1

Æ

FN3093.3

ICL7135

4

1

/

2

Digit, BCD Output, A/D Converter

The Intersil ICL7135 precision A/D converter, with its

multiplexed BCD output and digit drivers, combines dual-

slope conversion reliability with

±

1 in 20,000 count accuracy

and is ideally suited for the visual display DVM/DPM market.

The 2.0000V full scale capability, auto-zero, and auto-

polarity are combined with true ratiometric operation, almost

ideal differential linearity and true differential input. All

necessary active devices are contained on a single CMOS

lC, with the exception of display drivers, reference, and a

clock.

The ICL7135 brings together an unprecedented combination

of high accuracy, versatility, and true economy. It features

auto-zero to less than 10

µ

V, zero drift of less than 1

µ

V/

o

C,

input bias current of 10pA (Max), and rollover error of less

than one count. The versatility of multiplexed BCD outputs is

increased by the addition of several pins which allow it to

operate in more sophisticated systems. These include

STROBE, OVERRANGE, UNDERRANGE, RUN/HOLD and

BUSY lines, making it possible to interface the circuit to a

microprocessor or UART.

Features

∑ Accuracy Guaranteed to

±

1 Count Over Entire

±

20000

Counts (2.0000V Full Scale)

∑ Guaranteed Zero Reading for 0V Input

∑ 1pA Typical Input Leakage Current

∑ True Differential Input

∑ True Polarity at Zero Count for Precise Null Detection

∑ Single Reference Voltage Required

∑ Overrange and Underrange Signals Available for Auto-

Range Capability

∑ All Outputs TTL Compatible

∑ Blinking Outputs Gives Visual Indication of Overrange

∑ Six Auxiliary Inputs/Outputs are Available for Interfacing to

UARTs, Microprocessors, or Other Circuitry

∑ Multiplexed BCD Outputs

∑

Pb-Free Available (RoHS Compliant)

