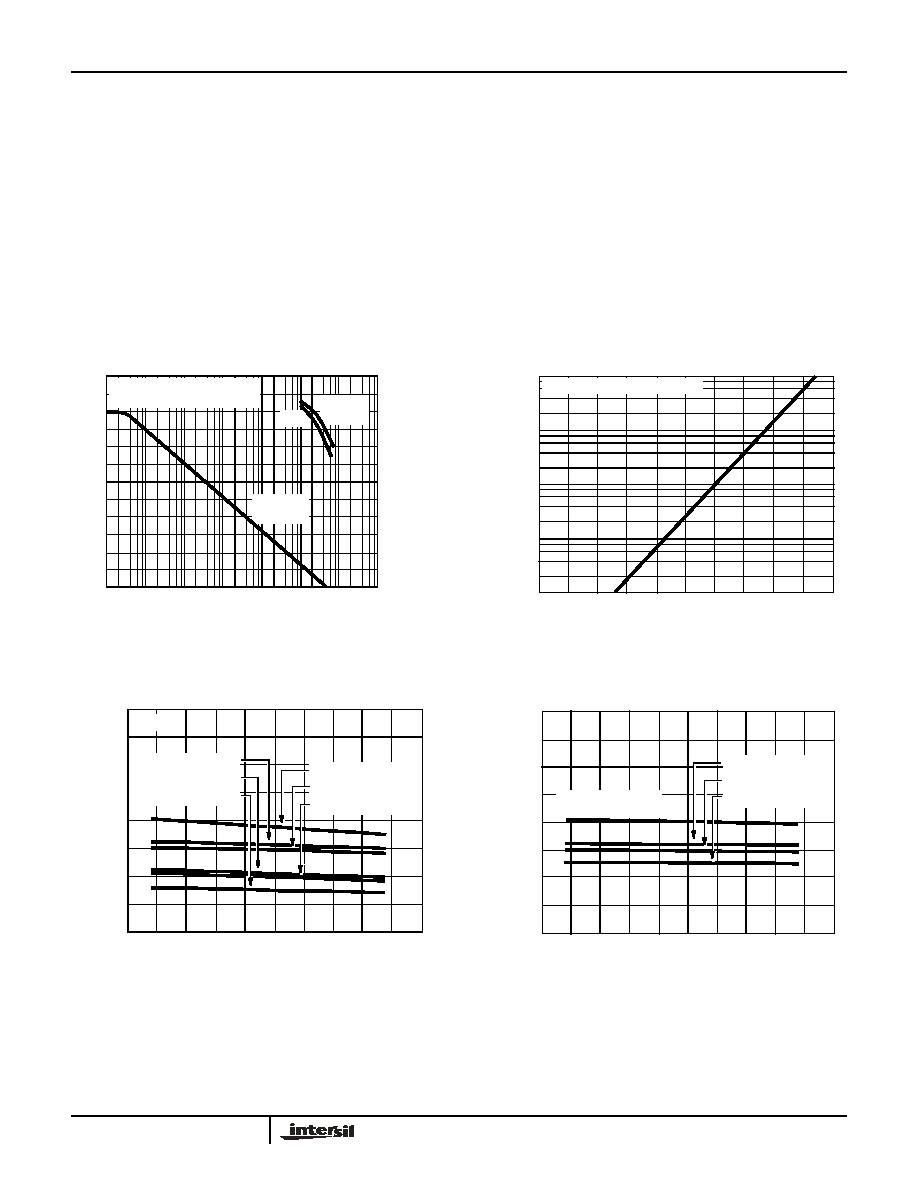

1

Æ

CA3140, CA3140A

4.5MHz, BiMOS Operational Amplifier with

MOSFET Input/Bipolar Output

The CA3140A and CA3140 are integrated circuit operational

amplifiers that combine the advantages of high voltage

PMOS transistors with high voltage bipolar transistors on a

single monolithic chip.

The CA3140A and CA3140 BiMOS operational amplifiers

feature gate protected MOSFET (PMOS) transistors in the

input circuit to provide very high input impedance, very low

input current, and high speed performance. The CA3140A

and CA3140 operate at supply voltage from 4V to 36V

(either single or dual supply). These operational amplifiers

are internally phase compensated to achieve stable

operation in unity gain follower operation, and additionally,

have access terminal for a supplementary external capacitor

if additional frequency roll-off is desired. Terminals are also

provided for use in applications requiring input offset voltage

nulling. The use of PMOS field effect transistors in the input

stage results in common mode input voltage capability down

to 0.5V below the negative supply terminal, an important

attribute for single supply applications. The output stage

uses bipolar transistors and includes built-in protection

against damage from load terminal short circuiting to either

supply rail or to ground.

The CA3140A and CA3140 are intended for operation at

supply voltages up to 36V (

±

18V).

Features

∑ MOSFET Input Stage

- Very High Input Impedance (Z

IN

) -1.5T

(Typ)

- Very Low Input Current (I

l

) -10pA (Typ) at

±

15V

- Wide Common Mode Input Voltage Range (V

lCR

) - Can

be Swung 0.5V Below Negative Supply Voltage Rail

- Output Swing Complements Input Common Mode

Range

∑ Directly Replaces Industry Type 741 in Most

∑ Applications

Applications

∑ Ground-Referenced Single Supply Amplifiers in

Automobile and Portable Instrumentation

∑ Sample and Hold Amplifiers

∑ Long Duration Timers/Multivibrators

(

µ

seconds-Minutes-Hours)

∑ Photocurrent Instrumentation

∑ Peak Detectors

∑ Active Filters

∑ Comparators

∑ Interface in 5V TTL Systems and Other Low

Supply Voltage Systems

∑ All Standard Operational Amplifier Applications

∑ Function Generators

∑ Tone Controls

∑ Power Supplies

∑ Portable Instruments

∑ Intrusion Alarm Systems

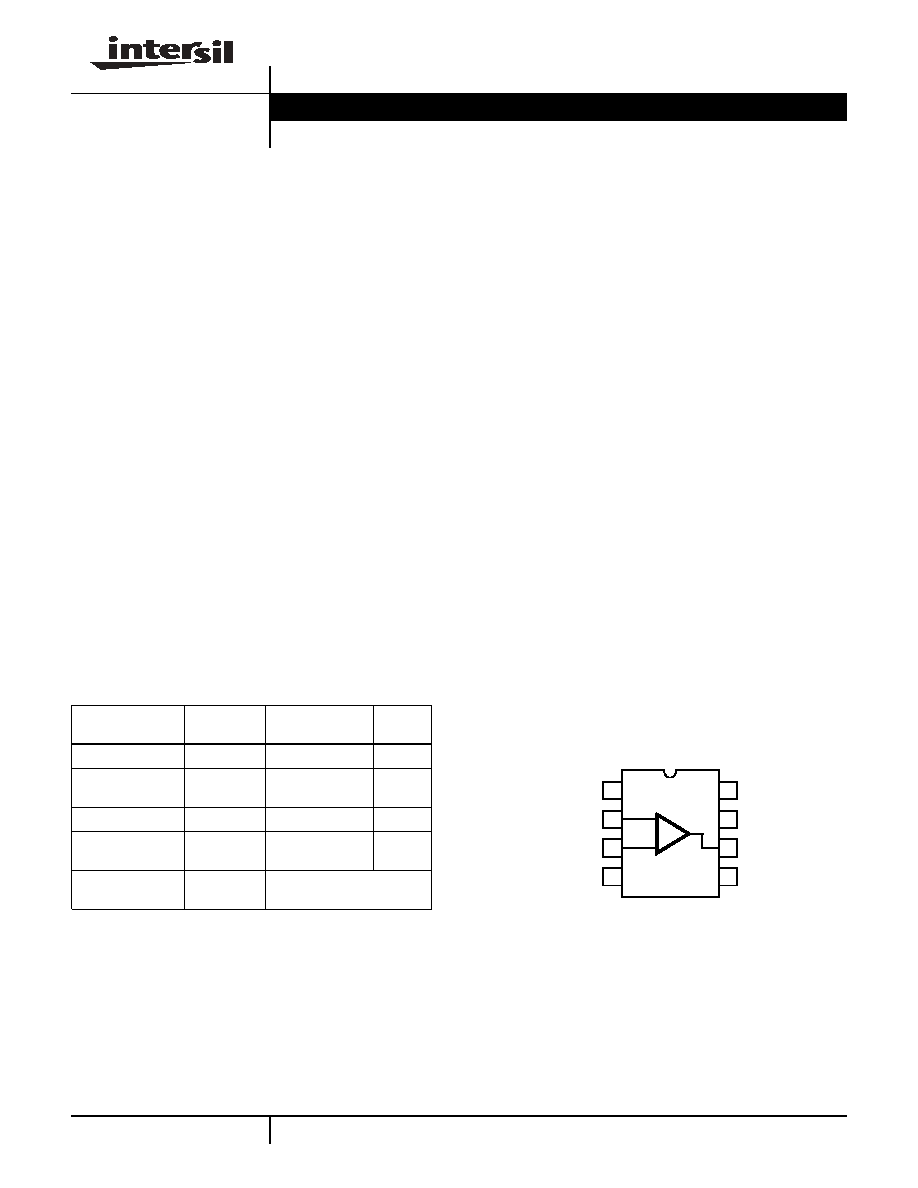

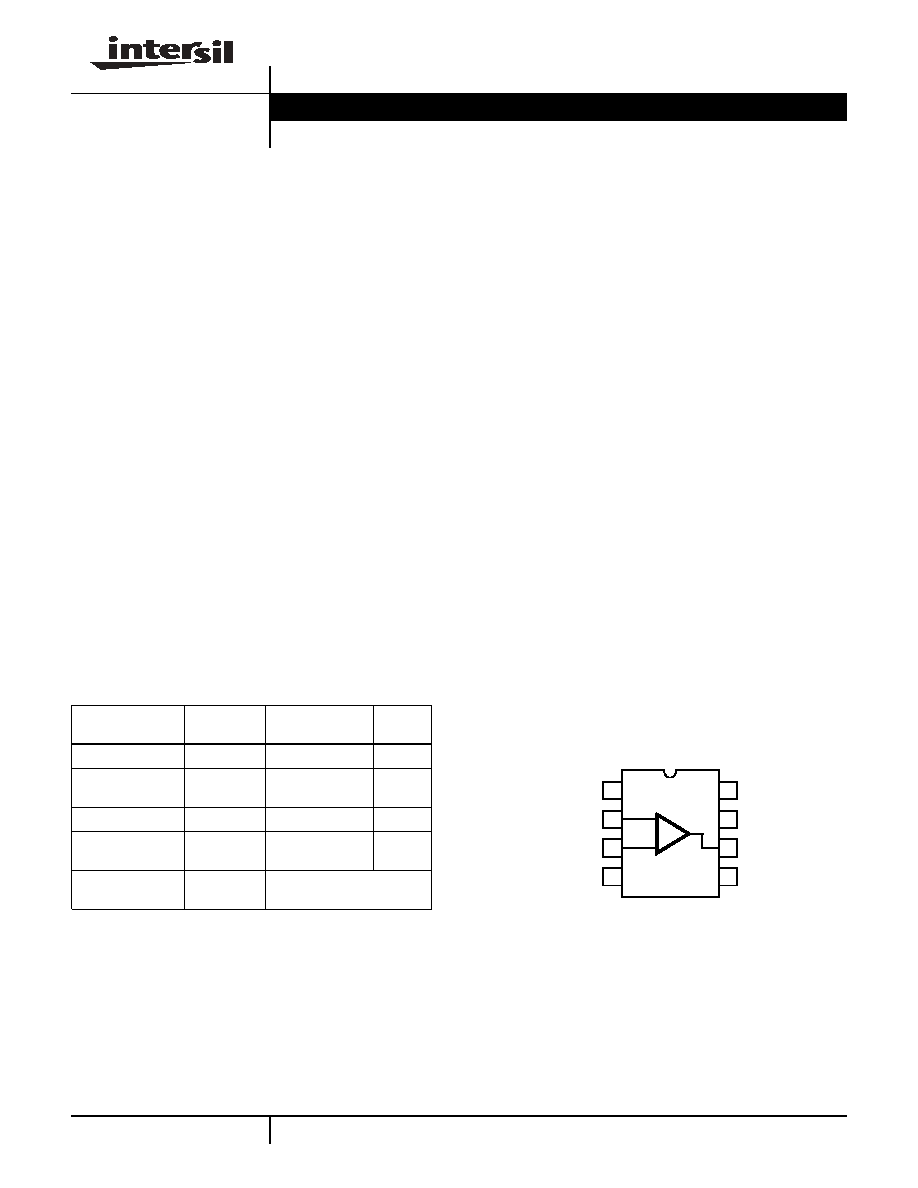

Pinout

CA3140 (PDIP, SOIC)

TOP VIEW

Ordering Information

PART NUMBER

(BRAND)

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

CA3140AE

-55 to 125

8 Ld PDIP

E8.3

CA3140AM

(3140A)

-55 to 125

8 Ld SOIC

M8.15

CA3140E

-55 to 125

8 Ld PDIP

E8.3

CA3140M

(3140)

-55 to 125

8 Ld SOIC

M8.15

CA3140M96

(3140)

-55 to 125

8 Ld SOIC Tape and Reel

INV. INPUT

NON-INV.

