1

Æ

FN4806.1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2003. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

HC5503PRC

Low Cost SLIC For Large Telecom

Switches

The HC5503PRC is a low cost SLIC optimized for large

Telecom switches. It combines a flexible voltage feed

architecture with the Intersil latch-free DI bonded wafer

process, to provide a low component count, carrier class

solution at very low cost. The re-configurable design permits

simple, economical solutions for campus-wide call center

and PBX applications. External components can be used in

conjunction with the high battery voltage capability to meet

the complex impedance and long loop drive requirements of

Central Office switches, worldwide.

Features

∑ Wide Operating Battery Range (-40V to -58V)

∑ Single Additional +5V Supply

∑ 30mA Short Loop Current Limit

∑ Ring Relay Driver

∑ Switch Hook and Ring Trip Detect

∑ Low On-Hook Power Consumption

∑ On-Hook Transmission

∑ ITU-T Longitudinal Balance Performance

∑ Loop Power Denial Function

∑ Thermal Protection

∑ Supports Tip, Ring or Balanced Ringing Schemes

∑ Low Profile SO, PLCC, and QFN Surface Mount

Packaging

Applications

∑ Central Office, PBX, Call Centers

∑ Related Literature

- AN571, Using Ring Sync with HC-5502A and HC-5504

SLICs

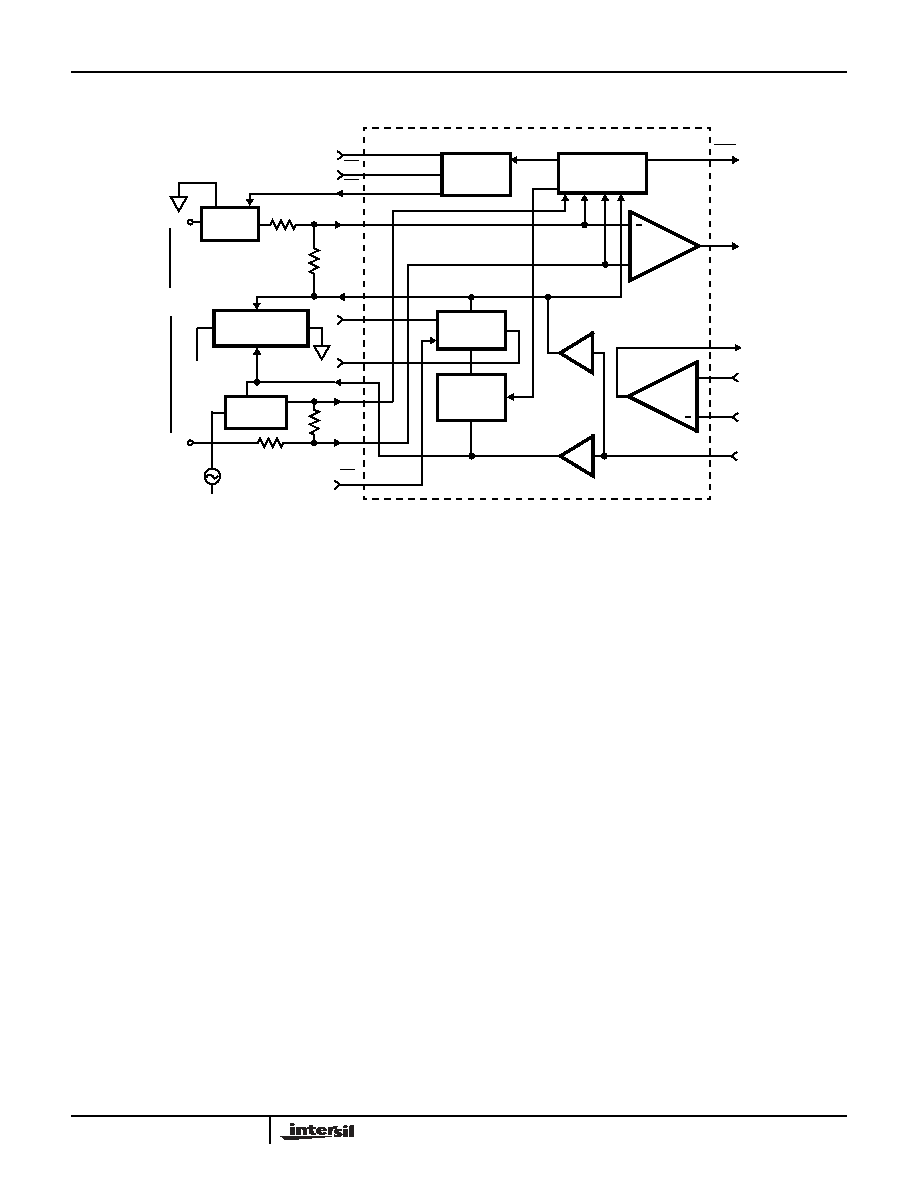

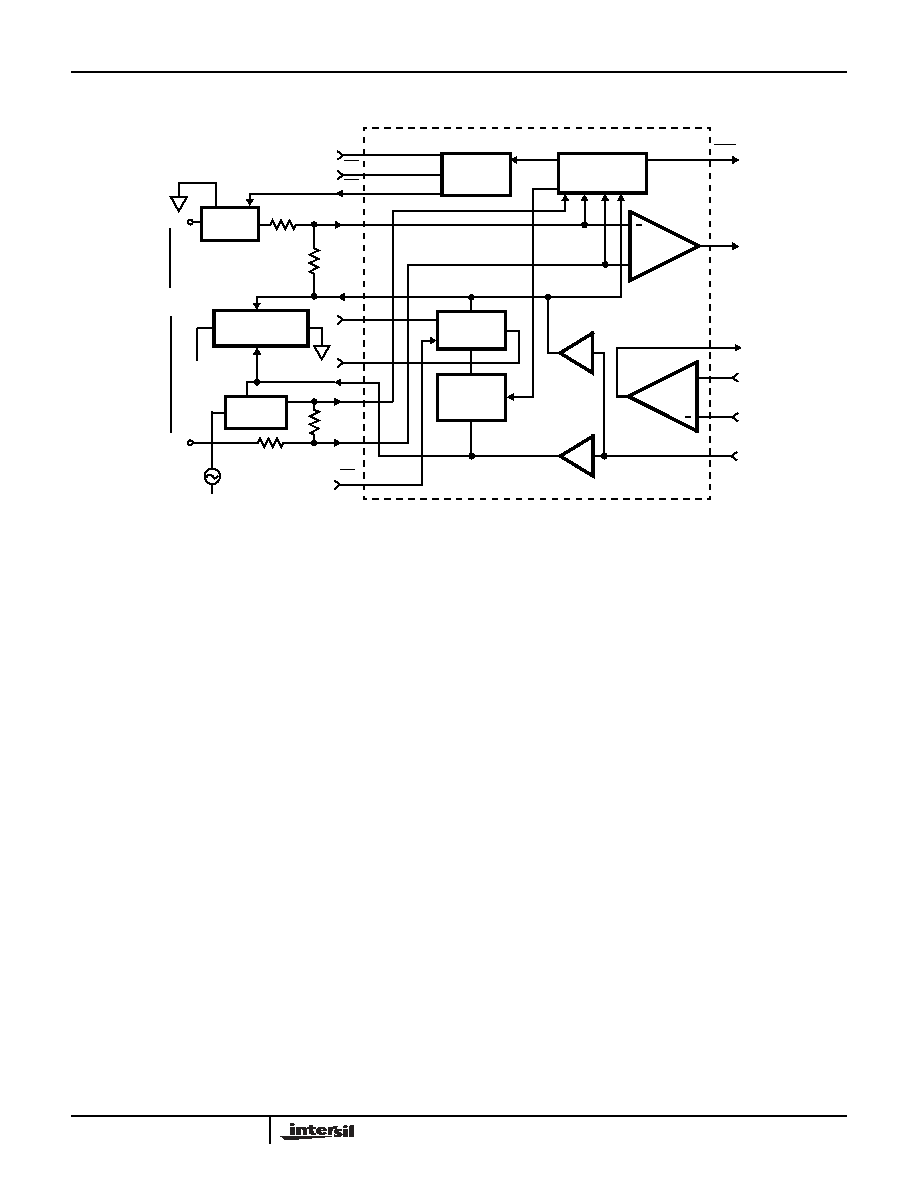

Block Diagram

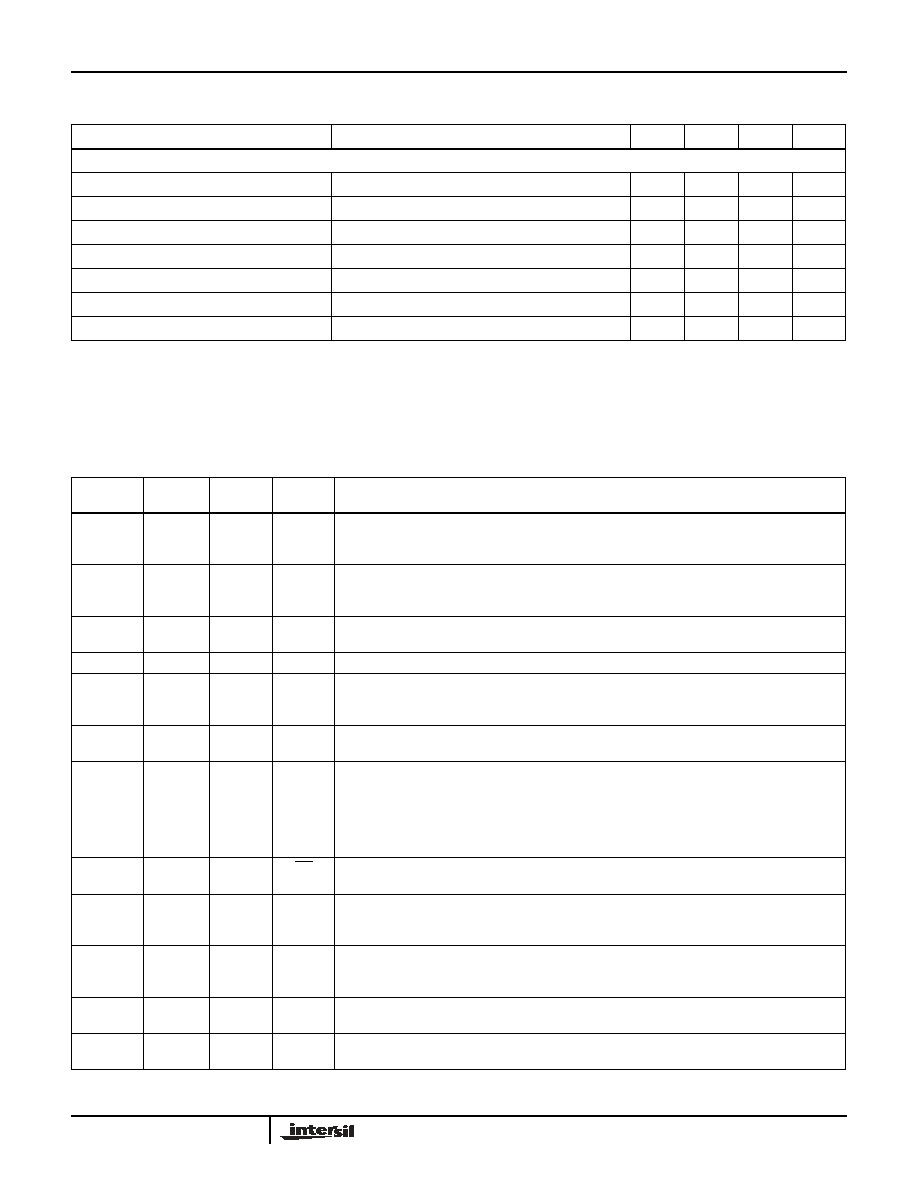

Ordering Information

PART NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG. NO.

HC5503PRCM

0 to 70

28 Ld PLCC

N28.45

HC5503PRCB

0 to 70

24 Ld SOIC

M24.3

HC5503PRCR

0 to 70

32 Ld QFN 7 X 7

L32.7X7A

RD

RFS

TIP

TF

RING

RF

V

BAT

V

CC

BGND

DGND

TX

RX

SHD

RS

RC

PD

RING RELAY

DRIVER

4-WIRE

INTERFACE

VF SIGNAL

PATH

LOOP CURRENT

DETECTOR

BIAS

LOGIC

INTERFACE

RING TRIP

DETECTOR

2-WIRE

INTERFACE

C1

C

2

AGND

THERMAL LIMIT

-

+

OUT

+IN

-IN

Data Sheet

February 2003

2

Absolute Maximum Ratings

Thermal Information