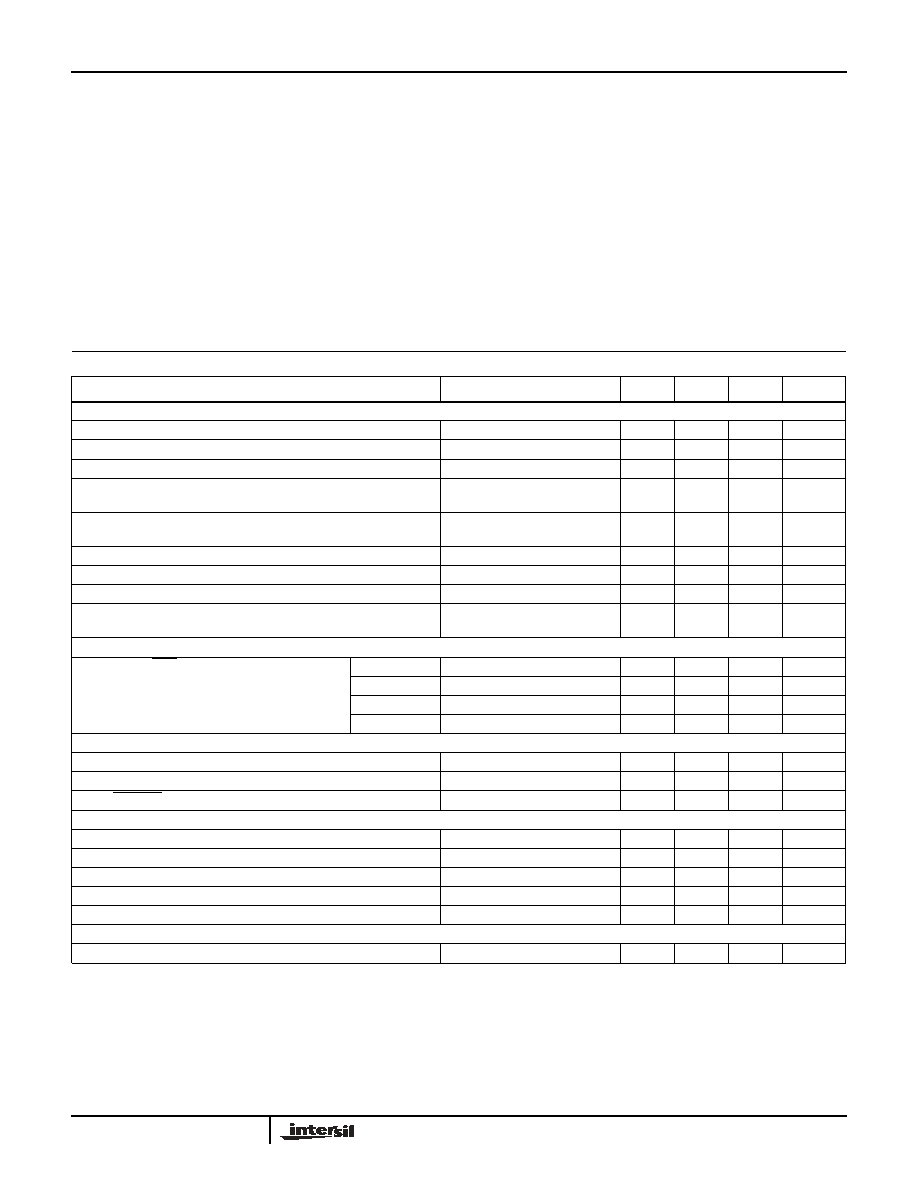

Pinout

ICL7135

(PDIP)

TOP VIEW

Ordering Information

PART NUMBER

TEMP.

RANGE (∞C)

PACKAGE

PKG.

DWG. #

ICL7135CPI

0 to 70

28 Ld PDIP

E28.6

ICL7135CPIZ

(Note 1)

0 to 70

28 Ld PDIP

(Pb-free) (Note 2)

E28.6

NOTES:

1. Intersil Pb-free products employ special Pb-free material sets;

molding compounds/die attach materials and 100% matte tin

plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations.

Intersil Pb-free products are MSL classified at Pb-free peak

reflow temperatures that meet or exceed the Pb-free

requirements of IPC/JEDEC J STD-020C.

2. Pb-free PDIPs can be used for through hole wave solder

processing only. They are not intended for use in Reflow solder

processing applications.

V-

REFERENCE

NALOG COMMON

INT OUT

AZ IN

BUFF OUT

REF CAP -

REF CAP +

IN LO

IN HI

V+

(MSD) D5

(LSB) B1

B2

UNDERRANGE

STROBE

R/H

DIGITAL GND

POL

BUSY

D2

D3

D4

(MSB) B8

B4

OVERRANGE

CLOCK IN

(LSD) D1

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Data Sheet

October 25, 2004

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2000, 2004. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

2

FN3093.3

Typical Application Schematic

28

27

26

25

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

24

SET V

REF

= 1.000V

V

REF

IN

SIGNAL

-5V

+5V

100k

27

100k

100K

ANALOG

GND

INPUT

1

µ

F

0.47

µ

F

1

µ

F

0.1

µ

F

100k

ICL7135

CLOCK IN

120kHz

0V

6

ANODE

DRIVER

TRANSISTORS

SEVEN

SEG.

DECODE

DISPLAY

ICL7135

3

FN3093.3

Absolute Maximum Ratings

Thermal Information

Supply Voltage V+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+6V

V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -9V

Analog Input Voltage (Either Input) (Note 1) . . . . . . . . . . . . V+ to V-

Reference Input Voltage (Either Input). . . . . . . . . . . . . . . . . V+ to V-

Clock Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND to V+

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

o

C to 70

o

C

Thermal Resistance (Typical, Note 2) . . . . . . . . . . . . .

JA

(

o

C/W)

PDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300

o

C

NOTE: Pb-free PDIPs can be used for through hole wave solder

processing only. They are not intended for use in Reflow solder

processing applications.

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Input voltages may exceed the supply voltages provided the input current is limited to +100

µ

A.

2.

