| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CA3081 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

CA3081, CA3082

General Purpose High Current NPN

Transistor Arrays

CA3081 and CA3082 consist of seven high current (to

100mA) silicon NPN transistors on a common monolithic

substrate. The CA3081 is connected in a common emitter

configuration and the CA3082 is connected in a common

collector configuration.

The CA3081 and CA3082 are capable of directly driving

seven segment displays, and light emitting diode (LED)

displays. These types are also well suited for a variety of

other drive applications, including relay control and thyristor

firing.

Features

∑ CA3081 - Common Emitter Array

∑ CA3082 - Common Collector Array

∑ Directly Drive Seven Segment Incandescent Displays and

Light Emitting Diode (LED) Display

∑ 7 Transistors Permit a Wide Range of Applications in

Either a Common Emitter (CA3081) or Common Collector

(CA3082) Configuration

∑ High I

C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA (Max)

∑ Low V

CESAT

(at 50mA) . . . . . . . . . . . . . . . . . . 0.4V (Typ)

Applications

∑ Drivers for

- Incandescent Display Devices

- LED Displays

∑ Relay Control

∑ Thyristor Firing

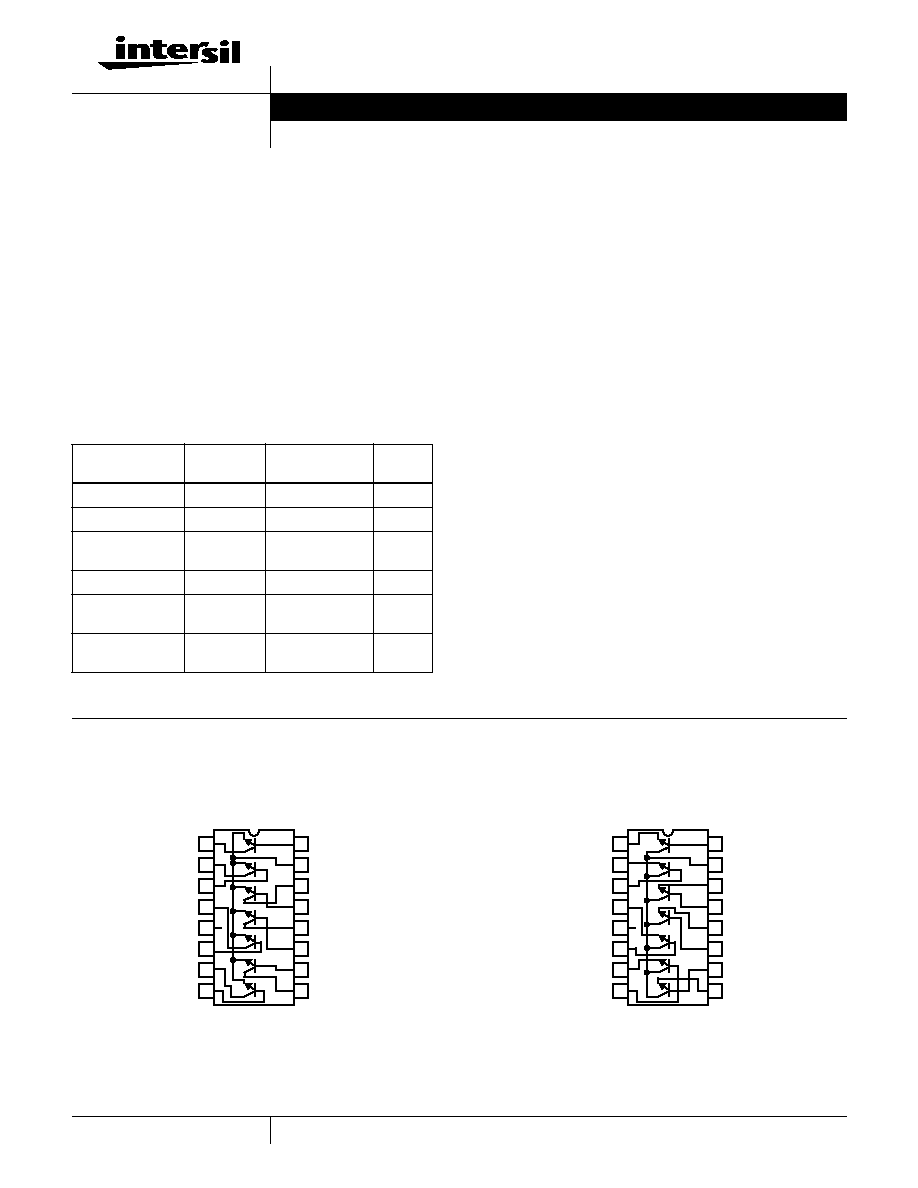

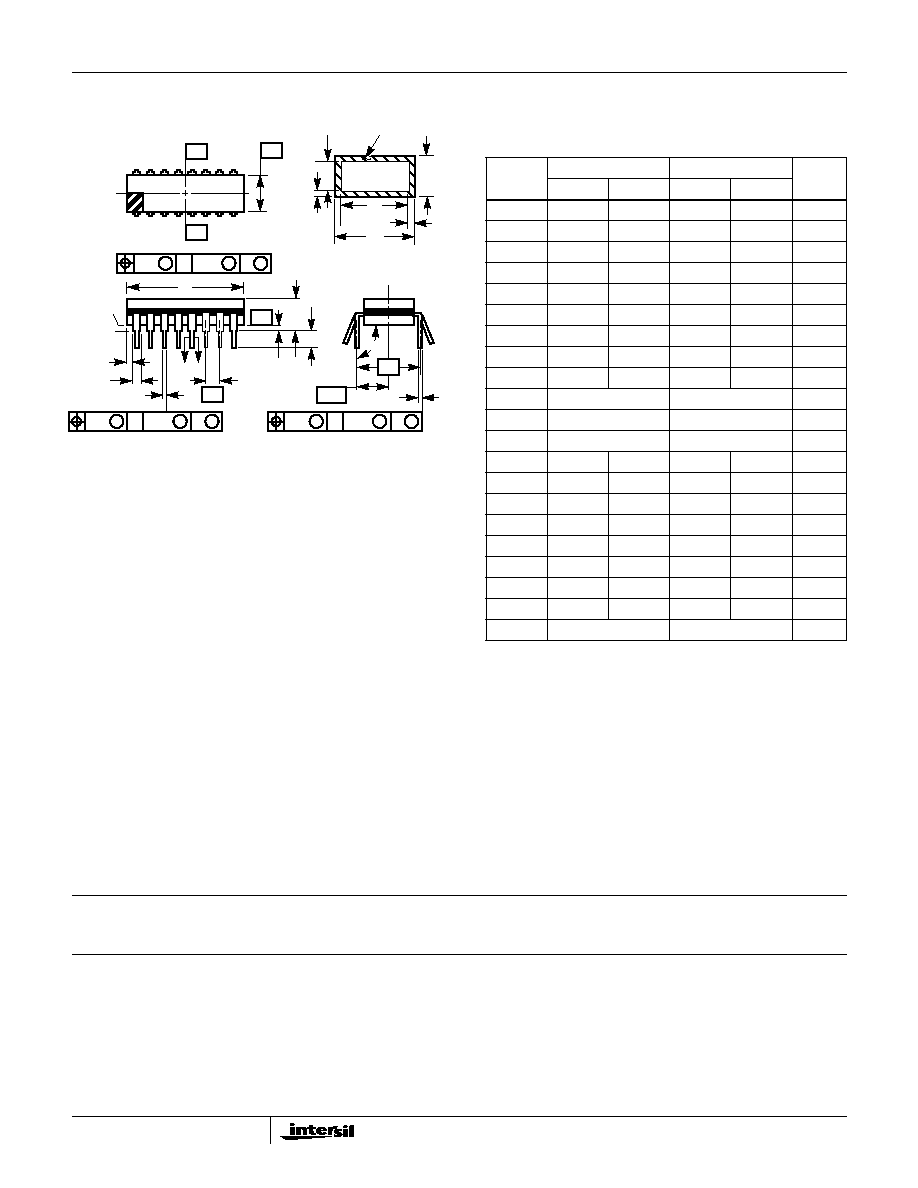

Pinouts

Ordering Information

PART NUMBER

(BRAND)

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

CA3081

-55 to 125

16 Ld PDIP

E16.3

CA3081F

-55 to 125

16 Ld CERDIP

F16.3

CA3081M

(3081)

-55 to 125

16 Ld SOIC

M16.15

CA3082

-55 to 125

16 Ld PDIP

E16.3

CA3082M

(3082)

-55 to 125

16 Ld SOIC

M16.15

CA3082M96

(3082)

-55 to 125

16 Ld SOIC Tape

and Reel

M16.15

CA3081

COMMON EMITTER CONFIGURATION

(PDIP, CERDIP, SOIC)

