| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HTC750xSI | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

HIGH TECH

CHIPS, INC.

04/30/00 1

PDIP, SOIC

1

8

2

7

3

6

4

5

HTC750XXX

VDD GND

NU MOUT

NU CNTL

D1 D0

Melody Generator

1.0 General description.

This circuit is designed to work as melody generator. HTC750 will play selected melody (selection is

done by driving D0 and D1 inputs to low or high value) and once melody is finished it will enter power

saving mode which we call Sleep mode. In Sleep mode HTC750 consumes less then few microamps

of current. One of possible uses of HTC750 is designing it in doorbell. This device was designed

using our proprietary melody storing scheme to optimize

internal memory usage. HTC750 can play up to four melodies.

It can directly drive piezo-electrical sound source or with use of

external amplifier can drive speakers. Control output is

provided to control external relay or power switch. This output

goes high for duration of melody and could be used to control

the power to HTC750 and amplifier for duration of melody.

Possible uses are:

∑ Musical

doorbell.

∑ Melody generator for alarm clock.

∑ Musical

toys.

∑ Musical boxes for gifts, accessories or jewelry.

Features:

∑ Single chip solution.

∑ Minimum external components.

∑ Four

selectable

melodies.

∑ Minimum power consumption while in SLEEP mode.

Doorbell design using HTC750

C1

0.1uF

R3

1K

4.5V

BT1

Q1

NPN

Q2

PNP

LS1

8ohm

C3

47uF

1

2

4

3

R2

100K

R1

100K

U1

HTC750

NU

2

NU

3

MOUT

7

VDD

1

CNTL

6

D1

4

D0

5

GND

8

S1

HIGH TECH

CHIPS, INC.

04/30/00 2

2.0 Functional Description.

We will use schematics above to describe HTC750 operation. At power up HTC750 plays melody set

by dip-switch. After finishing melody it goes into sleep mode and drives all outputs to GND. In

prototypes we build using above schematics current consumption was less then 10uA. This current is

negligible enough to leave circuit constantly powered on. When device is in Sleep mode only way of

waking up the circuit is to recycle power. This is done using S1 pushbutton. Note that we are using

pushbutton with normal closed contacts. When this pushbutton is activated power to HTC750 is cut

down and when this pushbutton is released then part will play the melody. One can use pushbutton

with normal open contacts but it could result partial reproduction of melody.

Note the way CNTL output is used to save energy during Sleep mode. Energy saving is achieved by

cutting power to R1 and R2 resistors when part enters into Sleep mode and preventing battery

discharge through those resistors when associated dip-switch is on. T1 and T2 form simple current

amplifier to drive 8-ohm speaker. Almost any small signal transistor could be used in this amplifier.

Note that this amplifier will introduce additional distortions to amplified signal, because transistors are

not biased. This is done intentionally to simplify amplifier circuit and add one distinct character. This

amplifier does not use any current when its input is driven low. Any other amplifier circuit could be

used as long as care is taken to shut down the amplifier with CNTL output of HTC750 to save buttery.

This could be done by external relay. Quality of sound could be further enhanced if low pass filter is

added to output of HTC750. Please see Application note for HTC750.

Pin out description.

Abbreviations used: O - output, I - input, P - power.

Pin

Name

I / O Description

Notes

1

VDD

P

Power

+2.5V to +5.5V

2

NU

I

Not Used

Tie it to GND or VDD.

3

NU

I

Not Used

Tie it to GND or VDD.

4

D1

I

Melody selection input.

Tie it to GND or VDD.

5

D0

I

Melody selection input.

Tie it to GND or VDD.

6

CNTL

O

Control output

This output is driven high when part plays

melody. Can deliver up to 25mA current.

7

MOUT

O

Melody output

Signal on this output is square wave.

8

GND

P

Ground

Connect to ground.

3.0 Melody selection with D[0:1]

D1

D0

MELODY

GND

GND

Number 1

GND

VDD

Number 2

VDD

GND

Number 3

VDD

GND

Number 4

HIGH TECH

CHIPS, INC.

04/30/00 3

This table shows melody played when D0 and D1 are tied to ground or power. Note that this

part comes with different sets of melodies and those melody samples will be made available

for download.

4.0 Electrical characteristics.

Voltage on VDD pin in respect to GND

+2.5 to +5.5V

Operational current with no external load

3 mA

1

Current used in SLEEP mode

4uA

1

MOUT

output low voltage max (5mA load)

0.4V

1

MOUT

output high voltage min (5mA source)

VDD-0.7V

1

MOUT

maximum sink current

25mA

1

MOUT

maximum source current

25mA

1

CNTL

output low voltage max (5mA load)

0.4V

1

CNTL

output high voltage min (5mA source)

VDD-0.7V

1

CNTL

maximum sink current

25mA

1

CNTL

maximum source current

25mA

1

NOTES:

1. Those values are characterized but not tested.

5.0 Ordering information.

H

T

C

7

5

0

X

X

X

OPTIONAL: Temperature range:

C = 0

o

C to +70

o

C , I = - 40

o

C to + 85

o

C.

