Document Outline

- HC-5509A1

- SLIC Subscriber Line Interface Circuit

- 0o to +75oC

- -40o to +85oC

- 0o to +75oC

- -40o to +85oC

- 0o to +75oC

- -40o to +85oC

- 0o to +75oC

- -40o to +85oC

- Specifications HC-5509A1

- Specifications HC-5509A1

- -

- 100

- -

- kW

- -

- -

- 20

- W

- +1.5

- -

- -

- VPEAK

- 26

- 35

- -

- dB

- 30

- 40

- -

- dB

- 30

- 40

- -

- dB

- 58

- 63

- -

- dB

- 50

- 55

- -

- dB

- -

- -

- -67

- dBmp

- -

- -

- 23

- dBrnC

- -

- -

- 30

- mArms

- -

- ±0.05

- ±0.2

- dB

- -

- ±0.05

- ±0.2

- dB

- -

- -

- ±0.12

- dB

- -

- ±0.02

- ±0.05

- dB

- -

- -

- ±0.05

- dB

- -

- -

- ±0.1

- dB

- -

- -

- ±0.3

- dB

- -

- -

- 1

- ms

- -

- -

- 1

- ms

- -

- -

- 1.5

- ms

- -

- 40

- -

- dB

- -

- -

- -52

- dB

- -

- -

- 5

- dBrnC

- -

- -

- -85

- dBmp

- -

- -

- 15

- dBrn

- 20

- 29

- -

- dB

- 20

- 29

- -

- dB

- 20

- 29

- -

- dB

- 20

- 29

- -

- dB

- 30

- -

- -

- dB

- 30

- -

- -

- dB

- 20

- 25

- -

- dB

- 20

- 25

- -

- dB

- 50

- -

- 500

- ms

- 20

- 40

- 60

- mA

- 10

- -

- -

- %

- -

- ±3

- ±5

- mA

- -

- 30

- -

- mA

- -

- 60

- -

- mA

- -

- 90

- -

- mA

- -

- 12

- 15

- mA

- 8

- 12

- 16

- mA

- 140

- -

- 160

- oC

- 9.5

- 13.5

- 17.5

- mA

- -

- 0.1

- 0.5

- ms

- -

- 0.2

- 0.5

- V

- -

- ±10

- ±100

- mA

- -

- -

- 0.8

- V

- 2.0

- -

- 5.5

- V

- -

- -

- ±100

- mA

- -

- 0.1

- 0.5

- V

- 2.7

- -

- -

- V

- -

- 200

- -

- mW

- -

- -

- 6

- mA

- -6

- -

- -

- mA

- -

- ±5

- -

- mV

- -

- ±10

- -

- nA

- -

- 1

- -

- MW

- -

- ±3

- -

- VP-P

- -

- 1

- -

- MHz

- 1

- 2

- AG

- 2

- 3

- VB+

- 3

- 4

- C1

- 4

- 8

- F1

- 5

- 9

- F0

- 6

- 10

- RS

- 7

- 11

- SHD

- 8

- 12

- GKD

- 9

- 13

- TST

- 10

- 14

- ALM

- 11

- 18

- ILMT

- 12

- 19

- OUT1

- 13

- 20

- -IN1

- 14

- 22

- TIP

- 15

- 24

- RING

- 16

- 25

- RFS

- 17

- 27

- VRX

- 18

- 31

- LAO

- 19

- 32

- VTX

- 20

- 33

- PRI

- 21

- 34

- PR

- NA

- 35

- DG

- 22

- 36

- BG

- 23

- 37

- RD