TOP VIEW

CA3082

COMMON COLLECTOR CONFIGURATION

(PDIP, SOIC)

TOP VIEW

14

15

16

9

13

12

11

10

1

2

3

4

5

7

6

8

SUBSTRATE

14

15

16

9

13

12

11

10

1

2

3

4

5

7

6

8

SUBSTRATE

Data Sheet

November 1999

File Number

480.5

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

2

Absolute Maximum Ratings

T

A

= 25

o

C

Thermal Information

Collector-to-Emitter Voltage (V

CEO

) . . . . . . . . . . . . . . . . . . . . . .16V

Collector-to-Base Voltage (V

CBO

) . . . . . . . . . . . . . . . . . . . . . . . 20V

Collector-to-Substrate Voltage (V

CIO

, Note 1). . . . . . . . . . . . . . 20V

Emitter-to-Base Voltage (V

EBO

) . . . . . . . . . . . . . . . . . . . . . . . . . 5V

Collector Current (I

C

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA

Base Current (I

B

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -55

o

C to 125

o

C

Thermal Resistance (Typical, Note 2)

JA

(

o

C/W)

JC

(

o

C/W)

CERDIP Package . . . . . . . . . . . . . . . . .

115

45

PDIP Package . . . . . . . . . . . . . . . . . . .

100

N/A

SOIC Package . . . . . . . . . . . . . . . . . . .

190

N/A

Maximum Power Dissipation (Any One Transistor) . . . . . . . 500mW

Maximum Junction Temperature (Ceramic Package) . . . . . . . . .175

o

C

Maximum Junction Temperature (Plastic Package) . . . . . . . .150

o

C

Maximum Storage Temperature Range . . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. The collector of each transistor of the CA3081 and CA3082 is isolated from the substrate by an integral diode. The substrate must be connected

to a voltage which is more negative than any collector voltage in order to maintain isolation between transistors and provide normal transistor

action. To avoid undesired coupling between transistors, the substrate terminal (5) should be maintained at either DC or signal (AC) ground. A

suitable bypass capacitor can be used to establish a signal ground.

2.

JA

is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications

For Equipment Design at T

A

= 25

o

C

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

Collector-to-Base Breakdown Voltage

V

(BR)CBO

I

C

= 500

µ

A, I

E

= 0

20

60

-

V

Collector-to-Substrate Breakdown Voltage

V

(BR)CIO

I

C

= 500

µ

A, I

B

= 0

20

60

-

V

Collector-to-Emitter Breakdown Voltage

V

(BR)CEO

I

C

= 1mA, I

B

= 0

16

24

-

V

Emitter-to-Base Breakdown Voltage

V

(BR)EBO

I

C

= 500

µ

A

5.0

6.9

-

V

DC Forward Current Transfer Ratio

h

FE

V

CE

= 0.5V, I

C

= 30mA

30

68

-

-

V

CE

= 0.8V, I

C

= 50mA

40

70

-

-

Base-to-Emitter Saturation Voltage (Figure 4)

V

BESAT

I

C

= 30mA, I

B

= 1mA

-

0.87

1.2

V

Collector-to-Emitter Saturation Voltage

V

CESAT

CA3081, CA3082

I

C

= 30mA, I

B

= 1mA

-

0.27

0.5

V

CA3081 (Figure 5)

I

C

= 50mA, I

B

= 5mA

-

0.4

0.7

V

CA3082 (Figure 5)

I

C

= 50mA, I

B

= 5mA

-

0.4

0.8

V

Collector Cutoff Current

I

CEO

V

CE

= 10V, I

B

= 0

-

-

10

µ

A

Collector Cutoff Current

I

CBO

V

CB

= 10V, I

E

= 0

-

-

1.0

µ

A

Typical Read - Out Driver Applications

FIGURE 1. SCHEMATIC DIAGRAM SHOWING ONE

TRANSISTOR OF THE CA3081 DRIVING ONE

SEGMENT OF AN INCANDESCENT DISPLAY

FIGURE 2. SCHEMATIC DIAGRAM SHOWING ONE

TRANSISTOR OF THE CA3082 DRIVING A LIGHT

EMITTING DIODE (LED)

FROM

DECODER

1/7 CA3081

(COMMON EMITTER)

V+

1 SEGMENT OF INCANDESCENT DISPLAY

(DR2000 SERIES OR EQUIVALENT)

1/7 CA3082

(COMMON COLLECTOR)

