| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: MTE1122IP | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

1995 Microchip Technology Inc.

Preliminary

DS21112B-page 1

FEATURES

∑ Energy Management Controller

∑ Based on 8-bit RISC Technology

∑ Proprietary Power Management Algorithm

∑ Reduces the power consumption of induction

motor systems

∑ 5V Operation

∑ 18-pin PDIP and SOIC Packages

∑ 8-bit Analog-to-Digital (A/D) Converter

∑ Automatic Power-on Reset

∑ Power-up Timer

∑ Commercial and Industrial Temperature Range

Operation

∑ Multiple parts can be slaved for three-phase oper-

ation

INTRODUCTION

The MTE1122 is an Energy Management Controller IC

for single-phase induction motors. This CMOS device

is based on Microchip Technology Inc's RISC proces-

sor core and proprietary algorithms. When combined

with some external analog components, it will provide

an electronic system that economically reduces the

operating costs of small induction motors by as much

as 58%. It will also allow motors to run cooler and with

less vibration. The system operates on single phase

110 or 220 VAC.

PACKAGE TYPE

FIGURE 1: SYSTEM BLOCK DIAGRAM

V

SS

1

P-Sense

V

SS

RESET

V

SS

ZC-Sense

TTRIG

NC

NC

∑

1

2

3

4

5

6

7

8

9

V

SS

Gate Input

OSC1

OSC2

V

DD

IND

NC

NC

NC

18

17

16

15

14

13

12

11

10

M

T

E1

122

18-Lead PDIP/SOIC

MTE1122

LINE IN

LINE OUT

TO MOTOR

TRIAC

VOLTAGE

ZERO-CROSS

VOLTAGE AMP

CURRENT

ZERO-CROSS

V

CC

POWER

NEUTRAL IN

NEUTRAL OUT

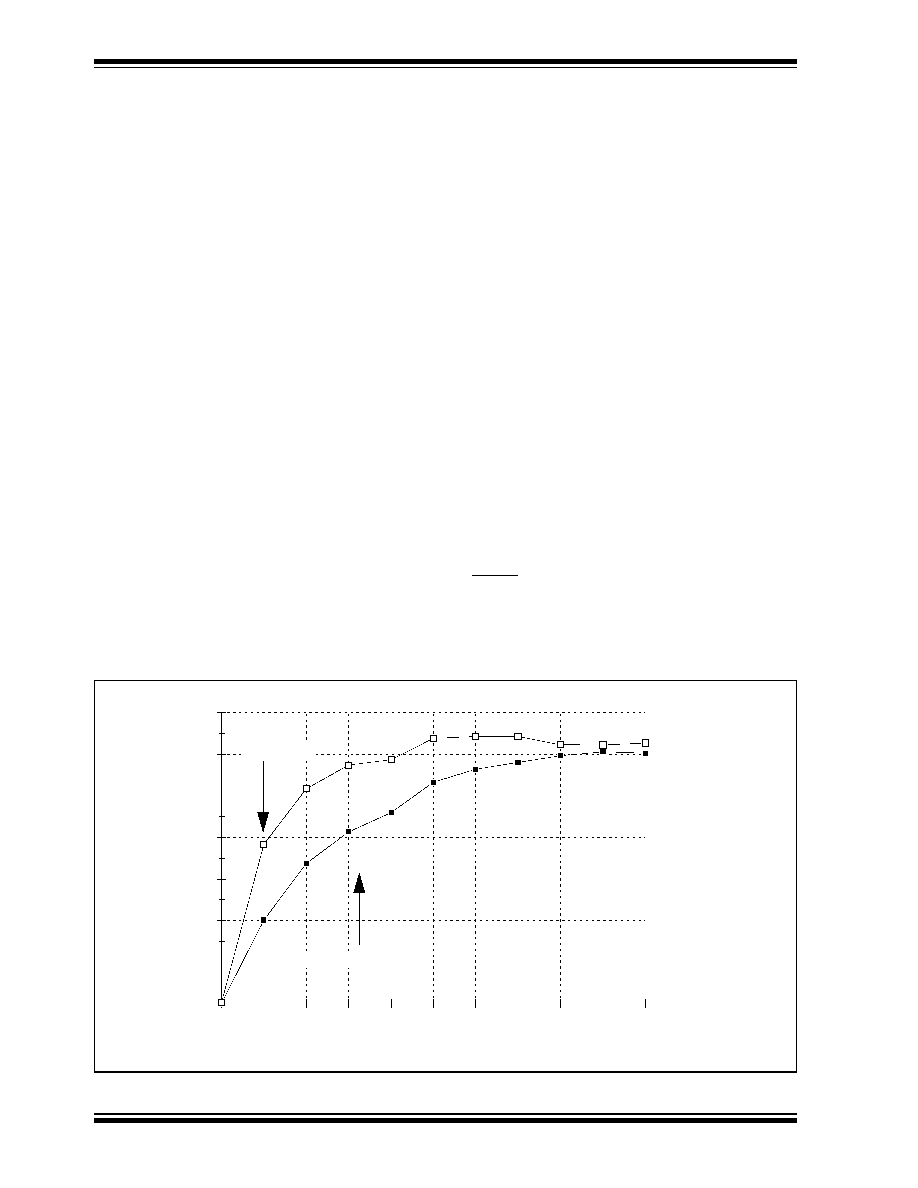

FIGURE 2: ENERGY SAVINGS

0 . 0

10.0

20.0

30.0

40.0

50.0

60.0

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

8 0

9 0

1 0 0

P

e

r

c

ent Sa

vin

g

s

Percent Load

MTE1122

Energy Management Controller IC

MTE1122

DS21112B-page 2

Preliminary

©

1995 Microchip Technology Inc.

FUNCTIONAL DESCRIPTION

Single-phase induction motors run most efficiently at

full load. As the applied load lessens, a greater portion

of the energy consumed by the motor is wasted, mostly

as heat.

It is estimated by the EPA that 50% of the energy pro-

duced in the US is consumed by small electric motors,

and that 20% of this energy does no useful work. There

are perhaps three major reasons for this:

1.

Over-specification -- sometimes its easier or

costs no more to specify a larger motor than

determine actual loads.

2.

Worst case design -- pumps, conveyers, fans,

and the like must be able to operate properly

with clogged filters, maximum heads, or speci-

fied loads. If filters are clean, or loads are lower,

the motor will be running only partly loaded.

3.

Idle time -- many times, systems can't be shut

down conveniently when not in use.

Number 1 above can be corrected by proper design.

For example, in modern refrigerators, the compressor

systems have been optimized quite effectively. Num-

bers 2 and 3 can not be improved using traditional

approaches. This is where the MTE1122 provides a

new, cost-effective solution.

The MTE1122 calculates the amount of load on a motor

connected to it, and adjusts the motor's supply voltage

to match that load. For example, if the load is lower

than the motor's rated load, the voltage to the motor

can be reduced, thus decreasing the energy used by

the motor.

A 1/3 HP motor will typically see 85 VAC at no load

when powered through the MTE1122, for an energy

savings of as much as 58%.

