| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: AD590 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

12-3

August 1997

AD590

2-Wire, Current Output

Temperature Transducer

Features

∑ Linear Current Output . . . . . . . . . . . . . . . . . . . . 1

µ

A/

o

K

∑ Wide Temperature Range . . . . . . . . . . . -55

o

C to 150

o

C

∑ Two-Terminal Device Voltage In/Current Out

∑ Wide Power Supply Range . . . . . . . . . . . . . +4V to +30V

∑ Sensor Isolation From Case

∑ Low Cost

Description

The AD590 is an integrated-circuit temperature transducer

which produces an output current proportional to absolute tem-

perature. The device acts as a high impedance constant current

regulator, passing 1

µ

A/

o

K for supply voltages between +4V and

+30V. Laser trimming of the chip's thin film resistors is used to

calibrate the device to 298.2

µ

A output at 298.2

o

K (25

o

C).

The AD590 should be used in any temperature-sensing

application between -55

o

C to 150

o

C in which conventional

electrical temperature sensors are currently employed. The

inherent low cost of a monolithic integrated circuit combined

with the elimination of support circuitry makes the AD590 an

attractive alternative for many temperature measurement sit-

uations. Linearization circuitry, precision voltage amplifiers,

resistance measuring circuitry and cold junction compensa-

tion are not needed in applying the AD590. In the simplest

application, a resistor, a power source and any voltmeter can

be used to measure temperature.

In addition to temperature measurement, applications include

temperature compensation or correction of discrete

components, and biasing proportional to absolute temperature.

The AD590 is particularly useful in remote sensing applica-

tions. The device is insensitive to voltage drops over long

lines due to its high-impedance current output. Any well

insulated twisted pair is sufficient for operation hundreds of

feet from the receiving circuitry. The output characteristics

also make the AD590 easy to multiplex: the current can be

switched by a CMOS multiplexer or the supply voltage can

be switched by a logic gate output.