V+

R (NOTE)

LIGHT EMITTING DIODE (LED)

40736R

NOTE:

The Resistance for R is determined by the relationship:

Where: V

P

= Input Pulse Voltage

V

F

= Forward Voltage Drop Across the Diode

R

V

P

V

BE

V

F

LED

(

)

≠

≠

I LED

(

)

-------------------------------------------------------

=

R

0 for V

P

V

BE

V

F

LED

(

)

+

=

=

V

P

0V

CA3081, CA3082

3

Typical Performance Curves

FIGURE 3. DC FORWARD CURRENT TRANSFER RATIO vs

COLLECTOR CURRENT

FIGURE 4. BASE-TO-EMITTER SATURATION VOLTAGE vs

COLLECTOR CURRENT

FIGURE 5. COLLECTOR-TO-EMITTER SATURATION

VOLTAGE vs COLLECTOR CURRENT

FIGURE 6. COLLECTOR-TO-EMITTER SATURATION

VOLTAGE vs COLLECTOR CURRENT

100

90

80

70

60

50

40

DC FOR

W

ARD CURRENT

0.1

1

10

100

COLLECTOR CURRENT (mA)

T

A

= 70

o

C

T

A

= 25

o

C

T

A

= 0

o

C

V

CE

= 3V

TRANSFER RA

TIO (h

FE

)

1.0

0.9

0.8

0.7

0.6

B

ASE-T

O-EMITTER

1

10

100

COLLECTOR CURRENT (mA)

T

A

= 25

o

C

h

FE

= 10

SA

TURA

TION V

O

L

T

A

GE (V)

1

0.8

0.6

0.4

0.2

0

1

10

100

COLLECT

OR-T

O-EMITTER

COLLECTOR CURRENT (mA)

MAXIMUM

TYPICAL

h

FE

= 10

T

A

= 25

o

C

SA

TURA

TION V

O

L

T

A

GE (V)

1.2

1

0.8

0.6

0.4

0.2

0

1

10

100

COLLECT

OR-T

O-EMITTER

COLLECTOR CURRENT (mA)

MAXIMUM

TYPICAL

h

FE

= 10

T

A

= 70

o

C

SA

TURA

TION V

O

L

T

A

GE (V)

