoder

with both chroma burst and line locked digital phase locked

loops. The HMP8112 contains two 8-bit A/D converters and

an I

2

C port for programming internal registers.

Analog Video/Mux Inputs

The Luminance channel has three analog video inputs that

can be used for composite or the Y input of a S-Video signal,

and one analog input for chrominance. LIN2 is used with CIN

to interface an S-Video input. Three composite or two com-

posite and one S-Video inputs can be applied to the

HMP8112 at any one time. Control of the analog front end is

selected by bits 2 and 1 of the Video Input Control Register.

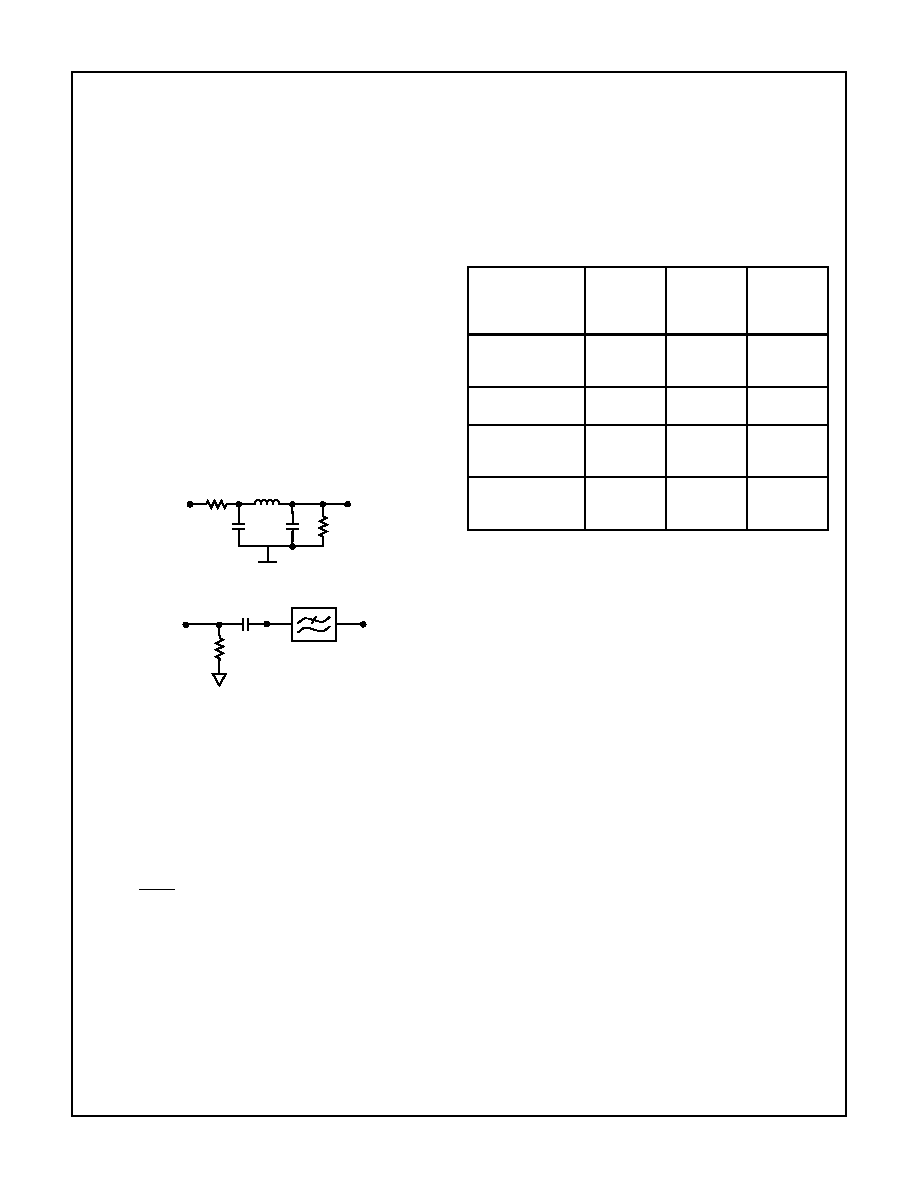

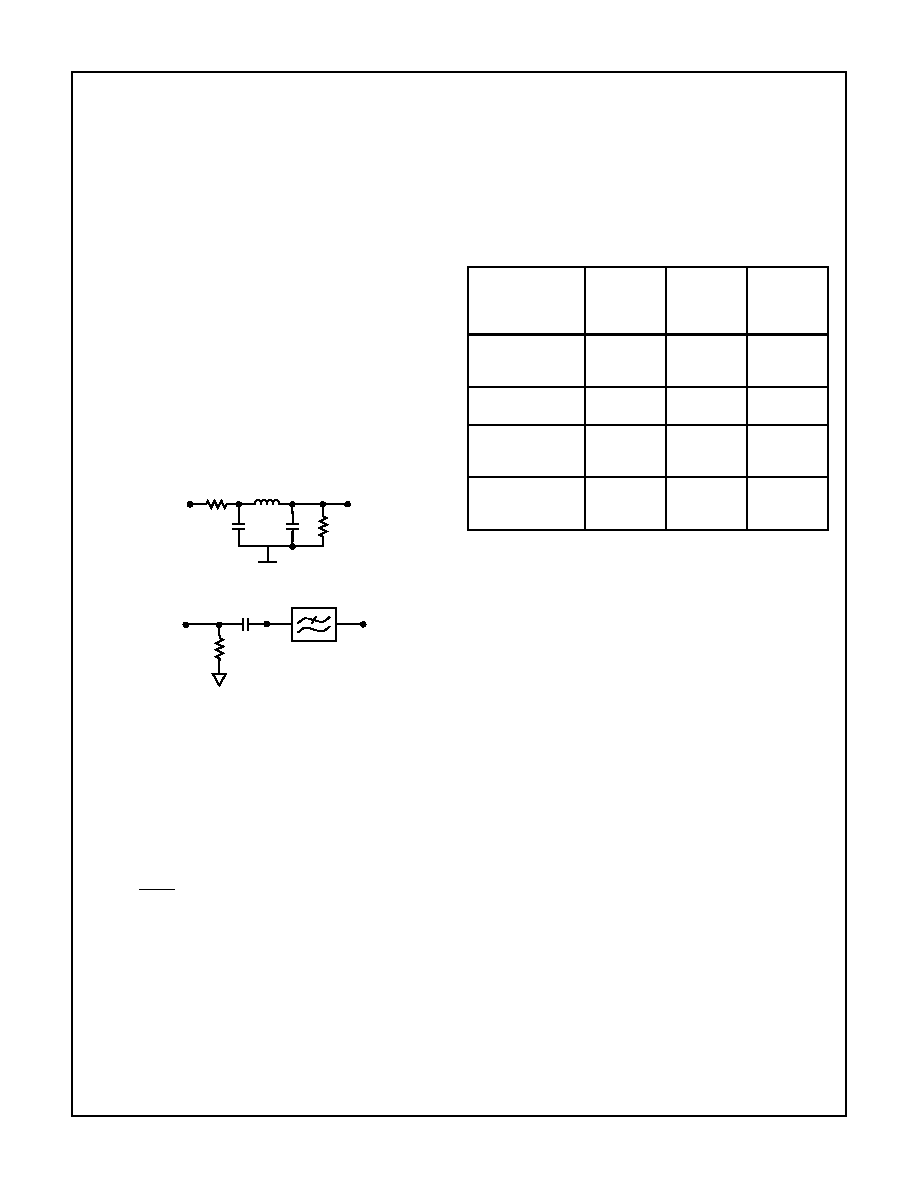

Anti-Aliasing Filter

An external anti-alias filter is required to achieve optimum

performance and prevent high frequency components from

being aliased back into the video image. For the LIN inputs a

single filter is connected to L_OUT and L_ADIN. For CIN the

anti-aliasing filter should be connected to the CIN input. A

recommended filter is shown below.

AGC And Clamp Circuit

Inputs LIN0-2 contain a sync tip AGC amplifier. During the

sync tip the value of the A/D is driven to code 0 by gaining up

the video input signal. The sync tip AGC is sampled during the

HAGC pulse time which is controlled by the HAGC Pulse Start

Time and End Time registers. The LIN0-2 inputs apply a DC

clamp reference to the back porch of the video. This is con-

trolled by the DC-RESTORE Pulse Start Time and End Time

Registers.

After a

RESET

, a change of the video standard, or a PLL

Chrominance Subcarrier Ratio Register load, HAGC and DC

RESTORE are overlapped, until LOCKED is asserted. (the

PLL has acquired a stable line lock). This is the acquisition

mode of the PLL where the decoder is trying to lock to a new

video source. Once the PLL is LOCKED, HAGC and DC

RESTORE are moved out to the default programmed values

in the user programming registers. The HAGC should be set

coincident to the incoming horizontal sync signal. The HAGC

pulse should be set to a width of 2

µ

s.

Once the PLL is locked the DC RESTORE signal is moved

out to the default programmed values in the user program-

ming registers. The DC RESTORE pulse can be pro-

grammed with the DC RESTORE Start and End time control

registers. DC RESTORE should be asserted 6.5

µ

s after the

falling edge of horizontal sync (0

HSYNC

) and held for a dura-

tion of 2

µ

s. Both HAGC and DC RESTORE are synchronous

to the output sample rate (OSR) converter and are clocked

in OSR (pixel clock) clock periods. The OSR clock rate is

dependent on the input standard used. See Table 1 for the

register values used for the different video standards.

White Peak Enable

The white peak enable input, (WPE) enables or disables the

white peak control. Enabled, (logic high) when the digital

outputs exceed code 248, the AGC will reduce the gain of

the video amplifier to prevent over-ranging the A/D. If dis-

abled, the AGC operates normally, keeping the horizontal

sync tip at code 0 and allowing the A/D's range to go to 255

at the maximum peak input.

NTSC/PAL Decoder

The NTSC/PAL decoder is designed to convert incoming

Composite or Separated (SVHS, Y/C) video into it's YCbCr

component parts. The digital phase locked loops are

designed to synchronize to the various NTSC/PAL stan-

dards. They provide a stable internal 4xf

SC

(Frequency of

the Color Sub-Carrier) video clock for color demodulation,

and a line locked clock for vertical spatial pixel alignment.

The decoder uses the CLK to run the A/D converters and the

phase locked loops. This asynchronous master clock for the

decoder eliminates the need for a unique clock source in a Mul-

timedia application. CLK can run from 20MHz to 30MHz when

using the 16-bit Synchronous Data output Mode. The user

must program the CLK to Color Sub-Carrier Ratio to match the

CLK frequency used (see Internal Phase Locked Loops discus-

sion). When using the 8-bit Burst Data Output Mode the CLK

should be a 24.5454MHz, 27MHz or 29.5MHz depending on

the output video standard chosen. The crystal oscillator must

have a

±

50ppm accuracy and a 60/40% duty cycle symmetry to

ensure proper operation. Since the video data from the external

A/D's are sampled at the CLK frequency a sample rate con-

verter is employed to convert the data from the CLK rate to the

AGND

680

82

µ

H

15pF

15pF

5.62k

L_OUT

(PIN 9)

L_ADIN

(PIN 8)

CIN

(PIN 19)

75

1.0

µ

F

CHROMA

IN

FIGURE 1. RECOMMENDED ANTI-ALIASING FILTER

LOW PASS FILTER

TABLE 1. HAGC AND DC RESTORE VALUES

VIDEO

OUTPUT

STANDARD

HAGC

START/END

VALUES

DC

RESTORE

START/END

VALUES

HSYNC

START/END

VALUES

Square Pixel

NTSC

640x480

02F8/0008

H

0028/0040

H

0020/0050

H

CCIR601 NTSC

720x480

033F/0000

H

0037/0052

H

033B/0060

H

CCIR601

PAL

720X512

033F/0000

H

0037/0052

H

033B/0060

H

Square Pixel

PAL

768X512

03A0/0018

H

0040/0054

H

0020/0070

H

HMP8112

7

internal decoding frequency of 4xf

SC

.