- 24

- 38

- VFB

- 25

- 39

- TF2

- NA

- 40

- TF1

- 26

- 41

- RF1

- NA

- 42

- RF2

- 27

- 43

- VB-

- 28

- 44

- C2

- 1, 5, 6, 7, 15, 16, 17, 21, 23, 26, 28, 29, 30

- NC

- FIGURE 1.�TYPICAL LINE CIRCUIT APPLICATION WITH THE MONOLITHIC SLIC

- Specifications HC-5509A1

- HC-5509A1

- HC-5509A1

- HC-5509A1

- HC-5509A1

- HC-5509A1

- HC-5509A1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

,

8-131

Æ

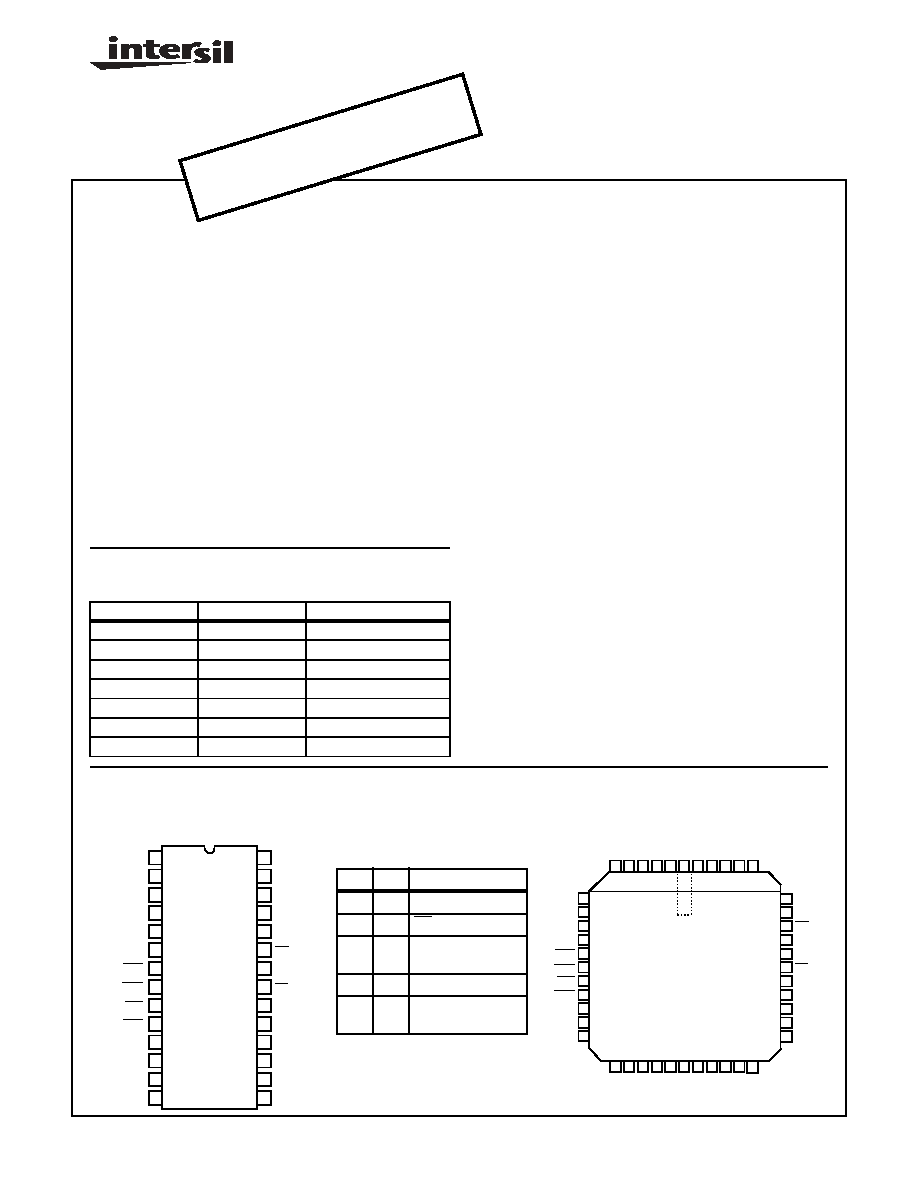

Description

The HC-5509A1 telephone Subscriber Line Interface Circuit

integrates most of the BORSCHT functions on a monolithic

IC. The device is manufactured in a Dielectric Isolation (DI)

process and is designed for use as a high voltage interface

between the traditional telephone subscriber pair (Tip and

Ring) and the low voltage filtering and coding/decoding func-

tions of the line card. Together with a secondary protection

diode bridge and "feed" resistors, the device will withstand

1000V lightning induced surges, in plastic packages. The

SLIC also maintains specified transmission performance in

the presence of externally induced longitudinal currents. The

BORSCHT functions that the SLIC provides are:

∑

Battery Feed with Subscriber Loop Current Limiting

∑

Overvoltage Protection

∑

Ring Relay Driver

∑

Supervisory Signaling Functions

∑

Hybrid Functions (with External Op-Amp)

∑

Test (or Battery Reversal) Relay Driver

In addition, the SLIC provides selective denial of power to

subscriber loops, a programmable subscriber loop current

limit from 20 to 60mA, a thermal shutdown with an alarm out-

put and line fault protection. Switch hook detection, ring trip

detection and ground key detection functions are also incor-

porated in the SLIC device.

The HC-5509A1 SLIC is ideally suited for line card designs

in PBX and CO systems, replacing traditional transformer

solutions.

Features

∑ DI Monolithic High Voltage Process

∑ Compatible with Worldwide PBX and CO Performance

Requirements

∑ Controlled Supply of Battery Feed Current with Programmable

Current Limit

∑ Operates with 5V Positive Supply (V

B+

)