JA

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

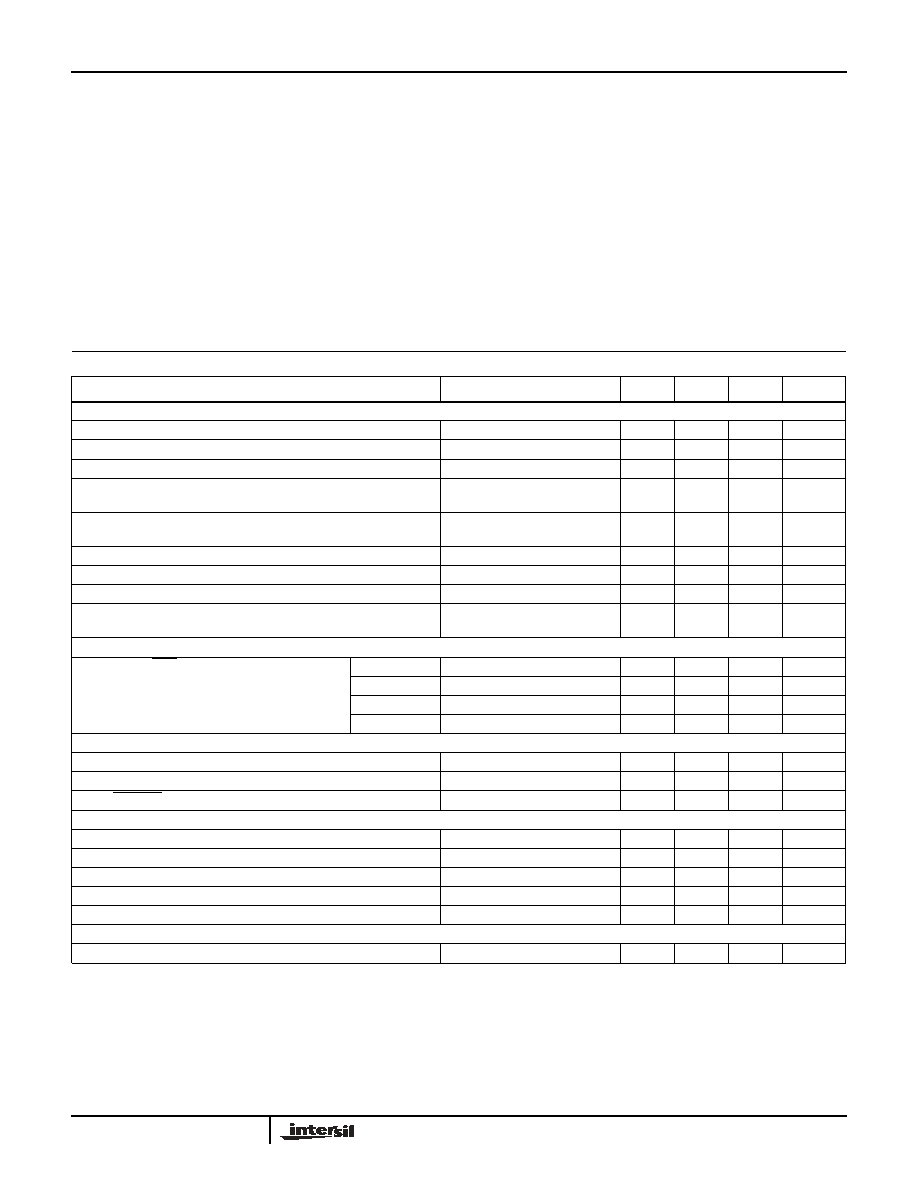

Electrical Specifications

V+ = +5V, V- = -5V, T

A

= 25

o

C, f

CLK

Set for 3 Readings/s, Unless Otherwise Specified

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNITS

ANALOG (Notes 3, 4)

Zero Input Reading

V

lN

= 0V, V

REF

= 1.000V

-00000

+00000

+00000

Counts

Ratiometric Error (Note 4)

V

lN

= V

REF

= 1.000V

-3

0

+3

Counts

Linearity Over

±

Full Scale (Error of Reading from Best Straight Line)

-2V

V

IN

+2V

-

0.5

1

LSB

Differential Linearity (Difference Between Worse Case Step of

Adjacent Counts and Ideal Step)

