HA13557AFH

Combo (Spindle & VCM) Driver

ADE-207-234A (Z)

2nd. Edition

July 1997

Description

This COMBO Driver for HDD application consists of Sensorless Spindle Driver and BTL type VCM

Driver.

Bipolar Process is applied and a "Soft Switching Circuit" for less commutation noise and a "Booster

Circuit" for smaller Saturation Voltage of Output Transistor are also implemented.

Features

∑

Soft Switching Driver

∑

Small Surface Mount Package: FP-48T (QFP48 Pin)

∑

Low thermal resistance: 30

∞

C/W with 4 layer multi glass-epoxy board

∑

Low output saturation voltage

Spindle

1.44 V Typ (@1.8 A)

VCM

1.0 V Typ (@1.0 A)

Functions

∑

2.2 A Max/3-phase motor driver

∑

1.5 A Max BTL VCM Driver

∑

Auto retract

∑

Soft Switching Matrix

∑

Start up circuit

∑

Booster

∑

Speed Discriminator

∑

Internal Protector (OTSD, LVI)

∑

POR

∑

Power monitor

HA13557AFH

2

Pin Arrangement

1

2

3

4

5

6

36

35

34

33

32

31

30

29

28

27

26

25

VBST

VCMP

VCMN

BC2

BC1

GND

TAB

GND

W

RNF

PCOMP

CT

V

TAB

TAB

TAB

COMPOUT

NC*

NC*

GAIN

VCMENAB

GND

GND

POR

SPNENAB

READY

CLOCK

CNTSEL

RS

RETON

RETPOW

Vpsv

LVI2

GND

GND

OPIN(≠)

VCTL

OPIN(

+

)

RESINH

VREF1

U

C-PUMP

CLREF

R1

Vpss

GND

13 14 15 16 17 18

19 20 21 22 23 24

48 47 46 45 44 43

42 41 40 39

37

38

*NC : No internal connection

Please note that there is no isolation check between pin 34 and pin 35

at the testing of this IC.

(Top View)

7

8

9

10

11

12

GND

V

SS

LVI1

DELAY

COMM

POLSEL

HA13557AFH

3

Pin Description

Pin Number Pin Name

Function

1

VBST

Boosted voltage output to realize the low output saturation voltage

2

VCMP

Output terminal on VCM driver

3

VCMN

Output terminal on VCM driver

4

BC2

To be attached the external capacitor for booster circuitry

5

BC1

ditto

6, TAB, 7

GND

Ground pins

8

W

W phase output terminal on spindle motor driver

9

RNF

Sensing input for output current on spindle motor driver

10

PCOMP

To be attached the external capacitor for phase compensation of spindle

motor driver

11

CT

To be attached the center tap of the spindle motor for B-EMF sensing

12

V

V phase output terminal on spindle motor driver

13

U

U phase output terminal on spindle motor driver

14

C-PUMP

To be attached the external integral constants for speed control of spindle

motor

15

CLREF

Reference voltage input for current limiter of spindle motor driver

16

R1

To be attached the external resistor for setting up the oscillation frequency of

start-up circuitry and the gain of speed control loop of spindle motor driver

17

Vpss

Power supply for spindle motor driver

18, TAB, 19

GND

Ground pins

20

V

SS

Power supply for small signal block

21

LVI1

Sensing input for power monitor circuitry

22

DELAY

To be attached the external capacitor to generate the delay time for power on

reset signal

23

COMM

To be attached the external capacitor for setting up the oscillation frequency

24

POLSEL

To be selected the input status corresponding to the pole number of spindle

motor

25

CNTSEL

To select the count Number of Speed Discriminator

26

CLOCK

Master clock input for this IC

27

READY

Output of speed lock detector for spindle motor

28

SPNENAB

To select the status of spindle motor driver

29

POR

Output of power on reset signal for HDD system

30, TAB, 31

GND

Ground pins

32

VCMENAB

To select the status of VCM driver

33

GAIN

To select the Transfer conductance gm of VCM driver

HA13557AFH

4

Pin Description (cont)

Pin Number Pin Name

Function

34

NC

No function

35

NC

No function

36

COMPOUT

Comparator output to detect the direction of output current on VCM driver

37

VREF1

Regulated voltage output to be used as reference of peripheral ICs

38

RESINH

Used for inhibiting the restart function of the spindle motor driver after power

down

39

OPIN (+)

Non inverted input of OP.Amp. to be used for filtering the signal on PWMOUT

40

VCTL

OP.Amp. output, this signal is used as control signal for VCM driver output

41

OPIN (≠)

Inverted input of OP.Amp. to be used for filtering the signal on PWMOUT

42, TAB, 43

GND

Ground pins

44

LVI2

Sensing input for power monitor circuitry

45

Vpsv

Power supply for VCM driver

46

RETPOW

Power supply for retract circuitry

47

RETON

To be attached the base terminal of external transistor for retracting

48

RS

Sensing input for output current on VCM driver

HA13557AFH

5

Block Diagram

V

SS

(+5V)

V

SS

C102

B-EMF

AMP.

START-UP

CIRCUIT

CHARGE

PUMP

SOFT

SWITCHING

MATRIX

COMMUTATION

LOGIC

CURRENT

CONTROL

(D1)

1/32

SPEED DISCRI.

(CNT)

SPEED

READY

Vref1

(=4.6V)

OTSD

BOOSTER

POWER

MONITOR

POR

Delay

OPAMP.

