1

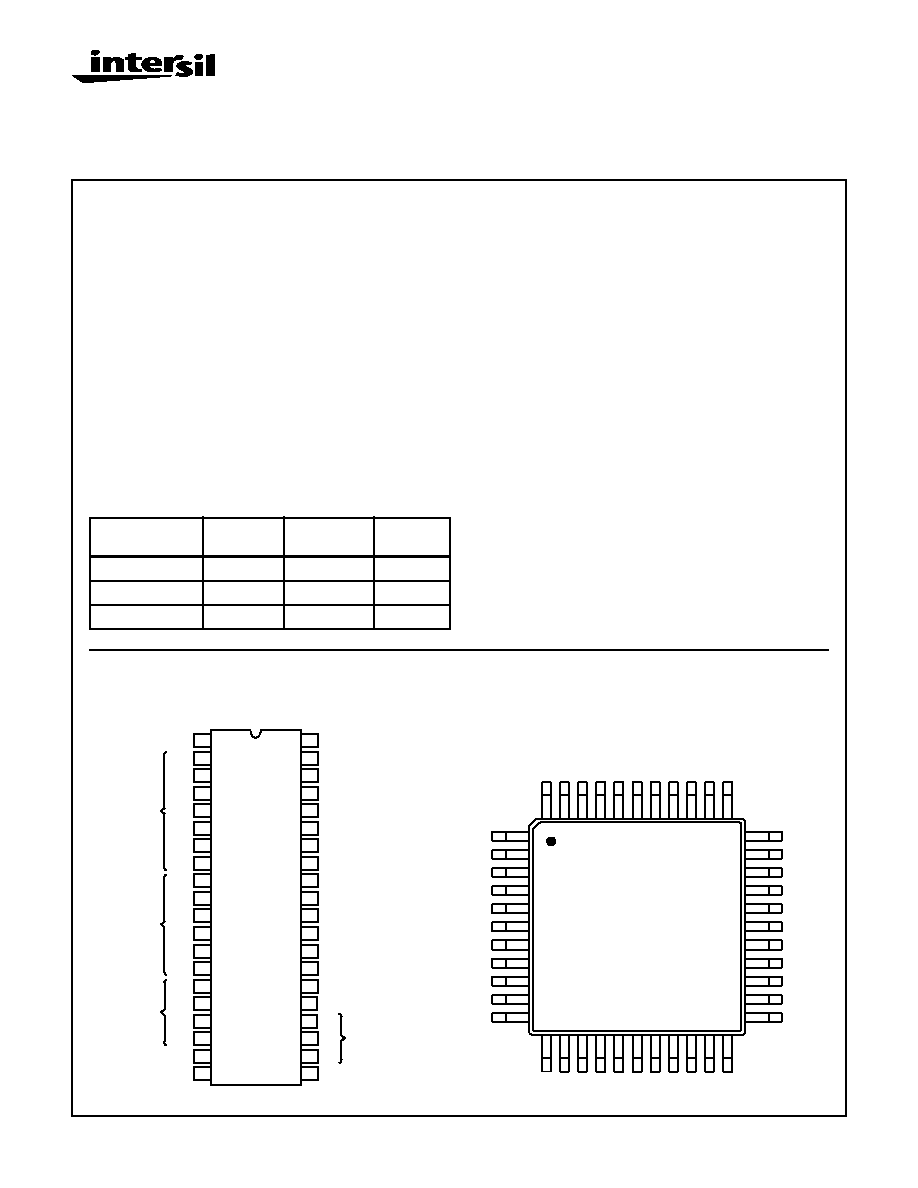

ICL7116, ICL7117

3

1

/

2

Digit, LCD/LED Display,

A/D Converter with Display Hold

January 1998

Features

∑ HOLD Reading Input Allows Indefinite Display Hold

∑ Guaranteed Zero Reading for 0V Input

∑ True Polarity at Zero for Precise Null Detection

∑ 1pA Typical Input Current

∑ Direct Display Drive

- LCD ICL7116

- LED lCL7117

∑ Low Noise - Less Than 15

µ

V

P-P

(Typ)

∑ On Chip Clock and Reference

∑ Low Power Dissipation - Typically Less Than 10mW

∑ No Additional Active Circuits Required

∑ Surface Mount Package Available

Description

The Intersil ICL7116 and ICL7117 are high performance, low

power, 3

1

/

2

digit, A/D converters. Included are seven segment

decoders, display drivers, a reference, and a clock. The

ICL7116 is designed to interface with a liquid crystal display

(LCD) and includes a multiplexed backplane drive. The

ICL7117 will directly drive an instrument size, light emitting

diode (LED) display.

The ICL7116 and ICL7117 have all of the features of the

ICL7106 and ICL7107 with the addition of a HOLD Reading

input. With this input, it is possible to make a measurement

and retain the value on the display indefinitely. To make room

for this feature the reference low input has been connected

to Common internally rather than being fully differential.

These circuits retain the accuracy, versatility, and true econ-

omy of the ICL7106 and ICL7107. They feature auto-zero to

less than 10

µ

V, zero drift of less than 1

µ

V/

o

C, input bias cur-

rent of 10pA maximum, and roll over error of less than one

count. The versatility of true differential input is of particular

advantage when measuring load cells, strain gauges and

other bridge-type transducers. And finally, the true economy

of single power supply operation (ICL7116) enables a high

performance panel meter to be built with the addition of only

eleven passive components and a display.

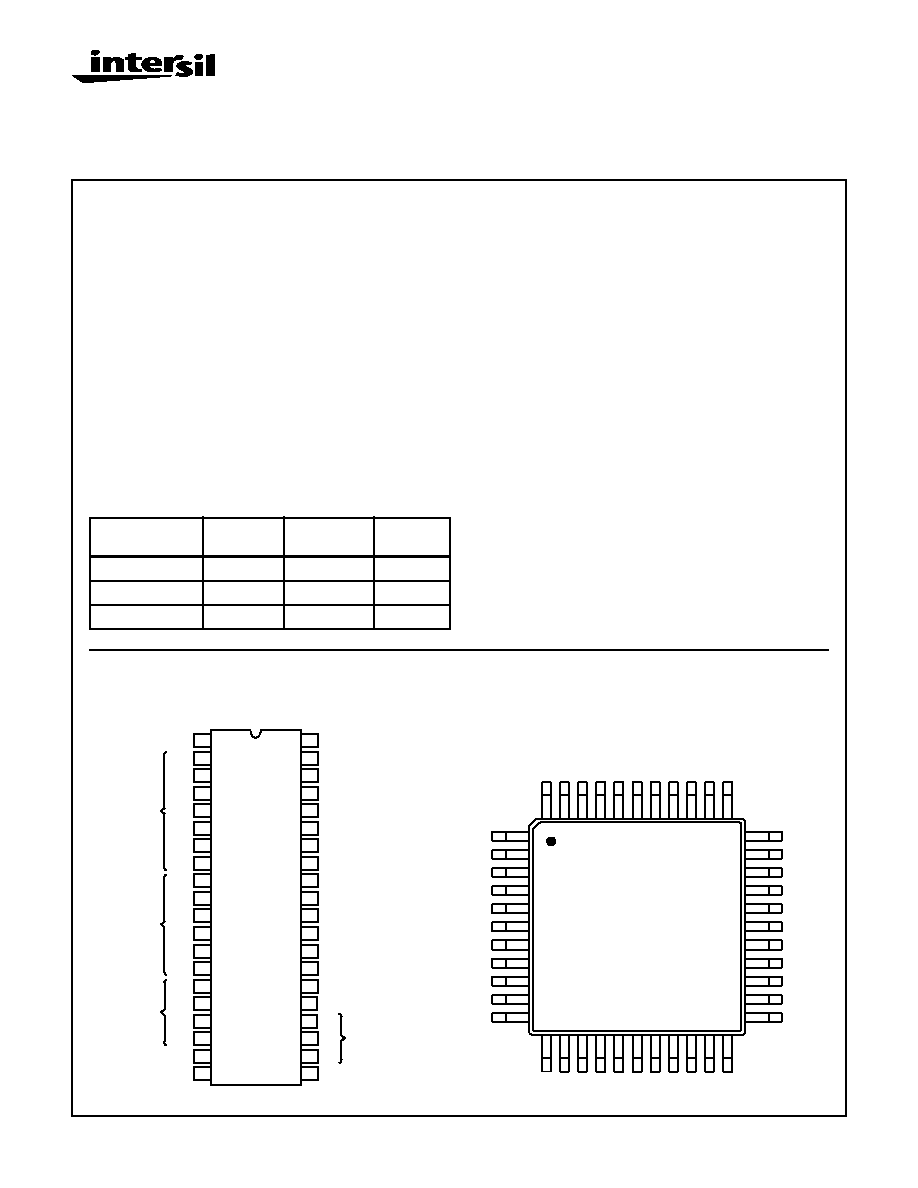

Pinouts

Ordering Information

PART NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG. NO.

ICL7116CPL

0 to 70

40 Ld PDIP

E40.6

ICL7116CM44

0 to 70

44 Ld MQFP

Q44.10x10

ICL7117CPL

0 to 70

40 Ld PDIP

E40.6

ICL7116, ICL7117 (PDIP)

TOP VIEW

ICL7116 (MQFP)

TOP VIEW

13

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

HLDR

D1

C1

B1

A1

F1

G1

E1

D2

C2

B2

A2

F2

E2

D3

B3

F3

E3

(1000) AB4

POL

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

+

C

REF

-

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V-

G2 (10's)

C3

A3

G3

BP/GND

(1's)

(10's)

(100's)

(MINUS)

(100's)

OSC 2

NC

OSC 3

TEST

NC

NC

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17

OSC 1

HLDR

D1

C1

B1

A1 F1 G1 E1 D2 C2

28

27

26

25

24

23

22

21

20

19

18

B2 A2 F2 E2 D3

B3

F3

E3

AB4

POL

BP

39 38 37 36 35 34

33

32

31

30

29

44 43 42 41 40

IN HI

IN LO

A-Z

B

UFF

INT

V-

NC

G2

C3

A3

G3

REF HI

V+

C

REF

+

C

REF

-

COMMON

File Number

3083.2

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

|

Copyright

©

Intersil Corporation 1999

2

Absolute Maximum Ratings

Thermal Information

Supply Voltage

ICL7116, V+ to V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

ICL7117, V+ to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6V

ICL7117, V- to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-9V

Analog Input Voltage (Either Input) (Note 1). . . . . . . . . . . . . V+ to V-

Reference Input Voltage (Either Input) . . . . . . . . . . . . . . . . . V+ to V-

Clock Input

ICL7116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TEST to V+

ICL7117 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND to V+

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

o

C to 70

o

C

Thermal Resistance (Typical, Note 2)

JA

(

o

C/W)

PDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

MQFP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . .

80

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . .-65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300

o

C

(MQFP - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Input voltages may exceed the supply voltages provided the input current is limited to

±

100

µ

A.

2.

JA

is measured with the component mounted on an evaluation PC board in free air.