∑ Internal Ring Relay Driver and a Utility Relay Driver

∑ High Impedance Mode for Subscriber Loop

∑ High Temperature Alarm Output

∑ Low Power Consumption During Standby Functions

∑ Switch Hook, Ground Key, and Ring Trip Detection

∑ Selective Power Denial to Subscriber

∑ Voice Path Active During Power Denial

∑ On Chip Op-Amp for 2 Wire Impedance Matching

Applications

∑ Solid State Line Interface Circuit for PBX or Central Office

Systems, Digital Loop Carrier Systems

∑ Hotel/Motel Switching Systems

∑ Direct Inward Dialing (DID) Trunks

∑ Voice Messaging PBX's

∑ High Voltage 2W/4W, 4W/2W Hybrid

Ordering Information

PART NUMBER

TEMP. RANGE

PACKAGE

HC1-5509A1-5

0

o

to +75

o

C

28 Lead Ceramic DIP

HC1-5509A1-9

-40

o

to +85

o

C

28 Lead Ceramic DIP

HC3-5509A1-5

0

o

to +75

o

C

28 Lead Plastic DIP

HC3-5509A1-9

-40

o

to +85

o

C

28 Lead Plastic DIP

HC4P5509A1-5

0

o

to +75

o

C

44 Lead PLCC

HC4P5509A1-9

-40

o

to +85

o

C

44 Lead PLCC

HC9P5509A1-5

0

o

to +75

o

C

28 Lead SOIC

PRELIMINARY

May 1997

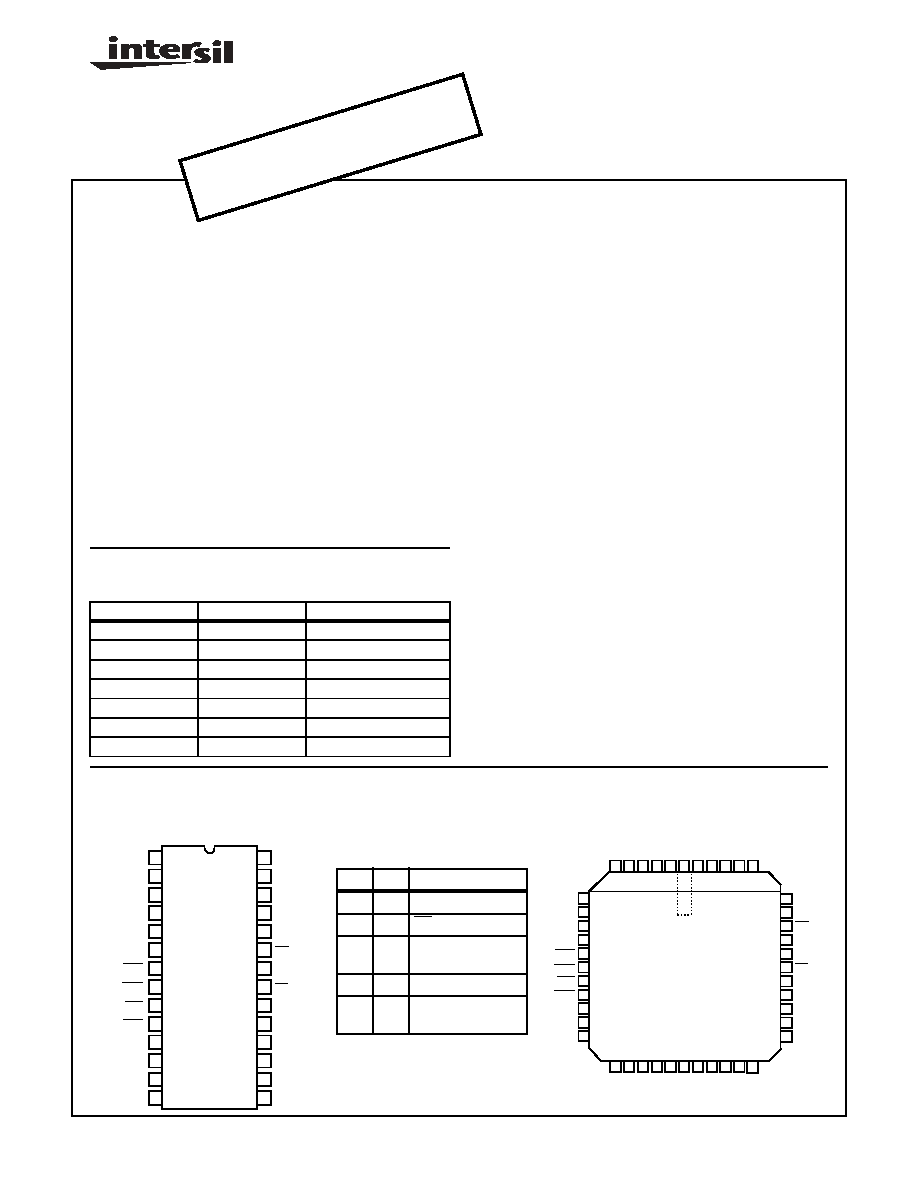

Pinouts

HC-5509A1 (PDIP, CDIP, SOIC)

TOP VIEW

C2

RF

TF

VFB

VTX

LAO

VRX

RFS

RING

VB-

BG

28

27

26

24

23

22

21

20

19

18

17

16

15

25

PR

RD

PRI

VB+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AG

RS

ILMT

OUT 1

-IN 1

TIP

F0

C1

F1

SHD

GKD

TST

ALM

TRUTH TABLE

F1

F0

ACTION

0

0

Normal Loop Feed

0

1

RD Active

1

0

Power Down Latch

RESET

1

0

Power on RESET

1

1

Loop Power

Denial Active

HC-5509A1 (PLCC)

TOP VIEW

15

14

13

12

11

10

9

8

7

17

16

N/C

F1

F0

ALM

N/C

N/C

RS

SHD

N/C

C1

VB

+

AG

C2

VB

-

RF

2

RF

1

TF1

X

GKD

IL

M

T

OU

T

1

-I

N

1

TI

P

RI

NG

RF

S

VR

X

N/C

1

2

3

4

5

6

40

41

42

43

44

18 19 20 21 22 23 24 25 26 27 28

31

32

33

34

35

36

37

38

39

29

30

TF2

VFB

RD

DG

VTX

LAO

N/C

N/C

BG

PR

PRI

TST

N/C

N/C

N/C

N/C

N/C

N/C

HC-5509A1

SLIC

Subscriber Line Interface Circuit

File Number

3567.1

NOT

REC

OMM

END

ED F

OR N

EW D

ESIG

NS

See

HC5

509A

1R30

60

or co

ntac

t our

Tec

hnic

al Su

ppor

t Cen

ter a

t

1-888

-INTE

RSIL

or w

ww.i

nters

il.com

/tsc

8-132

Specifications HC-5509A1

Absolute Maximum Ratings

(Note 1)