V-

1

2

3

4

8

7

6

5

STROBE

V+

OUTPUT

OFFSET

NULL

OFFSET

NULL

INPUT

-

+

Data Sheet

November 2002

FN957.7

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

2

Absolute Maximum Ratings

Thermal Information

DC Supply Voltage (Between V+ and V- Terminals) . . . . . . . . . 36V

Differential Mode Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 8V

DC Input Voltage . . . . . . . . . . . . . . . . . . . . . (V+

+8V) To (V- -0.5V)

Input Terminal Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1mA

Output Short Circuit Duration

(Note 2) . . . . . . . . . . . . . . Indefinite

Operating Conditions

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . -55

o

C to 125

o

C

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

JC

(

o

C/W)

PDIP Package . . . . . . . . . . . . . . . . . . .

115

N/A

SOIC Package . . . . . . . . . . . . . . . . . . .

165

N/A

Maximum Junction Temperature (Plastic Package) . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1.

JA

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details

2. Short circuit may be applied to ground or to either supply.

Electrical Specifications

V

SUPPLY

=

±

15V, T

A

= 25

o

C

PARAMETER

SYMBOL

TEST CONDITIONS

TYPICAL VALUES

UNITS

CA3140

CA3140A

Input Offset Voltage Adjustment Resistor

Typical Value of Resistor

Between Terminals 4 and 5 or 4 and 1 to

Adjust Max V

IO

4.7

18

k

Input Resistance

R

I

1.5

1.5

T

Input Capacitance

C

I

4

4

pF

Output Resistance

R

O

60

60

Equivalent Wideband Input Noise Voltage

(See Figure 27)

e

N

BW = 140kHz, R

S

= 1M

48

48

µ

V

Equivalent Input Noise Voltage (See Figure 35)

e

N

R

S

= 100

f = 1kHz

40

40

nV/

Hz

f = 10kHz

12

12

nV/

Hz

Short Circuit Current to Opposite Supply

I

OM

+

Source

40

40

mA

I

OM

-

Sink

18

18

mA

Gain-Bandwidth Product, (See Figures 6, 30)

f

T

4.5

4.5

MHz

Slew Rate, (See Figure 31)

SR

9

9

V/

µ

s

Sink Current From Terminal 8 To Terminal 4 to

Swing Output Low

220

220

µ

A

Transient Response (See Figure 28)

t

r

R

L

= 2k

C

L

= 100pF

Rise Time

0.08

0.08

µ

s

OS

Overshoot

10

10

%

Settling Time at 10V

P-P

, (See Figure 5)

t

S

R

L

= 2k

C

L

= 100pF

Voltage Follower

To 1mV

4.5

4.5

µ

s

To 10mV

1.4

1.4

µ

s

Electrical Specifications

For Equipment Design, at V

SUPPLY

=

±

15V, T

A

= 25

o

C, Unless Otherwise Specified

PARAMETER

SYMBOL

CA3140

CA3140A

UNITS

MIN

TYP

MAX

MIN

TYP

MAX

Input Offset Voltage

|V

IO

|

-

5

15

-

2

5

mV

Input Offset Current

|I

IO

|

-

0.5

30

-

0.5

20

pA

Input Current

I

I

-

10

50

-

10

40

pA

Large Signal Voltage Gain (Note 3)

(See Figures 6, 29)

A

OL

20

100

-

20

100

-

kV/V

86

100

- 86

100

-

dB

CA3140, CA3140A

3

Common Mode Rejection Ratio

(See Figure 34)

CMRR

-

32

320

-

32

320

µ

V/V

70

90

-

70

90

-

dB

Common Mode Input Voltage Range (See Figure 8)

V

ICR

-15

-15.5 to +12.5

11

-15

-15.5 to +12.5

12

V

Power-Supply Rejection Ratio,

V

IO

/

V

S

(See Figure 36)

PSRR

-

100

150

-

100

150

µ

V/V

76

80

-

76

80

-

dB

Max Output Voltage (Note 4)

(See Figures 2, 8)

V

OM

+

+12

13

-

+12

13

-

V

V

OM

-

-14

-14.4

-

-14

-14.4

-

V

Supply Current (See Figure 32)

I+

-

4

6

-

4

6

mA

Device Dissipation

P

D

-

120

180 -

120

180

mW

Input Offset Voltage Temperature Drift

V

IO

/

T

-

8

-

-

6

-

µ

V/

o

C

NOTES:

3. At V

O

= 26V

P-P

, +12V, -14V and R

L

= 2k

.

4. At R

L

= 2k

.

Electrical Specifications

For Equipment Design, at V

SUPPLY

=

±

15V, T

A

= 25

o

C, Unless Otherwise Specified (Continued)

PARAMETER

SYMBOL

CA3140

CA3140A

UNITS

MIN

TYP

MAX

MIN

TYP

MAX

Electrical Specifications

For Design Guidance At V+ = 5V, V- = 0V, T

A

= 25

o

C

PARAMETER

SYMBOL

TYPICAL VALUES

UNITS

CA3140

CA3140A

Input Offset Voltage

|V

IO

|

5

2

mV

Input Offset Current

|I

IO

|

0.1

0.1

pA

Input Current

I

I

2

2

pA

Input Resistance

R

I

1

1

T

Large Signal Voltage Gain (See Figures 6, 29)

A

OL

100

100

kV/V

100

100

dB

Common Mode Rejection Ratio

CMRR

32

32

µ

V/V

90

90

dB

Common Mode Input Voltage Range (See Figure 8)

V

ICR

-0.5

-0.5

V

2.6

2.6

V

Power Supply Rejection Ratio

PSRR

V

IO

/

V

S

100

100

µ

V/V

80

80

dB

Maximum Output Voltage (See Figures 2, 8)

V

OM

+

3

3

V

V

OM

-

0.13

0.13

V

Maximum Output Current:

Source

I

OM

+

10

10

mA

Sink

I

OM

-

1

1

mA

Slew Rate (See Figure 31)

SR

7

7

V/

µ

s

Gain-Bandwidth Product (See Figure 30)

f

T

3.7

3.7

MHz

Supply Current (See Figure 32)