V

BST

Vss

(+5V)

LVI1

R101

R102

R104

R103

LVI2

Vps

(+12V)

DELAY

C106

GND

POR

(L:RESET)

R105 Vss(+5V)

COMP

OUT

COMPARATOR

RS

VCMN

R

L

R

S

R110

VCMP

RETON

RETPOW

Qret2

C109

Vpsv

PCOMP

C110

R

NF

W

V

U

U

V

W

SPINDLE

DRIVER

RETRACT

DRIVER

VCM

DRIVER

Vss

Vps

P

N

≠

+

V

BST

1

4

5

32

33

35

34

37

39

41

40

27

25

26

24

28

16

15

14

23

21 44

22

11

13

12

8

9

10

45

46

47

2

3

48

36

29

20

17

V

BST

≠

+

Vps(+12V)

Vpss

C101

CT

C103 COMM

C2

CLREF

C1

C-PUMP

R1b

R1

R1a

SPNENAB

POLSEL

CLOCK

(5MHz Typ)

CNTSEL

READY

VCTL

OPIN(≠)

OPIN(+)

Vref1

NC

NC

GAIN

VCM ENAB

BC1

C104

C105

BC2

V

BST

≠

+

38

RESINH

C

X

R

X

C111

TAB

6, 7, 18, 19, 30,

31, 42, 43

R113

Qret1

R112

R109

R111

D1

C112

D2

D3

D4

HA13557AFH

6

Truth Table

Table 1

Truth Table (1)

SPNENAB

Spindle Driver

H

ON

Open

Cut off

L

Braking

Table 2

Truth Table (2)

VCMENAB

VCM Driver

H

ON

L

Cut off

Table 3

Truth Table (3)

OTSD

Spindle Driver

VCM Driver

Retract Driver

POR

not Active

See table 1

See table 2

Cut off

X

Active

Cut off

Cut off

ON

L

Table 4

Truth Table (4)

POLSEL

(D1)

Comment

H

--

Test Mode

Open

1/12

for 8 poles motor

L

1/18

for 12 poles motor

Table 5

Truth Table (5)

CNTSEL

CNT

Rotation Speed

(at CLOCK = 5 MHz)

H

2605

3,600 rpm

Open

2084

4,500 rpm

L

1736

5,400 rpm

HA13557AFH

7

Table 6

Truth Table (6)

RESINH

Spindle Driver

H

Inhibiting the restart after power down

L

Not inhibiting the restart after power down

Table 7

Truth Table (7)

GAIN

VCM Driver

H

High Gain Mode

L

Low Gain Mode

HA13557AFH

8

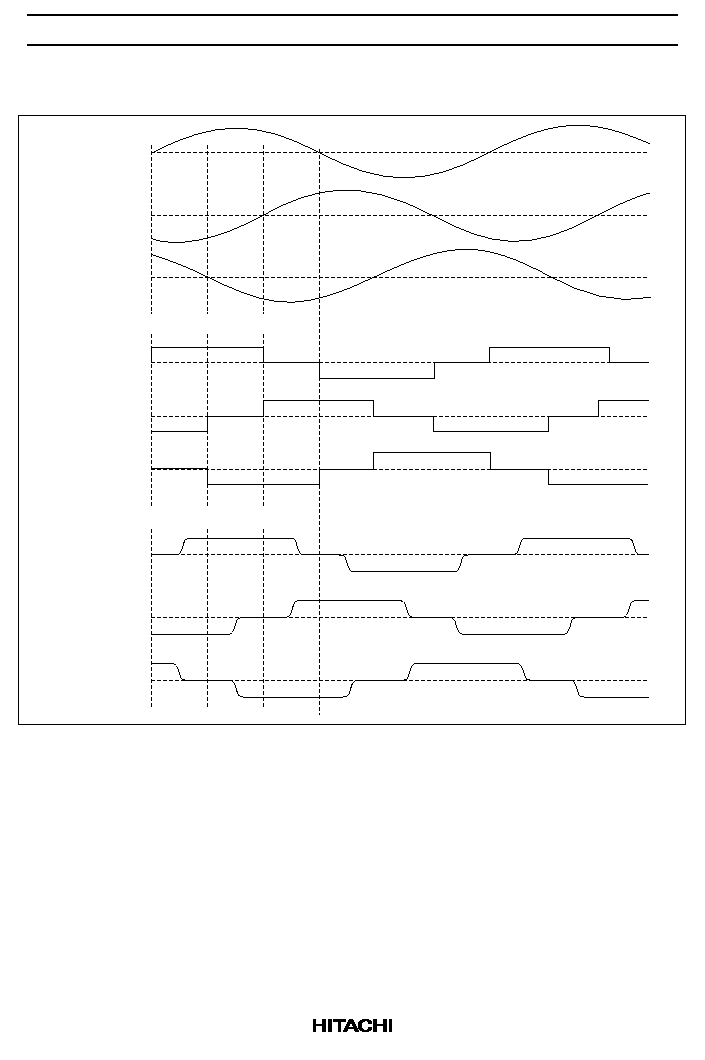

Timing Chart

1. Power on reset (1)

Vhys

Vsd

1.0V

MAX

0

POR

Vps and

V

SS

t

DLY

t

t

Note:

1.

How to determine the threshold voltage Vsd and the delay time t

DLY

both are shown in the

external components table.

HA13557AFH

9

2. Power on reset (2)

,,

,,

V

PS

or

V

SS

Spindle

Driver

VCM

Driver

POR

ON

OFF

ON

OFF

,,

,,

,,

,,

,,

,,

Retract

Driver

t

por

t

por

<

1

µ

s

<

1

µ

s

Retract

Note:

2.

Retract driver need B-EMF voltage or another power supply.

HA13557AFH

10

3. Motor start-up seaquence

,,,

,

,

,,

(a) Timing chart of start-up seaquence

SPNENAB

Rotation

Speed

Internal

READY

READY

(Pin 27)

(b) Retry circuitry for misstart-up

Open

No

0

Synchronous

Driving

Driving by

B-EMF

sensing

Switching

t

delay

*

2

Soft Switching*

3

No+

No*

1

No≠

No*

1

t

,,

,,

Motor

on

Synchronous

driving

Driving by

B-EMF

sensing

(Motor off)

(Motor stop)

(not stop)

Motor

stop

detector

Note *1. Speed lock detection range

No is as follows.

*2. READY output goes to High, if the rotation speed error keeps to be less than

No longer time than tdelay.

No =1.2% when CNTSEL=H

=1.5% when CNTSEL=Open

=1.8% when CNTSEL=L

tdelay=

[ms]

250 ∑ 10

7

fclk [Hz]

*3. The turning point of driving mode from switching synchronize to the turning

point of READY output from Low to High.

The HA13557FH has the motor stop detector as shown hatching block. This function is monitoring

the situation of the motor while the motor is running by B-EMF sensing. If the motor will be caused a

misstarting up, the motor will be automatically restarted within 200 ms after the motor stopped. This

function increase the reliability for the motor starting up.