Operating Conditions

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +15V

Maximum Supply Voltages

(V

B+

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7V

(V

B+

)-(V

B-

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +75V

Junction Temperature Ceramic . . . . . . . . . . . . . . . . . . . . . . +175

o

C

Junction Temperature Plastic. . . . . . . . . . . . . . . . . . . . . . . . +150

o

C

Lead Temperature (Soldering 10 Sec.) . . . . . . . . . . . . . . . . +300

o

C

Operating Temperature Range

HC-5509A1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

o

C to +75

o

C

HC-5509A1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40

o

C to +85

o

C

Storage Temperature Range . . . . . . . . . . . . . . . . . -65

o

C to +150

o

C

Relay Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5V to +12V

Positive Power Supply (V

B+

) . . . . . . . . . . . . . . . . . . . . . . . . +5V

±

5%

Negative Power Supply (V

B-

) . . . . . . . . . . . . . . . . . . . . -42V to -58V

Loop Resistance (R

L

) . . . . . . . . . . . . . . . . . 200

to 1750

(Note 2)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

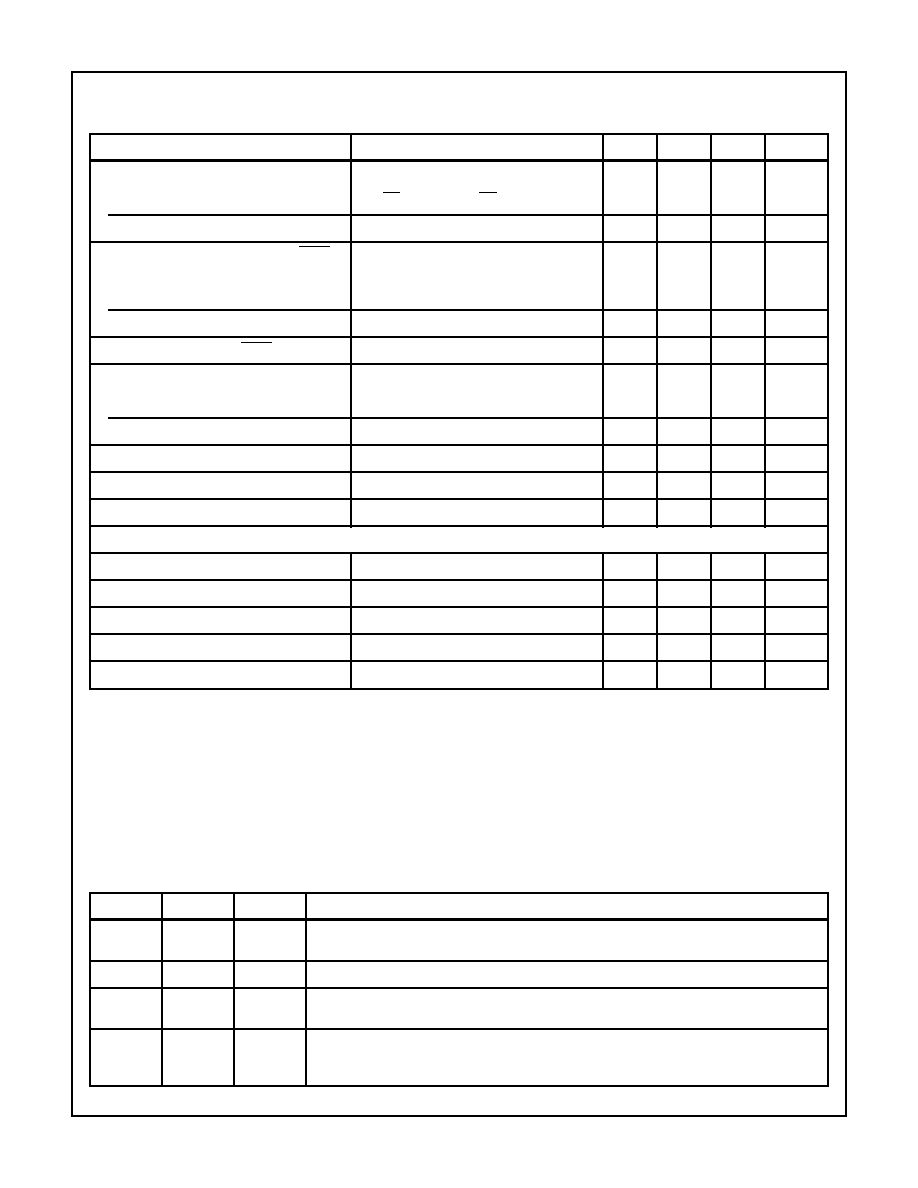

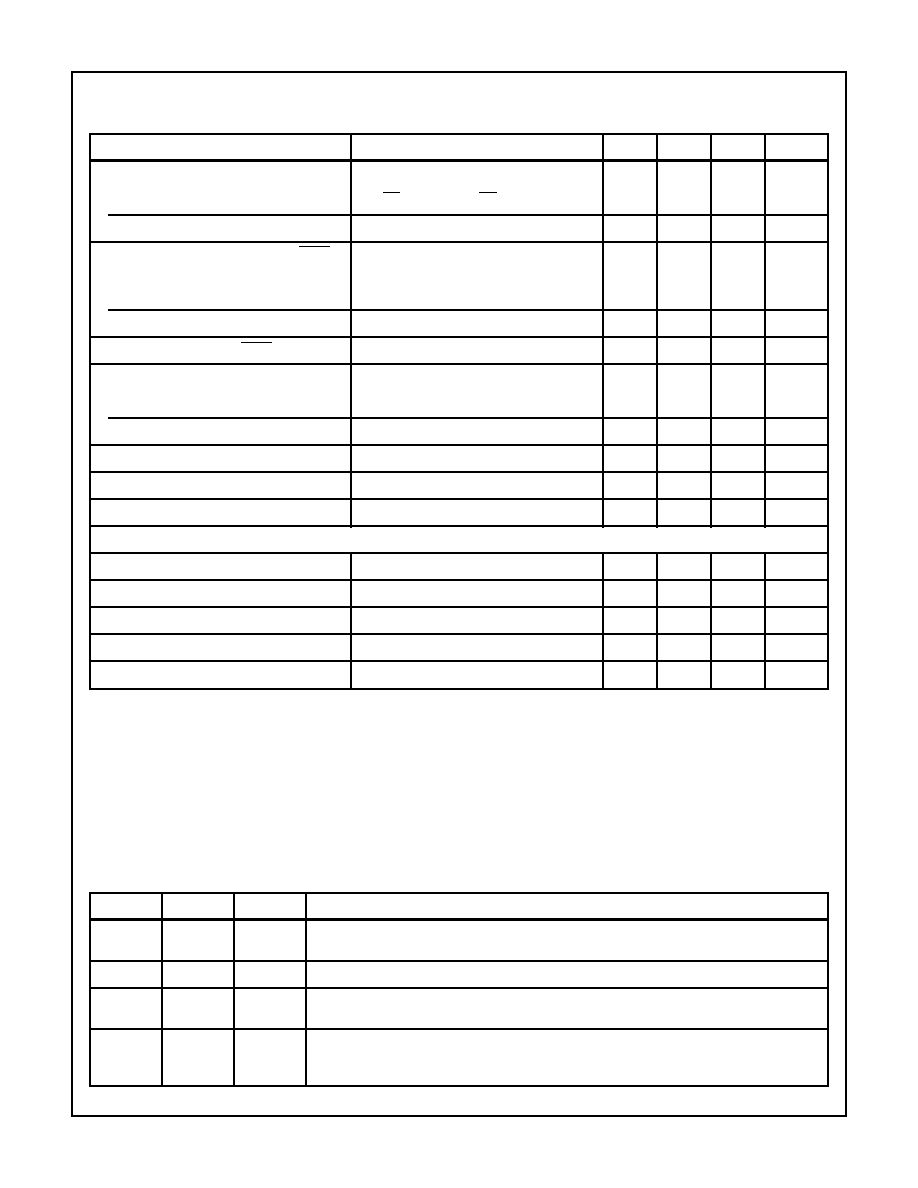

Electrical Specifications

Unless Otherwise Specified, Typical Parameters are at T

A

= +25

o

C, Min-Max Parameters are over

Operating Temperature Range, V

B-

= -48V, V

B+

= +5V, AG = DG = BG = 0V. All A.C. Parameters are

specified at 600

2-Wire terminating impedance.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