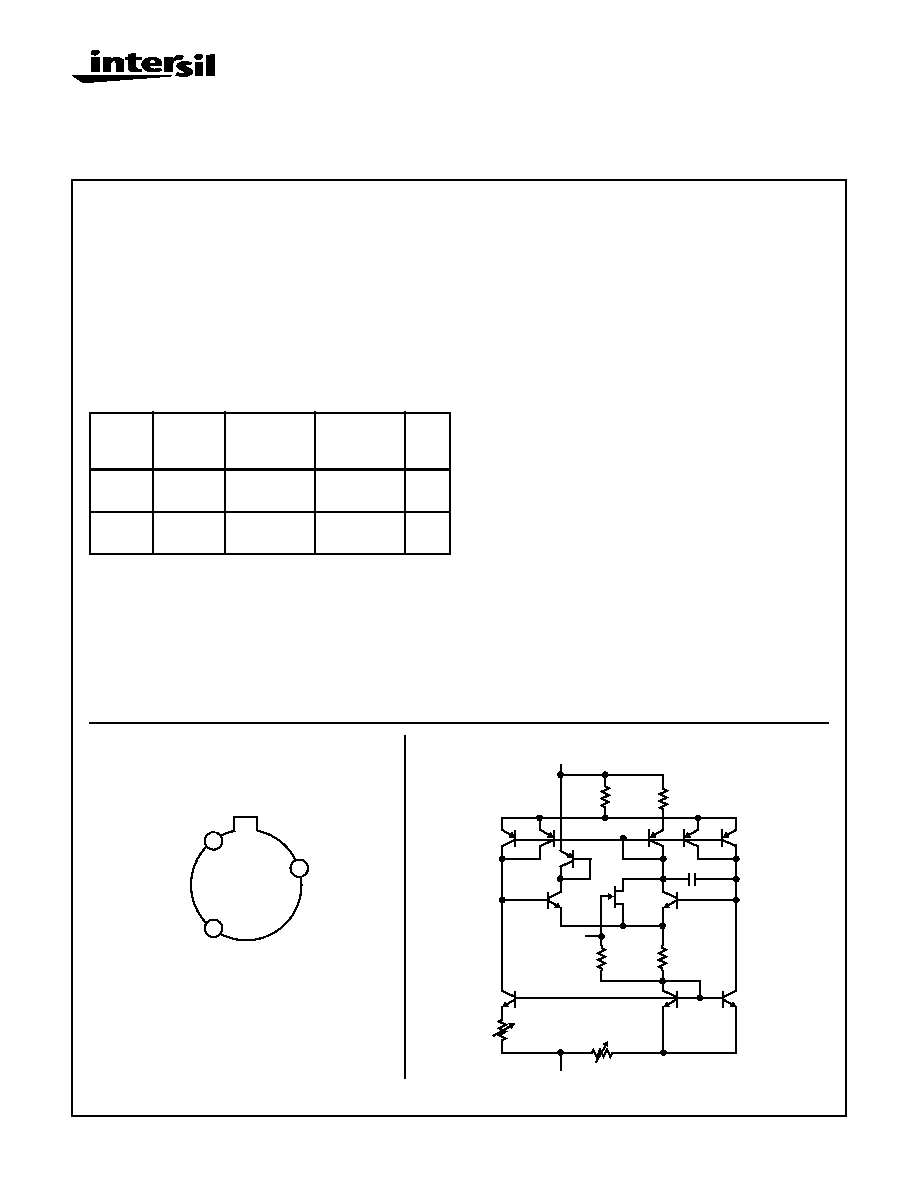

Ordering Information

PART

NUMBER

NON-

LINEARITY

(

o

C)

TEMP. RANGE

(

o

C)

PACKAGE

PKG.

NO.

AD590IH

±

3.0

-55 to 150

3 Ld Metal Can

(TO-52)

T3.A

AD590JH

±

1.5

-55 to 150

3 Ld Metal Can

(TO-52)

T3.A

Pinout

AD590

(METAL CAN)

Functional Diagram

CASE

-

1

2

3

+

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

Q12

R1 260

R2 1040

C1 26pF

R3 5k

R4 11k

R6 820

R5 146

1

1

8

-

+

CHIP

SUBSTRATE

File Number

3171.1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

|

Copyright

©

Intersil Corporation 1999

12-4

Absolute Maximum Ratings

T

A

= 25

o

C

Thermal Information

Supply Forward Voltage (V+ to V-) . . . . . . . . . . . . . . . . . . . . . . +44V

Supply Reverse Voltage (V+ to V-) . . . . . . . . . . . . . . . . . . . . . . .-20V

Breakdown Voltage (Case to V+ to V-) . . . . . . . . . . . . . . . . . .

±

200V

Rated Performance Temperature Range TO-52. . . . -55

o

C to 150

o

C

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -55

o

C to 150

o

C

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

JC

(

o

C/W)

Metal Can Package . . . . . . . . . . . . . . .

200

120

Maximum Junction Temperature (Metal Can Package) . . . . . . . 175

o

C

Maximum Storage Temperature Range . . . . . . . . . .-65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300

o

C

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air.

