| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: DS2408 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

DS2408

1-Wire 8-Channel Addressable Switch

www.maxim-ic.com

FEATURES

ß Eight Channels of Programmable I/O with

Open-Drain Outputs

ß On-Resistance of PIO Pulldown Transistor

100

W (max); Off-Resistance 10MW (typ)

ß Individual Activity Latches Capture

Asynchronous State Changes at PIO Inputs

for Interrogation by the Bus Master

ß Data-Strobe Output to Synchronize PIO

Logic States to External Read/Write Circuitry

ß Built-in Multidrop Controller Ensures

Compatibility with Other Dallas

Semiconductor 1-Wire

Æ

Net Products

ß Supports 1-Wire Conditional Search

Command with Response Controlled by

Programmable PIO Conditions

ß Unique Factory-Lasered 64-Bit Registration

Number Ensures Error-Free Device Selection

and Absolute Part Identity

ß Communicates to Host with a Single Digital

Signal at 15.3kbps or 100kbps using 1-Wire

Protocol

ß Operating Range: 2.8V to 5.25V, -40∞C to

+85∞C

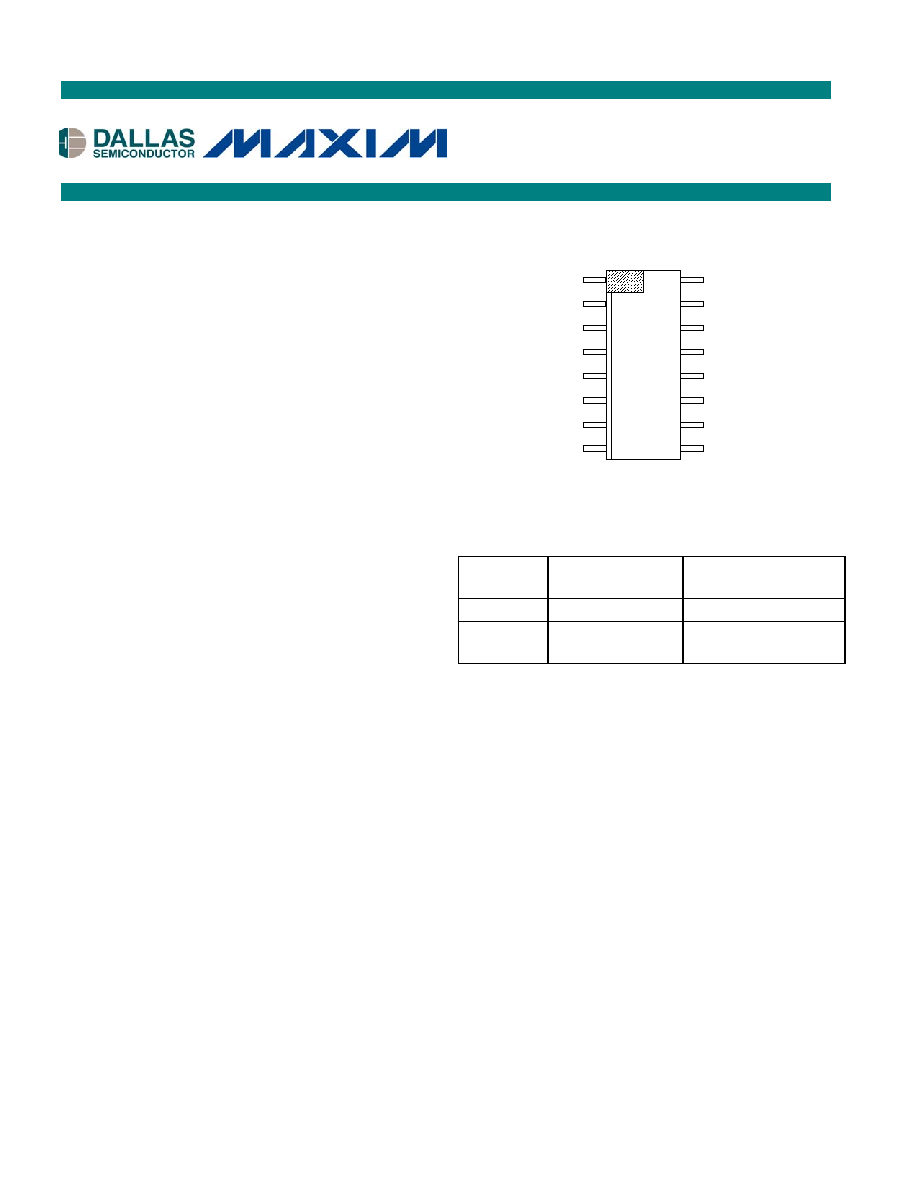

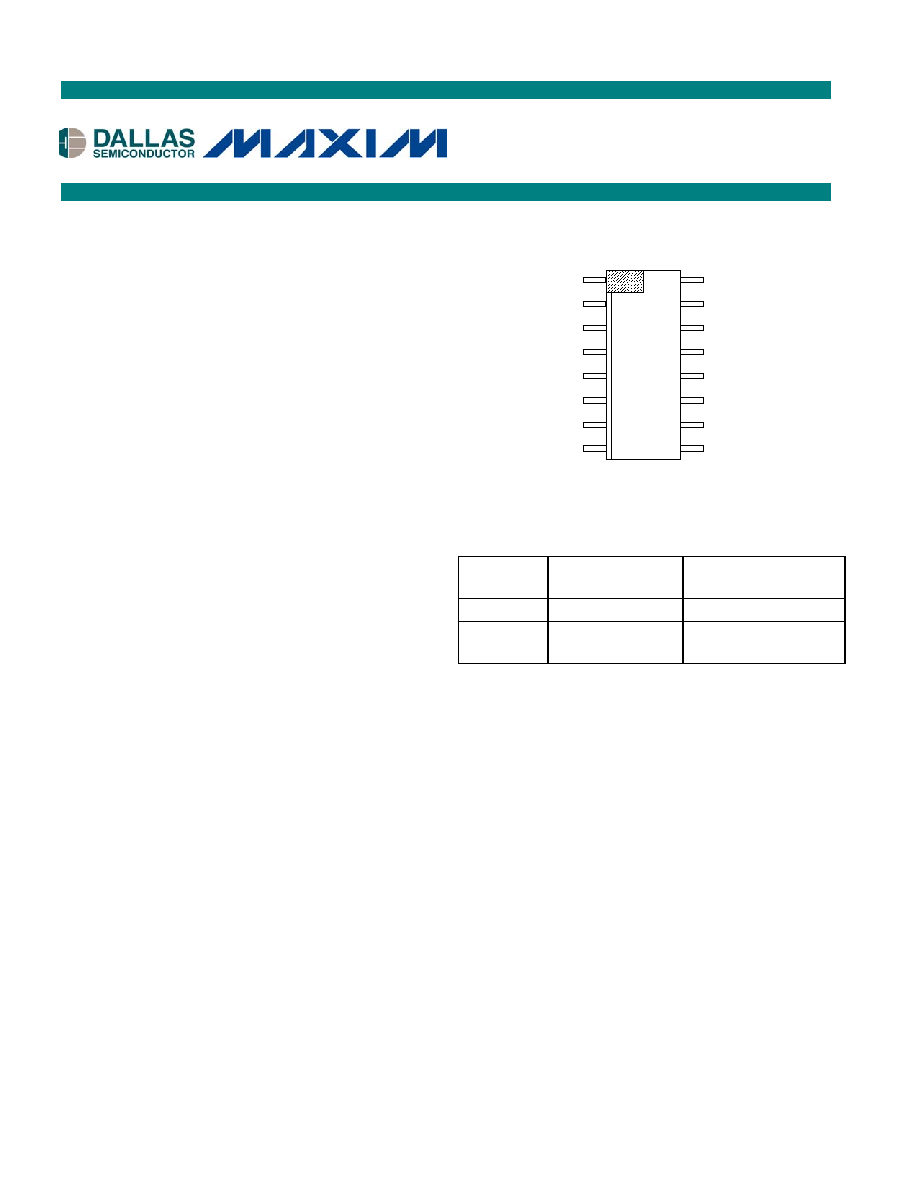

PIN CONFIGURATION

16

15

14

13

12

11

10

9

N.C.

N.C.

P1

P2

P3

P4

RSTZ

P5

N.C.

P0

V

CC

I/O

GND

N.C.

P7

P6

1

2

3

4

5

6

7

8

150-mil SO

ORDERING INFORMATION

PART

TEMP

RANGE

PACKAGE

DS2408S -40∞C to +85∞C 16-Pin SO, 150 mil

DS2408S

/T&R

-40

∞C to +85∞C

Tape-and-Reel of

DS2408S

DESCRIPTION

The DS2408 is an 8-channel, programmable I/O 1-Wire chip. PIO outputs are configured as open-drain

and provide an on resistance of 100

W max. A robust PIO channel-access communication protocol ensures

that PIO output-setting changes occur error-free. A data-valid strobe output can be used to latch PIO logic

states into external circuitry such as a D/A converter (DAC) or microcontroller data bus.

DS2408 operation is controlled over the single-conductor 1-Wire bus. Device communication follows the

standard Dallas Semiconductor 1-Wire protocol. Each DS2408 has its own unalterable and unique 64-bit

ROM registration number that is factory lasered into the chip. The registration number guarantees unique

identification and is used to address the device in a multidrop 1-Wire net environment. Multiple DS2408

devices can reside on a common 1-Wire bus and can operate independently of each other. The DS2408

also supports 1-Wire conditional search capability based on PIO conditions or power-on-reset activity;

the conditions to cause participation in the conditional search are programmable. The DS2408 has an

optional V

CC

supply connection. When an external supply is absent, device power is supplied parasitically

from the 1-Wire bus. When an external supply is present, PIO states are maintained in the absence of the

1-Wire bus power source. The RSTZ signal is configurable to serve as either a hard-wired reset for the

PIO output or as a strobe for external circuitry to indicate that a PIO write or PIO read has completed.