Maximum Continuous Supply Voltages

(V

B

-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -60 to 0.5V

(V

B

+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5 to 7V

(V

B

+ - V

B

-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75V

Relay Drive Voltage (V

RD

). . . . . . . . . . . . . . . . . . . . . . . . -0.5 to 15V

Operating Conditions

Operating Temperature Range . . . . . . . . . . . . . . . . . . . 0

o

C to 70

o

C

Relay Driver Voltage (V

RD

) . . . . . . . . . . . . . . . . . . . . . . . . 5V to 12V

Positive Supply Voltage (V

B

+) . . . . . . . . . . . . . . . . . . 4.75V to 5.25V

Negative Supply Voltage (V

B

-) . . . . . . . . . . . . . . . . . . .-40V to -58V

High Level Logic Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . 2.4V

Low Level Logic Input Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 0.6V

Subscriber Loop Resistance . . . . . . . . . . . . . . . . . . . 200

- 1800

Thermal Resistance (Typical, Note 2, 3)

JA

(

o

C/W)

24 Lead SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

75

28 Lead PLCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65

32 Lead 7x7 QFN . . . . . . . . . . . . . . . . . . . . . . . . . .

32

Maximum Junction Temperature Plastic . . . . . . . . . . . . . . . . .150

o

C

Maximum Storage Temperature Range . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300

o

C

(PLCC and SOIC - Lead Tips Only)

Die Characteristics

Transistor Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Diode Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Die Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137 x 102

Substrate Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Connected

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bipolar-DI

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Absolute maximum ratings are limiting values, applied individually, beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied.

2.

JA

is measured with the component mounted on an evaluation PC board in free air.

3.