A.C. TRANSMISSION PARAMETERS

RX Input Impedance

300Hz to 3.4kHz (Note 3)

-

100

-

k

TX Output Impedance

300Hz to 3.4kHz (Note 3)

-

-

20

4W Input Overload Level

300Hz to 3.4kHz R

L

= 1200

,

600

Reference

+1.5

-

-

V

PEAK

2W Return Loss

Matched for 600

(Note 3)

SRL LO

26

35

-

dB

ERL

30

40

-

dB

SRL HI

30

40

-

dB

2W Longitudinal to Metallic Balance

Off Hook

Per ANSI/IEEE STD 455-1976 (Note 3)

300Hz to 3400Hz

58

63

-

dB

4W Longitudinal Balance

Off Hook

300Hz to 3400Hz (Note 3)

50

55

-

dB

Low Frequency Longitudinal Balance

R.E.A. Test Circuit

-

-

-67

dBmp

I

LINE

= 40mA T

A

= +25

o

C (Note 3)

-

-

23

dBrnC

Longitudinal Current Capability

I

LINE

= 40mA T

A

= +25

o

C (Note 3)

-

-

30

mArms

Insertion Loss

0dBm at 1kHz, Referenced 600

2W/4W

-

±

0.05

±

0.2

dB

4W/2W

-

±

0.05

±

0.2

dB

4W/4W

-

-

±

0.12

dB

Frequency Response

300Hz to 3400Hz (Note 3) Referenced to

Absolute Level at 1kHz, 0dBm Referenced

600

-

±

0.02

±

0.05

dB

Level Linearity

Referenced to -10dBm (Note 3)

2W to 4W and 4W to 2W

+3 to -40dBm

-

-

±

0.05

dB

-40 to -50dBm

-

-

±

0.1

dB

-50 to -55dBm

-

-

±

0.3

dB

Absolute Delay

(Note 3)

8-133

Specifications HC-5509A1

2W/4W

300Hz to 3400Hz

-

-

1

µ

s

4W/2W

300Hz to 3400Hz

-

-

1

µ

s

4W/4W

300Hz to 3400Hz

-

-

1.5

µ

s

Transhybrid Loss, THL

(Note 3) See Figure 1

-

40

-

dB

Total Harmonic Distortion

2W/4W, 4W/2W, 4W/4W

Reference Level 0dBm at 600

300Hz to 3400Hz (Note 3)