1 of 36

061604

1-Wire is a registered trademark of Dallas Semiconductor.

DS2408

ABSOLUTE MAXIMUM RATINGS*

P0 to P7, RSTZ, I/O Voltage to GND

-0.5V, +6V

P0 to P7, RSTZ, I/O combined sink current

20mA

Operating Temperature Range

-40∞C to +85∞C

Junction Temperature

+150∞C

Storage Temperature Range

-55∞C to +125∞C

Lead Temperature (10s)

See J-STD-020A specification

* This is a stress rating only and functional operation of the device at these or any other conditions

above those indicated in the operation sections of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods of time may affect reliability.

ELECTRICAL CHARACTERISTICS

(V

CC

= 0V or

≥ V

PUP

, T

A

= -40∞C or +85∞C.)

PARAMETER SYMBOL CONDITIONS

MIN TYP MAX UNITS

Standard speed

2.8

5.25

1-Wire Pullup

Voltage

V

PUP

Overdrive speed

3.3

5.25

V

Standby Supply

Current

I

CCS

V

CC

at V

PUP,

I/O pin at 0.3V

1 µA

I/O Pin General Data

1-Wire Pullup

Resistance

R

PUP

(Notes 1, 2)

2.2

k

W

Input Capacitance

C

IO

(Notes 3, 4)

1200

pF

Input Load Current

I

L

I/O pin at V

PUP,

V

CC

at 0V

1 µA

High-to-Low

Switching Threshold

V

TL

(Notes 4, 5, 6)

0.5

3.2 V

Input-Low Voltage

V

IL

(Notes 1, 7)

0.30

V

Low-to-High

Switching Threshold

V

TH

(Notes 4, 5, 8)

0.8

3.4 V

Switching Hysteresis

V

HY

(Notes 9, 4)

0.16

0.73

V

Output-Low Voltage

at 4mA

V

OL

(Note 10)

0.4 V

Standard speed, R

PUP

=

2.2k

W

5

Overdrive speed, R

PUP

=

2.2k

W

2

Recovery Time

(Note 1)

t

REC

Overdrive speed, Directly

prior to reset pulse; R

PUP

= 2.2k

W

5

µs

Standard speed

0.5

5

Rising-Edge Hold-off

Time (Notes 11, 4)

t

REH

Overdrive speed

0.5

2

µs

Standard speed

65

Timeslot Duration

(Notes 1, 12)

t

SLOT

Overdrive speed

10

µs

2 of 36

DS2408

PARAMETER SYMBOL CONDITIONS

MIN TYP MAX UNITS

I/O Pin, 1-Wire Reset, Presence-Detect Cycle

Standard speed, V

PUP

>

4.5V

480

720

Standard speed

660

720

Reset-Low Time

(Notes 1, 12)

t

RSTL

Overdrive speed

53

80

µs

Standard speed

15

60

Presence-Detect High

Time (Note 12)

t

PDH

Overdrive speed

2

7

µs

Standard speed, V

PUP

>

4.5V

1

5

Standard speed

1

8

Presence-Detect Fall

Time (Note 13)

t

FPD

Overdrive speed

1

µs

Standard speed, V

PUP

>

4.5V

60

240

Standard speed

60

280

Presence-Detect Low

Time (Note 12)

t

PDL

Overdrive speed

7

27

µs

Standard speed, V

PUP

>

4.5V

65

75

Standard speed

68

75

Presence-Detect

Sample Time (Note 1)

t

MSP

Overdrive speed

8

9

µs

I/O Pin, 1-Wire Write

Standard speed

60

120

Write-0 Low Time

(Notes 1, 12)

t

W0L

Overdrive speed

8

13

µs

Standard speed

5

15 -

e

Write-1 Low Time

(Notes 1, 12, 14)

t

W1L

Overdrive speed

1

1.8 -

e

µs

Standard speed

15

60

Write Sample Time

(Slave Sampling)

(Note 12)

t

SLS

Overdrive speed

1.8

8

µs

I/O Pin, 1-Wire Read

Standard speed

5

15 -

d

Read-Low Time

(Notes 1, 15)

t

RL

Overdrive speed

1

1.8 -

d

µs

Standard speed

15

60

Read-0 Low Time

(Data From Slave)

(Note 12)

t

SPD

Overdrive speed

1.8

8

µs

Standard speed

t

RL

+

d

15

Read-Sample Time

(Notes 1, 12, 15)

t

MSR

Overdrive speed

t

RL

+

d

1.8

µs

P0 to P7, RSTZ Pin

Input-Low Voltage

V

IL

(Notes 1, 7)

0.30

V

Input-High Voltage

V

IH

V

X

= max (V

PUP

,V

CC

)

(Note 1)

V

X

- 0.8

5.25 V

Output-Low Voltage

at 4mA

V

OL

(Note 10)

0.4 V

Leakage Current

I

LP

5.25V at the pin

1

µA

Output Fall Time

t

FPIO

(Notes 4, 16)

100

ns

Minimum-Sensed

PIO Pulse

t

PWMIN

(Notes 4, 17)

1

5 µs

3 of 36

DS2408

Note 1:

System Requirement

Note 2:

Maximum allowable pullup resistance is a function of the number of 1-Wire devices in the

system and 1-Wire recovery times. The specified value here applies to systems with only one

device and with the minimum 1-Wire recovery times. For more heavily loaded systems, an

active pullup such as that found in the DS2480B may be required.

Note 3:

If a 2.2k

W resistor is used to pull up the data line to V

PUP

, 5µs after power has been applied,

the parasite capacitance does not affect normal communications.

Note 4:

Guaranteed by design--not production tested.

Note 5:

V

TL

, V

TH

are a function of the internal supply voltage.

Note 6:

Voltage below which, during a falling edge on I/O, a logic '0' is detected.

Note 7:

The voltage on I/O needs to be less or equal to V

ILMAX

whenever the master drives the line

low.

Note 8:

Voltage above which, during a rising edge on I/O, a logic '1' is detected.

Note 9:

After V

TH

is crossed during a rising edge on I/O, the voltage on I/O has to drop by V

HY

to be

detected as logic '0'.

Note 10: The I-V characteristic is linear for voltages less than 1V.

Note 11: The earliest recognition of a negative edge is possible at t

REH

after V

TH

has been reached

before.

Note 12: Highlighted numbers are NOT in compliance with the published 1-Wire standards. See

comparison table below.

Note 13: Interval during the negative edge on I/O at the beginning of a presence detect pulse between

the time at which the voltage is 90% of V

PUP

and the time at which the voltage is 10% of

V

PUP

.

Note 14: e represents the time required for the pullup circuitry to pull the voltage on I/O up from V

IL

to V

TH

.

Note 15: d represents the time required for the pullup circuitry to pull the voltage on I/O up from V

IL

to the input high threshold of the bus master.

Note 16: Interval during the device-generated negative edge on any PIO pin or the RSTZ pin between

the time at which the voltage is 90% of V

PUP

and the time at which the voltage is 10% of

V

PUP

. PIO pullup resistor = 2.2k

W.

Note 17: Width of the narrowest pulse which trips the activity latch (for any PIO pin) or causes a reset

(for the RSTZ pin). For a pulse duration t

PW

: If t

PW

< t

PWMIN(min)

, the pulse will be rejected. If

t

PWMIN(min)

< t

PW

< t

PWMIN(max)

, the pulse may or may not be rejected. If t

PW

> t

PWMIN(max)

the

pulse will be recognized and latched.

Note 18: Maximum instantaneous pulldown current through all port pins and the RSTZ pin combined.

No requirement for current balance among different pins.

STANDARD VALUES

DS2408 VALUES

STANDARD

SPEED

OVERDRIVE

SPEED

STANDARD

SPEED

OVERDRIVE

SPEED

PARAMETER

NAME

MIN MAX MIN MAX MIN MAX MIN MAX

t

SLOT

(incl. t

REC

)

61µs (undef.) 7µs (undef.)

65µs

1)

(undef.) 10µs

(undef.)

t

RSTL

480µs (undef.) 48µs 80µs 660µs

720µs

53µs

80µs

t

PDH

15µs 60µs 2µs 6µs 15µs 60µs 2µs 7µs

t

PDL

60µs 240µs 8µs 24µs 60µs 280µs

7µs

27µs

t

W0L

60µs 120µs 6µs 16µs 60µs 120µs 8µs

13µs

t

SLS

, t

SPD

15µs 60µs 2µs 6µs 15µs 60µs 1.8µs

8µs

1)

Intentional change, longer recovery-time requirement due to modified 1-Wire front end.

4 of 36

DS2408

PIN DESCRIPTION

PIN

NAME

DESCRIPTION

1 N.C.

Not

Connected

2 P0

I/O Pin of Channel 0. Logic input/open-drain output with 100

W maximum

on-resistance; 0V to 5.25V operating range. Power-on default is

indeterminate. If it is application-critical for the outputs to power up in the

"off" state, the user should attach an appropriate power-on-reset circuit or

supervisor IC to the RSTZ pin.

3 V

CC

Optional Power Supply Input. Range 2.8V to 5.25V; must be tied to GND

if not used.

4

I/O

1-Wire Interface. Open-drain, requires external pullup resistor.

5 GND

Ground

6 N.C.

Not

Connected

7

P7

I/O Pin of Channel 7. Same characteristics as P0.

8

P6

I/O Pin of Channel 6. Same characteristics as P0.

9

P5

I/O Pin of Channel 5. Same characteristics as P0.

10 RSTZ

SW configurable PIO reset input (

RST

) or open-drain strobe output

(

STRB

). When configured as

RST

, a LOW input sets all PIO outputs to

the "off" state by setting all bits in the PIO Output Latch State Register.

When configured as

STRB

, an output strobe will occur after a PIO write

(see Channel-Access Write command) or after a PIO Read (see Channel-

Access Read command). The power-on default function of this pin is

RST

.