HA13557AFH

11

4. Braking & Shut down the Spindle Driver

,,

,,

SPNENAB

Open

ON

CUT OFF

BRAKING

CUT OFF

> 20

µ

s

Open

Note:

The SPNENAB should be selected the open state after braking to reduce the supply current from

Vps and V

SS

.

5. Start-up of the Spindle motor

,

Open

SPNENAB

COMM

I

U

I

V

I

W

GND

SOURCE

0

SINK

SOURCE

0

SINK

SOURCE

0

SINK

2T

COMM

4T

COMM

4T

COMM

4T

COMM

4T

COMM

4T

COMM

6T

COMM

8T

COMM

10T

COMM

12T

COMM

14T

COMM

16T

COMM

16T

COMM

not detecting the B-EMF

detecting the B-EMF

Synchronous Driving for motor start up

Driving by

B-EMF sensing

t

COMM

(see External Components Table)

Vth1

Vth2

HA13557AFH

12

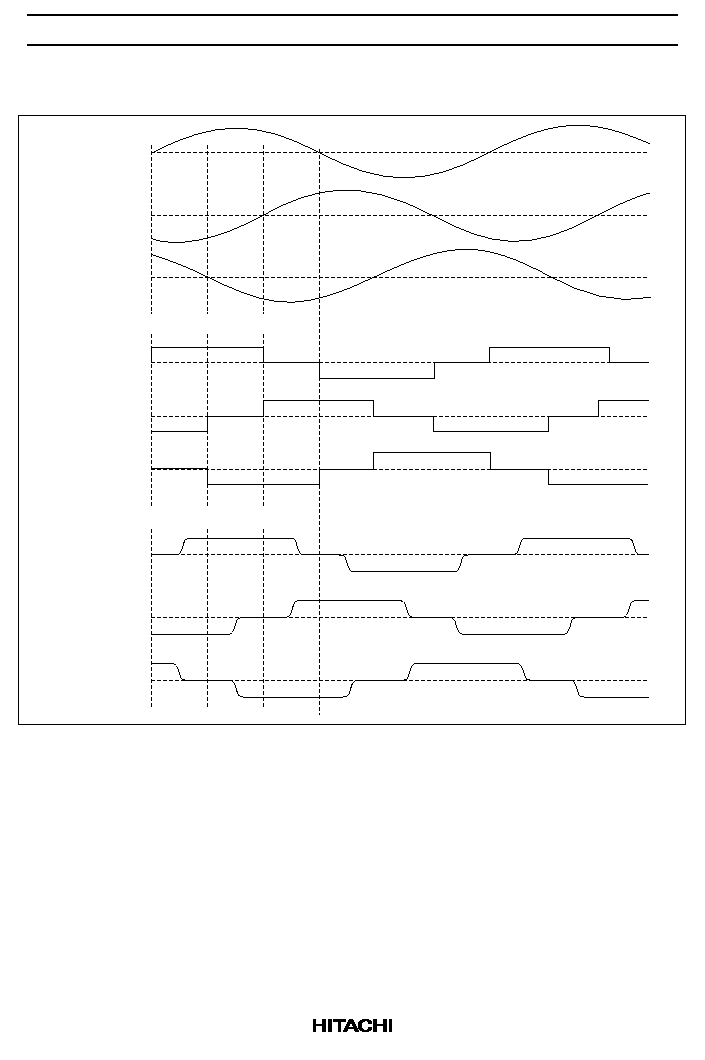

6. Acceleration and Running the spindle motor

U

BEMF

V

BEMF

W

BEMF

Iu

Iv

Iw

Iu

Iv

Iw

+

≠

0

+

≠

0

+

≠

0

SOURCE

SINK

0

SOURCE

SINK

0

SOURCE

SINK

0

SOURCE

SINK

0

SOURCE

SINK

0

SOURCE

SINK

0

(1) Acceleration(switching mode)

(2) Running (soft switching mode)

HA13557AFH

13

Application

5

4

1

23

15

16

14

24

25

27

26

28

32

33

38

37

41

40

39

36

20

29

22

21

44

48

3

2

47

46

45

10

9

8

12

13

11

17

BC1

BC2

VBST

COMM

CLREF

R1

C-PUMP

POLSEL

CNTSEL

READY

CLOCK

SPNENAB

VCMENAB

GAIN

RESINH

VREF1

OPIN(≠)

VCTL

OPIN(+)

COMPOUT

V

SS

POR

DELAY

C106

C102

R105

R101

R102

V

SS

(+5V)

R4

C4

C3

R3

C5

R6

R1a

R1b

C2

R2

C1

C103

C105

C104

Vpss

CT

U

V

W

RNF

PCOMP

Vpsv

RETPOW

RETON

VCMP

VCMN

RS

LVl2

LVl1

C101

R

NF

C110

C109

R103

R104

Qret2

D1

R

S

RL

V

PS

(+12V)

HA13557AFH

GND

C

X

R

X

R8

R7

PWMIN

R5

C111

6 7 18 19 30 31 42 43 TAB

R111

R109

Qret1

Qret3

R113

R110

C112

R112

D3

D4

D2

HA13557AFH

14

External Components

Parts No.

Recommended Value

Purpose

Note

R1a

(R1a + R1b)

10 k

V/I converter

1, 4, 6

R1b

(R1a + R1b)

10 k

R2

--

Integral constant

3

R3 to R8

--

PWM filter

9

R101, R102

--

Setting of LVI1 voltage

7

R103, R104

--

Setting of LVI2 voltage

7

R105

5.6 k

Pull up

R109, R110

(R109 + R110)

10 k

Retout voltage adjust

R111, R112, R113

--

Retract Driver

RS

1.0

Current sensing for VCM Driver

10

Rnf

--

Current sensing for Spindle Driver

1

R

X

--

Reduction for gain peaking

11

C1, C2

--

Integral constant

3

C3 to C6

--

PWM filter

9

C

X

--

Reduction for gain peaking

11

C101

0.1

µ

F

Power supply by passing

C102

0.1

µ

F

Power supply by passing

C103

--

Oscillation for start-up

6

C104

0.22

µ

F

for booster

C105

2.2

µ

F

for booster

C106

0.33

µ

F

Delay for POR

8

C109

0.1

µ

F

Power supply by passing

C110, C111

0.22

µ

F

Phase compensation

C112

--

Phase compensation for Retract

Qret1, Qret2, Qret3

--

Retract Driver

12

D1

TBD

Prevent of counter current

D2, D3, D4

Si ∑ Diode

for rectification

HA13557AFH

15

Notes: 1. Output maximum current on spindle motor driver Ispnmax is determined by following equation.