JA

for the QFN package is measured in free air with the component mounted on a high effective thermal conductivity test board with direct

attach features including conductive thermal vias. See Tech Brief TB379 and TB389 for additional information and board layout consideration

Electrical Specifications

Unless Otherwise Specified, V

B

- = -48V, V

B

+ = 5V, AG = BG = DG = 0V, R

P

= 50

, R

S

= 100

, Typical

Parameters. T

A

= 25

o

C. Min-Max Parameters are Over Operating Temperature Range

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

On Hook Power Dissipation

I

LONG

= 0 (Note 4)

-

113

-

mW

Off Hook Power Dissipation

R

L

= 600

, I

LONG

= 0 (Notes 3, 4)

-

750

-

mW

On Hook I

B

+

R

L

=

, I

LONG

= 0

-

1.4

-

mA

Off Hook I

B

+

R

L

= 600

, I

LONG

= 0

-

2.8

-

mA

On Hook I

B

-

R

L

=

, I

LONG

= 0

-

2.2

-

mA

Off Hook I

B

-

R

L

= 600

, I

LONG

= 0

-

31

-

mA

Off Hook Loop Current

R

L

= 1800

(I

LOOP

= 0)

18

-

-

mA

Off Hook Loop Current

R

L

= 200

, I

LONG

= 0 (Note 3)

25

30

35

mA

Fault Currents

TIP to Ground

-

27

-

mA

RING to Ground

-

55

-

mA

TIP to RING

-

30

-

mA

TIP and RING to Ground

-

69

-

mA

Ring Relay Drive V

OL

I

OL

= 62mA

-

0.2

0.5

V

Ring Relay Driver Off Leakage

V

RD

= 12V, RC = 1 = HIGH, T

A

= 25

o

C

-

-

100

µ

A

DC Ring Trip Threshold

8.1

10.8

13.5

mA

Switch Hook Detection Threshold

5.0

7.5

10

mA

Loop Current During Power Denial

R

L

= 200

-

3.2

-

mA

Dial Pulse Distortion

(Note 4)

0

-

0.5

ms

Receive Input Impedance

(Note 4)

-

110

-

k

Transmit Output Impedance

(Note 4)

-

10

20

HC5503PRC

3

2-Wire Return Loss

(Referenced to 600

+ 2.16

µ

F), R

P

= R

S

= 150

(Note 4)

SR

L

LO

-

15.5

-

dB

ER

L

-

24

-

dB

SR

L

HI

-

31

-

dB

Longitudinal Balance

1V

RMS

200Hz - 3400Hz, (Note 4) IEEE Method

0

o

C

T

A

75

o

C, R

P

= R

S

= 150

2-Wire Off Hook (Note 4)

53

58

-

dB

2-Wire On Hook (Note 4)

53

58

-

dB

4-Wire Off Hook

50

58

-

dB

Insertion Loss

At 1kHz, 0dBm Input Level, Referenced 600

,

R

P

= R

S

= 150

2-Wire to 4-Wire, 4-Wire to 2-Wire

-

±

0.05

±

0.2

dB

Frequency Response

200 - 3400Hz Referenced to Absolute Loss at 1kHz and

0dBm Signal Level, R

P

= R

S

= 150

(Note 4)

-

±

0.02

±

0.05

dB

Idle Channel Noise

R

P

= R

S

= 150

(Note 4)

2-Wire to 4-Wire, 4-Wire to 2-Wire

-

1

5

dBrnC

-

-89

-85

dBm0p

Absolute Delay

R

P

= R

S

= 150

(Note 4)

2-Wire to 4-Wire, 4-Wire to 2-Wire

-

-

2

µ

s

Trans Hybrid Loss

Balance Network Set Up for 600

Termination at 1kHz,

R

P

= R

S

= 150

(Note 4)

30

40

-

dB

Overload Level

V

B

+ = +5V, R

P

= R

S

= 150

(Note 4)

2-Wire to 4-Wire, 4-Wire to 2-Wire

1.5

-

-

V

PEAK

Level Linearity

2-Wire to 4-Wire, 4-Wire to 2-Wire (Note 4)

At 1kHz, (Note 4) Referenced to 0dBm Level,

R

P

= R

S

= 150

+3 to -40dBm

-

-

±

0.05

dB

-40 to -50dBm

-

-

±

0.1

dB

-50 to -55dBm

-

-

±

0.3

dB

Power Supply Rejection Ratio

R

P

= R

S

= 150

(Note 4)

30 - 60Hz, R

L

= 600

V

B

+ to 2-Wire

15

-

-

dB

V

B

+ to Transmit

15

-

-

dB

V

B

- to 2-Wire

15

-

-

dB

V

B

- to Transmit

15

-

-

dB

V

B

+ to 2-Wire

200 - 16kHz, R

L

= 600

,

R

P

= R

S

= 150

30

-

-

dB

V

B

+ to Transmit

30

-

-

dB

V

B

- to 2-Wire

30

-

-

dB

V

B

- to Transmit

30

-

-

dB

Logic Input Current (RS, RC, PD)

0V

V

IN

5V

-

-

±

100

µ

A

Logic Inputs

Logic `0' V

IL

-

-

0.8

V

Logic `1' V

IH

2.0

-

5.5

V

Logic Outputs

Logic `0' V

OL

I

LOAD

800

µ

A, V

B

+ = 5V

-

0.1

0.5

V

Logic `1' V

OH

I

LOAD

40

µ

A, V

B

+ = 5V

2.7

-

5.0

V

Electrical Specifications

Unless Otherwise Specified, V

B

- = -48V, V

B

+ = 5V, AG = BG = DG = 0V, R

P

= 50

, R

S

= 100

, Typical

Parameters. T

A

= 25

o

C. Min-Max Parameters are Over Operating Temperature Range (Continued)

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

HC5503PRC

4

UNCOMMITTED OP AMP SPECIFICATIONS

Input Offset Voltage

-

±

5

-

mV

Input Offset Current

-

±

10

-

nA

Input Bias Current

-

20

-

nA

Differential Input Resistance

(Note 4)

-

1

-

M

Output Voltage Swing

R

L

= 10K, V

B

+ = 5V

-

±

3

-

V

PEAK

Output Resistance

A

VCL

= 1 (Note 4)

-

10

-

Small Signal GBW

(Note 4)

-

1

-

MHz

NOTES:

4. I

LONG

= Longitudinal Current.

5. These parameters are controlled by design or process parameters and are not directly tested. These parameters are characterized upon initial

design release, upon design changes which would affect these characteristics, and at intervals to assure product quality and specification

compliance.

Electrical Specifications

Unless Otherwise Specified, V

B

- = -48V, V

B

+ = 5V, AG = BG = DG = 0V, R

P

= 50

, R

S

= 100

, Typical

Parameters. T

A

= 25

o

C. Min-Max Parameters are Over Operating Temperature Range (Continued)

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Pin Descriptions

28 PIN

PLCC

24 PIN

DIP/SOIC

7 x 7

QFN

SYMBOL

DESCRIPTION

2

1

28

TIP

An analog input connected to the TIP (more positive) side of the subscriber loop through a sense

resistor (R

S

) and a ring relay contact. Functions with the Ring terminal to receive voice signals

from the telephone and for loop monitoring purposes.

3

2

31

RING

An analog input connected to the RING (more negative) side of the subscriber loop through a

sense resistor (R

S

) and a ring relay contact. Functions with the Tip terminal to receive voice

signals from the telephone and for loop monitoring purposes.

4

3

32

RFS

Senses ring side of loop for ground key and ring trip detection. During ringing, the ring signal is

inserted into the line at this node and RF is isolated from RFS via a relay.

5

4

1

V

B

+

Positive Voltage Source - Most positive supply. V

B

+ is typically.

6

5

3

C

1

Capacitor #1 - An external capacitor to be connected between this terminal and analog ground.

Required for proper operation of the loop current limiting function, and for filtering V

B

-. Typical

value is 0.3

µ

F, 30V.