-2V

V

IN

+2V

-

0.01

-

LSB

Rollover Error (Difference in Reading for Equal Positive and

Negative Voltage Near Full Scale)

-V

lN

+V

lN

2V

-

0.5

1

LSB

Noise (Peak-to-Peak Value Not Exceeded 95% of Time), e

N

V

lN

= 0V, Full scale = 2.000V

-

15

-

µ

V

Input Leakage Current, I

ILK

V

lN

= 0V

-

1

10

pA

Zero Reading Drift (Note 7)

V

lN

= 0V, 0

o

C to 70

o

C

-

0.5

2

µ

V/

o

C

Scale Factor Temperature Coefficient, T

C

(Notes 5 and 7)

V

lN

= +2V, 0

o

C to 70

o

C

Ext. Ref. 0ppm/

o

C

-

2

5

ppm/◊

o

C

DIGITAL INPUTS

Clock In, Run/Hold (See Figure 2)

V

INH

2.8

2.2

-

V

V

INL

-

1.6

0.8

V

I

INL

V

IN

= 0V

-

0.02

0.1

mA

I

INH

V

IN

= +5V

-

0.1

10

µ

A

DIGITAL OUTPUTS

All Outputs, V

OL

I

OL

= 1.6mA

-

0.25

0.40

V

B1 , B2 , B4 , B8 , D1 , D2 , D3 , D4 , D5 , V

OH

I

OH

= -1mA

2.4

4.2

-

V

BUSY, STROBE, OVERRANGE, UNDERRANGE, POLARITY, V

OH

I

OH

= -10

µ

A

4.9

4.99

-

V

SUPPLY

+5V Supply Range, V+

+4

+5

+6

V

-5V Supply Range, V-

-3

-5

-8

V

+5V Supply Current, I+

f

C

= 0

-

1.1

3.0

mA

-5V Supply Current, I-

f

C

= 0

-

0.8

3.0

mA

Power Dissipation Capacitance, C

PD

vs Clock Frequency

-

40

-

pF

CLOCK

Clock Frequency (Note 6)

DC

2000

1200

kHz

NOTES:

3. Tested in 4

1

/

2

digit (20.000 count) circuit shown in Figure 3. (Clock frequency 120kHz.)

4. Tested with a low dielectric absorption integrating capacitor, the 27

INT OUT resistor shorted, and R

lNT

= 0. See Component Value Selection Discussion.

5. The temperature range can be extended to 70

o

C and beyond as long as the auto-zero and reference capacitors are increased to absorb the higher leakage

of the ICL7135.

6. This specification relates to the clock frequency range over which the lCL7135 will correctly perform its various functions See "Max Clock Frequency"

section for limitations on the clock frequency range in a system.

7. Parameter guaranteed by design or characterization. Not production tested.

ICL7135

4

FN3093.3

FIGURE 1. ICL7135 TEST CIRCUIT

FIGURE 2. ICL7135 DIGITAL LOGIC INPUT

FIGURE 3. ANALOG SECTION OF ICL7135

28

27

26

25

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

24

SET V

REF

= 1.000V

V

REF

IN

SIGNAL

-5V

+5V

100k

27

100k

100K

ANALOG

GND

INPUT

1

µ

F

0.47

µ

F

1

µ

F

0.1

µ

F

100k

ICL7135

0V

CLOCK

IN

120kHz

UNDERRANGE

OVERRANGE

STROBE

RUN/HOLD

DIGITAL GND

POLARITY

CLOCK IN

BUSY

LSD DI

D2

D3

D4

MSB B8

B4

V-

REF

ANALOG GND

INT OUT

A-Z IN

BUF OUT

REF CAP 1

REF CAP 2

IN LO-

IN HI+

V+

MSD D5

LSB B1

B2

V

+

PAD

DIG GND

C

REF+

REF HI

IN HI

INT

A/Z

ANALOG

AZ

IN LO

ZI

C

REF

BUFFER

COMMON

INPUT

COMPARATOR

C

AZ

C

INT

R

INT

INTEGRATOR

INPUT

V

+

V

-

POLARITY

ZERO-

LOW

HIGH

CROSSING

DETECTOR

F/F

DE(+)