I+

1.6

1.6

mA

Device Dissipation

P

D

8

8

mW

Sink Current from Terminal 8 to Terminal 4 to Swing Output Low

200

200

µ

A

CA3140, CA3140A

4

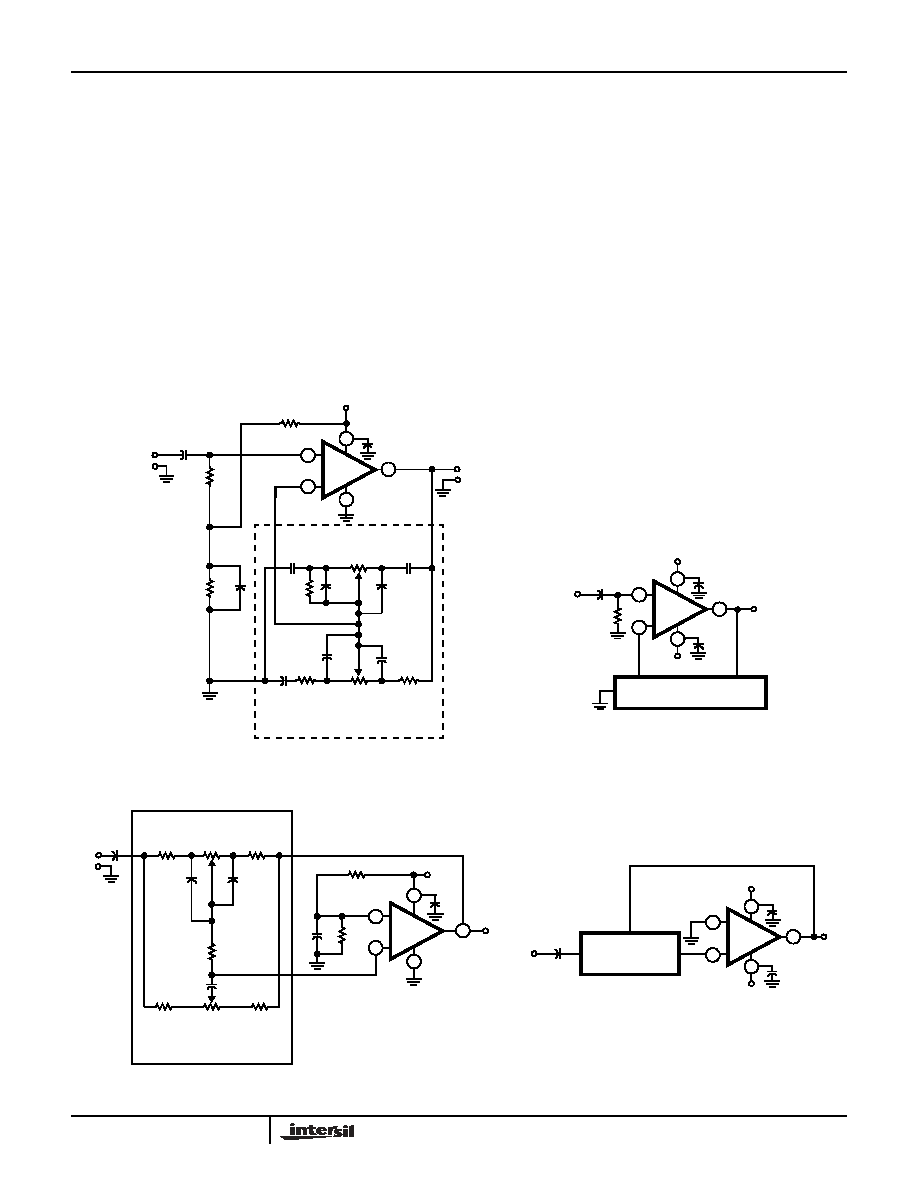

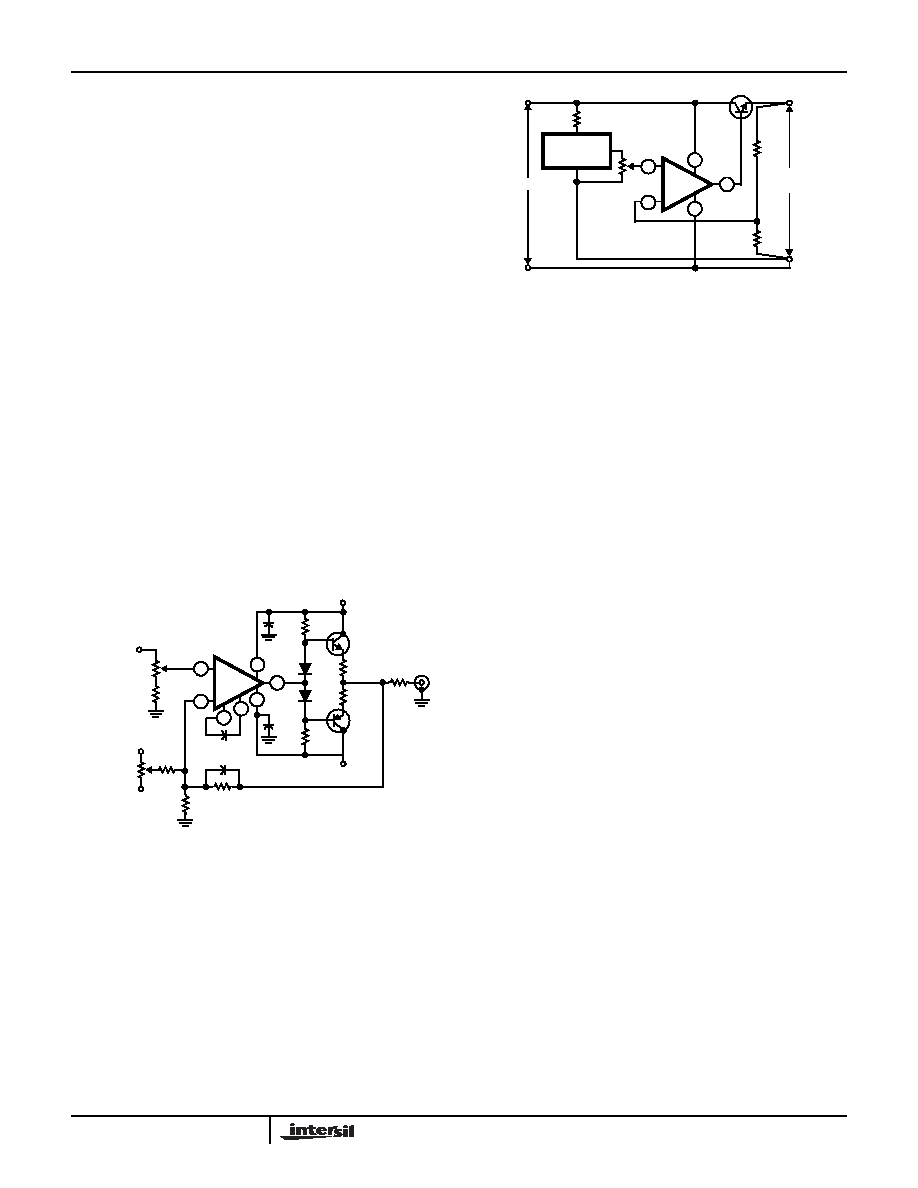

Block Diagram

Schematic Diagram

A

10

A

10,000

C

1

12pF

5

A

1

1

8

4

6

7

2

3

OFFSET

STROBE

NULL

OUTPUT

INPUT

+

-

200

µ

A

200

µ

A

1.6mA

2

µ

A

2mA

2mA

4mA

V+

V-

BIAS CIRCUIT

CURRENT SOURCES

AND REGULATOR

R

5

500

R

4

500

Q

11

Q

12

R

2

500

R

3

500

Q

10

Q

9

D

5

D

4

D

3

5

1

8

STROBE

OFFSET NULL

3

2

NON-INVERTING

INPUT

INVERTING

INPUT

+

-

C

1

12pF

Q

13

Q

15

Q

16

Q

21

Q

20

D

8

Q

19

Q

18

Q

17

R

11

20

R

9

50

R

8

1K

R

12

12K

R

14

20K

R

13

5K

D

7

R

10

1K

OUTPUT

D

6

4

V-

V+

6

7

DYNAMIC CURRENT SINK

OUTPUT STAGE

SECOND STAGE

INPUT STAGE

BIAS CIRCUIT

D

2

Q

8

Q

4

Q

3

Q

5

Q

2

Q

6

Q

7

D

1

Q

1

R

1

8K

Q

14

R

7

30

R

6

50

NOTE: All resistance values are in ohms.

CA3140, CA3140A

5

Application Information

Circuit Description

As shown in the block diagram, the input terminals may be

operated down to 0.5V below the negative supply rail. Two

class A amplifier stages provide the voltage gain, and a

unique class AB amplifier stage provides the current gain

necessary to drive low-impedance loads.

A biasing circuit provides control of cascoded constant current

flow circuits in the first and second stages. The CA3140

includes an on chip phase compensating capacitor that is

sufficient for the unity gain voltage follower configuration.

Input Stage

The schematic diagram consists of a differential input stage

using PMOS field-effect transistors (Q

9

, Q

10

) working into a

mirror pair of bipolar transistors (Q

11

, Q

12

) functioning as load

resistors together with resistors R

2

through R

5

. The mirror pair

transistors also function as a differential-to-single-ended

converter to provide base current drive to the second stage

bipolar transistor (Q

13

). Offset nulling, when desired, can be

effected with a 10k

potentiometer connected across

Terminals 1 and 5 and with its slider arm connected to Terminal

4. Cascode-connected bipolar transistors Q

2

, Q

5

are the

constant current source for the input stage. The base biasing

circuit for the constant current source is described

subsequently. The small diodes D

3

, D

4

, D

5

provide gate oxide

protection against high voltage transients, e.g., static electricity.

Second Stage

Most of the voltage gain in the CA3140 is provided by the

second amplifier stage, consisting of bipolar transistor Q

13

and its cascode connected load resistance provided by

bipolar transistors Q

3

, Q

4

. On-chip phase compensation,

sufficient for a majority of the applications is provided by C

1

.

Additional Miller-Effect compensation (roll off) can be

accomplished, when desired, by simply connecting a small

capacitor between Terminals 1 and 8. Terminal 8 is also

used to strobe the output stage into quiescence. When

terminal 8 is tied to the negative supply rail (Terminal 4) by

mechanical or electrical means, the output Terminal 6

swings low, i.e., approximately to Terminal 4 potential.

Output Stage

The CA3140 Series circuits employ a broad band output stage

that can sink loads to the negative supply to complement the

capability of the PMOS input stage when operating near the

negative rail. Quiescent current in the emitter-follower cascade

circuit (Q

17

, Q

18

) is established by transistors (Q

14

, Q

15

)

whose base currents are "mirrored" to current flowing through

diode D

2

in the bias circuit section. When the CA3140 is

operating such that output Terminal 6 is sourcing current,

transistor Q

18

functions as an emitter-follower to source current

from the V+ bus (Terminal 7), via D

7

, R

9

, and R

11

. Under these

conditions, the collector potential of Q

13

is sufficiently high to

permit the necessary flow of base current to emitter follower

Q

17

which, in turn, drives Q

18

.

When the CA3140 is operating such that output Terminal 6 is

sinking current to the V- bus, transistor Q

16

is the current

sinking element. Transistor Q

16

is mirror connected to D

6

, R

7

,

with current fed by way of Q

21

, R

12

, and Q

20

. Transistor Q

20

,

in turn, is biased by current flow through R

13

, zener D

8

, and

R

14

. The dynamic current sink is controlled by voltage level

sensing. For purposes of explanation, it is assumed that output

Terminal 6 is quiescently established at the potential midpoint

between the V+ and V- supply rails. When output current

sinking mode operation is required, the collector potential of

transistor Q

13

is driven below its quiescent level, thereby

causing Q

17

, Q

18

to decrease the output voltage at Terminal 6.

Thus, the gate terminal of PMOS transistor Q

21

is displaced

toward the V- bus, thereby reducing the channel resistance of

Q

21

. As a consequence, there is an incremental increase in

current flow through Q

20

, R

12

, Q

21

, D

6

, R

7

, and the base of

Q

16

. As a result, Q

16

sinks current from Terminal 6 in direct

response to the incremental change in output voltage caused

by Q

18

. This sink current flows regardless of load; any excess

current is internally supplied by the emitter-follower Q

18

. Short

circuit protection of the output circuit is provided by Q

19

, which

is driven into conduction by the high voltage drop developed

across R

11

under output short circuit conditions. Under these

conditions, the collector of Q

19

diverts current from Q

4

so as to

reduce the base current drive from Q

17

, thereby limiting current

flow in Q

18

to the short circuited load terminal.

Bias Circuit

Quiescent current in all stages (except the dynamic current

sink) of the CA3140 is dependent upon bias current flow in R

1

.

The function of the bias circuit is to establish and maintain

constant current flow through D

1

, Q

6

, Q

8

and D

2

. D

1

is a diode

connected transistor mirror connected in parallel with the base

emitter junctions of Q

1

, Q

2

, and Q

3

. D

1

may be considered as a

current sampling diode that senses the emitter current of Q

6

and automatically adjusts the base current of Q

6

(via Q

1

) to

maintain a constant current through Q

6

, Q

8

, D

2

. The base

currents in Q

2

, Q

3

are also determined by constant current flow

D

1

. Furthermore, current in diode connected transistor Q

2

establishes the currents in transistors Q

14

and Q

15

.

Typical Applications

Wide dynamic range of input and output characteristics with

the most desirable high input impedance characteristics is

achieved in the CA3140 by the use of an unique design based

upon the PMOS Bipolar process. Input common mode voltage

range and output swing capabilities are complementary,

allowing operation with the single supply down to 4V.

The wide dynamic range of these parameters also means

that this device is suitable for many single supply

applications, such as, for example, where one input is driven

below the potential of Terminal 4 and the phase sense of the

output signal must be maintained ≠ a most important

consideration in comparator applications.