The input sample rate converter will interpolate between

existing CLK samples to create the chroma locked (4xf

SC

)

samples needed for the color decoder. An interpolation is

done to create the 4xf

SC

pixel and a correction factor is then

applied..

The decoder can be used with the following video sources:

Analog Composite - NTSC M, - PAL B, D, G, H, I, N

And Special Combination PAL N

Analog S - VHS (Y/C) - NTSC M, PAL B, D, G, H, I, N

And Special Combination PAL N

Color Separation, And Demodulation

To separate the chrominance modulated color information

from the baseband luminance signal, a 2 line comb filter is

employed. In NTSC signals the color information changes

phase 180

o

from one line to the next. This interleaves the

chrominance information at half line intervals throughout the

NTSC video spectrum. Therefore, NTSC has 227.5 cycles of

chrominance per NTSC line. The half of a cycle causes the

next reference burst to be 180

o

out of phase with the previ-

ous line's burst. The two line comb efficiently removes the

chrominance information from the baseband luminance sig-

nal. When decoding NTSC, the decoder maintains full lumi-

nance bandwidth horizontally throughout the chrominance

carrier frequency range. Unlike most 2 line comb filter sepa-

ration techniques, vertical bandwidth is maintained by

means of a proprietary transform technique.

For PAL systems there are 283.75 cycles of chrominance

per line. Chrominance information is spaced at quarter line

intervals with a reference phase of 135

o

. The reference

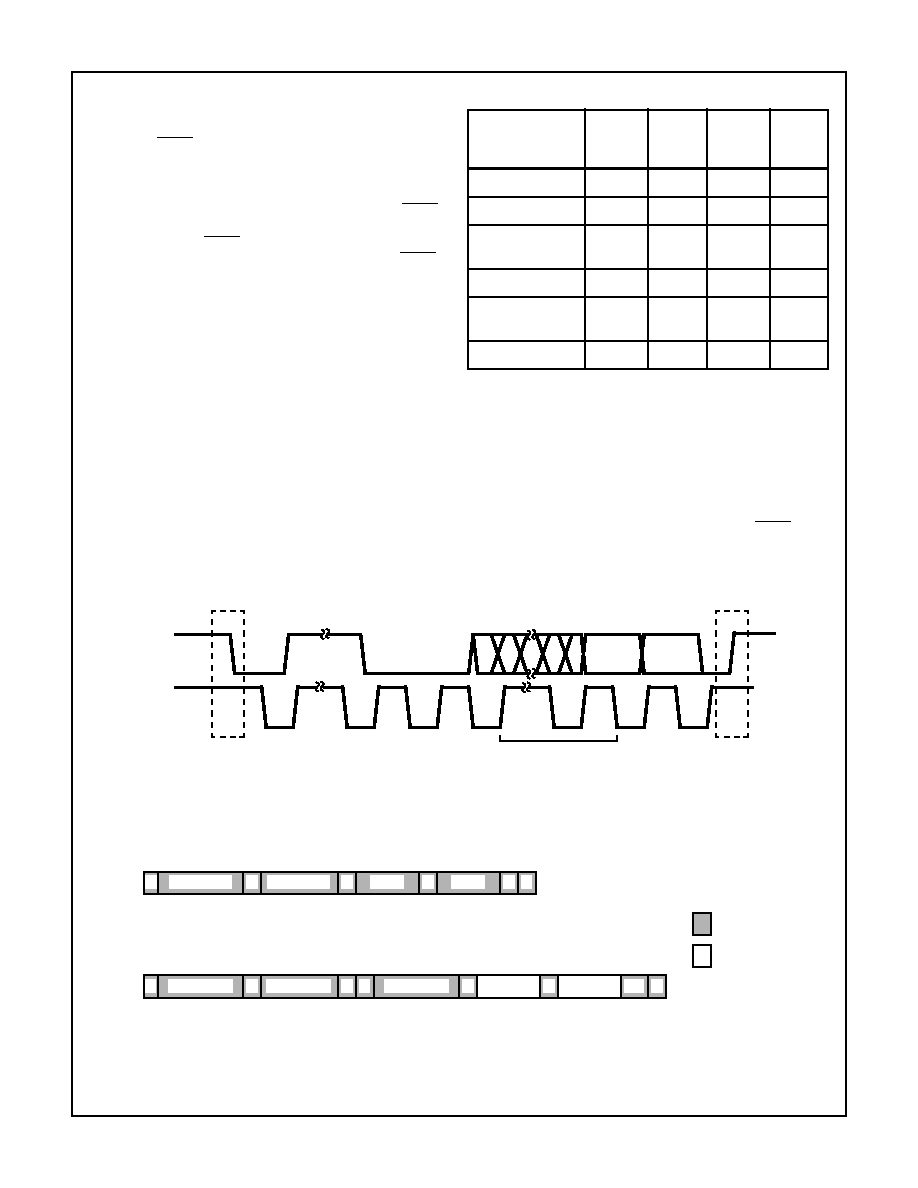

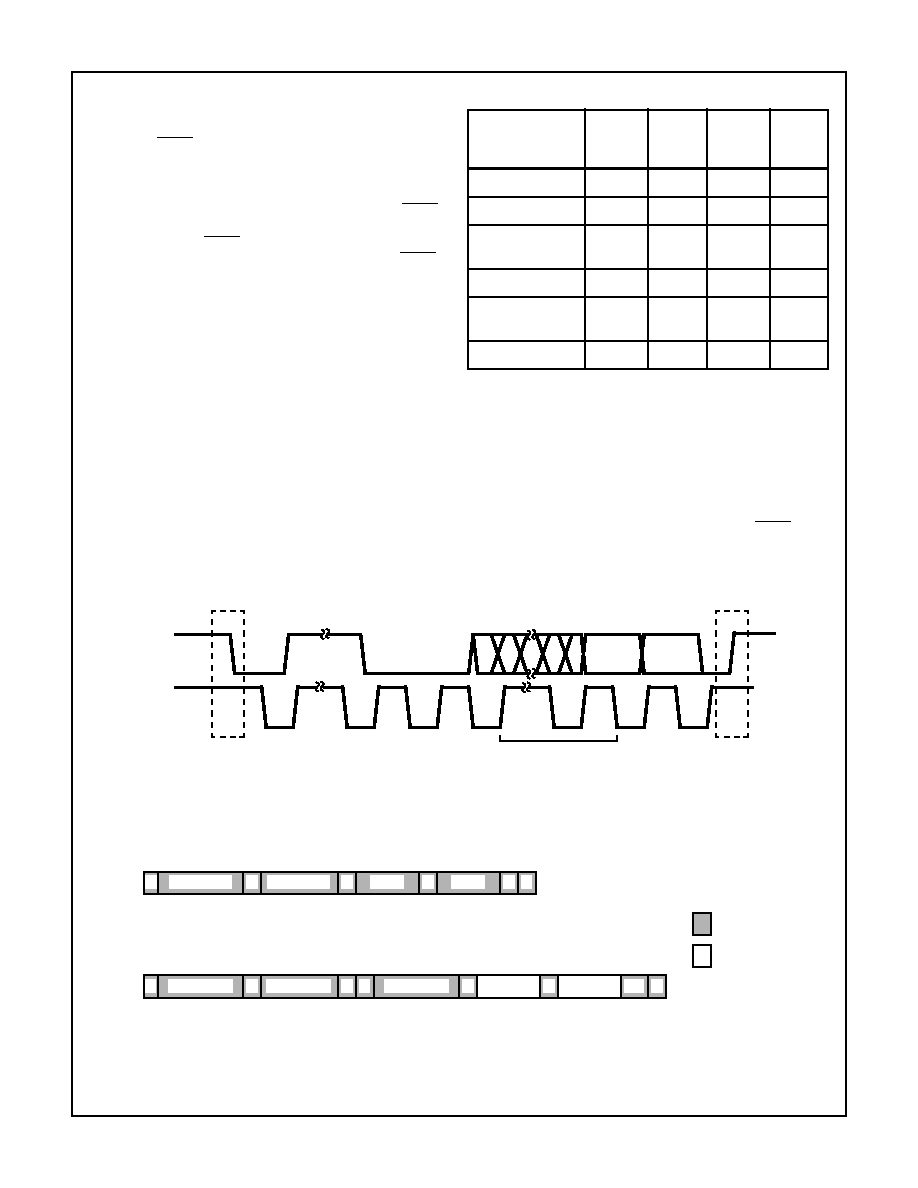

FIGURE 2A. PLL ACQUISITION MODE

FIGURE 2B. PLL LOCKED MODE

VIDEO INPUT

HAGC

DC RESTORE

OVERLAPPED CONTROL

t

PW

= 2.0

µ

s

0

HSYNC

VIDEO INPUT

HAGC

DC RESTORE

START

TIME

END

TIME

START

TIME

END

TIME

6.5

µ

s

0

HSYNC

TIME

INCOMING VIDEO SAMPLES

TIME

RESAMPLED VIDEO

4xf

SC

FIGURE 3. SAMPLE RATE CONVERSION

FREQUENCY

AMPLITUDE

f

H

/2

f

H

/2

f

H

Y

I, Q

Y

FREQUENCY

AMPLITUDE

Y

Y

I, Q

FIGURE 4. COMPOSITE NTSC INTERLEAVE SCHEME

HMP8112

8

phase alternates from line to line by 90

o

. To fully separate

the PAL chrominance and luminance signals the user select-

able filters should be enabled. The chroma notch filter built

into the luminance channel should be enabled for PAL sys-

tems to reduce cross luminance effects. The low pass filter

in the chrominance processing chain helps to reduce cross

color products.

The demodulator in the decoder decodes the color compo-

nents into U and V. The U and V components are converted

to Cb and Cr components after the decoding process.

YCbCr has a usable data range as shown in Figure 4. The

data range for Y is limited to a minimum of 16.

The decoder is compatible with all NTSC and PAL video for-

mats available throughout the world. Table 2 shows the com-

patible video standards.

Horizontal Sync Detection

Horizontal sync is detected in the Output Sample Rate con-

verter (OSR). The OSR spatially aligns the pixels in the verti-

cal direction by using the horizontal sync information

embedded in the digital video data stream. The HSYNC

sync pulse out of the decoder is a video synchronous output

pin. This signal follows the horizontal sync of an input video

source. If there is no source the HSYNC pin will continue to

run at video rates due to the Line Locked PLL free-running.