Ispnmax =

[A]

∑

R1b

R1a + R1b

V

R1

R

NF

(1)

where, V

R1

: Reference Voltage on Pin 16 [V] (= 1.17)

2. Input clock frequency fclk on pin 26 is determined by following equation.

fclk =

∑ N

O

∑ P ∑ D1 ∑ (CNT ≠ 0.5) [Hz]

4

5

(2)

where, N

O

:

Standard rotation speed [rpm]

P:

Number of pole

D1: Dividing ratio on divider 1

D1

= 1/12 (when Pin 24 = Open) for 8 pole motor

= 1/18 (when Pin 24 = Low) for 12 pole motor

CNT:Count number on speed discriminator

CNT = 2605 (when Pin 25 = High)

= 2084 (when Pin 25 = Open)

= 1736 (when Pin 25 = Low)

3. Integral constants R2, C1 and C2 can be designed as follows.

O

=

[rad/s]

∑ 2 ∑

∑

1

10

N

O

60

(3)

R2 =

[

]

∑

1

9.55

Rnf ∑ J ∑

O

∑ N

O

∑ (R1a + R1b)

V

R1

∑ K

T

∑ Gctl

(4)

C1 =

[F]

1

10 ∑

O

∑ R2

(5)

C2 = 10 ∑ C1

[F]

(6)

where, J:

Moment of inertia [kg∑cm∑s

2

]

K

T

:

Torque constant [kg∑cm/A]

Gctl: Current control amp gain from pin 14 to pin 9 (= 0.794)

4. It is notice that rotation speed error Nerror is caused by leak current Icer2 on pin 14 and this

error depend on R1a and R1b as following equation.

Nerror = Icer2 ∑

[%]

∑ 100

(R1a + R1b)

VR1

(7)

where, Icer2: Ieak current on pin 14 [A]

5. Oscillation period t

COMM

on pin 23 which period determine the start up characteristics, is should be

chosen as following equation.

t

COMM

=

∑

[s]

to

J

P ∑ K

T

∑ Ispnmax

1

8

∑

J

P ∑ K

T

∑ Ispnmax

1

4

(8)

HA13557AFH

16

6. The capacitor C103 on pin 23 can be determined by t

COMM

and following equation.

C103 =

∑

[F]

VR1

R1a + R1b

∑

t

COMM

Vth

H

≠ Vth

L

1

4

(9)

where, Vth

H

: Threshold voltage on start up circuit [V] (= 2.0)

Vth

L

: Threshold voltage on start up circuit [V] (= 0.5)

7. LVI operatig voltage Vsd1, Vsd2 and its hysteresis voltage Vhys1, Vhys2 can be determined by

following equations.

for V

SS

R101

R102

Vsd1 = 1 + ∑ Vth4

[V]

(10)

R101

R102

Vhys1 = 1 + ∑ Vhyspm

[V]

(11)

for Vps

R103

R104

Vsd2 = 1 + ∑ Vth3

[V]

(12)

R103

R104

Vhys2 = 1 + ∑ Vhyspm

[V]

(13)

where, Vth3, Vth4: Threshold voltage on pin 21 and pin 44 [V] (= 1.39)

Vhyspm:

Hysteresis voltage on pin 21 and pin 44 [mV] (= 40)

Shut down voltage Vsd1, Vsd2 can be designed by the following range.

Vsd1

4.25 [V], Vsd2

10 [V]

8. The delay time t

DLY

of

POR

for power on reset is determined as follows.

C106 ∑ Vth5

I

CH3

t

DLY

=

[s]

(14)

where, Vth5: Threshold voltage on pin 22 [V] (= 1.4)

I

CH3

:

Charge current on pin 22 [

µ

A] (= 6)

9. The differential voltage (Vctl ≠ V

REF1

) using for control of VCM driver depend on PWMDAC input

PWMIN as follows.

D

PWM

≠ 50

100

Vctl ≠ V

REF1

= 2 ∑ V

REF1

∑

R6

R5

∑

∑ H

FLT

(s)

(15)

where, D

PWM

:

Duty cycle on PWMIN [%]

H

FLT(S)

:

Normalized transfer function from PWMIN to pin 40 (Vctl) as shown in

equation (17)

To be satisfied with above equation (15), it is notice that the ratio of R6 to R7 must be choosen

as shown below.

R8

R7

= 2 ∑

R6

R5

∑

1

R6

R5

1 ≠

(16)

HA13557AFH

17

=

1

R6

R5

1 + s ∑ C5 ∑ R// ≠ C3 ∑ (R// + R3) ∑

+ C4 ∑ (R// + R3 + R4)

R6

R5

+ s

2

∑ C5 ∑ C4 ∑ R// ∑ (R3 + R4) ≠ C5 ∑ C3 ∑ R// ∑ R3 ∑

+ C3 ∑ C4 ∑ R4 ∑ (R// + R3)

+ s

3

∑ C3 ∑ C4 ∑ C5 ∑ R// ∑ R3 ∑ R4

H

FLT

(s)

(17)

where,

R// =

R7 ∑ R8

R7 + R8

(18)

If you choose the R// << R3, then equation (17) can be simplified as following equation.

H

FLT

(s) =

1

∑

1

s

n

1 +2 ∑

∑

s

O

1 +

+

s

n

2

(19)

where,

O

=

1

C5 ∑ R//

(20)

n =

1

C3 ∑ C4 ∑ R3 ∑ R4

(21)

=

C4 ∑ (R3 + R4) ≠ C3 ∑ R3 ∑

2 ∑ C3 ∑ C4 ∑ R3 ∑ R4

R6

R5

(22)

10. The relationship between the output current Ivcm and the input voltage (Vctl ≠ V

REF1

) on VCM

driver is as follows.