11

P4

I/O pin of channel 4; same characteristics as P0

12

P3

I/O pin of channel 3; same characteristics as P0

13

P2

I/O pin of channel 2; same characteristics as P0

14

P1

I/O pin of channel 1; same characteristics as P0

15 N.C.

Not

connected

16 N.C.

Not

connected

APPLICATION

The DS2408 is a multipurpose device. Typical applications include port expander for microcontrollers,

remote multichannel sensor/actuator, communication and control unit of a microterminal, or as network

interface of a microcontroller. Typical application circuits and communication examples are found later

in this data sheet (Figures 17 to 22).

OVERVIEW

5 of 36

Figure 1 shows the relationships between the major function blocks of the DS2408. The device has two

main data components: 1) 64-bit lasered ROM, and 2) 64-bit register page of control and status registers.

Figure 2 shows the hierarchical structure of the 1-Wire protocol. The bus master must first provide one of

the eight ROM function commands: 1) Read ROM, 2) Match ROM, 3) Search ROM, 4) Conditional

Search ROM, 5) Skip ROM, 6) Overdrive-Skip ROM, 7) Overdrive-Match ROM, or 8) Resume. Upon

completion of an Overdrive ROM command byte executed at standard speed, the device will enter

overdrive mode, where all subsequent communication occurs at a higher speed. The protocol required for

these ROM function commands is described in Figure 12. After a ROM function command is success-

fully executed, the control functions become accessible and the master may provide any one of the five

available commands. The protocol for these control commands is described in Figure 8. All data is read

and written least significant bit first.

DS2408

Figure 1. DS2408 BLOCK DIAGRAM

V

CC

64-BIT

LASERED ROM

CRC16

GENERATOR

REGISTER

PAGE

REGISTER

FUNCTION

CONTROL

1-WIRE

FUNCTION

CONTROL

PORT

FUNCTION

CONTROL

I/O

GND

PARASITE POWER

INTERNAL V

CC

PORT

INTER-

FACE

RSTZ

P0

P1

P2

P3

P4

P5

P6

P7

Figure 2. HIERARCHICAL STRUCTURE FOR 1-Wire PROTOCOL

1-Wire Net

Other

Devices

Bus

Master

Command

Level:

1-Wire ROM Function

Commands

DS2408-Specific

Control Function

Commands

DS2408

Available

Commands:

Read ROM

Match ROM

Search ROM

Skip ROM

Conditional Search

ROM

Overdrive Match

Overdrive Skip

Resume

Read PIO Registers

Channel Access Read

Channel Access Write

Write Conditional

Search Register

Reset Activity Latches

Data Field

Affected:

64-BIT ROM, RC-FLAG

64-BIT ROM, RC-FLAG

64-BIT ROM, RC-FLAG

RC-FLAG

64-BIT ROM, RC-FLAG, Port Status,

Cond. Search Settings,

64-BIT ROM, RC-FLAG, OD-Flag

RC-FLAG, OD-Flag

RC-FLAG

PIO Registers

Port Input Latches

Port Output Latches

Conditional Search Register

Activity Latches

Cmd.

Codes:

33h

55h

F0h

CCh

ECh

69h

3Ch

A5h

F0h

F5h

5Ah

CCh

C3h

6 of 36

DS2408

PARASITE POWER

The DS2408 can derive its power entirely from the 1-Wire bus by storing energy on an internal capacitor

during periods of time when the signal line is high. During low times the device continues to operate from

this "parasite" power source until the 1-Wire bus returns high to replenish the parasite (capacitor) supply.

If power is available, the V

CC

pin should be connected to the external voltage supply.

Figure 3. 64-BIT LASERED ROM

MSB

LSB

8-BIT

CRC CODE

48-BIT SERIAL NUMBER

8-BIT FAMILY

CODE (29h)

MSB

LSB

MSB

LSB

MSB

LSB

64-BIT LASERED ROM

Each DS2408 contains a unique ROM code that is 64 bits long. The first 8 bits are a 1-Wire family code.

The next 48 bits are a unique serial number. The last eight bits are a CRC of the first 56 bits. See Figure 3

for details. The 1-Wire CRC is generated using a polynomial generator consisting of a shift register and

XOR gates as shown in Figure 4. The polynomial is X

8

+ X

5

+ X

4

+ 1. Additional information about the

Dallas 1-Wire Cyclic Redundancy Check is available in Application Note 27.

The shift register bits are initialized to 0. Then, starting with the least significant bit of the family code,

one bit at a time is shifted in. After the eighth

bit of the family code has been entered, the serial number is

entered. After the serial number has been entered, the shift register contains the CRC value. Shifting in

the eight bits of CRC returns the shift register to all 0s.

Figure 4. 1-Wire CRC GENERATOR

X

0

X

1

X

2

X

3

X

4

X

5

X

6

X

7

X

8

POLYNOMIAL = X

8

+ X

5

+ X

4

+ 1

1

st

STAGE

2

nd

STAGE

3

rd

STAGE

4

th

STAGE

6

th

STAGE

5

th

STAGE

7

th

STAGE

8

th

STAGE

INPUT DATA

REGISTER ACCESS

The registers needed to operate the DS2408 are organized as a Register Page, as shown in Figure 5. All

registers are volatile, i. e., they lose their state when the device is powered down. PIO, Conditional

Search, and Control/Status registers are read/written using the device level Read PIO Registers and Write

Conditional Search Register commands described in subsequent sections and Figure 8 of this document.

7 of 36

DS2408

Figure 5. DS2408 REGISTER ADDRESS MAP

ADDRESS RANGE

ACCESS TYPE

DESCRIPTION

0000h to 0087h

R

Undefined Data

0088h R

PIO

Logic

State

0089h

R

PIO Output Latch State Register

008Ah

R

PIO Activity Latch State Register

008Bh

R/W

Conditional Search Channel Selection Mask

008Ch

R/W

Conditional Search Channel Polarity Selection

008Dh R/W

Control/Status

Register

008Eh to 008Fh

R

These Bytes Always Read FFh

PIO Logic-State Register

The logic state of the PIO pins can be obtained by reading this register using the Read PIO Registers

command. Reading this register does not generate a signal at the RSTZ pin, even if it is configured as

STRB

. See the Channel-Access commands description for details on

STRB

.

PIO Logic State Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

0088h

P7 P6 P5 P4 P3 P2 P1 P0

This register is read-only. Each bit is associated with the pin of the respective PIO channel as shown in

Figure 6. The data in this register is sampled at the last (most significant) bit of the byte that proceeds

reading the first (least significant) bit of this register. See the Read PIO Registers command description

for details.

PIO Output Latch State Register

The data in this register represents the latest data written to the PIO through the Channel-access Write

command. This register is read using the Read PIO Registers command. Reading this register does not

generate a signal at the RSTZ pin, even if it is configured as

STRB

. See the Channel-access commands

description for details on

STRB

. This register is not affected if the device reinitializes itself after an ESD

hit.

PIO Output Latch State Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

0089h PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0

This register is read-only. Each bit is associated with the output latch of the respective PIO channel as

shown in Figure 6.

The flip-flops of this register will power up in a random state. If the chip has to power up with all PIO

channels off, a LOW pulse must be generated on the RSTZ pin, e.g., by means of an open-drain CPU

supervisor chip (see Figure 20). When using an RC circuit to generate the power-on reset, make sure that

RSTZ is NOT configured as strobe output (ROS bit in control/status register 008Dh needs to be 0).

8 of 36

DS2408

PIO Activity Latch State Register

The data in this register represents the current state of the PIO activity latches. This register is read using

the Read PIO Registers command. Reading this register does not generate a signal at the RSTZ pin, even

if it is configured as

STRB

. See the Channel-access commands description for details on

STRB

.

PIO Activity Latch State Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

008Ah AL7 AL6 AL5 AL4 AL3 AL2 AL1 AL0

This register is read-only. Each bit is associated with the activity latch of the respective PIO channel as

shown in Figure 6. This register is cleared to 00h by a power-on reset, by a low pulse on the RSTZ pin

(only if RSTZ is configured as

RST

input), or by successful execution of the Reset Activity Latches

command.

Figure 6. CHANNEL I/O AND RSTZ SIMPLIFIED LOGIC DIAGRAM

PIO

OUTPUT

LATCH

PIO ACTIVITY

LATCH

EDGE

DETECTOR

PORT

FUNCTION

CONTROL

TO ACTIVITY LATCH

STATE REGISTER

TO PIO LOGIC

STATE REGISTER

TO PIO

OUTPUT LATCH

STATE REG.

R

Q

D

D

Q

S

Q

Q

"1"

CLR ACT LATCH

ROS

STRB

CHANNEL

I/O PIN

RSTZ

PIN

DATA

CLOCK

POWER ON

RESET

9 of 36

DS2408

Conditional Search Channel Selection Mask Register

The data in this register controls whether a PIO channel qualifies for participation in the conditional

search command. To include one or more of the PIO channels, the bits in this register that correspond to

those channels need to be set to 1. This register can only be written through the Write Conditional Search

Registers command.

Conditional Search Channel Selection Mask Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

008Bh SM7 SM6 SM5 SM4 SM3 SM2 SM1 SM0

This register is read/write. Each bit is associated with the respective PIO channel as shown in Figure 7.

This register is cleared to 00h by a power-on reset

Conditional Search Channel Polarity Selection Register

The data in this register specifies the polarity of each selected PIO channel for the device to respond to

the conditional search command. Within a PIO channel, the data source may be either the channel's input

signal (pin) or the channel's activity latch, as specified by the PLS bit in the Control/Status register at ad-

dress 008Dh. This register can only be written through the Write Conditional Search Registers command.

Conditional Search Channel Polarity Selection Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

008Ch SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

This register is read/write. Each bit is associated with the respective PIO channel as shown in Figure 7.

This register is cleared to 00h by a power-on reset.

