© 2000 IXYS All rights reserved

1 - 3

V

RSM

V

RRM

Type

V

DSM

V

DRM

V

V

1300

1200

HVL 900 - 12io1

1500

1400

HVL 900 - 14io1

1700

1600

HVL 900 - 16io1

1900

1800

HVL 900 - 18io1

Symbol

Test Conditions

Maximum Ratings

I

RMS

T

Water

= 17

∞

C; watervolume = 4 l/min

900

A

I

TSM

, I

FSM

T

VJ

= 45

∞

C;

t = 10 ms (50 Hz)

9200

A

V

R

= 0

t = 8.3 ms (60 Hz)

10100

A

T

VJ

= T

VJM

t = 10 ms (50 Hz)

8000

A

V

R

= 0

t = 8.3 ms (60 Hz)

8800

A

I

2

t

T

VJ

= 45

∞

C

t = 10 ms (50 Hz)

423 000

A

2

s

V

R

= 0

t = 8.3 ms (60 Hz)

423 000

A

2

s

T

VJ

= T

VJM

t = 10 ms (50 Hz)

320 000

A

2

s

V

R

= 0

t = 8.3 ms (60 Hz)

321 000

A

2

s

(di/dt)

cr

T

VJ

= T

VJM

repetitive, I

T

= 960 A

100

A/

m

s

f =50 Hz, t

P

= 200

m

s

V

D

= 2/3 V

DRM

I

G

= 1 A,

di

G

/dt = 1 A/

m

s

(dv/dt)

cr

T

VJ

= T

VJM

; V

DR

= 2/3 V

DRM

1000

V/

m

s

R

GK

=

•

; method 1 (linear voltage rise)

P

GM

T

VJ

= T

VJM

t

P

=

30

m

s

120

W

I

T

= I

TAVM

t

P

= 500

m

s

60

W

P

GAV

20

W

V

RGM

10

V

T

VJ

-40...+140

∞

C

T

VJM

140

∞

C

T

stg

-40...+125

∞

C

V

ISOL

50/60 Hz, RMS

t = 1 min

3000

V~

I

ISOL

£

1 mA

t = 1 s

3600

V~

Weight

Typical including screws

1300

g

Features

q

Isolation between water and electrical

connections with Direct copper

bonded Al

2

O

3

-ceramic

q

Planar passivated chips

q

Isolation voltage 3600 V~

q

Keyed gate/cathode twin pins

Applications

q

Large resistance welding equipment

q

Large electroplating equipment

AC Controller

with Isolated Water Flow

Data according to IEC 60747 refer to a single thyristor unless otherwise stated.

IXYS reserves the right to change limits, test conditions and dimensions

013

HVL 900

I

RMS

= 900 A

V

RRM

= 1200-1800 V

Preliminary data

1

2/3

5

6

4

7

© 2000 IXYS All rights reserved

2 - 3

Symbol

Test Conditions

Characteristic Values

I

RRM

, I

DRM

T

VJ

= T

VJM

; V

R

= V

RRM

; V

D

= V

DRM

40

mA

V

T

, V

F

I

T

, I

F

= 600 A; T

VJ

= 25

∞

C

1.32

V

V

T0

For power-loss calculations only

0.8

V

r

T

0.68

m

W

V

GT

V

D

= 6 V;

T

VJ

= 25

∞

C

2

V

T

VJ

= -40

∞

C

3

V

I

GT

V

D

= 6 V;

T

VJ

= 25

∞

C

150

mA

T

VJ

= -40

∞

C

220

mA

V

GD

T

VJ

= T

VJM

;

V

D

= 2/3 V

DRM

0.25

V

I

GD

T

VJ

= T

VJM

;

V

D

= 2/3 V

DRM

10

mA

I

L

T

VJ

= 25

∞

C; t

P

= 30

m

s; V

D

= 6 V

200

mA

I

G

= 0.45 A; di

G

/dt = 0.45 A/

m

s

I

H

T

VJ

= 25

∞

C; V

D

= 6 V; R

GK

=

•

150

mA

t

gd

T

VJ

= 25

∞

C; V

D

= 1/2 V

DRM

2

m

s

I

G

= 1 A; di

G

/dt = 1 A/

m

s

Q

S

T

VJ

= 125

∞

C; I

T

, I

F

= 300 A; -di/dt = 50 A/

m

s

760

m

C

I

RM

275

A

R

thJW

per thyristor ; 180∞ el; watervolume = 4 l/min

0.203

K/W

d

S

Creeping distance on surface

12.7

mm

d

A

Creepage distance in air

9.6

mm

a

Maximum allowable acceleration

50 m/s

2

O

ptional accessories for modules

Keyed Gate/Cathode twin plugs with wire length = 350 mm, gate = yellow, cathode = red