HSYNC can be moved throughout the video line using the

HSYNC Start and End time registers. This 10-bit register

allows the HSYNC to be moved in OSR clock increments

(12.27MHZ, 13.5MHz or 14.75MHz).

Vertical Sync And Field Detection

The vertical sync and field detect circuit of the decoder uses

a low time counter to detect the vertical sync sequence in

the video data stream. The low time counter accumulates

the low time encounted after the horizontal sync edge or at

the start of each line. When the low time count exceeds the

vertical

sync

detect

threshold,

VSYNC

is

asserted

immediately. VSYNC will remain asserted for a minimum of 1

line. The FIELD flag is updated at the same time as the

VSYNC line. The FIELD pin is a `0' for ODD fields and a `1'

for even fields.

In the case of lost vertical sync or excessive noise that would

prevent the detection of vertical sync, the FIELD flag will

continue to toggle. Lost vertical sync is declared if after 337

lines a vertical sync period was not detected for 3 succes-

sive lines. When this occurs the phase locked loops are ini-

tialized to the acquisition state.

The VSYNC pulse out of the decoder follows the vertical

sync detection and is typically 6.5 lines long. The VSYNC

will run at the field rate of the selected video standard

selected. For NTSC the field rate is 60Hz and for PAL the

field rate is 50Hz. This signal will continue to run even in the

event of no incoming video signal.

Internal Phase Locked Loops

The HMP8112 has two independent digital phase locked

loops on chip. A chroma phase-locked loop is implemented

to maintain chroma lock for demodulation of the color chan-

nel, and a line locked phase lock loop is implemented to

maintain vertical spatial alignment. The phase locked loops

are designed to maintain lock even in the event of VCR

headswitches and multipath noise.

The HMP8112 can use a main crystal (CLK) of 20MHz to

30MHz. The crystal is used as a reference frequency for the

internal phase locked loops. The ratio of the crystal fre-

quency to the video standard is programmed into an internal

register for the PLLs to correctly decode video.

The HMP8112 decoder contains 2 sample rate converters

and 2 phase locked loops that lock to the incoming video. The

input sample rate converter synchronizes the digitized video

from the CLK rate to a 4xf

SC

rate. The chrominance is sepa-

rated from the luminance and then demodulated. The Chroma

phase locked loop uses the CLK source as the PLL reference

frequency. To initialize the chroma PLL, the CLK to 4xf

SC

ratio

must be loaded. For example, if the CLK was 27MHz and the

video signal is NTSC (4 x 3.579545MHz = 14.318MHz) then

the ratio loaded is 0.5302895 in 16-bit precision.

FREQUENCY

AMPLITUDE

f

H

/4

f

H

Y

I, Q

Y

FREQUENCY

AMPLITUDE

Y

Y

f

H

/4

I, Q

I, Q

I, Q

FIGURE 5. COMPOSITE PAL INTERLEAVE SCHEME

Y DATA

RANGE

Cb DATA

RANGE

Cr DATA

RANGE

16

128

248

255

0

16

128

240

255

0

16

128

240

255

212

44

212

44

BLACK

WHITE

100%

BLUE

100%

BLUE

75%

YELLOW

100%

YELLOW

75%

RED

100%

RED

75%

CYAN

100%

CYAN

75%

FIGURE 6. YCbCr DATA RANGES

HMP8112

9

(4 x f

SC

)/CLK = Chroma PLL Value

(4 x 3.579545MHz) / 27MHz = 0.5302895

This value must be loaded to correctly separate and decode

the video signal. A default Chroma PLL Value is used after a

system RESET is applied. The default assumes a CLK of

27MHz and NTSC as the video standard. The default value

is 0.5302895. An ideal 4xf

SC

line should have 910 pixels for

NTSC and 1135 for PAL.

The Output Sample rate converter is locked to the horizontal

line frequency and is used to spatially align pixels in a field.

The LOCKED flag signals when the phase locked loop is

within a

±

4 pixel range of the horizontal sync edge. When

line errors exceed that range the LOCKED flag is cleared.

In cases where VCRs are used in Pause, Fast Forward or

Fast Reverse, lines are typically dropped or added by the

VCR. In a worst case scenario a VCR line tolerance will vary

by

±

8%. The standard detect logic checks the line count

against the given standard to determine an error. VCRs in

trick mode cannot cause a standard error. With an NTSC

standard VCR the number of lines in a field should not

exceed 285. Greater than 285 lines in a field is interpreted

as a PAL video source. An ideal NTSC source should have

262.5 lines per field and a PAL source should have 312.5

lines per field.

The HMP8112 can detect a STANDARD Error that signals

when the video received does not match the standard that

was programmed into the Video Input Control Register. This

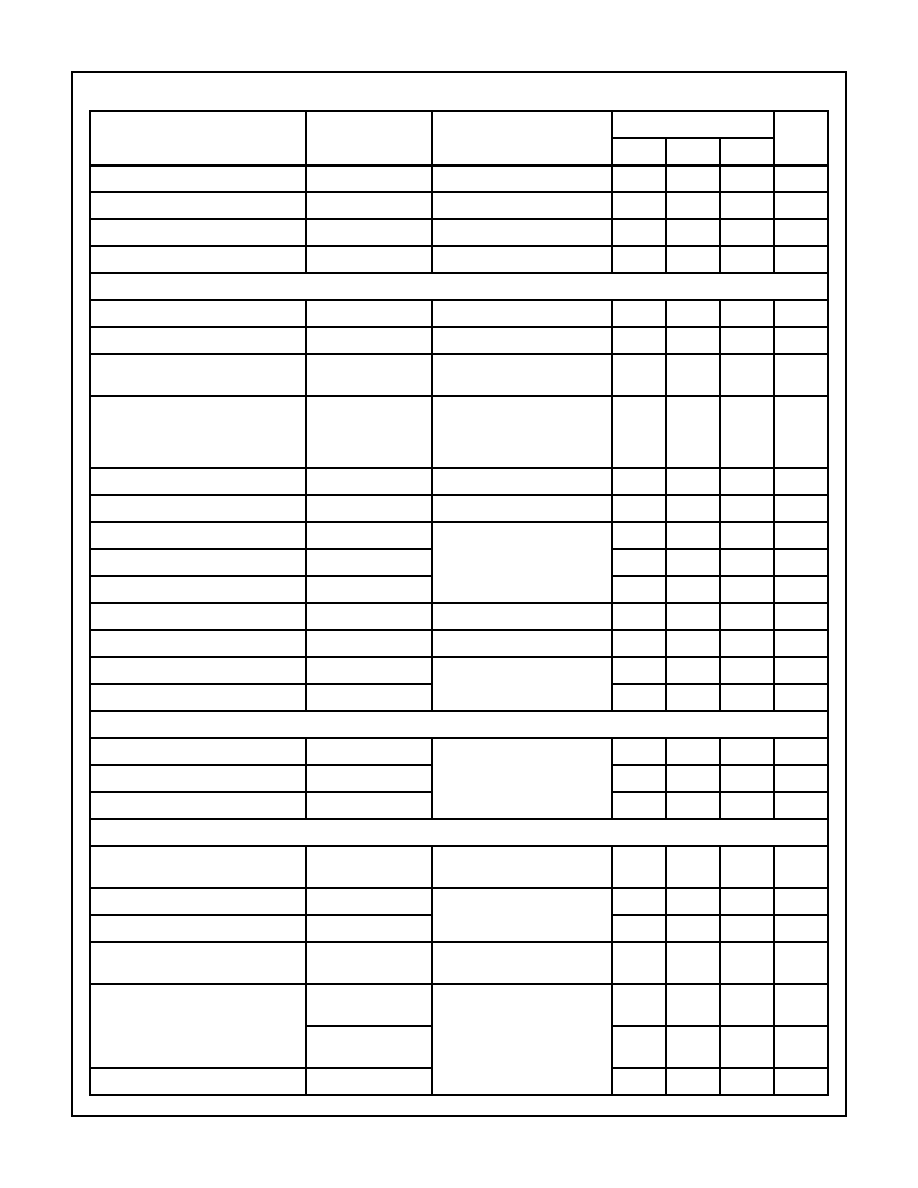

TABLE 2. COMPATIBLE VIDEO INPUT STANDARDS

STANDARD

COLOR

SUBCARRIER

f

SC

NUMBER OF

FIELDS PER

SECOND

NUMBER OF

VERTICAL

LINES

LINE

FREQUENCY

NOMINAL

BANDWIDTH

BLACK

SETUP TO

BLANK

NTSC M

3.579545MHz

60Hz

525

15,734

(

±

0.0003%)

4.2MHz

7.5 IRE

PAL B, D, G, H, I

4.43361875MHz

50Hz

625

15,625

(

±

0.02%)

5.0MHz

0 IRE

PAL M

3.579545MHz

60Hz

525

15,750

(

±

0.0003%)

4.2MHz

7.5 IRE

PAL N

4.43361875MHz

50Hz

625

15,625

(

±

0.15%)

4.2MHz

7.5 IRE

Special

Combination

PAL N

3.58205625MHz

50Hz

625

15,750

(

±

0.15%)

4.2MHz

7.5 IRE

O

V

VIDEO INPUT

LOW TIME

VSYNC

FIELD

VSYNC DETECT

THRESHOLD

`EVEN' FIELD

COUNTER

6.5 LINES

FIGURE 7. VSYNC TIMING AND THE EVEN TO ODD TRANSITION

O

V

VIDEO INPUT

LOW TIME

VSYNC

FIELD

VSYNC DETECT

THRESHOLD

`ODD' FIELD

COUNTER

6.5 LINES

FIGURE 8. VSYNC TIMING AND THE ODD TO EVEN TRANSITION

HMP8112

10

flag, when asserted, tells the user that the video standard

that was expected was not found and a different standard

should be selected in the Video Input Control register. The

error flag is cleared after a RESET or after the Chroma PLL

Clock Ratio register has been loaded via the I

2

C bus. After

the flag is cleared the standard error logic verifies the video

standard. The error flag is set after 2 vertical sync periods

have passed and the line count did not match the expected

line count.

Video Adjustments

The HMP8112 allows the user to vary such video parame-

ters as Contrast, Brightness, Sharpness, Hue and Color Sat-

uration. These adjustments can be made via the I

2

C

interface. Contrast, brightness and sharpness are luminance

controls. The full dynamic range of the luminance channel

can be used by selecting the IRE setup cancellation mode.

This mode will remove the IRE setup and blanking level off-

set to take advantage of the full dynamic range of the lumi-

nance processing path. The sharpening filters allow the

enhancement of low, mid and high frequency components of

the luminance signal to compensate for low amplitude video.

Vertical sharpness is also controlled via the I

2

C interface.

Hue and Color saturation controls enhance the CbCr com-

ponents of the incoming video, all under user control.