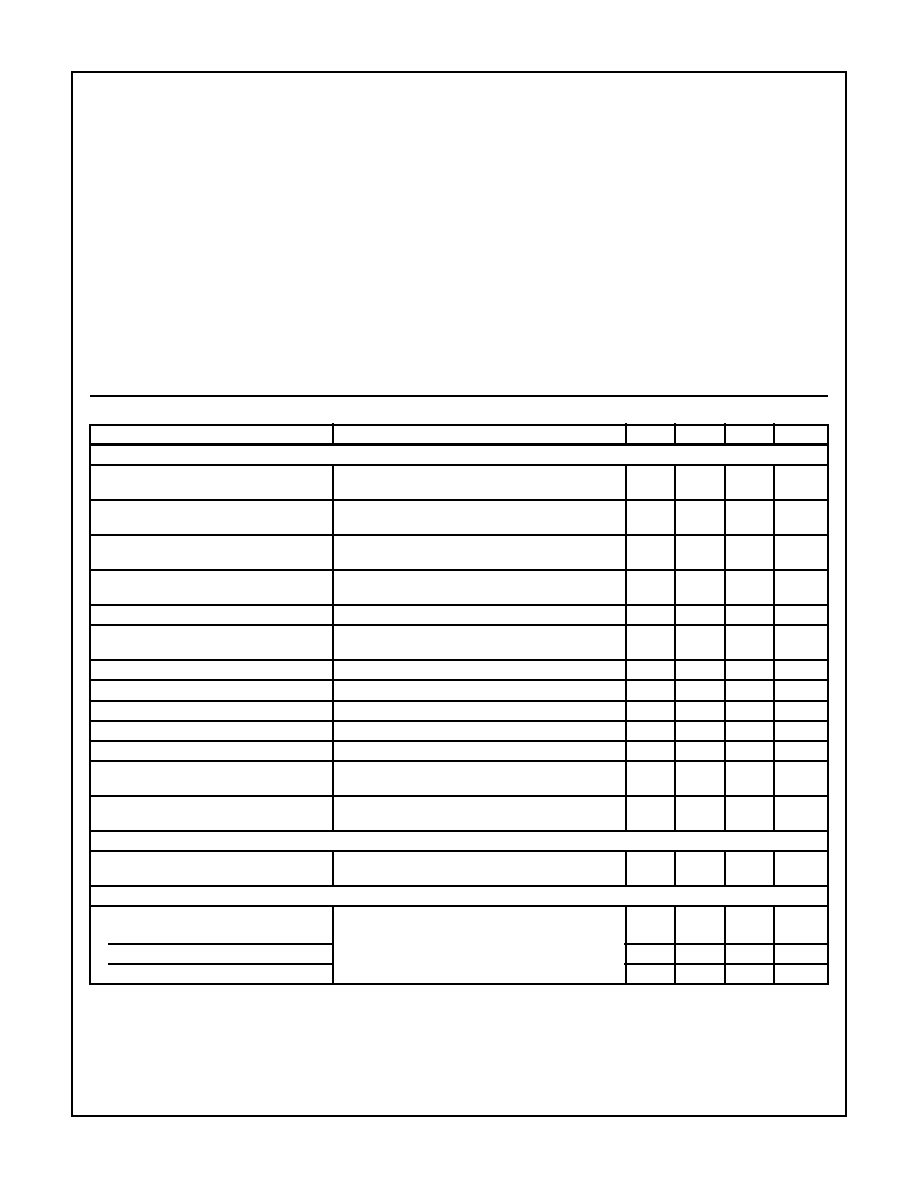

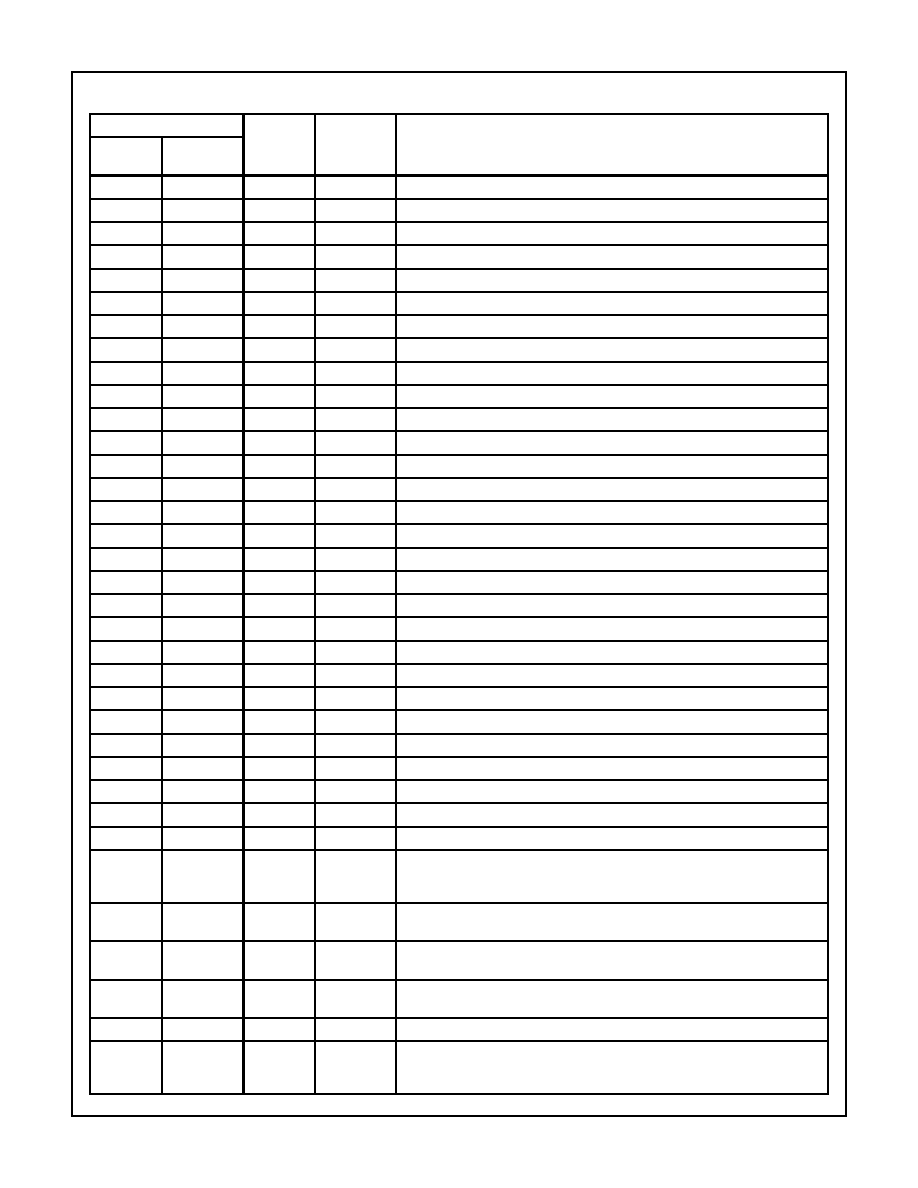

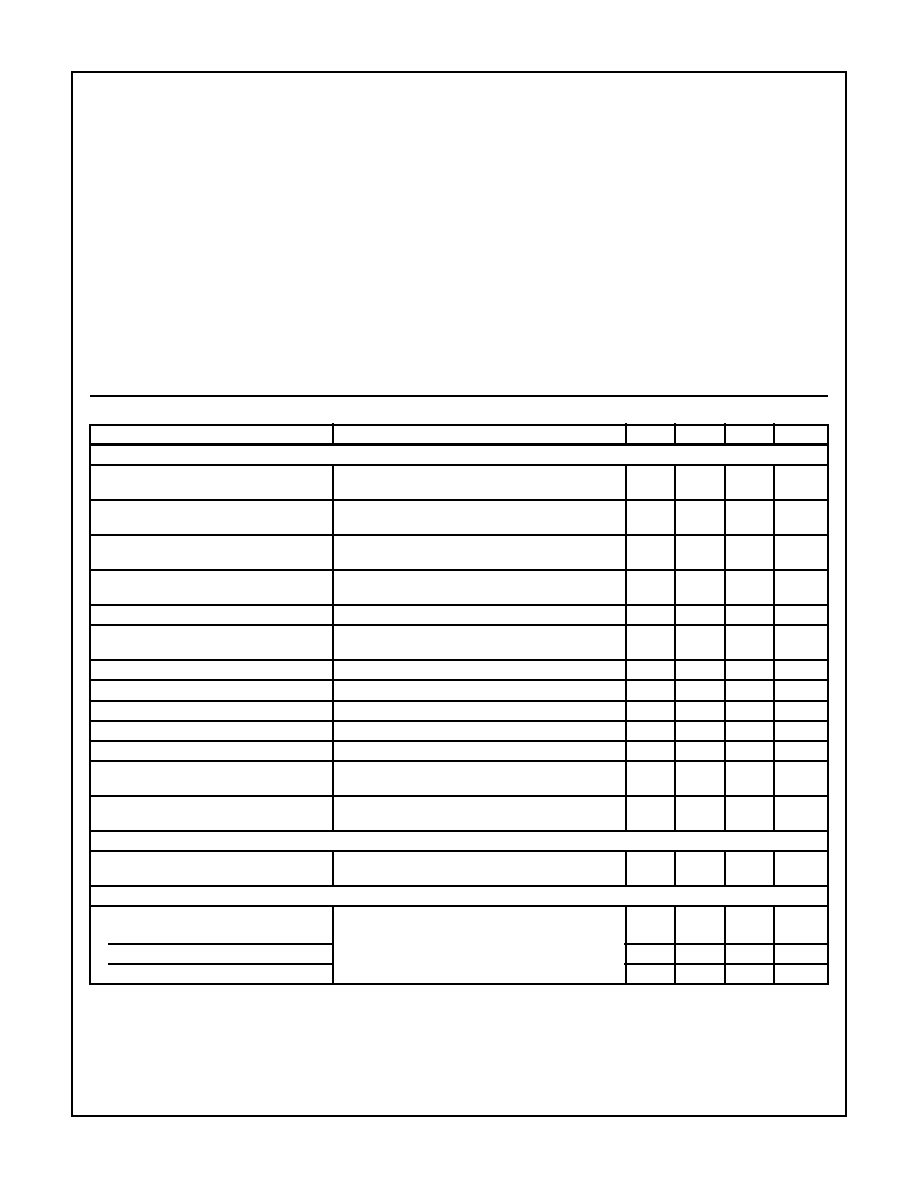

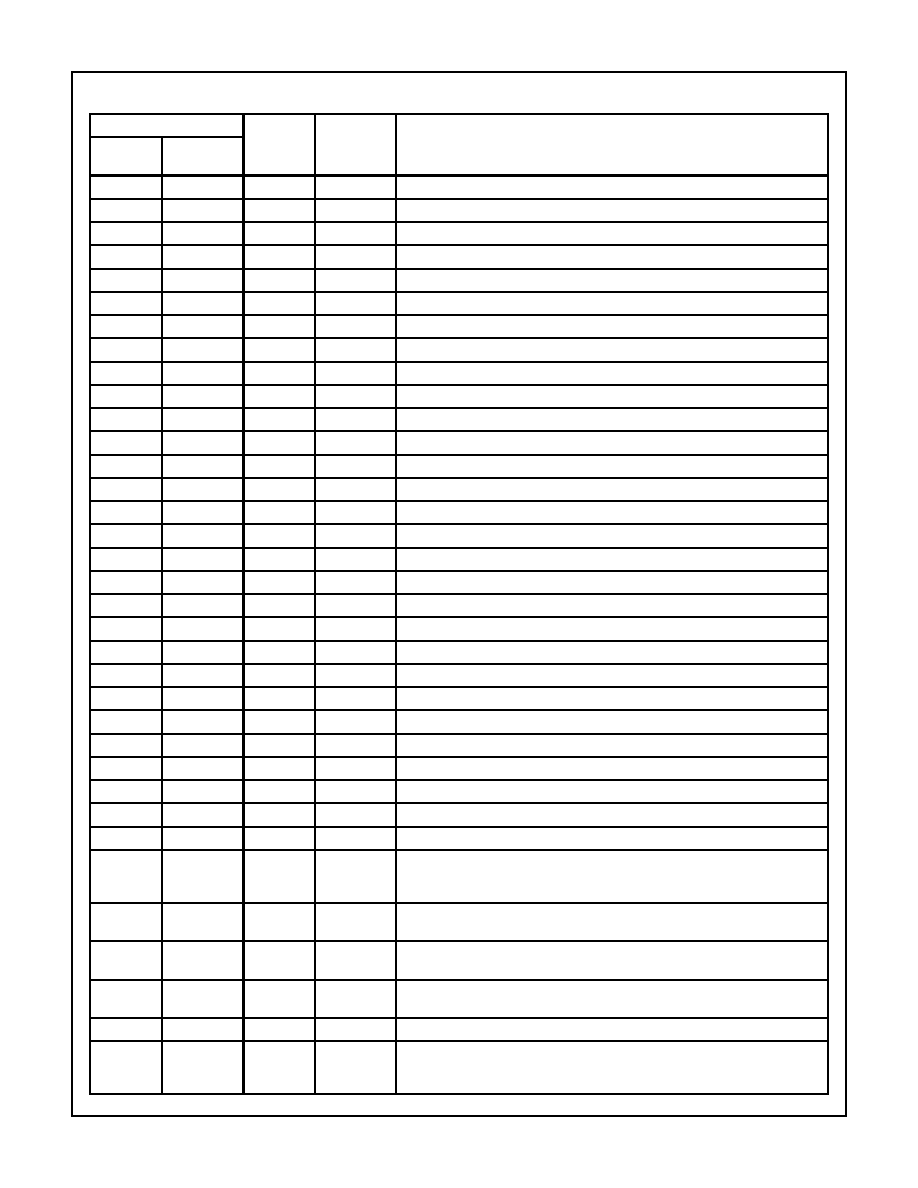

Electrical Specifications

(Note 3) T

A

= 25

o

C, f

CLOCK

= 48kHz, V

REF

= 100mV

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

SYSTEM PERFORMANCE

Zero Input Reading

V

IN

= 0V, Full Scale = 200mV

-000.0

±

000.0

+000.0

Digital

Reading

Ratiometric Reading

V

lN

= V

REF

, V

REF

= 100mV

999

999/

1000

1000

Digital

Reading

Rollover Error

-V

IN

= +V

lN

195mV Difference in Reading for Equal

Positive and Negative Inputs Near Full Scale

-

±

0.2

±

1

Counts

Linearity

Full Scale = 200mV or Full Scale = 2V Maximum

Deviation from Best Straight Line Fit (Note 5)