Type ZY 180 L (L = Left for pin pair 4/5)

UL 758, style 1385,

Type ZY 180 R (R = Right for pin pair 6/7)

CSA class 5851, guide 460-1-1

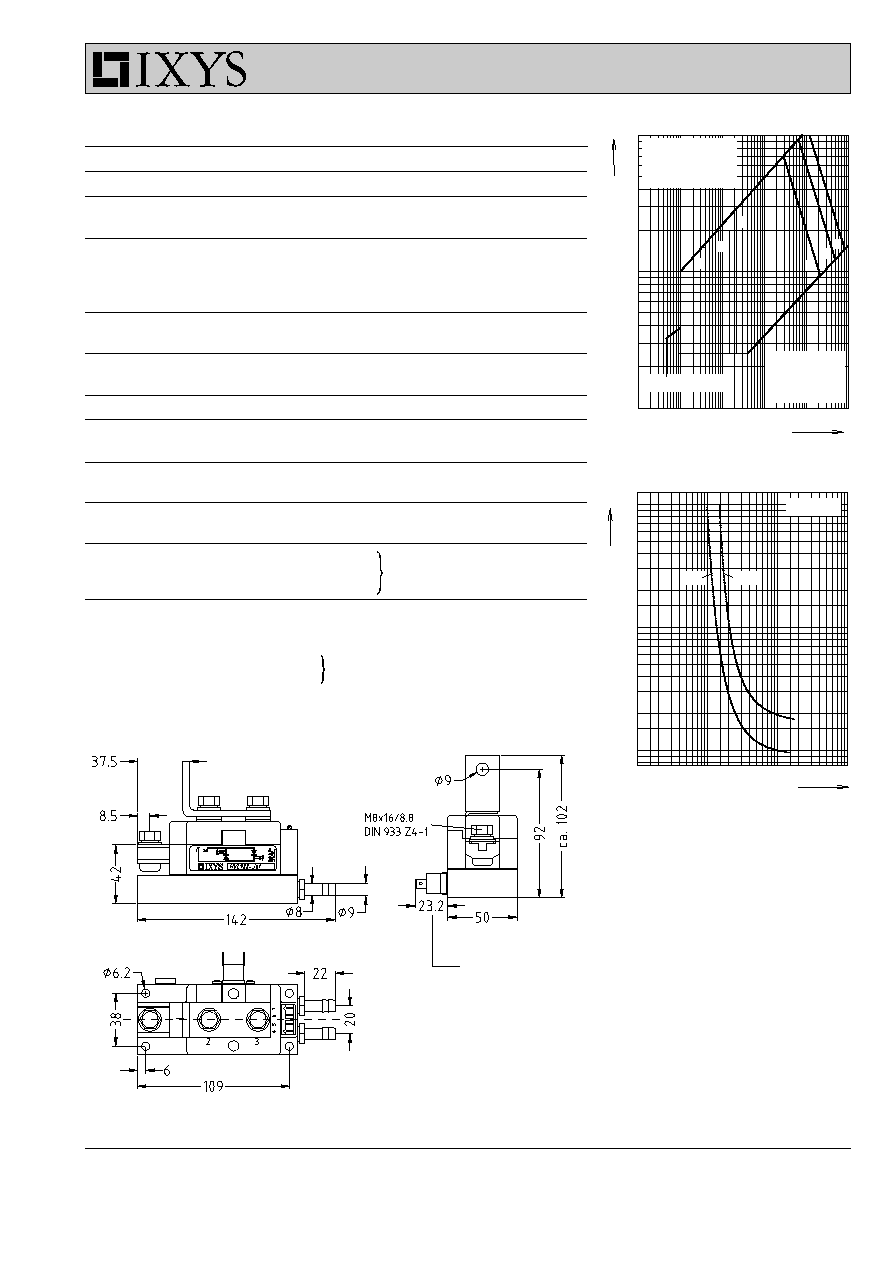

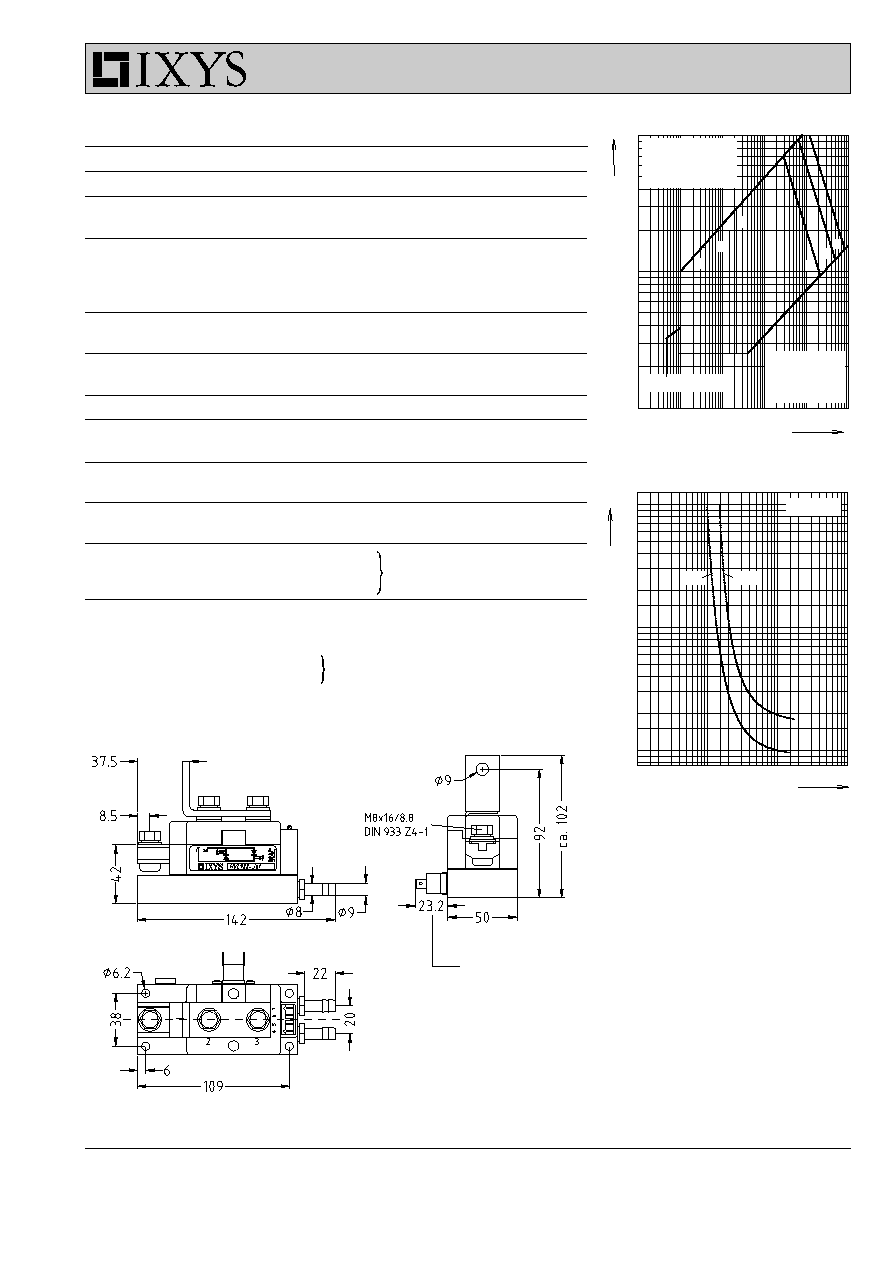

Fig. 1 Gate trigger characteristics

Fig. 2 Gate trigger delay time

HVL 900

0.01

0.1

1

10

1

10

100

10

-3

10

-2

10

-1

10

0

10

1

10

2

0.1

1

10

I

G

V

G

A

A

I

G

1: I

GT

, T

VJ

= 140

∞

C

2: I

GT

, T

VJ

= 25

∞

C

3: I

GT

, T

VJ

= -40

∞

C

µ

s

t

gd

V

4: P

GM

= 20 W

5: P

GM

= 60 W

6: P

GM

= 120 W

I

GD

, T

VJ

= 140

∞

C

4

2

1

5

6

Limit

typ.