Luminance Adjustments

The Luminance data can be adjusted in the HMP8112. The

user can adjust brightness and contrast of the Y or lumi-

nance data. The user can also set the IRE or setup subtrac-

tion value to eliminate the black pedestal offset from NTSC

signals. The Contrast adjustment range can exceed a value

of one so as to take full advantage of the 8-bit dynamic

range for Y. The user control settings executes the equation

Y

OUT

= (Y - IRE Setup + BRIGHTNESS) x CONTRAST

Brightness

The user can control the brightness of the incoming video by

programming the Brightness register. The brightness adjust-

ment will offset the Y component. The brightness register is

an 8-bit register where the bottom 7 bits are brightness con-

trol and the top bit is the IRE setup. The IRE setup for NTSC

is 70 and the setup for PAL is 63.

When the IRE bit is set (1) then the value of 70 is subtracted

from the Y data, and if the IRE bit is cleared (0) then the val-

ues of 63 is subtracted. The brightness control bits BR[6-0]

will brighten the picture as the value is increased. BR = -64

is the darkest and BR = +63 is the brightest. The default

value of the register after a RESET is 0 (80

H

).

Contrast

The contrast adjustment will allow the user to increase and

decrease the gain of the Y data. The contrast factor is an 8-bit

number (as shown below) that ranges from 0 to 1.999.

X.XXXXXXX

The default value after a RESET is 1.47 (BD

H

).

Hue or Tint Adjust

The Hue adjustment is applied to the U and the V color differ-

ence signal. The Hue adjusts the phase of the given UV data.

The Hue can be adjusted by

±

30

o

in 1/4

o

increments. This is

achieved by changing the Burst Phase Locked reference

point. Figure 10 shows the block diagram for the color adjust-

ment section. This default value for this register is 0 (00

H

).

Horizontal/Vertical Sharpness

The frequency characteristics of the video waveform can be

altered to enhance the sharpness of the picture. The Horizontal

Sharpness register acts as a 4 band equalizer where the ampli-

tude of specific frequency ranges can be enhanced or dimin-

ished. The Sharpness Control Register allows the Low (LF),

Mid (MF) and High Frequency (HF) bands of the luminance sig-

nal to be enhanced. Vertical Sharpness can be adjusted to 1 or

a factor of 0. The RESET default is a factor of 1.0

TABLE 3. USER CONTROLLED SETTINGS

USER VIDEO SETTINGS

Brightness

Contrast

Hue or Tint

Horizontal Sharpness

Vertical Sharpness

Color Saturation

IRE BLACK SETUP

+

+

-

X

BRIGHTNESS

CONTRAST

Y DATA

FROM

DECODER

Y'

8

FIGURE 9. LUMINANCE CONTROL SETTINGS PATH

(0 TO 1.999)

(NTSC = 70, PAL = 63)

(-64 TO +63)

DEMODULATED

UV DATA

UV DATA

VIDEO

DATA

HUE OFFSET

HUE

ADJUST

+

TO INPUT SAMPLE

RATE

CONVERTER

LOOP

CHROMA

PHASE LOCKED

COLOR

DECODER

CHROMA

AGC AND

USER

SETTINGS

FIGURE 10. HUE ADJUST BLOCK DIAGRAM

HMP8112

11

The 2-bit values allow 4 choices of scaling factors. The

sharpness control helps to compensate for losses in the

scaling interpolators that can reduce the amplitude of high

frequency components.

The Color Killer

(AGC Hysteresis and Loop Limits)

The color killer will disable the color difference path and set

the U and V components to zero. The automatic color killer

circuitry uses the AGC threshold to determine the maximum

and minimum gain factor limits. The loop filter determines

how much the AGC gain factor can be changed within one

line. The maximum gain factor (Max = 8) and the minimum

gain factor (Min = 0.5) will limit the range of the AGC. When

the gain factor exceeds the maximum gain factor of 8, the

gain factor is limited to 8. Once the signal has an amplitude

of 1/16th, the nominal video the color killer is enabled and

the chroma phase locked loop holds it's last phase refer-

ence. While the color killer is enabled, the U and V compo-

nents are forced to zero. Once the input video signal reaches

1/7th the optimum amplitude the color killer is disabled and

the color is returned.

The dynamic range of the AGC allows it to compensate for

video that is 1/8 to 2 times the specified nominal of 1V

P-P

.

Saturation

The color saturation component is controlled via the Color

Saturation Registers. The color saturation is applied to the

UV components after the AGC function. The saturation value

is multiplied by the UV data to increase the color intensity.

The data range is from 0 to 1.96875 where 1.96875 is the

brightest intensity. This is an 8-bit number in the form:

X.XXX XXXX

The default value after a RESET is 1.2074 (9D

H

).

I

2

C Control Interface

The HMP8112 utilizes an I

2

C control bus interface to pro-

gram the internal configuration registers. This standard

mode (up to 100 KBPS) interface consists of the bidirec-

tional Serial Data Line (SDA) and the Serial Clock Line

(SCL). The implementation on the HMP8112 is a simple

slave interface that will not respond to general calls and can-

not initiate a transfer. When the device is not active, the SDA

and SCL control pins should be pulled high through external

4k

pullup resistors.

The I

2

C clock/data timing is shown below in Figure 13. The

HMP8112 contains 29 internal registers used to program and

configure the Decoder. The I

2

C control port contains a pointer

register that auto-increments through the entire register space

and can be written. The autoincrement pointer will wrap after

the last register has been accessed (Product ID Register) and

should be set to the desired starting address each time an

access is started. For a write transfer, the I

2

C device base

address is the first part of a serial transfer. Then the internal

register pointer is loaded. Then a series of registers can be

written. If multiple registers are written, the pointer register will

autoincrement up through the register address space. A stop

cycle is used to end the transfer after the desired number of

registers are programmed.

For a read transfer, the I

2

C device address is the first part of

the serial transfer. Then the internal register pointer is

loaded. At this point another start cycle is initiated to access

the individual registers. Figure 14 shows the programming

flow for read transfer of the internal registers. Multiple regis-

ters can be read and the pointer register will autoincrement

up through the pointer register address space. On the last

data read, an acknowledge should not be issued. A stop

cycle is used to end the transfer after the desired number of

registers are read.

Product ID Register

The HMP8112 contains a product ID register that can be

used to identify the presence of a board during a Plug 'n Play

detection software algorithm. The Product ID code is 12

H

and the register is the last register in the HMP8112 (1B

H

).

Output Data Port Modes

The HMP8112 can output data in 2 formats, an 8-bit Burst

mode and a 16-bit Synchronous Pixel Transfer mode. In 16-bit

Synchronous Pixel Transfer Mode pixel data is output at the

TABLE 4. SHARPNESS GAIN FACTOR SELECTS

XF1

XF0

GAIN FACTOR

0

0

SCALED BY 1.0

0

1

SCALED BY 2.0

1

0

SCALED BY 4.0

1

1

SCALED BY 0

˜

4096

FACTOR

GAIN

MIN

I

2

C

COLOR

KILLER

LINE

COUNT

UV

DATA

AGC

ENABLE

FIGURE 11. LOOP FILTER BLOCK DIAGRAM (HYSTERESIS)

FACTOR

GAIN

MAX

AGC

GAIN

FACTOR

+5V

HMP8112

VIDEO

DECODER

+5V

SDA

SCL

+5V

40

41

4k

4k

FIGURE 12. PULLUP RESISTOR CONFIGURATION

HMP8112

12

CLK frequency and Table 5 shows the number of data points

per video line to expect for a given standard. Data is output as

4:2:2 subsampled data in a Y-Cb/Y-Cr 16-bit sequence. The

Data Valid (DVLD) flag is asserted when video data is present

on the 16-bit output port of the HMP8112 (Y[7:0], CbCr[7:0]).

The ACTIVE flag is asserted when the active video portion of

the horizontal scan line is present on the data output port. See

Figure 15 for Synchronous Pixel Transfer Mode timing. DVLD is

asserted every time the output sample rate converter has a

valid output. When DVLD and ACTIVE are used together the

visual portion of the image can be captured. When DVLD is

used alone all valid data during the Horizontal, Vertical and Ref-

erence Burst Timing are available. ACTIVE is asserted from

lines 22 through 262.5 and lines 285.5 through 525 for NTSC

(and PAL M). Active is asserted from lines 23.5 through 310

and lines 336 through 623.5 for PAL (B, D, G, H, I, N, Comb N).

The CLK can be run on a 20MHz - 30MHz clock source. Data

will be output (on average) at the Output Data Rate shown in

Table 5 for a given standard. Data is clocked out synchronous

to CLK and will come in bursts. To smooth out the data rate to

a regular rate a CLK of 2X the average output data rate can

be used. In the 16-bit pixel transfer, data is sequenced on the

CbCr[7:0] data bus, starting with Cb and then Cr.

For Burst Mode output format the Y[7:0] output bus is used

to transfer all YCbCr data in 8-bit format. The data is also

4:2:2 subsampled but will only contain the active video por-

tion of the line. The HMP8112 uses an internal 32 deep fifo

to handle latencies between the output sample rate and the

CLK frequency. In this mode, the data is clocked out at the

CLK rate and only clock frequencies of 24.5454MHz, 27MHz

and 29.5MHz can be used. In 8-bit data mode, the data is

sequenced on the Y[7:0] bus in Cb, Y, Cr, Y format. ACTIVE

is asserted as soon as the mode is selected. DVLD when

asserted indicates a valid active pixel is available. Pixels dur-

ing the horizontal and vertical blanking are not available.

Only the active portions of the video line are output.

