| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ISL6529CR | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

Æ

ISL6529, ISL6529A

Dual Regulator≠Synchronous Rectified

Buck PWM and Linear Power Controllers

The ISL6529, ISL6529A provide the power control and

protection for two output voltages in high-performance

graphics cards and other embedded processor applications.

The dual-output controllers drive two N-Channel MOSFETs

in a synchronous rectified buck converter topology and one

N-Channel MOSFET in a linear configuration. The ISL6529,

ISL6529A provide both a regulated high current, low voltage

supply and an independent, lower current supply integrated

in a 14-lead SOIC package. The controllers are ideal for

graphic card applications where regulation of both the

graphics processing unit (GPU) and memory supplies is

required.

The synchronous rectified buck converters incorporate

simple, single feedback loop, voltage-mode control with fast

transient response. Both the switching regulator and linear

regulator provide a maximum static regulation tolerance of

±

2% over line, load, and temperature ranges. Each output is

user-adjustable by means of external resistors.

An integrated soft-start feature brings both supplies into

regulation in a controlled manner. Each output is monitored

via the FB pins for undervoltage events. If either output

drops below 51.5% of the nominal output level, both

converters are shut down.

Features

∑ Provides two regulated voltages

- One synchronous rectified buck PWM controller

- One linear controller

∑ Both controllers drive low cost N-Channel MOSFETs

∑ 12V direct drive saves external components

∑ Small converter size

- 600kHz constant frequency operation

- Small external component count

∑ Excellent output voltage regulation

- Both outputs: ±1% over temperature - ISL6529AC

- Both outputs: ±2% over temperature - ISL6529C

∑ 5V down conversion

∑ PWM and linear output voltage range: down to 0.8V

∑ Simple single-loop voltage-mode PWM control design

∑ Fast PWM converter transient response

- High-bandwidth error amplifier

- Full 0-100% duty ratio

∑ Linear controller drives N-Channel MOSFET pass transistor

∑ Fully-adjustable outputs

∑ Undervoltage fault monitoring on both outputs

∑ QFN Package:

- Compliant to JEDEC PUB95 MO-220

QFN - Quad Flat No Leads - Package Outline

- Near Chip Scale Package footprint, which improves

PCB efficiency and has a thinner profile

∑

Pb-Free Available (RoHS Compliant)

Applications

∑ Graphics≠GPU and memory supplies

∑ ASIC power supplies

∑ Embedded processor and I/O supplies

∑ DSP supplies

Related Literature

∑ Technical Brief TB363 Guidelines for Handling and

Processing Moisture Sensitive Surface Mount Devices

(SMDs)

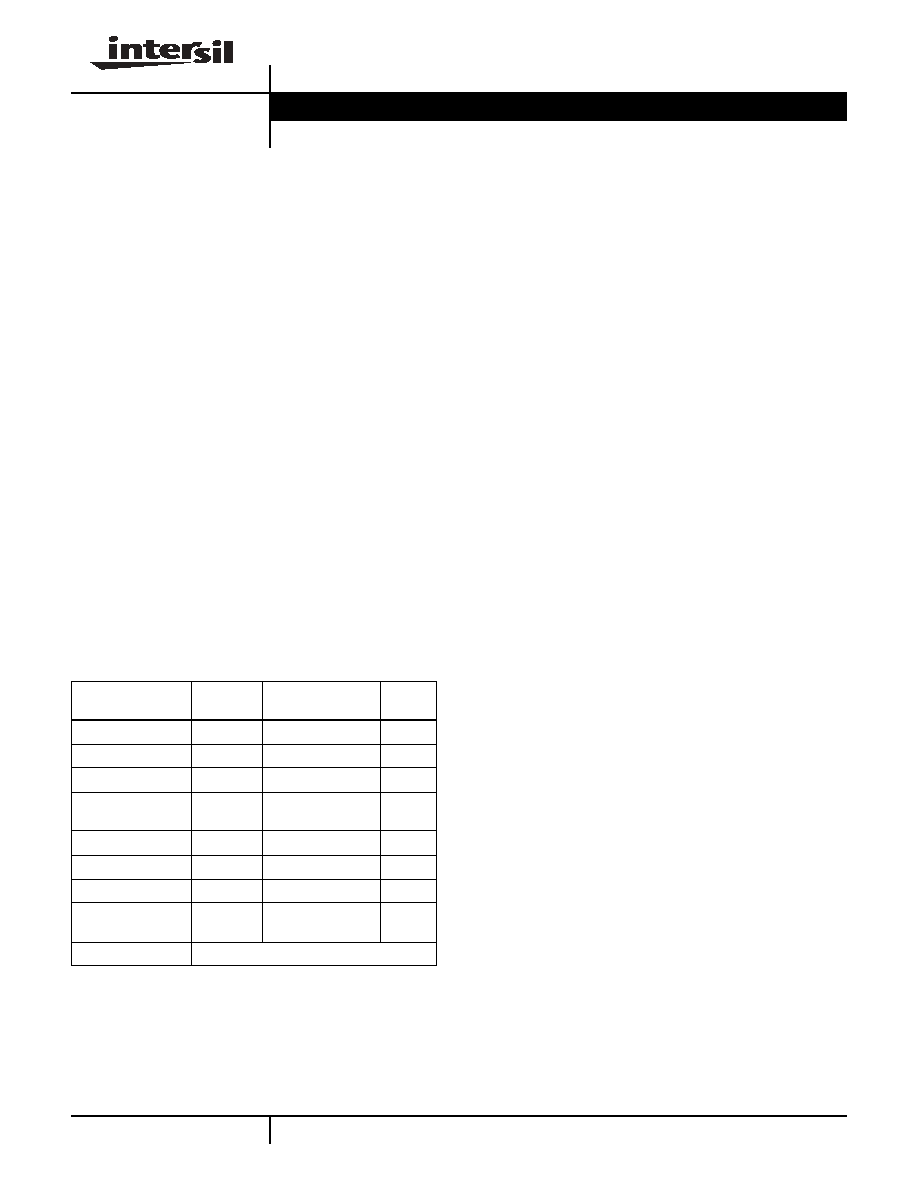

Ordering Information

PART NUMBER*

TEMP.

RANGE (∞C)

PACKAGE

PKG.

DWG. #

ISL6529ACB

0 to 70

14 Ld SOIC

M14.15

ISL6529ACBZ (Note)

0 to 70

14 Ld SOIC (Pb-free) M14.15

ISL6529ACR

0 to 70

16 Ld 5x5 QFN

L16.5x5B

ISL6529ACRZ (Note)

0 to 70

16 Ld 5x5 QFN

(Pb-free)

L16.5x5B

ISL6529CB

0 to 70

14 Ld SOIC

M14.15

ISL6529CBZ (Note)

0 to 70

14 Ld SOIC (Pb-free) M14.15

ISL6529CR

0 to 70

16 Ld 5x5 QFN

L16.5x5B

ISL6529CRZ (Note)

0 to 70

16 Ld 5x5 QFN

(Pb-free)

L16.5x5B

ISL6529EVAL1

Evaluation Board

*Add "-T" suffix for tape and reel.

NOTE: Intersil Pb-free products employ special Pb-free material sets;

molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both

SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or

exceed the Pb-free requirements of IPC/JEDEC J STD-020.

Data Sheet

April 12, 2005

FN9070.5

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002-2005. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

2

FN9070.5

April 12, 2005

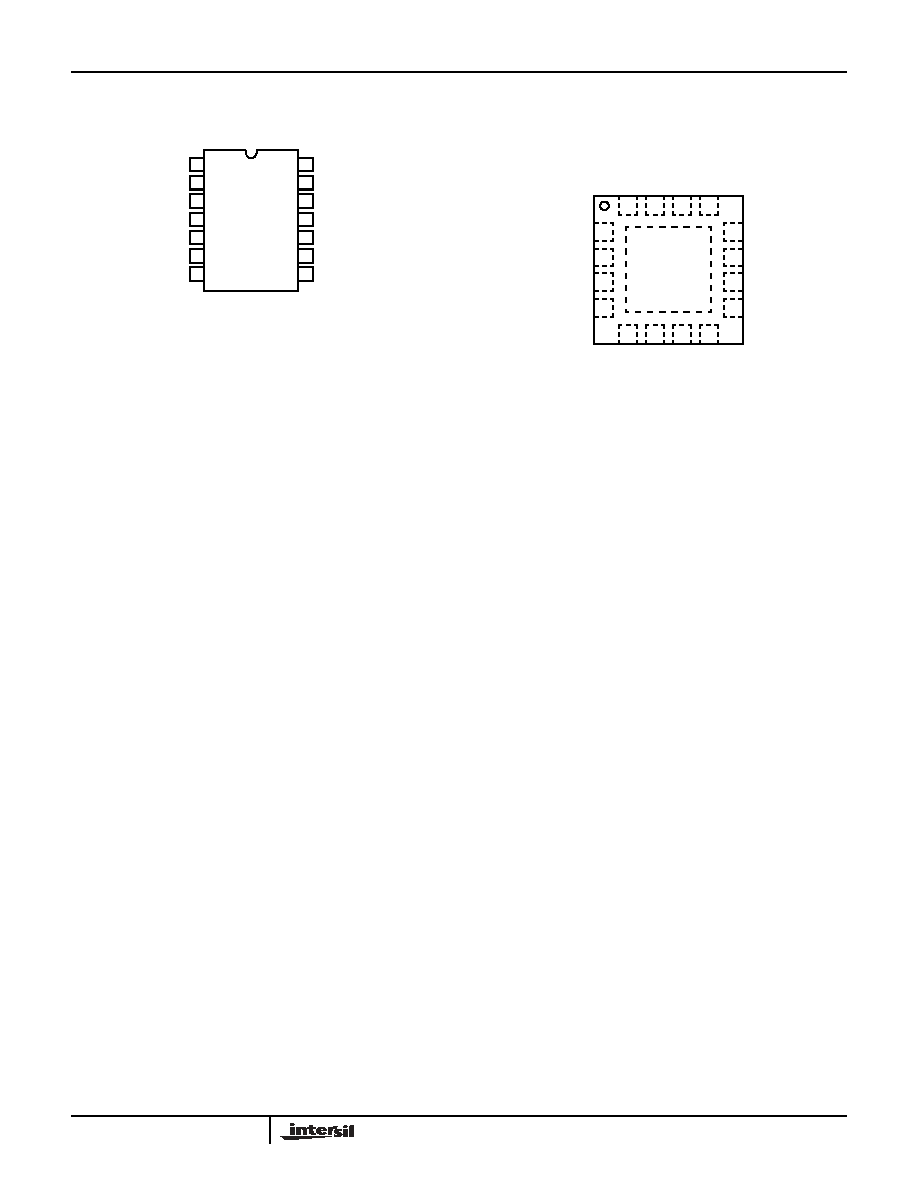

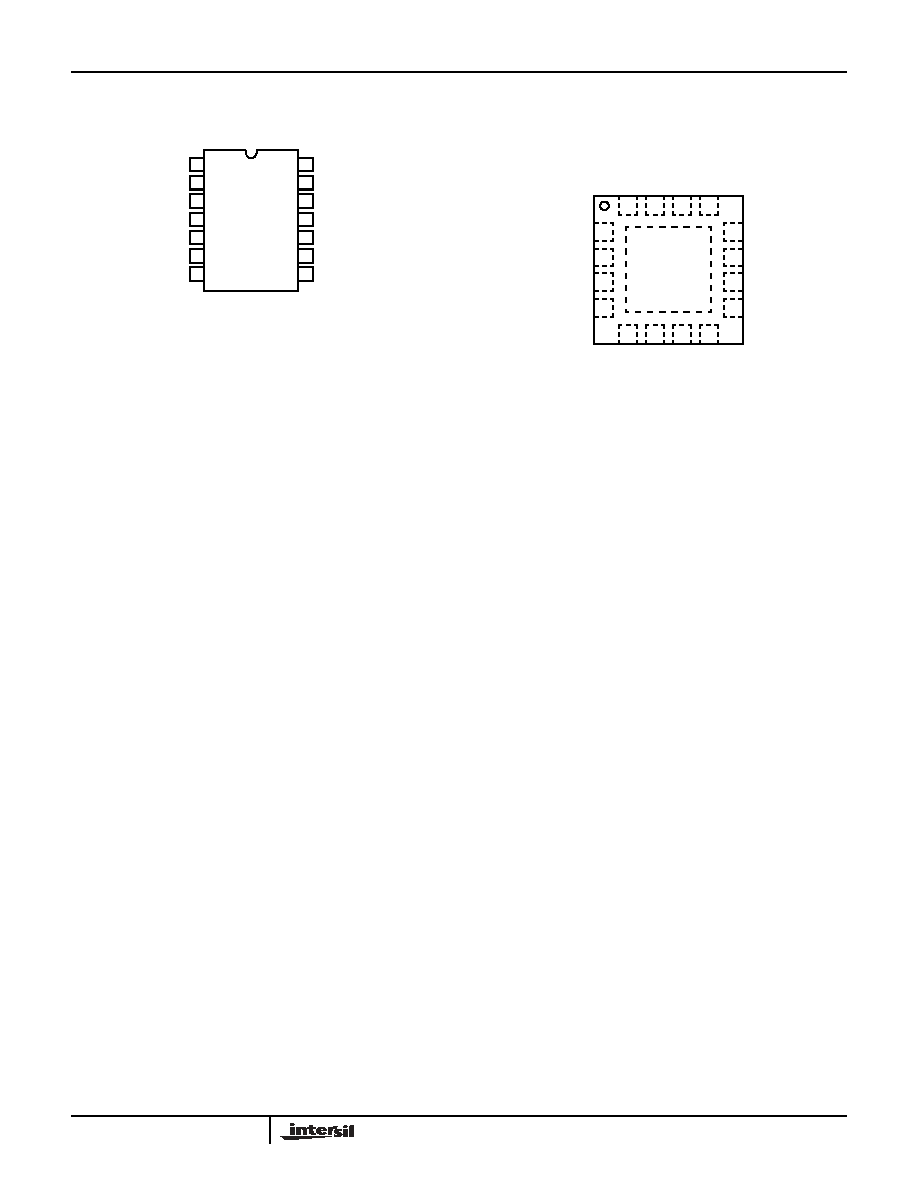

Pinouts

ISL6529, ISL6529A (SOIC)

TOP VIEW

ISL6529, ISL6529A (QFN)

TOP VIEW

5VCC

GND

DRIVE2

FB2

UGATE

FB

COMP

LGATE

14

13

12

11

1

2

3

4

10

9

8

5

6

7

12VCC

PGND

NC

NC = NO INTERNAL CONNECTION

NC

NC

NC

PGND

GND

5VCC

DRIVE2

LG

ATE

NC

UGATE

NC

12VCC

NC

COMP

FB

FB

2

NC

NC

NC

NC = NO INTERNAL CONNECTION

1

3

4

15

16

14

13

2

12

10

9

11

6

5

7

8

ISL6529, ISL6529A

3

FN9070

.5

Apr

il 12, 200

5

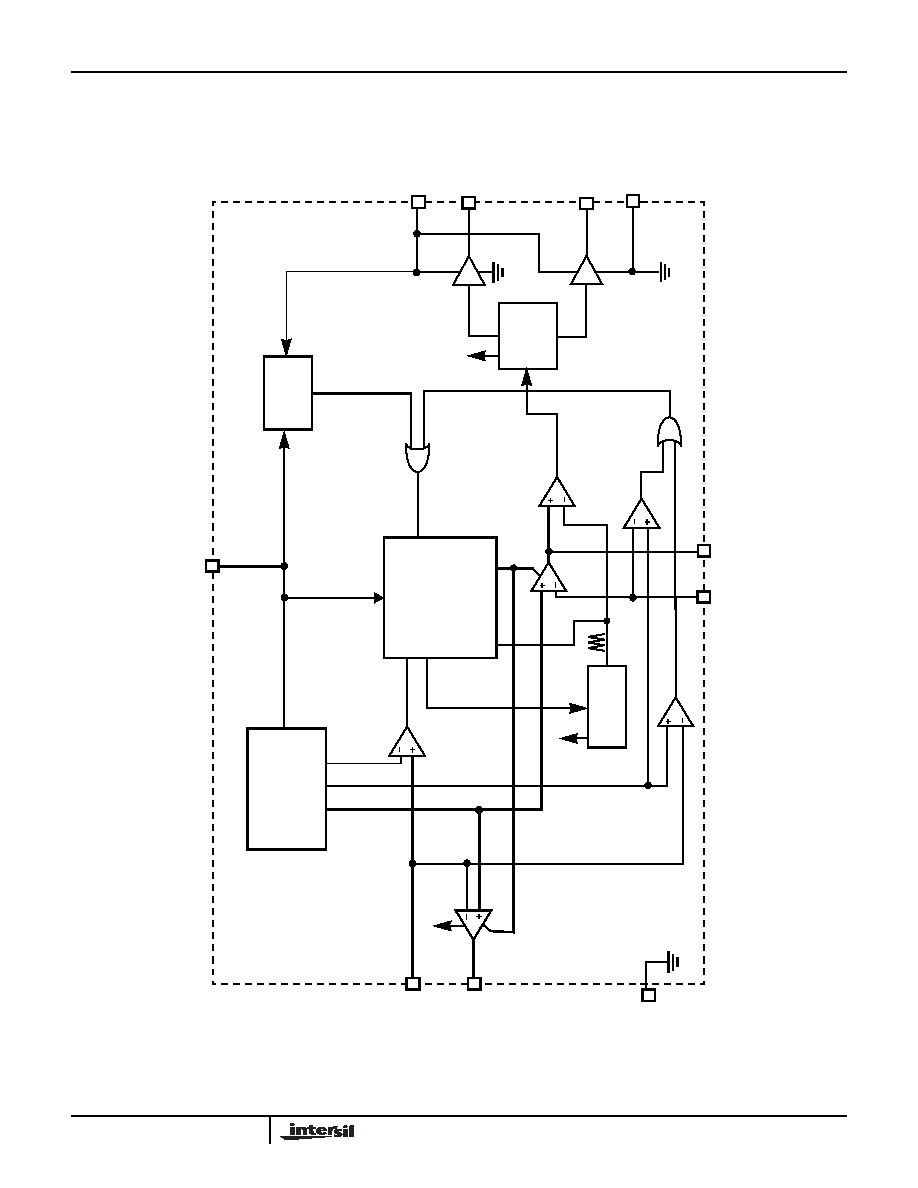

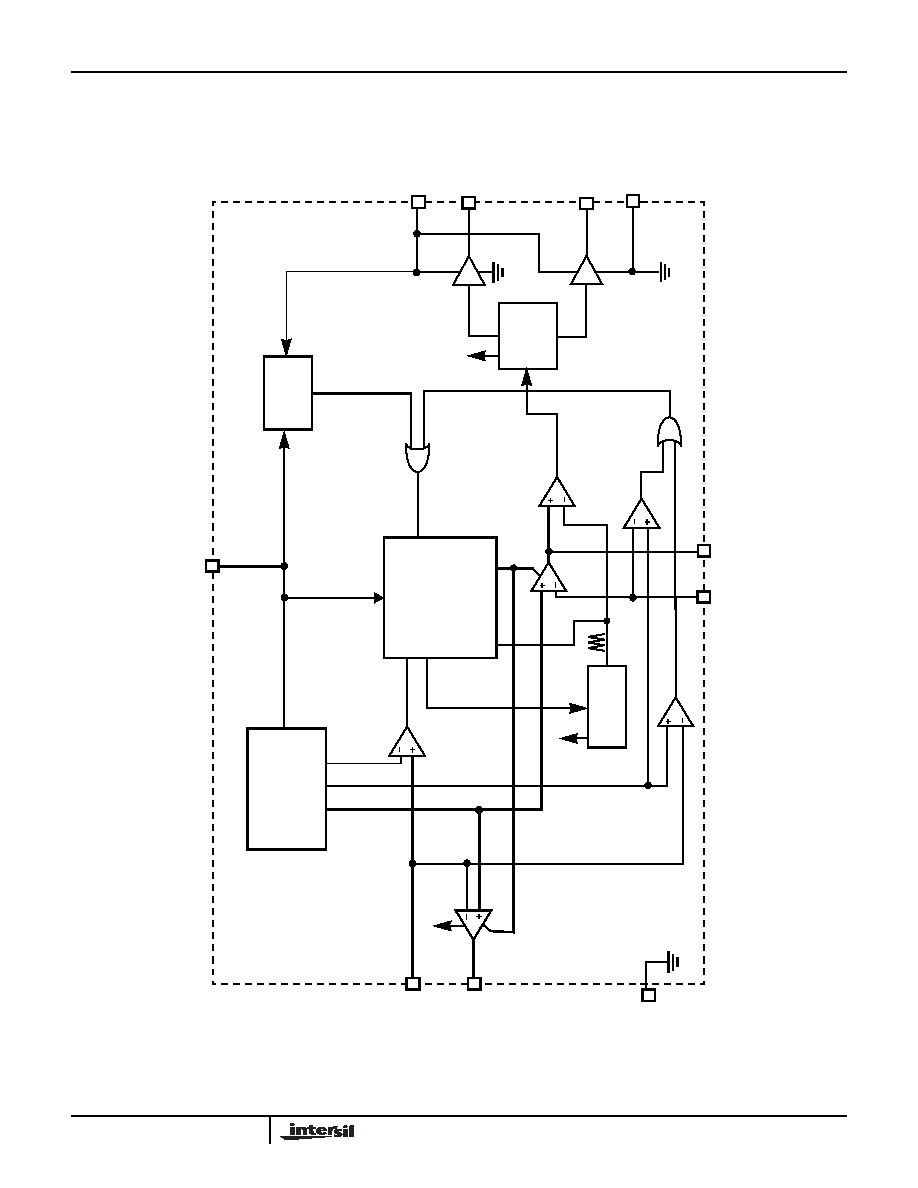

Block Diagram

SOFT-

START

COMP1

EA1

5VCC

PWM

GND

UGATE

DRIVE2

FB2

POWER-ON

RESET (POR)

OSCILLATOR

AND FAULT

LOGIC

FB

COMP

EA2

UV2

VOLTAGE

REFERENCE

RESTART

UV1

INHIBIT

SOFT-START

INHIBIT

SOFT-START

0.

80

V

0.

41

V

LGATE

12VCC

GATE

LOGIC

+5VCC

+5V

PGND

12VCC

SHUTDOWN

1.

28

V

ISL6529, ISL6529A

4

FN9070.5

April 12, 2005

ISL6529, ISL6529A

Simplified Power System Diagram

Typical Application

PWM

+5V

V

OUT1

Q1

Q3

V

OUT2

LINEAR

ISL6529

CONTROLLER

CONTROLLER

+

+V

IN

Q2

+

+12V

ISL6529A

GND

12VCC

+V

IN

+5V

V

OUT1

UGATE

Q1

FB

COMP

1.5V

DRIVE2

Q3

FB2

C

OUT2

C

IN

C

OUT1

L

OUT

ISL6529

V

OUT2

2.5V

+

+

+

PHASE

C

BP

Q2

(+5V or +3.3V)

LGATE

+12V

C

BP

5VCC

PGND

ISL6529A

5

FN9070.5

April 12, 2005

ISL6529, ISL6529A

Absolute Maximum Ratings

Thermal Information

UGATE, LGATE, DRIVE2,. . . . . . . . . . . . . . . GND - 0.3V to 12VCC

5VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +7V

12VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +14V

FB, FB2, COMP, . . . . . . . . . . . . . . . . . GND - 0.3V to 5VCC + 0.3V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 4kV

Operating Conditions

Supply Voltage on 5VCC . . . . . . . . . . . . . . . . . . . . . . . . . +5V ±10%

Supply Voltage on 12VCC . . . . . . . . . . . . . . . . . . . . . . . +12V ±10%

Supply Voltage to drain of Upper MOSFETs . . . +3.3V to +5V ±10%

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . . 0∞C to 70∞C

Junction Temperature Range . . . . . . . . . . . . . . . . . . . 0∞C to 125∞C

Thermal Resistance

JA

(∞C/W)

JC

(∞C/W)

SOIC Package (Note 1) . . . . . . . . . . . .

68

NA

QFN Package (Notes 2, 3). . . . . . . . . .

36

5

Maximum Junction Temperature (Plastic Package) . . . . . . . 150∞C

Maximum Storage Temperature Range . . . . . . . . . -65∞C to 150∞C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300∞C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1.

JA

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

2.

JA

is measured in free air with the component mounted on a high effective thermal conductivity test board with "direct attach" features. See

Tech Brief TB379.

3.

For

JC

, the "case temp" location is the center of the exposed metal pad on the package underside.

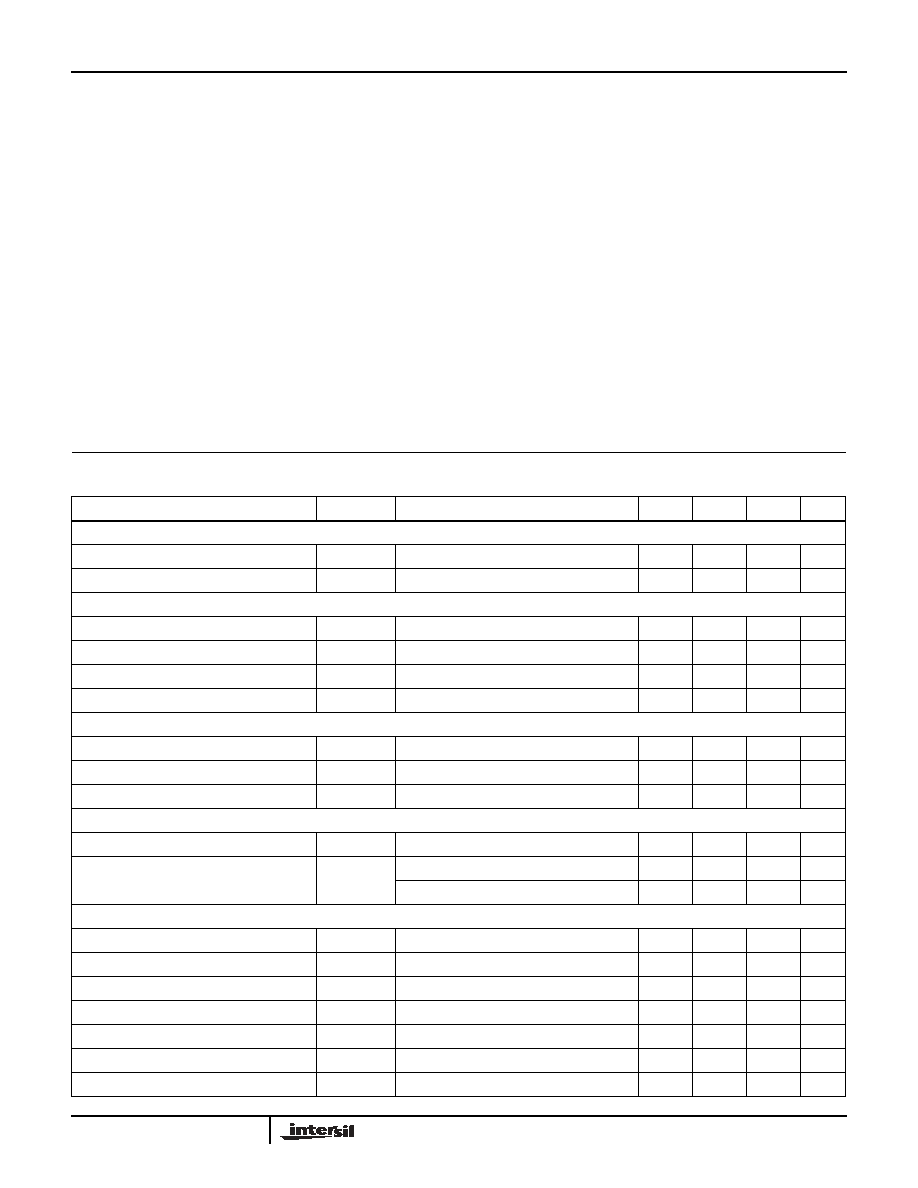

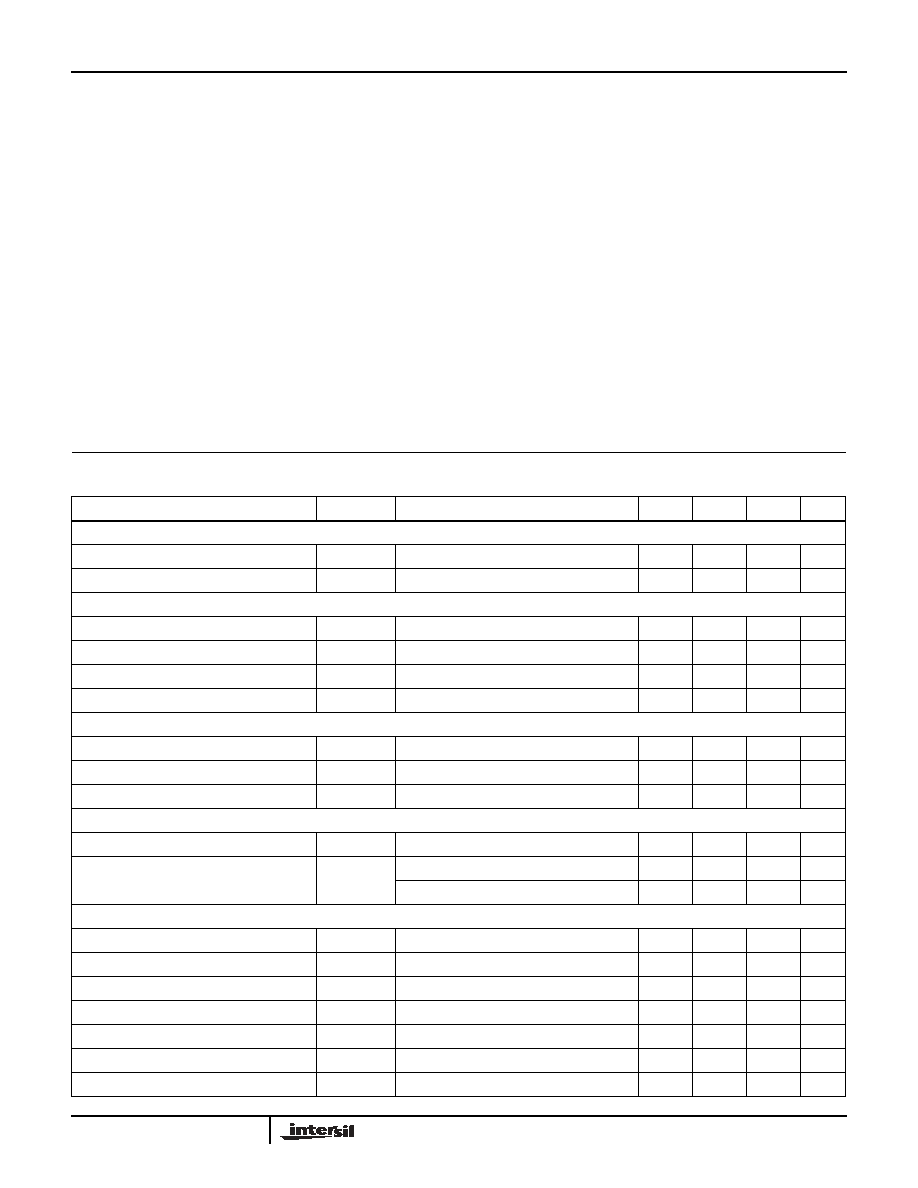

Electrical Specifications

Recommended Operating Conditions, Unless Otherwise Noted. Refer to Block and Simplified Power System

Diagrams, and Typical Application Schematic

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

VCC SUPPLY CURRENT

Nominal Supply Current 12VCC

I

CC

UGATE, LGATE and DRIVE2 Open

-

2.7

3.0

mA

Nominal Supply Current 5VCC

I

CC

UGATE, LGATE and DRIVE2 Open

-

3.5

4.5

mA

POWER-ON RESET

Rising 5VCC Threshold

12VCC = 12V

4.25

4.4

4.5

V

Falling 5VCCThreshold

12VCC = 12V

3.75

3.82

4.0

V

Rising 12VCC Threshold

5VCC = 5V

9.6

10.3

10.8

V

Falling 12VCCThreshold

5VCC = 5V

9.3

9.6

10.2

V

OSCILLATOR AND SOFT-START

Free Running Frequency

F

OSC

550

600

650

kHz

Ramp Amplitude

DV

OSC

-

1.5

-

V

P-P

Soft-Start Interval

T

SS

3.1

3.45

3.75

ms

REFERENCE VOLTAGE

Reference Voltage

V

REF

-

0.800

-

V

System Accuracy

ISL6529C

-2.0

-

+2.0

%

ISL6529AC

-1.0

-

+1.0

%

PWM CONTROLLER ERROR AMPLIFIER

DC Gain

R

L

= 10K, C

L

= 10pF

-

80

-

dB

Gain-Bandwidth Product

GBWP

R

L

= 10K, C

L

= 10pF

-

15

-

MHz

Slew Rate

SR

R

L

= 10K, C

L

= 10pF

-

6

-

V/

µ

s

FB Input Current

I

I

V

FB

= 0.8V

-

20

150

nA

COMP High Output Voltage

V

OUT

High

3.0

4.5

-

V

COMP Low Output Voltage

V

OUT

Low

-

0.5

1.0

V

COMP High Output, Source Current

I

OUT

High

-2.5

-6.8

-

mA

6

FN9070.5

April 12, 2005

Functional Pin Descriptions

LGATE (Pin 1), (Pin 16 QFN)

Lower gate drive output. Connect to gate of the low-side

MOSFET.

PGND (Pin 2), (Pin 1 QFN)

This pin is the power ground return for the lower gate driver.

GND (Pin 3), (Pin 2 QFN)

Signal ground for the IC. All voltage levels are measured

with respect to this pin. Place via close to pin to minimize

impedance path to ground plane.

5VCC (Pin 4), (Pin 3 QFN)

Provide a well decoupled 5V bias supply for the IC to this

pin. The voltage at this pin is monitored for Power-On Reset

(POR) purposes.

DRIVE2 (Pin 5), (Pin 4 QFN)

Connect this pin to the gate terminal of an external

N-Channel MOSFET transistor. This pin provides the gate

voltage for the linear regulator pass transistor. It also

provides a means of compensating the error amplifier for

applications where the user needs to optimize the regulator

transient response.

COMP Low Output, Sink Current

I

OUT

Low

2.5

3.5

-

mA

Undervoltage Level (V

FB

/V

REF

)

V

UV

-

51.5

-

%

PWM CONTROLLER GATE DRIVERS

UGATE and LGATE Maximum Voltage

V

HGATE

12VCC = 12V

11

12

-

V

UGATE and LGATE Minimum Voltage

V

LGATE

12VCC = 12V

-

0

0.5

V

UGATE and LGATE Source Current

I

GATE

12VCC = 12V

-

-1

-

A

UGATE and LGATE Sink Current

I

GATE

12VCC = 12V

-

1

-

A

UGATE and LGATE OUTPUT IMPEDANCE

R

DS(on)

12VCC = 12V

-

3.1

4.3

LINEAR REGULATOR (DRIVE2)

DC Gain

R

L

= 10K, C

L

= 10pF

-

80

-

dB

Gain-Bandwidth Product

GBWP

R

L

= 10K, C

L

= 10pF

-

15

-

MHz

Slew Rate

SR

R

L

= 10K, C

L

= 10pF

-

6

-

V

/µ

s

FB2 Input Current

I

I

V

FB2

= 0.8V

-

20

150

nA

Drive2 High Output Voltage

V

OUT

High

9.5

10.3

-

V

Drive2 Low Output Voltage

V

OUT

Low

-

0.1

1.0

V

Drive2 High Output Source Current

I

OUT

High

-0.7

-1.4

-

mA

Drive2 Low Output Sink Current

I

OUT

Low

0.85

1.2

-

mA

Over-Voltage Level (V

FB2

/V

REF

)

V

OV

Percent of Nominal

-

160

-

%

Under-Voltage Level (V

FB2

/V

REF

)

V

UV

Percent of Nominal

-

51.5

-

%

REGULATOR ISOLATION

Change in Linear Regulator Output Voltage

(Note 4)

Vout

Linear Output = 2.5V, 6A Load Change on PWM

-

<0.5

-

%

Change in PWM Regulator Output Voltage

(Note 4)

Vout

PWM Output = 1.5V, 1A Load Change on Linear

-

<0.5

-

%

NOTE:

4. Measured in the evaluation board.

Electrical Specifications

Recommended Operating Conditions, Unless Otherwise Noted. Refer to Block and Simplified Power System

Diagrams, and Typical Application Schematic (Continued)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

5VCC

GND

DRIVE2

FB2

UGATE

FB

COMP

LGATE

14

13

12

11

1

2

3

4

10

9

8

5

6

7

12VCC

PGND

NC

NC = NO INTERNAL

NC

NC

NC

CONNECTION

ISL6529, ISL6529A

7

FN9070.5

April 12, 2005

FB2 (Pin 6), (Pin 5 QFN)

Connect the output of the linear regulator to this pin

through a properly sized resistor divider. The voltage at this

pin is regulated to 0.8V. This pin is also monitored for

undervoltage events.

Pulling and holding FB2 above 1.28V shuts down both

regulators. Releasing FB2 initiates soft-start on both regulators.

NC (Pins 7, 8, 11, and 12), (Pins 6, 7, 8, 11, 13 and

15 QFN)

No internal connection.

FB (Pin 9), (Pin 9 QFN) and COMP (Pin 10), (Pin 10

QFN)

FB and COMP are the available external pins of the error

amplifier. The FB pin is the inverting input of the error amplifier

and the COMP pin is the error amplifier output. These pins are

used to compensate the voltage-mode control feedback loop of

the standard synchronous rectified buck converter.

12VCC(Pin 13), (Pin 12 QFN)

Provides bias voltage for the gate drivers.The voltage at this

pin is monitored for Power-On Reset (POR) purposes.

UGATE (Pin 14), (Pin 14 QFN)

Connect UGATE to the upper MOSFET gate. This pin

provides the gate drive for the MOSFET.

Description

Operation Overview

The ISL6529 monitors and precisely controls two output

voltage levels. Refer to the Block Diagram, Simplified Power

System Diagram, and Typical Application Schematic on pp.

2≠3. The controller is intended for use in graphics cards or

embedded processor applications with 5V and 12V bias input

available. The IC integrates both a standard buck PWM

controller and a linear controller. The PWM controller is

designed to regulate the high current GPU voltage (V

OUT1

).

The PWM controller regulates the output voltage to a level

programmed by a resistor divider. The linear controller is

designed to regulate the lower current local memory voltage

(V

OUT2

) through an external N-Channel MOS pass transistor.

Initialization

The ISL6529 automatically initializes upon application of

input power. Special sequencing of the input supplies is not

necessary. The POR function continually monitors the input

bias supply voltage at the 5VCC and 12VCC pins. The POR

function initiates soft-start operation after these supply

voltages exceed their POR threshold voltages.

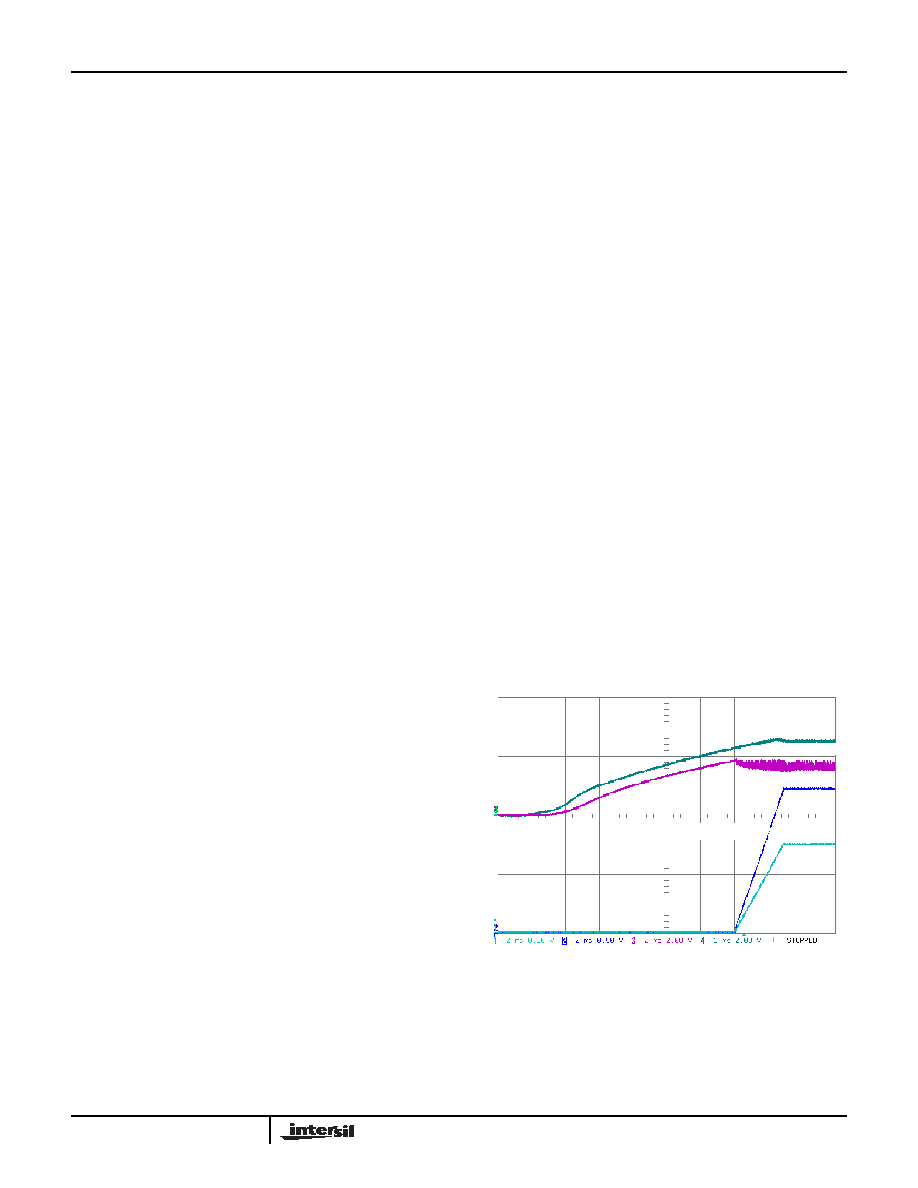

Soft-Start

The POR function initiates the digital soft-start sequence.

Both the linear regulator error amplifier and PWM error

amplifier reference inputs are forced to track a voltage level

proportional to the soft-start voltage. As the soft-start voltage

slews up, the PWM comparator regulates the output relative

to the tracked soft-start voltage, slowly charging the output

capacitor(s). Simultaneously, the linear output follows the

smooth ramp of the soft-start function into normal regulation.

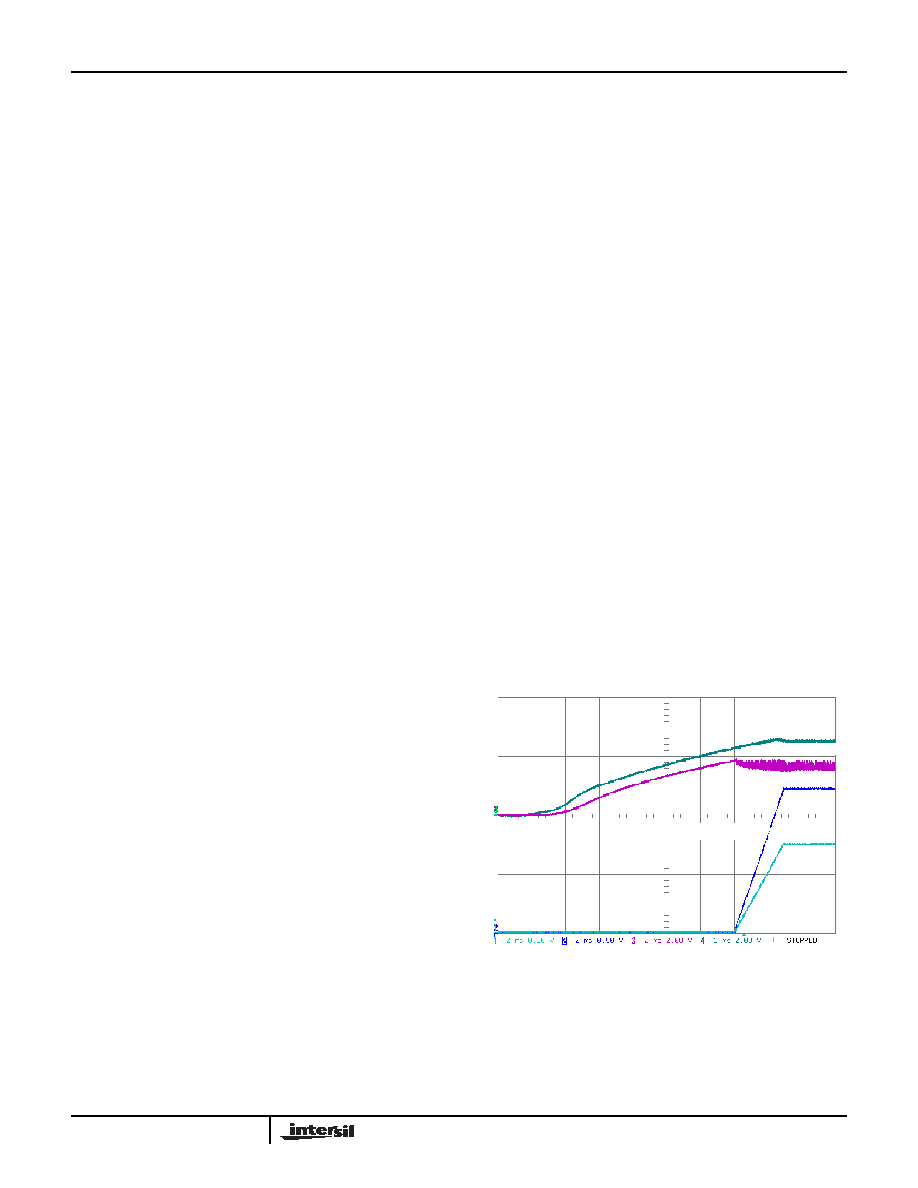

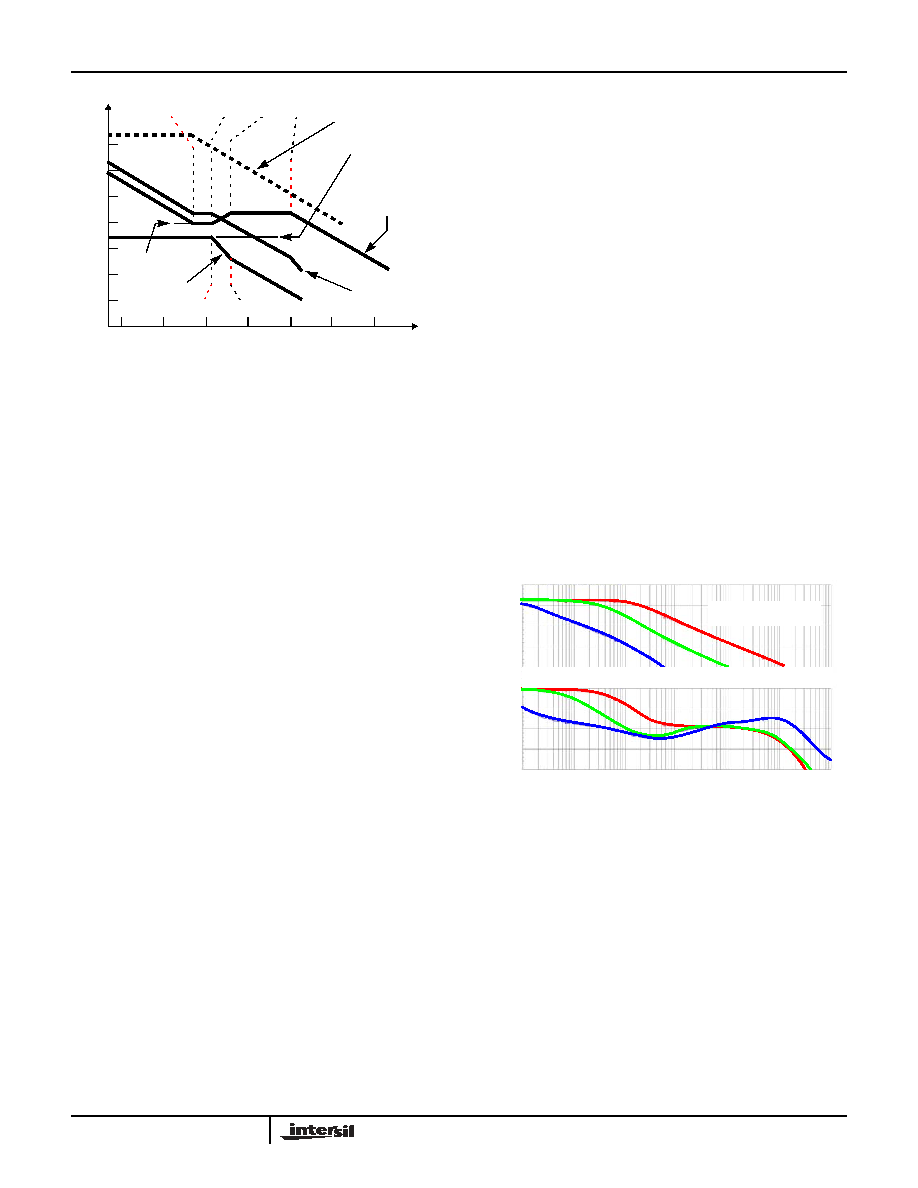

Figure 1 shows the soft-start sequence of an ISL6529

evaluation board powered by an ATX supply. Note the

uniform linear output voltage rise of the two ISL6529 output

voltages. Once the voltage on 5VCC crosses the POR

thresholds, both outputs begin their soft-start sequence. The

triangle waveform from the PWM oscillator is compared to

the rising error amplifier output voltage. As the error amplifier

voltage increases, the pulse-width on the PWM increases to

reach its steady-state duty cycle. The error amplifier

reference of the linear controller also rises relative to the

soft-start reference.

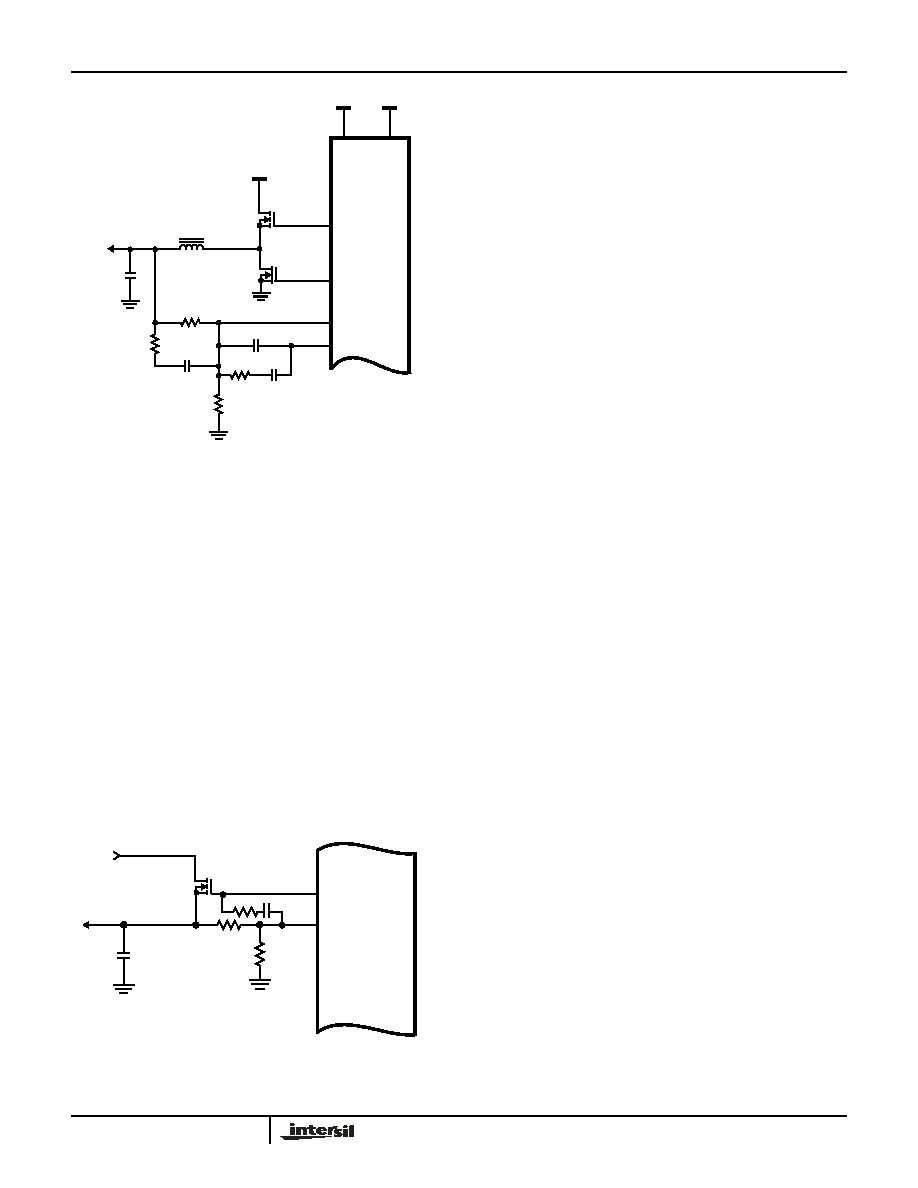

Figure 2 shows the controlled stepped output voltage rise

and associated charging current of a 390

µ

F polymer

capacitor. By providing many small steps of current that

effectively charge the output capacitor, the potentially large

peak current resulting from a sudden, uncontrolled voltage

rise is eliminated.

The clock for the DAC producing the 30mV steps is

approximately 18.5kHz, so there is a 18.5kHz ripple current

component that lasts for the approximate 2.8ms start-up

interval. A few clock cycles are used for initialization to

insure that soft-start begins near zero volts.

FIGURE 1. ATX SUPPLY POWERING AN ISL6529

EVALUATION BOARD

5VCC INPUT

3.3V INPUT

1.5V OUTPUT

2.4V OUTPUT

ISL6529, ISL6529A

8

FN9070.5

April 12, 2005

Undervoltage Protection

The FB and FB2 pins are monitored during converter

operation by two separate undervoltage (UV) comparators. If

the FB voltage drops below 51.5% of the reference voltage

(0.41V), a fault signal is generated. The internal fault logic

shuts down both regulators simultaneously when the fault

signal triggers a restart.

Figure 3 illustrates the protection feature responding to a UV

event on V

OUT1

. At time t0, VOUT1 has dropped below

51.5% of the nominal output voltage. Both outputs are quickly

shut down and the internal soft-start function begins

producing soft-start ramps. The delay interval, t0 to t3, seen

by the output is equivalent to three soft-start cycles. After a

short delay interval of 10.5ms, the fourth internal soft-start

cycle initiates a normal soft-start ramp of the output, at time t3.

Both outputs are brought back into regulation by time t4, as

long as the UV event has cleared.

Had the cause of the UV still been present after the delay

interval, the UV protection circuitry becomes active

approximately 875ms into the soft-start interval. A fault

signal could then be generated and the outputs once again

shut down. The resulting hiccup mode style of protection

would continue to repeat indefinitely.

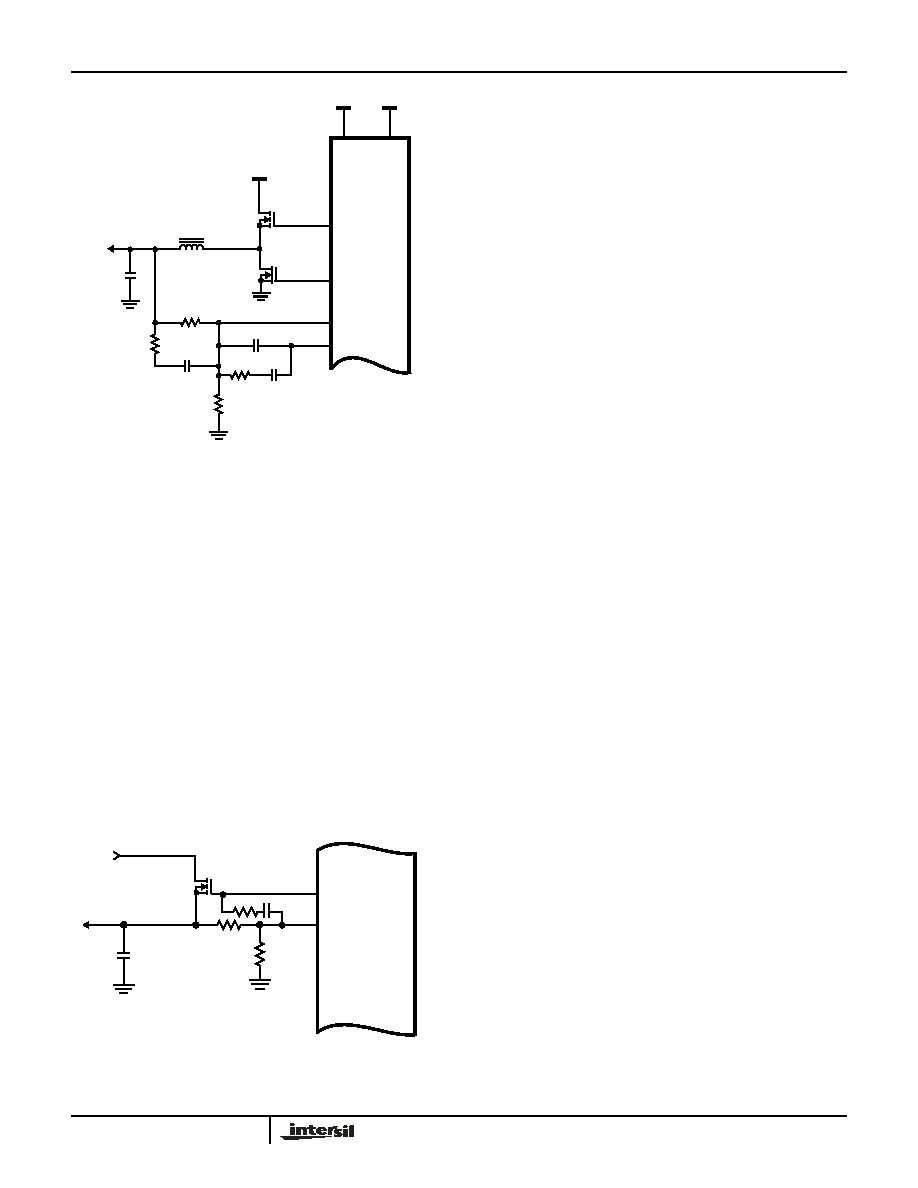

Output Voltage Selection

The output voltage of the PWM converter can be programmed

to any level between V

IN

(i.e. +3.3V) and the internal

reference, 0.8V . An external resistor divider is used to scale

the output voltage relative to the reference voltage and feed it

back to the inverting input of the error amplifier (see Figure 4).

CAPACITOR CURRENT

CAPACITOR CURRENT

1.5V OUTPUT

1.5V OUTPUT

FIGURE 2. TOP SCOPE TRACES ARE VOLTAGE RAMP AND

CAPACITOR CURRENT. LOWER TRACES ARE

TIME AND VOLTAGE EXPANSION OF UPPER

SCOPE TRACES.

FIGURE 3. UNDERVOLTAGE PROTECTION RESPONSE

0V

0V

TIME

V

OUT2

(2.5V)

t1

t2

t3

t0

t4

(0.5V/DIV)

V

OUT1

(1.5V)

INTERNAL SOFT-START FUNCTION

V

OUT2

(2.5V)

DELAY INTERVAL

DELAY INTERVAL

ISL6529, ISL6529A

9

FN9070.5

April 12, 2005

However, since the value of R1 affects the values of the rest

of the compensation components, it is advisable to keep its

value less than 5k

. Depending on the value chosen for R1,

R4 can be calculated based on the following equation:

If the output voltage desired is 0.8V, simply route VOUT1

back to the FB pin through R1, but do not populate R4.

The linear regulator output voltage is also set by means of

an external resistor divider as shown in Figure 5. The two

resistors used to set the output voltage should not exceed a

parallel equivalent value, referred to as R

FB

, of 5k

. This

restriction is due to the manner of implementation of the soft-

start function. The following relationship must be met:

To ensure the parallel combination of the feedback resistors

meets this criteria, choose a target value for R

FB

of less than

5k

and then apply the following equations:

where V

OUT2

is the desired linear regulator output voltage

and V

REF

is the internal reference voltage, 0.8V. For an

output voltage of 0.8V, simply populate R5 with a value less

than 5k

and do not populate R6.

Converter Shutdown

Pulling and holding the FB2 pin above a typical threshold of

1.28V will shut down both regulators. Upon release of the

FB2 pin, the regulators enter into a soft-start cycle which

brings both outputs back into regulation.

PWM Controller Feedback Compensation

A simplified representation of the voltage-mode control loop

used for output regulation by the converter is shown in

Figure 6. The output voltage, V

OUT

, is fed back to the

negative input of the error amplifier which is regulated to the

reference voltage level, V

REF

. The error amplifier output,

V

E/A

, is compared with the triangle wave produced by the

oscillator, V

OSC

, to provide a pulse-width modulated (PWM)

signal from the PWM comparator. This signal is then used to

switch the MOSFET and produce a PWM waveform with an

amplitude of V

IN

at the PHASE node. The square-wave

PHASE voltage is then smoothed by the output filter, L

OUT

and C

OUT

, to produce a DC voltage level.

The modulator transfer function is defined as V

OUT

/V

E/A

.

The internal PWM comparator and driver circuits equate to a

DC gain block dominated by the supply voltage, V

IN

, divided

by the peak-to-peak magnitude of the triangle wave,

V

OSC

.

The output filter components, L

OUT

and C

OUT

, shape the

overall modulator small-signal transfer function by

contributing a double pole break frequency at F

LC

and a

zero at F

ESR

.

FIGURE 4. OUTPUT VOLTAGE SELECTION OF THE PWM

+

R1

C

OUT1

+5V

+3.3V

V

OUT1

R4

L

OUT

ISL6529

Q1

FB

UGATE

12VCC

COMP

R2

C1

C2

R3

C3

5VCC

+12V

Q2

LGATE

ISL6529A

R4

R1 0.8V

◊

V

OUT1

0.8V

≠

--------------------------------------

=

(EQ. 1)

R

FB

R5 R6

◊

R5 R6

+

---------------------- 5k

<

=

(EQ. 2)

DRIVE2

FB2

C

OUT2

ISL6529

V

OUT2

+3.3V

IN

R5

R6

FIGURE 5. OUTPUT VOLTAGE SELECTION OF THE LINEAR

+

V

OUT2

0.8

1 R5

R6

--------

+

◊

=

Q3

C4

R12

For frequency compensation considerations

set R5 to 4.64k and adjust R6 for the required voltage.

ISL6529A

R5

V

OUT2

V

REF

------------------- R

FB

◊

=

(EQ. 3)

R6

R5 V

REF

◊

V

OUT2

V

REF

≠

----------------------------------------

=

(EQ. 4)

ISL6529, ISL6529A

10

FN9070.5

April 12, 2005

Modulator Break Frequency Equations

The compensation network consists of the error amplifier

and the impedance networks Z

IN

and Z

FB

. They provide the

link between the modulator transfer function and a

controllable closed loop transfer function of V

OUT

/V

REF

. The

goal of component selection for the compensation network is

to provide a loop gain with high 0dB crossing frequency

(f

0dB

) and adequate phase margin. Phase margin is the

difference between the closed loop phase at f

0dB

and 180

degrees .

Compensation Break Frequency Equations

Follow this procedure for selecting compensation

components by locating the poles and zeros of the

compensation network:

1. Set the loop gain (R2/R1) to provide a converter

bandwidth of one quarter of the switching frequency.

2. Place the first

compensation zero, F

Z1

, below the output

filter double pole (~75% F

LC

).

3. Position the second compensation zero, F

Z2

, at the

output filter double pole, F

LC

.

4. Locate the first compensation pole, F

P1

, at the output

filter ESR zero, F

ESR

.

5. Position the second compensation pole at half the

converter switching frequency, F

SW

.

6. Check gain against error amplifier's open-loop gain.

7. Estimate phase margin; repeat if necessary.

FIGURE 6. VOLTAGE-MODE BUCK CONVERTER

COMPENSATION DESIGN

V

OUT

V

REF

L

OUT

C

O

ESR

V

IN

V

OSC

ERROR

AMP

PWM

DRIVER

(PARASITIC)

+

-

0.8V

R1

R3

R2

C3

C2

C1

COMP

V

OUT

FB

Z

FB

ISL6529

Z

IN

COMP

DETAILED COMPENSATION COMPONENTS

PHASE

V

E/A

+

-

+

+

Z

FB

Z

IN

OSC

F

LC

1

2

L

O

C

O

◊

◊

----------------------------------------

=

F

ESR

1

2

ESR C

O

◊

◊

-----------------------------------------

=

(EQ. 5)

(EQ. 6)

F

Z1

1

2

R

◊

2 C1

◊

-----------------------------------

=

F

Z2

1

2

R1 R3

+

(

)

C3

◊

◊

-------------------------------------------------------

=

F

P1

1

2

R

2

C1 C2

◊

C1 C2

+

----------------------

◊

◊

-------------------------------------------------------

=

F

P2

1

2

R

◊

3 C3

◊

-----------------------------------

=

(EQ. 10)

(EQ. 11)

(EQ. 8)

(EQ. 9)

Zeros:

Poles:

X1

-

+

INTERNAL 0.8V

REFERENCE

C4

C

ISS

= C

GS

+ C

GD

REGULATED OUTPUT

R

LOAD

1/gfs

ESR

GATE

SOURCE

DRAIN

R

SAMPLE

C

OUTPUT

SIMPLIFIED MODEL

OF THE MOSFET

R12

AMPLIFIER

ERROR

ISL6529

DRIVE2

FB

C

GD

C

GS

C16

INPUT VOLTAGE

R5

R6

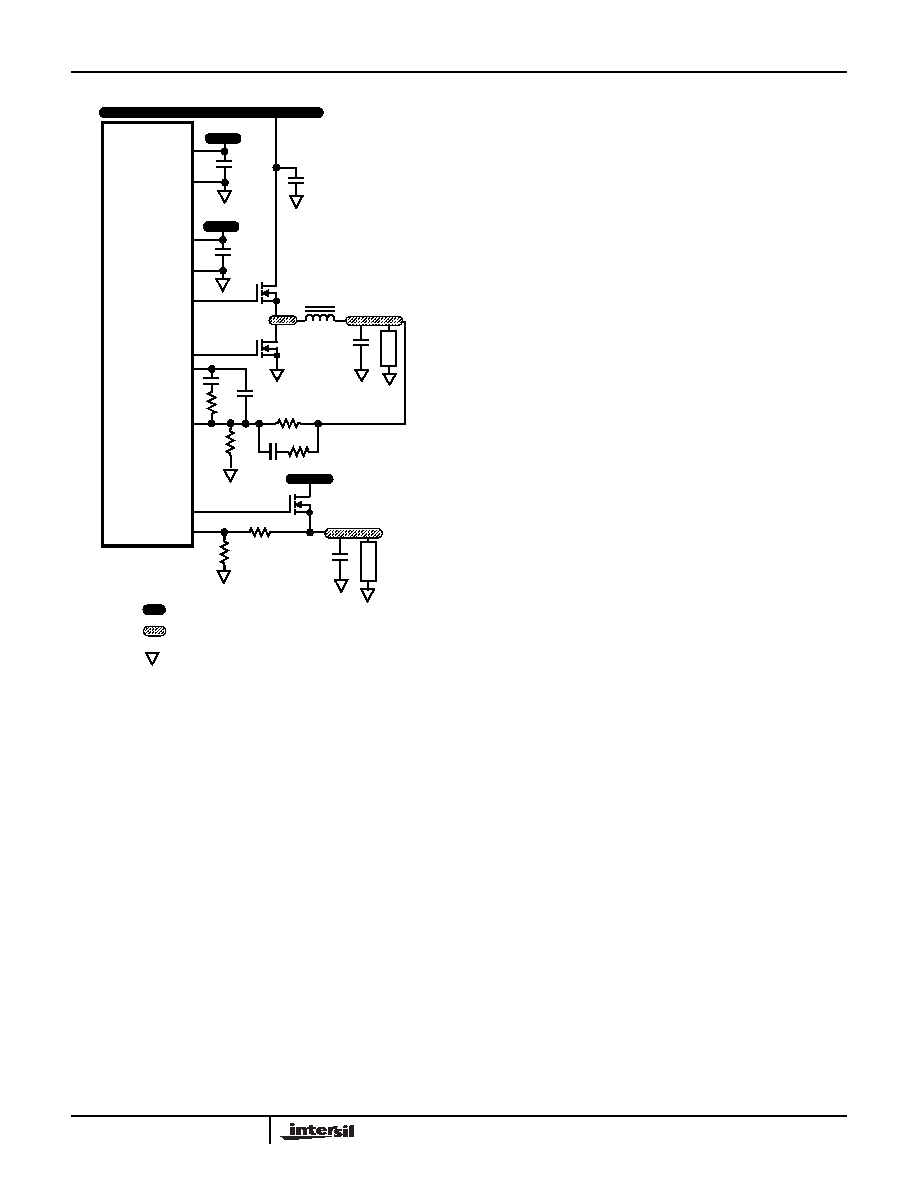

FIGURE 7. FIGURE A. SIMPLIFIED DIAGRAM OF THE LINEAR VOLTAGE REGULATOR

ISL6529, ISL6529A

11

FN9070.5

April 12, 2005

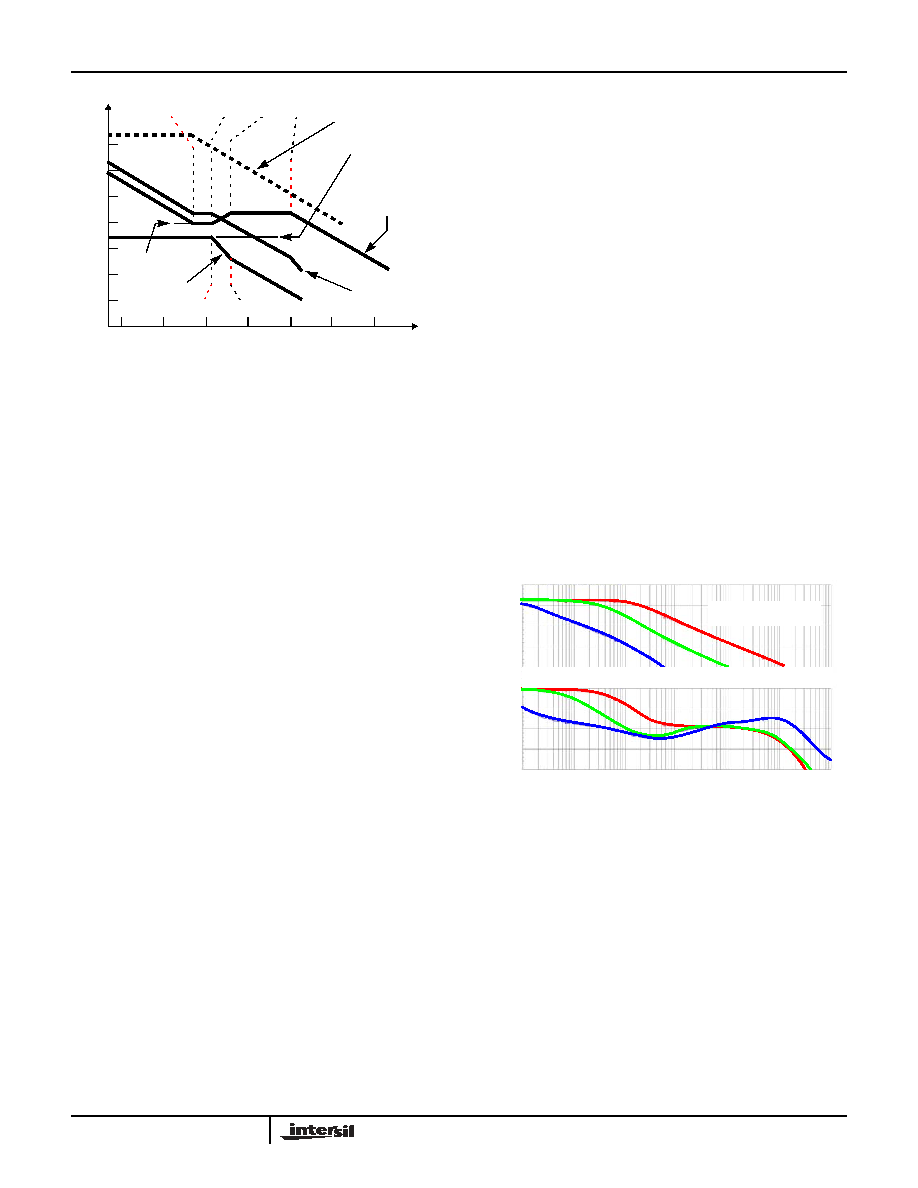

Figure

8

shows an asymptotic plot of the DC-DC converter's

gain vs. frequency. The actual modulator gain has a high

gain peak dependent on the quality factor (Q) of the output

filter, which is not shown in Figure

8

. Using the above

procedure should yield a compensation gain similar to the

curve plotted. The open loop error amplifier gain bounds the

compensation gain. Check the compensation gain at F

P2

with the capabilities of the error amplifier.

The compensation gain uses external impedance networks

Z

FB

and Z

IN

to provide a stable, high bandwidth (BW)

overall loop. A stable control loop has a gain crossing with

-20dB/decade slope and a phase margin greater than 45

degrees. Include worst case component variations when

determining phase margin.

Linear Regulator Compensation

The linear regulator in the ISL6529 is not internally

compensated and therefore allows the user to optimize

regulator performance with regard to transient load

response. Although the compensation network shown in the

application examples in this data sheet provide conservative

compensation for a variety of loads, performance can be

enhanced with attention to load requirements.

Low ESR capacitors can cause stability concerns in discrete

IC regulators. Even regulators that are internally

compensated can become unstable when these capacitors

are placed across their output. There have been suggestions

to add series resistance to these capacitors to stabilize the

regulator. This approach seems self defeating and throws

away a desirable quality.

Component Considerations

Many unsuspected poles and zeros develop with the

selection of external components and operating conditions

like output MOSFET transistors, output filter capacitors and

load current. These elements will be discussed beginning

with the influence of the MOSFET series output resistance,

the 1/gfs term shown in Figure 7. At low load currents and

low transconductance, the effective output resistance can be

as high as several kilohms. The low MOSFET gfs with

accompanying high series resistance and large values of

output capacitance form a low frequency pole that for many

cases becomes the dominate pole in the system and often

results in a stable no load system. As the load current is

increased, the MOSFET series output resistance is reduced

and moves the output pole into a higher frequency region,

adding phase shift that can result in a marginally stable or

unstable system.

Low output capacitor ESR can result in stability problems as

mentioned above. In contrast, high output capacitor ESR

can improve the system stability. The capacitor and its series

resistance function as a zero, often canceling other poles in

the loop. Figure 9 shows a system simulation with a 300

µ

F,

100m

high ESR output capacitor. A single 10pF capacitor

from input to output of the error amplifier stabilizes the

system for load currents through the 1mA to 3A range.

Contrast this with Figure 10 that shows a Bode plot of

simulations of this regulator operating with a 100

µ

F, 5m

low ESR output capacitor. Note the phase approaching 180∞

at high current. This is in contrast to the response previously

shown with the 300

µ

F high ESR capacitor. The 300

µ

F

output capacitor and its ESR provide phase lead to cancel or

offset the pole formed with the MOSFET output resistance

and 300

µ

F capacitance. Also notice that system stability

varies widely with load current. A system can oscillate at no

load and be stable at full load, The converse is also possible.

Oscillation can also occur at load currents between the

current extremes.

FIGURE 8. ASYMPTOTIC BODE PLOT OF CONVERTER GAIN

100

80

60

40

20

0

-20

-40

-60

F

P1

F

Z2

10M

1M

100K

10K

1K

100

10

OPEN LOOP

ERROR AMP GAIN

F

Z1

F

P2

F

LC

F

ESR

COMPENSATION

G

A

IN

(

d

B)

FREQUENCY (Hz)

GAIN

MODULATOR

GAIN

LOOP GAIN

20

VIN

VOSC

------------------

log

20

R2

R1

---------

log

10

1K

100

10K

100K

1M

10M

FREQUENCY (Hz)

80

60

40

20

0

0

-50

-150

-100

-200

GAI

N

d

B

PHASE

DEGREES

1mA

1mA

55mA

3A

3A

3A

55mA

1mA

BODE PLOT OF COMPENSATED REGULATOR AT 3 OUTPUT CURRENTS

OUTPUT CAPACITOR

300

µ

F, 100m

FIGURE 9. LOOP RESPONSE WITH ONLY C16 = 10pF

COMPENSATION

ISL6529, ISL6529A

12

FN9070.5

April 12, 2005

The Compensation Network

To provide for system stability with a low ESR output

capacitor, where pole cancellation by the capacitor is outside

the frequencies of interest, a phase lead network must be

used to compensate for the phase lag resulting from

MOSFET output resistance and the output capacitor.

Figure 11 shows the type II compensation network

configuration and a simplified straight line representation of

the network response. By using the equations in Figure 11,

the values of R12 and C4 can be adjusted to the frequency

where phase lead begins. The second equation shows the

upper frequency where phase advance is complete. After

capacitor C4 becomes effectively an ac short, the mid band

gain is set by the R12/R5 ratio as shown on Figure 11.

Several simulations illustrate the compensation with the

more difficult 5m

, 100

µ

F output capacitor. Figure 10

previously showed the Bode plots where the phase

response comes dangerously near the oscillatory 180∞ state

at unity gain. A type II network applied across the error

amplifier inverting input to the output can be configured to

perform this function.

Figure 12 shows the Bode plot of only the compensation

network with the system to illustrate the phase boost in the

system. Essentially the phase lead region must be moved to

advance the phase where it is close to an oscillatory state.

Increasing the value of C4 moves the response lower, aiding

the lagging phase at low frequencies and low load current.

This operation will reduce phase compensation at higher

80

60

40

20

0

0

-50

-150

-100

-200

10

1K

100

10K

100K

1M

10M

GAI

N

dB

PHASE DEGRE

E

S

FREQUENCY (Hz)

BODE PLOT OF REGULATOR (N0 COMP) AT 3 OUTPUT CURRENTS

3A

55mA

1mA

3A

55mA

1mA

55mA

1mA

FIGURE 10. LOOP RESPONSE WITH ONLY 100µF, 5m

OUTPUT CAPACITOR

0

10

20

30

40

50

60

70

80

10

100

1,000

10,000

100,000

1,000,000

10,000,000

60

40

20

0

80

-90

-45

P

H

A

S

E (DEGRE

ES)

GAI

N

(

d

B

)

0

-135

10 100

1K

10K

100K

1M

10M

FREQUENCY (Hz)

1

2

R12 C4

-----------------------------------

20

R12

R5

-----------

log

1

2

R12

C16 C4

C16 C4

+

-------------------------

----------------------------------------------------------

R5

C4

INTERNAL 0.8V

REFERENCE

-

+

REGULATED

R12

C16

FB

TO MOSFET

DRIVE 2

ISL6529

OUTPUT

FIGURE 11. SCHEMATIC AND BODE PLOT OF

COMPENSATION NETWORK

80

60

40

20

0

0

-50

-150

-100

-200

GAI

N

d

B

P

HASE DEGRE

E

S

10

1K

100

10K

100K

1M

10M

FREQUENCY (Hz)

BODE PLOT OF REGULATOR (COMP ONLY) AT 3 OUTPUT CURRENTS

3A

3A

1mA

54mA

1mA

COMPENSATION:

C16 = 10pF

C4 = 470pF

R16 = 200K

FIGURE 12. LOOP RESPONSE WITH COMPENSATION

NETWORK ONLY

135∞

80

60

40

20

0

0

-50

-150

-100

-200

GAI

N

dB

PHAS

E DE

GREE

S

10

1K

100

10K

100K

1M

10M

FREQUENCY (Hz)

BODE PLOT OF COMPENSATED REGULATOR AT 3 OUTPUT CURRENTS

3A

54mA

3A

1mA

54mA

3A

1mA

1mA

COMPENSATION:

C16 = 10pF

C4 = 470pF

R16 = 200K

FIGURE 13. INVERTING INPUT TO OUTPUT GAIN AND

PHASE WITH COMPENSATION AND 100µF, 5m

OUTPUT CAPACITOR

ISL6529, ISL6529A

13

FN9070.5

April 12, 2005

frequencies and high load current. Figure 13 shows the

results of the complete system with output capacitor and

compensation network for 45∞ of phase margin.

Because of the large variety of capacitors, varying ESRs and

PC board layouts, Table 1, based upon system simulations

is provided as a starting point guide to aid in the selection of

compensation networks for output capacitors values of 1

µ

F,

10

µ

F, 100

µ

F and 1000

µ

F with ESR values of 5m

, 30m

and 100m

for each capacitor value. The frequencies

associated with the compensation elements are also shown

to aid in component selection.

Parallel capacitors of the same value and type can be

treated as a combination. For example three 100

µ

F, 10m

capacitors may be treated as one 300

µ

F, 3.3m

capacitor.

Mixed capacitors require more attention. For example the

compensation for a 1000

µ

F, low ESR capacitor will suffice

for a shunting 10

µ

F, low ESR capacitor.

TABLE 1. COMPENSATION NETWORKS FOR LINEAR REGULATOR

CAP

ESR

DETAIL

OUTPUT CAPACITOR

1

µ

F

10

µ

F

100

µ

F

1000

µ

F

5m

Comp

Network

C16 = 10pF

R12 = 47K

C4 = 200pF

C16 = 10pF

R12 = 47K

C4 = 470pF

C16 = 10pF

R12 = 200K

C4 = 470pF

C16 = 10pF

R12 = 470K

C4 = 470pF

Low Fq Zero (C4 & R12)

17kHz

7.2kHz

1.7kHz

720Hz

High Fq

Pole (C16 & R12)

338kHz

338kHz

80kHz

34kHz

MidbandGain R12/R5

20dB

20dB

33dB

40dB

OUTPUT CAP

& ESR Zero Fq

32MHz

3.2MHz

320kHz

32kHz

30m

Comp

Network

C16 = 10pF

R12 = 47K

C4 = 200pF

C16 = 10pF

R12 = 47K

C4 = 470pF

C16 = 10pF

R12 = 200K

C4 = 470pF

C16 = 10pF

Low Fq

Zero (C4 & R12)

17kHz

17kHz

1.7kHz

-

High Fq

Pole (C16 & R12)

338kHz

338kHz

80kHz

-

Midband Gain R12/R5

20dB

20dB

33dB

-

OUTPUT Cap

& ESR Zero Fq

5.3MHz

530kHz

53kHz

5.3kHz

100m

Comp

Network

C16 = 10pF

R12 = 47K

C4 = 200pF

C16 = 10pF

R12 = 47K

C4 = 470pF

C16 = 10pF

C16= 10pF

Low Fq

Zero (C4 & R12)

17kHz

17kHz

-

-

High Fq

Pole (C16 & R12)

338kHz

338kHz

-

-

Midband Gain R12/R5

20dB

20dB

-

-

OUTPUT Cap

& ESR Zero Fq

1.6MHz

160kHz

16kHz

1.6kHz

ISL6529, ISL6529A

14

FN9070.5

April 12, 2005

The final test for a system is transient load current

performance. Ringing or oscillation indicates that the

compensation network must be adjusted to assure stable

operation with component and environmental variations.

Figures 14 and 15 are scope shots that show the regulator

with only with a 1500

µ

F, 100m

capacitor with high

frequency ringing with no compensation. A 27pF capacitor,

C16 was added in Figure 15. The output step is about

260mV for the 3A load current for an ESR in the order of

90m

. After the load current is removed, the output network

parasitics ring for about 5

µ

s.

Application Guidelines

Layout Considerations

Layout is very important in high frequency switching

converter design. With power devices switching efficiently at

600kHz, the resulting current transitions from one device to

another cause voltage spikes across the interconnecting

impedances and parasitic circuit elements. These voltage

spikes can degrade efficiency, radiate noise into the circuit,

and lead to device over-voltage stress. Careful component

layout and printed circuit board design minimizes the voltage

spikes in the converters.

As an example, consider the turn-off transition of the PWM

MOSFET. Prior to turn-off, the MOSFET is carrying the full

load current. During turn-off, current stops flowing in the

MOSFET and is picked up by the lower MOSFET and

parasitic diode. Any parasitic inductance in the switched

current path generates a large voltage spike during the

switching interval. Careful component selection, tight layout

of the critical components, and short, wide traces minimizes

the magnitude of voltage spikes.

There are two sets of critical components in a DC-DC converter

using the ISL6529, ISL6529A. The switching components are

the most critical because they switch large amounts of energy,

and therefore tend to generate large amounts of noise. Next

are the small signal components which connect to sensitive

nodes or supply critical bypass current and signal coupling.

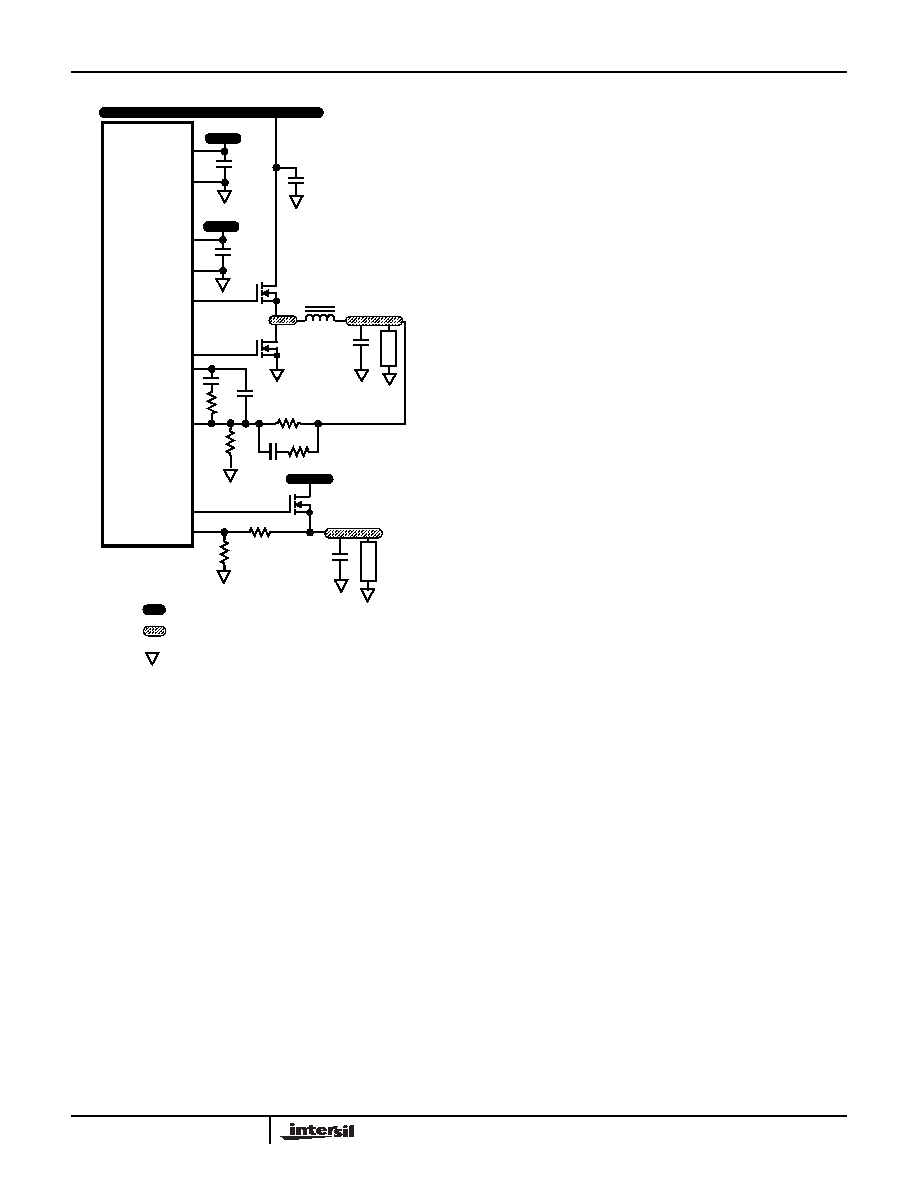

A multi-layer printed circuit board is recommended. Figure

16 shows the connections of the critical components in the

converter. Note that capacitors C

IN

and C

OUT

could each

represent numerous physical capacitors. Dedicate one solid

layer, usually a middle layer of the PC board, for a ground

plane and make all critical component ground connections

through vias to this layer. Dedicate another solid layer as a

power plane and break this plane into smaller islands of

common voltage levels. Keep the metal runs from the

PHASE terminal to the output inductor short. The power

plane should support the input and output power nodes. Use

copper filled polygons on the top and bottom circuit layers for

the phase node. Use the remaining printed circuit layers for

small signal wiring. The wiring traces from the UGATE pin to

the MOSFET gate should be kept short and wide enough to

easily handle the 1A of drive current.

The switching components should be placed close to the

ISL6529, ISL6529A first. Minimize the length of the

connections between the input capacitors, C

IN

, and the

power switches by placing them nearby. Position both the

ceramic and bulk input capacitors as close to the upper

MOSFET drain as possible. Position the output inductor and

output capacitors between the upper MOSFET and lower

diode and the load.

FIGURE 14. 3A TRANSIENT LOAD APPLIED TO THE

REGULATOR NO COMPENSATION

FIGURE 15. 3A TRANSIENT LOAD APPLIED TO THE

REGULATOR 27pF COMPENSATION

OUTPUT VOLTAGE

200mV/DIV

LOAD CURRENT, 1A/DIV

LOAD CURRENT, 1A/DIV

OUTPUT VOLTAGE

200mV/DIV

ISL6529, ISL6529A

15

FN9070.5

April 12, 2005

The critical small signal components include any bypass

capacitors, feedback components, and compensation

components. Position the bypass capacitors, C

BP

, close to

the VCC pin with a via directly to the ground plane. Place the

PWM converter compensation components close to the FB

and COMP pins. The feedback resistors for both regulators

should also be located as close as possible to the relevant

FB pin with vias tied straight to the ground plane as required.

Component Selection Guidelines

Output Capacitor Selection

Output capacitors are required to filter the output and supply

the load transient current. The filtering requirements are a

function of switching frequency and output current ripple.

The load transient requirements are a function of the

transient load current slew rate (di/dt) and magnitude. These

requirements are generally met with a mix of capacitors and

careful layout.

PWM Regulator Output Capacitors

Modern digital ICs can produce high transient load slew

rates. High frequency capacitors initially supply the transient

current and slow the load rate-of-change seen by the bulk

capacitors. The bulk filter capacitor selection is generally

determined by the effective series resistance (ESR) and

voltage rating requirements rather than actual capacitance

requirements.

High frequency decoupling capacitors should be placed as

close to the power pins of the load as physically possible. Be

careful not to add inductance in the circuit board wiring that

could cancel the usefulness of these low inductance

components. Consult with the manufacturer of the load on

specific decoupling requirements.

Specialized low-ESR capacitors intended for switching-

regulator applications are recommended for the bulk

capacitors. The bulk capacitor's ESR determines the output

ripple voltage and the initial voltage drop following a high

slew-rate transient edge. Aluminum electrolytic, tantalum,

and special polymer capacitor ESR values are related to the

case size with lower ESR available in larger case sizes.

However, the equivalent series inductance (ESL) of these

capacitors increases with case size and can reduce the

usefulness of the capacitor to high slew-rate transient

loading. Unfortunately, ESL is not a specified parameter.

Work with your capacitor supplier and measure the

capacitor's impedance with frequency to select a suitable

component. In most cases, multiple electrolytic capacitors of

small case size perform better than a single large case

capacitor.

PWM Output Inductor Selection

The PWM converter requires an output inductor. The output

inductor is selected to meet the output voltage ripple

requirements and sets the converter response time to a load

transient. The inductor value determines the converter's

ripple current and the ripple voltage is also a function of the

ripple current. The ripple voltage and current are

approximated by the following equations:

Increasing the value of inductance reduces the output ripple

current and voltage ripple. However, increasing the

inductance value will slow the converter response time to a

load transient.

One of the parameters limiting the converter's response to a

load transient is the time required to slew the inductor

current. Given a sufficiently fast control loop design, the

ISL6529 will provide either 0% or 100% duty cycle in

response to a load transient. The response time is the time

V

OUT1

+5 VCC

ISLAND ON POWER PLANE LAYER

ISLAND ON CIRCUIT PLANE LAYER

L

OUT

C

OUT1

C

IN

+3.3 V

IN

KEY

COMP

ISL6529

UGATE

R4

R

2

C

BP

FB

DRIVE2

GND

5VCC

FIGURE 16. PRINTED CIRCUIT BOARD POWER PLANES

AND ISLANDS

R1

V

OUT2

FB2

C

2

VIA CONNECTION TO GROUND PLANE

C

OUT2

LO

AD

LO

A

D

Q1

+3.3 V

IN

R5

R6

PHASE

R

3

C

3

C

1

Q2

+12 VCC

C

BP

PGND

12VCC

Q3

LGATE

I

V

IN

V

OUT

≠

F

S

L

◊

--------------------------------

V

OUT

V

IN

----------------

◊

=

V

OUT

I

ESR

◊

=

(EQ. 11)

(EQ. 12)

ISL6529, ISL6529A

16

FN9070.5

April 12, 2005

interval required to slew the inductor current from an initial

current value to the final current level. During this interval the

difference between the inductor current and the load current

must be supplied by the output capacitor(s). Minimizing the

response time can minimize the output capacitance

required.

The response time to a transient is different for the

application of load and the removal of load. The following

equations give the approximate response time interval for

application and removal of a transient load:

where I

TRAN

is the transient load current step, t

RISE

is the

response time to the application of load, and t

FALL

is the

response time to the removal of load.

With a +3.3V input source, the worst case response time can

be either at the application or removal of load and dependent

upon the output voltage setting. Be sure to check both of

these equations at the minimum and maximum output levels

for the worst case response time.

Input Capacitor Selection

The important parameters for the bulk input capacitors are

the voltage rating and the RMS current rating. For reliable

operation, select bulk input capacitors with voltage and

current ratings above the maximum input voltage and largest

RMS current required by the circuit. The capacitor voltage

rating should be at least 1.25 times greater than the

maximum input voltage and a voltage rating of 1.5 times is a

conservative guideline. The RMS current rating requirement

for the input capacitor of a buck regulator is approximately

1/2 of the summation of the DC load current.

Use a mix of input bypass capacitors to control the voltage

overshoot across the switching MOSFETs. Use ceramic

capacitance for the high frequency decoupling and bulk

capacitors to supply the RMS current. Small ceramic

capacitors can be placed very close to the upper MOSFET

to suppress the voltage induced in the parasitic circuit

impedances. Connect them directly to ground with a via

placed very close to the ceramic capacitor footprint.

For a through-hole design, several aluminum electrolytic

capacitors may be needed. For surface mount designs,

tantalum or special polymer capacitors can be used, but

caution must be exercised with regard to the capacitor surge

current rating. These capacitors must be capable of handling

the surge-current at power-up.

TRANSISTOR SELECTION/CONSIDERATIONS

The ISL6529, ISL6529A require three external transistors.

One N-Channel MOSFET is used as the upper switch in a

standard buck topology PWM converter. Another MOSFET

is used as the lower synchronous switch. The linear

controller drives the gate of an N-Channel MOS transistor

used as the series pass element. The chosen MOSFET

r

DS(ON)

determines the maximum drop out voltage of the

regulator. For all practical purposes, the MOSFET appears

as a variable resistor. All he MOSFET transistors should be

selected based upon r

DS(ON)

, gate supply requirements,

and thermal management considerations.

Upper MOSFET SWITCH Selection

In high-current applications, the MOSFET power dissipation,

package selection and heatsink are the dominant design

factors. The power dissipation includes two loss

components; conduction loss and switching loss. The

conduction losses account for a large portion of the power

dissipation of the upper MOSFET. Switching losses also

contribute to the overall MOSFET power loss.

where I

o

is the maximum load current, D is the duty cycle of

the converter (defined as V

O

/V

IN

), t

SW

is the switching

interval, and F

SW

is the PWM switching frequency.

The lower MOSFET has only conduction losses since it

switches with zero voltage across the device. Conduction

loss is:

These equations assume linear voltage-current transitions

and are approximations. The gate-charge losses are

dissipated by the ISL6529 and do not heat the MOSFET.

However, large gate-charge increases the switching interval,

t

SW

, which increases the upper MOSFET switching losses.

Ensure that the MOSFET is within its maximum junction

temperature at high ambient temperature by calculating the

temperature rise according to package thermal-resistance

specifications. A separate heatsink may be necessary

depending upon MOSFET power, package type, ambient

temperature, air flow, and load current requirements.

The gate drive to the switching transistors ranges from

slightly below 12V to ground. Because of the large voltage

swing, logic-level transistors are not necessary in this

application.

t

RISE

L

O

I

TRAN

◊

V

IN

V

OUT

≠

--------------------------------

=

t

FALL

L

O

I

TRAN

◊

V

OUT

-------------------------------

=

(EQ. 13)

(EQ. 14)

P

ConductionUpper

I

o

2

r

DS on

(

)

◊

D

◊

P

Switching

1

2

---I

o

V

IN

◊

t

SW

◊

F

SW

◊

(EQ. 15)

(EQ. 16)

P

ConductionLower

I

o

2

r

DS on

(

)

◊

1 D

≠

(

)

◊

(EQ. 17)

ISL6529, ISL6529A

17

FN9070.5

April 12, 2005

However, if logic-level transistors or transistors with low

V

GS(on)

are used, close attention to layout guidelines should

be exercised, as the low gate threshold could lead to some

shoot-through despite counteracting circuitry present aboard

the ISL6529.

N-Channel MOSFET Transistor Selection

The main criteria for selection of the linear regulator pass

transistor is package selection for efficient removal of heat.

Select a package and heatsink that maintains the junction

temperature below the rating with a maximum expected

ambient temperature.

The power dissipated in the linear regulator is:

where I

O

is the maximum output current and V

OUT

is the

nominal output voltage of the linear regulator.

References

Intersil documents are available on the web at

http://www.intersil.com.

[1] Technical Brief, Intersil Corporation, TB417,

http://www.intersil.com/data/tb/tb417.pdf

ISL6529 Converter Application Circuit

P

LINEAR

I

O

V

IN

V

OUT

≠

(

)

◊

(EQ. 18)

FIGURE 17. POWER SUPPLY APPLICATION CIRCUIT FOR A GRAPHICS CONTROLLER

+3.3V

C12

1500

µ

F

47nF

R2

10.7k

5VCC

VOUT2

GND

C1

(1A)

VOUT1

(6A)