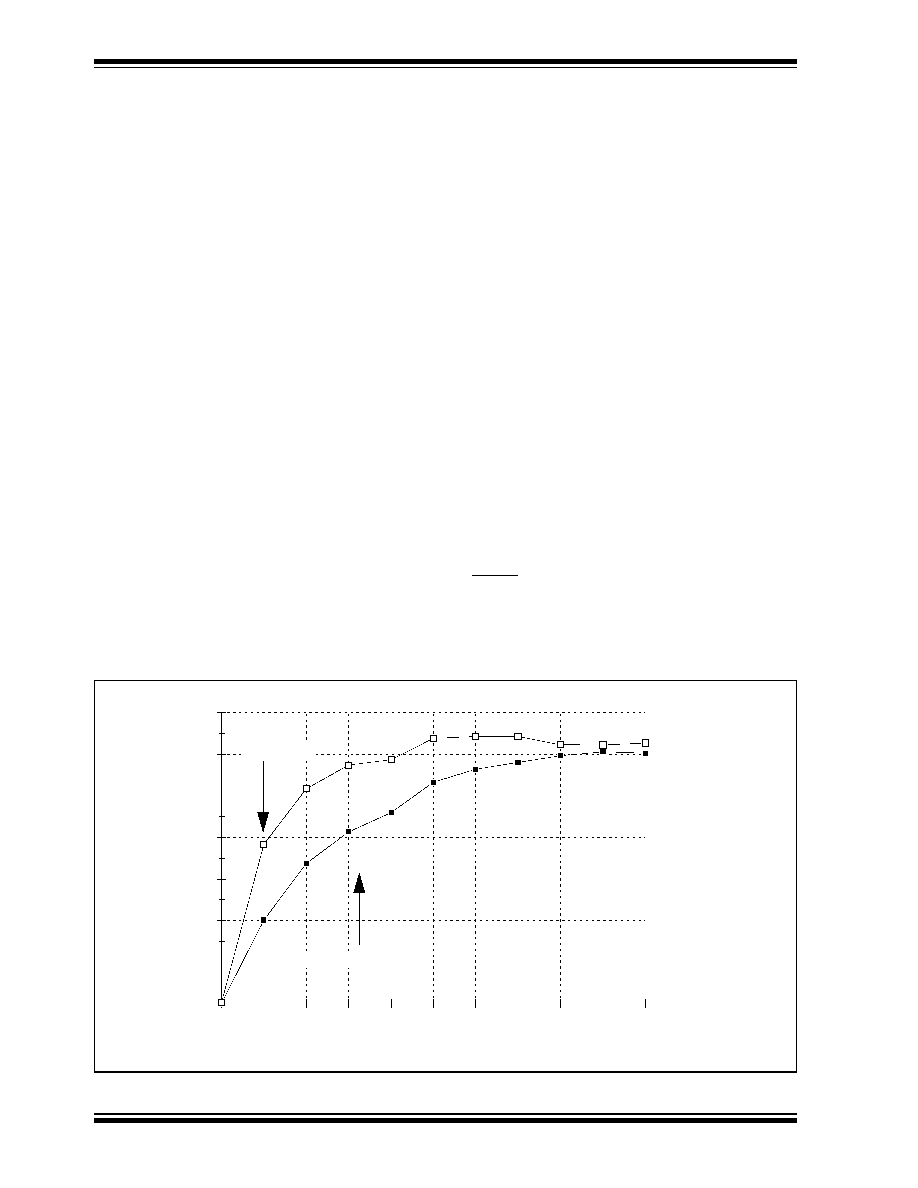

A system block diagram is shown in Figure 1. A graph

of energy savings vs. motor load is shown in Figure 2.

A graph of motor efficiency with and without an

MTE1122-based energy management controller (EMC)

is shown in Figure 3. The data for the graphs are

shown in Table 1. These figures are based on a 1/3 HP

induction motor coupled to a dynamometer. Actual

savings may vary based on motor size, motor load and

motor construction.

PINOUT DESCRIPTIONS

P-Sense - analog input that is used by the device to

measure the load voltage.

Gate Enable - analog input that monitors the voltage

across the triac. It is used as a current feedback mech-

anism.

IND - TTL-compatible output that indicates that the sys-

tem is operating normally. It is intended to control an

LED or another indicator device.

ZC-Sense - TTL-compatible input that is used to deter-

mine the zero crossing point of the AC voltage wave-

form.

TTRIG - TTL-compatible output that is used to drive the

triac.

RESET - TTL-compatible input used to reset the device

by holding this pin low.

OSC1, OSC2 - Oscillator crystal or resonator connec-

tions.

FIGURE 3: MOTOR EFFICIENCY

0 . 0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

8 0

9 0

1 0 0

E

f

fic

i

ency

Percent Load

With E.M.C.

Without E.M.C.