T

VJ

= 25

∞

C

3

(Thermoswitch

on request)

© 2000 IXYS All rights reserved

3 - 3

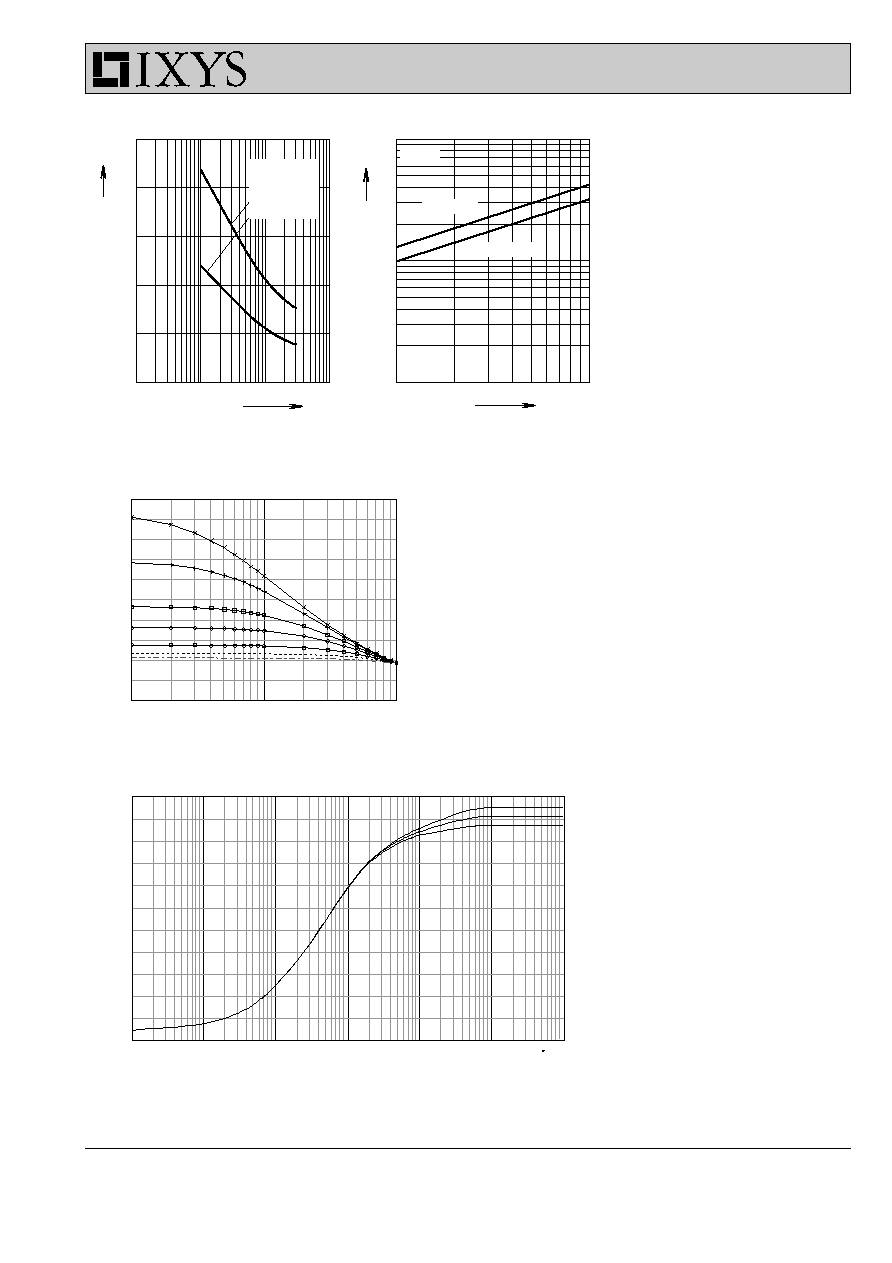

2 l/min

4 l/min

6 l/min

Fig. 6 Transient thermal impedance vs. time

1

10

10

4

10

5

10

6

0.001

0.01

0.1

1

0

2000

4000

6000

8000

10000

I

2

t

s

t

ms

t

A

2

s

I

TSM

A

80 % V

RRM

T

VJ

= 45∞C

50 Hz

T

VJ

= 140∞C

T

VJ

= 140∞C

T

VJ

= 45∞C

V

R

= 0V

Fig. 3 Surge overload current

I

TSM

: Crest value, t: duration

Fig. 4 I

2

t versus time (1-10 ms)

1

10

100

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

ED [%]

Ir

m

s

[A

]

Fig. 5 Rated rms current vs. duty cycle

n=1

n=100

n=50

n=25

n=10

n=5

n=2

0.001

0.01

0.1

1

10

100

1 10

3

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

0.22

t [s]

Z

t

h

[K

/W

]

HVL 900