-

±

0.2

±

1

Counts

Common Mode Rejection Ratio

V

CM

=

±

1V, V

IN

= 0V, Full Scale = 200mV (Note 5)

-

50

-

µ

V/V

Noise

V

IN

= 0V, Full Scale = 200mV (Peak-To-Peak Value

Not Exceeded 95% of Time) (Note 5)

-

15

-

µ

V

Leakage Current Input

V

lN

= 0 (Note 5)

-

1

10

pA

Zero Reading Drift

V

lN

= 0, 0

o

C To

70

o

C (Note 5)

-

0.2

1

µ

V/

o

C

Scale Factor Temperature Coefficient

V

IN

= 199mV, 0

o

C To

70

o

C (Note 5)

-

1

5

ppm/

o

C

V+ Supply Current

V

IN

= 0 (Does Not Include LED Current for ICL7117)

-

1.0

1.8

mA

V- Supply Current

ICL7117 Only

-

0.6

1.8

mA

COMMON Pin Analog Common Voltage

25k

Between Common and Positive Supply (With

Respect to + Supply)

2.4

3.0

3.2

V

Temperature Coefficient of Analog Common

25k

Between Common and Positive Supply (With

Respect to + Supply) (Note 5)

-

80

-

ppm/

o

C

DISPLAY DRIVER (ICL7116 ONLY)

Peak-To-Peak Segment Drive Voltage

Peak-To-Peak Backplane Drive Voltage

V+ = to V- = 9V, (Note 4)

4

5.5

6

V

DISPLAY DRIVER (ICL7117 ONLY)

Segment Sinking Current

V+ = 5V, Segment Voltage = 3V

(Except Pins 19 and 20)

5

8

-

mA

Pin 19 Only

10

16

-

mA

Pin 20 Only

4

7

-

mA

NOTES:

3. Unless otherwise noted, specifications apply to both the ICL7116 and ICL7117. ICL7116 is tested in the circuit of Figure 1. ICL7117 is

tested in the circuit of Figure 2.

4. Back plane drive is in phase with segment drive for `off' segment, 180 degrees out of phase for `on' segment. Frequency is 20 times con-

version rate. Average DC component is less than 50mV.