©

1995 Microchip Technology Inc.

Preliminary

DS21112B-page 3

MTE1122

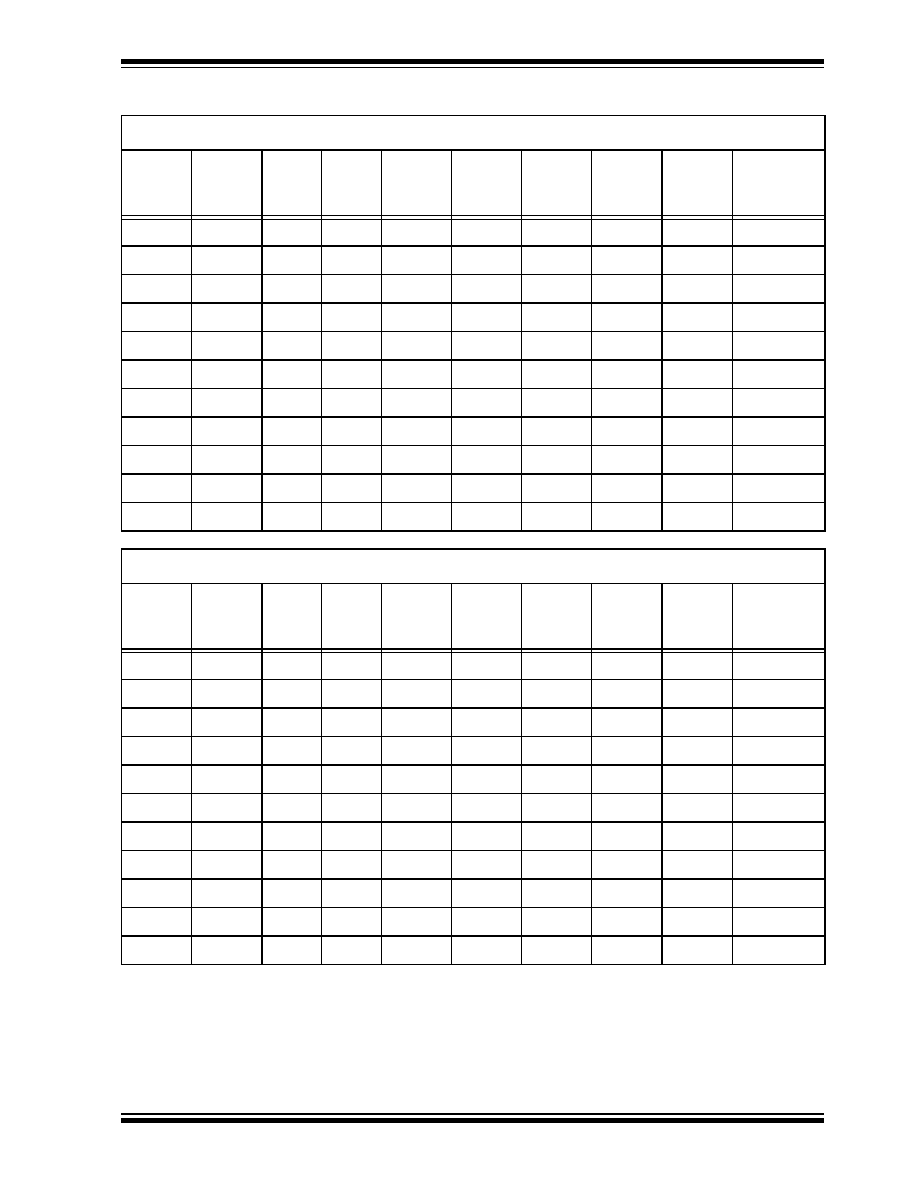

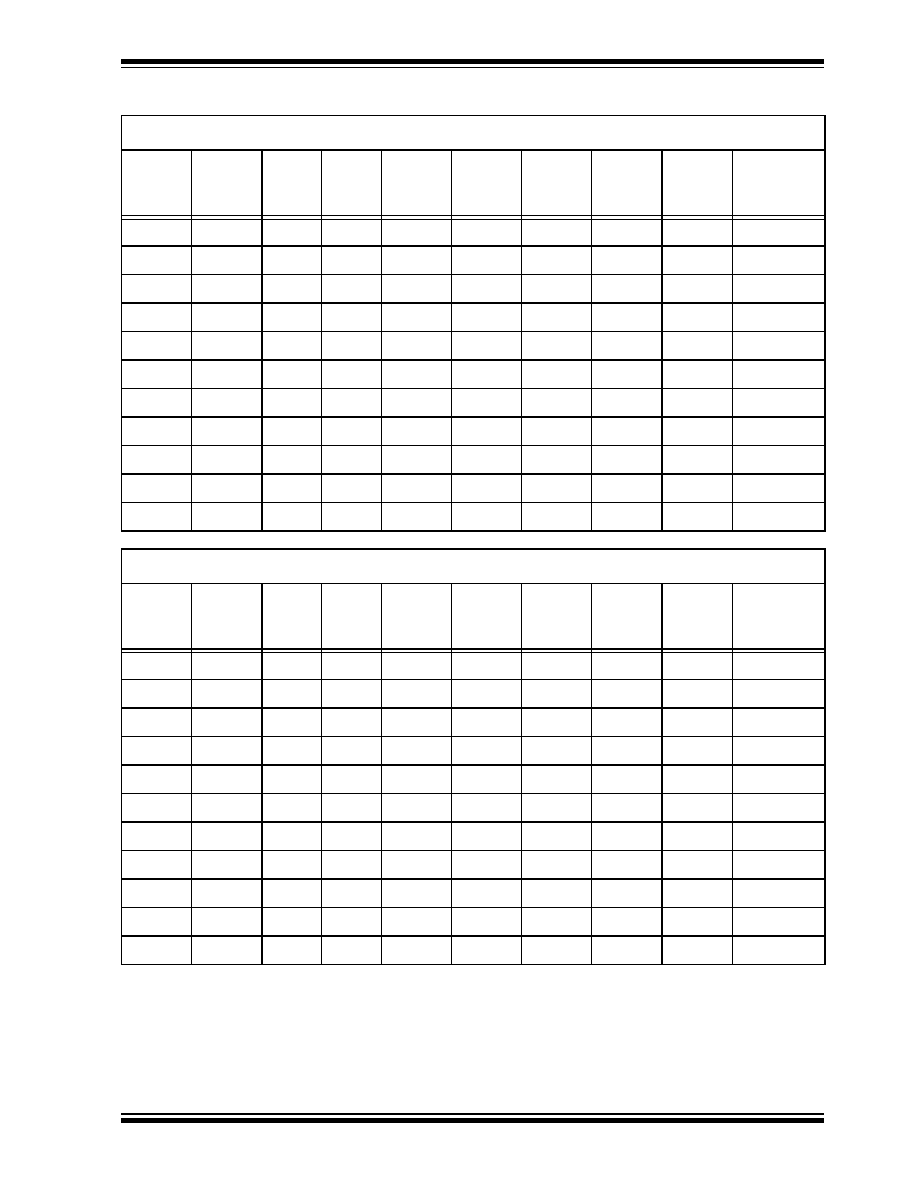

TABLE 1:

OPERATING PARAMTER COMPARISONS

1/3 HP Motor without E.M.C.

Load

(%)

Load

(Nm)

Vrms

Irms

(A)

Power

Factor

Power

In (W)

RPM

Power

Out (W)

Power

Out

(HP)

Efficiency

(%)

0

0.00

115

5.7

0.18

120

1791

0

0.00

0.2

10

0.14

115

5.7

0.20

130

1788

26

0.04

20.1

20

0.29

115

5.7

0.24

160

1781

54

0.07

33.7

30

0.43

115

5.7

0.29

193

1777

80

0.11

41.4

40

0.57

115

5.7

0.35

229

1768

105

0.14

46.0

50

0.72

115

5.8

0.37

249

1764

133

0.18

53.3

60

0.86

115

5.8

0.42

280

1758

158

0.21

56.4

70

1.00

115

6.0

0.46

315

1750

183

0.25

58.0

80

1.14

116

6.1

0.49

348

1744

208

0.28

59.7

90

1.29

115

6.3

0.53

386

1736

234

0.31

60.6

100

1.43

116

6.5

0.57

428

1727

258

0.35

60.3

1/3 HP Motor with E.M.C.

Load

(%)

Load

(Nm)

Vrms

Irms

(A)

Power

Factor

Power

In (W)

RPM

Power

Out (W)

Power

Out

(HP)

Efficiency

(%)

0

0.00

113

3.1

0.14

50

1794

0

0.00

0.4

10

0.14

113

3.2

0.19

68

1786

26

0.04

38.4

20

0.29

113

3.5

0.26

104

1775

54

0.07

51.7

30

0.43

113

3.8

0.32

138

1764

79

0.11

57.4

40

0.57

113

4.1

0.38

178

1755

104

0.14

58.7

50

0.72

113

4.3

0.42

206

1749

132

0.18

63.8

60

0.86

112

4.6

0.47

243

1740

156

0.21

64.3

70

1.00

112

4.9

0.51

281

1730

181

0.24

64.3

80

1.14

112

5.3

0.55

329

1722

205

0.27

62.3

90

1.29

112

5.6

0.59

371

1713

231

0.31

62.2

100

1.43

111

6.0

0.61

406

1705

255

0.34

62.7

MTE1122

DS21112B-page 4

Preliminary

©

1995 Microchip Technology Inc.

ELECTRICAL CHARACTERISTICS

Absolute Maximum Rating

Ambient temperature under bias .................................................................................................................-55 to +125∞C