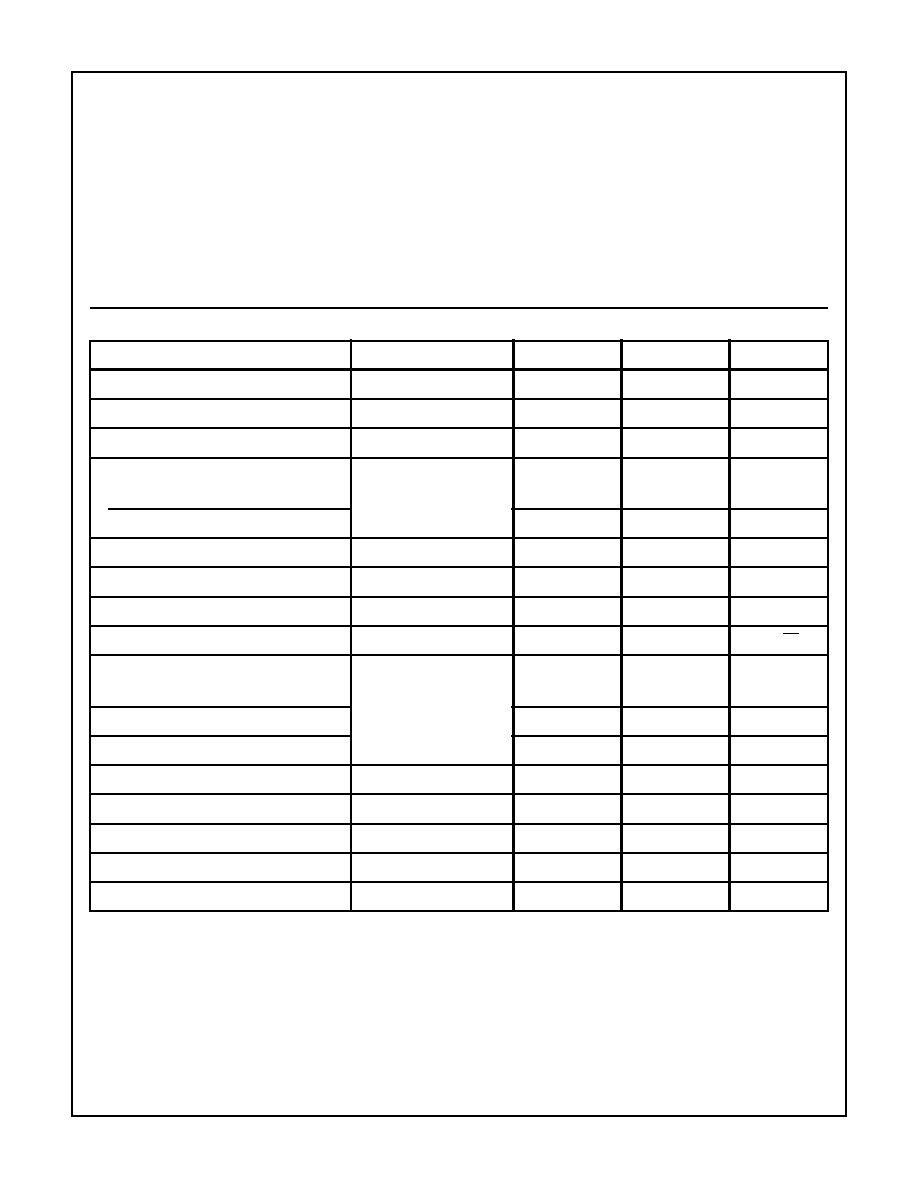

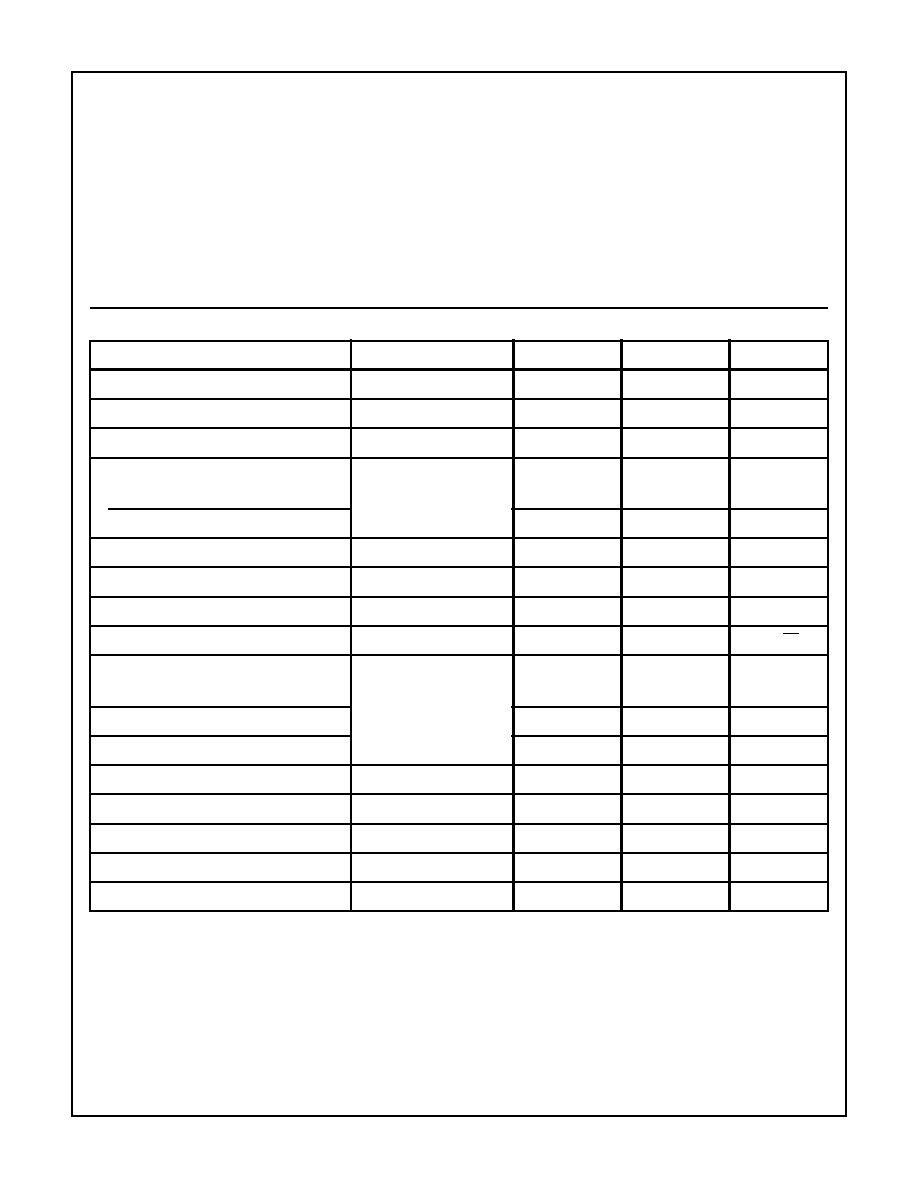

Electrical Specifications

Typical Values at T

A

= 25

C, V+ = 5V, Unless Otherwise Specified

PARAMETER

TEST CONDITIONS

AD590I

AD590J

UNITS

Nominal Output Current at 2

o

C (298.2

o

K)

298.2

298.2

µ

A

Nominal Temperature Coefficient

1.0

1.0

µ

A/

o

K

Calibration Error at 25

o

C

Notes 1, 5

±

10.0 Max

±

5.0 Max

o

C

Absolute Error

-55

o

C to 150

o

C, Note 7

Without External Calibration Adjustment

±

20.0 Max

±

10.0 Max

o

C

With External Calibration Adjustment

±

5.8 Max

±

3.0 Max

o

C

Non-Linearity

Note 6

±

3.0 Max

±

1.5 Max

o

C

Repeatability

Notes 2, 6

±

0.1 Max

±

0.1 Max

o

C

Long Term Drift

Notes 3, 6

±

0.1 Max

±

0.1 Max

o

C/Month

Current Noise

40

40

pA

/

Hz

Power Supply Rejection

+4V < V+ < +5V

0.5

0.5

µ

A/V

+5V < V+ < +15V

0.2

0.2

µ

A/V

+15V < V+ < +30V

0.1

0.1

µ

A/V

Case Isolation to Either Lead

10

10

10

10

Effective Shunt Capacitance

100

100

pF

Electrical Turn-On Time

Note 1

20

20

µ

s

Reverse Bias Leakage Current

Note 4

10

10

pA

Power Supply Range

+4 to +30

+4 to +30

V

NOTES:

2. Does not include self heating effects.

3. Maximum deviation between 25

o

C reading after temperature cycling between -55

o

C and 150

o

C.

4. Conditions constant +5V, constant 125

o

C.

5. Leakage current doubles every 10

o

C.