5. Not tested, guaranteed by design.

ICL7116, ICL7117

3

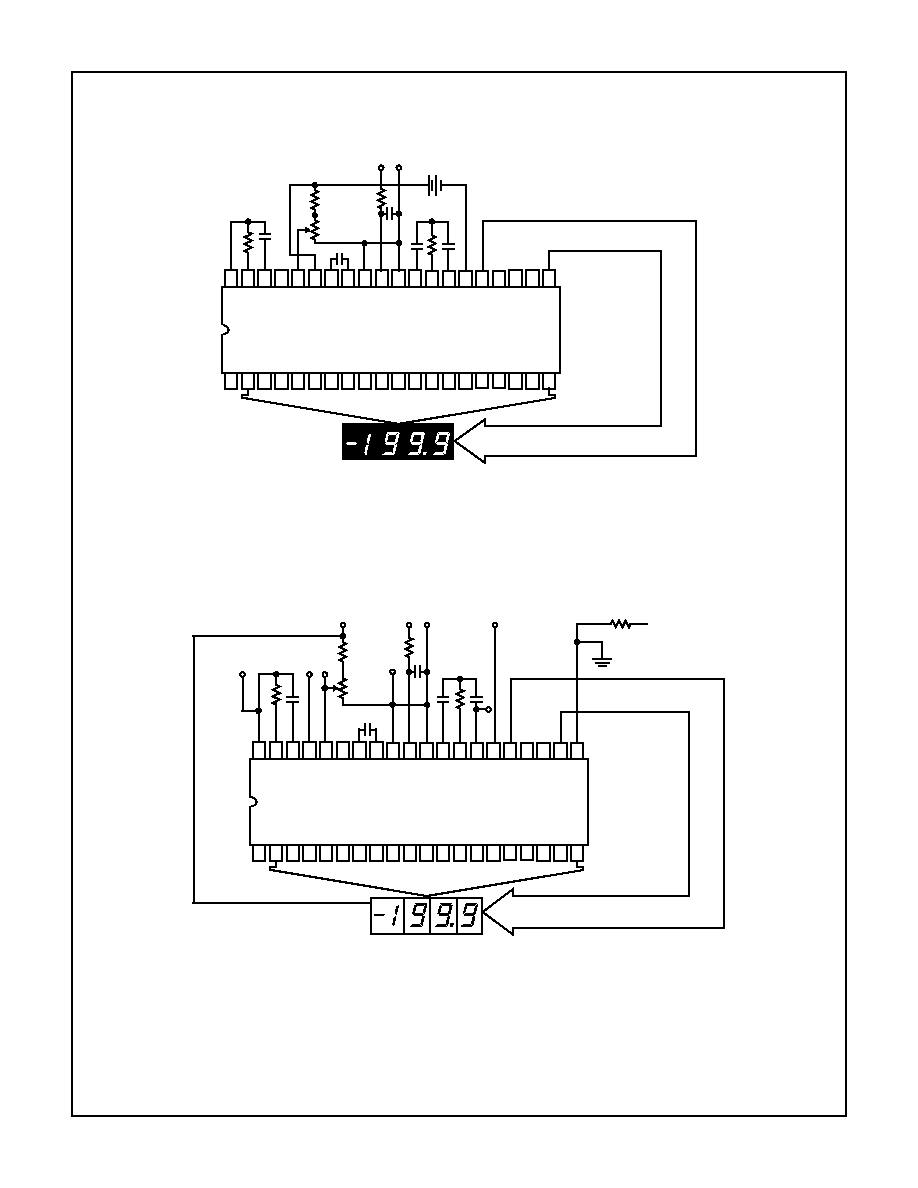

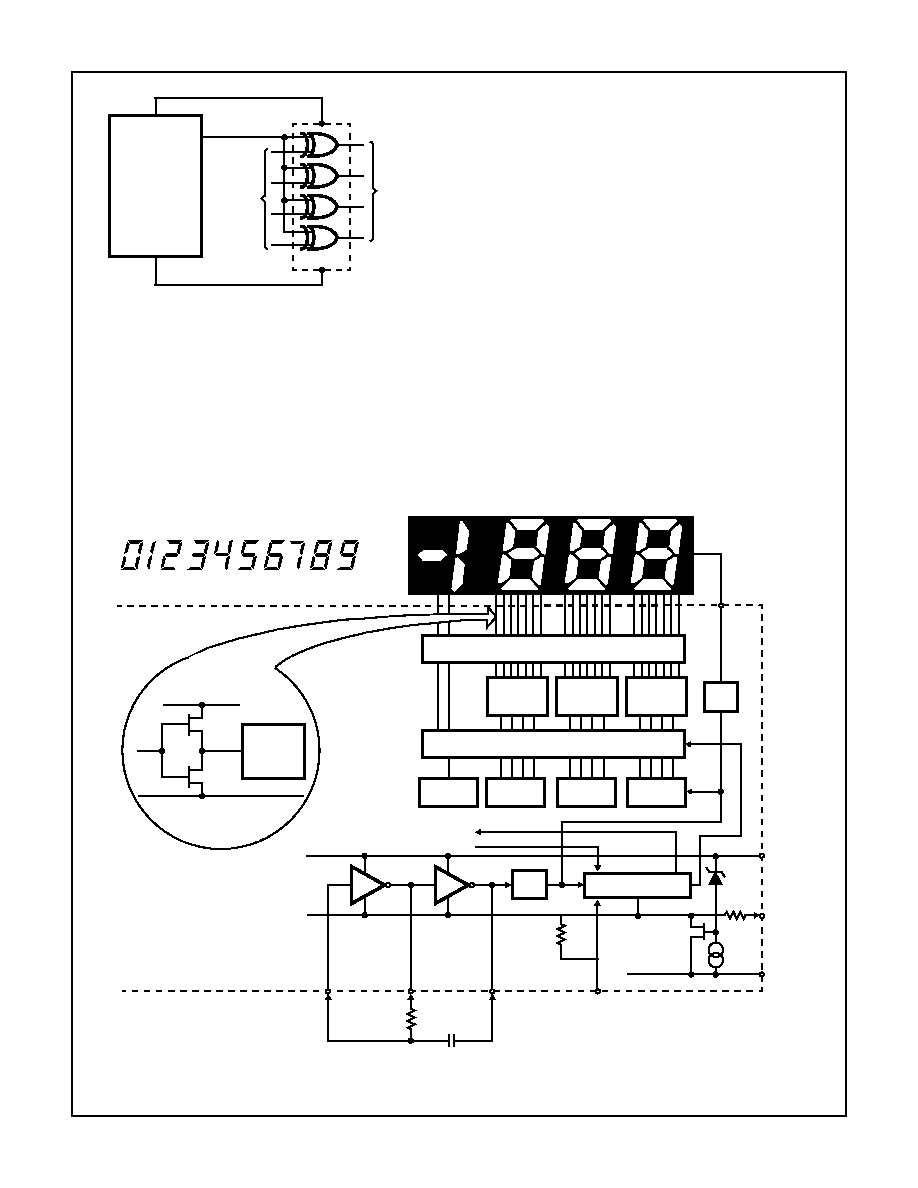

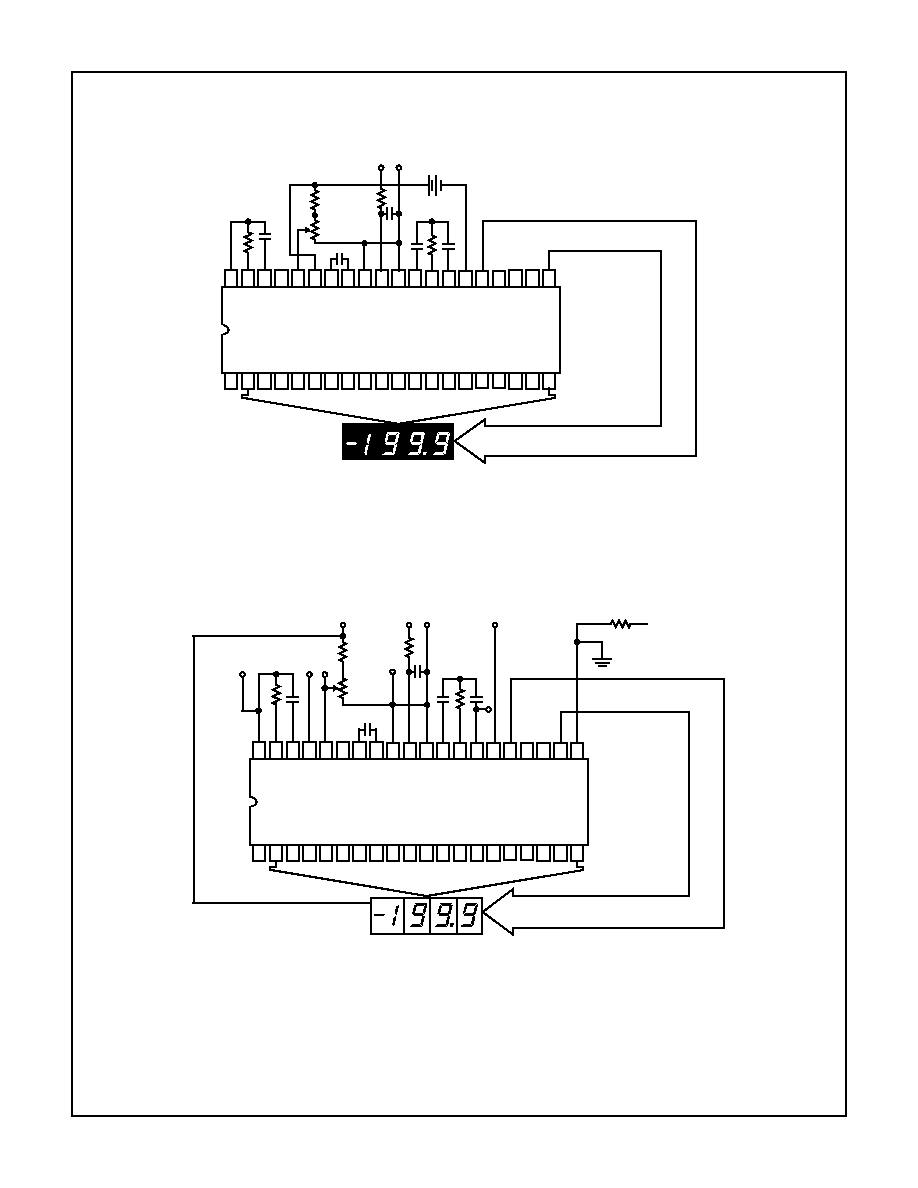

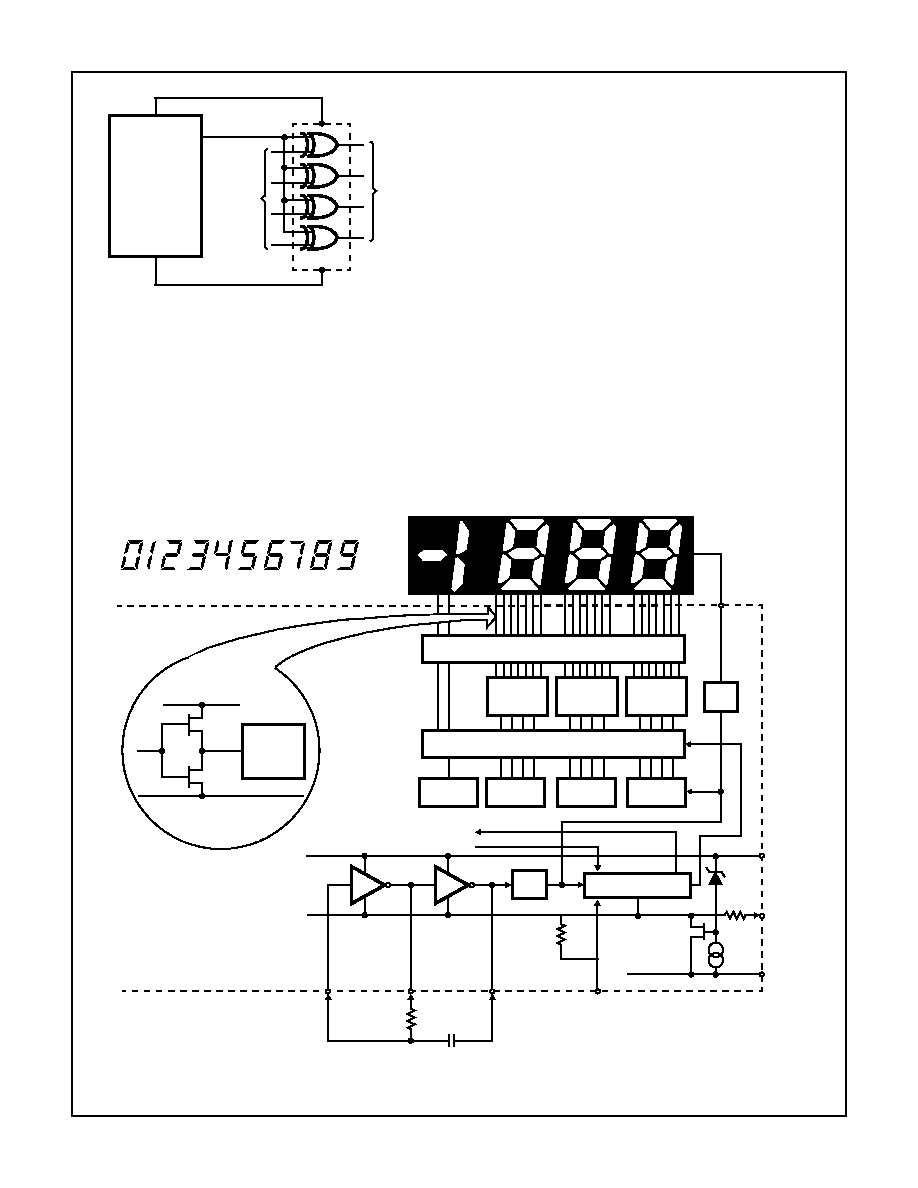

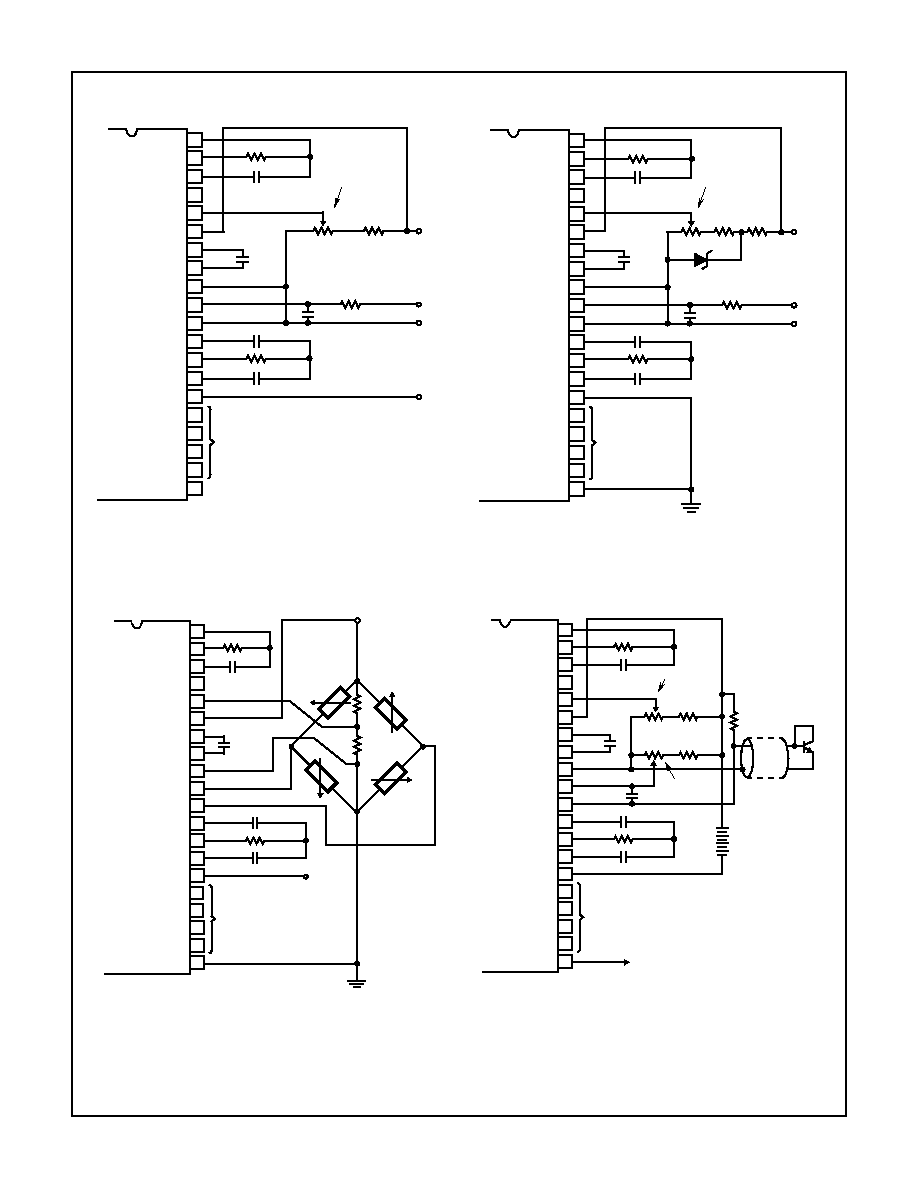

Typical Applications and Test Circuits

FIGURE 1. ICL7116 TEST CIRCUIT AND TYPICAL APPLICATION WITH LCD DISPLAY COMPONENTS SELECTED FOR 200mV

FULL SCALE

FIGURE 2. ICL7117 TEST CIRCUIT AND TYPICAL APPLICATION WITH LED DISPLAY COMPONENTS SELECTED FOR 200mV

FULL SCALE

13

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

HLDR

D1

C1

B1

A1

F1

G1

E1

D2

C2

B2

A2

F2

E2

D3

B3

F3

E3

AB4

POL

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

+

C

REF

-

COM

IN HI

IN LO

A-Z

B

UFF

INT

V-

G2

C3

A3

G3

BP

DISPLAY

DISPLAY

C

1

C

2

C

3

C

4

R

3

R

1

R

4

C

5

+

-

IN

R

5

R

2

ICL7116

C

1

= 0.1

µ

F

C

2

= 0.47

µ

F

C

3

= 22

µ

F

C

4

= 100pF

C

5

= 0.01

µ

F

R

1

= 24k

R

2

= 47k

R

3

= 100k

R

4

= 1k

R

5

= 1M

9V

+

-

13

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

HLDR

D1

C1

B1

A1

F1

G1

E1

D2

C2

B2

A2

F2

E2

D3

B3

F3

E3

AB4

POL

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

+

C

REF

-

COM

IN HI

IN LO

A-Z

B

UFF

INT

V-

G2

C3

A3

G3

GND

DISPLAY

DISPLAY

C

1

C

2

C

3

C

4

R

3

R

1

R

4

C

5

+

-

IN

R

5

R

2

ICL7117

+5V

-5V

TO

DECIMAL

POINT

R

6

TP

1

TP

2

TP

5

TP

4

TP

3

C

1

= 0.1

µ

F

C

2

= 0.47

µ

F

C

3

= 22

µ

F

C

4

= 100pF

C

5

= 0.01

µ

F

R

1

= 24k

R

2

= 47k

R

3

= 100k

R

4

= 1k

R

5

= 1M

R

6

= 150

ICL7116, ICL7117

4

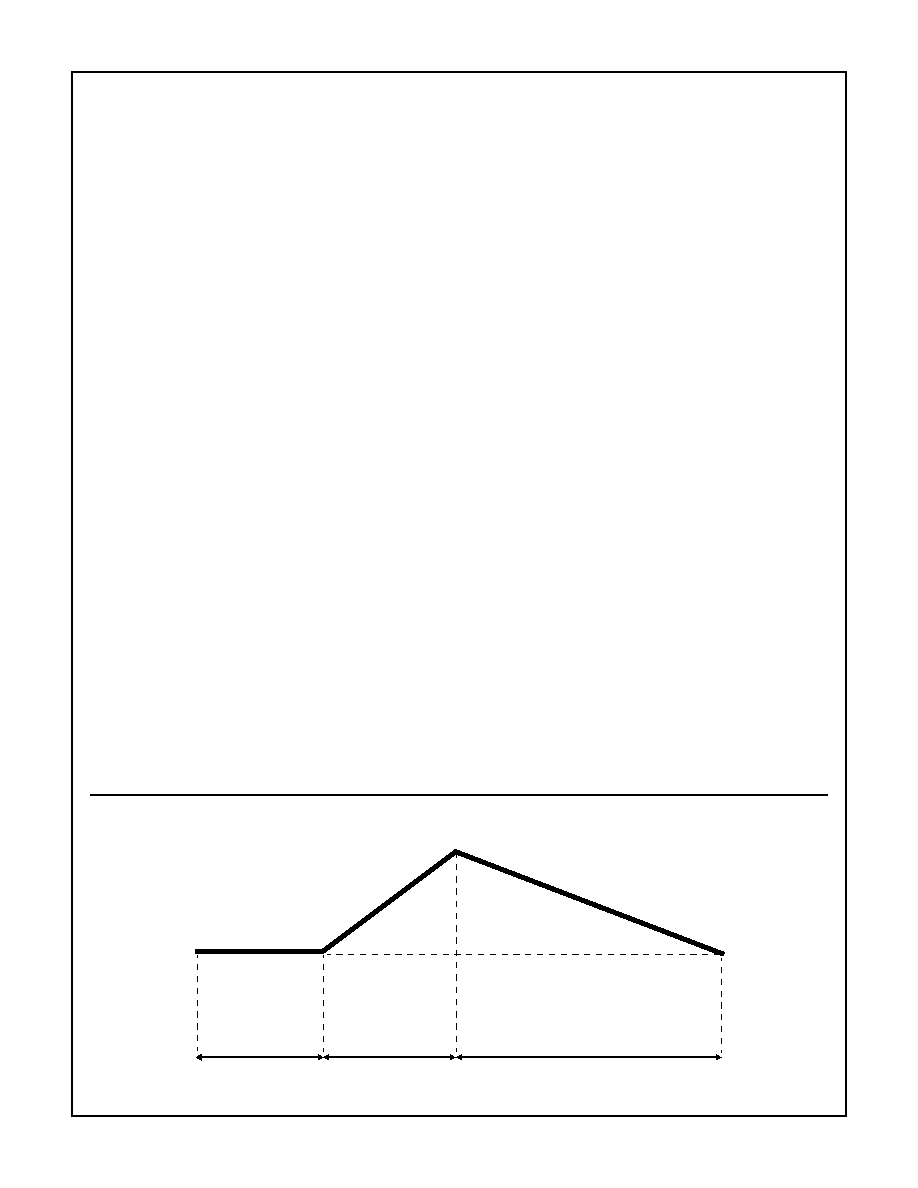

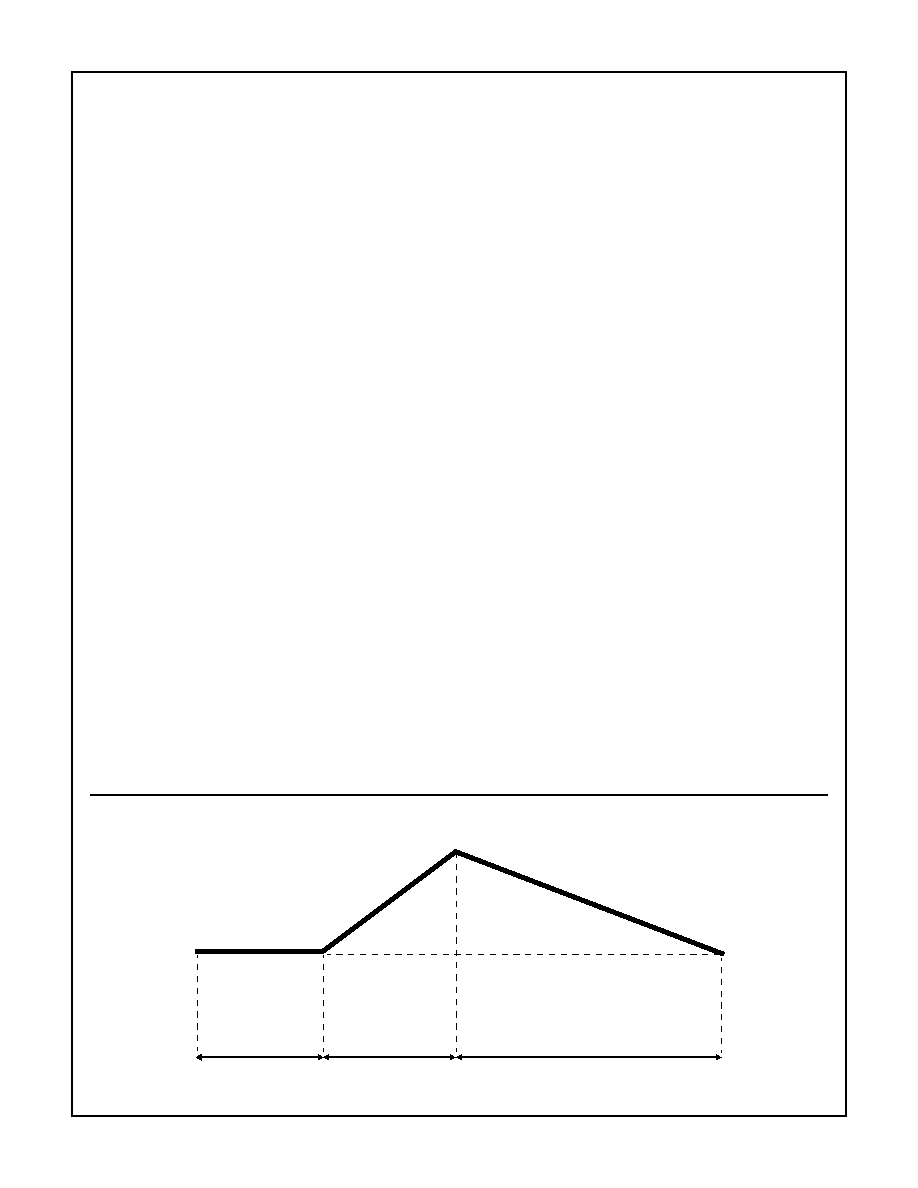

Typical Integrator Amplifier Output Waveform (INT Pin)

Design Information Summary Sheet

∑ OSCILLATOR FREQUENCY

f

OSC

= 0.45/RC

C

OSC

> 50pF; R

OSC

> 50k

f

OSC

(Typ) = 48kHz

∑ OSCILLATOR PERIOD

t

OSC

= RC/0.45

∑ INTEGRATION CLOCK FREQUENCY

f

CLOCK

= f

OSC

/4

∑ INTEGRATION PERIOD

t

INT

= 1000 x (4/f

OSC

)

∑ 60/50Hz REJECTION CRITERION

t

INT

/t

60Hz

or t

lNT

/t

50Hz

= Integer

∑ OPTIMUM INTEGRATION CURRENT

I

INT

= 4

µ

A

∑ FULL SCALE ANALOG INPUT VOLTAGE

V

lNFS

(Typ) = 200mV or 2V

∑ INTEGRATE RESISTOR

∑ INTEGRATE CAPACITOR

∑ INTEGRATOR OUTPUT VOLTAGE SWING

∑ V

INT

MAXIMUM SWING:

(V- + 1.0V) < V

INT

< (V+ - 0.5V), V

INT

(Typ) = 2V

∑ DISPLAY COUNT

∑ CONVERSION CYCLE

t

CYC

= t

CL0CK

x 4000

t

CYC

= t

OSC

x 16,000

when f

OSC

= 48KHz; t

CYC

= 333ms

∑ COMMON MODE INPUT VOLTAGE

(V- + 1V) < V

lN

< (V+ - 0.5V)

∑ AUTO-ZERO CAPACITOR

0.01

µ

F < C

AZ

< 1

µ

F

∑ REFERENCE CAPACITOR

0.1

µ

F < C

REF

< 1

µ

F

∑ V

COM

Biased between V+ and V-.

∑ V

COM

V+ - 2.8V

Regulation lost when V+ to V- <

6.8V.

If V

COM

is externally pulled down to (V + to V -)/2,

the V

COM

circuit will turn off.

∑ ICL7116 POWER SUPPLY: SINGLE 9V

V+ - V- = 9V

Digital supply is generated internally

V

TEST

V+ - 4.5V

∑ ICL7116 DISPLAY: LCD

Type: Direct drive with digital logic supply amplitude.

∑ ICL7117 POWER SUPPLY: DUAL

±

5.0V

V+ = +5V to GND

V- = -5V to GND

Digital Logic and LED driver supply V+ to GND

∑ ICL7117 DISPLAY: LED

Type: Non-Multiplexed Common Anode

R

INT

V

INFS

I

INT

-----------------

=

C

INT

t

INT

(

)

I

INT

(

)

V

INT

--------------------------------

=

V

INT

t

INT

(

)

I

INT

(

)

C

INT

--------------------------------

=

COUNT

1000

V

IN

V

REF

---------------

◊

=

AUTO ZERO PHASE

(COUNTS)

2999 - 1000

SIGNAL INTEGRATE

PHASE FIXED

1000 COUNTS

DE-INTEGRATE PHASE

0 - 1999 COUNTS

TOTAL CONVERSION TIME = 4000 x t

CLOCK

= 16,000 x t

OSC

ICL7116, ICL7117

5

Pin Descriptions

PIN NUMBER

NAME

FUNCTION

DESCRIPTION

40 PIN DIP

44 PIN

FLATPACK

1

8

HLDR

Input

Display Hold Control.

2

9

D1

Output

Driver Pin for Segment "D" of the display units digit.

3

10

C1

Output

Driver Pin for Segment "C" of the display units digit.

4

11

B1

Output

Driver Pin for Segment "B" of the display units digit.

5

12

A1

Output

Driver Pin for Segment "A" of the display units digit.

6

13

F1

Output

Driver Pin for Segment "F" of the display units digit.

7

14

G1

Output

Driver Pin for Segment "G" of the display units digit.

8

15

E1

Output

Driver Pin for Segment "E" of the display units digit.

9

16

D2

Output

Driver Pin for Segment "D" of the display tens digit.

10

17

C2

Output

Driver Pin for Segment "C" of the display tens digit.

11

18

B2

Output

Driver Pin for Segment "B" of the display tens digit.

12

19

A2

Output

Driver Pin for Segment "A" of the display tens digit.

13

20

F2

Output

Driver Pin for Segment "F" of the display tens digit.

14

21

E2

Output

Driver Pin for Segment "E" of the display tens digit.

15

22

D3

Output

Driver pin for segment "D" of the display hundreds digit.

16

23

B3

Output

Driver pin for segment "B" of the display hundreds digit.

17

24

F3

Output

Driver pin for segment "F" of the display hundreds digit.

18

25

E3

Output

Driver pin for segment "E" of the display hundreds digit.

19

26