7

6

4

DG

Digital Ground - To be connected to zero potential and serves as a reference for all digital inputs

and outputs on the SLIC microcircuit.

9

7

5

RS

Ring Synchronization Input - A TTL - compatible clock input. The clock should be arranged such

that a positive pulse transition occurs on the zero crossing of the ring voltage source, as it

appears at the RFS terminal. For Tip side injected systems, the RS pulse should occur on the

negative going zero crossing and for Ring injected systems, on the positive going zero crossing.

This ensures that the ring relay activates and deactivates when the instantaneous ring voltage

is near zero. If synchronization is not required, the pin should be tied to 5V.

10

8

6

RD

Relay Driver - A low active open collector logic output. When enabled, the external ring relay is

energized.

11

9

7, 8

TF

Tip Feed - A low impedance analog output connected to the TIP terminal through a sense

resistor (R

S

). Functions with the RF terminal to provide loop current, feed voice signals to the

telephone set, and sink longitudinal current.

12

10

9, 10

RF

Ring Feed - A low impedance analog output connected to the RING terminal through a sense

resistor (R

S

). Functions with the TF terminal to provide loop current, feed voice signals to the

telephone set, and sink longitudinal current.

13

11

11

V

B

-

Negative Voltage Source - Most negative supply. V

B

- is typically -48V with an operational range

of -42V to -58V. Frequently referred to as "battery".

14

12

12

BG

Battery Ground - To be connected to zero potential. All loop current and some quiescent current

flows into this ground terminal.

HC5503PRC

5

16

13

13

SHD

Switch Hook Detection - A low active LS TTL - compatible logic output. This output is enabled

for loop currents exceeding the switch hook threshold.

17

14

14,19

NC

Used during production test. Leave disconnected.

18

15

15

PD

Power Denial - A low active TTL - Compatible logic input. When enabled, the ring feed voltage

collapses to the tip feed voltage (~4V). The DC feed is disabled, but the AC transmission is

maintained. The switch hook detect (SHD) is not necessarily valid, and the relay driver (RD)

output is disabled.

19

16

16

RC

Ring Command - A low active TTL - Compatible logic input. When enabled, the relay driver (RD)

output goes low on the next high level of the ring sync (RS) input, as long as the SLIC is not in

the power denial state (PD = 0) or the subscriber is not already off- hook (SHD = 0).

20

17

NC

Leave disconnected.

21

18

20

OUT

The analog output of the spare operational amplifier.

23

19

21

-IN

The inverting analog input of the spare operational amplifier.

24

20

22

+IN

The non-inverting analog input of the spare operational amplifier.

25

21

23

RX

Receive Input, Four Wire Side - A high impedance analog input which is internally biased.

Capacitive coupling to this input is required. AC signals appearing at this input differentially drive

the Tip feed and Ring feed terminals.

26

22

25

C

2

Capacitor #2 - An external capacitor to be connected between this terminal and analog ground.

This capacitor is required for the proper operation of ring trip detection. Recommended value

0.82

µ

F

±

10% 10V non-polarized.

27

23

26

AG

Analog Ground - To be connected to zero potential and serves as a reference for the transmit

output (TX) and receive input (RX) terminals.

28

24

27

TX

Transmit Output, Four Wire Side - A low impedance analog output proportional to the loop

current. Transhybrid balancing must be performed beyond this output to completely implement

two to four wire conversion. This output is unbalanced and referenced to analog ground. Since

the DC level of this output varies with loop current, capacitive coupling to the next stage is

essential.

1, 8, 15, 22

2, 17,

18,24, 29,

30,

NC

No internal connection.

NOTE: All grounds (AG, BG, and DG) must be applied before V

B

+ or V

B

-. Failure to do so may result in premature failure of the part. If a user wishes

to run separate grounds off a line card, the AG must be applied first.

Pin Descriptions

(Continued)