CA3140, CA3140A

6

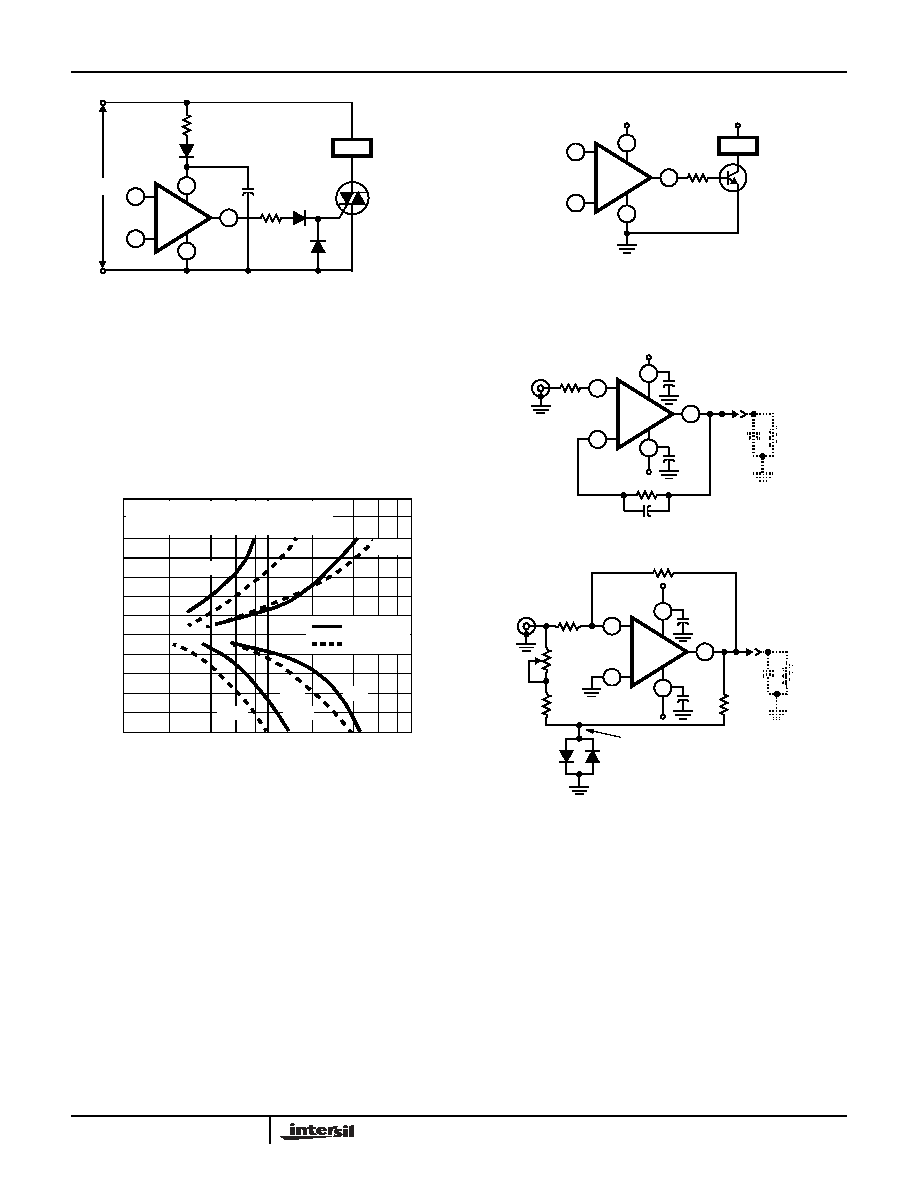

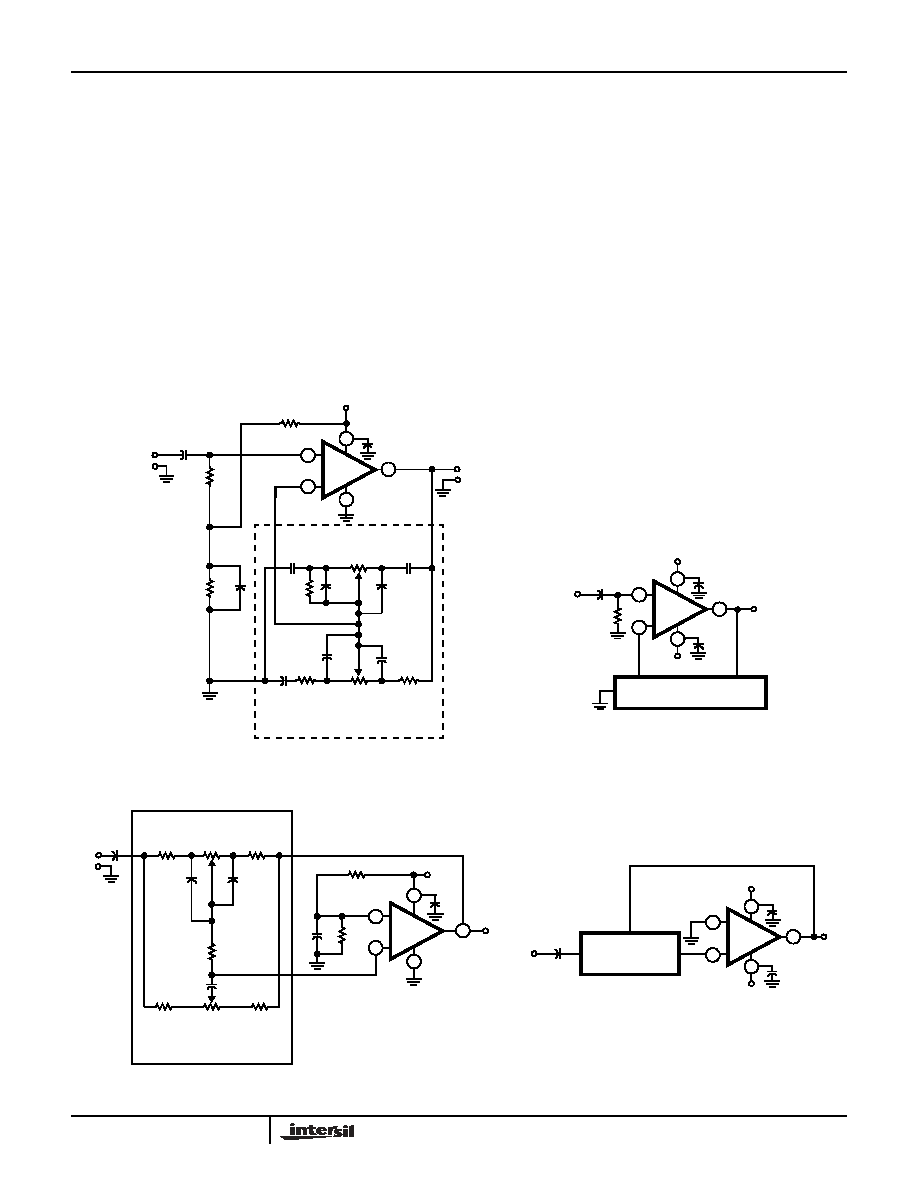

Output Circuit Considerations

Excellent interfacing with TTL circuitry is easily achieved

with a single 6.2V zener diode connected to Terminal 8 as

shown in Figure 1. This connection assures that the

maximum output signal swing will not go more positive than

the zener voltage minus two base-to-emitter voltage drops

within the CA3140. These voltages are independent of the

operating supply voltage.

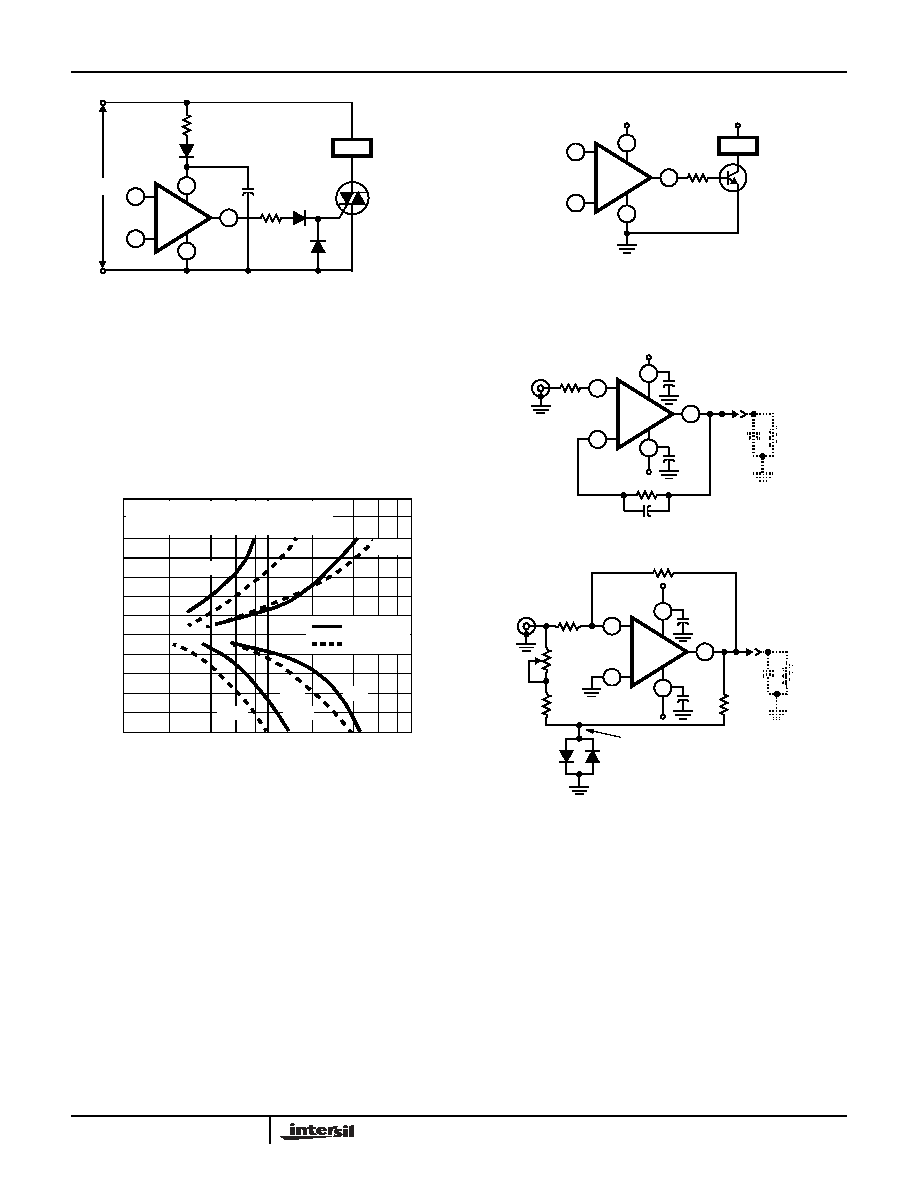

Figure 2 shows output current sinking capabilities of the

CA3140 at various supply voltages. Output voltage swing to

the negative supply rail permits this device to operate both

power transistors and thyristors directly without the need for

level shifting circuitry usually associated with the 741 series

of operational amplifiers.

Figure 4 shows some typical configurations. Note that a

series resistor, R

L

, is used in both cases to limit the drive

available to the driven device. Moreover, it is recommended

that a series diode and shunt diode be used at the thyristor

input to prevent large negative transient surges that can

appear at the gate of thyristors, from damaging the

integrated circuit.

Offset Voltage Nulling

The input offset voltage can be nulled by connecting a 10k

potentiometer between Terminals 1 and 5 and returning its

wiper arm to terminal 4, see Figure 3A. This technique,

however, gives more adjustment range than required and

therefore, a considerable portion of the potentiometer

rotation is not fully utilized. Typical values of series resistors

(R) that may be placed at either end of the potentiometer,

see Figure 3B, to optimize its utilization range are given in

the Electrical Specifications table.

An alternate system is shown in Figure 3C. This circuit uses

only one additional resistor of approximately the value

shown in the table. For potentiometers, in which the

resistance does not drop to 0

at either end of rotation, a

value of resistance 10% lower than the values shown in the

table should be used.

Low Voltage Operation

Operation at total supply voltages as low as 4V is possible

with the CA3140. A current regulator based upon the PMOS

threshold voltage maintains reasonable constant operating

current and hence consistent performance down to these

lower voltages.

The low voltage limitation occurs when the upper extreme of

the input common mode voltage range extends down to the

voltage at Terminal 4. This limit is reached at a total supply

voltage just below 4V. The output voltage range also begins to

extend down to the negative supply rail, but is slightly higher

than that of the input. Figure 8 shows these characteristics and

shows that with 2V dual supplies, the lower extreme of the input

common mode voltage range is below ground potential.

3

2

4

CA3140

8

6

7

V+

5V TO 36V

6.2V

5V

LOGIC

SUPPLY

5V

TYPICAL

TTL GATE

FIGURE 1. ZENER CLAMPING DIODE CONNECTED TO

TERMINALS 8 AND 4 TO LIMIT CA3140 OUTPUT

SWING TO TTL LEVELS

1

0.01

0.1

LOAD (SINKING) CURRENT (mA)

1.0

10

10

100

1000

OUT

P

UT

ST

AGE T

RANSIST

O

R (

Q

15

, Q

16

)

SAT

URAT

ION VOL

T

A

GE (

m

V)