PACKAGE:

S ≠ 208 mil SOIC

D ≠ 300 mil PDIP.

MELODY

PART NUMBER.

HIGH TECH

CHIPS, INC.

04/30/00 4

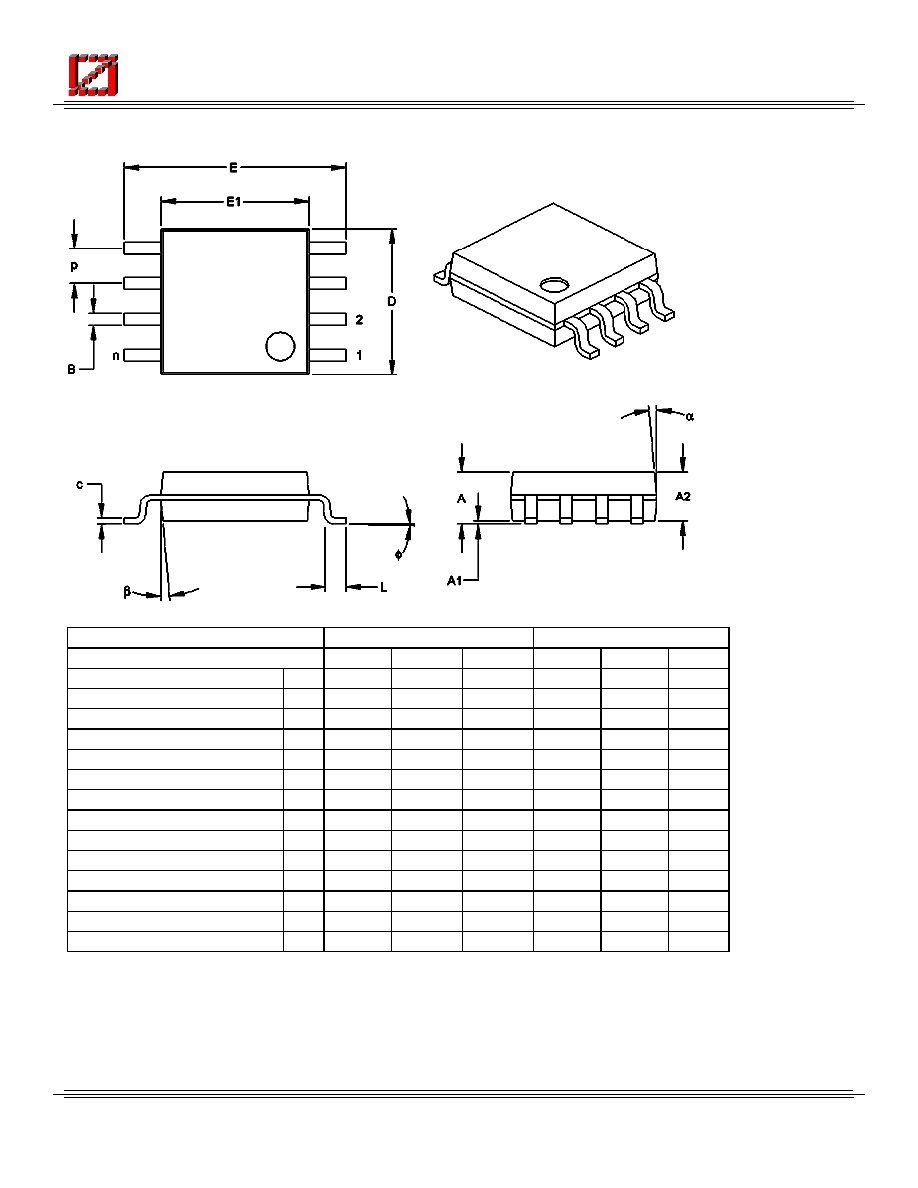

6.0 Mechanical information.

8-Lead Plastic Dual In-line (P) ≠ 300 mil (PDIP)

Units

INCHES*

MILLIMETERS

Dimension Limits

MIN

NOM

MAX

MIN

NOM

MAX

Number of Pins

n

8

8

Pitch

p

.100

2.54

Top to Seating Plane

A

.140

.155

.170

3.56

3.94

4.32

Molded Package Thickness

A2

.115

.130

.145

2.92

3.30

3.68

Base to Seating Plane

A1

.015

0.38

Shoulder to Shoulder Width

E

.300

.313

.325

7.62

7.94

8.26

Molded Package Width

E1

.240

.250

.260

6.10

6.35

6.60

Overall Length

D

.360

.373

.385

9.14

9.46

9.78

Tip to Seating Plane

L

.125

.130

.135

3.18

3.30

3.43

Lead Thickness

c

.008

.012

.015

0.20

0.29

0.38

Upper Lead Width

B1

.045

.058

.070

1.14

1.46

1.78

Lower Lead Width

B

.014

.018

.022

0.36

0.46

0.56

Overall Row Spacing

eB

.310

.370

.430

7.87

9.40

10.92

Mold Draft Angle Top

5

10

15

5

10

15

Mold Draft Angle Bottom

5

10

15

5

10

15

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash protrusions. Mold flash or protrusions shell

not exceed .010" (0.254mm)per side.