Figure 7. Conditional Search Logic

AL7

P7

PLS

SP0

SM0

CT

SM7

SP7

AL0

P0

CSR

INPUT FROM

CHANNELS 1 TO 6

(NOT SHOWN)

CHANNEL 0

CHANNEL 7

10 of 36

DS2408

Control/Status Register

The data in this register reports status information, determines the function of the RSTZ pin and further

configures the device for conditional search. This register can only be written through the Write Condi-

tional Search Registers command.

Control/Status Register Bitmap

ADDR

b7 b6 b5 b4 b3 b2 b1 b0

008Dh VCCP

0

0

0

PORL ROS CT

PLS

This register is read/write. Without V

CC

supply, this register reads 08h after a power-on reset. The func-

tional assignments of the individual bits are explained in the table below. Bits 4 to 6 have no function;

they will always read 0 and cannot be set to 1.

Control/Status Register Details

BIT DESCRIPTION

BIT(S)

DEFINITION

PLS: Pin or Activity

Latch Select

b0

Selects either the PIO pins or the PIO activity latches as input for the

conditional search.

0: pin selected (default)

1: activity latch selected

CT: Conditional Search

Logical Term

b1

Specifies whether the data of two or more channels needs to be OR'ed

or AND'ed to meet the qualifying condition for the device to respond to a

conditional search. If only a single channel is selected in the channel

selection mask (008Bh) this bit is a don't care.

0: bitwise OR (default)

1: bitwise AND

ROS: RSTZ Pin Mode

Control

b2

Configures RSTZ as either RST input or STRB output

0: configured as RST input (default)

1: configured as STRB output

PORL: Power-On Reset

Latch

b3

Specifies whether the device has performed a power-on reset. This bit

can only be cleared to 0 under software control. As long as this bit is 1

the device will always respond to a conditional search.

VCCP: V

CC

Power

Status (Read-Only)

b7 For

V

CC

powered operation the V

CC

pin needs to be tied to a voltage

source

≥ V

PUP

.

0:

V

CC

pin is grounded

1:

V

CC

-powered operation

The interaction of the various signals that determine whether the device responds to a conditional search

is illustrated in Figure 7. The selection mask SM selects the participating channels. The polarity selection

SP determines for each channel whether the channel signal needs to be 1 or 0 to qualify. The PLS bit

determines whether all channel signals are taken from the activity latches or I/O pins. The signals of all

channels are fed into an AND gate as well as an OR gate. The CT bit finally selects the AND'ed or

OR'ed result as the conditional search response signal CSR.

Note on CT bit:

OR

The qualifying condition is met if the input (pin state or activity latch) for one or more selected

channels matches the corresponding polarity.

AND For the qualifying condition to be met, the input (pin state or activity latch) for every selected

channel must match the corresponding polarity.

11 of 36

DS2408

Figure 8-1. CONTROL FUNCTIONS FLOW CHART

Bus Master TX

TA1 (T7:T0), TA2 (T15:T8)

Y

N

F0h

Read PIO Reg.?

Y

N

Address

< 90h?

To Figure 8

2

nd

Part

From Figure 8

2

nd

Part

Bus Master TX Control

Function Command

To ROM Functions

Flow Chart (Figure 12)

From ROM Functions

Flow Chart (Figure 12)

DS2408 sets Register

Address = (T15:T0)

Bus Master RX Data Byte

from Register Address

Bus Master RX CRC16

of Command, Address,

Data Bytes

Bus Master

RX "1"s

Y

N

DS2408 Incre-

ments Address

Counter

Y

Y

N

N

Master

TX Reset?

Address

< 90h?

Master

TX Reset?

Master

TX Reset?

Y

N

Note:

To read the three PIO state and latch

register bytes, the target address should

be 0088h. Returned data for a target

address <0088h is undefined.

Address

= 88h?

Y

N

DS2408 Samples

PIO Pin Status

1)

Note 1)

See the command

description for the

exact timing of the

PIO pin sampling.

12 of 36

DS2408

Figure 8-2. CONTROL FUNCTIONS FLOW CHART

From Figure 8

1

st

Part

To Figure 8

1

st

Part

To Figure 8

3

rd

Part

From Figure 8

3

rd

Part

F5h

Channel Access

Read?

DS2408 Samples

PIO Pin Status

PIO Sample

Counter = 0

Y

N

Sample Count

= 31?

Y

N

Master

TX Reset?

Bus Master RX

PIO Pin Status

DS2408 Increments

PIO Sample Counter

DS2408 Samples

PIO Pin Status

Bus Master RX

PIO Pin Status

PIO Sample

Counter = 0

DS2408 Samples

PIO Pin Status

Bus Master RX

CRC16 of Command

and 32 Bytes of PIO

Pin Status (1

st

Pass)

CRC16 of 32 Bytes

of PIO Pin Status

(Subsequent Passes)

Y

N

5Ah

Channel Access

Write?

Bus Master TX new

PIO Output Data Byte

Bus Master TX

inverted new PIO

Output Data Byte

Transmission

OK?

DS2408 Updates

PIO Pin Status

Bus Master RX

Confirmation AAh

DS2408 Samples

PIO Pin Status

Bus Master RX

PIO Pin Status

Y

N

Master

TX Reset?

N

Y

Bus Master

RX "1"s

Y

N

Master

TX Reset?

Note 1)

See the command

description for the

exact timing of the

PIO pin sampling

and updating.

Note 2)

If the RSTZ pin is con-

figured as output, a

STRB\ is generated

during the first two bits

of this byte.

N

Y

2)

2)

1)

1)

1)

1)

2)

1)

13 of 36

DS2408

Figure 8-3. CONTROL FUNCTIONS FLOW CHART

From Figure 8

2

nd

Part

To Figure 8

2

nd

Part

CCh

Write C. Search

Reg.?

Bus Master TX

TA1 (T7:T0), TA2 (T15:T8)

N

Y

8Bh

£ Address £

8Dh?

Y

N

Master

TX Reset?

Bus Master TX

Data Byte

DS2408 Incre-

ments Address

Counter

DS2408 Copies

Data to Register

Y

N

C3h

Reset Activity

Latches?

DS2408 Clears all

PIO Activity Latches

Bus Master RX

Confirmation AAh

Y

N

Master

TX Reset?

Y

N

Master

TX Reset?

Bus Master

RX "1"s

Y

N

Master

TX Reset?

Note:

To read 8Bh to 8Dh

use the Read PIO

Registers command.

Y

N

14 of 36

DS2408

CONTROL FUNCTION COMMANDS

Once a ROM function command is completed, the Control Function Commands can be issued. The

Control Functions Flow Chart (Figure 8) describes the protocols necessary for accessing the PIO

channels and the special function registers of the DS2408. The communication between the master and

the DS2408 takes place either at standard speed (default, OD = 0) or at overdrive speed (OD = 1). If not

explicitly set into the overdrive mode, the device operates at standard speed.

Read PIO Registers [F0h]

The Read PIO Registers command is used to read any of the device's registers. After issuing the

command, the master must provide the 2-byte target address. After these two bytes, the master reads data

beginning from the target address and may continue until address 008Fh. If the master continues reading,

it will receive an inverted 16-bit CRC of the command, address bytes, and all data bytes read from the

initial starting byte through the end of the register page. This CRC16 is the result of clearing the CRC

generator and then shifting in the command byte followed by the two address bytes and the data bytes

beginning at the first addressed location and continuing through to the last byte of the register page. After

the bus master has received the CRC16, the DS2408 responds to any subsequent read-time slots with

logical 1's until a 1-Wire Reset command is issued. If this command is issued with target address 0088h

(PIO Logic State Register), the PIO sampling takes place during the transmission of the MS bit of TA2. If

the target address is lower than 0088h, the sampling takes place while the master reads the MS bit from

address 0087h.

Channel-Access Read [F5h]

In contrast to reading the PIO logical state from address 88h, this command reads the status in an endless

loop. After 32 bytes of PIO pin status the DS2408 inserts an inverted CRC16 into the data stream, which

allows the master to verify whether the data was received error-free. A Channel-Access Read can be

terminated at any time with a 1-Wire Reset.

Figure 9. CHANNEL-ACCESS READ TIMING

IO (1-Wire)

STRB\

Example - Sampled State = 72h

MS 2 bits of pre-

vious byte (8Dh)

LS 2 bits of data

byte (72h)

t

SPD

t

SPD

t

SPD

Sampling Point

Notes:

1) The "previous byte" could be the command code, the data byte resulting from the previous PIO

sample, or the MS byte of a CRC16. The example shows a read-1 time slot.

2) The sample point timing also applies to the Channel-access Write command, with the "previous byte"

being the write confirmation byte (AAh). No

STRB

pulse results when sampling occurs during a

Channel-Access Write command.

15 of 36

DS2408

The status of all eight PIO channels is sampled at the same time. The first sampling occurs during the last

(most significant) bit of the command code F5h. While the master receives the MSB of the PIO status

(i.e., the status of pin P7) the next sampling occurs and so on until the master has received 31 PIO

samples. Next, the master receives the inverted CRC16 of the command byte and 32 PIO samples (first

pass) or the CRC of 32 PIO samples (subsequent passes). While the last (most significant) bit of the CRC

is transmitted the next PIO sampling takes place. The delay between the beginning of the time slot and

the sampling point is independent of the bit value being transmitted and the data direction (see Figure 9).

If the RSTZ pin is configured as

STRB

, a strobe signal will be generated during the transmission of the

first two (least significant) bits of PIO data. The strobe can signal a FIFO or a microcontroller to apply

the next data byte at the PIO for the master to read through the 1-Wire line.

Case #1 - MS Bit of new PIO state is 0

Example - Old State = 39h, New state = 72h

Case #2 - MS Bit of new PIO state is 1

Example - Old State = 72h, New state = 93h

Channel-Access Write [5Ah]

The Channel-Access Write command is the only way to write to the PIO output-latch state register

(address 0089h), which controls the open-drain output transistors of the PIO channels. In an endless loop

this command first writes new data to the PIO and then reads back the PIO status. The implicit read-after-

write can be used by the master for status verification or for a fast communication with a microcontroller

that is connected to the port pins and RSTZ for synchronization. A Channel-Access Write can be termi-

nated at any time with a 1-Wire Reset.