Ivcm(s) = Vctl ≠ V

REF1

∑ Kvcm ∑

1

Rs

∑ Hvcm(s)

(23)

where, Vctl:

Input control voltage for VCM driver on pin 40 [V]

V

REF1

:

Reference voltage on pin 37 [V] (= 4.6)

Kvcm:

DC gain of VCM driver

(= 1.74 for High gain mode)

(= 0.44 for Low gain mode)

Hvcm(s): Transfer function of VCM driver as shown following equation

Hvcm(s) =

1 + 2 ∑

VCM

∑

s

VCM

+

2

1

s

VCM

(24)

where,

VCM

=

P

∑

Rs

Lm

(25)

HA13557AFH

18

1

2

VCM

=

∑

1 +

R

L

Rs

∑

1

P

∑

Rs

Lm

(26)

where,

p: Bandwidth of internal power amplifiers for VCM driver [rad/s]

(= 3∑

∑10

6

)

Lm: Inductance of the VCM coil [H]

R

L

:

Resistance of the VCM coil [

]

and from above equations the -3 dB bandwidth f

VCMC

of VCM driver is as following equation.

VCM

2 ∑

f

VCMC

=

∑

1 ≠ 2 ∑

VCM

2

+

2 ∑

VCM

2

≠ 1

2

+ 1

(27)

11. The frequency response of VCM driver maybe have a gain peaking because of the resonation of

the motor coil impedance. If you want to tune up for this characteristics, you can reduce the

peaking by additional snubber circuit R

X

and C

X

as follows.

BTL Driver

R

X

C

X

1/2 V

PS

≠

+

≠

+

R3

R3

Coil

N

RS

P

R

S

Figure 1 VCM Driver Block Diagram

20

10

0

≠10

≠20

100

1k

10k

100k

Frequency (Hz)

I

O

(dB)

Normal

C

X

= 0.22

µ

F

R

X

= 560

(for example) R

L

= 14.7

, R

S

= 1

, L = 1.7 mH, Gain = L

HA13557AFH

19

12. The Qret3 collector voltage Vret is determined by

Vret ≠ V

F

(D1) ≠ Vsat

VL

R

L

+ Rs

Iret =

R109

R110

Vret = V

RT

(

.

.

+ 1)

R109

R110

(Vretpow

V

RT

(

+ 1))

(28)

where, Vretpow:

Applied voltage on pin 46 [V]

V

RT

:

Reference voltage of Retract (toward voltage of Qret2) [V]

V

F

(D1):

Foward voltage of D1 [V]

Vsat

VL

:

Saturation voltage on pin 3 at retracting [V]

(See electrical characteristics)

HA13557AFH

20

Absolute Maximum Ratings (Ta = 25

∞

C)

Item

Symbol

Rating

Unit

Notes

Power supply voltage

Vps

+15

V

1

Signal supply voltage

V

SS

+7

V

2

Input voltage

V

IN

V

SS

V

3

Output current-Spindle

Iospn (Peak)

2.2

A

Iospn (DC)

1.8

A

Output current-VCM

Iovcm (Peak)

1.5

A

Iovcm (DC)

1.0

A

Power dissipation

P

T

5

W

4

Junction temperature

Tj

+150

∞

C

5, 6

Storage temperature

Tstg

≠55 to +125

∞

C

Notes: 1. Operating voltage range is 10.2 V to 13.8 V.

2. Operating voltage range is 4.25 V to 5.75 V.

3. Applied to Pin 24, 25, 26, 28, 32, 33 and pin 38

4. Operating junction temperature range is Tjop = 0

∞

C to +125

∞

C.