CA3081, CA3082

4

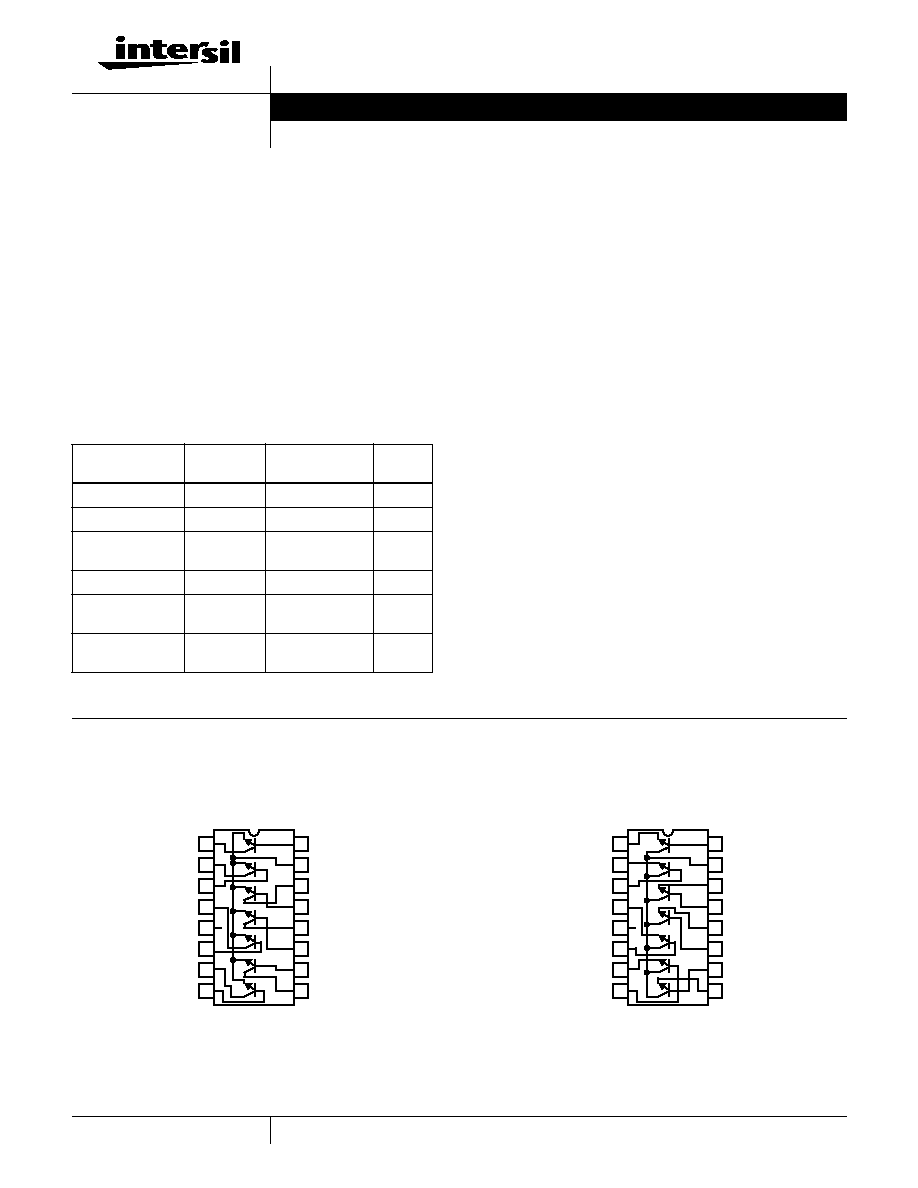

CA3081, CA3082

Dual-In-Line Plastic Packages (PDIP)

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the "MO Series Symbol List" in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in JE-

DEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and

are measured with the leads constrained to be perpendic-

ular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads unconstrained.

e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

e

A

-C-

C

L

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A1

-A-

0.010 (0.25)

C

A

M

B S

E16.3

(JEDEC MS-001-BB ISSUE D)