Figure 10. CHANNEL-ACCESS WRITE TIMING

IO (1-Wire)

PIO

STRB\

39h

72h

t

SLS

t

SPD

t

SPD

MS 2 bits of inverted

new-state byte (8Dh)

LS 2 bits of confir-

mation byte (AAh)

MS 2 bits of inverted

new-state byte (6Ch)

LS 2 bits of confir-

mation byte (AAh)

72h

93h

t

SPD

t

SPD

V

TH

Note:

Both examples assume that the RSTZ pin is configured as

STRB

output. If RSTZ is configured as

RST

input (default), the RSTZ pin needs to be tied high (to V

CC

or V

PUP

) for the Channel-Access Write to

function properly. Leaving the pin floating will force the output transistors of the PIO channels to the

"off" state and the PIO output latches will all read "1". See Figure 6 for a schematic of the logic.

After the command code the master transmits a byte that determines the new state of the PIO output

transistors. The first (least significant) bit is associated to P0. To switch the output transistor off (non-

conducting) the corresponding bit value is 1. To switch the transistor on that bit needs to be 0. This way

the data byte transmitted as the new PIO output state arrives in its true form at the PIO pins. To protect

the transmission against data errors, the master has to repeat the new PIO byte in its inverted form. Only

if the transmission was successful will the PIO status change. The actual transition at the PIO to the new

state occurs during the last (most significant) bit of the inverted new PIO data byte and depends on the

polarity of that bit, as shown in Figure 10. If this bit is a 1, the transition begins after t

SLS

is expired; in

case of a 0, the transition begins at the end of the time slot, when the V

TH

threshold is crossed. To inform

the master about the successful change of the PIO status, the DS2408 transmits a confirmation byte with

16 of 36

DS2408

the data pattern AAh. If the RSTZ pin is configured as

STRB

, a strobe signal will be generated during the

transmission of the first two (least significant) bits of the confirmation byte. The strobe can signal a FIFO

or a microcontroller to read the new data byte from the PIO. While the last bit of the confirmation byte is

transmitted, the DS2408 samples the status of the PIO pins, as shown in Figure 9, and sends it to the

master. Depending on the data, the master can either continue writing more data to the PIO or issue a 1-

Wire reset to end the command.

Write Conditional Search Register [CCh]

This command is used to tell the DS2408 the conditions that need to be met for the device to respond to a

Conditional Search command, to define the function of the RSTZ pin and to clear the power-on reset flag.

After issuing the command the master sends the 2-byte target address, which must be a value between

008Bh and 008Dh. Next the master sends the byte to be written to the addressed cell. If the address was

valid, the byte is immediately written to its location in the register page. The master now can either end

the command by issuing a 1-Wire reset or send another byte for the next higher address. Once register

address 008Dh has been written, any subsequent data bytes will be ignored. The master has to send a 1-

Wire reset to end the command. Since the Write Conditional Search Register flow does not include any

error-checking for the new register data, it is important to verify correct writing by reading the registers

using the Read PIO Registers command.

Reset Activity Latches [C3h]

Each PIO channel includes an activity latch that is set whenever there is a state transition at a PIO pin.

This change may be caused by an external event/signal or by writing to the PIO. Depending on the

application there may be a need to reset the activity latch after having captured and serviced an external

event. Since there is only read access to the PIO Activity Latch State Register, the DS2408 supports a

special command to reset the latches. After having received the command code, the device resets all

activity latches simultaneously. There are two ways for the master to verify the execution of the Reset

Activity Latches command. The easiest way is to start reading from the 1-Wire line right after the

command code is transmitted. In this case the master will read AAh bytes until it sends a 1-Wire reset.

The other way to verify execution is to read register address 008Ah.

1-WIRE BUS SYSTEM

The 1-Wire bus is a system that has a single bus master and one or more slaves. In all instances the

DS2408 is a slave device. The bus master is typically a microcontroller or PC. For small configurations

the 1-Wire communication signals can be generated under software control using a single port pin. For

multisensor networks, the DS2480B 1-Wire line driver chip or serial port adapters based on this chip

(DS9097U series) are recommended. This simplifies the hardware design and frees the microprocessor

from responding in real time.

The discussion of this bus system is broken down into three topics: hardware configuration, transaction

sequence, and 1-Wire signaling (signal types and timing). The 1-Wire protocol defines bus transactions in

terms of the bus state during specific time slots that are initiated on the falling edge of sync pulses from

the bus master.

HARDWARE CONFIGURATION

The 1-Wire bus has only a single line by definition; it is important that each device on the bus be able to

drive it at the appropriate time. To facilitate this, each device attached to the 1-Wire bus must have open

drain or tri-state outputs. The 1-Wire port of the DS2408 is open-drain with an internal circuit equivalent

to that shown in Figure 11.

17 of 36

DS2408

Figure 11. HARDWARE CONFIGURATION

OPEN-DRAIN

PORT PIN

RX = RECEIVE

TX = TRANSMIT

100

W

MOSFET

V

PUP

RX

TX

TX

RX

DATA

SEE

TEXT

SIMPLE BUS MASTER

DS2408 1-Wire PORT

R

PUP

DS2480B

+5V

HOST CPU

VDD

POL

RXD

TXD

VPP

1-W

NC

GND

SERIAL IN

SERIAL OUT

SERIAL

PORT

TO 1-Wire DATA

DS2480B BUS MASTER

A multidrop bus consists of a 1-Wire bus with multiple slaves attached. At standard speed the 1-Wire bus

has a maximum data rate of 15.3kbps. Communication speed for 1-Wire devices can be typically boosted

to 142kbps by activating the overdrive mode; however, the maximum overdrive data rate for the DS2408

is 100kbps. The value of the pullup resistor primarily depends on the network size and load conditions.

For most applications the optimal value of the pullup resistor will be approximately 2.2k

W for standard

speed and 1.5k

W for overdrive speed.

The idle state for the 1-Wire bus is high. If for any reason a transaction needs to be suspended, the bus

MUST be left in the idle state if the transaction is to resume. If this does not occur and the bus is left low

for more than 16µs (overdrive speed) or more than 120µs (standard speed), one or more devices on the

bus may be reset. With the DS2408 the bus must be left low for no longer than 13µs at overdrive speed to

ensure that none of the slave devices on the 1-Wire bus performs a reset. The DS2408 communicates

properly when used in conjunction with a DS2480B 1-Wire driver and serial port adapters that are based

on this driver chip. When operating the device in overdrive or below 4.5V, some 1-Wire I/O timing

values must be modified (see EC table).

18 of 36

DS2408

TRANSACTION SEQUENCE

The protocol for accessing the DS2408 through the 1-Wire port is as follows:

ß Initialization

ß ROM Function Command

ß Control Function Command

ß Transaction/Data

Illustrations of the transaction sequence for the various control function commands are found later in this

document.

INITIALIZATION

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence

consists of a reset pulse transmitted by the bus master followed by presence pulse(s) transmitted by the

slave(s). The presence pulse lets the bus master know that the DS2408 is on the bus and is ready to

operate. For more details, see the 1-Wire Signaling section.

ROM FUNCTION COMMANDS

Once the bus master has detected a presence, it can issue one of the seven ROM function commands. All

ROM function commands are eight bits long. A list of these commands follows (see the flowchart in

Figure 12).

Read ROM [33h]

This command allows the bus master to read the DS2408's 8-bit family code, unique 48-bit serial number,

and 8-bit CRC. This command can only be used if there is a single device on the bus. If more than one

slave is present on the bus, a data collision will occur when all slaves try to transmit at the same time

(open drain will produce a wired-AND result). The resultant family code and 48-bit serial number will

result in a mismatch of the CRC.

Match ROM [55h]

The Match ROM command, followed by a 64-bit ROM sequence, allows the bus master to address a spe-

cific DS2408 on a multidrop bus. Only the DS2408 that exactly matches the 64-bit ROM sequence will

respond to the following control function command. All slaves that do not match the 64-bit ROM se-

quence will wait for a reset pulse. This command can be used with either single or multiple devices on the

bus.

Search ROM [F0h]

When a system is initially brought up, the bus master might not know the number of devices on the

1-Wire bus or their 64-bit ROM codes. The Search ROM command allows the bus master to use a

process of elimination to identify the 64-bit ROM codes of all slave devices on the bus. The search ROM

process is the repetition of a simple three-step routine: read a bit, read the complement of the bit, then

write the desired value of that bit. The bus master performs this simple, three-step routine on each bit of

the ROM. After one complete pass, the bus master knows the contents of the ROM in one device. The

remaining number of devices and their ROM codes may be identified by additional passes. See

Application Note 187 for a detailed discussion on the Search ROM command process including a

software example.

Conditional Search [ECh]

19 of 36

The Conditional Search ROM command operates similarly to the Search ROM command except that only

devices fulfilling the specified condition will participate in the search. The condition is specified by the

Conditional Search channel and polarity selection (addresses 008Bh, 008Ch), the bit functions CT and

DS2408

PLS of the Control/Status Register (address 008Dh), and the state of the PIO channels. See Figure 7 for a

description of the Conditional Search logic. The device also responds to the Conditional Search if the

PORL bit is set. The Conditional Search ROM provides an efficient means for the bus master to deter-

mine devices on a multidrop system that have to signal an important event, such as a state change at a

PIO pin caused by an external signal. After each pass of the conditional search that successfully deter-

mined the 64-bit ROM for a specific device on the multidrop bus, that particular device can be individu-

ally accessed as if a Match ROM had been issued, since all other devices will have dropped out of the

search process and will be waiting for a reset pulse.