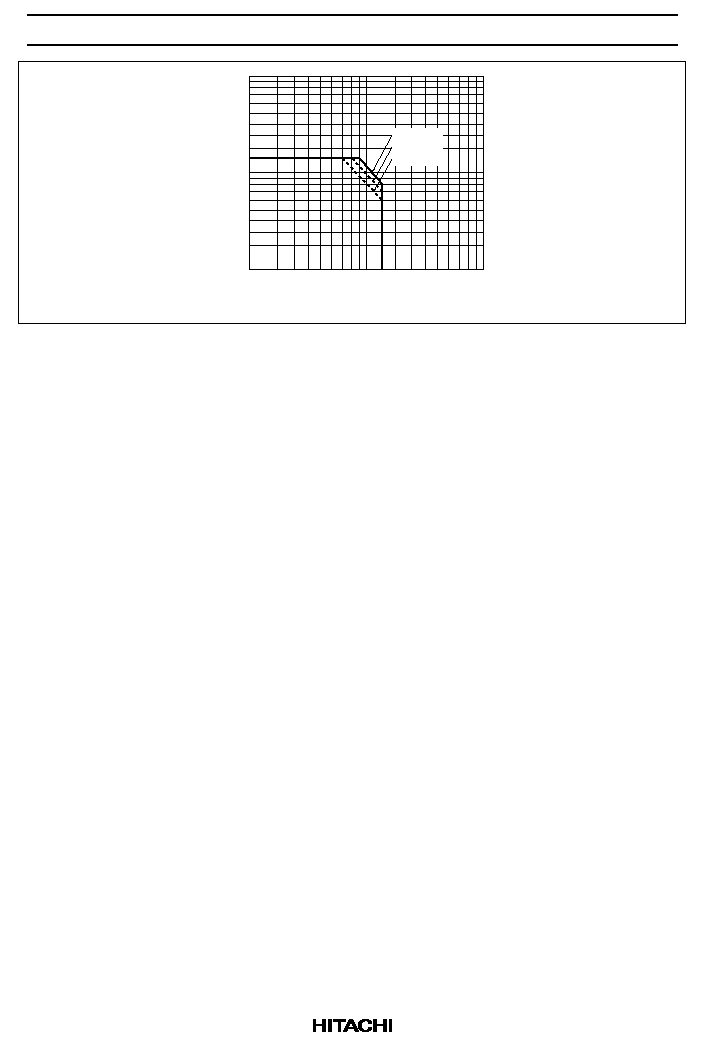

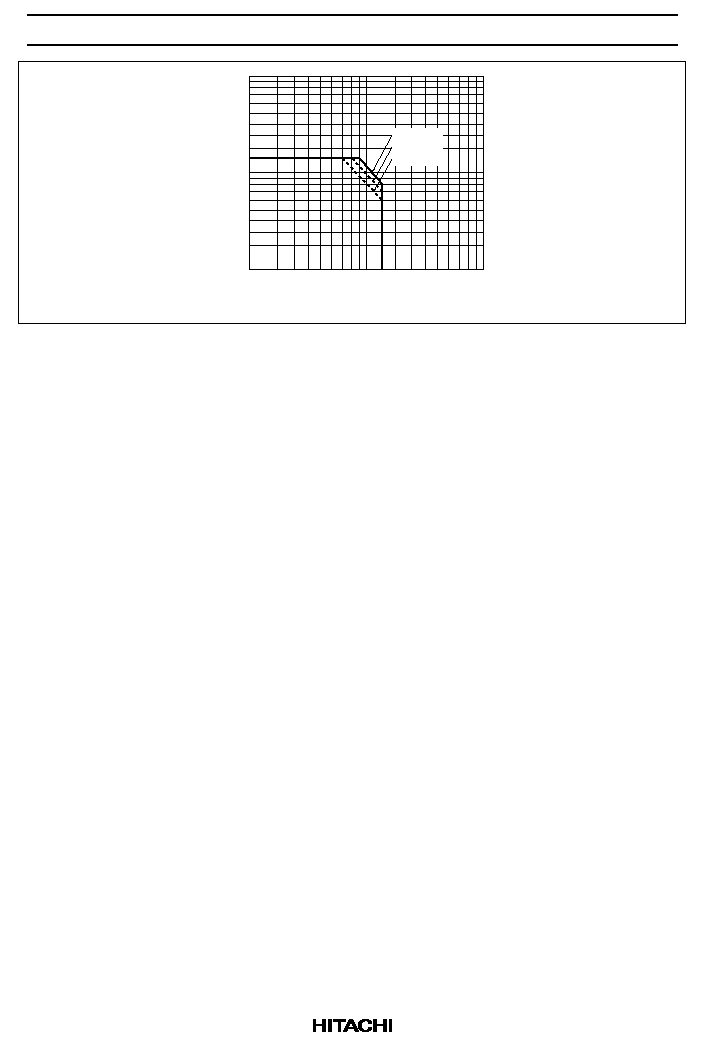

5. ASO of upper and lower power transistor are shown below.

Operating locus must be within the ASO.

6. The OTSD (Over Temperature Shut Down) function is built in this IC to avoid same damages by

over heat of this chip. However, please note that if the junction temperature of this IC becomes

higher than the operating maximum junction temperature (Tjopmax = 125

∞

C), the reliability of this

IC often goes down.

7. Thermal resistance:

j-a

30

∞

C/W with 4 layer multi glass-epoxy board

10

1

10

100

VCE (V)

IC (A)

15

1

0.1

t=10ms

t=50ms

t=100ms

2.2

Figure 2 ASO of Output Stages (Spindle)

HA13557AFH

21

10

1

10

100

VCE (V)

IC (A)

15

1.5

1

0.1

t=10ms

t=50ms

t=100ms

Figure 3 ASO of Output Stages (VCM)

HA13557AFH

22

Electrical Characteristics (Ta = 25

∞

C, Vps = 12 V, V

SS

= 5 V)

Item

Symbol Min

Typ

Max

Unit

Test Conditions

Applicable

Pins

Note

Supply

current

for V

SS

I

SS0

--

5.8

7.0

mA

SPNENAB = Open

VCMENAB = L

20

I

SS1

--

21

27

mA

SPNENAB = H

VCMENAB = H

20

for Vps

Ips0

--

1.7

2.2

mA

SPNENAB = Open

VCMENAB = L

17, 45

Ips1

--

19

24

mA

SPNENAB = H

VCMENAB = H

17, 45

Logic input 1

(GAIN)

(RESINH)

Input low voltage V

IL1

--

--

0.8

V

33, 38

Input high

voltage

V

IH1

2.0

--

--

V

Input low current I

IL1

--

--

±

10

µ

A

Input = GND

Input high

current

I

IH1

--

--

±

10

µ

A

Input = 5.0 V

Logic input 2

(CLOCK)

Input low voltage V

IL2

--

--

0.8

V

26

Input high

voltage

V

IH2

3.5

--

--

V

Input low current I

IL2

--

≠180

≠260

µ

A

Input = GND

Input high

current

I

IH2

--

230

330

µ

A

Input = 5.0 V

Logic input 3

(VCMENAB)

Input low voltage V

IL3

--

--

0.8

V

32

Input high

voltage

V

IH3

2.0

--

--

V

Input low current I

IL3

--

--

±

10

µ

A

Input = GND

Input high

current

I

IH3

--

--

330

µ

A

Input = 5.0 V

Logic input 4

(SPNENB)

Input low voltage V

IL4

--

--

1.0

V

28

Input middle

voltage

V

IM4

2.0

--

3.1

V

Input high

voltage

V

IH4

3.9

--

--

V

HA13557AFH

23

Electrical Characteristics (Ta = 25

∞

C, Vps = 12 V, V

SS

= 5 V) (cont)

Item

Symbol Min

Typ

Max

Unit

Test Conditions

Applicable

Pins

Note

Logic input 4

(SPNENB)

Input low current I

IL4

≠75

≠105

≠150

µ

A

Input = GND

28

Input high

current

I

IH4

75

105

150

µ

A

Input = 5.0V

Input dead

current

I

DEAD

±

10

--

--

µ

A

Logic input 5

(POLSEL)

(CONTSEL)

Input low voltage V

IL5

--

--

1.0

V

24, 25

Input middle

voltage

V

IM5

2.0

--

3.1

V

Input high

voltage

V

IH5

3.9

--

--

V

Input low current I

IL5

≠38

≠53

≠75

µ

A

Input = GND

Input high

current

I

IH5

38

53

75

µ

A

Input = 5.0V

Spindle

driver

Total saturation

voltage

Vsatspn --

1.44

2.0

V

Ispn = 1.8A

8, 12, 13

--

--

0.75

V

Ispn = 0.6A

Saturation at

braking

Vbreak

--

--

0.7

V

Ibreak = 0.6A

Leak current

Icer1

--

--

±

2.0

mA

SPNENAB=Open

Current limiter

reference

voltage

V

OCL

430

480

530

mV

V

CLREF

= 500mV

R

NF

= 1.0

9

Control amp

gain

Gctl

--

≠2

±

2

dB

R

NF

= 1.0

9, 14

Clamp diode

forward voltage

Vdf

1.6

1.9

2.2

V

Idf = 0.5A

8, 12, 13

B-EMF amp. Input sensitivity

Vmin

60

90

125

mVp-p

8, 12, 13

1

Charge

pump

Reference

voltage

VR1

1.06

1.17

1.28

V

R1a+R1b = 24k

14, 16

Charge current

I

CH1

40

45

50

µ

A

C ≠ PUMP = 1.0V

Discharge

current

I

DIS1

≠40

≠45

≠50

µ

A

Leak current

Icer2

--

--

±

50

nA

HA13557AFH

24

Electrical Characteristics (Ta = 25

∞

C, Vps = 12 V, V

SS

= 5 V) (cont)