6. Mechanical strain on package may disturb calibration of device.

7. Guaranteed but not tested.

8. -55

o

C Guaranteed by testing at 25

o

C and 150

o

C.

AD590

12-5

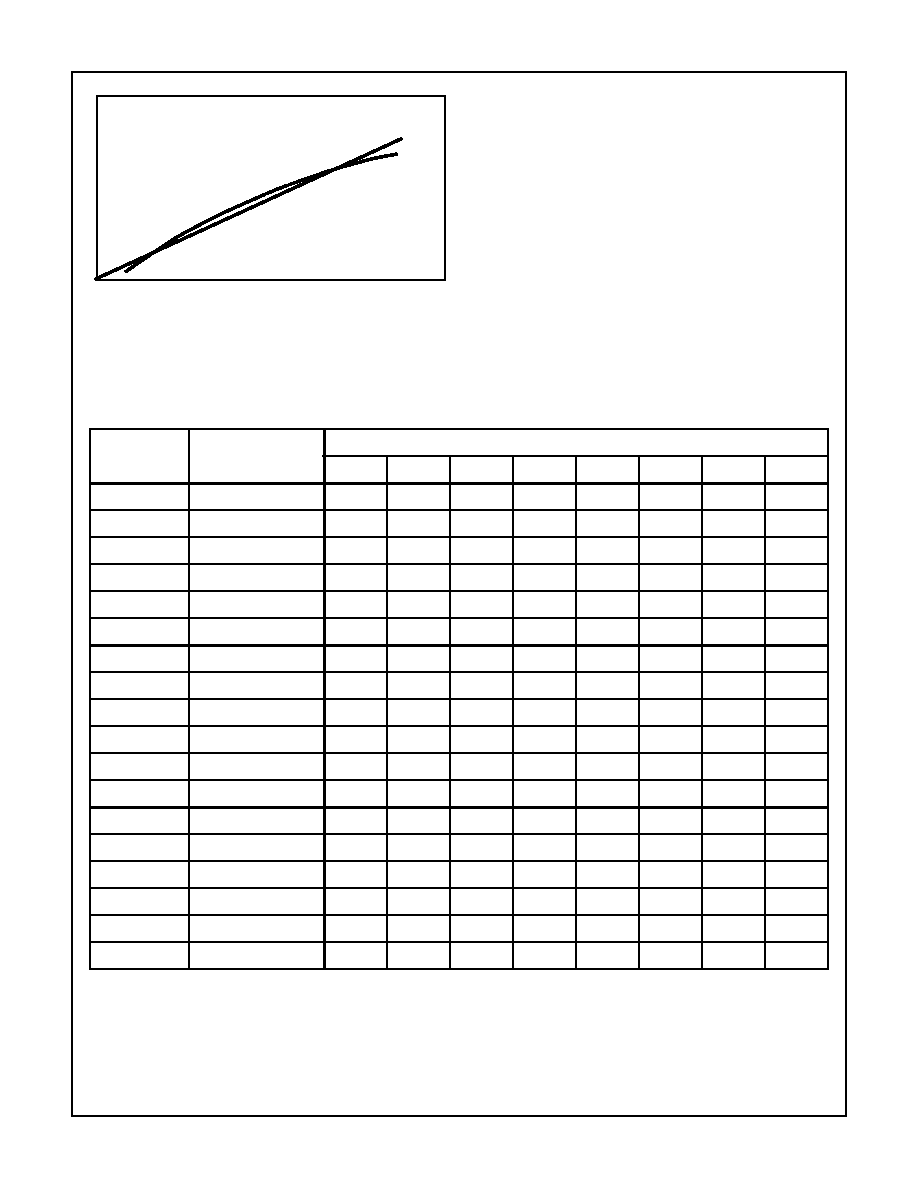

Trimming Out Errors

The ideal graph of current versus temperature for the AD590

is a straight line, but as Figure 1 shows, the actual shape is

slightly different. Since the sensor is limited to the range of

-55

o

C to 150

o

C, it is possible to optimize the accuracy by

trimming. Trimming also permits extracting maximum

performance from the lower-cost sensors.