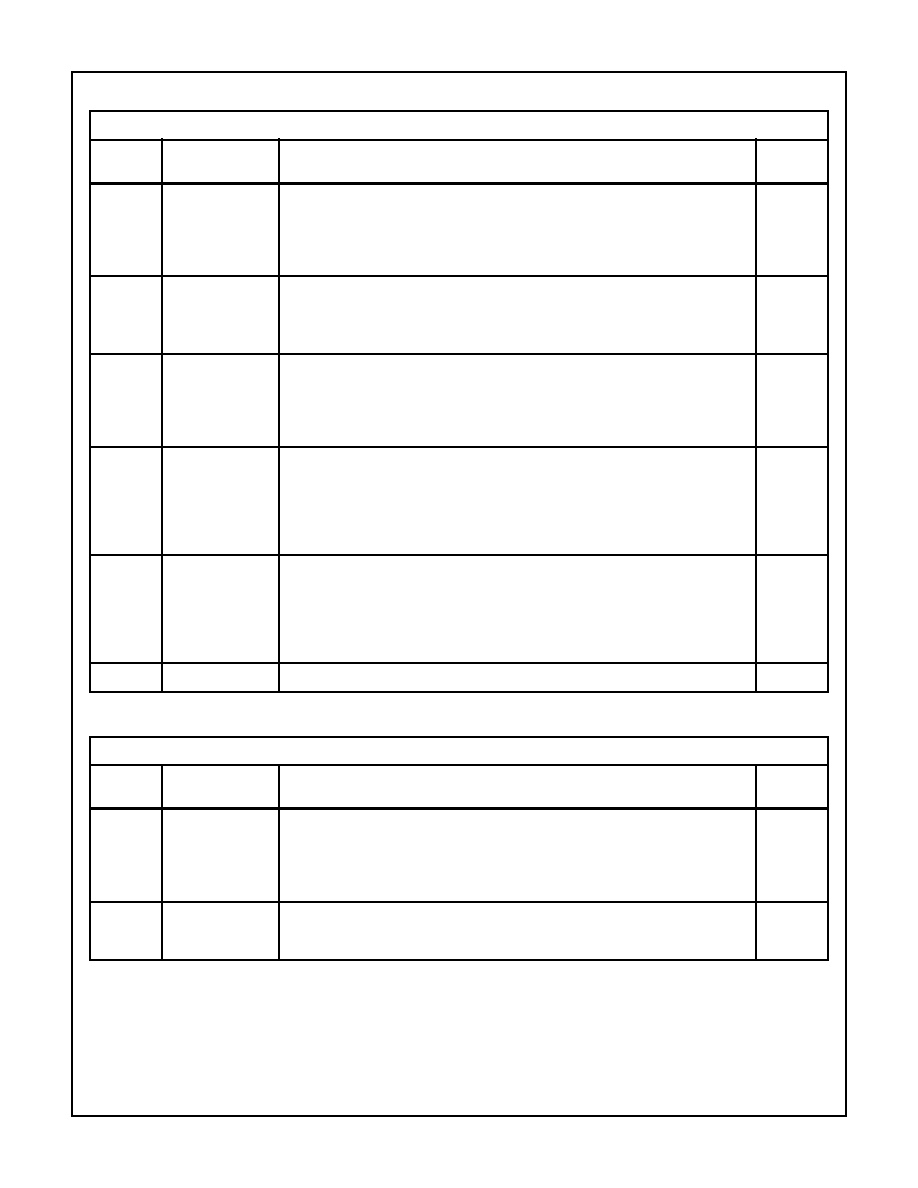

TABLE 5. OUTPUT MODE STANDARDS

STANDARD

OUTPUT

DATA

RATE

ACTIVE

PIXELS/

LINE

TOTAL

PIXELS/

LINE

TOTAL

LINES/

FIELD

NTSC Square Pixel

12.27MHz

640

780

262.5

NTSC CCIR 601

13.5MHz

720

858

262.5

PAL B, D, G, H, I, N,

COMB N, CCIR601

13.5MHz

720

864

312.5

PAL M CCIR 601

13.5MHz

720

858

262.5

PAL B, D, G, H, I, N

Square Pixel

14.74MHz

768

944

312.5

PAL M Square Pixel 14.74MHz

640

780

312.5

SDA

SCL

START

CONDITION

S

1-7

ADDRESS

8

R/W

9

ACK

1-7

DATA

8

9

ACK

STOP

CONDITION

P

FIGURE 13. I

2

C SERIAL TIMING FLOW

S = START CYCLE

P = STOP CYCLE

A = ACKNOWLEDGE

FROM MASTER

FROM HMP8112

0x88

DATA WRITE

DATA

DATA

0x88

DATA READ

REGISTER

POINTED

TO BY

SUBADDR

REGISTER

POINTED

TO BY

SUBADDR

NA = NO ACKNOWLEDGE

0x89

1000 100 (R/W)

1000 100 (R/W)

FIGURE 14. REGISTER WRITE PROGRAMMING FLOW

S

CHIP ADDR

A

SUB ADDR

A

DATA

DATA

A

A

P

NA

A

A

CHIP ADDR

S

A

SUB ADDR

A

CHIP ADDR

S

P

HMP8112

13

Reset

The RESET pin is used to return the decoder to an initializa-

tion state. This pin should be used after a power-up to set

the part into a known state. The internal registers are

returned to their RESET state and the Serial I

2

C port is

returned to inactive state. The RESET pin is an active low

signal and should be asserted for minimum of 1 CLK cycle.

After a RESET or a software reset has occurred all output

pins are three-stated. The following pins must be pulled high

to ensure proper operation:

HSYNC

VSYNC

DVLD

ACTIVE

FIELD

A 10K or smaller pullup resistor to V

CC

is recommended.

/

CLK

Y

N

Y

0

Y

1

Y

2

t

DLY

DVLD

Y[7-0]

ACTIVE

t

DVLD

Cr

N

Cb

0

Cr

0

Cb

1

CbCr[7-0]

NOTE 1

NOTE 2

NOTES:

1. Y0 is the first active luminance pixel of a line. Cb0 and Cr0 are first active chrominance pixels in a line. Cb and Cr will alternate every cycle

due to the 4:2:2 subsampling.

2. Active is asserted for lines 22-262.5 and 285.5-525. DVLD is asserted for every valid pixel during both active and blanking regions. DVLD

is asserted during vertical and horizontal sync.

FIGURE 15A. OUTPUT TIMING 16-BIT MODE

LINES 1-21

(LINES 1-23.5)

(LINES 23.5-310)

(LINES 311-335)

(LINES 336-623.5)

LINES 263.5-284

NTSC M, N PAL M

(PAL B, D, G, H, I, N COMB N)

(PAL B, D, G, H, I, N COMB N)

NTSC M, N PAL M

FIGURE 15B. ACTIVE VIDEO REGIONS IN 16-BIT MODE

<- PIXEL 0

LINES 285-525

<- PIXEL 0

LINES 22-263.5

PIXEL 1

PIXEL 2

PIXEL 3

PIXEL N

PIXEL N-1

PIXEL N-2

PIXEL N-3

CLK

DVLDY

t

DLY

Y[7-0]

ACTIVE

t

DVLD

Cb

0

Y

0

Cr

0

Y

1

Cb

2

Y

2

Cr

2

FIGURE 16. OUTPUT TIMING 8-BIT MODE

HMP8112

14

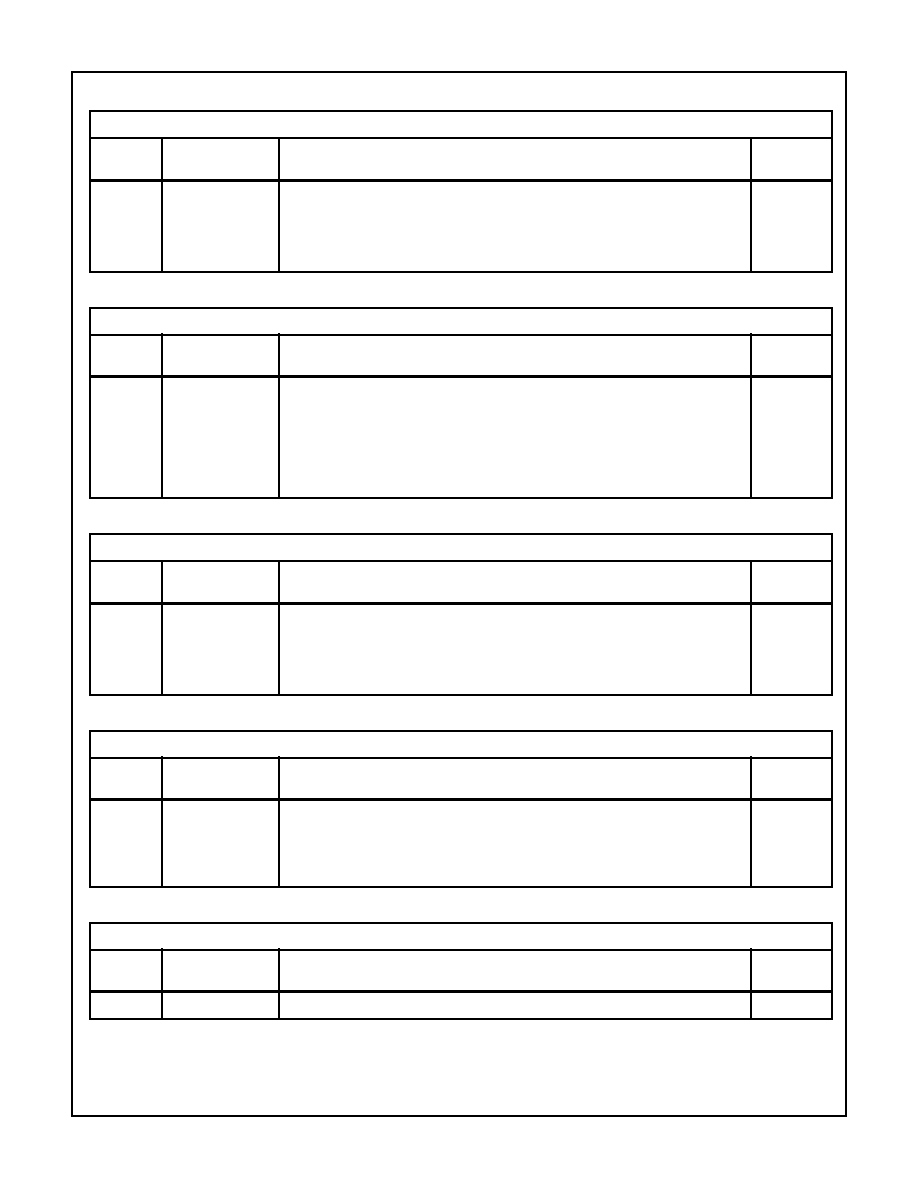

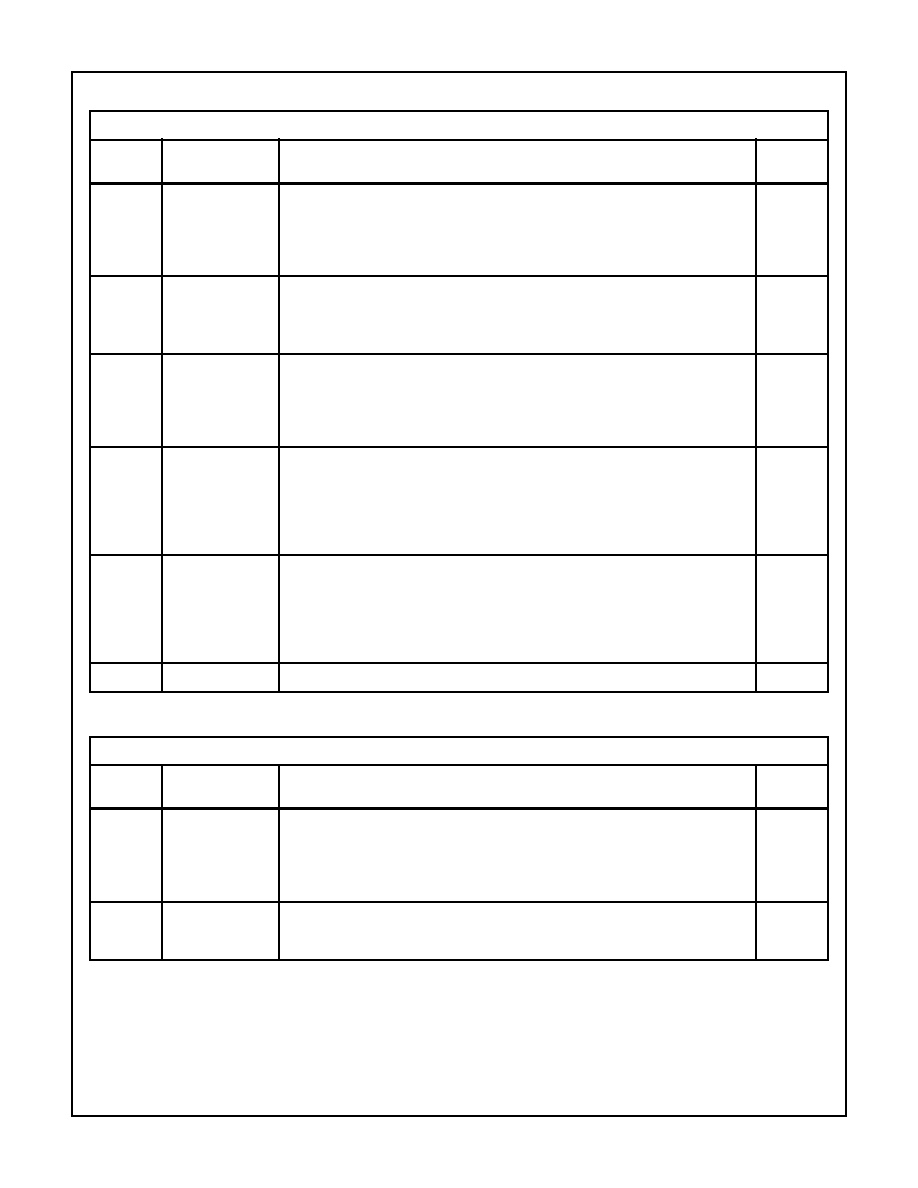

TABLE 6. VIDEO INPUT CONTROL

DESTINATION ADDRESS = 00

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 6

Video Input

Standard

These bits select the video input standard.