Item

Symbol Min

Typ

Max

Unit

Test Conditions

Applicable

Pins

Note

Speed discri Operating

frequency

fclk

--

--

8.0

MHz

26

Start up

circuit

Threshold

voltage

Vth

H

1.6

1.8

2.0

V

16, 23

Vth

L

0.3

0.5

0.7

V

Charge current

I

CH2

21

23

26

µ

A

R1a + R1b = 24

k

Discharge

current

I

DIS2

≠19

≠22

≠25

µ

A

COMM = 1 V

READY

Output high

voltage

Vohr

V

SS

≠ 0.4

--

V

SS

V

I

O

= ≠1 mA

27

Output low

voltage

Volr

--

--

0.4

V

I

O

= 1 mA

VCM driver

Total saturation

voltage

Vsatvcm --

1.0

1.38

V

Ivcm = 1.0 A

2, 3

--

0.5

0.69

V

Ivcm = 0.5 A

Output leak

current

Icer3

--

--

±

2.0

mA

Vce = 15 V

Total output

offset voltage

Voff(H)

--

--

±

20

mV

V

CTL

= OP (≠)

V

REF

= OP (+)

2, 48

Voff(L)

--

--

±

10

mV

Output

quiescent

voltage

Vqvcm

5.6

6.0

6.4

V

R

L

= 14

,

R

S

= 1.0

2, 3

Total gain

bandwidth

B

--

26

--

kHz

R

S

= 1.0

,

R

L

= 28

2, 3

1

--

50

--

kHz

R

S

= 1.0

,

R

L

= 14

Transfer gain

gm (H)

--

1.74

±

5%

A/V

Higain-mode

R

S

= 1.0

,

R

L

= 14

2, 34, 48

gm (L)

--

0.44

±

5%

A/V

Logain-mode

R

S

= 1.0

,

R

L

= 14

HA13557AFH

25

Electrical Characteristics (Ta = 25

∞

C, Vps = 12 V, V

SS

= 5 V) (cont)

Item

Symbol

Min

Typ

Max

Unit

Test Conditions

Applicable

Pins

Note

Retract

driver

Retpow voltage

Vretpow

0.8

--

--

V

Ireton = 0.1 mA

46

Retout sink

current

Ireton

5

8

--

mA

Vretpow = 4.0 V

Output leak

current

Icer4

--

--

±

10

µ

A

Vreton = 15 V,

Vretpow = 15 V

37

Low side

saturation

voltage

VsatVL

0.2

0.33

0.45

V

Iret = 0.1 A

3

OP Amp

Input current

Iinop

--

--

±

500

nA

39, 41

Input offset

voltage

Vosop

--

--

(

±

7)

mV

1

Common mode

input voltage

range

Vcmop

0

--

Vps

≠ 0.2

V

Output high

voltage

Vohop

Vps

≠ 1.3

--

--

V

Iout = 1.0 mA

40

Output low

voltage

Volop

--

--

1.1

V

Iout = 1.0 mA

Comparator Input sensitivity

Vmin2

±

9

0

--

mV

2, 3, 36

1

Output low

voltage

Volcp

--

--

0.4

V

I

O

= 1 mA

36

Output high

voltage

Vohcp

V

SS

≠ 1.8

--

V

SS

V

I

O

= 1 mA

Vref1

Output voltage

Vref1

--

4.0

±

3%

V

I

O

= 20 mA

37

Output

resistance

Ro1

--

--

5.0

I

O

= 20 mA

Power

monitor

Threshold

voltage

Vth3

≠2%

1.39

+3%

V

V

SS

= 5 V

44

2

Hysteresis

Vhyspm1 25

40

55

mV

V

SS

= 5 V

Threshold

voltage

Vth4

≠2%

1.38

+3%

V

V

SS

= 4 V

21

2

Hysteresis

Vhyspm2 25

40

55

mV

V

SS

= 4 V

HA13557AFH

26

Electrical Characteristics (Ta = 25

∞

C, Vps = 12 V, V

SS

= 5 V) (cont)