16 LEAD DUAL-IN-LINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.210

-

5.33

4

A1

0.015

-

0.39

-

4

A2

0.115

0.195

2.93

4.95

-

B

0.014

0.022

0.356

0.558

-

B1

0.045

0.070

1.15

1.77

8, 10

C

0.008

0.014

0.204

0.355

-

D

0.735

0.775

18.66

19.68

5

D1

0.005

-

0.13

-

5

E

0.300

0.325

7.62

8.25

6

E1

0.240

0.280

6.10

7.11

5

e

0.100 BSC

2.54 BSC

-

e

A

0.300 BSC

7.62 BSC

6

e

B

-

0.430

-

10.92

7

L

0.115

0.150

2.93

3.81

4

N

16

16

9

Rev. 0 12/93

5

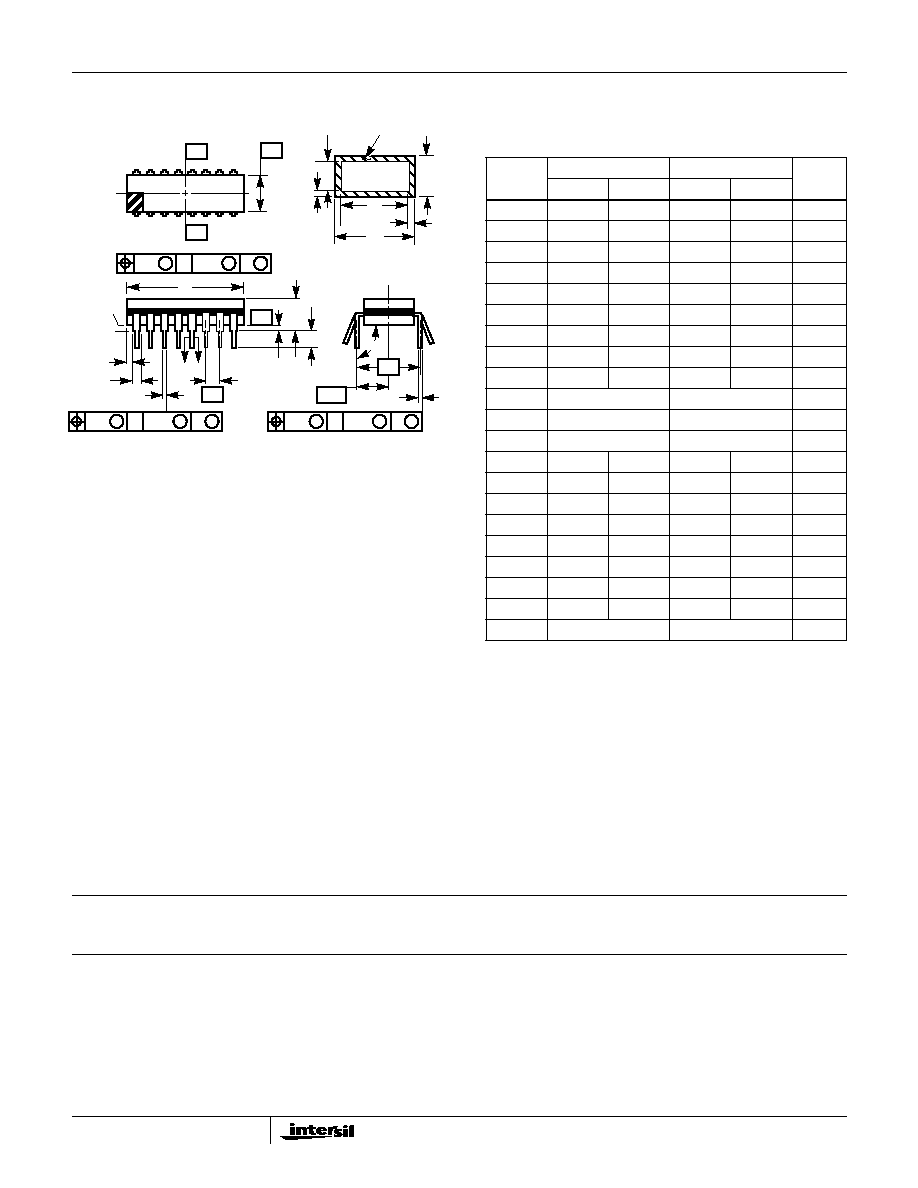

CA3081, CA3082

Small Outline Plastic Packages (SOIC)

NOTES:

1. Symbols are defined in the "MO Series Symbol List" in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension "E" does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. "L" is the length of terminal for soldering to a substrate.

7. "N" is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width "B", as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm

(0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

0.25(0.010)

B

M

M

M16.15

(JEDEC MS-012-AC ISSUE C)

16 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.0532

0.0688

1.35

1.75

-

A1

0.0040

0.0098

0.10

0.25

-

B

0.013

0.020

0.33

0.51

9

C

0.0075

0.0098

0.19

0.25

-

D

0.3859

0.3937

9.80

10.00

3

E

0.1497

0.1574

3.80

4.00

4

e

0.050 BSC

1.27 BSC

-

H

0.2284

0.2440

5.80

6.20

-

h

0.0099

0.0196

0.25

0.50

5

L

0.016

0.050

0.40

1.27

6

N

16

16

7

0

o

8

o

0

o

8

o

-

Rev. 0 12/93

6

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time with-

out notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

CA3081, CA3082

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

NOTES:

1. Index area: A notch or a pin one identification mark shall be locat-

ed adjacent to pin one and shall be located within the shaded

area shown. The manufacturer's identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

bbb

C A - B

S

c

Q

L

A

SEATING

BASE

D

PLANE

PLANE

-D-

-A-

-C-

-B-

D

E

S1

b2

b

A

e

M

c1

b1

(c)

(b)

SECTION A-A

BASE

LEAD FINISH

METAL

e

A/2

A

M

S

S

ccc

C A - B

M

D

S

S

aaa

C A - B

M

D

S

S

e

A

F16.3

MIL-STD-1835 GDIP1-T16 (D-2, CONFIGURATION A)

16 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.200

-

5.08

-

b

0.014

0.026

0.36

0.66

2

b1

0.014

0.023

0.36

0.58

3

b2

0.045

0.065

1.14

1.65

-

b3

0.023

0.045

0.58

1.14

4

c

0.008

0.018

0.20

0.46

2

c1

0.008

0.015

0.20

0.38

3

D

-

0.840

-

21.34

5

E

0.220

0.310

5.59

7.87

5

e

0.100 BSC

2.54 BSC

-

eA

0.300 BSC

7.62 BSC

-

eA/2

0.150 BSC

3.81 BSC

-

L

0.125

0.200

3.18

5.08

-

Q

0.015

0.060

0.38

1.52

6

S1

0.005

-

0.13

-

7

90

o

105

o

90

o

105

o

-

aaa

-

0.015

-

0.38

-

bbb

-

0.030

-

0.76

-

ccc

-

0.010

-

0.25

-

M

-

0.0015

-

0.038

2, 3

N

16

16

8

Rev. 0 4/94