AB4

Output

Driver pin for both "A" and "B" segments of the display thousands digit.

20

27

POL

Output

Driver pin for the negative sign of the display.

21

28

BP/GND

Output

Driver pin for the LCD backplane/Power Supply Ground.

22

29

G3

Output

Driver pin for segment "G" of the display hundreds digit.

23

30

A3

Output

Driver pin for segment "A" of the display hundreds digit.

24

31

C3

Output

Driver pin for segment "C" of the display hundreds digit.

25

32

G2

Output

Driver pin for segment "G" of the display tens digit.

26

34

V-

Supply

Negative power supply.

27

35

INT

Output

Integrator amplifier output. To be connected to integrating capacitor.

28

36

BUFF

Output

Input buffer amplifier output. To be connected to integrating resistor.

29

37

A-Z

Input

Integrator amplifier input. To be connected to auto-zero capacitor.

30

31

38

39

IN LO

IN HI

Input

Differential inputs. To be connected to input voltage to be measured. LO and HI

designators are for reference and do not imply that LO should be connected to

lower potential, e.g., for negative inputs IN LO has a higher potential than IN HI.

32

40

COMMON

Supply/

Output

Internal voltage reference output.

33

34

41

42

C

REF

-

C

REF

+

Connection pins for reference capacitor.

35

36

43

44

V+

REF HI

Supply

Power Supply.

37

3

TEST

Input

Display test. Turns on all segments when tied to V+.

38

39

40

4

6

7

OSC3

OSC2

OSC1

Output

Output

Input

Device clock generator circuit connection pins.

ICL7116, ICL7117

6

Detailed Description

Analog Section

Figure 3 shows the Analog Section for the ICL7116 and

ICL7117. Each measurement cycle is divided into three

phases. They are (1) auto-zero (A-Z), (2) signal integrate

(INT) and (3) de-integrate (DE).

Auto-Zero Phase

During auto-zero three things happen. First, input high and low

are disconnected from the pins and internally shorted to analog

COMMON. Second, the reference capacitor is charged to the

reference voltage. Third, a feedback loop is closed around the

system to charge the auto-zero capacitor C

AZ

to compensate

for offset voltages in the buffer amplifier, integrator, and compar-

ator. Since the comparator is included in the loop, the A-Z accu-

racy is limited only by the noise of the system. In any case, the

offset referred to the input is less than 10

µ

V.

Signal Integrate Phase

During signal integrate, the auto-zero loop is opened, the inter-

nal short is removed, and the internal input high and low are

connected to the external pins. The converter then integrates

the differential voltage between IN HI and IN LO for a fixed time.

This differential voltage can be within a wide common mode

range: up to 1V from either supply. If, on the other hand, the

input signal has no return with respect to the converter power

supply, IN LO can be tied to analog COMMON to establish the

correct common mode voltage. At the end of this phase, the

polarity of the integrated signal is determined.

De-Integrate Phase

The final phase is de-integrate, or reference integrate. Input

low is internally connected to analog COMMON and input

high is connected across the previously charged reference

capacitor. Circuitry within the chip ensures that the capacitor

will be connected with the correct polarity to cause the

integrator output to return to zero. The time required for the

output to return to zero is proportional to the input signal.

Specifically the digital reading displayed is:

.

Differential Input

The input can accept differential voltages anywhere within the

common mode range of the input amplifier, or specifically from

0.5V below the positive supply to 1V above the negative sup-

ply. In this range, the system has a CMRR of 86dB typical.

However, care must be exercised to assure the integrator out-

put does not saturate. A worst case condition would be a large

positive common mode voltage with a near full scale negative

differential input voltage. The negative input signal drives the

integrator positive when most of its swing has been used up

by the positive common mode voltage. For these critical appli-

cations the integrator output swing can be reduced to less

than the recommended 2V full scale swing with little loss of

accuracy. The integrator output can swing to within 0.5V of

either supply without loss of linearity.

Differential Reference

The reference voltage can be generated anywhere within the

power supply voltage of the converter. The main source of

common mode error is a roll-over voltage caused by the

reference capacitor losing or gaining charge to stray capacity

on its nodes. If there is a large common mode voltage, the

reference capacitor can gain charge (increase voltage) when

called up to de-integrate a positive signal but lose charge

(decrease voltage) when called up to de-integrate a negative

input signal. This difference in reference for positive or

negative input voltage will give a roll-over error. However, by

selecting the reference capacitor such that it is large enough

in comparison to the stray capacitance, this error can be

held to less than 0.5 count worst case. (See Component

Value Selection.)