-

-

-52

dB

Idle Channel Noise

(Note 3)

2W and 4W

C-Message

-

-

5

dBrnC

Psophometric

-

-

-85

dBmp

3kHz Flat

-

-

15

dBrn

Power Supply Rejection Ratio

(Note 3)

30Hz to 200Hz, R

L

= 600

V

B+

to 2W

20

29

-

dB

V

B+

to 4W

20

29

-

dB

V

B-

to 2W

20

29

-

dB

V

B-

to 4W

20

29

-

dB

V

B+

to 4W

(Note 3)

200Hz to 16kHz, R

L

= 600

30

-

-

dB

V

B-

to 2W

30

-

-

dB

V

B-

to 4W

20

25

-

dB

V

B-

to 4W

20

25

-

dB

Ring Sync Pulse Width

50

-

500

µ

s

D.C. PARAMETERS

Loop Current Programming

Limit Range

20

40

60

mA

Accuracy

10

-

-

%

Loop Current During Power Denial

R

L

= 200

-

±

3

±

5

mA

Fault Currents

TIP to Ground

-

30

-

mA

RING to Ground

-

60

-

mA

TIP and RING to Ground

-

90

-

mA

Switch Hook Detection Threshold

-

12

15

mA

Ground Key Detection Threshold

8

12

16

mA

Thermal ALARM Output

Safe Operating Die Temperature Exceeded

140

-

160

o

C

Ring Trip Comparator Threshold

See Typical Applications for more informa-

tion

9.5

13.5

17.5

mA

Dial Pulse Distortion

-

0.1

0.5

ms

Electrical Specifications

Unless Otherwise Specified, Typical Parameters are at T

A

= +25

o

C, Min-Max Parameters are over

Operating Temperature Range, V

B-

= -48V, V

B+

= +5V, AG = DG = BG = 0V. All A.C. Parameters are

specified at 600

2-Wire terminating impedance. (Continued)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

8-134

Specifications HC-5509A1

Relay Driver Outputs

On Voltage V

OL

I

OL

(PR) = 60mA, I

OL

(RD) = 30mA

-

0.2

0.5

V

Off Leakage Current

V

OH

= 13.2V

-

±

10

±

100

µ

A

TTL/CMOS Logic Inputs (F0, F1, RS, TEST,

PRI)

Logic `0' V

IL

-

-

0.8

V

Logic `1' V

IH

2.0

-

5.5

V

Input Current (F0, F1, RS, TEST, PRI)

0V

V

IN

5V

-

-

±

100

µ

A

Logic Outputs

Logic `0' V

OL

I

LOAD

= 800

µ

A

-

0.1

0.5

V

Logic `1' V

OH

I

LOAD

= 40

µ

A

2.7

-

-

V

Power Dissipation On Hook

Relay Drivers Off

-

200

-

mW

I

B+

V

B+

= +5.25V, V

B-

= -58V, R

LOOP

=

-

-

6

mA

I

B-

V

B+

= +5.25V, V

B

- = -58V, R

LOOP

=

-6

-

-

mA

UNCOMMITED OP AMP PARAMETERS

Input Offset Voltage

-

±

5

-

mV

Input Offset Current

-

±

10

-

nA

Differential Input Resistance

(Note 2)

-

1

-

M

Output Voltage Swing

R

L

= 10k

-

±

3

-

V

P-P

Small Signal GBW

(Note 2)

-

1

-

MHz

NOTES:

1. Absolute maximum ratings are limiting values, applied individually, beyond which the serviceability of the circuit may be impaired. Func-

tional operability under any of these conditions is not necessarily implied.

2. May Be Extended to 1900

With Application Circuit.

3. These parameters are controlled by design or process parameters and are not directly tested. These parameters are characterized upon

initial design release, upon design changes which would affect these characteristics, and at intervals to assure product quality and spec-

ification compliance.

Pin Descriptions

DIP/SOIC

PLCC

SYMBOL

DESCRIPTION

1

2

AG

Analog Ground - To be connected to zero potential. Serves as a reference for the transmit output

and receive input terminals.

2

3

VB+

Positive Voltage Source - Most Positive Supply.

3

4

C1

Capacitor #C1 - An external capacitor to be connected between this terminal and analog ground.

Required for proper operation of the loop current limiting function.

4

8

F1

Function Address #1 - A TTL and CMOS compatible input used with F0 function address line to

externally select logic functions. The three selectable functions are mutually exclusive. See Truth

Table on page1. F1 should be toggled high after power is applied.

Electrical Specifications

Unless Otherwise Specified, Typical Parameters are at T

A

= +25

o

C, Min-Max Parameters are over

Operating Temperature Range, V

B-

= -48V, V

B+

= +5V, AG = DG = BG = 0V. All A.C. Parameters are

specified at 600

2-Wire terminating impedance. (Continued)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

8-135

HC-5509A1

5

9

F0

Function Address #0 - A TTL and CMOS compatible input used with F1 function address line to

externally select logic functions. The three selectable functions are mutually exclusive. See Truth

Table on page 1.

6

10

RS

Ring Synchronization Input - A TTL - compatible clock input. The clock is arranged such that a

positive pulse (50 - 500

µ

s) occurs on the zero crossing of the ring voltage source, as it appears

at the RFS terminal. For Tip side injected systems, the RS pulse should occur on the negative

going zero crossing and for Ring injected systems, on the positive going zero crossing. This en-

sures that the ring delay activates and deactivates when the instantaneous ring voltage is near

zero. If synchronization is not required, the pin should be tied to +5.