28 PIN

PLCC

24 PIN

DIP/SOIC

7 x 7

QFN

SYMBOL

DESCRIPTION

HC5503PRC

6

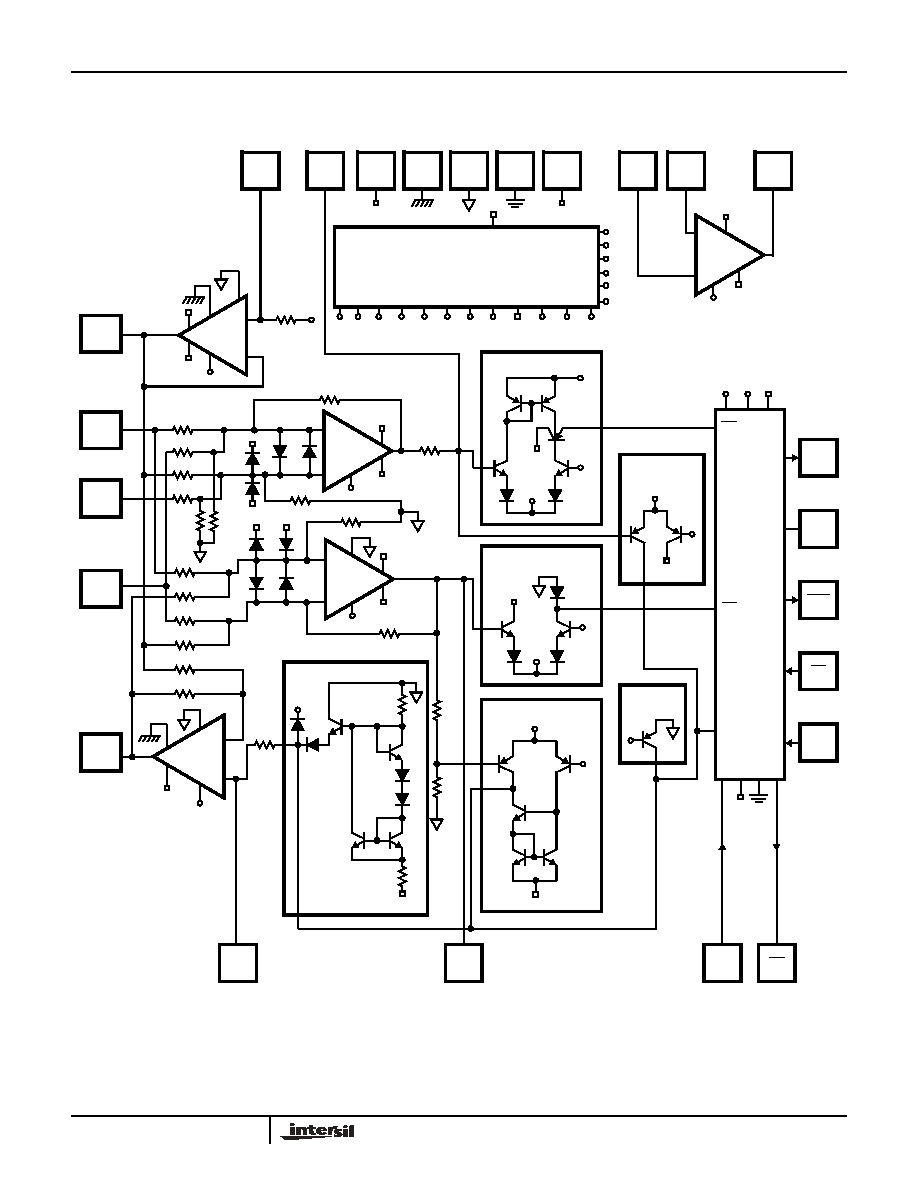

Functional Diagram

+

DIFF

AMP

+

OP

AMP

LOOP

MONITORING

RING

CONTROL

2-WIRE

LOOP

SECONDARY

PROTECTION

LINE

DRIVERS

TIP

RING

V

B

-

V

B

-

PD

POWER DENIAL

R

P

RING

R

S

RF

BG

TF

TIP

RD

RC

RS

RING SYNC

RING COMMAND

RING

TRIP

SHD

TX

TRANSMIT

OUTPUT

OUT

+IN

-IN

RX

RECEIVE

INPUT

SLIC MICROCIRCUIT

1/2 RING

RELAY

V

B

-

RING

VOLTAGE

RFS

1/2 RING

RELAY

R

S

SWITCH HOOK

DETECTION

-1

+1

BATTERY

FEED

LOOP

CURRENT

LIMITER

R

P

R

S

: 100

; 1/2W to 2W depending on surge requirements

R

P

: 50

; 1/2W to 2W depending on surge requirements

HC5503PRC

7

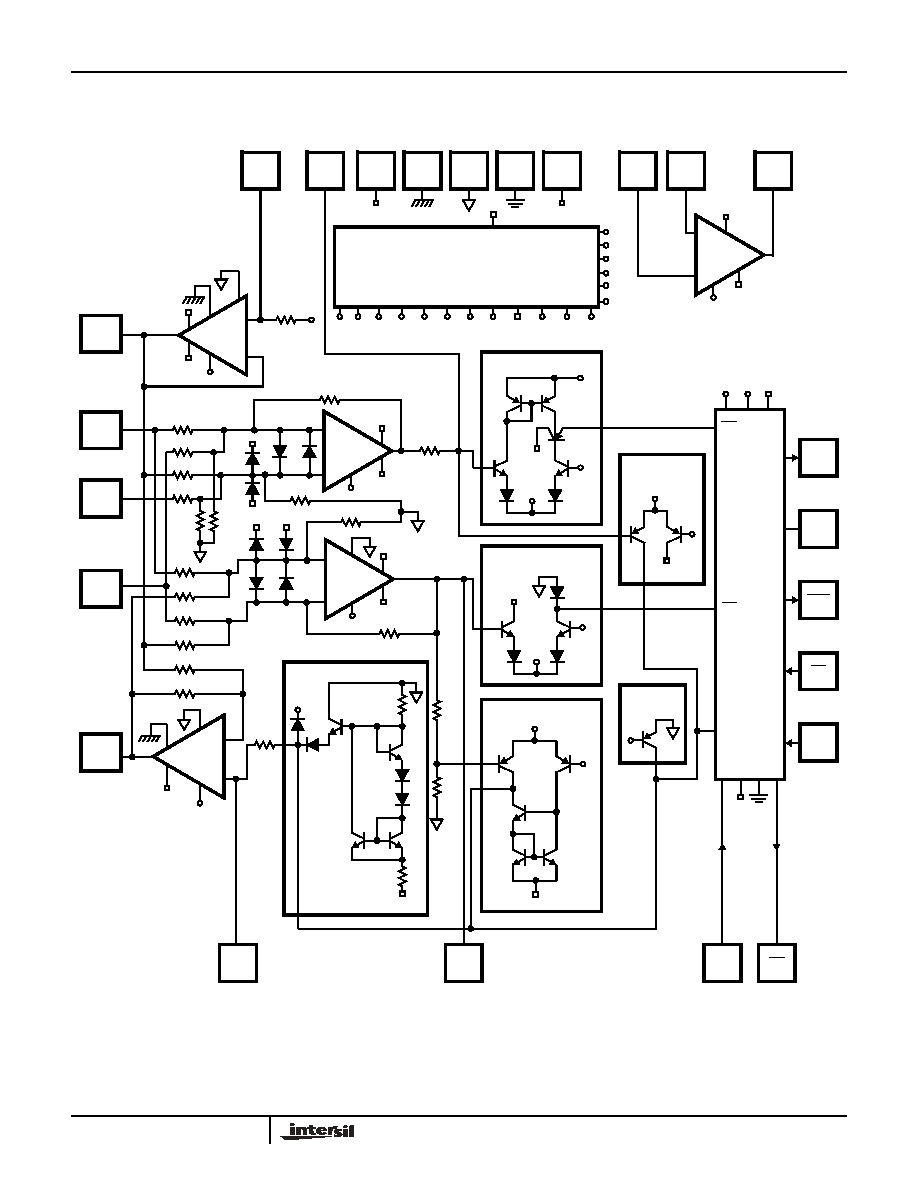

SLIC FUNCTIONAL SCHEMATIC

SOIC PIN NUMBERS SHOWN

V

B2

V

B1

V

B2

V

B3

V

B4

V

B5

5V

I

B1

I

B2

I

B3

I

B4

I

B5

I

B6

I

B7

I

B8

V

BAT

I

B9

I

B10

I

B11

V

B

+

V

B

+

A-100

TRANSV'L

I/V AMP

-

+

I

B6

R

6

R

5

R

11

V

B

+

R

7

R

8

R

10

R

9

R

22

R

23

R

3

R

4

R

1

R

2

R

16

R

15

V

BAT

V

BAT

R

12

V

BAT

V

B

+

A-200

LONG'L

I/V AMP

I

B7

-

+

R

20

V

BAT

V

B

+

A-400

TIP FEED

AMP

I

B4

-

+

RING

FEED

SENSE

V

BAT

V

BAT

5V

V

B4

I

B8

RING TRIP DETECTOR

+

SWITCH HOOK

V

B1

I

B6

+

R

18

DETECTOR

V

B

+

Q

D28

Q

D27

V

BAT

-

+

-

GND SHORTS

CURRENT

LIMITING

I

B1

V

B3

THERMAL

LIMITING

V

B5

STTL

AND LOGIC

INTERFACE

RFC

SH

GK

V

B5

-

+

I

B2

LOAD CURRENT

LIMITING

R

14

R

13

V

BAT

V

BAT/2

REFERENCE

R

21

V

BAT

A-300

RING FEED

AMP

I

B5

-

+

RING

RF

TIP

TF

10

2

3

1

9

RX

C2

V

BAT

BAT

ANA

DIG

V

B

+

GND

GND

GND

21

22

11

12

23

6

4

+

-

OUT

20

19

18

A-500

OP AMP

V

BAT

I

B3

V

B

+

V

B

+

5V I

B10

V

BAT

PD

15

RC

SHD

NC

NC

16

13

17

14

TX

C1

RS

RD

8

7

24

5

R

17

V

B2

V

B

+

R

19

V

BAT

Q

D3

Q

D36

VOLTAGE AND CURRENT

BIAS NETWORK

HC5503PRC

8

Surge Protection

The SLIC device, in conjunction with an external protection

bridge, will withstand high voltage lightning surges and

power line crosses.

The voltage withstand capability of pins `Tip', `Ring' and

`RFs' is

±

450V with respect to ground, as shown in Table 1.

This device is intended for use with an appropriate

secondary protection circuit scheme.

The SLIC will withstand longitudinal currents up to a

maximum or 30mA

RMS

, 15mA

RMS

per leg, without any

performance degradation.