DISPLAY COUNT

1000

V

IN

V

REF

-----------------

=

FIGURE 3. ANALOG SECTION OF ICL7116 AND ICL711

DE-

DE+

C

INT

C

AZ

R

INT

BUFFER

A-Z

INT

A-Z

COMPARATOR

IN HI

COMMON

IN LO

31

32

30

DE-

DE+

INT

A-Z

34

C

REF

+

36

REF HI

C

REF

A-Z

33

C

REF

-

28

29

27

TO

DIGITAL

SECTION

A-Z AND DE

(±)

INTEGRATOR

INT

STRAY

STRAY

V+

10

µ

A

N

INPUT

HIGH

2.8V

6.2V

V+

35

INPUT

LOW

A-Z

26

V

-

+

-

+

-

+

-

+

ICL7116, ICL7117

7

Analog COMMON

This pin is included primarily to set the common mode

voltage for battery operation (ICL7116) or for any system

where the input signals are floating with respect to the power

supply. The COMMON pin sets a voltage that is approxi-

mately 2.8V less than the positive supply. This is selected to

give a minimum end-of-life battery voltage of about 6.8V.

However, analog COMMON has some of the attributes of a

reference voltage. When the total supply voltage is large

enough to cause the zener to regulate (>6.8V), the COM-

MON voltage will have a low voltage coefficient (0.001%/V),

low output impedance (

15

), and a temperature coefficient

typically less than 80ppm/

o

C.

The limitations of the on chip reference should also be

recognized, however. With the ICL7117, the internal heat-

ing which results from the LED drivers can cause some

degradation in performance. Due to their higher thermal

resistance, plastic parts are poorer in this respect than

ceramic. The combination of reference Temperature

Coefficient (TC), internal chip dissipation, and package

thermal resistance can increase noise near full scale from

25

µ

V to 80

µ

V

P-P

. Also the linearity in going from a high

dissipation count such as 1000 (20 segments on) to a low

dissipation count such as 1111 (8 segments on) can suffer

by a count or more. Devices with a positive TC reference

may require several counts to pull out of an over-range con-

dition. This is because over-range is a low dissipation

mode, with the three least significant digits blanked. Simi-

larly, units with a negative TC may cycle between over

range and a non-over range count as the die alternately

heats and cools. All these problems are of course

eliminated if an external reference is used.

The ICL7116, with its negligible dissipation, suffers from

none of these problems. In either case, an external

reference can easily be added, as shown in Figure 4.

Analog COMMON is also used as the input low return during

auto-zero and de-integrate. If IN LO is different from analog

COMMON, a common mode voltage exists in the system

and is taken care of by the excellent CMRR of the converter.

However, in some applications IN LO will be set at a fixed

known voltage (power supply common for instance). In this

application, analog COMMON should be tied to the same

point, thus removing the common mode voltage from the

converter. The same holds true for the reference voltage. If

reference can be conveniently tied to analog COMMON, it

should be since this removes the common mode voltage

from the reference system.

Within the lC, analog COMMON is tied to an N-Channel FET

that can sink approximately 30mA of current to hold the

voltage 2.8V below the positive supply (when a load is trying

to pull the common line positive). However, there is only

10

µ

A of source current, so COMMON may easily be tied to a

more negative voltage thus overriding the internal reference.

TEST

The TEST pin serves two functions. On the ICL7116 it is

coupled to the internally generated digital supply through a

500

resistor. Thus it can be used as the negative supply for

externally generated segment drivers such as decimal points

or any other annunciator the user may want to include on the

LCD display. Figures 5 and 6 show such an application. No

more than a 1mA load should be applied.

The second function is a "lamp test". When TEST is pulled

high (to V+) all segments will be turned on and the display

should read "-1888". The TEST pin will sink about 5mA under

these conditions.

CAUTION: On the ICL7116, in the lamp test mode, the segments

have a constant DC voltage (no square-wave) and may burn the

LCD display if left in this mode for several minutes.

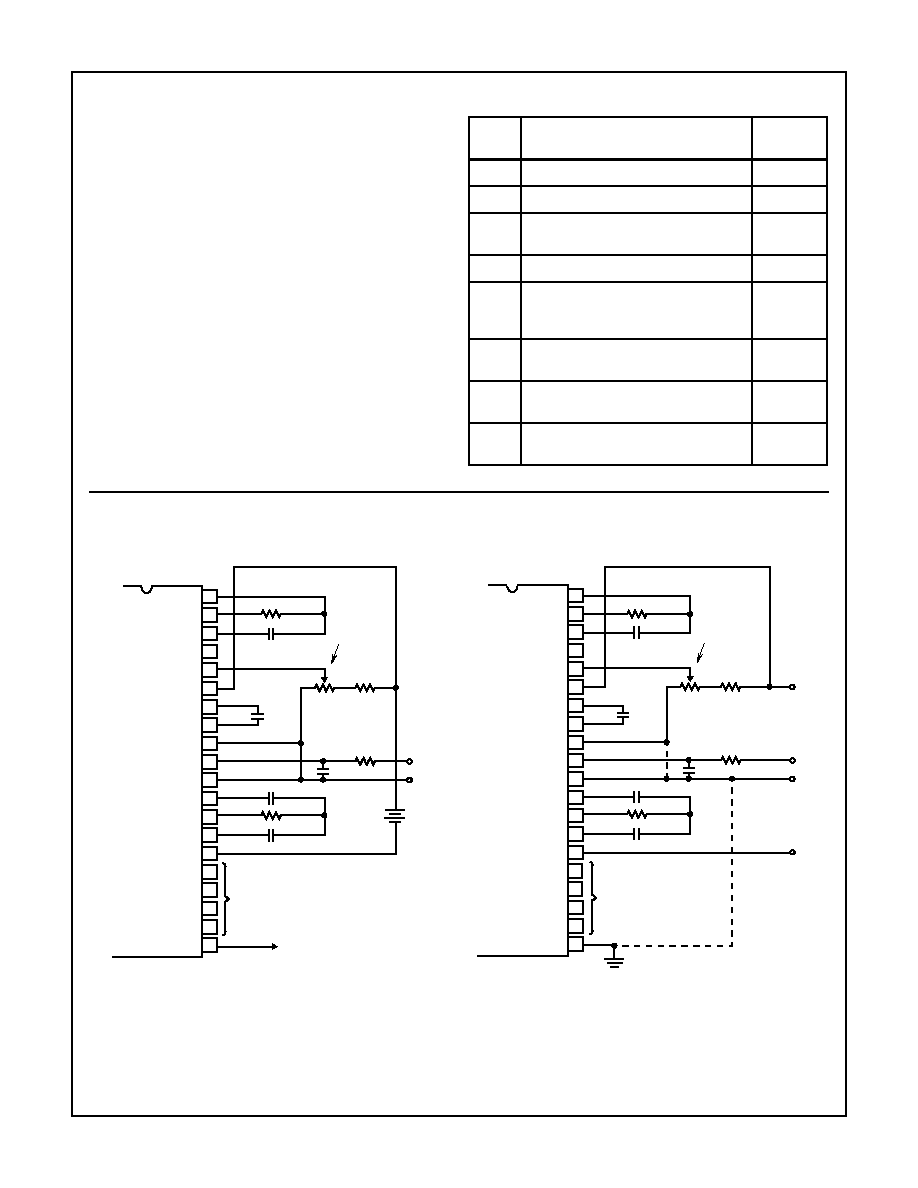

FIGURE 4A.

FIGURE 4B.

FIGURE 4. USING AN EXTERNAL REFERENCE

ICL7116

V

COMMON

ICL7117

REF HI

V+

V-

6.8V

ZENER

I

Z

ICL7116

V

REF HI

COMMON

V+

ICL8069

1.2V

REFERENCE

6.8k

20k

ICL7117

ICL7116

V+

BP

TEST

21

37

TO LCD

BACKPLANE

TO LCD

DECIMAL

POINT

1M

FIGURE 5. SIMPLE INVERTER FOR FIXED DECIMAL POINT

ICL7116, ICL7117

8

HOLD Reading Input

The HLDR input will prevent the latch from being updated

when this input is at logic "1". The chip will continue to make

A/D conversions, however, the results will not be updated to

the internal latches until this input goes low. This input can be

left open or connected to TEST (ICL7116) or GROUND

(ICL7117) to continuously update the display. This input is

CMOS compatible, and has a 70k

(See Figure 7) typical

resistance to either TEST (ICL7116) or GROUND (ICL7117).

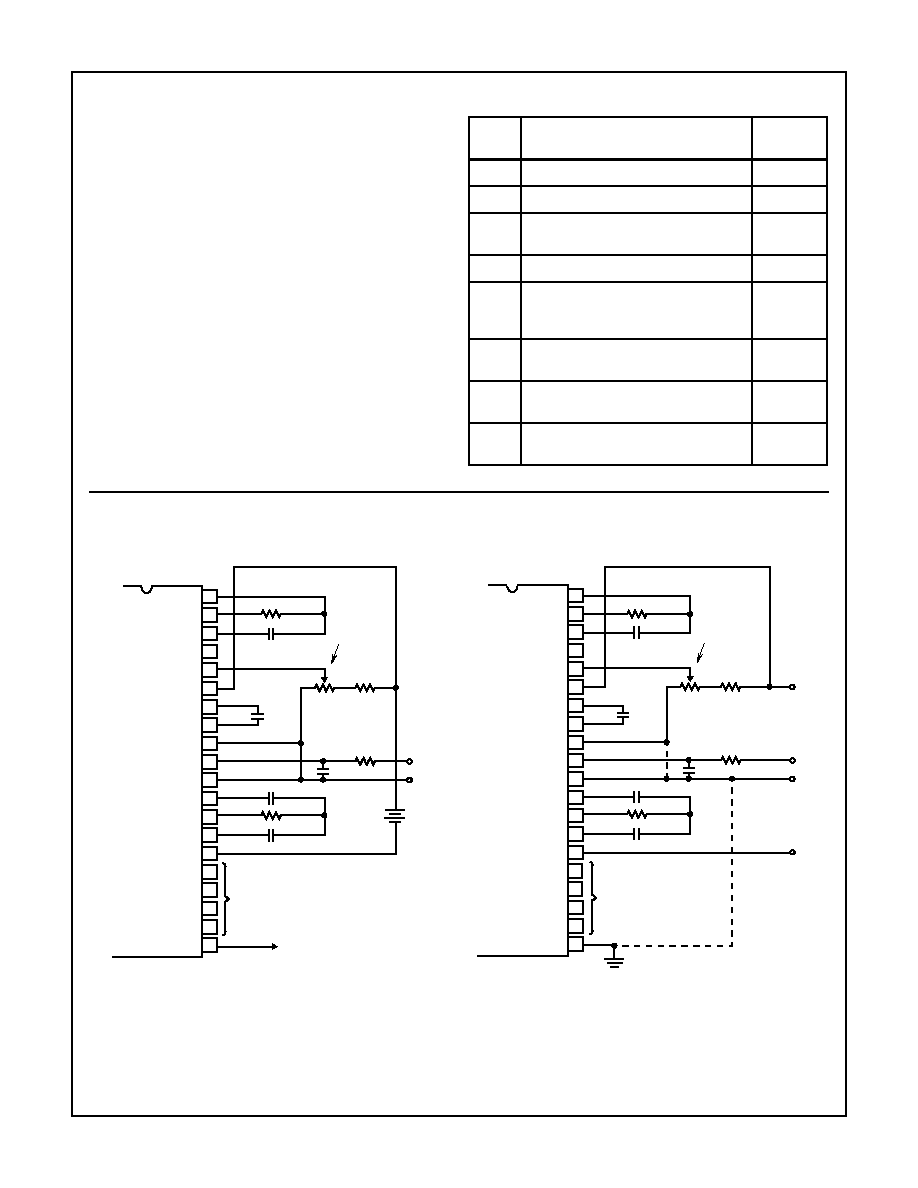

Digital Section

Figures 7 and 8 show the digital section for the ICL7116 and

ICL7117, respectively. In the ICL7116, an internal digital

ground is generated from a 6V Zener diode and a large

P-Channel source follower. This supply is made stiff to absorb

the relative large capacitive currents when the back plane

(BP) voltage is switched. The BP frequency is the clock fre-

quency divided by 800. For three readings/second this is a

60Hz square wave with a nominal amplitude of 5V. The seg-

ments are driven at the same frequency and amplitude and

are in phase with BP when OFF, but out of phase when ON. In

all cases negligible DC voltage exists across the segments.

Figure 8 is the Digital Section of the ICL7117. It is identical

to the ICL7116 except that the regulated supply and back

plane drive have been eliminated and the segment drive has

been increased from 2mA to 8mA, typical for instrument size

common anode LED displays. Since the 1000 output (pin 19)

must sink current from two LED segments, it has twice the

drive capability or 16mA.