JEDEC Equivalent:MS-001

HIGH TECH

CHIPS, INC.

04/30/00 5

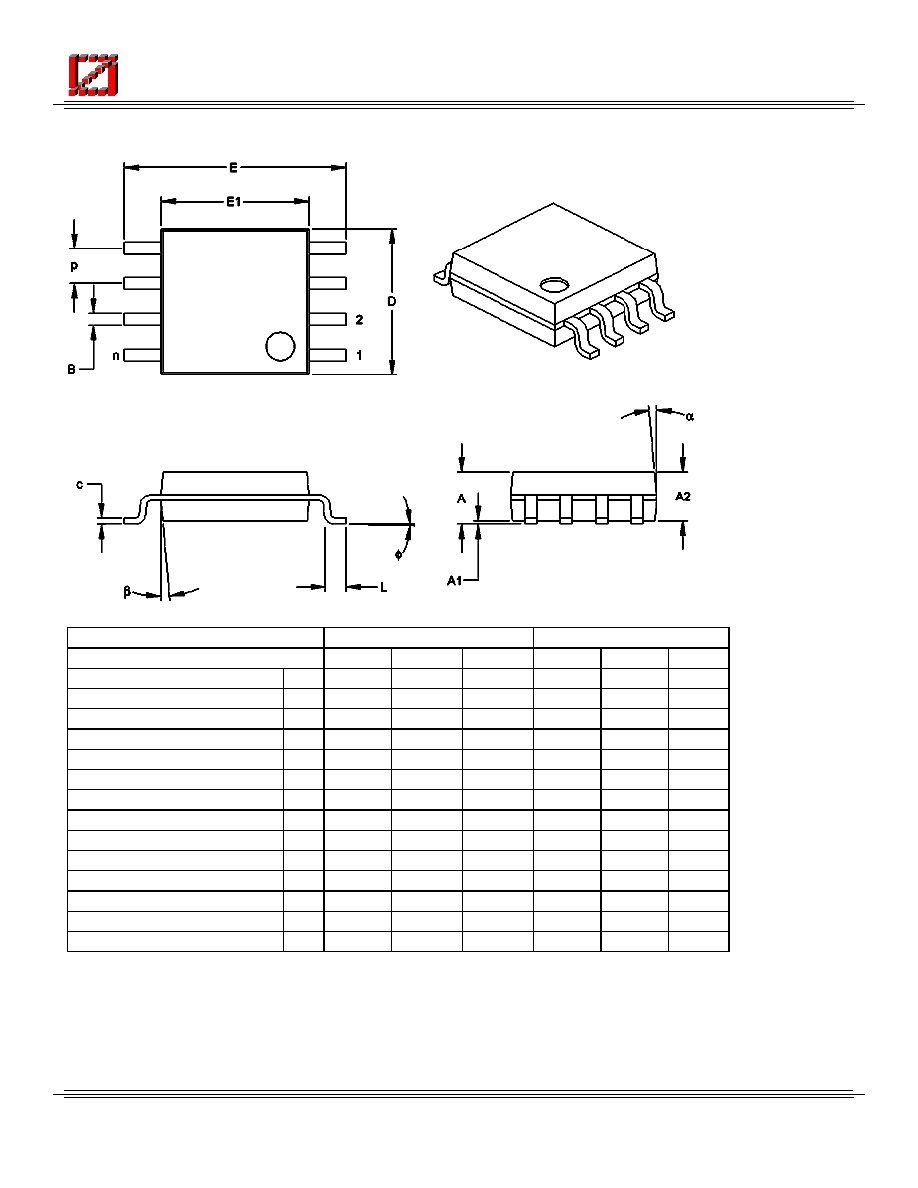

8-Lead Plastic Small Outline (SM) ≠ Medium, 208 mil (SOIC)

Units

INCHES

*

MILLIMETERS

Dimension Limits

MIN

NOM

MAX

MIN

NOM

MAX

Number of Pins

n

8

8

Pitch

P

.050

1.27

Overall Height

A

.070

.075

.080

1.78

1.97

2.03

Molded Package Thickness

A2

.069

.074

.078

1.75

1.88

1.98

Standoff

A1

.002

.005

.010

0.05

0.13

0.25

Overall Width

E

.300

.313

.325

7.62

7.95

8.26

Molded Package Width

E1

.201

.208

.212

5.11

5.28

5.38

Overall Length

D

.202

.205

.210

5.13

5.21

5.33

Foot Length

L

.020

.025

.030

0.51

0.64

0.76

Foot Angle

0

4

8

0

4

8

Lead Thickness

c

.008

.009

.010

0.20

0.23

0.25

Lead Width

B

.014

.017

.020

0.36

0.43

0.51

Mold Draft Angle Top

0

12

15

0

12

15

Mold Draft Angle Bottom

0 12

15

0

12

15

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash protrusions. Mold flash or

protrusions shell not exceed .010" (0.254mm)per side.