00 = PAL B, G, H, I, N; 4.43MHz subcarrier; 50fps; 625 lines/frame;

01 = PAL M; 3.58MHz subcarrier; 60fps; 525 lines/frame;

10 = Special PAL N; 3.58MHz subcarrier; 50fps; 625 lines/frame;

11 = NTSC M; 3.58MHz subcarrier; 60fps; 525 lines/frame (default);

11

B

5

Color Trap Filter

Disable

This bit enables the color subcarrier trap filter. The filter removes the color subcarrier infor-

mation from the luminance channel. The filter should be enabled for PAL Standard systems.

0 = Enabled

1 = Disabled (default)

1

B

4

Chrominance Low

Pass Filter Disable

This bit enables the chrominance low pass filter. This filter band limits the chrominance

channel to remove luminance artifacts. This filter should be enabled for PAL Standard

systems.

0 = Enabled

1 = Disabled (default)

1

B

3

Automatic Color

Gain Control

This bit enables the color AGC function. When this bit is set the color AGC will automati-

cally adjust the chrominance channel gain, to drive the color reference burst to a nominal

±

20 IRE's. When this bit is cleared the color AGC gain factor is set to 1.0 and the color

saturation must be adjusted to obtain nominal CrCb values.

0 = Disabled

1 = Enabled (default)

1

B

2 - 1

A/D Converter

Multiplexor Selects

These bits control the A/D input select multiplexers and whether S-Video is being input as

follows: MUXSEL1,0 =

0, 0 = Select Composite Video Input #0, set decoder for Composite

1, 0 = Select Composite Video Input #1, set decoder for Composite

0, 1 = Select Composite Video Input #2, set decoder for Composite

1, 1 = Select S-Video Y and C Inputs

00

B

0

Not Used

Write Ignored, Read 0's

X

B

TABLE 7. LUMINANCE BRIGHTNESS CONTROL

DESTINATION ADDRESS = 01

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7

IRE Setup

Cancellation Control

This bit enables the black setup cancelation circuit for NTSC sources. When this bit is set

a value of 73 is used to strip the sync information from the video signal. When this bit is

cleared a value of 64 is used to strip the sync information.

0 = subtract 64 from the luminance signal

1 = subtract 73 from the luminance signal

1

B

6 - 0

Luminance

Brightness Control

These bits control the brightness adjustment to the luminance channel. The brightness

adjustment value is a number that ranges from +63 to -64. This register is in the two's

complement format, where bit 6 is the sign bit.

000 0000

B

HMP8112

15

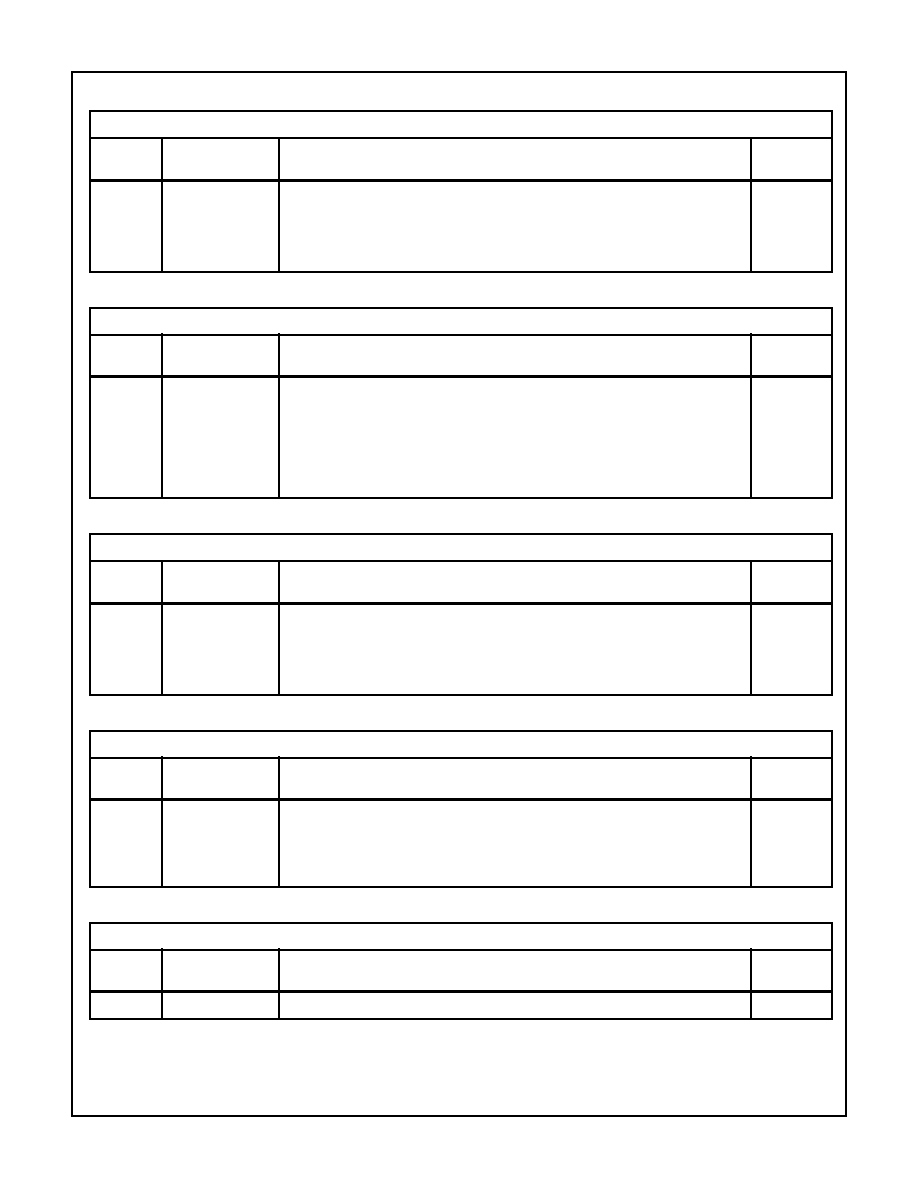

TABLE 8. LUMINANCE CONTRAST ADJUST REGISTER

DESTINATION ADDRESS = 02

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Luminance Contrast

Adjust Factor

This register sets the contrast adjust factor. This value is multiplied by the luminance data

and allows the data to be scaled from 0 to a factor of +1.96875. This 8-bit number is a

fractional number as shown below:

2

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

The contrast factor is applied after the brightness.

1011 1101

B

TABLE 9. HUE ADJUST REGISTER

DESTINATION ADDRESS = 03

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Hue Phase Adjust

This register sets the hue phase offset adjustment. This 8-bit number is applied as a

phase offset to the CbCr data coming out of the demodulator. This 8-bit number is a in

the range of +127 to -128. The hue adjust has as range of 30

o

with each count in this

register allowing a 0.25

o

phase adjustment. This register is in two's complement format,

where bit 7 is the sign bit.

0000 0000

B

TABLE 10. LUMINANCE SHARPNESS CONTROL REGISTER

DESTINATION ADDRESS = 04

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 6

High Frequency

Enhancement Factor

These bits adjust the amplitude of high frequency components in the luminance video

signal. The attenuation or multiplication of the high frequency components is adjusted as

shown below:

00 = Multiply high frequency components by 1.0

01 = Multiply high frequency components by 2.0

10 = Multiply high frequency components by 4.0

11 = Zero out high frequency components.

00

B

5 - 4

Middle Frequency

Enhancement

Factor

These bits adjust the amplitude of middle frequency components in the luminance video

signal. The attenuation or multiplication of the middle frequency components is adjusted

as shown below:

00 = Multiply middle frequency components by 1.0

01 = Multiply middle frequency components by 2.0

10 = Multiply middle frequency components by 4.0

11 = Zero out middle frequency components.

00

B

3 - 2

Low Frequency

Enhancement

Factor

These bits adjust the amplitude of low frequency components in the luminance video sig-

nal. The attenuation or multiplication of the low frequency components is adjusted as

shown below:

00 = Multiply low frequency components by 1.0

01 = Multiply low frequency components by 2.0

10 = Multiply low frequency components by 4.0

11 = Zero out low frequency components.

00

B

1 - 0

Vertical High

Frequency

Enhancement

Factor

These bits adjust the amplitude of vertical high frequency components in the luminance

video signal. The attenuation or multiplication of the vertical high frequency components

is adjusted as shown below:

00 = Multiply vertical high frequency components by 1.0

01 = Reserved.

10 = Reserved.

11 = Zero out vertical high frequency components.

00

B

HMP8112

16

TABLE 11. COLOR SATURATION ADJUST FACTOR

DESTINATION ADDRESS = 05

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Color Saturation

Adjust Factor

This register sets the color saturation adjust factor. This value is multiplied by the chromi-

nance (CbCr) data and allows the data to be scaled from 0 to a factor of +1.96875. This 8-bit

number is a fractional number as shown below:

2

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

The contrast factor is applied after the brightness.

1001 1101

B

TABLE 12. PHASE LOCKED LOOP CHROMINANCE SUBCARRIER TO BUS CLOCK FREQUENCY RATIO

DESTINATION ADDRESS = 06

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Chroma PLL Ratio

These bits are used to program the ratio of the incoming video chrominance color sub-

carrier frequency to the BUS Clock used. This number serves as the reference frequency

of the chrominance PLL and must be very accurate. This is the lower byte of the ratio and

encompasses the following range:

2

-9

2

-10

2

-11

2

-12

2

-13

2

-14

2

-15

2

-16

The default value is for a CLK frequency of 27MHz and a color subcarrier of 3.579545

MHz.