LOGIC GATE SCHEMATIC

15

5

6

12

4

16

13

A

B

C

C

B

A

TTL

TO

STTL

TTL

TO

STTL

TTL

TO

STTL

TO

R

21

SHD

RD

PD

RC

RS

TTL

TO

STTL

DELAY

LOGIC BIAS

RELAY

DRIVER

SH

GK

11

14

3

9

7

8

10

2

1

SCHOTTKY LOGIC

TABLE 1.

PARAMETER

TEST

CONDITION

PERFORMANCE

(MAX)

UNITS

Longitudinal Surge 10

µ

s Rise/

1000

µ

s Fall

±

450 (Plastic)

V

PEAK

Metallic Surge

10

µ

s Rise/

1000

µ

s Fall

±

450 (Plastic)

V

PEAK

T/GND

R/GND

10

µ

s Rise/

1000

µ

s Fall

±

450 (Plastic)

V

PEAK

50/60Hz Current

T/GND

R/GND

11 Cycles

Limited to

10A

RMS

315 (Plastic)

V

RMS

HC5503PRC

9

HC5503PRC

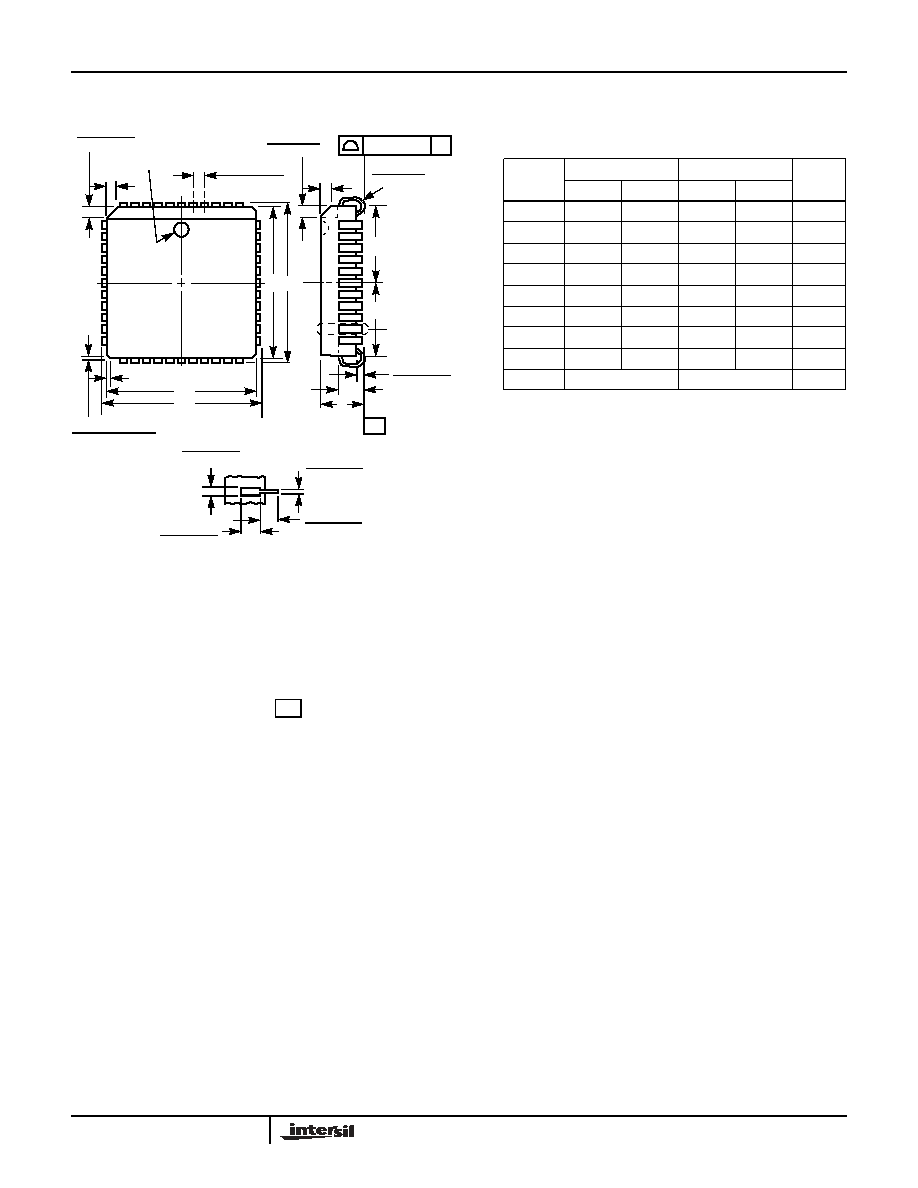

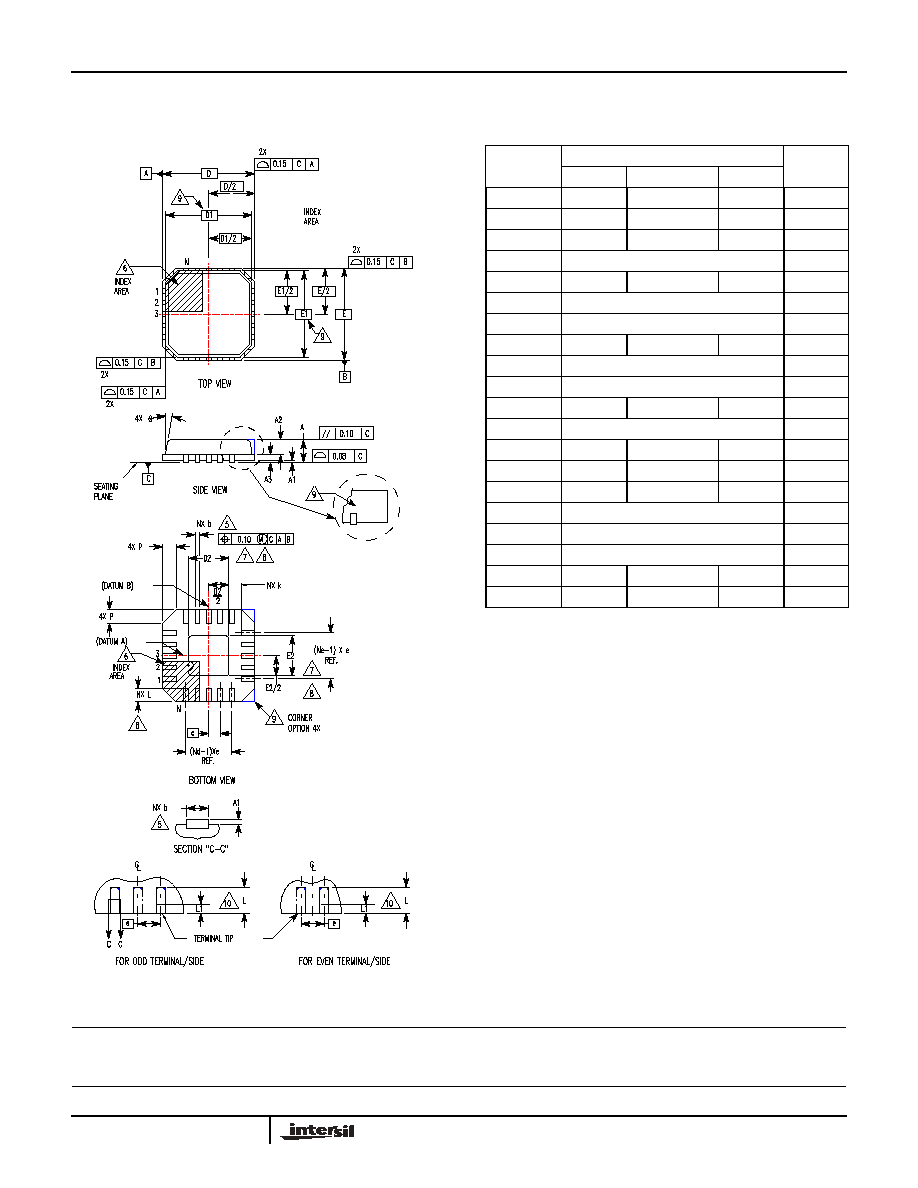

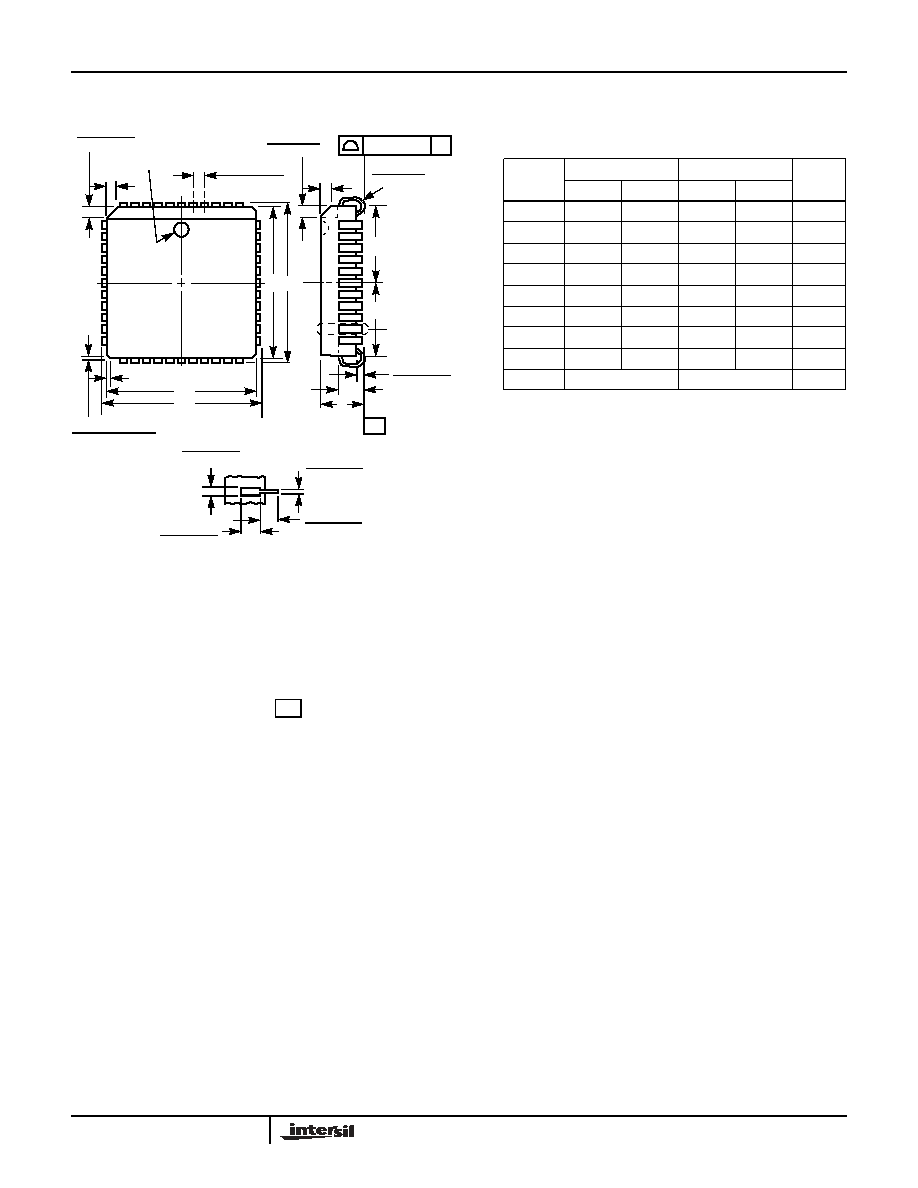

Plastic Leaded Chip Carrier Packages (PLCC)

NOTES:

1. Controlling dimension: INCH. Converted millimeter dimensions are

not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. Dimensions D1 and E1 do not include mold protrusions. Allowable

mold protrusion is 0.010 inch (0.25mm) per side. Dimensions D1

and E1 include mold mismatch and are measured at the extreme

material condition at the body parting line.

4. To be measured at seating plane

contact point.

5. Centerline to be determined where center leads exit plastic body.

6. "N" is the number of terminal positions.

-C-

A1

A

SEATING

PLANE

0.020 (0.51)

MIN

VIEW "A"

D2/E2

0.025 (0.64)

0.045 (1.14)

R

0.042 (1.07)

0.056 (1.42)

0.050 (1.27) TP

E

E1

0.042 (1.07)

0.048 (1.22)

PIN (1) IDENTIFIER

CL

D1

D

0.020 (0.51) MAX

3 PLCS

0.026 (0.66)

0.032 (0.81)

0.045 (1.14)

MIN

0.013 (0.33)

0.021 (0.53)

0.025 (0.64)

MIN

VIEW "A" TYP.

0.004 (0.10)

C

-C-

D2/E2

CL

N28.45

(JEDEC MS-018AB ISSUE A)

