Subminiature

Axial Lead and Cartridge Fuses

PICO

Æ

II

Slo-Blo

Æ

Fuse 473 Series

391

w w w . l i t t e l f u s e . c o m

The PICO

Æ

II Slo-Blo

Æ

fuse combines time delay performance

characteristics with the proven reliability of a PICO

Æ

fuse.

∑

RoHS Compliant

version now available, use ordering suffix `L'

(see example on data sheet).

ELECTRICAL CHARACTERISTICS:

% of Ampere

Opening

Rating

Time

100%

4 hours, Minimum

200%

1 second, Min.; 60 seconds, Max.

300%

0.2 second, Min.; 3 seconds, Max.

800%

0.02 second, Min.; 0.1 second, Max.

AGENCY APPROVALS:

Recognized under the Components Program

of Underwriters Laboratories and Certified by CSA. Approved by METI

from 1 through 5 amperes.

AGENCY FILE NUMBERS:

UL E10480, CSA LR 29862.

INTERRUPTING RATING:

50 amperes at 125 VDC/VAC

ENVIRONMENTAL SPECIFICATIONS:

Operating Temperature:

≠55∞C to 125∞C.

Shock: MIL-STD-202, Method 213, Test Condition I

(100 G's peak for 6 milliseconds).

Vibration:

MIL-STD-202, Method 201 (10≠55 Hz); MIL-STD-202,

Method 204, Test Condition C (55≠2000 Hz at 10 G's Peak).

Salt Spray:

MIL-STD-202, Method 101, Test Condition B.

Insulation Resistance (After Opening):

MIL-STD-202,

Method 302, (10,000 ohms minimum at 100 volts).

Resistance to Soldering Heat:

MIL-STD-202,

Method 210, Test Condition C (20 sec at 260∞C).

Thermal Shock:

MIL-STD-202, Method 107,

Test Condition B (≠65∞C to 125∞C).

Moisture Resistance:

MIL-STD-202, Method 106

(90≠98% RH), Heat (65∞C).

PHYSICAL SPECIFICATIONS:

Materials:

Encapsulated, Epoxy-Coated Body; Solder Coated Copper

Wire Leads. RoHS Compliant Product: Pure Tin coated copper

wire leads.

Soldering Parameters:

Wave Solder -- 260∞C, 3 seconds maximum.

Solderability:

MIL-STD-202, Method 208.

Lead Pull Force:

MIL-STD-202, Method 211, Test Condition A (will

withstand a 10 lb. axial pull test).

PATENTED

ORDERING INFORMATION:

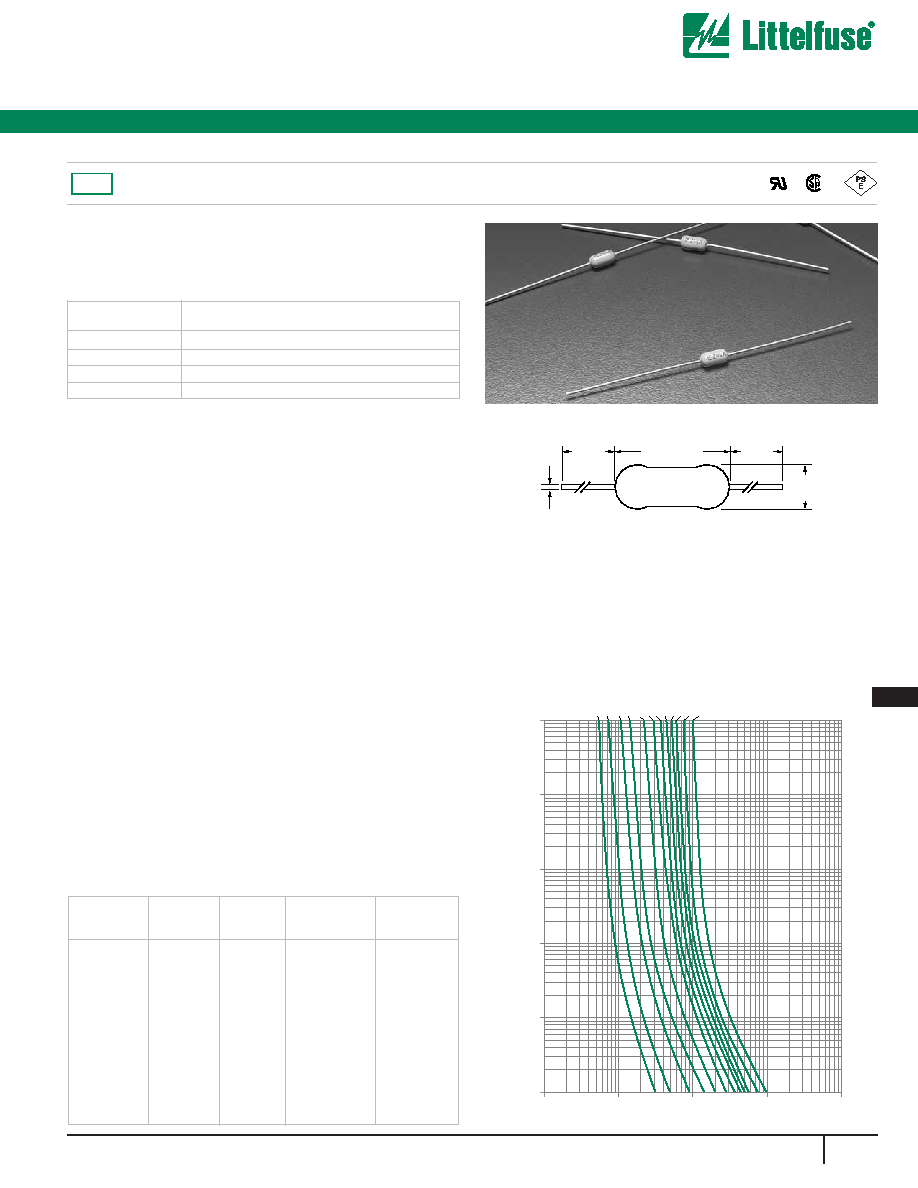

1000

100

10

1

0.1

0.01

1000

100

10

1

0.1

.375A .50A

.75A 1.0A 1.5A 2.0A 2.5A 3.0A 3.5A 4.0A 5.0A 7.0A

TIME IN SECONDS

CURRENT IN AMPERES

Nominal

Nominal

Catalog

Ampere

Voltage

Resistance

Melting I

2

t

Number

Rating

Rating

Cold Ohms

A

2

Sec.

0473.375

3/8

125

1.74

0.0850

0473.500

1/2

125

1.13

0.210

0473.750

3/4

125

0.460

0.760

0473 001

1

125

0.267

2.01

0473 01.5

1

1

/

2

125

0.116

3.94

0473 002

2

125

0.0712

7.60

0473 2.25

2

1

/

4

125

0.0630

9.28

0473 02.5

2

1

/

2

125

0.0520

13.0

0473 003

3

125

0.0380

21.0

0473 03.5

3

1

/

2

125

0.0240

26.8

0473 004

4

125

0.0194

35.0

0473 005

5

125

0.0133

54.8

0473 007

7

125

0.0092

105.0

Average Time Current Curves

F

L

1 A

38.1

(1.5")

38.1

(1.5")

7.11 (.280")

REF.

0.64 (.025")

DIA.

3.175 (.125")

DIA. REF.

Æ

Æ

PACKAGING SPECIFICATIONS:

Tape and Reel per EIA-296;

T1: 2.062" (52.4mm) taped spacing; 4,000 per reel.

Options:

For

RoHS Compliant

devices add the letter `L' to end of

packaging suffix. Example: 473001.YRT1L (RoHS Compliant 1A,

4,000 per reel).

RoHS

11

AXIAL LEAD AND

CAR

TRIDGE FUSES