Skip ROM [CCh]

This command can save time in a single-drop bus system by allowing the bus master to access the control

functions without providing the 64-bit ROM code. If more than one slave is present on the bus and a

Read command is issued following the Skip ROM command, data collision will occur on the bus as

multiple slaves transmit simultaneously (open-drain pulldowns will produce a wired-AND result).

Resume Command [A5h]

In a typical application the DS2408 can be accessed several times to complete a control or adjustment

function. In a multidrop environment this means that the 64-bit ROM sequence of a Match ROM com-

mand has to be repeated for every access. To maximize the data throughput in a multidrop environment,

the Resume Command function is implemented. This function checks the status of the RC flag and, if it is

set, directly transfers control to the control functions, similar to a Skip ROM command. The only way to

set the RC flag is through successfully executing the Match ROM, Search ROM, Conditional Search

ROM, or Overdrive-Match ROM command. Once the RC flag is set, the device can be repeatedly

accessed through the Resume Command function. Accessing another device on the bus will clear the RC

flag, preventing two or more devices from simultaneously responding to the Resume Command function.

Skip ROM [3Ch]

On a single-drop bus this command can save time by allowing the bus master to access the control

functions without providing the 64-bit ROM code. Unlike the normal Skip ROM command, the

Overdrive Skip ROM sets the DS2408 in the overdrive mode (OD = 1). All communication following

this command has to occur at overdrive speed until a reset pulse of minimum 480µs duration resets all

devices on the bus to standard speed (OD = 0). When issued on a multidrop bus this command will set all

overdrive-supporting devices into overdrive mode. To subsequently address a specific overdrive-

supporting device, a reset pulse at overdrive speed has to be issued followed by a Match ROM or Search

ROM command sequence. This will speed up the time for the search process. If more than one slave

supporting overdrive is present on the bus and the Overdrive Skip ROM command is followed by a Read

command, data collision will occur on the bus as multiple slaves transmit simultaneously (open-drain

pulldowns will produce a wired-AND result).

Overdrive Match ROM [69h]

The Overdrive Match ROM command followed by a 64-bit ROM sequence transmitted at overdrive

speed allows the bus master to address a specific DS2408 on a multidrop bus and to simultaneously set it

in overdrive mode. Only the DS2408 that exactly matches the 64-bit ROM sequence will respond to the

subsequent control function command. Slaves already in overdrive mode from a previous Overdrive Skip

or Match command will remain in overdrive mode. All overdrive-capable slaves will return to standard

speed at the next Reset Pulse of minimum 480µs duration. The Overdrive Match ROM command can be

used with either single or multiple devices on the bus.

20 of 36

DS2408

Figure 12-1. ROM FUNCTIONS FLOW CHART

From Figure 12

2

nd

Part

To Control Functions

Flow Chart (Figure 8)

Master TX Bit 0

Master TX Bit 63

Master TX Bit 1

RC = 1

DS2408 TX

CRC Byte

DS2408 TX

Serial Number

(6 Bytes)

DS2408 TX

Family Code

(1 Byte)

Bit 0

Match?

Y

N

Bit 1

Match?

Y

N

Bit 63

Match?

Y

N

DS2408 TX Bit 0

DS2408 TX Bit 0

Master TX Bit 0

DS2408 TX Bit 1

DS2408 TX Bit 1

Master TX Bit 1

DS2408 TX Bit 63

DS2408 TX Bit 63

Master TX Bit 63

RC = 1

Bit 0

Match?

Y

N

Bit 1

Match?

Y

N

Bit 63

Match?

Y

N

To Figure 12

2

nd

Part

RC = 0

RC = 0

RC = 0

RC = 0

Y

Y

Y

Y

N

F0h

Search ROM

Command?

N

55h

Match ROM

Command?

N

ECh

Cond. Search

Command?

N

33h

Read ROM

Command?

To Figure 12

2

nd

Part

From Control Functions

Flow Chart (Figure 8)

Bus Master TX ROM

Function Command

DS2408 TX

Presence Pulse

OD

Reset Pulse?

N

Y

OD = 0

Bus Master TX

Reset Pulse

From Figure 12, 2

nd

Part

Condition Met?

Y

N

DS2408 TX Bit 0

DS2408 TX Bit 0

Master TX Bit 0

DS2408 TX Bit 1

DS2408 TX Bit 1

Master TX Bit 1

DS2408 TX Bit 63

DS2408 TX Bit 63

Master TX Bit 63

RC = 1

Bit 0

Match?

Y

N

Bit 1

Match?

Y

N

Bit 63

Match?

Y

N

21 of 36

DS2408

Figure 12-2. ROM FUNCTIONS FLOW CHART

From Figure 12

1

st

Part

From Figure 12

1

st

Part

To Figure 12, 1

st

Part

RC = 1 ?

N

Y

RC = 0 ; OD = 1

Master TX Bit 0

Master TX Bit 63

Master TX Bit 1

RC = 1

Bit 0

Match?

Y

N

Bit 1

Match?

Y

N

Bit 63

Match?

Y

N

Y

N

69h

Overdrive Match

ROM?

RC = 0 ; OD = 1

Master

TX Reset ?

Y

N

Master

TX Reset ?

N

Y

Y

N

3Ch

Overdrive

Skip ROM?

Y

N

A5h

Resume

Command?

RC = 0

Y

N

CCh

Skip ROM

Command?

To Figure 12

1

st

Part

22 of 36

DS2408

1-WIRE SIGNALING

The DS2408 requires strict protocols to ensure data integrity. The protocol consists of four types of

signaling on one line: Reset Sequence with Reset Pulse and Presence Pulse, Write-Zero, Write-One, and

Read-Data. Except for the presence pulse, the bus master initiates all these signals. The DS2408 can

communicate at two different speeds, standard speed, and overdrive speed. If not explicitly set into the

overdrive mode, the DS2408 will communicate at standard speed. While in overdrive mode, the fast

timing applies to all waveforms.

To get from idle to active, the voltage on the 1-Wire line needs to fall from V

PUP

below the V

TL

threshold.

To get from active to idle, the voltage needs to rise from V

ILMAX

past the V

TH

threshold. The V

ILMAX

voltage is relevant for the DS2408 when determining a logical level, not triggering any events.

Figure 13 shows the initialization sequence required to begin any communication with the DS2408. A

Reset Pulse followed by a Presence Pulse indicates the DS2408 is ready to receive data, given the correct

ROM and control function command. If the bus master uses slew-rate control on the falling edge, it must

pull down the line for t

RSTL

+ t

F

to compensate for the edge. A t

RSTL

duration of 480µs or longer will exit

the overdrive mode returning the device to standard speed. If the DS2408 is in overdrive mode and t

RSTL

is no longer than 80µs the device will remain in overdrive mode.

Figure 13. INITIALIZATION PROCEDURE "RESET AND PRESENCE PULSES"

RESISTOR

MASTER

DS2408

t

RSTL

t

PDL

t

RSTH

t

PDH

MASTER TX "RESET PULSE" MASTER RX "PRESENCE PULSE"

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

e

t

F

t

REC

t

MSP

After the bus master has released the line it goes into receive mode (RX). The 1-Wire bus is then pulled

to V

PUP

via the pullup resistor or, in case of a DS2480B driver, by active circuitry. When the V

TH

threshold is crossed, the DS2408 waits for t

PDH

and then transmits a Presence Pulse by pulling the line

low for t

PDL

. To detect a presence pulse, the master must test the logical state of the 1-Wire line at t

MSP

.

The t

RSTH

window must be at least the sum of t

PDHMAX

, t

PDLMAX

, and t

RECMIN

. Immediately after t

RSTH

is

expired, the DS2408 is ready for data communication. In a mixed population network, t

RSTH

should be

extended to a minimum of 480µs at standard speed and 48µs at overdrive speed to accommodate other 1-

Wire devices.

23 of 36

DS2408

Read/Write Time Slots

Data communication with the DS2408 takes place in time slots, which carry a single bit each. Write time

slots transport data from bus master to slave. Read time slots transfer data from slave to master. The

definitions of the write and read time slots are illustrated in Figure 14.

All communication begins with the master pulling the data line low. As the voltage on the 1-Wire line

falls below the threshold V

TL

, the DS2408 starts its internal time base. The tolerance of the slave time

base creates a slave-sampling window, which stretches from t

SLSMIN

to t

SLSMAX

. The voltage on the data

line at the sampling point determines whether the DS2408 decodes the time slot as 1 or 0.

Master-to-Slave

For a write-one time slot, the voltage on the data line must have crossed the V

THMAX

threshold after the

write-one low time t

W1LMAX

has expired. For a write-zero time slot, the voltage on the data line must stay

below the V

THMIN

threshold until the write-zero low time t

W0LMIN

has expired. For most reliable

communication, the voltage on the data line should not exceed V

ILMAX

during the entire t

W0L

window.

After the V

THMAX

threshold has been crossed, the DS2408 needs a recovery time t

REC

before it is ready for

the next time slot.

Figure 14. READ/WRITE TIMING DIAGRAM

Write-One Time Slot

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

DS2408

Sampling

Window

t

SLSMIN

t

F

t

SLOT

t

W1L

t

SLSMAX

e

Write-Zero Time Slot

t

REC

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

DS2408

Sampling

Window

t

SLSMIN

t

F

t

SLOT

t

SLSMAX

t

W0L

24 of 36

DS2408

Read-Data Time Slot

RESISTOR

MASTER

DS2408

t

REC

V

PUP

V

IHMASTER

V

TH

V

TL

V

ILMAX

0V

Master

Sampling

Window

t

SPDMIN

d

t

F

t

SLOT

t

RL

t

MSR

t

SPDMAX

Slave-to-Master

A read-data time slot begins like a write-one time slot. The voltage on the data line must remain below

V

TLMIN

until the read low time t

RL

has expired. During the t

RL

window, when responding with a 0, the

DS2408 starts pulling the data line low; its internal timing generator determines when this pulldown ends

and the voltage starts rising again. When responding with a 1, the DS2408 does not hold the data line low

at all, and the voltage starts rising as soon as t

RL

is over.