7

11

SHD

Switch Hook Detection - An active low LS TTL compatible logic output. A line supervisory output.

8

12

GKD

Ground Key Detection - An active low LS TTL compatible logic output. A line supervisory output.

9

13

TST

A TTL logic input. A low on this pin will set a latch and keep the SLIC in a power down mode until

the proper F1, F0 state is set and will keep ALM low. See Truth Table on page 1.

10

14

ALM

A LS TTL compatible active low output which responds to the thermal detector circuit when a safe

operating die temperature has been exceeded. When TST is forced low by an external control

signal, ALM is latched low until the proper F1, F0 state and TST input is brought high. The ALM

can be tied directly to the TST pin to power down the part when a thermal fault is detected and

then reset with F0, F1. See Truth Table on page 1. It is possible to ignore transient thermal over-

load conditions in the SLIC by delaying the response to the TST pin from the ALM. Care must be

exercised in attempting this as continued thermal overstress may reduced component life.

11

18

ILMT

Loop Current Limit - Voltage on this pin sets the short loop current limiting conditions using a re-

sistive voltage divider.

12

19

OUT1

The analog output of the spare operational amplifier.

13

20

-IN1

The inverting analog input of the spare operational amplifier.

14

22

TIP

An analog input connected to the TIP (more positive) side of the subscriber loop through a feed

resistor and ring relay contact. Functions with the RING terminal to receive voice signals from

the telephone and for loop monitoring purpose.

15

24

RING

An analog input connected to the RING (more negative) side of the subscriber loop through a

feed resistor. Functions with the TIP terminal to receive voice signals from the telephone and for

loop monitoring purposes.

16

25

RFS

Ring Feed Sense - Senses RING side of the loop for Ground Key Detection. During Ring injected

ringing the ring signal at this node is isolated from RF via the ring relay. For Tip injected ringing,

the RF and RFS pins must be shorted.

17

27

VRX

Receive Input, Four Wire Side - A high impedance analog input. AC signals appearing at this in-

put drive the Tip Feed and Ring Feed amplifiers differentially.

18

31

LAO

Longitudinal Amplifier Output - A low impedance output to be connected to C2 through a low pass

filter. Output is proportional to the difference in I

TIP

and I

RING

.

19

32

VTX

Transmit Output, Four Wire Side - A low impedance analog output which represents the differ-

ential voltage across TIP and RING. Transhybrid balancing must be performed beyond this out-

put to completely implement two to four wire conversion. This output is referenced to analog

ground. Since the D.C. level of this output varies with loop current, capacitive coupling to the next

stage is necessary.

20

33

PRI

A TTL compatible input used to control PR. PRI active High = PR active low.

21

34

PR

An active low open collector output. Can be used to drive a Polarity Reversal Relay.

NA

35

DG

Digital Ground - To be connected to zero potential - serves as reference for all digital inputs and

outputs on the SLIC.

22

36

BG

Battery Ground - Tube connected to zero potential. All loop current and some quiescent current

flows into this terminal.

Pin Descriptions (Continued)

DIP/SOIC

PLCC

SYMBOL

DESCRIPTION

8-136

HC-5509A1

23

37

RD

Ring Relay Driver - An active low open collector output. Used to drive a relay that switches ring-

ing signals onto the 2-Wire line.

24

38

VFB

Feedback input to the tip feed amplifier; may be used in conjunction with transmit output signal

and the spare op-amp to accommodate 2W line impedance matching.

25

39

TF2

Tip Feed - A low impedance analog output connected to the TIP terminal through a feed resistor.

Functions with the RF terminal to provide loop current, and to feed voice signals to the telephone

set and to sink longitudinal currents. Must be tied to TF1.

NA

40

TF1

Tie directly to TF2 in the PLCC application.

26

41

RF1

Ring Feed - A low impedance analog output connected to the RING terminal through a feed re-

sistor. Functions with the TF terminal to provide loop current, feed voice signals to the telephone

set, and to sink longitudinal currents. Tie directly to RF2.

NA

42

RF2

Tie directly to RF1 in the PLCC application.

27

43

VB-

The battery voltage source. The most negative supply.

28

44

C2

Capacitor #2 - An external capacitor to be connected between this terminal and ground. It pre-

vents false ring trip detection from occurring when longitudinal currents are induced onto the sub-

scriber loop from power lines and other noise sources. This capacitor should be nonpolarized.

1, 5, 6, 7,

15, 16,

17, 21,

23, 26,

28, 29, 30

NC

No internal connection.

NOTE:

1. All grounds (AG, BG, DG) must be applied before V

B+

or V

B-

. Failure to do so may result in premature failure of the part. If a user wishes

to run separate grounds off a line card, the AG must be applied first.

Pin Descriptions (Continued)

DIP/SOIC

PLCC

SYMBOL

DESCRIPTION

8-137

HC-5509A1

Functional Diagram

DIP OR SOIC

R

2R

C1

VRX

OUT 1

2R

R/2

+

TA

2R

2R

90k

+

LA

25k

25k

17

12

RF1

3

SHD

FAULT

DET

OP AMP

+

VFB

VTX

+

RTD

GKD

GM

28

11

RF2

VB

REF

VB/2

-IN 1

13

24

19

THERM

LTD

18

C2

LAO

ILMT

Die Characteristics

Transistor Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Diode Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Die Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 x 120

Substrate Potential . . . . . . . . . . . . . . . . . . . . . . . Connected

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bipolar-DI

Thermal Constants (

o

C/W)

JA

JC

Ceramic DIP . . . . . . . . . . . . . . . . . . . .