SUPPLY VOLTAGE (V-) = 0V

T

A

= 25

o

C

SUPPLY VOLTAGE (V+) = +5V

+15V

+30V

FIGURE 2. VOLTAGE ACROSS OUTPUT TRANSISTORS (Q

15

AND Q

16

) vs LOAD CURRENT

FIGURE 3A. BASIC

FIGURE 3B. IMPROVED RESOLUTION

FIGURE 3C. SIMPLER IMPROVED RESOLUTION

FIGURE 3. THREE OFFSET VOLTAGE NULLING METHODS

3

2

4

CA3140

7

6

V+

5

1

V-

10k

3

2

4

CA3140

7

6

V+

5

1

V-

10k

R

R

3

2

4

CA3140

7

6

V+

5

1

V-

10k

R

CA3140, CA3140A

7

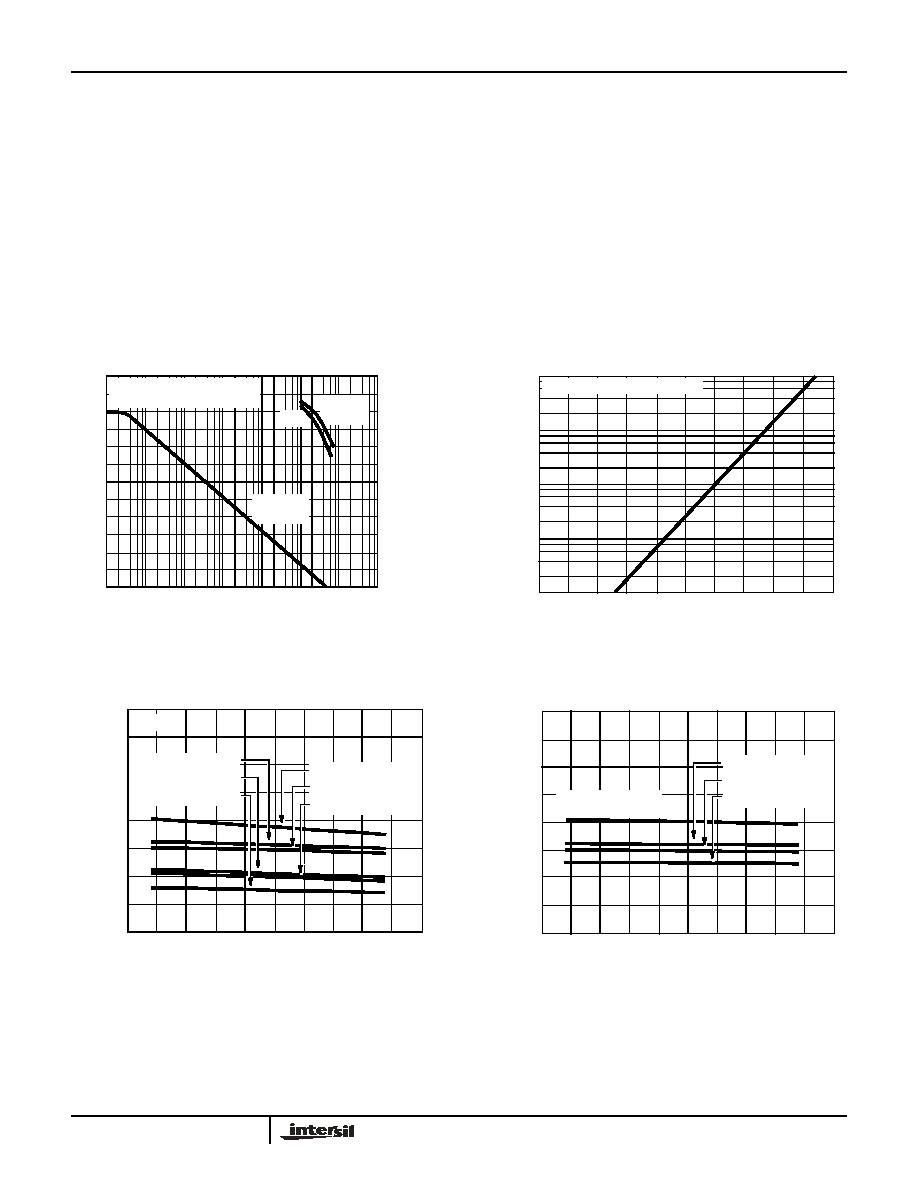

Bandwidth and Slew Rate

For those cases where bandwidth reduction is desired, for

example, broadband noise reduction, an external capacitor

connected between Terminals 1 and 8 can reduce the open

loop -3dB bandwidth. The slew rate will, however, also be

proportionally reduced by using this additional capacitor.

Thus, a 20% reduction in bandwidth by this technique will

also reduce the slew rate by about 20%.

Figure 5 shows the typical settling time required to reach

1mV or 10mV of the final value for various levels of large

signal inputs for the voltage follower and inverting unity gain

amplifiers.

The exceptionally fast settling time characteristics are largely

due to the high combination of high gain and wide bandwidth

of the CA3140; as shown in Figure 6.

Input Circuit Considerations

As mentioned previously, the amplifier inputs can be driven

below the Terminal 4 potential, but a series current limiting

resistor is recommended to limit the maximum input terminal

current to less than 1mA to prevent damage to the input

protection circuitry.

Moreover, some current limiting resistance should be

provided between the inverting input and the output when

FIGURE 4. METHODS OF UTILIZING THE V

CE(SAT)

SINKING CURRENT CAPABILITY OF THE CA3140 SERIES

3

2

4

CA3140

7

6

LOAD

R

L

R

S

MT

2

MT

1

30V

NO LOAD

120V

AC

3

2

4

CA3140

7

6

V+

+HV

LOAD

R

L

FIGURE 5A. WAVEFORM

FIGURE 5B. TEST CIRCUITS

FIGURE 5. SETTLING TIME vs INPUT VOLTAGE

SETTLING TIME (

µ

s)

0.1

I

N

P

U

T

VO

LTA

G

E

(

V

)

1.0

10

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

1mV

10mV

10mV

1mV

1mV

1mV

10mV

FOLLOWER

INVERTING

LOAD RESISTANCE (R

L

) = 2k

LOAD CAPACITANCE (C

L

) = 100pF

10

8

6

4

2

0

-2

-4

-6

-8

-10

10mV

3

2

CA3140

6

SIMULATED

LOAD

4

-15V

0.1

µ

F

5.11k

0.1

µ

F

7

+15V

5k

2k

100pF

5k

INVERTING

SETTLING POINT

200

4.99k

D

1

1N914

D

2

1N914

2

CA3140

6

SIMULATED

LOAD

4

-15V

0.1

µ

F

0.1

µ

F

7

+15V

2k

100pF

0.05

µ

F

2k

3

10k

FOLLOWER

CA3140, CA3140A

8

the CA3140 is used as a unity gain voltage follower. This

resistance prevents the possibility of extremely large input

signal transients from forcing a signal through the input

protection network and directly driving the internal constant

current source which could result in positive feedback via the

output terminal. A 3.9k

resistor is sufficient.

The typical input current is on the order of 10pA when the

inputs are centered at nominal device dissipation. As the

output supplies load current, device dissipation will increase,

raising the chip temperature and resulting in increased input

current. Figure 7 shows typical input terminal current versus

ambient temperature for the CA3140.

It is well known that MOSFET devices can exhibit slight

changes in characteristics (for example, small changes in

input offset voltage) due to the application of large

differential input voltages that are sustained over long

periods at elevated temperatures.

Both applied voltage and temperature accelerate these

changes. The process is reversible and offset voltage shifts of

the opposite polarity reverse the offset. Figure 9 shows the

typical offset voltage change as a function of various stress

voltages at the maximum rating of 125

o

C (for metal can); at

lower temperatures (metal can and plastic), for example, at

85

o

C, this change in voltage is considerably less. In typical

linear applications, where the differential voltage is small and

symmetrical, these incremental changes are of about the

same magnitude as those encountered in an operational

amplifier employing a bipolar transistor input stage.

FIGURE 6. OPEN LOOP VOLTAGE GAIN AND PHASE vs

FREQUENCY

FIGURE 7. INPUT CURRENT vs TEMPERATURE

FIGURE 8. OUTPUT VOLTAGE SWING CAPABILITY AND COMMON MODE INPUT VOLTAGE RANGE vs SUPPLY VOLTAGE

10

1

10

3

10

4

10

5

10

6

10

7

10

8

FREQUENCY (Hz)

O

PEN L

OO

P V

O

LT

A

G

E

G

AIN

(

dB

)

100

80

60

40

20

0

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

10

2

OP

E

N

L

O

OP

P

H

A

S

E

-75

-90

-105

-120

-135

-150

(

D

EG

REES

)

R

L

= 2k

,

C

L

= 0pF

R

L

= 2k

,

C

L

= 100pF

OL

SUPPLY VOLTAGE: V

S

=

±

15V

TEMPERATURE (

o

C)

-60

-40

-20

0

20

40

60

80

100 120

140

INPUT

CU

RRE

N

T

(

p

A)

1K

100

1

10K

10

SUPPLY VOLTAGE (V+, V-)

0

5

10

15

20

25

-1.5

-2.0

-1.0

-2.5

R

L

=

+V

OUT

AT T

A

= 125

o

C

+V

OUT

AT T

A

= 25

o

C

+V

OUT

AT T

A

= -55

o

C

+V

ICR

AT T

A

= 125

o

C

+V

ICR

AT T

A

= 25

o

C

+V

ICR

AT T

A

= -55

o

C

-3.0

0

-0.5

INPUT

AND

O

UT

PUT

V

O

LT

A

G

E EX

C

UR

S

I

O

N

S

F

R

OM

T

E

RM

INAL

7

(

V

+)

SUPPLY VOLTAGE (V+, V-)

0

5

10

15

20

25

-V

ICR

AT T

A

= 125

o

C

-V

ICR

AT T

A

= 25

o

C

-V

ICR

AT T

A

= -55

o

C

-V

OUT

FOR

T

A

= -55

o

C to 125

o

C

INPUT

AND

OUT

P

UT

VOL

T

AG

E EXCURSIONS

F

R

O

M

T

E

RM

I

NAL

4

(

V

-

)

0

-0.5

0.5

-1.0

-1.5

1.5

1.0

CA3140, CA3140A

9

Super Sweep Function Generator

A function generator having a wide tuning range is shown in

Figure 10. The 1,000,000/1 adjustment range is

accomplished by a single variable potentiometer or by an

auxiliary sweeping signal. The CA3140 functions as a non-

inverting readout amplifier of the triangular signal developed

across the integrating capacitor network connected to the

output of the CA3080A current source.

Buffered triangular output signals are then applied to a

second CA3080 functioning as a high speed hysteresis

switch. Output from the switch is returned directly back to the

input of the CA3080A current source, thereby, completing

the positive feedback loop

The triangular output level is determined by the four 1N914

level limiting diodes of the second CA3080 and the resistor

divider network connected to Terminal No. 2 (input) of the

CA3080. These diodes establish the input trip level to this

switching stage and, therefore, indirectly determine the

amplitude of the output triangle.

Compensation for propagation delays around the entire loop

is provided by one adjustment on the input of the CA3080.

This adjustment, which provides for a constant generator

amplitude output, is most easily made while the generator is

sweeping. High frequency ramp linearity is adjusted by the

single 7pF to 60pF capacitor in the output of the CA3080A.

It must be emphasized that only the CA3080A is

characterized for maximum output linearity in the current

generator function.

Meter Driver and Buffer Amplifier

Figure 11 shows the CA3140 connected as a meter driver

and buffer amplifier. Low driving impedance is required of

the CA3080A current source to assure smooth operation of

the Frequency Adjustment Control. This low-driving

impedance requirement is easily met by using a CA3140

connected as a voltage follower. Moreover, a meter may be

placed across the input to the CA3080A to give a logarithmic

analog indication of the function generator's frequency.

Analog frequency readout is readily accomplished by the

means described above because the output current of the

CA3080A varies approximately one decade for each 60mV

change in the applied voltage, V

ABC

(voltage between

Terminals 5 and 4 of the CA3080A of the function generator).

Therefore, six decades represent 360mV change in V

ABC

.

Now, only the reference voltage must be established to set

the lower limit on the meter. The three remaining transistors

from the CA3086 Array used in the sweep generator are

used for this reference voltage. In addition, this reference

generator arrangement tends to track ambient temperature

variations, and thus compensates for the effects of the

normal negative temperature coefficient of the CA3080A

V

ABC

terminal voltage.

Another output voltage from the reference generator is used

to insure temperature tracking of the lower end of the

Frequency Adjustment Potentiometer. A large series

resistance simulates a current source, assuring similar

temperature coefficients at both ends of the Frequency

Adjustment Control.

To calibrate this circuit, set the Frequency Adjustment

Potentiometer at its low end. Then adjust the Minimum

Frequency Calibration Control for the lowest frequency. To

establish the upper frequency limit, set the Frequency

Adjustment Potentiometer to its upper end and then adjust

the Maximum Frequency Calibration Control for the

maximum frequency. Because there is interaction among

these controls, repetition of the adjustment procedure may

be necessary. Two adjustments are used for the meter. The

meter sensitivity control sets the meter scale width of each

decade, while the meter position control adjusts the pointer

on the scale with negligible effect on the sensitivity

adjustment. Thus, the meter sensitivity adjustment control

calibrates the meter so that it deflects

1

/

6

of full scale for

each decade change in frequency.

Sine Wave Shaper

The circuit shown in Figure 12 uses a CA3140 as a voltage

follower in combination with diodes from the CA3019 Array

to convert the triangular signal from the function generator to

a sine-wave output signal having typically less than 2%

THD. The basic zero crossing slope is established by the

10k

potentiometer connected between Terminals 2 and 6

of the CA3140 and the 9.1k

resistor and 10k

potentiometer from Terminal 2 to ground. Two break points

are established by diodes D

1

through D

4

. Positive feedback

via D

5

and D

6

establishes the zero slope at the maximum

and minimum levels of the sine wave. This technique is

necessary because the voltage follower configuration

approaches unity gain rather than the zero gain required to

shape the sine wave at the two extremes.

7

6

5

4

3

2

0

O

F

F

SET VO

LT

AG

E

S

H

I

F

T (

m

V)

0

500 1000 1500 2000 2500 3000 3500 4000 4500

TIME (HOURS)

1

DIFFERENTIAL DC VOLTAGE

(ACROSS TERMINALS 2 AND 3) = 0V

OUTPUT VOLTAGE = V+ / 2

T

A

= 125

o

C

FOR METAL CAN PACKAGES

DIFFERENTIAL DC VOLTAGE

(ACROSS TERMINALS 2 AND 3) = 2V

OUTPUT STAGE TOGGLED

FIGURE 9. TYPICAL INCREMENTAL OFFSET VOLTAGE

SHIFT vs OPERATING LIFE

CA3140, CA3140A

10

FIGURE 10A. CIRCUIT

Top Trace: Output at junction of 2.7

and 51

resistors;

5V/Div., 500ms/Div.

Center Trace: External output of triangular function generator;

2V/Div., 500ms/Div.

Bottom Trace: Output of "Log" generator; 10V/Div., 500ms/Div.

FIGURE 10B. FIGURE FUNCTION GENERATOR SWEEPING

1V/Div., 1s/Div.

Three tone test signals, highest frequency

0.5MHz. Note the slight

asymmetry at the three second/cycle signal. This asymmetry is due to

slightly different positive and negative integration from the CA3080A

and from the PC board and component leakages at the 100pA level.

FIGURE 10C. FUNCTION GENERATOR WITH FIXED

FREQUENCIES

FIGURE 10D. INTERCONNECTIONS

FIGURE 10. FUNCTION GENERATOR

0.1

µ

F

1N914

6

7

4

2

3

0.1

µ

F

5.1k

10k

2.7k

6

7

4

2

5

-15V

13k

+15V

CENTERING

10k

-15V

910k

62k

11k

10k

EXTERNAL

OUTPUT

11k

HIGH

FREQUENCY

LEVEL

7-60pF

EXTERNAL

OUTPUT

TO OUTPUT

AMPLIFIER

OUTPUT

AMPLIFIER

TO

SINE WAVE

SHAPER

2k

FREQUENCY

ADJUSTMENT

HIGH

FREQ.

SHAPE

SYMMETRY

THIS NETWORK IS USED WHEN THE

OPTIONAL BUFFER CIRCUIT IS NOT USED

-15V

+15V

10k

120

39k

100k

3

6

3

2

4

7

7.5k

+15V

+15V

15k

360

360

2M

7-60

pF

-15V

-15V

+15V

51

pF

+

CA3080A

-

CA3140

CA3080

+

-

+

-

5

-15V

FROM BUFFER METER

DRIVER (OPTIONAL)

FREQUENCY

ADJUSTMENT

METER DRIVER

AND BUFFER

AMPLIFIER

FUNCTION

GENERATOR

SINE WAVE

SHAPER

M

POWER

SUPPLY

±

15V

-15V

+15V

DC LEVEL

ADJUST

51

WIDEBAND

LINE DRIVER

SWEEP

GENERATOR

GATE

SWEEP

V-

SWEEP

LENGTH

EXTERNAL

INPUT

OFF

V-

COARSE

RATE

FINE

RATE

EXT.

INT.

CA3140, CA3140A

11

FIGURE 11. METER DRIVER AND BUFFER AMPLIFIER

FIGURE 12. SINE WAVE SHAPER

FIGURE 13. SWEEPING GENERATOR

FREQUENCY

CALIBRATION

MINIMUM

200

µ

A

METER

FREQUENCY

CALIBRATION

MAXIMUM

METER

SENSITIVITY

ADJUSTMENT

METER

POSITION

ADJUSTMENT

CA3080A

6

3

2

4

7

+

CA3140

-

FREQUENCY

ADJUSTMENT

10k

620

4.7k

0.1

µ

F

12k

2k

500k

620k

51k

3M

510

510

2k

3.6k

-15V

M

11

14

13

3

/

5

OF CA3086

5

4

TO CA3080A

OF FUNCTION

GENERATOR

(FIGURE 10)

7

8

6

9

1k

2.4k

2.5

k

+15V

SWEEP IN

10

12

6

3

2

4

7

+

CA3140

-

7

2

8

5

6

1

4

3

9

5.1k

0.1

µ

F

-15V

D

1

D

4

D

2

D

3

D

6

D

5

CA3019

DIODE ARRAY

EXTERNAL

OUTPUT

+15V

+15V

-15V

100

k

SUBSTRATE

OF CA3019

TO

WIDEBAND

OUTPUT

AMPLIFIER

7.5k

5.6k

-15V

R3 10k

10k

0.1

µ

F

1M

9.1k

R

1

10k

R

2

1k

430

4

7

+

CA3140

-

0.1

+15V

-

15V

2

3

6

µ

F

0.1

µ

F

COARSE

RATE

SAWTOOTH

SYMMETRY

0.47

µ

F

0.047

µ

F

4700pF

470pF

7

3

2

6

4

+

CA3140

-

5

1

3

2

4

1

5

51k

6.8k

91k

10k

100

390

3.9

25k

+15V

-15V

10k

10k

100k

30k

43k

LOG

VIO

50k

LOG

RATE

10k

GATE

PULSE

OUTPUT

-15V

EXTERNAL OUTPUT

TO FUNCTION GENERATOR "SWEEP IN"

SWEEP WIDTH

TO OUTPUT

AMPLIFIER

36k

51k

75k

50k

SAWTOOTH

"LOG"

TRIANGLE

+15V

+15V

4

7

+

CA3140

-

3

2

6

+15V

TRANSISTORS

FROM CA3086

ARRAY

ADJUST

TRIANGLE

SAWTOOTH

"LOG"

8.2k

100k

100k

FINE

RATE

SAWTOOTH

22M

1M

18M

750k

"LOG"

1N914

1N914

SAWTOOTH AND

RAMP LOW LEVEL

SET (-14.5V)

-15V

CA3140, CA3140A

12

This circuit can be adjusted most easily with a distortion

analyzer, but a good first approximation can be made by

comparing the output signal with that of a sine wave

generator. The initial slope is adjusted with the

potentiometer R

1

, followed by an adjustment of R

2

. The final

slope is established by adjusting R

3

, thereby adding

additional segments that are contributed by these diodes.

Because there is some interaction among these controls,

repetition of the adjustment procedure may be necessary.

Sweeping Generator

Figure 13 shows a sweeping generator. Three CA3140s are

used in this circuit. One CA3140 is used as an integrator, a

second device is used as a hysteresis switch that

determines the starting and stopping points of the sweep. A

third CA3140 is used as a logarithmic shaping network for

the log function. Rates and slopes, as well as sawtooth,

triangle, and logarithmic sweeps are generated by this

circuit.

Wideband Output Amplifier

Figure 14 shows a high slew rate, wideband amplifier

suitable for use as a 50

transmission line driver. This

circuit, when used in conjunction with the function generator

and sine wave shaper circuits shown in Figures 10 and 12

provides 18V

P-P

output open circuited, or 9V

P-P

output

when terminated in 50

. The slew rate required of this

amplifier is 28V/

µ

s (18V

P-P

x

x 0.5MHz).

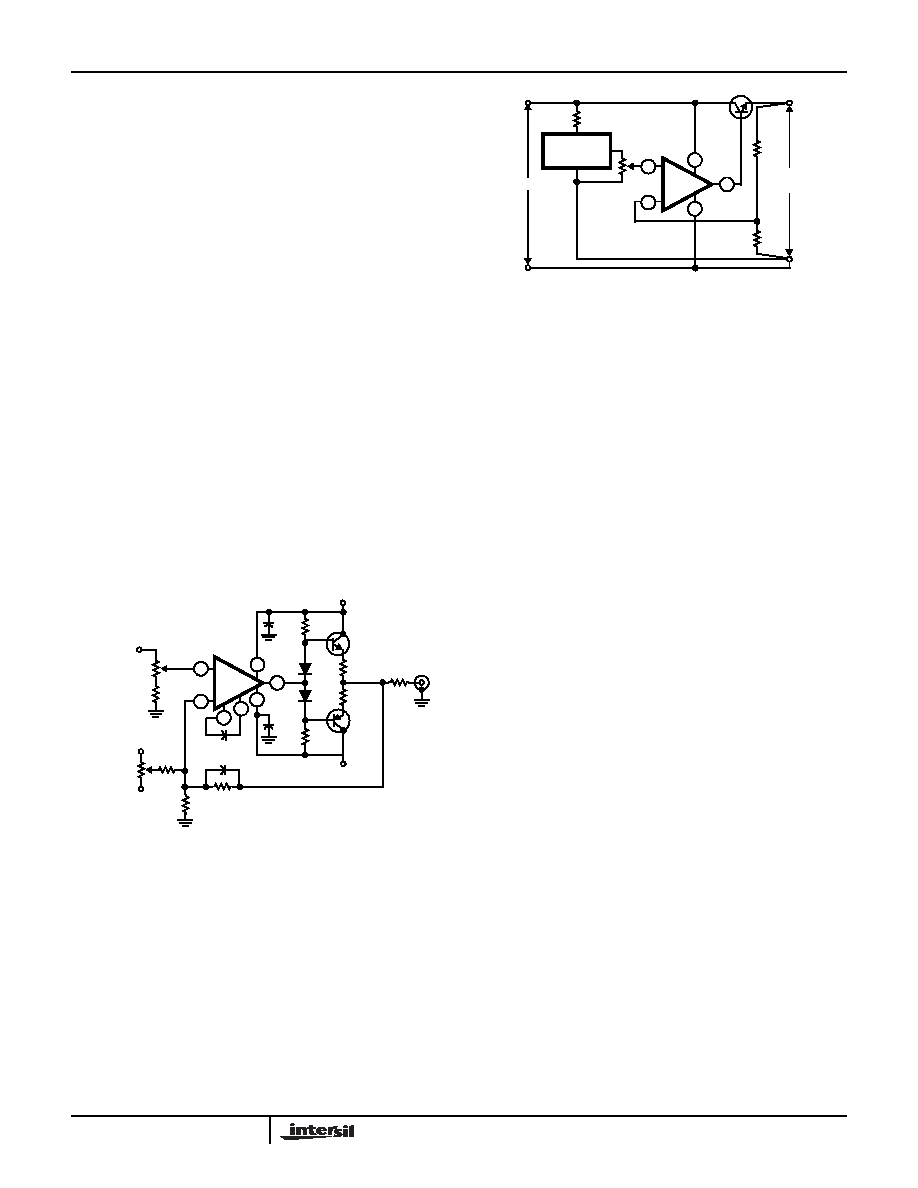

Power Supplies

High input impedance, common mode capability down to the

negative supply and high output drive current capability are

key factors in the design of wide range output voltage

supplies that use a single input voltage to provide a

regulated output voltage that can be adjusted from

essentially 0V to 24V.

Unlike many regulator systems using comparators having a

bipolar transistor input stage, a high impedance reference

voltage divider from a single supply can be used in

connection with the CA3140 (see Figure 15).

Essentially, the regulators, shown in Figures 16 and 17, are

connected as non inverting power operational amplifiers with a

gain of 3.2. An 8V reference input yields a maximum output

voltage slightly greater than 25V. As a voltage follower, when

the reference input goes to 0V the output will be 0V. Because

the offset voltage is also multiplied by the 3.2 gain factor, a

potentiometer is needed to null the offset voltage.

Series pass transistors with high I

CBO

levels will also

prevent the output voltage from reaching zero because there

is a finite voltage drop (V

CESAT

) across the output of the

CA3140 (see Figure 2). This saturation voltage level may

indeed set the lowest voltage obtainable.

The high impedance presented by Terminal 8 is

advantageous in effecting current limiting. Thus, only a small

signal transistor is required for the current-limit sensing

amplifier. Resistive decoupling is provided for this transistor

to minimize damage to it or the CA3140 in the event of

unusual input or output transients on the supply rail.

Figures 16 and 17, show circuits in which a D2201 high speed

diode is used for the current sensor. This diode was chosen

for its slightly higher forward voltage drop characteristic, thus

giving greater sensitivity. It must be emphasized that heat

sinking of this diode is essential to minimize variation of the

current trip point due to internal heating of the diode. That is,

1A at 1V forward drop represents one watt which can result in

significant regenerative changes in the current trip point as the

diode temperature rises. Placing the small signal reference

amplifier in the proximity of the current sensing diode also

helps minimize the variability in the trip level due to the

negative temperature coefficient of the diode. In spite of those

limitations, the current limiting point can easily be adjusted

over the range from 10mA to 1A with a single adjustment

potentiometer. If the temperature stability of the current

limiting system is a serious consideration, the more usual

current sampling resistor type of circuitry should be employed.

A power Darlington transistor (in a metal can with heatsink),

is used as the series pass element for the conventional

current limiting system, Figure 16, because high power

Darlington dissipation will be encountered at low output

voltage and high currents.

2

6

8

1

4

7

+

CA3140

-

50

µ

F

25V

2.2

k

2N3053

1N914

2.2

k

1N914

2.7

2.7

2N4037

+

-

+

-

50

µ

F

25V

3

SIGNAL

LEVEL

ADJUSTMENT

2.5k

200

2.4pF

2pF

-15V

+15V

OUTPUT

DC LEVEL

ADJUSTMENT

-15V

+15V

3k

200

1.8k

51

2W

OUT

NOMINAL BANDWIDTH = 10MHz

t

r

= 35ns

FIGURE 14. WIDEBAND OUTPUT AMPLIFIER

6

3

2

4

7

+

CA3140

-

VOLTAGE

REFERENCE

VOLTAGE

ADJUSTMENT

REGULATED

OUTPUT

INPUT

FIGURE 15. BASIC SINGLE SUPPLY VOLTAGE REGULATOR

SHOWING VOLTAGE FOLLOWER

CA3140, CA3140A

13

A small heat sink VERSAWATT transistor is used as the

series pass element in the fold back current system, Figure

17, since dissipation levels will only approach 10W. In this

system, the D2201 diode is used for current sampling.

Foldback is provided by the 3k

and 100k

divider network

connected to the base of the current sensing transistor.

Both regulators provide better than 0.02% load regulation.

Because there is constant loop gain at all voltage settings, the

regulation also remains constant. Line regulation is 0.1% per

volt. Hum and noise voltage is less than 200

µ

V as read with a

meter having a 10MHz bandwidth.

Figure 18A shows the turn ON and turn OFF characteristics

of both regulators. The slow turn on rise is due to the slow

rate of rise of the reference voltage. Figure 18B shows the

transient response of the regulator with the switching of a

20

load at 20V output.

FIGURE 16. REGULATED POWER SUPPLY

FIGURE 17. REGULATED POWER SUPPLY WITH

"FOLDBACK" CURRENT LIMITING

5V/Div., 1s/Div.

FIGURE 18A. SUPPLY TURN-ON AND TURNOFF

CHARACTERISTICS

Top Trace: Output Voltage;

200mV/Div., 5

µ

s/Div.

Bottom Trace: Collector of load switching transistor, load = 1A;

5V/Div., 5

µ

s/Div.

FIGURE 18B. TRANSIENT RESPONSE

FIGURE 18. WAVEFORMS OF DYNAMIC CHARACTERISTICS OF POWER SUPPLY CURRENTS SHOWN IN FIGURES 16 AND 17

1

3

75

3k

100

2

1k

1k

D2201

CURRENT

LIMITING

ADJUST

2N6385

POWER DARLINGTON

2

1k

1

3

8

2N2102

1k

+30V

INPUT

4

CA3140

7

1

6

5

100k

2

3

180k

56pF

1k

82k

250

µ

F

+

-

0.01

µ

F

100k

14

10

6

9

8

50k

13

5

µ

F

+

-

12

CA3086

2.2k

3

1

5

4

62k

VOLTAGE

ADJUST

10

µ

F

+

-

2.7k

1k

11

7

2

HUM AND NOISE OUTPUT <200

µ

V

RMS

(MEASUREMENT BANDWIDTH

~

10MHz)

LINE REGULATION 0.1%/V

LOAD REGULATION

(NO LOAD TO FULL LOAD)

<0.02%

OUTPUT

0.1

24V

AT 1A

1

2

1k

200

D2201

"FOLDBACK" CURRENT

LIMITER

2N5294

3k

8

2N2102

1k

+30V

INPUT

4

CA3140

7

1

6

5

100k

2

3

180k

56pF

1k

82k

250

µ

F

+

-

0.01

µ

F

100k

14

10

6

9

8

50k

13

5

µ

F

+

-

12

CA3086

2.2k

3

1

5

4

62k

VOLTAGE

ADJUST

10

µ

F

+

-

2.7k

1k

11

7

2

HUM AND NOISE OUTPUT <200

µ

V

RMS

(MEASUREMENT BANDWIDTH

~

10MHz)

LINE REGULATION 0.1%/V

LOAD REGULATION

(NO LOAD TO FULL LOAD)

<0.02%

OUTPUT

0V TO 25V

25V AT 1A

3

100k

"FOLDS BACK"

TO 40mA

100k

CA3140, CA3140A

14

Tone Control Circuits

High slew rate, wide bandwidth, high output voltage

capability and high input impedance are all characteristics

required of tone control amplifiers. Two tone control circuits

that exploit these characteristics of the CA3140 are shown in

Figures 19 and 20.

The first circuit, shown in Figure 20, is the Baxandall tone

control circuit which provides unity gain at midband and

uses standard linear potentiometers. The high input

impedance of the CA3140 makes possible the use of low-

cost, low-value, small size capacitors, as well as reduced

load of the driving stage.

Bass treble boost and cut are

±

15dB at 100Hz and 10kHz,

respectively. Full peak-to-peak output is available up to at

least 20kHz due to the high slew rate of the CA3140. The

amplifier gain is 3dB down from its "flat" position at 70kHz.

Figure 19 shows another tone control circuit with similar

boost and cut specifications. The wideband gain of this

circuit is equal to the ultimate boost or cut plus one, which in

this case is a gain of eleven. For 20dB boost and cut, the

input loading of this circuit is essentially equal to the value of

the resistance from Terminal No. 3 to ground. A detailed

analysis of this circuit is given in "An IC Operational

Transconductance Amplifier (OTA) With Power Capability"

by L. Kaplan and H. Wittlinger, IEEE Transactions on

Broadcast and Television Receivers, Vol. BTR-18, No. 3,

August, 1972.

FIGURE 19. TONE CONTROL CIRCUIT USING CA3130 SERIES (20dB MIDBAND GAIN)

FIGURE 20. BAXANDALL TONE CONTROL CIRCUIT USING CA3140 SERIES

4

7

+

CA3140

-

+30V

3

2

0.1

µ

F

6

0.005

µ

F

0.1

µ

F

2.2M

2.2M

5.1

M

0.012

µ

F

0.001

µ

F

0.022

µ

F

2

µ

F

18k

0.0022

µ

F

200k

(LINEAR)

100

pF

100pF

BOOST

TREBLE

CUT

BOOST

BASS

CUT

10k

1M

CCW (LOG)

100k

TONE CONTROL NETWORK

FOR SINGLE SUPPLY

-

+

+15V

3

0.1

µ

F

0.005

µ

F

5.1M

0.1

µ

F

-15V

2

6

7

4

+

CA3140

-

TONE CONTROL NETWORK

FOR DUAL SUPPLIES

NOTES:

5. 20dB Flat Position Gain.

6.

±

15dB Bass and Treble Boost and Cut

at 100Hz and 10kHz, respectively.

7. 25V

P-P

output at 20kHz.

8. -3dB at 24kHz from 1kHz reference.

4

7

+

CA3140

-

+32V

3

0.1

2.2M

2.2

M

FOR SINGLE SUPPLY

µ

F

6

2

0.1

µ

F

20pF

750

pF

750

pF

2.2M

0.047

µ

F

BOOST TREBLE

CUT

51k

5M

(LINEAR)

51k

TONE CONTROL NETWORK

BOOST

BASS

CUT

240k

5M

(LINEAR)

240k

+15V

3

0.1

µ

F

0.047

µ

F

0.1

µ

F

-15V

2

6

7

4

+

CA3140

-

FOR DUAL SUPPLIES

:

9.

±

15dB Bass and Treble Boost and Cut at 100Hz and 10kHz, Respectively.

10. 25V

P-P

Output at 20kHz.

11. -3dB at 70kHz from 1kHz Reference.

12. 0dB Flat Position Gain.

TONE CONTROL

NETWORK

CA3140, CA3140A

15

Wien Bridge Oscillator

Another application of the CA3140 that makes excellent use

of its high input impedance, high slew rate, and high voltage

qualities is the Wien Bridge sine wave oscillator. A basic Wien

Bridge oscillator is shown in Figure 21. When R

1

= R

2

= R

and C

1

= C

2

= C, the frequency equation reduces to the

familiar f = 1/(2

RC) and the gain required for oscillation,

A

OSC

is equal to 3. Note that if C

2

is increased by a factor of

four and R

2

is reduced by a factor of four, the gain required

for oscillation becomes 1.5, thus permitting a potentially

higher operating frequency closer to the gain bandwidth

product of the CA3140.

Oscillator stabilization takes on many forms. It must be

precisely set, otherwise the amplitude will either diminish or

reach some form of limiting with high levels of distortion. The

element, R

S

, is commonly replaced with some variable

resistance element. Thus, through some control means, the

value of R

S

is adjusted to maintain constant oscillator output.

A FET channel resistance, a thermistor, a lamp bulb, or

other device whose resistance increases as the output

amplitude is increased are a few of the elements often

utilized.

Figure 22 shows another means of stabilizing the oscillator

with a zener diode shunting the feedback resistor (R

F

of

Figure 21). As the output signal amplitude increases, the

zener diode impedance decreases resulting in more

feedback with consequent reduction in gain; thus stabilizing

the amplitude of the output signal. Furthermore, this

combination of a monolithic zener diode and bridge rectifier

circuit tends to provide a zero temperature coefficient for this

regulating system. Because this bridge rectifier system has

no time constant, i.e., thermal time constant for the lamp

bulb, and RC time constant for filters often used in detector

networks, there is no lower frequency limit. For example,

with 1

µ

F polycarbonate capacitors and 22M

for the

frequency determining network, the operating frequency is

0.007Hz.

As the frequency is increased, the output amplitude must be

reduced to prevent the output signal from becoming slew-

rate limited. An output frequency of 180kHz will reach a slew

rate of approximately 9V/

µ

s when its amplitude is 16V

P-P

.

Simple Sample-and-Hold System

Figure 23 shows a very simple sample-and-hold system

using the CA3140 as the readout amplifier for the storage

capacitor. The CA3080A serves as both input buffer

amplifier and low feed-through transmission switch (see

Note 13). System offset nulling is accomplished with the

CA3140 via its offset nulling terminals. A typical simulated

load of 2k

and 30pF is shown in the schematic.

In this circuit, the storage compensation capacitance (C

1

) is

only 200pF. Larger value capacitors provide longer "hold"

periods but with slower slew rates. The slew rate is:

NOTE:

13. AN6668 "Applications of the CA3080 and CA 3080A High

Performance Operational Transconductance Amplifiers".