Item

Symbol Min

Typ

Max

Unit

Test Conditions

Applicable

Pins

Note

POR

Output low

voltage

V

OL2

--

--

0.4

V

I

O

= 1 mA

29

V

OL3

--

--

0.4

V

I

O

= 1 mA

V

SS

= Vps = 1.0 V

Output leak

current

Icer5

--

--

±

10

µ

A

Vpor = 7 V

Threshold

voltage

Vth5

--

1.4

±

5%

V

22

Charge current

I

CH3

--

6

±

25%

µ

A

Discharge

current

I

DIS3

40

--

--

mA

OTSD

Operating

temperature

Tsd

125

150

--

∞

C

1

Hysteresis

Thys

--

25

--

∞

C

1

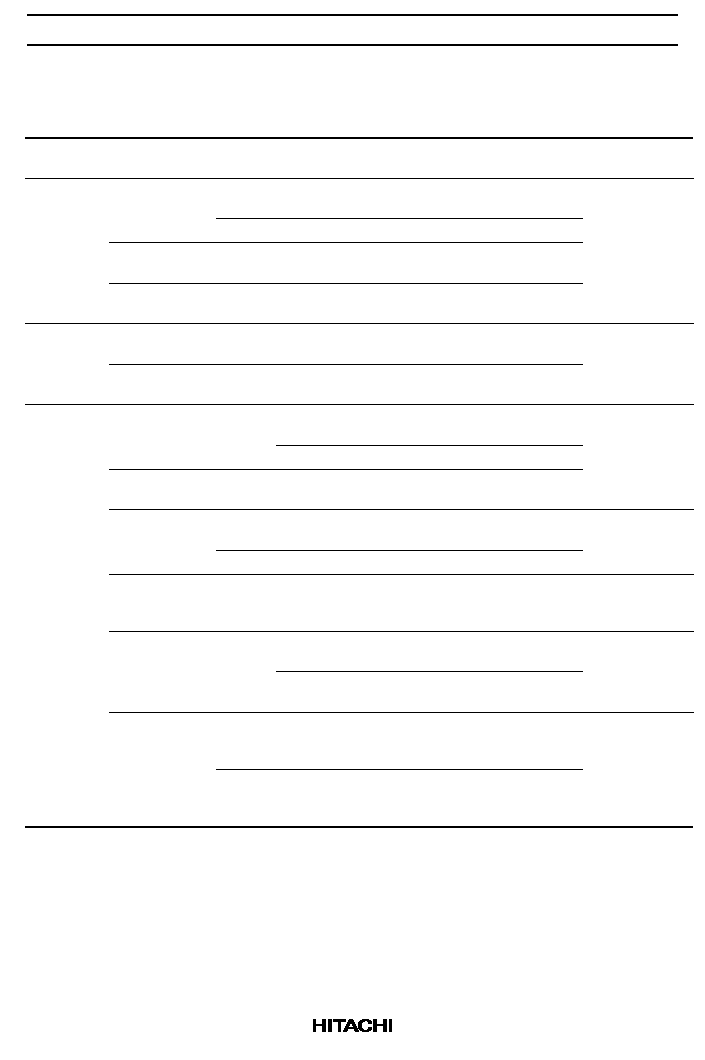

Notes: 1. Design guide only.

2. Variations of threshold voltage Vth3 and Vth4 depending on the power supply V

SS

are shown in

figure 4.

1.42

1.41

1.33

3.8

Power supply V

SS

(V)

Threshold voltage Vth3, Vth4 (V)

4.0

5.0

4.2 4.4 4.6 4.8

5.2 5.4

6.0

5.6 5.8

1.40

1.39

1.38

1.37

1.36

1.35

1.34

Test condition of Vth3

Test condition of Vth4

Figure 4

HA13557AFH

27

Package Dimensions

Unit: mm

36

0 ≠ 10

∞

0.1

0.13 M

17.2

±

0.2

25

37

48

1

12

24

13

17.2

±

0.2

0.3

±

0.05

0.65

3.05 Max

0.1

±

0.1

1.6

0.8

±

0.3

14

2.7

0.17

±

0.05

0.825

2.925

2.925

4.85

2.425

2.925 2.925

0.825

4.85

2.425

Hitachi code

EIAJ code

JEDEC code

FP-48T

--

--

Cautions

1. Hitachi neither warrants nor grants licenses of any rights of Hitachi's or any third party's patent,

copyright, trademark, or other intellectual property rights for information contained in this document.

Hitachi bears no responsibility for problems that may arise with third party's rights, including

intellectual property rights, in connection with use of the information contained in this document.

2. Products and product specifications may be subject to change without notice. Confirm that you have

received the latest product standards or specifications before final design, purchase or use.

3. Hitachi makes every attempt to ensure that its products are of high quality and reliability. However,

contact Hitachi's sales office before using the product in an application that demands especially high

quality and reliability or where its failure or malfunction may directly threaten human life or cause risk

of bodily injury, such as aerospace, aeronautics, nuclear power, combustion control, transportation,

traffic, safety equipment or medical equipment for life support.

4. Design your application so that the product is used within the ranges guaranteed by Hitachi particularly

for maximum rating, operating supply voltage range, heat radiation characteristics, installation

conditions and other characteristics. Hitachi bears no responsibility for failure or damage when used

beyond the guaranteed ranges. Even within the guaranteed ranges, consider normally foreseeable

failure rates or failure modes in semiconductor devices and employ systemic measures such as fail-

safes, so that the equipment incorporating Hitachi product does not cause bodily injury, fire or other

consequential damage due to operation of the Hitachi product.

5. This product is not designed to be radiation resistant.

6. No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without

written approval from Hitachi.

7. Contact Hitachi's sales office for any questions regarding this document or Hitachi semiconductor

products.

Hitachi, Ltd.

Semiconductor & Integrated Circuits.

Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

Tel: Tokyo (03) 3270-2111 Fax: (03) 3270-5109

Copyright ' Hitachi, Ltd., 1999. All rights reserved. Printed in Japan.

Hitachi Asia Pte. Ltd.

16 Collyer Quay #20-00

Hitachi Tower

Singapore 049318

Tel: 535-2100

Fax: 535-1533

URL

NorthAmerica

: http:semiconductor.hitachi.com/

Europe

: http://www.hitachi-eu.com/hel/ecg

Asia (Singapore)

: http://www.has.hitachi.com.sg/grp3/sicd/index.htm

Asia (Taiwan)

: http://www.hitachi.com.tw/E/Product/SICD_Frame.htm

Asia (HongKong)

: http://www.hitachi.com.hk/eng/bo/grp3/index.htm

Japan

: http://www.hitachi.co.jp/Sicd/indx.htm

Hitachi Asia Ltd.

Taipei Branch Office

3F, Hung Kuo Building. No.167,

Tun-Hwa North Road, Taipei (105)

Tel: <886> (2) 2718-3666

Fax: <886> (2) 2718-8180

Hitachi Asia (Hong Kong) Ltd.

Group III (Electronic Components)

7/F., North Tower, World Finance Centre,

Harbour City, Canton Road, Tsim Sha Tsui,

Kowloon, Hong Kong

Tel: <852> (2) 735 9218

Fax: <852> (2) 730 0281

Telex: 40815 HITEC HX

Hitachi Europe Ltd.

Electronic Components Group.

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire SL6 8YA, United Kingdom

Tel: <44> (1628) 585000

Fax: <44> (1628) 778322

Hitachi Europe GmbH

Electronic components Group

Dornacher Straße 3

D-85622 Feldkirchen, Munich

Germany

Tel: <49> (89) 9 9180-0

Fax: <49> (89) 9 29 30 00

Hitachi Semiconductor

(America) Inc.

179 East Tasman Drive,

San Jose,CA 95134

Tel: <1> (408) 433-1990

Fax: <1>(408) 433-0223

For further information write to: