PD -2.531

∑ Fast Recovery time characteristic

∑ Eletrically isolated base plate

∑ Large creepage distance between terminal

∑ Simplified mechanical designs, rapid assembly

Features

Description

This SOT-227 modules with FRED rectifier are available in two basic

configurations. They are the antiparallel and the parallel configurations.

The antiparallel configuration (HFA120EA60) is used for simple series

rectifier and high voltage application. The parallel configuration

(HFA120FA60) is used for simple parallel rectifier and high current application.

The semiconductor in the SOT-227 package is isolated from the copper

base plate, allowing for common heatsinks and compact assemblies to be

built.

These modules are intended for general applications such as power

supplies, battery chargers, electronic welders, motor control, DC chopper,

and inverters.

Ultrafast, Soft Recovery Diode

HEXFRED

TM

HFA120FA60, HFA120EA60

S O T -22 7

V

R

= 600V

V

F

(typ.)* = 1.4V

I

F(AV)

= 60A

Q

rr

(typ.) = 270nC

I

RRM

(typ.)

= 7.0A

t

rr

(typ.)

= 65ns

di

(rec)M

/dt (typ.)* = 270A/µs

K2

A2

K1

A1

A1

A2

K1

K2

HFA120FA60

HFA120EA60

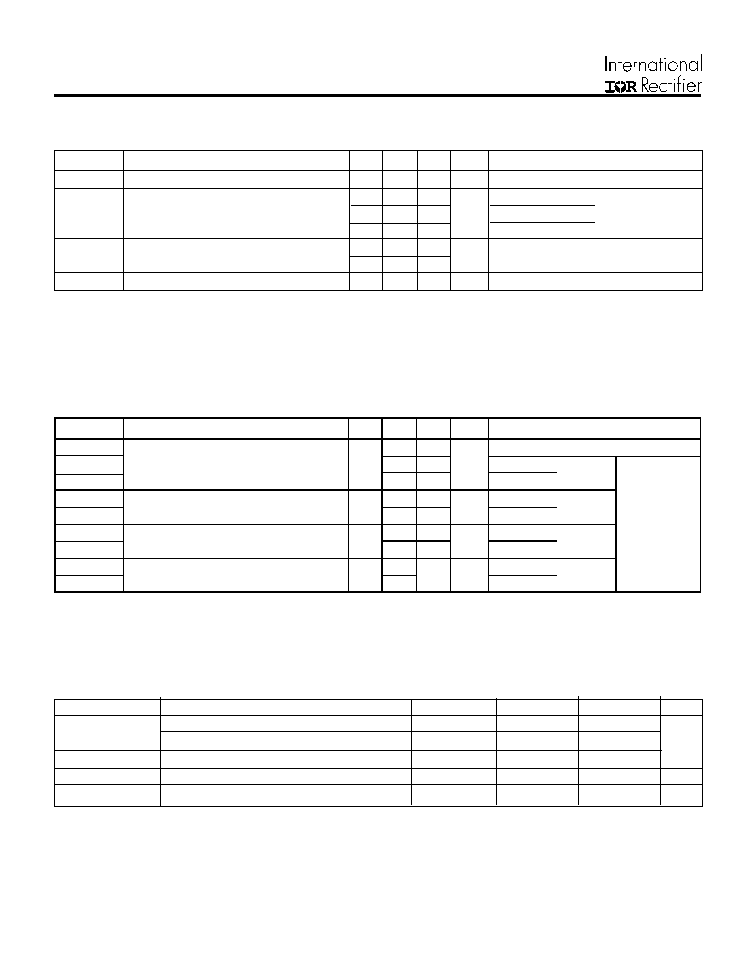

Parameter

Max.

Units

V

R

Cathode-to-Anode Voltage

600

V

I

F

@ T

C

= 25∞C

Continuous Forward Current

75

I

F

@ T

C

= 100∞C

Continuous Forward Current

40

I

FSM

Single Pulse Forward Current

TBD

I

FRM

Maximum Repetitive Forward Current

180

V

ISOL

RMS Isolation Voltage, Any Terminal to Case, t=1 min

2500

V

P

D

@ T

C

= 25∞C

Maximum Power Dissipation

180

P

D

@ T

C

= 100∞C

Maximum Power Dissipation

71

T

J

Operating Junction and

T

STG

Storage Temperature Range

*125 ∞C

Absolute Maximum Ratings (per Leg)

W

A

∞C

10/09/97

-55 to +150

HFA120FA60, HFA120EA60

Parameter

Min.

Typ.

Max.

Units

R

JC

Junction-to-Case, Single Leg Conducting

≠≠≠≠

≠≠≠≠

0.70

Junction-to-Case, Both Legs Conducting

≠≠≠≠

≠≠≠≠

0.35

R

CS

Case-to-Sink, Flat , Greased Surface

≠≠≠≠

0.05

≠≠≠≠

Wt

Weight

≠≠≠≠

30

≠≠≠≠

gm

Mounting Torque

≠≠≠≠

1.3

≠≠≠≠

(N∑m)

Parameter

Min. Typ. Max. Units Test Conditions

t

rr

Reverse Recovery Time

≠≠≠

34

≠≠≠

I

F

= 1.0A, di

f

/dt = 200A/µs, V

R

= 30V

t

rr1

≠≠≠

65

98

ns

T

J

= 25∞C

t

rr2

≠≠≠

130

200

T

J

= 125∞C

I

F

= 60A

I

RRM1

Peak Recovery Current

≠≠≠

7.0

13

T

J

= 25∞C

I

RRM2

≠≠≠

13

23

T

J

= 125∞C

V

R

= 200V

Q

rr1

Reverse Recovery Charge

≠≠≠

270

410

T

J

= 25∞C

Q

rr2

≠≠≠

490

740

T

J

= 125∞C

di

f

/dt = 200A/µs

di

(rec)M

/dt1

Peak Rate of Fall of Recovery Current

≠≠≠

350

≠≠≠

T

J

= 25∞C

di

(rec)M

/dt2

During t

b

≠≠≠

270

≠≠≠

T

J

= 125∞C

Parameter

Min. Typ. Max. Units

Test Conditions

V

BR

Cathode Anode Breakdown Voltage

600

≠≠≠

≠≠≠

V

I

R

= 100µA

≠≠≠

1.5

1.7

I

F

= 60A

≠≠≠

1.9

2.1

V

I

F

= 120A

≠≠≠

1.4

1.6

I

F

= 60A, T

J

= 125∞C

≠≠≠

2.5

20

V

R

= V

R

Rated

≠≠≠

130 2000

T

J

= 125∞C, V

R

= 0.8 x V

R

Rated

D

Rated

C

T

Junction Capacitance

≠≠≠

120

170

pF

V

R

= 200V

Electrical Characteristics (per Leg) @ T

J

= 25∞C (unless otherwise specified)

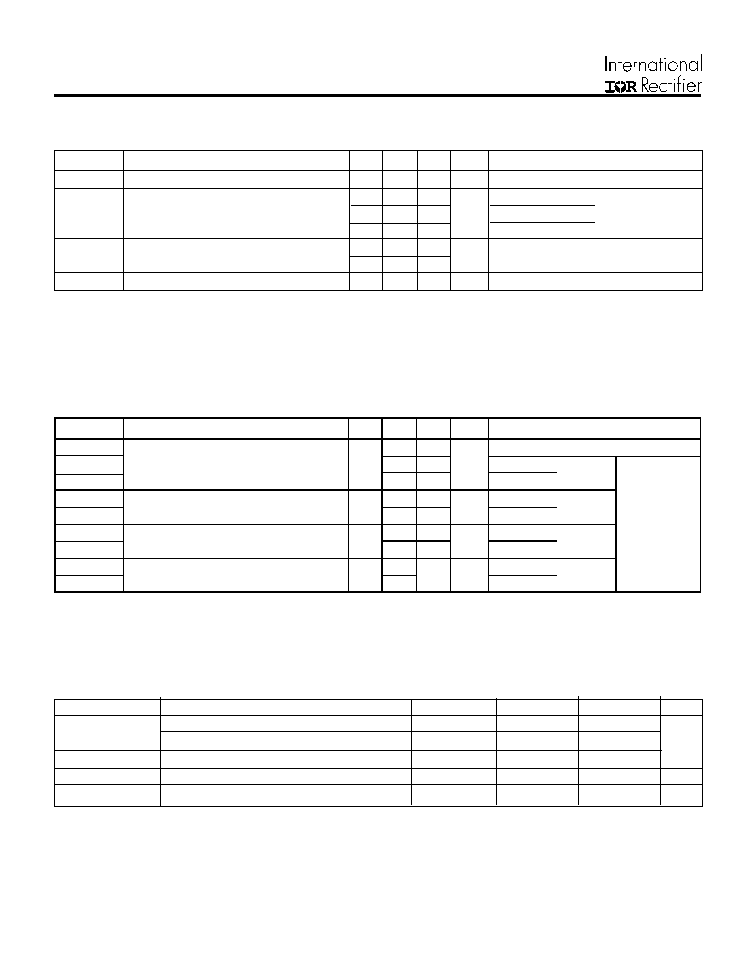

Dynamic Recovery Characteristics (per Leg) @ T

J

= 25∞C (unless otherwise specified)

A/µs

nC

A

See Fig. 3

See Fig. 2

See Fig. 1

See Fig. 5, 6 & 16

See Fig. 7& 8

See Fig. 9 & 10

See Fig. 11 & 12

V

FM

Max Forward Voltage

µA

Max Reverse Leakage Current

I

RM

∞C/W

K/W

Thermal - Mechanical Characteristics

HFA120FA60, HFA120EA60

Fig. 4 - Maximum Thermal Impedance Z

thjc

Characteristics, (per Leg)

Fig. 2 - Typical Reverse Current vs. Reverse

Voltage, (per Leg)

Fig. 3 - Typical Junction Capacitance vs.