28 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.165

0.180

4.20

4.57

-

A1

0.090

0.120

2.29

3.04

-

D

0.485

0.495

12.32

12.57

-

D1

0.450

0.456

11.43

11.58

3

D2

0.191

0.219

4.86

5.56

4, 5

E

0.485

0.495

12.32

12.57

-

E1

0.450

0.456

11.43

11.58

3

E2

0.191

0.219

4.86

5.56

4, 5

N

28

28

6

Rev. 2 11/97

10

HC5503PRC

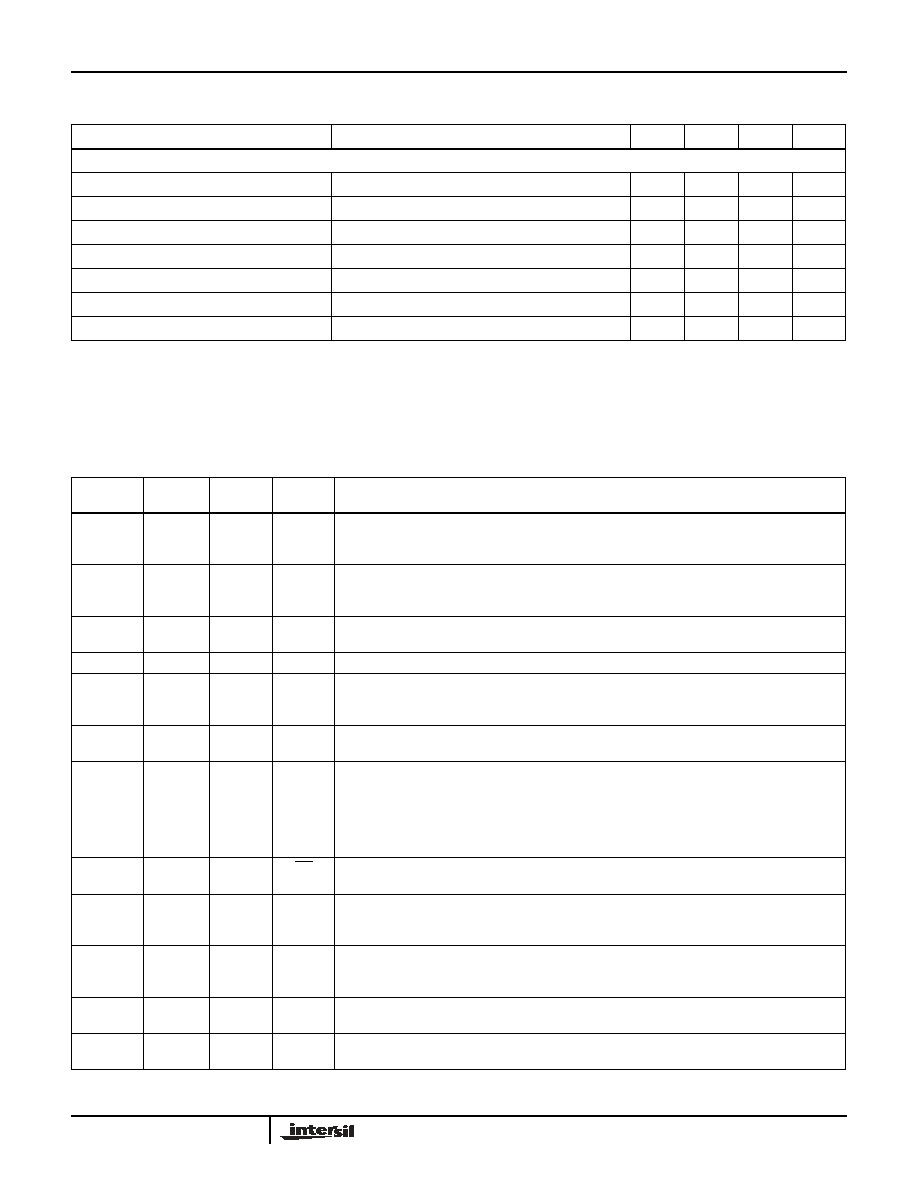

Small Outline Plastic Packages (SOIC)

NOTES:

1. Symbols are defined in the "MO Series Symbol List" in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension "E" does not include interlead flash or protrusions. Inter-

lead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. "L" is the length of terminal for soldering to a substrate.

7. "N" is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width "B", as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

µ

0.25(0.010)

B

M

M

M24.3

(JEDEC MS-013-AD ISSUE C)

24 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.0926

0.1043

2.35

2.65

-

A1

0.0040

0.0118

0.10

0.30

-

B

0.013

0.020

0.33

0.51

9

C

0.0091

0.0125

0.23

0.32

-

D

0.5985

0.6141

15.20

15.60

3

E

0.2914

0.2992

7.40

7.60

4

e

0.05 BSC

1.27 BSC

-

H

0.394

0.419

10.00

10.65

-

h

0.010

0.029

0.25

0.75

5

L

0.016

0.050

0.40

1.27

6

N

24

24

7

0

o

8

o

0

o

8

o

-

Rev. 0 12/93

11

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation's quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

HC5503PRC

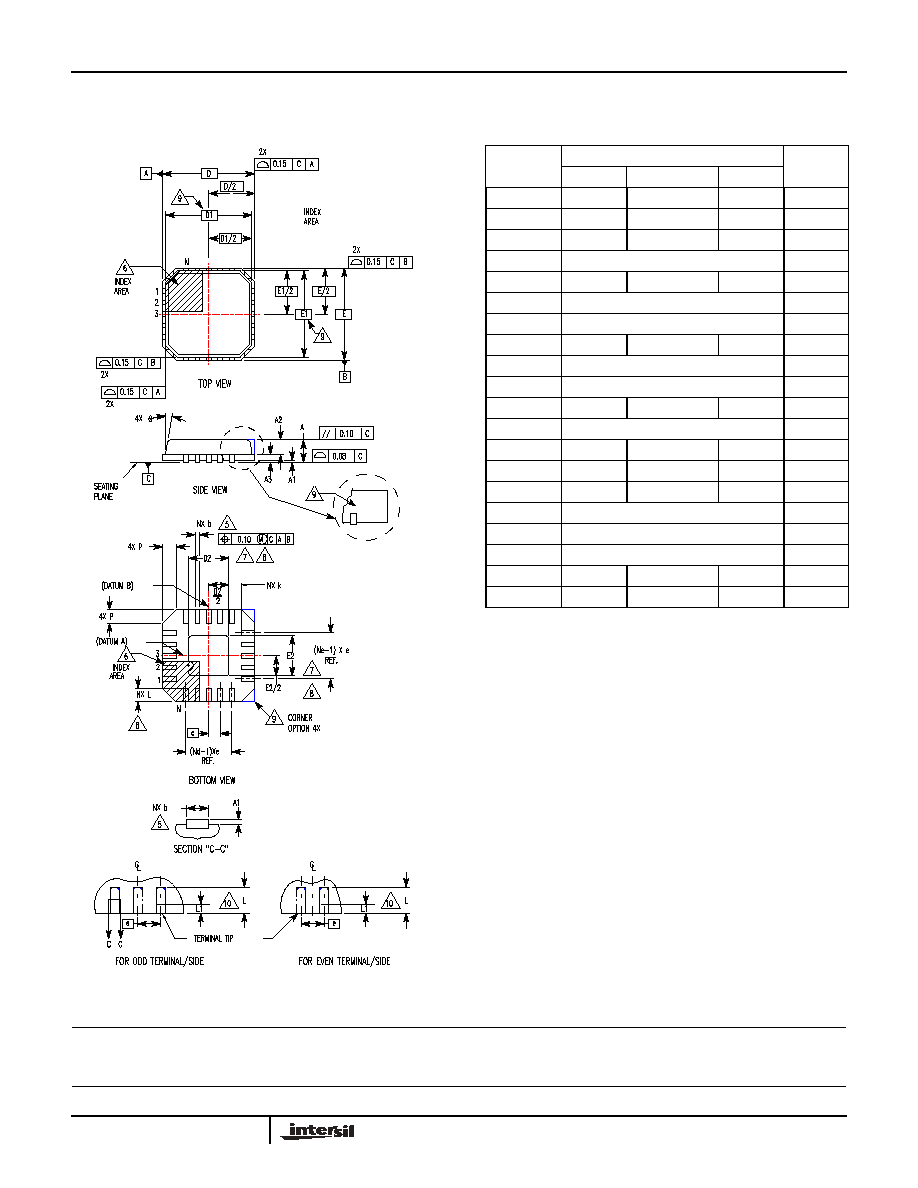

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

L32.7x7A

32 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220VKKC ISSUE C)

SYMBOL

MILLIMETERS

NOTES

MIN

NOMINAL

MAX

A

0.80

0.90

1.00

-

A1

-

-

0.05

-

A2

-

-

1.00

9

A3

0.20 REF

9

b

0.23

0.28

0.38

5, 8

D

7.00 BSC

-

D1

6.75 BSC

9

D2

4.95

5.10

5.25

7, 8

E

7.00 BSC

-

E1

6.75 BSC

9

E2

4.95

5.10

5.25

7, 8

e

0.65 BSC

-

k

0.25

-

-

-

L

0.35

0.60

0.75

8

L1 -

-

0.15

10

N

32

2

Nd

8

3

Ne

8

3

P

-

-

0.60

9

-

-

12

9

Rev. 1 10/02

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P &

are present when

Anvil singulation method is used and not present for saw

singulation.

10. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.