NOTES:

f

1

2

R

1

C

1

R

2

C

2

-------------------------------------------

=

A

OSC

1

C

1

C

2

-------

R

2

R

1

-------

+

+

=

A

CL

1

R

F

R

S

--------

+

=

C

1

R

2

R

1

C

2

OUTPUT

R

F

R

S

+

-

FIGURE 21. BASIC WIEN BRIDGE OSCILLATOR CIRCUIT

USING AN OPERATIONAL AMPLIFIER

8

5

4

3

1

9

6

CA3109

DIODE

ARRAY

+15V

0.1

µ

F

0.1

µ

F

-15V

2

6

7

4

+

CA3140

-

SUBSTRATE

OF CA3019

0.1

µ

F

7

7.5k

3.6k

500

OUTPUT

19V

P-P

TO 22V

P-P

THD <0.3%

3

R

2

C

2

1000pF

1000

pF

C

1

R

1

R

1

= R

2

= R

50Hz, R = 3.3M

100Hz, R = 1.6M

1kHz, R = 160M

10kHz, R = 16M

30kHz, R = 5.1M

2

FIGURE 22. WIEN BRIDGE OSCILLATOR CIRCUIT USING

CA3140

+15V

3.5k

30pF

2

6

1

+

CA3140

-

SIMULATED LOAD

NOT REQUIRED

100k

INPUT

0.1

0.1

µ

F

µ

F

7

0.1

µ

F

-15V

2k

3

400

200pF

6

4

5

7

4

+

CA3080A

-

0.1

µ

F

+15V

-15V

200pF

2k

2

3

5

2k

STROBE

SAMPLE

HOLD

-15

0

30k

1N914

1N914

2k

C

1

FIGURE 23. SAMPLE AND HOLD CIRCUIT

dv

dt

------

I

C

----

0.5mA 200pF

/

2.5V

µ

s

/

=

=

=

CA3140, CA3140A

16

Pulse "droop" during the hold interval is 170pA/200pF which is

0.85

µ

V/

µ

s; (i.e., 170pA/200pF). In this case, 170pA represents

the typical leakage current of the CA3080A when strobed off. If

C

1

were increased to 2000pF, the "hold-droop" rate will

decrease to 0.085

µ

V/

µ

s, but the slew rate would decrease to

0.25V/

µ

s. The parallel diode network connected between

Terminal 3 of the CA3080A and Terminal 6 of the CA3140

prevents large input signal feedthrough across the input

terminals of the CA3080A to the 200pF storage capacitor when

the CA3080A is strobed off. Figure 24 shows dynamic

characteristic waveforms of this sample-and-hold system.

Current Amplifier

The low input terminal current needed to drive the CA3140

makes it ideal for use in current amplifier applications such

as the one shown in Figure 25 (see Note 14). In this circuit,

low current is supplied at the input potential as the power

supply to load resistor R

L

. This load current is increased by

the multiplication factor R

2

/R

1

, when the load current is

monitored by the power supply meter M. Thus, if the load

current is 100nA, with values shown, the load current

presented to the supply will be 100

µ

A; a much easier current

to measure in many systems.

Note that the input and output voltages are transferred at the

same potential and only the output current is multiplied by

the scale factor.

The dotted components show a method of decoupling the

circuit from the effects of high output load capacitance and

the potential oscillation in this situation. Essentially, the

necessary high frequency feedback is provided by the

capacitor with the dotted series resistor providing load

decoupling.

Full Wave Rectifier

Figure 26 shows a single supply, absolute value, ideal full-

wave rectifier with associated waveforms. During positive

excursions, the input signal is fed through the feedback

network directly to the output. Simultaneously, the positive

excursion of the input signal also drives the output terminal

(No. 6) of the inverting amplifier in a negative going

excursion such that the 1N914 diode effectively disconnects

the amplifier from the signal path. During a negative going

excursion of the input signal, the CA3140 functions as a

normal inverting amplifier with a gain equal to -R

2

/R

1

. When

the equality of the two equations shown in Figure 26 is

satisfied, the full wave output is symmetrical.

NOTE:

14. "Operational Amplifiers Design and Applications", J. G. Graeme,

McGraw-Hill Book Company, page 308, "Negative Immittance

Converter Circuits".

Top Trace: Output; 50mV/Div., 200ns/Div.

Bottom Trace: Input; 50mV/Div., 200ns/Div.

Top Trace: Output Signal; 5V/Div, 2

µ

s/Div.

Center Trace: Difference of Input and Output Signals through

Tektronix Amplifier 7A13; 5mV/Div., 2

µ

s/Div.

Bottom Trace: Input Signal; 5V/Div., 2

µ

s/Div.

LARGE SIGNAL RESPONSE AND SETTLING TIME

SAMPLING RESPONSE

Top Trace: Output; 100mV/Div., 500ns/Div.

Bottom Trace: Input; 20V/Div., 500ns/Div.

FIGURE 24. SAMPLE AND HOLD SYSTEM DYNAMIC

CHARACTERISTICS WAVEFORMS

+15V

2

1

100k

0.1

µ

F

-15V

4

5

7

+

CA3140

-

0.1

µ

F

4.3k

10k

6

3

R

1

POWER

SUPPLY

10M

R

2

I

L

R

2

R

1

M

R

L

I

L

x

FIGURE 25. BASIC CURRENT AMPLIFIER FOR LOW CURRENT

MEASUREMENT SYSTEMS

CA3140, CA3140A

17

+15V

3

0.1

µ

F

8

5k

7

1

5

6

2

R

2

R

1

10k

R

3

1N914

10k

100k

OFFSET

ADJUST

4

PEAK

ADJUST

10k

+

CA3140

-

20V

P-P

Input BW (-3dB) = 290kHz, DC Output (Avg) = 3.2V

GAIN

R

2

R

1

-------

X

R

3

R

1

R

2

R

3

+

-----------------------------

=

=

=

R

3

X X

2

+

1 X

≠

-----------------

R

1

=

FOR X

0.5

5k

10k

---------------

R

2

R

1

-------

=

=

R

3

10k

0.75

0.5

-----------

15k

=

=

OUTPUT

0

INPUT

0

FIGURE 26. SINGLE SUPPLY, ABSOLUTE VALUE, IDEAL

FULL WAVE RECTIFIER WITH ASSOCIATED

WAVEFORMS

+15V

-15V

2

7

4

+

CA3140

-

3

0.01

µ

F

0.01

µ

F

6

1M

NOISE VOLTAGE

OUTPUT

30.1k

1k

R

S

BW (-3dB) = 140kHz

TOTAL NOISE VOLTAGE

(REFERRED TO INPUT) = 48

µ

V (TYP)

FIGURE 27. TEST CIRCUIT AMPLIFIER (30dB GAIN) USED FOR

WIDEBAND NOISE MEASUREMENT

Top Trace: Output; 50mV/Div., 200ns/Div.

Bottom Trace: Input; 50mV/Div., 200ns/Div.

FIGURE 28B. SMALL SIGNAL RESPONSE

(Measurement made with Tektronix 7A13 differential amplifier.)

Top Trace: Output Signal; 5V/Div., 5

µ

s/Div.

Center Trace: Difference Signal; 5mV/Div., 5

µ

s/Div.

Bottom Trace: Input Signal; 5V/Div., 5

µ

s/Div.

FIGURE 28C. INPUT-OUTPUT DIFFERENCE SIGNAL SHOWING

SETTLING TIME

FIGURE 28. SPLIT SUPPLY VOLTAGE FOLLOWER TEST

CIRCUIT AND ASSOCIATED WAVEFORMS

+15V

-15V

2

7

4

+

CA3140

-

3

0.1

µ

F

0.1

µ

F

6

0.05

µ

F

2k

10k

100pF

SIMULATED

LOAD

2k

BW (-3dB) = 4.5MHz

SR = 9V/

µ

s

FIGURE 28A. TEST CIRCUIT

INPUT

CA3140, CA3140A

18

Typical Performance Curves

FIGURE 29. OPEN-LOOP VOLTAGE GAIN vs SUPPLY

VOLTAGE AND TEMPERATURE

FIGURE 30. GAIN BANDWIDTH PRODUCT vs SUPPLY

VOLTAGE AND TEMPERATURE

FIGURE 31. SLEW RATE vs SUPPLY VOLTAGE AND

TEMPERATURE

FIGURE 32. QUIESCENT SUPPLY CURRENT vs SUPPLY

VOLTAGE AND TEMPERATURE

FIGURE 33. MAXIMUM OUTPUT VOLTAGE SWING vs

FREQUENCY

FIGURE 34. COMMON MODE REJECTION RATIO vs

FREQUENCY

125

100

75

50

25

O

PEN-

L

O

O

P VO

L

T

AG

E G

A

I

N

(

d

B)

0

5

10

15

20

SUPPLY VOLTAGE (V)

125

o

C

25

o

C

T

A

= -55

o

C

R

L

= 2k

25

0

G

A

IN BANDWI

D

T

H

PRO

DUCT

(

M

H

z

)

125

o

C

25

o

C

T

A

= -55

o

C

R

L

= 2k

20

10

0

5

10

15

20

SUPPLY VOLTAGE (V)

25

C

L

= 100pF

1

125

o

C

25

o

C

T

A

= -55

o

C

R

L

= 2k

5

10

15

20

SUPPLY VOLTAGE (V)

25

C

L

= 100pF

20

15

10

5

0

SLEW

RAT

E

(

V

/

µ

s)

0

7

6

5

4

3

0

5

10

15

20

SUPPLY VOLTAGE (V)

125

o

C

T

A

= -55

o

C

R

L

=

25

0

2

1

25

o

C

Q

U

I

E

S

C

ENT SUPPL

Y CUR

RE

NT (

m

A)

25

20

15

10

5

0

OUT

P

UT

S

W

ING

(V

P-

P

)

10K

100K

FREQUENCY (Hz)

1M

4M

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

120

100

80

60

40

20

0

COM

M

ON-

M

O

DE REJ

E

CT

ION RAT

IO (

d

B)

10

1

10

2

10

3

10

4

10

5

10

6

10

7

FREQUENCY (Hz)

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

CA3140, CA3140A

19

FIGURE 35. EQUIVALENT INPUT NOISE VOLTAGE vs

FREQUENCY

FIGURE 36. POWER SUPPLY REJECTION RATIO vs

FREQUENCY

Typical Performance Curves

(Continued)

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

FREQUENCY (Hz)

1

10

1

10

2

10

3

10

4

10

5

E

Q

U

I

V

A

L

E

NT

INP

U

T

NOIS

E

V

O

L

T

A

GE

(n

V

/

Hz)

100

10

1

1000

10

2

10

3

10

4

10

5

10

6

10

7

FREQUENCY (Hz)

POWER

SUPP

L

Y

REJ

E

CT

ION RAT

IO (

d

B) 100

80

60

40

20

0

+PSRR

-PSRR

SUPPLY VOLTAGE: V

S

=

±

15V

T

A

= 25

o

C

POWER SUPPLY REJECTION RATIO

(PSRR) =

V

IO

/

V

S

10

1

CA3140, CA3140A

20

Metallization Mask Layout

Dimensions in parenthesis are in millimeters and are derived

from the basic inch dimensions as indicated. Grid graduations

are in mils (10

-3

inch).

The photographs and dimensions represent a chip when it is

part of the wafer. When the wafer is cut into chips, the cleavage

angles are 57

o

instead of 90

with respect to the face of the

chip. Therefore, the isolated chip is actually 7 mils (0.17mm)

larger in both dimensions.

62-70

(1.575-1.778)

4-10

(0.102-0.254)

60

50

40

30

20

10

0

58-66

(1.473-1.676)

50

40

30

20

10

61

0

60 65

CA3140, CA3140A

21

CA3140, CA3140A

Dual-In-Line Plastic Packages (PDIP)

CL

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A

1

-A-

0.010 (0.25)

C A

M

B S

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the "MO Series Symbol List" in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protru-

sions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and

are measured with the leads constrained to be per-

pendicular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads uncon-

strained. e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

e

A

-C-

E8.3

(JEDEC MS-001-BA ISSUE D)

8 LEAD DUAL-IN-LINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.210

-

5.33

4

A1

0.015

-

0.39

-

4

A2

0.115

0.195

2.93

4.95

-

B

0.014

0.022

0.356

0.558

-

B1

0.045

0.070

1.15

1.77

8, 10

C

0.008

0.014

0.204

0.355

-

D

0.355

0.400

9.01

10.16

5

D1

0.005

-

0.13

-

5

E

0.300

0.325

7.62

8.25

6

E1

0.240

0.280

6.10

7.11

5

e

0.100 BSC

2.54 BSC

-

e

A

0.300 BSC

7.62 BSC

6

e

B

-

0.430

-

10.92

7

L

0.115

0.150

2.93

3.81

4

N

8

8

9

Rev. 0 12/93

22

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation's quality certifications can be viewed at www.intersil.com/design/quality