1100 0001

B

TABLE 13. PHASE LOCKED LOOP CHROMINANCE SUBCARRIER TO BUS CLOCK FREQUENCY RATIO

DESTINATION ADDRESS = 07

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 8

Chroma PLL Ratio

These bits are used to program the ratio of the incoming video chrominance color sub-

carrier frequency to the BUS Clock used. This number serves as the reference frequency

of the chrominance PLL and must be very accurate. This is the upper byte of the ratio

and encompasses the following range:

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

1000 0111

B

TABLE 14. HORIZONTAL AGC START TIME REGISTER

DESTINATION ADDRESS = 08

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Horizontal AGC

Pulse Programmable

Start Time

This register provides a programmable delay for the HAGC pulse that control the sync

tip AGC in the A/D converters. The start time of the HAGC pulse is set from the detection

of horizontal sync in the video data. HAGC is programmable in CLK increments and has

a fixed 1 clock delay following the falling edge of horizontal sync. This is the lower byte

of the 10-bit word.

0011 1111

B

TABLE 15. HORIZONTAL AGC START TIME REGISTER

DESTINATION ADDRESS = 09

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

Write Ignored, Read 0's.

XXXX XX

HMP8112

17

9 - 8

Horizontal AGC

Pulse Programmable

Start Time

This register provides a programmable delay for the HAGC pulse that control the sync

tip AGC in the A/D converters. The start time of the HAGC pulse is set from the detection

of horizontal sync in the video data. HAGC is programmable in CLK increments and has

a fixed 1 clock delay following the falling edge of horizontal sync. This is the upper byte

of the 10-bit word.

11

B

TABLE 16. HORIZONTAL AGC END TIME REGISTER

DESTINATION ADDRESS = 0A

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Horizontal AGC

Pulse Programmable

End Time

This register provides a programmable delay for the HAGC pulse that control the sync

tip AGC in the A/D converters. The end time of the HAGC pulse is set from the detection

of horizontal sync in the video data. HAGC is programmable in CLK increments and has

a fixed 1 clock delay following the falling edge of horizontal sync. This is the lower byte

of the 10-bit word.

0000 0000

B

TABLE 17. HORIZONTAL AGC END TIME REGISTER

DESTINATION ADDRESS = 0B

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

Write Ignored, Read 0's

XXXX XX

9 - 8

Horizontal AGC

Pulse Programmable

End Time

This register provides a programmable delay for the HAGC pulse that control the sync

tip AGC in the A/D converters. The end time of the HAGC pulse is set from the detection

of horizontal sync in the video data. HAGC is programmable in CLK increments and has

a fixed 1 clock delay following the falling edge of horizontal sync. This is the upper byte

of the 10-bit word.

00

B

TABLE 18. HORIZONTAL SYNC START TIME REGISTER

DESTINATION ADDRESS = 0C

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Horizontal Drive

Programmable Start

Time

This register provides a programmable delay for the external HDRIVE signal. The start

time of the HDRIVE pulse is set from the detection of horizontal sync in the video data.

HDRIVE is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the lower byte of the 10-bit word.

0011 1011

B

TABLE 19. HORIZONTAL SYNC START TIME REGISTER

DESTINATION ADDRESS = 0D

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

Write Ignored, Read 0's

XXXX XX

9 - 8

Horizontal Drive

Programmable Start

Time

This register provides a programmable delay for the external HDRIVE signal. The start

time of the HDRIVE pulse is set from the detection of horizontal sync in the video data.

HDRIVE is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the upper byte of the 10-bit word.

11

B

TABLE 15. HORIZONTAL AGC START TIME REGISTER (Continued)

DESTINATION ADDRESS = 09

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

HMP8112

18

TABLE 20. HORIZONTAL SYNC END TIME REGISTER

DESTINATION ADDRESS = 0E

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Horizontal Drive

Programmable End

Time

This register provides a programmable delay for the external HDRIVE signal. The end

time of the HDRIVE pulse is set from the detection of horizontal sync in the video data.

HDRIVE is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the lower byte of the 10-bit word.

0010 0000

B

TABLE 21. HORIZONTAL SYNC END TIME REGISTER

DESTINATION ADDRESS = 0F

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

Write Ignored, Read 0's

XXXX XX

9 - 8

Horizontal Drive

Programmable End

Time

This register provides a programmable delay for the external HDRIVE signal. The end

time of the HDRIVE pulse is set from the detection of horizontal sync in the video data.

HDRIVE is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the upper byte of the 10-bit word.

00

B

TABLE 22. PHASE LOCKED LOOP ADJUST REGISTER

DESTINATION ADDRESS = 10

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Phase Locked Loop

Filter Adjust Test

Register

The Phase Locked Loop time constants can be changed for testing purposes. It is rec-

ommended that the default value of (20

H

) always be used. The reset state is 00

H

.

0000 0000

B

TABLE 23. PHASE LOCKED LOOP SYNC DETECT WINDOW REGISTER

DESTINATION ADDRESS = 11

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Phase Locked Loop

Horizontal Sync

Detect Window

These bits control the PLL horizontal sync detect window. This window sets the length

of time that the line lock PLL will allow the detection of the HSYNC. HSYNC outside of

this window are declared missing and will cause the missing sync logic to start counting

missing syncs. For NTSC this value should be DD

H

and for PAL, FF

H

.

1101 1101

B

TABLE 24. DC RESTORE START TIME REGISTER

DESTINATION ADDRESS = 12

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

DC Restore

Programmable Start

Time

This register provides a programmable delay for the internal DC RES signal. The start

time of the DC RES pulse is set from the detection of horizontal sync in the video data.

DC RES is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This signal is used to run the GATE B pin of the A/D con-

verter. This is the lower byte of the 10-bit word.

0011 0111

B

HMP8112

19

TABLE 25. DC RESTORE START TIME REGISTER

DESTINATION ADDRESS = 13

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

XXXX XX

9 - 8

DC Restore

Programmable Start

Time

This register provides a programmable delay for the internal DC RES signal. The start

time of the DC RES pulse is set from the detection of horizontal sync in the video data.

DC RES is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the upper byte of the 10-bit word.

00

B

TABLE 26. DC RESTORE END TIME REGISTER

DESTINATION ADDRESS = 14

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

DC Restore

Programmable End

Time

This register provides a programmable delay for the internal DC RES signal. The end

time of the DC RES pulse is set from the detection of horizontal sync in the video data.

DC RES is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This signal is used to run the GATE B pin of the A/D con-

verter. This is the lower byte of the 10-bit word.

0101 0010

B

TABLE 27. DC RESTORE END TIME REGISTER

DESTINATION ADDRESS = 15

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

15 - 10

Not Used

XXXX XX

9 - 8

DC Restore

Programmable End

Time

This register provides a programmable delay for the external DC RES signal. The end

time of the DC RES pulse is set from the detection of horizontal sync in the video data.

DC RES is programmable in CLK increments and has a fixed 1 clock delay following the

falling edge of horizontal sync. This is the upper byte of the 10-bit word.

00

B

TABLE 28. OUTPUT FORMAT CONTROL REGISTER

DESTINATION ADDRESS = 16

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7

Square Pixel/ITU-R

BT601 Select

When "1", Square pixel output is selected, when "0" ITU-R BT601 output rate is selected.

0

B

6, 5, 4

Output Field Control

"FLD_CONT(2-0)"

These bits control the field capture rate of the HMP8112. The user can select every 4th

field, every other field or every field of video to be output to the data port.

000 = No Capture Enabled

001 = Capture every 4th field

010 = Capture every 2nd field

011 = Capture every 2nd odd field

100 = Capture every 2nd even field

101 = Capture every odd field

110 = Capture every even field

111 = Capture all fields

000

B

3

8/16 output Select

When "1", the 8-bit Burst Transfer output mode is selected. When "0", the 16-bit Synchro-

nous Pixel Transfer output mode is selected.

0

B

2

OEN

This bit enables the Y(7-0), CbCr(7-0), ACTIVE, HSYNC, VSYNC and DVLD outputs.

1 = Outputs enabled; 0 = three-stated.

0

B

HMP8112

20

1

Vertical Pixel Siting

When this bit is cleared (`0') the chrominance pixels have a 1/2 line pixel offset from their

associated luminance pixel in a 4:2:2 subsampled scheme. When this bit is set (`1') the

pixel siting is line aligned with the luminance pixels in a 4:2:2 subsampled scheme. The

bit is cleared by a RESET.

0

B

0

Not Used

Write Ignored, Read 0's

X

TABLE 29. SOFTWARE RESET AND VIDEO STATUS REGISTER

DESTINATION ADDRESS = 17

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7

Software Reset

When this bit is set to 1, the entire device except the I

2

C bus is reset to a known state

exactly like the RESET input. The software reset will initialize all register bits to their reset

state as well as place the PLLs back at the power-up state. Once set this bit is self clear-

ing after only 4 CLK periods. This bit is cleared on power-up by the external RESET pin.

0

B

6

Black Screen

This flag when set (`1') will set the output video to black when a lost vertical sync has

been detect. This flag is cleared after a RESET.

Read Only

5

Line Locked Flag

This flag when set (`1') indicates that the Line Locked-Phase Locked Loop has locked to

the video data. The state of this flag is reflected on the LOCKED output pin. This flag is

cleared after a RESET of Software Reset.

Read Only

4

Standard Error Flag

This flag when set (`1') indicates that the Standard detected does not match the one se-

lected in the Video Input Control Register. The standard is checked against a line count

and if the line count is significantly different than the expected value then this flag is trig-

gered. The state of this flag is reflected on the STANDARD_ERROR output pin. This flag

is cleared after a RESET or Software Reset.

Read Only

3 - 0

Not Used

Write ignored, Read 0's.

XXXX XX

TABLE 30. RESERVED

DESTINATION ADDRESS = 18

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Reserved Read

Only

This register is reserved for future use. This register will read all zero's and is write ig-

nored.

0000 0000

B

TABLE 31. RESERVED

DESTINATION ADDRESS = 19

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 6

Reserved Read

Only

This register is reserved for future use. This register will read all zero's and is write ig-

nored.

00

B

5

Lost HSYNC

Control

This bit controls when the PLL will declare lost horizontal sync, leave track mode and re-

turn to acquisition to acquire a new HSYNC reference. This bit should be used with

VCR's with extremely gross headswitch errors. When this bit is cleared, lost line lock is

declared after 12 missing horizontal syncs. When this bit is set, lost line lock is declared

after one missing horizontal sync and the line lock PLL will reacquire the first HSYNC is

detects. This bit is cleared by RESET.

0

B

4 - 0

Reserved Read

Only

This register is reserved for future use. This register will read all zero's and is write ignored.

0 0000

B

TABLE 28. OUTPUT FORMAT CONTROL REGISTER (Continued)

DESTINATION ADDRESS = 16

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

HMP8112

21

Pinout

80 LEAD PQFP

TOP VIEW

TABLE 32. RESERVED

DESTINATION ADDRESS = 1A

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Reserved Read

Only

This register is reserved for future use. This register will read all zero's and is write ig-

nored.

0000 0000

B

TABLE 33. PRODUCT ID REGISTER

DESTINATION ADDRESS = 1B

H

BIT

NUMBER

FUNCTION

DESCRIPTION

RESET

STATE

7 - 0

Product ID Code

This register contains the last two digits of the product part number for use as a software

ID. These bits are read only and always read 12

H

.