Storage Temperature.............................................................................................................................. -65∞C to +150∞C

Voltage on any pin with respect to V

SS

(except V

DD

and RESET).................................................... -0.6V to V

DD

+0.6V

Voltage on V

DD

with respect to V

SS

..................................................................................................................0 to +7.5V

Voltage on RESET with respect to V

SS

(Note 1) ................................................................................................0 to +14V

Total power Dissipation (Note 2) ...........................................................................................................................800mW

Max. Current out of V

SS

pin ...................................................................................................................................150mA

Max. Current into V

DD

pin ......................................................................................................................................100mA

Input Clamping Current, IIK (VI<0 or VI>V

DD

)

.................................................................................................................. ±

20mA

Output Clamping Current, IOK (V0<0 or V0>V

DD

)

.......................................................................................................... ±

20mA

Max. Output Current sunk by any I/O pin .................................................................................................................25mA

Max. Output Current sourced by any I/O pin............................................................................................................20mA

Note 1: Voltage spikes below V

SS

at the RESET pin, inducing currents greater than 80mA, may cause latch-up.

Thus, a series resistor of 50-100

should be used when applying a "low' level to the RESET pin rather than

pulling this pin directly to V

SS

.

Note 2: Total power dissipation should not exceed 800 mW for the package. Power dissipation is calculated as fol-

lows:

P

DIS

= V

DD

x {I

DD

-

I

OH

} +

{(V

DD

-V

OH

) x I

OH

} +

(V

OL

x I

OL

)