In both devices, the polarity indication is "on" for negative

analog inputs. If IN LO and IN HI are reversed, this indication

can be reversed also, if desired.

ICL7116

V+

BP

TEST

DECIMAL

POINT

SELECT

CD4030

GND

V+

TO LCD

DECIMAL

POINTS

FIGURE 6. EXCLUSIVE `OR' GATE FOR DECIMAL POINT DRIVE

7

SEGMENT

DECODE

SEGMENT

OUTPUT

0.5mA

2mA

INTERNAL DIGITAL GROUND

TYPICAL SEGMENT OUTPUT

V+

LCD PHASE DRIVER

LATCH

7

SEGMENT

DECODE

˜

200

LOGIC CONTROL

INTERNAL

V

TH

= 1V

7

SEGMENT

DECODE

1000's

100's

10's

1's

TO SWITCH DRIVERS

FROM COMPARATOR OUTPUT

DIGITAL

GROUND

˜

4

CLOCK

40

39

38

OSC 1

OSC 2

OSC 3

BACKPLANE

21

V+

TEST

V-

500

37

26

6.2V

COUNTER

COUNTER

COUNTER

COUNTER

35

1

HLDR

THREE INVERTERS

ONE INVERTER SHOWN

FOR CLARITY

70k

c

a

b

c

d

f

g

e

a

b

a

b

c

d

f

g

e

a

b

c

d

f

g

e

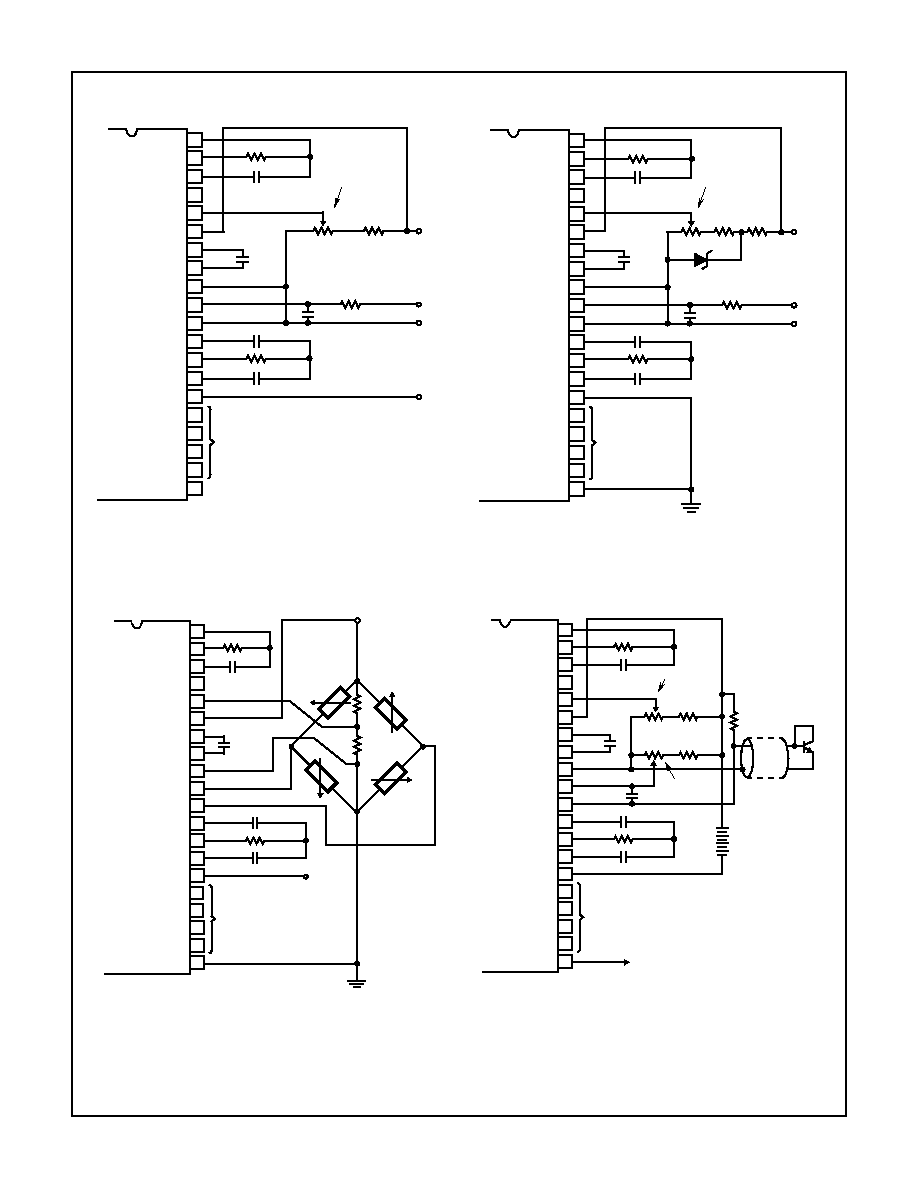

FIGURE 7. ICL7116 DIGITAL SECTION

ICL7116, ICL7117

9

System Timing

Figure 9 shows the clocking arrangement used in the

ICL7116 and ICL7117. Two basic clocking arrangements

can be used:

1. Figure 9A, an external oscillator connected to pin 40.

2. Figure 9B, an R-C oscillator using all three pins.

The oscillator frequency is divided by four before it clocks the

decade counters. It is then further divided to form the three

convert-cycle phases. These are signal integrate (1000

counts), reference de-integrate (0 to 2000 counts) and auto-

zero (1000 counts to 3000 counts). For signals less than full

scale, auto-zero gets the unused portion of reference de-

integrate. This makes a complete measure cycle of 4,000

counts (16,000 clock pulses) independent of input voltage.

For three readings/second, an oscillator frequency of 48kHz

would be used.

To achieve maximum rejection of 60Hz pickup, the signal

integrate cycle should be a multiple of 60Hz. Oscillator

frequencies of 240kHz, 120kHz, 80kHz, 60kHz, 48kHz,

40kHz, 33

1

/

3

kHz, etc. should be selected. For 50Hz rejec-

tion, Oscillator frequencies of 200kHz, 100kHz, 66

2

/

3

kHz,

50kHz, 40kHz, etc. would be suitable. Note that 40kHz (2.5

readings/second) will reject both 50Hz and 60Hz (also

400Hz and 440Hz).

7

SEGMENT

DECODE

TO

SEGMENT

0.5mA

8mA

DIGITAL GROUND

TYPICAL SEGMENT OUTPUT

V+

LATCH

7

SEGMENT

DECODE

LOGIC CONTROL

7

SEGMENT

DECODE

1000's

100's

10's

1's

TO SWITCH DRIVERS

FROM COMPARATOR OUTPUT

DIGITAL

GROUND

˜

4

CLOCK

40

39

38

OSC 1

OSC 2

OSC 3

V+

TEST

500

COUNTER

COUNTER

COUNTER

COUNTER

35

V+

37

21

1

HLDR

THREE INVERTERS

ONE INVERTER SHOWN

FOR CLARITY

70k

c

a

b

c

d

f

g

e

a

b

a

b

c

d

f

g

e

a

b

c

d

f

g

e

FIGURE 8. ICL7117 DIGITAL SECTION

CLOCK

INTERNAL TO PART

40

39

38

GND ICL7117

˜

4

CLOCK

INTERNAL TO PART

40

39

38

˜

4

R

C

TEST ICL7116

FIGURE 9B. RC OSCILLATOR

FIGURE 9. CLOCK CIRCUITS

FIGURE 9A. EXTERNAL OSCILLATOR

ICL7116, ICL7117

10

Component Value Selection

Integrating Resistor

Both the buffer amplifier and the integrator have a class A

output stage with 100

µ

A of quiescent current. They can

supply 4

µ

A of drive current with negligible nonlinearity. The

integrating resistor should be large enough to remain in this

very linear region over the input voltage range, but small

enough that undue leakage requirements are not placed on

the PC board. For 2V full scale, 470k

is near optimum and

similarly a 47k

for a 200mV scale.

Integrating Capacitor

The integrating capacitor should be selected to give the

maximum voltage swing that ensures tolerance buildup will

not saturate the integrator swing (approximately. 0.5V from

either supply). In the ICL7116 or the ICL7117, when the

analog COMMON is used as a reference, a nominal +2V full-

scale integrator swing is fine. For the ICL7117 with +5V

supplies and analog COMMON tied to supply ground, a

±

3.5V to +4V swing is nominal. For three readings/second

(48kHz clock) nominal values for C

lNT

are 0.22

µ

F and 0.1

µ

F,

respectively. Of course, if different oscillator frequencies are

used, these values should be changed in inverse proportion

to maintain the same output swing.

An additional requirement of the integrating capacitor is that

it must have a low dielectric absorption to prevent roll-over

errors. While other types of capacitors are adequate for this

application, polypropylene capacitors give undetectable

errors at reasonable cost.

Auto-Zero Capacitor

The size of the auto-zero capacitor has some influence on

the noise of the system. For 200mV full scale where noise is

very important, a 0.47

µ

F capacitor is recommended. On the

2V scale, a 0.047

µ

F capacitor increases the speed of recov-

ery from overload and is adequate for noise on this scale.

Reference Capacitor

A 0.1

µ

F capacitor gives good results in most applications.

Generally 1

µ

F will hold the roll-over error to 0.5 counts in this

instance.

Oscillator Components

For all ranges of frequency a 100k

resistor is recommended

and the capacitor is selected from the equation:

Reference Voltage

The analog input required to generate full scale output (2000

counts) is: V

lN

= 2V

REF

. Thus, for the 200mV and 2V scale,

V

REF

should equal 100mV and 1V, respectively. However, in

many applications where the A/D is connected to a

transducer, there will exist a scale factor other than unity

between the input voltage and the digital reading. For

instance, in a weighing system, the designer might like to

have a full scale reading when the voltage from the

transducer is 0.682V. Instead of dividing the input down to

200mV, the designer should use the input voltage directly

and select V

REF

= 0.341V. Suitable values for integrating

resistor and capacitor would be 120k

and 0.22

µ

F. This

makes the system slightly quieter and also avoids a divider

network on the input. The ICL7117 with

±

5V supplies can

accept input signals up to

±

4V. Another advantage of this

system occurs when a digital reading of zero is desired for

V

IN

0. Temperature and weighing systems with a variable

fare are examples. This offset reading can be conveniently

generated by connecting the voltage transducer between IN

HI and COMMON and the variable (or fixed) offset voltage

between COMMON and IN LO.

ICL7117 Power Supplies

3. The ICL7117 is designed to work from

±

5V supplies.

However, if a negative supply is not available, it can be

generated from the clock output with 2 diodes, 2

capacitors, and an inexpensive lC. Figure 10 shows this

application. See ICL7660 data sheet for an alternative.

In fact, in selected applications no negative supply is

required. The conditions to use a single +5V supply are:

1. The input signal can be referenced to the center of the

common mode range of the converter.

2. The signal is less than

±

1.5V.

3. An external reference is used.

f

0.45

RC

------------

For 48kHz Clock (3 Readings/sec),

=

C

100pF

.

=

ICL7117

V+

OSC 1

V-

OSC 2

OSC 3

GND

V+

V- = 3.3V

0.047

µ

F

10

µ

F

+

-

IN914

IN914

CD4009

FIGURE 10.

GENERATING NEGATIVE SUPPLY FROM +5V

ICL7116, ICL7117

11

Typical Applications

The ICL7116 and ICL7117 may be used in a wide variety of

configurations. The circuits which follow show some of the

possibilities, and serve to illustrate the exceptional versatil-

ity of these A/D converters.

The following application notes contain very useful

information on understanding and applying this part and

are available from Intersil Corporation.

Application Notes

NOTE #

DESCRIPTION

AnswerFAX

DOC. #

AN016

"Selecting A/D Converters"

9016

AN017

"The Integrating A/D Converter"

9017

AN018

"Do's and Don'ts of Applying A/D

Converters"

9018

AN023

"Low Cost Digital Panel Meter Designs"

9023

AN032

"Understanding the Auto-Zero and

Common Mode Performance of the

ICL7136/7/9 Family"

9032

AN046

"Building a Battery-Operated Auto

Ranging DVM with the ICL7106"

9046

AN047

"Games People Play with Intersil' A/D

Converters," edited by Peter Bradshaw

9047

AN052

"Tips for Using Single Chip 3

1

/

2

Digit A/D

Converters"

9052

Typical Applications

FIGURE 11. ICL7116 USING THE INTERNAL REFERENCE

FIGURE 12. ICL7117 USING THE INTERNAL REFERENCE

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

BP

100pF

SET V

REF

= 100mV

0.1

µ

F

0.01

µ

F

1M

100k

1k

22k

IN

+

-

9V

47k

0.22

µ

F

0.47

µ

F

TO BACKPLANE

TO DISPLAY

Values shown are for 200mV full scale, 3 readings/sec., floating

supply voltage (9V battery).