The sum of t

RL

+

d (rise time) on one side and the internal timing generator of the DS2408 on the other

side define the master sampling window (t

MSRMIN

to t

MSRMAX

) in which the master must perform a read

from the data line. For most reliable communication, t

RL

should be as short as permissible and the master

should read close to but no later than t

MSRMAX

. After reading from the data line, the master must wait until

t

SLOT

is expired. This guarantees sufficient recovery time t

REC

for the DS2408 to get ready for the next

time slot.

Improved Network Behavior

In a 1-Wire environment, line termination is possible only during transients controlled by the bus master

(1-Wire driver). 1-Wire networks therefore are susceptible to noise of various origins. Depending on the

physical size and topology of the network, reflections from end points and branch points can add up or

cancel each other to some extent. Such reflections are visible as glitches or ringing on the 1-Wire

communication line. Noise coupled onto the 1-Wire line from external sources can also result in signal

glitching. A glitch during the rising edge of a time slot can cause a slave device to lose synchronization

with the master and, as a consequence, result in a Search ROM command coming to a dead end or cause a

device level command to abort. For better performance in network applications, the DS2408 uses a new

1-Wire front end, which makes it less sensitive to noise and also reduces the magnitude of noise injected

by the slave device itself.

The 1-Wire front end of the DS2408 differs from traditional slave devices in four characteristics.

1) The falling edge of the presence pulse has a controlled slew rate. This provides a better match to the

line impedance than a digitally switched transistor, converting the high-frequency ringing known

from traditional devices into a smoother low-bandwidth transition. The slew rate control is specified

by the parameter t

FPD

, which has different values for standard and overdrive speed.

2) There is additional lowpass filtering in the circuit that detects the falling edge at the beginning of a

time slot. This reduces the sensitivity to high-frequency noise. This additional filtering does not apply

at overdrive speed.

25 of 36

DS2408

3) The input buffer was designed with hysteresis. If a negative glitch crosses V

TH

but doesn't go below

V

TH

- V

HY

, it will not be recognized (Figure 15, Case A). The hysteresis is effective at any 1-Wire

speed.

4) There is a time window specified by the rising edge hold-off time t

REH

during which glitches will be

ignored, even if they extend below the V

TH

- V

HY

threshold (Figure 15, Case B, t

GL

< t

REH

). Deep

voltage droops or glitches that appear late after crossing the V

TH

threshold and extend beyond the t

REH

window cannot be filtered out and will be taken as the beginning of a new time slot (Figure 15, Case

C, t

GL

≥ t

REH

).

Figure 15. NOISE SUPPRESSION SCHEME

V

PUP

V

TH

V

HY

0V

t

REH

t

GL

t

REH

t

GL

Case A

Case C

Case B

CRC GENERATION

The DS2408 has two different types of cyclic redundancy checks (CRCs). One CRC is an 8-bit type and

is stored in the most significant byte of the 64-bit ROM. The bus master can compute a CRC value from

the first 56 bits of the 64-bit ROM and compare it to the value stored within the DS2408 to determine if

the ROM data has been received error free. The equivalent polynomial function of this CRC is X

8

+ X

5

+

X

4

+ 1. This 8-bit CRC is received in the true (noninverted) form. It is computed at the factory and lasered

into the ROM.

The other CRC is a 16-bit type, generated according to the standardized CRC16-polynomial function X

16

+ X

15

+ X

2

+ 1. This CRC is used for error detection when reading data through the end of the register

page using the Read PIO Registers command, for fast verification of the data transfer when writing to or

reading from the scratchpad, and when reading from the PIO using the Channel-access Read command.

In contrast to the 8-bit CRC, the 16-bit CRC is always communicated in the inverted form. A CRC-

generator inside the DS2408 chip (Figure 16) calculates a new 16-bit CRC as shown in the command

flow chart of Figure 8. The bus master compares the CRC value read from the device to the one it

calculates from the data and decides whether to continue with an operation or to reread the portion of the

data with the CRC error.

With the Read PIO Registers flow chart, the 16-bit CRC value is the result of shifting the command byte

into the cleared CRC generator, followed by the 2 address bytes and the data bytes beginning at the target

address and ending with the last byte of the register page, address 008Fh.

With the initial pass through the Channel-access Read command flow, the CRC is generated by first

clearing the CRC generator and then shifting in the command code followed by 32 bytes of PIO pin data.

Subsequent passes through the command flow will generate a 16-bit CRC that is the result of clearing the

CRC generator and then shifting in 32 bytes read from the PIO pins. For more information on generating

CRC values see Application Note 27.

26 of 36

DS2408

Figure 16. CRC-16 HARDWARE DESCRIPTION AND POLYNOMIAL

POLYNOMIAL = X

16

+ X

15

+ X

2

+ 1

X

0

X

1

X

2

X

3

X

4

X

5

X

6

X

7

X

8

X

9

X

10

X

11

X

12

X

13

X

14

X

15

X

16

1

st

STAGE

2

nd

STAGE

3

rd

STAGE

4

th

STAGE

6

th

STAGE

5

th

STAGE

7

th

STAGE

8

th

STAGE

9

th

STAGE

10

th

STAGE

11

th

STAGE

12

th

STAGE

13

th

STAGE

14

th

STAGE

15

th

STAGE

16

th

STAGE

INPUT DATA

CRC

OUTPUT

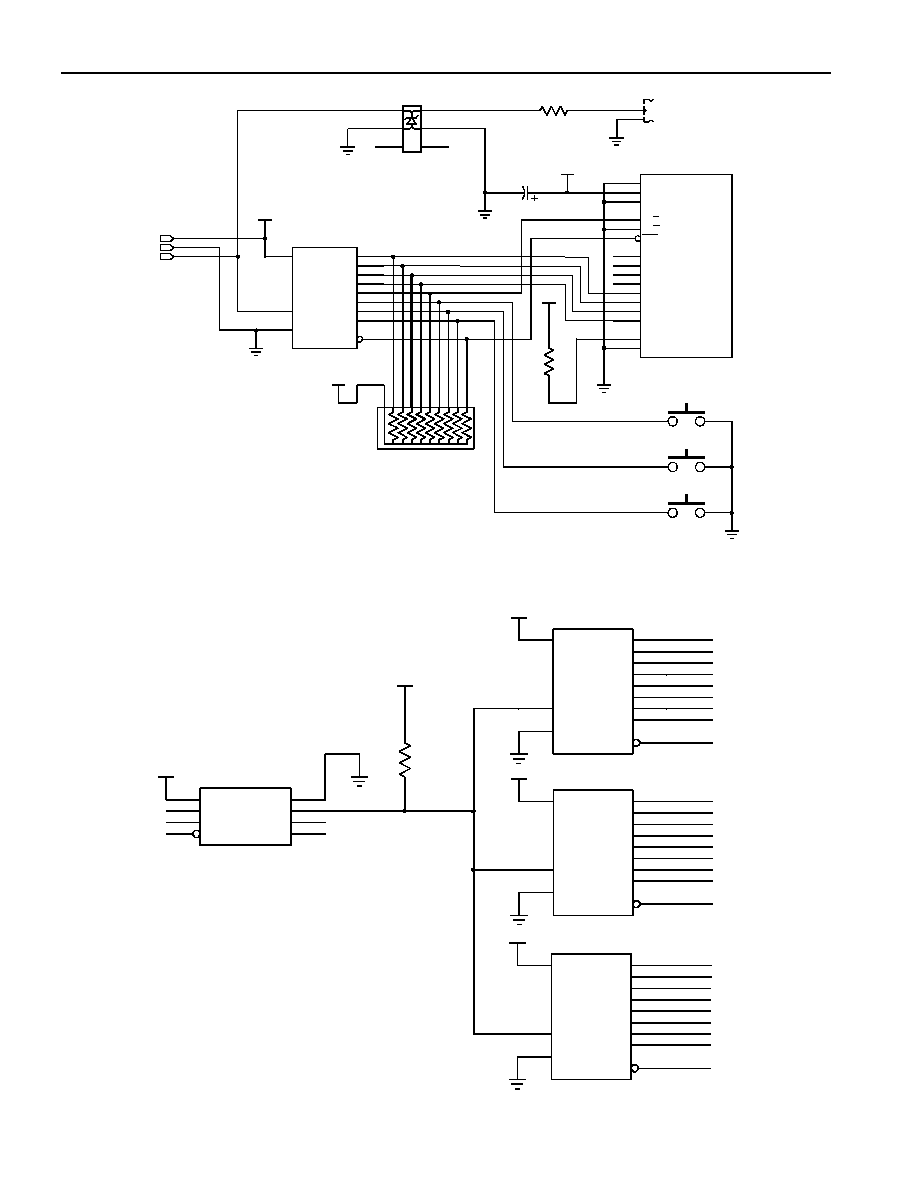

Figure 17. DS2408 AS SLAVE INTERFACE FOR MICROCONTROLLER

VCC

DS80C520

P1.0

3

P1.1

4

P1.2

5

P1.3

6

P1.4

7

P1.5

8

P1.6

9

P1.7

10

RST

12

P3 .7 / RD

22

P3 .6 / WR

21

P3.5/T1

20

P3.4/T0

19

P3 .3 / INT1

18

P3 .2 / INT0

17

P3.1/TXD0

16

P3.0/RXD0

15

EA

42

XTAL2

23

XTAL1

24

RTCX2

27

RTCX1

28

P2.6/AD14

36

P2.5/AD13

35

P2.4/AD12

34

P2.3/AD11

33

P2.2/AD10

32

P2.7/AD15

37

P2.1/AD9

31

P2.0/AD8

30

PSEN

38

ALE

39

P0.7/AD7

43

P0.6/AD6

44

P0.5/AD5

45

P0.4/AD4

46

P0.3/AD3

47

P0.2/AD2

48

P0.1/AD1

49

P0.0/AD0

50

47U

DS2408

P0

2

P1

14

P2

13

P3

12

P4

11

P5

9

P6

8

P7

7

10

GND

5

VCC

3

IO

4

PULLUP PROVIDED BY CPU

8051 Equiv CPU

GND

VCC

1W

RSTZ

The data direction (upload/download) is determined by application-specific data protocol.