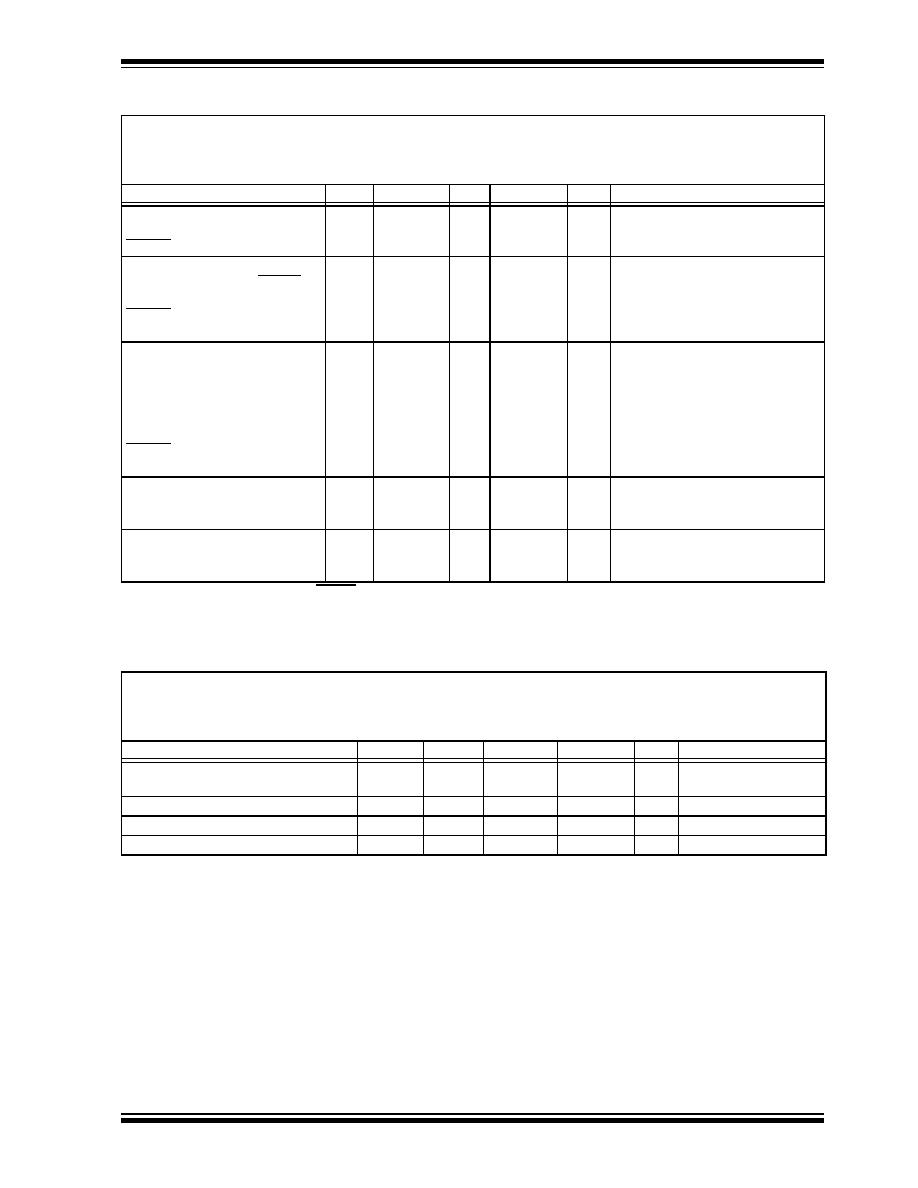

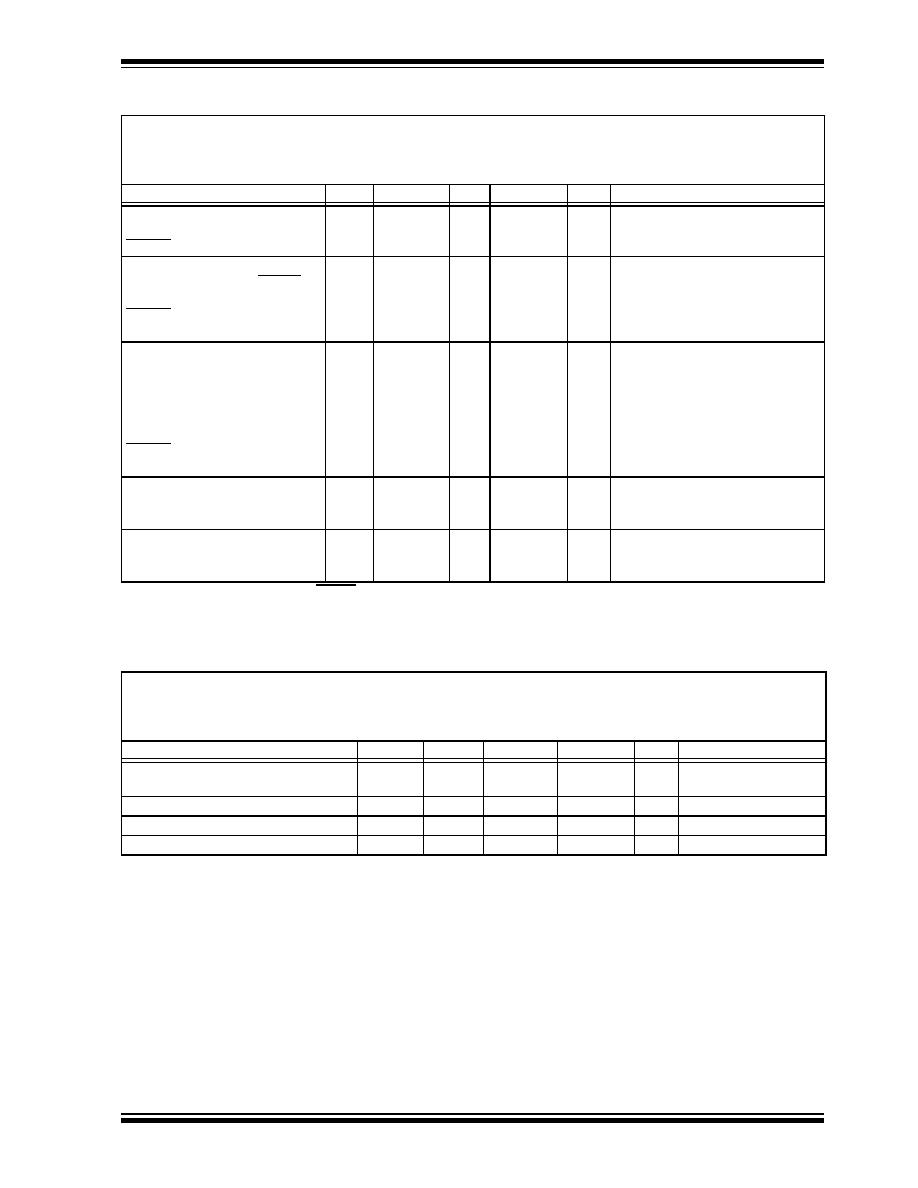

TABLE 2:

DC CHARACTERISTICS POWER SUPPLY PINS

NOTICE: Stresses above those listed under "Maximum Ratings" may cause permanent damage to the device. This

is a stress rating only and functional operation of the device or compliance to AC and DC parametric specifications at

those or any other conditions above those indicated in the operation listings of this specification is not implied. Expo-

sure to maximum rating conditions for extended periods may affect device reliability.