DE(-)

DE(-)

DE(+)

AZ

AZ

AUTO

ZERO

INT

1

2

3

4

5

6

11

10

9

8

7

-

+

-

+

+

C

REF

A/Z, DE(

±

), ZI

INT

ICL7135

5

FN3093.3

Detailed Description

Analog Section

Figure 3 shows the Block Diagram of the Analog Section for

the ICL7135. Each measurement cycle is divided into four

phases. They are (1) auto-zero (AZ), (2) signal-integrate

(INT), (3) de-integrate (DE) and (4) zero-integrator (Zl).

Auto-Zero Phase

During auto-zero, three things happen. First, input high and low

are disconnected from the pins and internally shorted to analog

COMMON. Second, the reference capacitor is charged to the

reference voltage. Third, a feedback loop is closed around the

system to charge the auto-zero capacitor C

AZ

to compensate

for offset voltages in the buffer amplifier, integrator, and

comparator. Since the comparator is included in the loop, the

AZ accuracy is limited only by the noise of the system. In any

case, the offset referred to the input is less than 10

µ

V.

Signal Integrate Phase

During signal integrate, the auto-zero loop is opened, the

internal short is removed, and the internal input high and low

are connected to the external pins. The converter then

integrates the differential voltage between IN HI and IN LO for a

fixed time. This differential voltage can be within a wide

common mode range; within one volt of either supply. If, on the

other hand, the input signal has no return with respect to the

converter power supply, IN LO can be tied to analog COMMON

to establish the correct common-mode voltage. At the end of

this phase, the polarity of the integrated signal is latched into

the polarity F/F.

De-Integrate Phase

The third phase is de-integrate or reference integrate. Input

low is internally connected to analog COMMON and input

high is connected across the previously charged reference

capacitor. Circuitry within the chip ensures that the capacitor

will be connected with the correct polarity to cause the inte-

grator output to return to zero. The time required for the out-

put to return to zero is proportional to the input signal.

Specifically the digital reading displayed is:

.

Zero Integrator Phase

The final phase is zero integrator. First, input low is shorted

to analog COMMON. Second, a feedback loop is closed

around the system to input high to cause the integrator

output to return to zero. Under normal condition, this phase

lasts from 100 to 200 clock pulses, but after an overrange

conversion, it is extended to 6200 clock pulses.

Differential Input

The input can accept differential voltages anywhere within the

common mode range of the input amplifier; or specifically

from 0.5V below the positive supply to 1V above the negative

supply. In this range the system has a CMRR of 86dB typical.

However, since the integrator also swings with the common

mode voltage, care must be exercised to assure the integrator

output does not saturate. A worst case condition would be a

large positive common-mode voltage with a near full scale

negative differential input voltage. The negative input signal

drives the integrator positive when most of its swing has been

used up by the positive common mode voltage. For these

critical applications the integrator swing can be reduced to

less than the recommended 4V full scale swing with some

loss of accuracy. The integrator output can swing within 0.3V

of either supply without loss of linearity.

Analog COMMON

Analog COMMON is used as the input low return during auto-

zero and de-integrate. If IN LO is different from analog

COMMON, a common mode voltage exists in the system and

is taken care of by the excellent CMRR of the converter.

However, in most applications IN LO will be set at a fixed

known voltage (power supply common for instance). In this

application, analog COMMON should be tied to the same

point, thus removing the common mode voltage from the

converter. The reference voltage is referenced to analog

COMMON.

Reference

The reference input must be generated as a positive voltage

with respect to COMMON, as shown in Figure 4.

OUTPUT COUNT

10,000

V

IN

V

REF

---------------

=

FIGURE 4A.

FIGURE 4B.

FIGURE 4. USING AN EXTERNAL REFERENCE

I

Z

6.8V

V-

ZENER

REF HI

ICL7135

COMMON

V+

6.8k

ICL8069

REF HI

ICL7135

COMMON

V+

V+

20k

1.2V

REFERENCE

ICL7135