DRIVE2

FB2

UGATE

COMP

FB

ISL6529

R5

4.64k

2.15k

R6

C14

1

µ

F

+5V

C7

1000

µ

F

C6

470

µ

F

C5

1

µ

F

C8

4.7

µ

F

Q1

L1

4.7

µ

H

C9

470

µ

F

C10

1

µ

F

R4

1.0k

R1

1.0k

1.2nF

C2

Q3

L1

MTD3055V

919AS-4R7M

Fairchild

TOKO

Q3

12VCC

Q2

PGND

LGATE

+12V

C15

1

µ

F

L2

TOKO

919AS-1R0N

L2

1

µ

H

6.8k

R12

470pF

C4

47nF

R3

10

C3

Q1, Q2 IRF7313

IR

2.5V

1.6V

R13

1.0k

ISL6529A

ISL6529, ISL6529A

18

FN9070.5

April 12, 2005

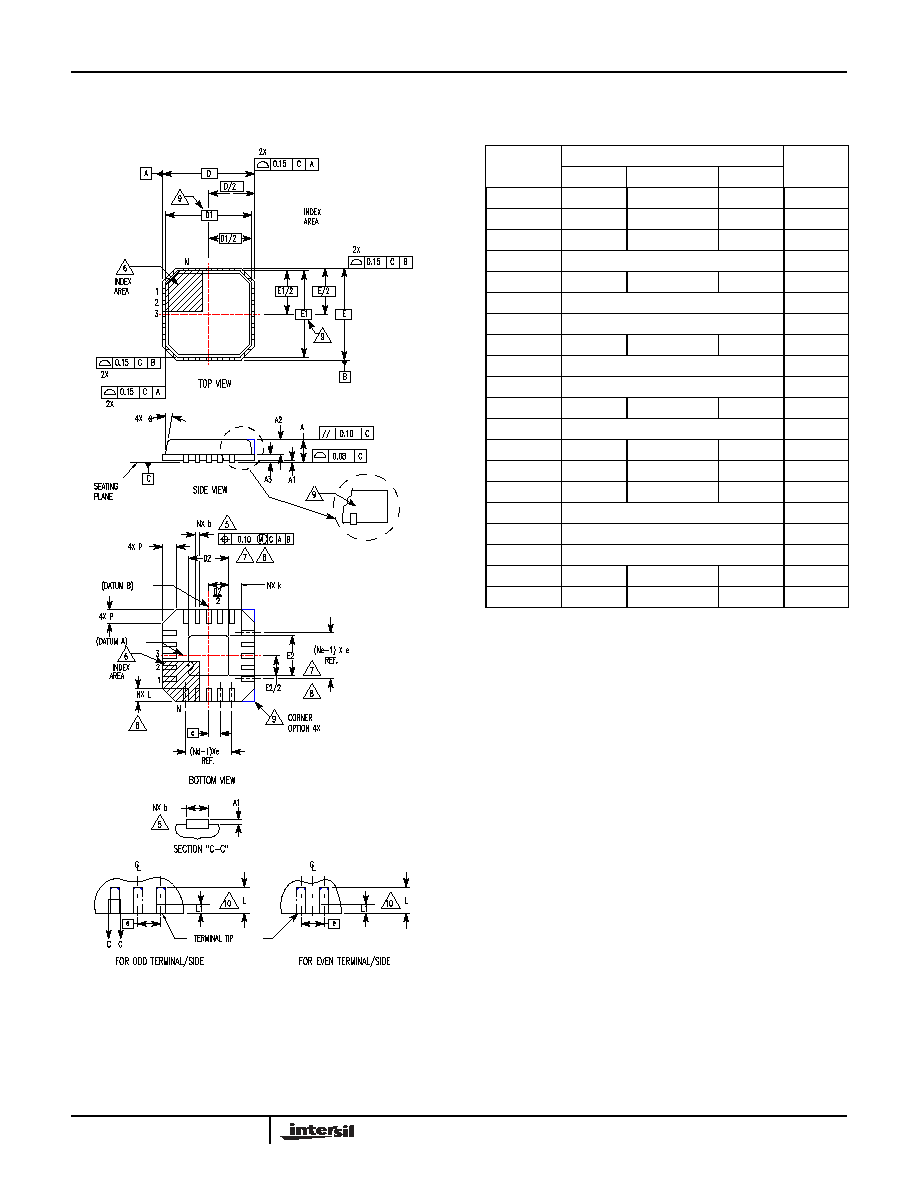

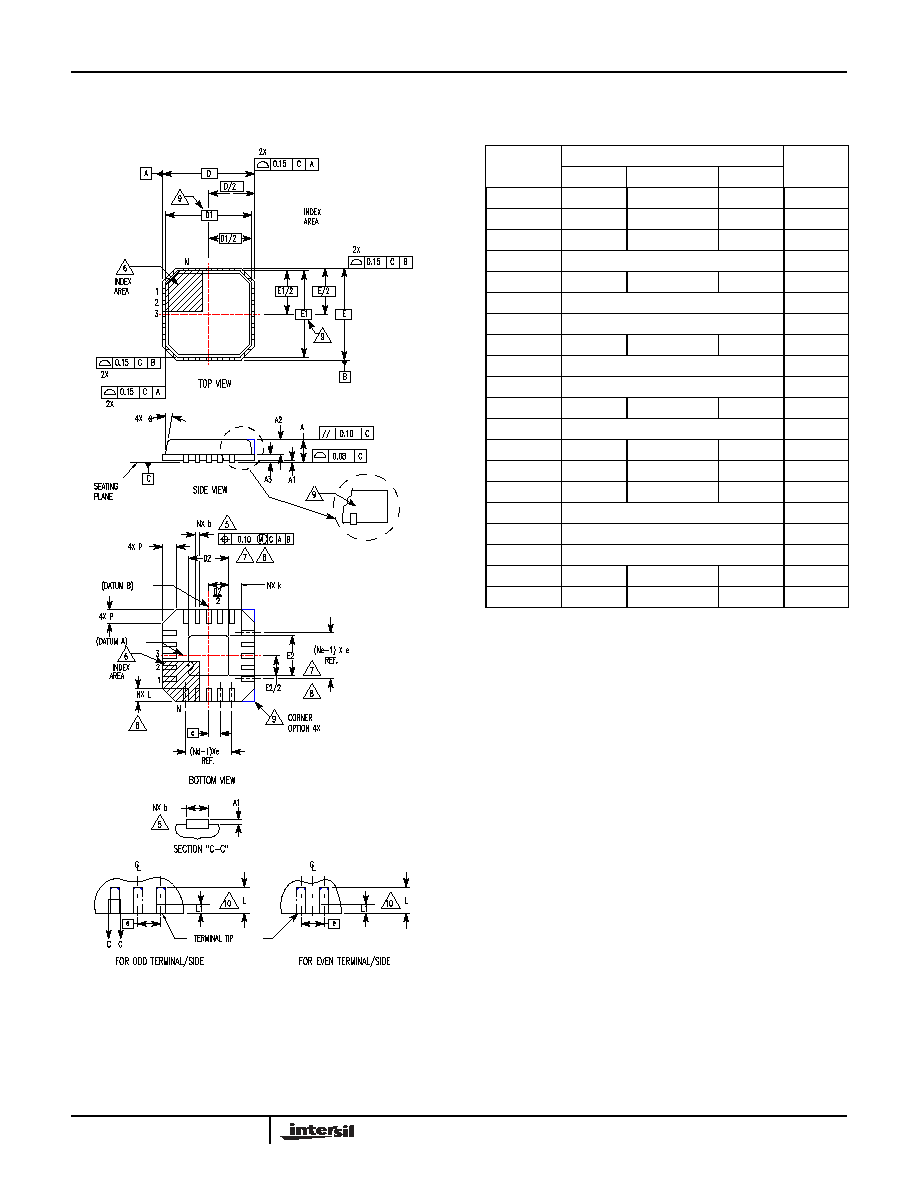

ISL6529, ISL6529A

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

L16.5x5B

16 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220VHHB ISSUE C)

SYMBOL

MILLIMETERS

NOTES

MIN

NOMINAL

MAX

A

0.80

0.90

1.00

-

A1

-

-

0.05

-

A2

-

-

1.00

9

A3

0.20 REF

9

b

0.28

0.33

0.40

5, 8

D

5.00 BSC

-

D1

4.75 BSC

9

D2

2.95

3.10

3.25

7, 8

E

5.00 BSC

-

E1

4.75 BSC

9

E2

2.95

3.10

3.25

7, 8

e

0.80 BSC

-

k

0.25

-

-

-

L

0.35

0.60

0.75

8

L1 -

-

0.15

10

N

16

2

Nd

4

3

Ne

4

3

P

-

-

0.60

9

-

-

12

9

Rev. 1 10/02

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P &

are present when

Anvil singulation method is used and not present for saw

singulation.

10. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.

19

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation's quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

FN9070.5

April 12, 2005

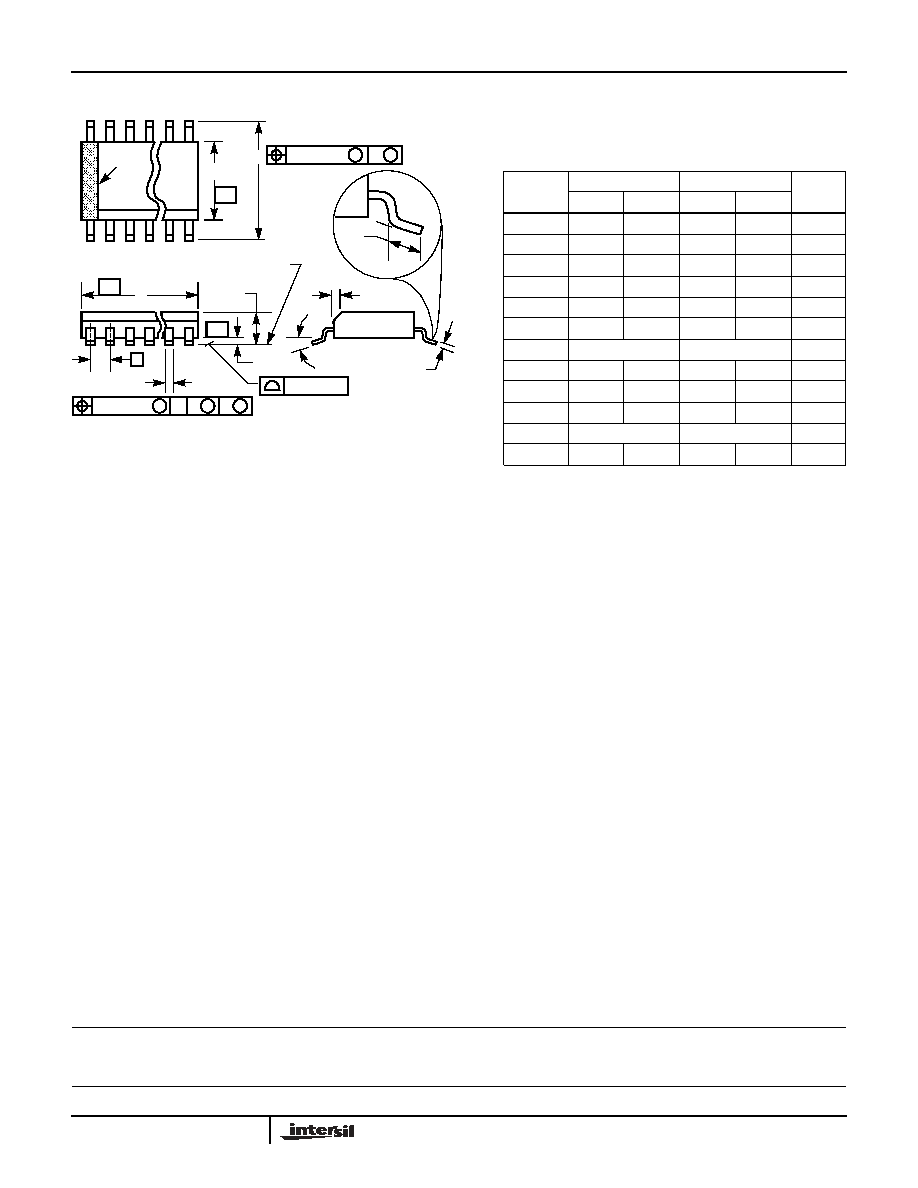

ISL6529, ISL6529A

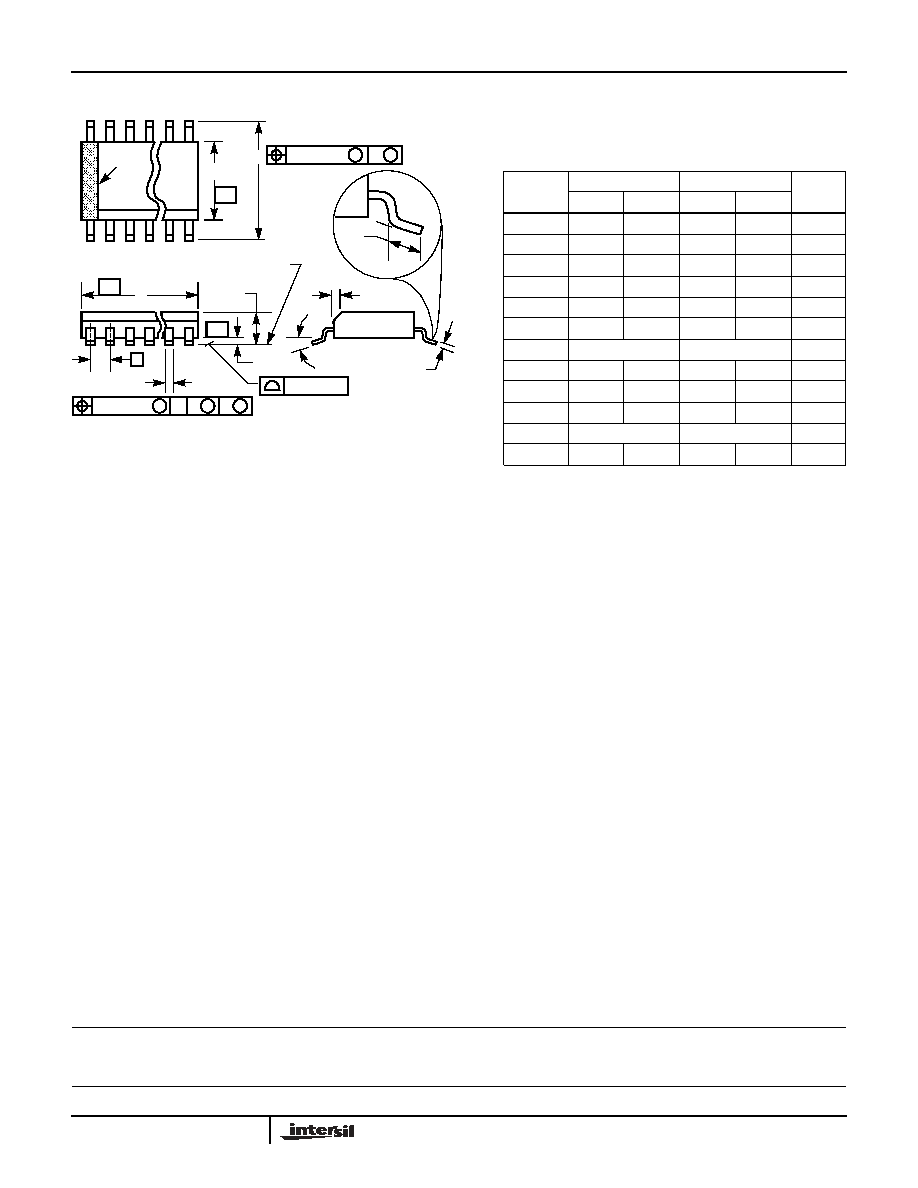

Small Outline Plastic Packages (SOIC)

NOTES:

1. Symbols are defined in the "MO Series Symbol List" in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension "E" does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. "L" is the length of terminal for soldering to a substrate.

7. "N" is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width "B", as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

µ

0.25(0.010)

B

M

M

M14.15

(JEDEC MS-012-AB ISSUE C)

14 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.0532

0.0688

1.35

1.75

-

A1

0.0040

0.0098

0.10

0.25

-

B

0.013

0.020

0.33

0.51

9

C

0.0075

0.0098

0.19

0.25

-

D

0.3367

0.3444

8.55

8.75

3

E

0.1497

0.1574

3.80

4.00

4

e

0.050 BSC

1.27 BSC

-

H

0.2284

0.2440

5.80

6.20

-

h

0.0099

0.0196

0.25

0.50

5

L

0.016

0.050

0.40

1.27

6

N

14

14

7

0

o

8

o

0

o

8

o

-

Rev. 0 12/93