Power Supply Pins

Standard Operating Conditions (unless otherwise stated)

Operating temperature

-40∞C

T

A

+ 85∞C for industrial,

0∞C

T

A

+70∞C for commercial

Operating voltage V

DD

= 4.0V to 6.0V

Characteristic

Sym

Min

Typ

(Note 1)

Max Units

Conditions

Supply Voltage

V

DD

4.0

6.0

V

V

DD

start voltage to guarantee

power on reset

V

POR

Vss

V

V

DD

rise rate to guarantee

Power-On Reset (Note 2)

S

VDD

0.05

V/ms

Supply Current (Note 3)

I

DD

1.8

3.3

mA

F

OSC

= 4 MHz, V

DD

= 5.5V

Note 1: Data in the column labeled "Typical" is based on characterization results at 25

∞

C. This data is for design guidance only and

is not tested for, or guaranteed by Microchip Technology.

2: This parameter is characterized but not tested.

3: The supply current is mainly a function of the operating voltage and frequency. Other factors such as I/O pin loading and

switching rate, oscillator type, internal code execution pattern, and temperature also have an impact on the current con-

sumption.

©

1995 Microchip Technology Inc.

Preliminary

DS21112B-page 5

MTE1122

TABLE 3:

DC CHARACTERISTICS: ALL PINS EXCEPT POWER SUPPLY

TABLE 4:

AC CHARACTERISTICS

All Pins Except Power

Standard Operating Conditions (unless otherwise stated)

Operating temperature

-40∞C

T

A

+ 85∞C for industrial,

0∞C

T

A

+70∞C for commercial

Operating voltage V

DD

= 4.0V to 6.0V

Characteristic

Sym

Min

Typ

Max

Units

Conditions

Input Low Voltage:

All Input Pins (Except OSC1)

RESET OSC1

V

IL

V

IH

V

SS

V

SS

0.2 V

DD

0.3 V

DD

V

V

Input High Voltage:

All Input Pins (Except RESET,

OSC1)

RESET

OSC1

V

IH

V

IH

V

IH

0.36 V

DD

0.85 V

DD

0.7 V

DD

V

DD

V

DD

V

DD

V

V

V

4.5V

V

DD

5.5V

Input Leakage Current:

(Notes 1,2)

IND, TTRIG, AC-Sense

P-Sense, Gate Input

RESET

OSC1

I

IL

±1

±1

±1

±1

µ

A

µ

A

µ

A

µ

A

V

SS

V

PIN

V

DD

,

Pin at hi-impedance

V

SS

V

PIN

V

DD

,

Pin at hi-impedance

V

SS

V

PIN

V

DD

V

SS

V

PIN

V

DD

Output Low Voltage:

All Output Pins

V

OL

0.6

V

I

OL

= 8.5mA, V

DD

= 4.5V,

-40

∞

C to +85

∞

C

Output High Voltage:

All Output Pins (Note 2)

V

OH

0.7 V

DD

V

I

OH

83.mA, V

DD

= 4.5V,

-40

∞

C to +85

∞

C

Note 1: The leakage current on the RESET pin is strongly dependent on the applied voltage level. The specified levels represent

normal operating conditions. Higher leakage current may be measured at different input voltages.

2: Negative current is defined as current coming out of the pin.

AC Characteristics

Standard Operating Conditions (unless otherwise stated)

Operating temperature

-40∞C

T

A

+ 85∞C for industrial,

0∞C

T

A

+70∞C for commercial

Operating voltage V

DD

= 4.0V to 6.0V

Characteristic

Sym

Min

Typ

Max

Units

Conditions

Oscillator Frequency

F

OSC

4

4

MHz

Clock in (OSC1) High or Low Time

T

CKHLXT

50

ns

Note

1

Clock in (OSC1) Rise or Fall Time

TCKRFXT

25

ns

Note 1

RESET Pulse Width (low)

T

MCL

200

ns

Note 1