+

-

Values shown are for 200mV full scale, 3 readings/sec. IN LO may

be tied to either COMMON for inputs floating with respect to

supplies, or GND for single ended inputs. (See discussion under

Analog COMMON.)

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

GND

100pF

SET V

REF

= 100mV

0.1

µ

F

0.01

µ

F

1M

100k

1k

22k

IN

+

-

47k

0.22

µ

F

0.47

µ

F

TO DISPLAY

+5V

-5V

ICL7116, ICL7117

12

FIGURE 13. ICL7116 AND ICL7117: RECOMMENDED

COMPONENT VALUES FOR 2.0V FULL SCALE

FIGURE 14. ICL7117 OPERATED FROM SINGLE +5V SUPPLY

FIGURE 15. ICL7117 MEASUREING RATIOMETRIC VALUES OF

QUAD LOAD CELL

FIGURE 16. ICL7116 USED AS A DIGITAL CENTIGRADE

THERMOMETER

Typical Applications

(Continued)

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

GND

100pF

SET V

REF

= 1.000V

0.1

µ

F

0.01

µ

F

1M

100k

25k

IN

+

470k

0.047

µ

F

TO DISPLAY

24k

V

-

V +

-

0.22

µ

F

An external reference must be used in this application, since the

voltage between V+ and V- is insufficient for correct operation of the

internal reference.

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

GND

100pF

SET V

REF

= 100mV

0.1

µ

F

0.01

µ

F

1M

100k

1k

10k

IN

+

-

47k

0.22

µ

F

0.47

µ

F

TO DISPLAY

+5V

15k

1.2V (ICL8069)

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

GND

100pF

0.1

µ

F

100k

0.47

µ

F

TO DISPLAY

The resistor values within the bridge are determined by the desired

sensitivity.

V+

0.22

µ

F

47k

V

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

OSC 1

OSC 2

OSC 3

TEST

REF HI

V+

C

REF

C

REF

COMMON

IN HI

IN LO

A-Z

BUFF

INT

V -

G2

C3

A3

G3

BP

100pF

0.1

µ

F

0.01

µ

F

100k

100k

1M

9V

47k

0.22

µ

F

0.47

µ

F

TO BACKPLANE

TO DISPLAY

A silicon diode-connected transistor has a temperature coefficient of

about -2mV/

o

C. Calibration is achieved by placing the sensing

transistor in ice water and adjusting the zeroing potentiometer for a

000.0 reading. The sensor should then be placed in boiling water

and the scale-factor potentiometer adjusted for a 100.0 reading.

SCALE

FACTOR

ADJUST

100k

220k

22k

SILICON NPN

MPS 3704 OR

SIMILAR

ZERO

ADJUST

ICL7116, ICL7117

13

ICL7116, ICL7117

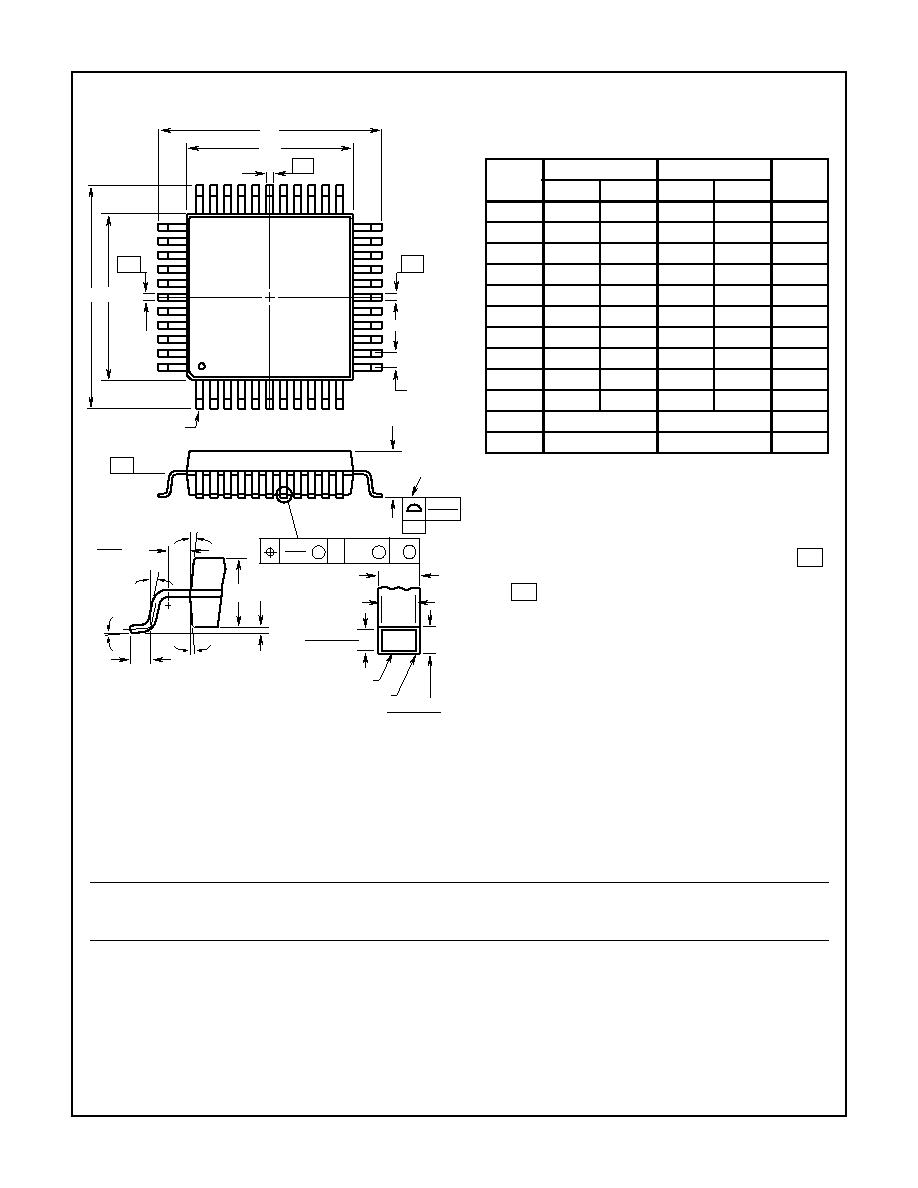

Dual-In-Line Plastic Packages (PDIP)

C

L

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A1

-A-

0.010 (0.25)

C

A

M

B S

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the "MO Series Symbol List" in Section 2.2

of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and

are measured with the leads constrained to be per-

pendicular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads uncon-

strained. e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

e

A

-C-

E40.6

(JEDEC MS-011-AC ISSUE B)

40 LEAD DUAL-IN-LINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.250

-

6.35

4

A1

0.015

-

0.39

-

4

A2

0.125

0.195

3.18

4.95

-

B

0.014

0.022

0.356

0.558

-

B1

0.030

0.070

0.77

1.77

8

C

0.008

0.015

0.204

0.381

-

D

1.980

2.095

50.3

53.2

5

D1

0.005

-

0.13

-

5

E

0.600

0.625

15.24

15.87

6

E1

0.485

0.580

12.32

14.73

5

e

0.100 BSC

2.54 BSC

-

e

A

0.600 BSC

15.24 BSC

6

e

B

-

0.700

-

17.78

7

L

0.115

0.200

2.93

5.08

4

N

40

40

9

Rev. 0 12/93

14

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

ICL7116, ICL7117

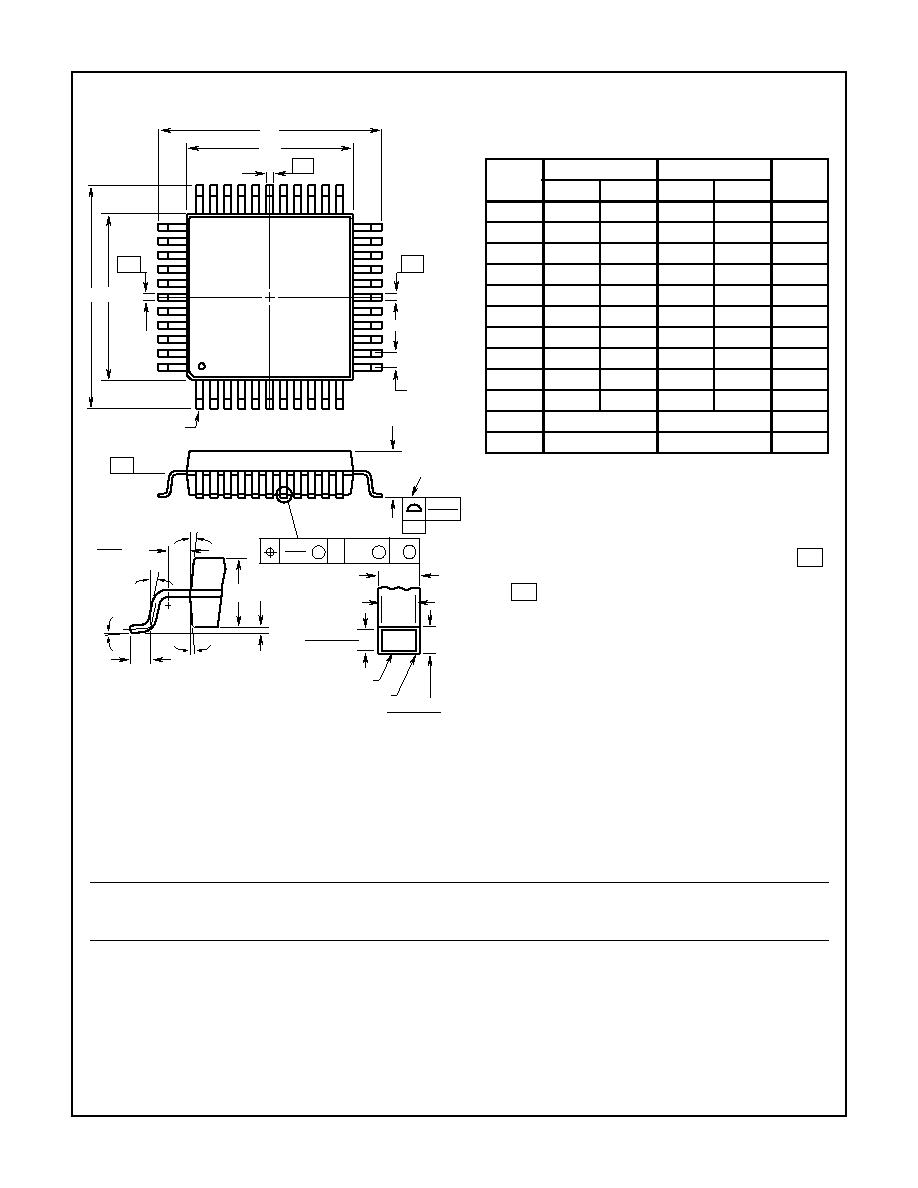

Metric Plastic Quad Flatpack Packages (MQFP/PQFP)

D

D1

E E1

-A-

PIN 1

A2 A1

A

5

o

-16

o

5

o

-16

o

0

o

-7

o

0.40

0.016

MIN

L

0

o

MIN

PLANE

B

0.005/0.009

0.13/0.23

WITH PLATING

BASE METAL

SEATING

0.005/0.007

0.13/0.17

B1

-B-

e

0.008

0.20

A-B

S

D

S

C

M

0.10

0.004

-C-

-D-

-H-

Q44.10x10

(JEDEC MO-108AA-2 ISSUE A)

44 LEAD METRIC PLASTIC QUAD FLATPACK PACKAGE

SYM-

BOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.093

-

2.35

-

A1

0.004

0.010

0.10

0.25

-

A2

0.077

0.083

1.95

2.10

-

B

0.012

0.018

0.30

0.45

6

B1

0.012

0.016

0.30

0.40

-

D

0.510

0.530

12.95

13.45

3

D1

0.390

0.398

9.90

10.10

4, 5

E

0.510

0.530

12.95

13.45

3

E1

0.390

0.398

9.90

10.10

4, 5

L

0.026

0.037

0.65

0.95

-

N

44

44

7

e

0.032 BSC

0.80 BSC

-

Rev. 1 1/94

NOTES:

1. Controlling dimension: MILLIMETER. Converted inch

dimensions are not necessarily exact.

2. All dimensions and tolerances per ANSI Y14.5M-1982.

3. Dimensions D and E to be determined at seating plane

.

4. Dimensions D1 and E1 to be determined at datum plane

.

5. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is 0.25mm (0.010 inch) per side.

6. Dimension B does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total.

7. "N" is the number of terminal positions.

-C-

-H-