48

12

Plastic DIP . . . . . . . . . . . . . . . . . . . . . .

51

21

PLCC . . . . . . . . . . . . . . . . . . . . . . . . . .

47

17

SOIC . . . . . . . . . . . . . . . . . . . . . . . . . .

72

22

Overvoltage Protection and Longitudinal

Current Protection

The SLIC device, in conjunction with an external protection

bridge, will withstand high voltage lightning surges and

power line crosses.

High voltage surge conditions are as specified in Table 1.

The SLIC will withstand longitudinal currents up to a maxi-

mum or 30mArms, 15mArms per leg, without any perfor-

mance degradation

.

TABLE 1.

PARAMETER

TEST

CONDITION

PERFORMANCE

(MAX)

UNITS

Longitudinal

Surge

10

µ

s Rise/

±

1000 (Plastic)

V

PEAK

1000

µ

s Fall

±

500 (Ceramic)

V

PEAK

Metallic Surge

10

µ

s Rise/

±

1000 (Plastic)

V

PEAK

1000

µ

s Fall

±

500 (Ceramic)

V

PEAK

T/GND

10

µ

s Rise/

±

1000 (Plastic)

V

PEAK

R/GND

1000

µ

s Fall

±

500 (Ceramic)

V

PEAK

50/60Hz Current

T/GND

11 Cycles

700 (Plastic)

V

RMS

R/GND

Limited to

10Arms

350 (Ceramic)

V

RMS

8-138

HC-5509A1

Functional Diagram (Continued)

PLCC

R

2R

VRX

OUT 1

2R

R/2

+

TA

2R

2R

90k

+

LA

25k

25k

27

19

RF1

4

SHD

FAULT

DET

OP AMP

+

VFB

VTX

+

RTD

GKD

GM

44

18

RF2

VB

REF

VB/2

20

38

32

THERM

LTD

31

-IN 1

C1

C2

LAO

ILMT

8-139

HC-5509A1

Logic Diagram

THERMAL

SHUT DOWN

RMAL

T

WN

CH

KEY

A

B

C

INJ

A

B

C

RELAY

DRIVER

NOTE: PRI is an independent switch driven by TTL input lev-

8-140

HC-5509A1

Applications Diagram

FIGURE 1. TYPICAL LINE CIRCUIT APPLICATION WITH THE MONOLITHIC SLIC

VB-

BG

C2

DG AG VB+ C1

C3

C4

+5V

ILIMIT

VRX+

VFB

VTX

-IN1

OUT1

RL1

CAC

KZ0

FROM PCM

FILTER/CODER

SYSTEM CONTROLLER

PRI RS

F1

F0

SHD GKD

TEST

ALARM

RB3

RING

RB1

K1A

TIP

RS1 CS1

PTC

Z1

PRIMARY

PROTECTION

K2

K1

+5V

+5V

KIB

150V

PEAK

(MAX)

VRING

RS2

CS2

RF2**

RF1**

RFS

RING

TF1**

TF2**

TIP

PR

RD

RB2

VB-

C5

KRF

RL2

*SECONDARY

PROTECTION

TO HYBIRD

BALANCE

NETWORK

***

CF2

RB4

RF2

CF1

LAO

RF1

SLIC

HC-5509A1

TYPICAL COMPONENT VALUES

C1 = 0.5

µ

F, 30V

RF1 = RF2 = 210k

, 1%

CF1 = CF2 = 0.22

µ

F, 10%, 20V Nonpolarized

C3 = 0.01

µ

F, 100V,

±

20%

C4 = 0.01

µ

F, 100V,

±

20%

C5 = 0.01

µ

F, 100V,

±

20%

C

AC

= 0.5

µ

F, 20V

KZ

0

= 60k

, (Z

0

= 600

, K = Scaling Factor = 100)

RL1, RL2; Current Limit Setting Resistors:

RL1 + RL2 > 90k

offset

I

LIMIT

= (0.6) (RL1 + RL2)/(200 x RL2), RL1 typically 100k

KR

F

= 20k

, RF = 2(R

B2

+ R

B4

), K = Scaling Factor = 100)

RB

1

= RB

2

= RB

3

= RB

4

= 50

(1% absolute, matching

requirements covered in a Tech Brief)

R

S1

= R

S2

= 1k

typically

CS1 = CS2 = 0.1

µ

F, 200V typically, depending on V

Ring

and

line length.

Z

1

= 150V to 200V transient protector. PTC used as ring

generator ballast.

* Secondary protection diode bridge recommended is 3A, 200V

type.

**TF1, TF2 and RF1, RF2 are on PLCC only and should be con-

nected together as shown.

***Not Present on DIP or SOIC packages.

NOTES:

1. All grounds (AG, BG, & DG) must be applied before V

B

+ or V

B

-. Failure to do so may result in premature failure of the part. If a user wishes

to run separate grounds off a line card, the AG must be applied first.

2. Application shows Ring Injected Ringing, a Balanced or Tip injected configuration may be used.

Additional information is contained in Application Note 549, "The HC-550X Telephone SLICs" By Geoff Phillips