The circuit of Figure 2 trims the slope of the AD590 output.

The effect of this is shown in Figure 3.

The circuit of Figure 4 trims both the slope and the offset.

This is shown in Figure 5. The diagrams are exaggerated to

show effects, but it should be clear that these trims can be

used to minimize errors over the whole range, or over any

selected part of the range. In fact, it is possible to adjust the

I-grade device to give less than 0.1

o

C error over the range

0

o

C to 90

o

C and less than 0.05

o

C error from 25

o

C to 60

o

C.

FIGURE 1. TRIMMING OUT ERRORS

I (

µ

A)

T (

o

K)

IDEAL

ACTUAL

(GREATLY

EXAGGERATED)

FIGURE 2. SLOPE TRIMMING

+5V

R 100

+

AD590

-

R = SLOPE

+

+

950

V

OUT

= 1mV/

o

K

FIGURE 3. EFFECT OF SLOPE TRIM

I (

µ

A)

T (

o

K)

IDEAL

ACTUAL

TRIMMED

FIGURE 4. SLOPE AND OFFSET TRIMMING

+10V

35.7k

R

1

2k

+

AD590

-

V

-

R

1

= OFFSET

R

2

= SLOPE

V

OUT

= 100mV/

o

C

97.6k

R

2

5k

FIGURE 5A. UNTRIMMED

FIGURE 5B. TRIM ONE: OFFSET

FIGURE 5C. TRIM TWO: SLOPE

AD590

12-6

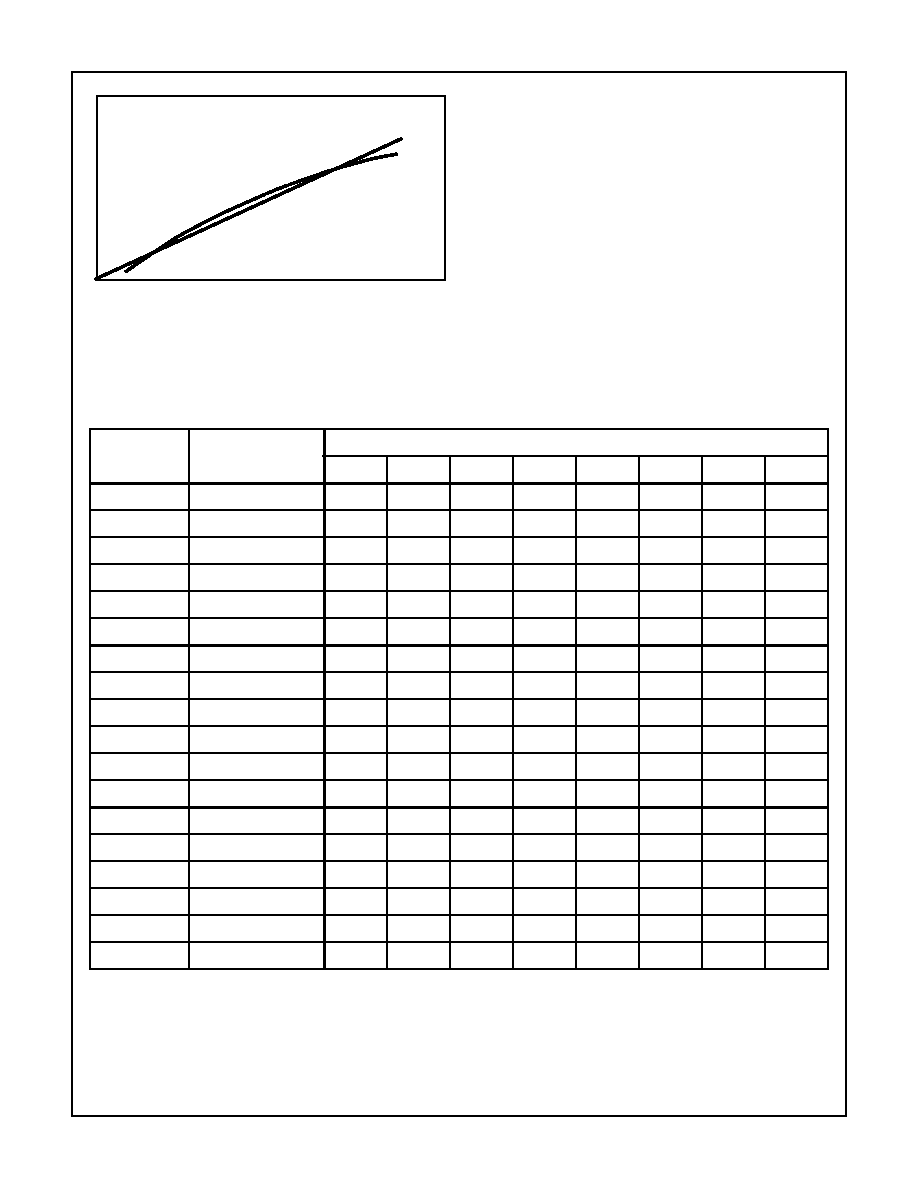

Accuracy

Maximum errors over limited temperature spans, with

V

S

= +5V, are listed by device grade in the following tables.

The tables reflect the worst-case linearities, which invariably

occur at the extremities of the specified temperature range.

The trimming conditions for the data in the tables are shown

in Figure 2 and Figure 4.

All errors listed in the tables are

±

o

C. For example, if

±

1

o

C

maximum error is required over the 25

o

C to 75

o

C range (i.e.,

lowest temperature of 25

o

C and span of 50

o

C), then the