Reverse Voltage, (per Leg)

Fig. 1 - Maximum Forward Voltage Drop

vs. Instantaneous Forward Current,

(per Leg)

Reverse Current - I

R

(µA)

Junction Capacitance -C

T

(pF)

Instantaneous Forward Current - I

F

(A)

1

10

100

1000

0.0

0.5

1.0

1.5

2.0

2.5

3.0

FM

T = 15 0∞C

T = 12 5∞C

T = 2 5∞C

J

J

J

Fo rward V olta ge D ro p - V (V)

0.1

1

10

100

1000

10000

0

200

400

600

R

T = 150∞C

T = 125 ∞C

T = 25∞C

J

J

J

Re ve rse Vo ltag e - V (V)

Reverse Voltage - V

R

( V )

10

100

1000

10000

1

10

100

1000

T = 25 ∞C

J

R eve rse Vo lta ge - V (V)

R

A

0.01

0.1

1

0.00001

0.0001

0.001

0.01

0.1

1

Notes:

1. Duty factor D =

t / t

2. Peak T

= P

x Z

+ T

1

2

J

DM

thJC

C

P

t

t

DM

1

2

t , Rectangular Pulse Duration (sec)

Thermal Response

(Z )

1

thJC

0.01

0.02

0.05

0.10

0.20

D = 0.50

SINGLE PULSE

(THERMAL RESPONSE)

HFA120FA60, HFA120EA60

Fig. 7 - Typical Stored Charge vs. di

f

/dt,

(per Leg)

Fig. 8 - Typical di

(rec)M

/dt vs. di

f

/dt,

(per Leg)

Fig. 5 - Typical Reverse Recovery vs. di

f

/dt,

(per Leg)

Fig. 6 - Typical Recovery Current vs. di

f

/dt,

(per Leg)

di (rec) M/dt-

(A

/µs)

Qrr-

(nC)

Irr-

(

A)

trr-

(ns)

40

80

120

160

200

100

1000

f

d i /dt - (A/µ s)

I = 1 20A

I = 60A

I = 30A

V = 200 V

T = 1 2 5∞C

T = 2 5 ∞C

R

J

J

F

F

F

1

10

100

100

1000

f

d i /dt - (A/µ s)

I = 120 A

I = 60A

I = 30A

V = 2 00 V

T = 125 ∞C

T = 25∞ C

R

J

J

F

F

F

0

1000

2000

3000

4000

100

1000

f

d i /dt - (A/µ s)

I = 12 0A

I = 60A

I = 30A

F

F

F

V = 20 0V

T = 1 2 5∞C

T = 2 5 ∞C

R

J

J

100

1000

10000

100

1000

f

d i /dt - (A/µ s)

I = 120A

I = 60A

I = 3 0A

V = 200 V

T = 1 25 ∞C

T = 2 5∞C

R

J

J

F

F

F

HFA120FA60, HFA120EA60

4. Q

rr

- Area under curve defined by t

rr

and I

RRM

t

rr

X I

RRM

Q

rr

=

2

5. di

(rec)M

/dt - Peak rate of change of

current during t

b

portion of t

rr

V

(A V A L )

R (R A T E D )

I

L (P K )

V

DE C AY

TIM E

Fig. 11 - Avalanche Test Circuit and Waveforms

Fig. 10 - Reverse Recovery Waveform and

Definitions

Fig. 9 - Reverse Recovery Parameter Test

Circuit

t

a

t

b

t

rr

Q

rr

I

F

I

R R M

I

R R M

0.5

di(re c) M/dt

0.75 I

R R M

5

4

3

2

0

1

di /dt

f

1. di

f

/dt - Rate of change of current

through zero crossing

2. I

RRM

- Peak reverse recovery current

3. trr - Reverse recovery time measured

from zero crossing point of negative

going I

F

to point where a line passing

through 0.75 I

RRM

and 0.50 I

RRM

extrapolated to zero current

R E VER SE R EC O VER Y C IR C U IT

IR F P 2 5 0

D . U . T .

L = 7 0 µ H

V = 20 0 V

R

0 .0 1

G

D

S

d if /d t

A D J U S T

C U R R E N T

M O N IT O R

H IG H -S PE ED

SW IT C H

D U T

R g = 2 5 o h m

+

FR EE -W H E EL

D I O D E

V d = 5 0 V

L = 1 0 0µ H