0001 0010

B

21

22

23

24

25 26 27 28 29 30 31 32 33 34 35 36

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

AGND

AV

CC

AGND

LIN0

NC

LIN2

LIN1

AGND

AGND

AV

CC

AGND

L_OUT

AGND

AV

CC

CLK

DGND

DV

CC

WPE

GAIN_CNTL

CCLAMP_CAP

DEC_L

DV

CC

DGND

DGND

RESET

DGND

TEST

L_ADIN

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

Y5

DV

CC

Y4

Y3

Y2

Y1

Y0

DGND

DV

CC

CbCr7

CbCr6

CbCr5

CbCr4

CbCr3

DGND

CbCr2

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

DGND

DV

CC

DEC_T

LA

GC_CAP

LCLAMP_CAP

DV

CC

DGND

DGND

HSYNC

VSYNC

DGND

DV

CC

D

VLD

A/D_TEST

NC

CIN

NC

63

62

61

A

CTIVE

Y7

DGND

DGND/NC

37 38 39 40

DV

CC

CLK

DGND

SD

A

DVCC/NC

CbCr1

CbCr0

SCL

44

43

42

41

17

18

19

20

80

AGND

NC

FIELD

Y6

AGND

AGND

AGND

HMP8112

22

Pin Description

NAME

PQFP PIN

NUMBER

INPUT/

OUTPUT

DESCRIPTION

LIN[0:2]

5, 6, 7

Input

Analog Video Inputs. Inputs 0 and 1 are composite inputs. Input 2 can be either a

composite input or the Y component of an S-Video signal.

CIN

19

Input

Analog Chroma input component of an S-Video Input.

WPE

27

Input

White Peak Enable. When enabled (`1'), the video amplifiers gain is reduced when

the digital output code exceeds 248. When disabled (`0') the video amplifier will clip

when the A/D reaches code 255.

GAIN_CTRL

28

Input

Gain Control Input. DC voltage to set the video amplifier's gain.

DEC_T

78

Input

Decoupling for A/D Converter Reference. Connect a 0.01

µ

F and 0.1

µ

F capacitors to

AGND.

DEC_L

30

Input

Decoupling for A/D Converter Reference. Connect a 0.01

µ

F and 0.1

µ

F capacitors to

AGND.

LAGC_CAP

77

Input

Capacitor Connection for Luminance AGC Circuit. Controls the AGC loop time con-

stant.

LCLAMP_CAP

76

Input

Capacitor Connection for Luminance Clamp Circuit. Controls the clamp loop time

constant.

CCLAMP_CAP

29

Input

Capacitor Connection for Chrominance Clamp Circuit. Controls the clamp loop time

constant.

L_ADIN

8

Input

Luminance A/D Converters input from antialiasing filter.

L_OUT

9

Output

Luminance or Composite Analog Video Amplifier output to antialiasing filter.

SDA

40

Input/

Output

The serial I

2

C serial input/output data line.

SCL

41

Input

The serial I

2

C serial bus clock line.

CLK

13, 38

Input

Master clock for the decoder. This clock is used to run the internal logic, A/D convert-

ers, and Phase Locked Loops. All I/O pins (except the I

2

C) are synchronous to this

master clock. A 50ppmcrystal should be used with a waveform symmetry of 60/40%

or better.

RESET

34

Input

Asynchronous Reset pin. Master Chip reset to initialize the internal states and set

the internal registers to a known state.

CbCr[0:7]

42, 43, 45,

47-51

Output

CbCr Data Output Port. The chrominance data output port of the decoder. Data is in

unsigned format and can range from 0 to 255. The CbCr data is subsampled to 4:2:2

format. In 4:2:2 format the CbCr bus toggles between Cb and Cr samples with the

first sample of a line always being Cb. The port is designed to minimize external logic

needed to interface to a VRAM Serial Access Port, DRAM or FIFO.

Y[0:7]

54-58, 60, 63,

64

Output

Y Data Output Port. The luminance data output port of the decoder. Data is in un-

signed format and can range from 16 to 255. The port is designed to minimize exter-

nal logic needed to interface to a VRAM Serial Access Port, DRAM or FIFO.

DVLD

66

Output

Data Valid. This pin signals when valid data is available on the data output ports. This

pin is three-stated after a RESET or software reset and should be pulled high

through a 10K resistor.

HSYNC

71

Output

Horizontal Sync. This video synchronous pulse is generated by the detection of hor-

izontal sync on the video input. In the absence of video, the HSYNC rate is set when

the internal PLL counters overflow. The HSYNC begin and end time can be pro-

grammed and is synchronous to CLK. This pin is three-stated after a RESET or soft-

ware reset and should be pulled high through a 10K resistor.

HMP8112

23

VSYNC

70

Output

Vertical Sync. This video synchronous pulse is generated by the detection of a vertical

sync on the video input. In the absence of video the VSYNC rate is set by the over flow

of the internal line rate counter. This pin is three-stated after a RESET or software reset

and should be pulled high through a 10K resistor.

FIELD

67

Output

Field Flag. When set (`0') this signals that an ODD field is presently being output from

the decoder. When cleared (`1') this signals an EVEN field. This flag will toggle when

no vertical sync is detected and 337 lines have elapsed. This pin is three-stated after

a RESET or software reset and should be pulled high through a 10K resistor.

ACTIVE

65

Output

Active Video Flag. This flag is asserted (`1') when the active portion of the video line

is available on the output port. This signal is always set during Burst Output data

mode. This flag is free running and synchronous to CLK. This pin is three-stated after

a RESET or software reset and should be pulled high through a 10K resistor.

TEST

36

Input

Test input. This pin is used for production test and should be connected to digital

ground.

DV

CC

26, 31,37, 44,

52, 59, 68, 75,

79

Input

5V Logic Supply Pins

DGND

25, 32, 33, 35,

39, 46, 53, 61,

62, 69, 72, 73,

80

Input

Digital Ground Pins

AV

CC

2, 12,14

Input

5V Analog Supply Pins

AGND

1, 3, 10, 11,

15,16, 21, 22,

23, 24

Input

Analog GND

A/D TEST

17

Output

A/D Test Pin. This pin should be left open.

NC

4, 18, 20, 74

NA

No Connect. These pins should be left open.

Pin Description

(Continued)

NAME

PQFP PIN

NUMBER

INPUT/

OUTPUT

DESCRIPTION

HMP8112

24

Absolute Maximum Ratings

Thermal Information

Digital Supply Voltage (V

CC

to DGND) . . . . . . . . . . . . . . . . . . . 7.0V

Digital Input Voltages . . . . . . . . . . . . . . . . . GND -0.5V to V

CC

0.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

Operating Temperature Range

HMP8112CN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

o

C to 70

o

C

Thermal Resistance (Typical, See Note 1)

JA

(

o

C/W)

PQFP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

Maximum Power Dissipation

HMP8112CN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9W

Maximum Storage Temperature Range . . . . . . . . . .-65

o

C to 150

o

C

Maximum Junction Temperatures . . . . . . . . . . . . . . . . . . . . . 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air. Dissipation rating assumes device is mounted with

all leads soldered to printed circuit board

Electrical Specifications

V

CC

= 5.0V, T

A

= 25

o

C

PARAMETER

SYMBOL

TEST CONDITION

HMP8112C

UNITS

MIN

TYP

MAX

POWER SUPPLY CHARACTERISTICS

Power Supply Voltage Range

DV

CC

, AV

CC

Note 2

4.75

5

5.25

V

Power Supply Current

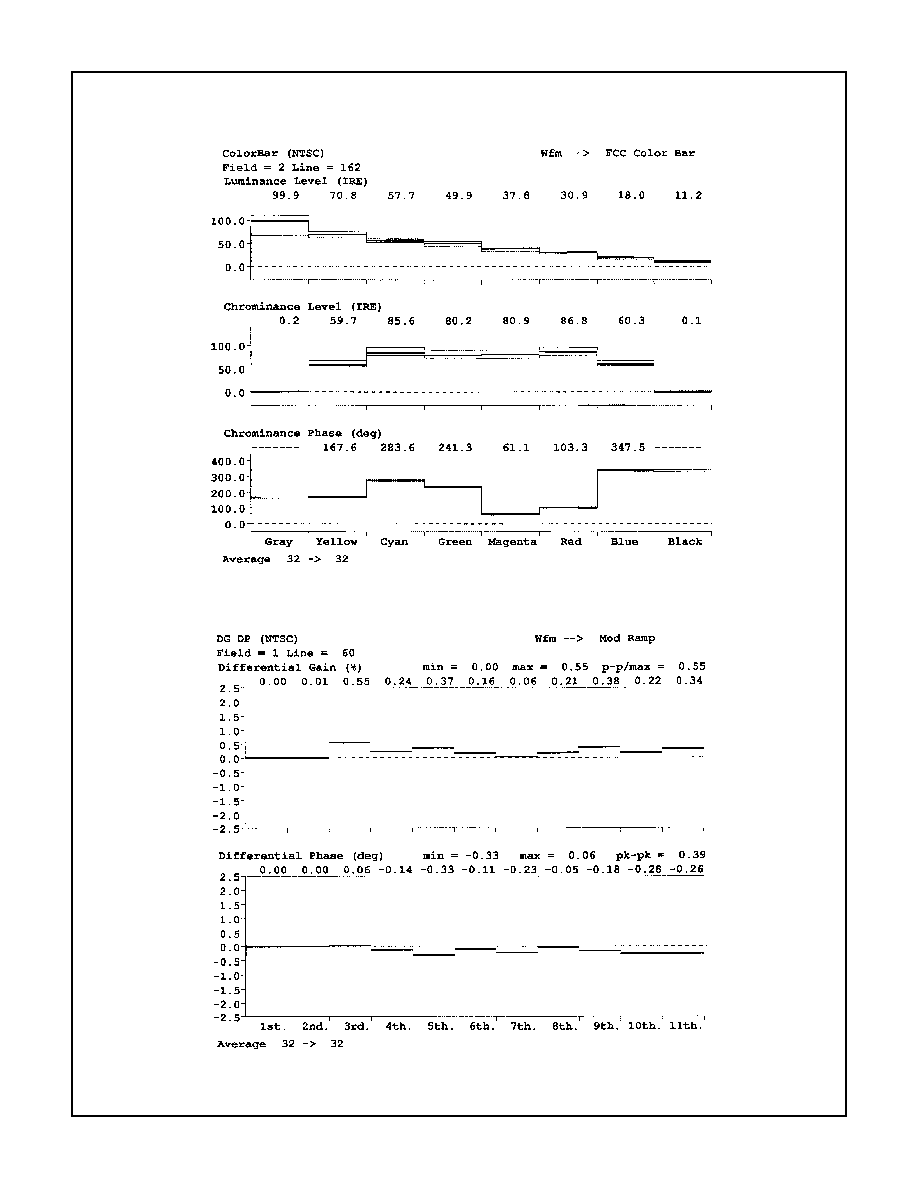

Digital I

CCOP

f

CLK

= 30MHz,

DV

CC

= 5.25V,

Outputs Not Loaded

-

45