trimming of a J-grade device, using the single-trim circuit

(Figure 2), will result in output having the required accuracy

over the stated range. An I-grade device with two trims

(Figure 4) will have less than

±

0.2

o

C error. If the requirement

is for less than

±

1.4

o

C maximum error, from -25

o

C to 75

o

C

(100

o

C span from -25

o

C), it can be satisfied by an I-grade

device with two trims.

FIGURE 5D. TRIM THREE: OFFSET AGAIN

FIGURE 5. EFFECT OF SLOPE AND OFFSET TRIMMING

I Grade Maximum Errors (

o

C)

NUMBER OF

TRIMS

TEMPERATURE

SPAN (

o

C)

LOWEST TEMPERATURE IN SPAN (

o

C)

-55

-25

0

25

50

75

100

125

None

10

8.4

9.2

10.0

10.8

11.6

12.4

13.2

14.4

None

25

10.0

10.4

11.0

11.8

12.0

13.8

15.0

16.0

None

50

13.0

13.0

12.8

13.8

14.6

16.4

18.0

-

None

100

15.2

16.0

16.6

17.4

18.8

-

-

-

None

150

18.4

19.0

19.2

-

-

-

-

-

None

205

20.0

-

-

-

-

-

-

-

One

10

0.6

0.4

0.4

0.4

0.4

0.4

0.4

0.6

One

25

1.8

1.2

1.0

1.0

1.0

1.2

1.6

1.8

One

50

3.8

3.0

2.0

2.0

2.0

3.0

3.8

-

One

100

4.8

4.5

4.2

4.2

5.0

-

-

-

One

150

5.5

4.8

5.5

-

-

-

-

-

One

205

5.8

-

-

-

-

-

-

-

Two

10

0.3

0.2

0.1

(Note 9)

(Note 9)

0.1

0.2

0.3

Two

25

0.5

0.3

0.2

(Note 9)

0.1

0.2

0.3

0.5

Two

50

1.2

0.6

0.4

0.2

0.2

0.3

0.7

-

Two

100

1.8

1.4

1.0

2.0

2.5

-

-

-

Two

150

2.6

2.0

2.8

-

-

-

-

-

Two

205

3.0

-

-

-

-

-

-

-

NOTE:

9. Less than

±

0.05

o

C.

AD590

12-7

NOTES

1. Maximum errors over all ranges are guaranteed based on

the known behavior characteristic of the AD590.