27 of 36

DS2408

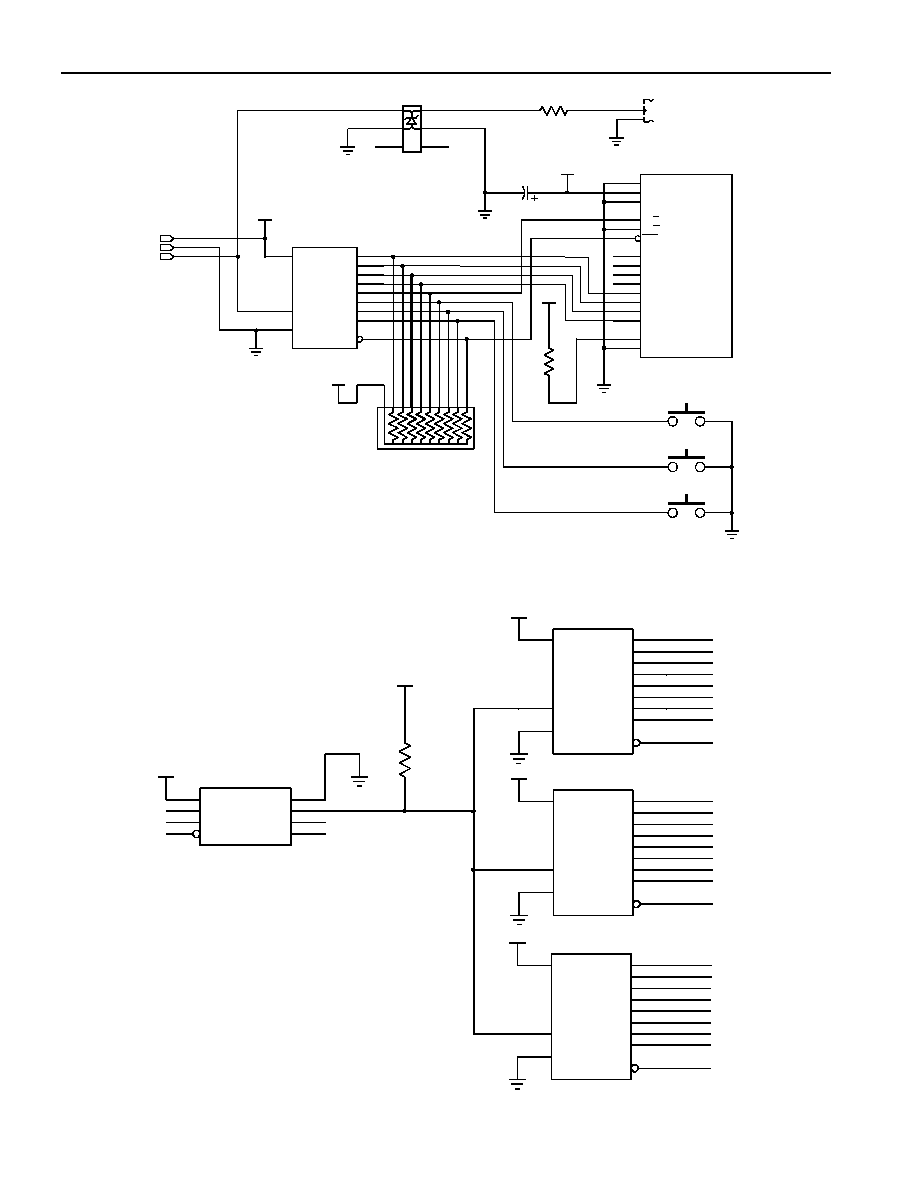

Figure 18. DS2408 AS SLAVE INTERFACE FOR INTELLIGENT DISPLAY

47

DS9503

1

2

5

6

3

4

47U

VCC

LEDK

16

LEDA

15

D7

14

D6

13

D5

12

D4

11

D3

10

D2

9

D1

8

D0

7

STB

6

R/ W

5

D/ C

4

CONTRAST

3

VCC

2

GND

1

VCC

10K

10

9

8

7

6

5

4

3

2

1

VCC

DS2408

P0

2

P1

14

P2

13

P3

12

P4

11

P5

9

P6

8

P7

7

10

GND

5

VCC

3

IO

4

Local iButton Probe

LCD Display

Up

Down

Select

5VDC

GND

1W

RSTZ

A

C

M160

1B

1

6

X

1

D

i

s

p

l

a

y

w

i

t

h

B

a

ck

L

i

g

h

t

VCC

Figure 19. DS2408 AS MICROCONTROLLER PORT EXPANDER

DS2408

IO

4

VCC

3

GND

5

10

P7

7

P6

8

P5

9

P4

11

P3

12

P2

13

P1

14

P0

2

VC

C

2.

2

K

VCC

PIC12C508

OSC2/P4

3

OSC1/P5

2

P0

7

P1

6

P2/CK

5

CLR/P3

4

GND

8

VCC

1

VCC

MICROCONTROLLER

WITH FEW I/O PINS

RSTZ

24 I/O LINES OR

3 BYTE-WIDE

BUSES FROM A

SINGLE PIN

IO

4

VCC

3

GND

5

10

P7

7

P6

8

P5

9

P4

11

P3

12

P2

13

P1

14

P0

2

VCC

RSTZ

DS2408

IO

4

VCC

3

GND

5

10

P7

7

P6

8

P5

9

P4

11

P3

12

P2

13

P1

14

P0

2

VCC

RSTZ

DS2408

28 of 36

DS2408

Figure 20. DS2408 AS µC-OPERATED KEYBOARD SCANNER

VCC

10k

W

10

9

8

7

6

5

4

3

2

1

10U

DS2408

P0

2

P1

14

P2

13

P3

12

P4

11

P5

9

P6

8

P7

7

10

GND

5

VCC

3

IO

4

POR Circuit

To More Switch Rows

(Up to 4 x 4, 3 x 5 or 2 x 6)

GND

VCC

RST

GND

DS1811

VCC

VCC

1W

RSTZ

The DS1811 has

an internal pull-up

resistor of 5.5 k

W

Figure 21. DS2408 AS PARASITE-POWERED PUSH-BUTTON SENSOR

BAT54

0.1U

100k

1 2 3 4 5 6 7 8 9 10

DS2408

P0

2

P1

14

P2

13

P3

12

P4

11

P5

9

P6

8

P7

7

10

GND

5

VCC

3

IO

4

SWITCHES OR PUSH-BUTTONS

Parasite

Power

VCC

1W

GND

RSTZ

29 of 36

DS2408

Figure 22. DS2408 AS MULTIPURPOSE SENSOR/ACTUATOR

10k

W

10

9

8

7

6

5

4

3

2

1

VCC

BSS-84

5V

1N4004

47U

VCC

OPTOISO

1

2

4

5

6

1k

W

470

W

VCC

LED

DS2408

P0

2

P1

14

P2

13

P3

12

P4

11

P5

9

P6

8

P7

7

10

GND

5

VCC

3

IO

4

4mA

8mA

1W

VCC

GND

RSTZ

SWITCHES

OR PUSH-

BUTTONS

ISOLATED

OUTPUT

DRY

CONTACT

LED INDI-

CATOR

VCC

30 of 36

DS2408

Command-Specific 1-Wire Communication Protocol--Legend

SYMBOL DESCRIPTION

RST

1-Wire Reset Pulse generated by master.

PD

1-Wire Presence Pulse generated by slave.

Select

Command and data to satisfy the ROM function protocol.

RPR

Command "Read PIO Registers".

CAR Command

"Channel-Access

Read".

CAW Command

"Channel-Access

Write".

WCS

Command "Write Conditional Search Register".

RAL

Command "Reset Activity Latches".

TA

Target Address TA1, TA2.

<data>

Transfer of an undetermined amount of data.

CRC16\

Transfer of an inverted CRC16.

FF loop

Indefinite loop where the master reads FF bytes.

AA loop

Indefinite loop where the master reads AA bytes.

<32 samples>,

CRC16\ loop

Indefinite loop where the master reads 32 PIO samples followed by an inverted CRC16.

<new state>, <new

state\>

Transfer of 2 bytes, where the second byte is the bit-inverse of the first byte. The first

byte will be taken as the new PIO state.

AAh, <read back>

Transfer of 2 bytes, where the first byte is a constant (AAh) and the second byte is the

current PIO state.

<new state>,

<invalid>

Transfer of 2 bytes, where the second byte is NOT the bit-inverse of the first byte.

Command-Specific 1-Wire Communication Protocol--Color Codes

Master to slave

Slave to master

Read PIO Registers (Success)

RST

PD

Select

RPR TA

<data>

CRC16\ FF loop

Read PIO Registers (Fail Address)

RST

PD

Select

RPR TA

FF loop

Channel-Access Read (Cannot Fail)

RST

PD

Select

CAR <32 samples>, CRC16\ loop

31 of 36

DS2408

Channel-Access Write (Success)

RST

PD

Select

CAW <new state>, <new state\>

AAh, <read back>

Channel-Access Write (Fail New State)

Loop

RST

PD

Select

CAW <new state>, <invalid>

FF loop

Write Conditional Search Register (Success)

RST

PD

Select

WCS TA

<data>

FF loop

Write Conditional Search Register (Fail Address)

RST

PD

Select

WCS TA

FF loop

Reset Activity Latches (Cannot Fail)

RST

PD

Select

RAL

AA loop

COMMUNICATION EXAMPLES

The examples in this section demonstrate the use of ROM and control functions in typical situations. The

first two examples are related to Figure 17. They show how to write to the PIO with readback for

verification or for receiving an immediate response (example 1) and how to read from the PIO in an