2. For one-trim accuracy specifications, the 205

o

C span is

assumed to be trimmed at 25

o

C; for all other spans, it is

assumed that the device is trimmed at the midpoint.

3. For the 205

o

C span, it is assumed that the two-trim

temperatures are in the vicinity of 0

o

C and 140

o

C; for all

other spans, the specified trims are at the endpoints.

4. In precision applications, the actual errors encountered

are usually dependent upon sources of error which are

often overlooked in error budgets. These typically

include:

a. Trim error in the calibration technique used

b. Repeatability error

c. Long term drift errors

Trim Error is usually the largest error source. This error

arises from such causes as poor thermal coupling between

the device to be calibrated and the reference sensor; refer-

ence sensor errors; lack of adequate time for the device

being calibrated to settle to the final temperature; radically

different thermal resistances between the case and the sur-

roundings (R

CA

) when trimming and when applying the

device.

Repeatability Errors arise from a strain hysteresis of the

package. The magnitude of this error is solely a function of

the magnitude of the temperature span over which the

device is used. For example, thermal shocks between 0

o

C

and 100

o

C involve extremely low hysteresis and result in

repeatability errors of less than

±

0.05

o

C. When the thermal-

shock excursion is widened to -55

o

C to 150

o

C, the device

will typIcally exhibit a repeatability error of

±

0.05

o

C (

±

0.10

guaranteed maximum).

Long Term Drift Errors are related to the average operating

temperature and the magnitude of the thermal-shocks

experienced by the device. Extended use of the AD590 at

temperatures above 100

o

C typically results in long-term drift

of

±

0.03

o

C per month; the guaranteed maximum is

±

0.10

o

C

per month. Continuous operation at temperatures below

100

o

C induces no measurable drifts in the device. Besides

the effects of operating temperature, the severity of thermal

shocks incurred will also affect absolute stability. For

thermal-shock excursions less than 100

o

C, the drift is diffi-

cult to measure (<0.03

o

C). However, for 200

o

C excursions,

the device may drift by as much as

±

0.10

o

C after twenty

such shocks. If severe, quick shocks are necessary in the

application of the device, realistic simulated life tests are rec-

ommended for a thorough evaluation of the error introduced

by such shocks.

J Grade Maximum Errors (

o

C)

NUMBER OF

TRIMS

TEMPERATURE

SPAN (

o

C)

LOWEST TEMPERATURE IN SPAN (oC)

-55

-25

0

25

50

75

100

125

None

10

4.2

4.6

5.0

5.4

5.8

6.2

6.6

7.2

None

25

5.0

5.2

5.5

5.9

6.0

6.9

7.5

8.0

None

50

6.5

6.5

6.4

6.9

7.3

8.2

9.0

-

None

100

7.7

8.0

8.3

8.7

9.4

-

-

-

None

150

9.2

9.5

9.6

-

-

-

-

-

None

205

10.0

-

-

-

-

-

-

-

One

10

0.3

0.2

0.2

0.2

0.2

0.2

0.2

0.3

One

25

0.9

0.6

0.5

0.5

0.5

0.6

0.8

0.9

One

50

1.9

1.5

1.0

1.0

1.0

1.5

1.9

-

One

100

2.3

2.2

2.0

2.0

2.3

-

-

-

One

150

2.5

2.4

2.5

-

-

-

-

-

One

205

3.0

-

-

-

-

-

-

-

Two

10

0.1

(Note 10)

(Note 10)

(Note 10)

(Note 10)

(Note 10)

(Note 10)

0.1

Two

25

0.2

0.1

(Note 10)

(Note 10)

(Note 10)

(Note 10)

0.1

0.2

Two

50

0.4

0.2

0.1

(Note 10)

(Note 10)

0.1

0.2

(Note 10)

Two

100

0.7

0.5

0.3

0.7

1.0

-

-

-

Two

150

1.0

0.7

1.2

-

-

-

-

-

Two

205

1.6

-

-

-

-

-

-

-

NOTE:

10. Less than

±

0.05

o

C.

AD590