APPLICATION MANUAL

R82E2.pdf 97.09.29

This is the PDF file of catalog No.R82E-2.

R82E2.pdf 97.09.29

This is the PDF file of catalog No.R82E-2.

Contents

1. Features of Murata Chip Trimmer Potentiometers

2. Specifications

1. Precautions in Storage

1. Considerations in Design

2. Standard Land Patterns

1. One Side Chip Mounting

2. Both Side Chip Mounting

3. Mixed Mounting of Chip Components

and Leaded Components

1. Solder Paste Stenciling

2. Mounting the Product

3. Compatibility with Chip Placers

4. Sensor Level Adjustment

5. Reflow Soldering

6. Adhesive Application and Curing

Types and Characteristics of Adhesive

7. Flux Coating

Types and Characteristics of Flux

8. Wave Soldering

9. Soldering and Resoldering with a Soldering Iron

10. Cleaning

1. Adjustments

2. Automatic Adjustments

3. Lock Painting

Ex.1. Poor Contact Caused by Flux Adhesion

Ex.2. Cracking of the Substrate

Ex.3. Poor Contact Caused by a Deformed Driver Plate

R82E2.pdf 97.09.29

This is the PDF file of catalog No.R82E-2.

POZ3 Series

1. Features of Murata Chip Trimmer Potentiometers

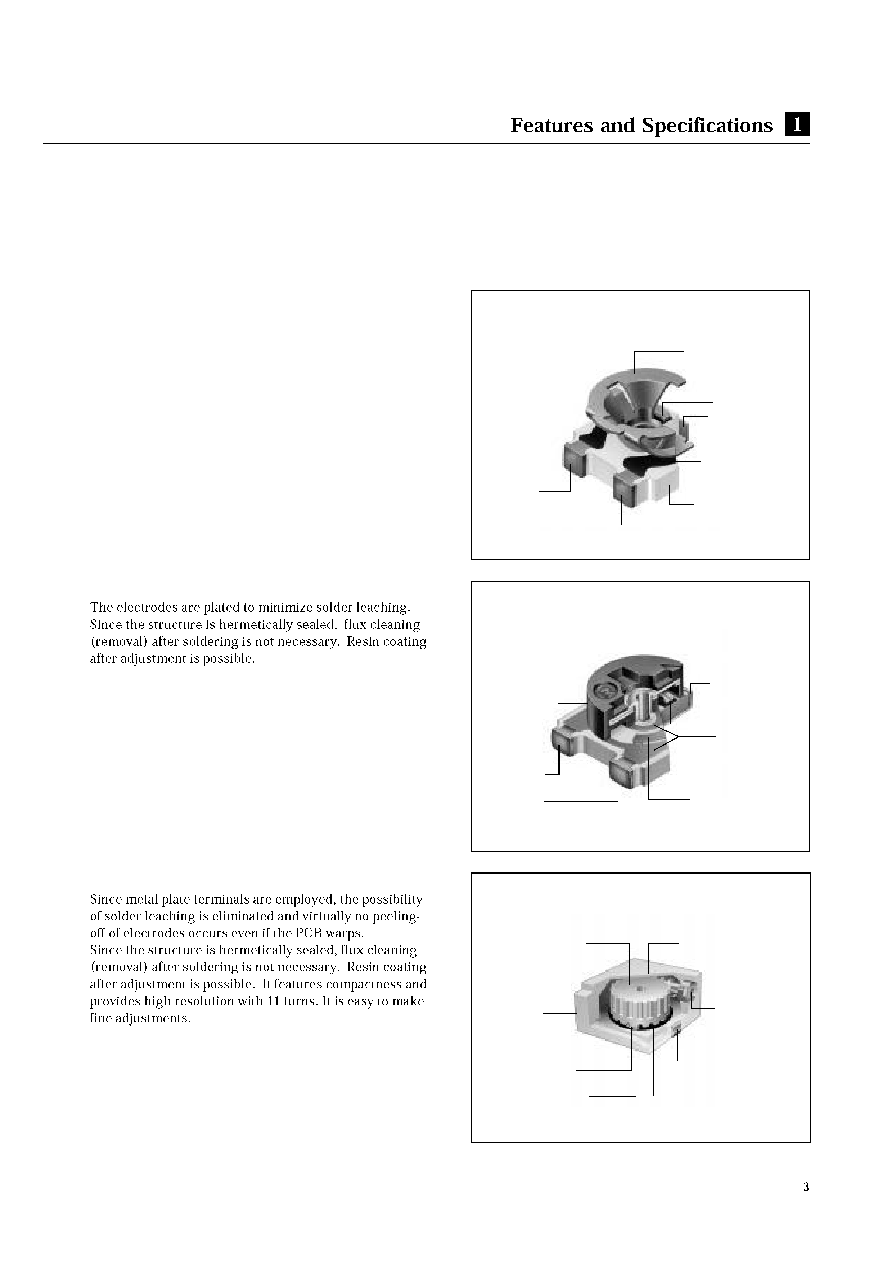

RVG3S08 (for reflow soldering)

Driver plate

Wiper

Resistive element

(carbon)

Resin substrate

Terminal (3)

Terminal (1)

Terminal (2)

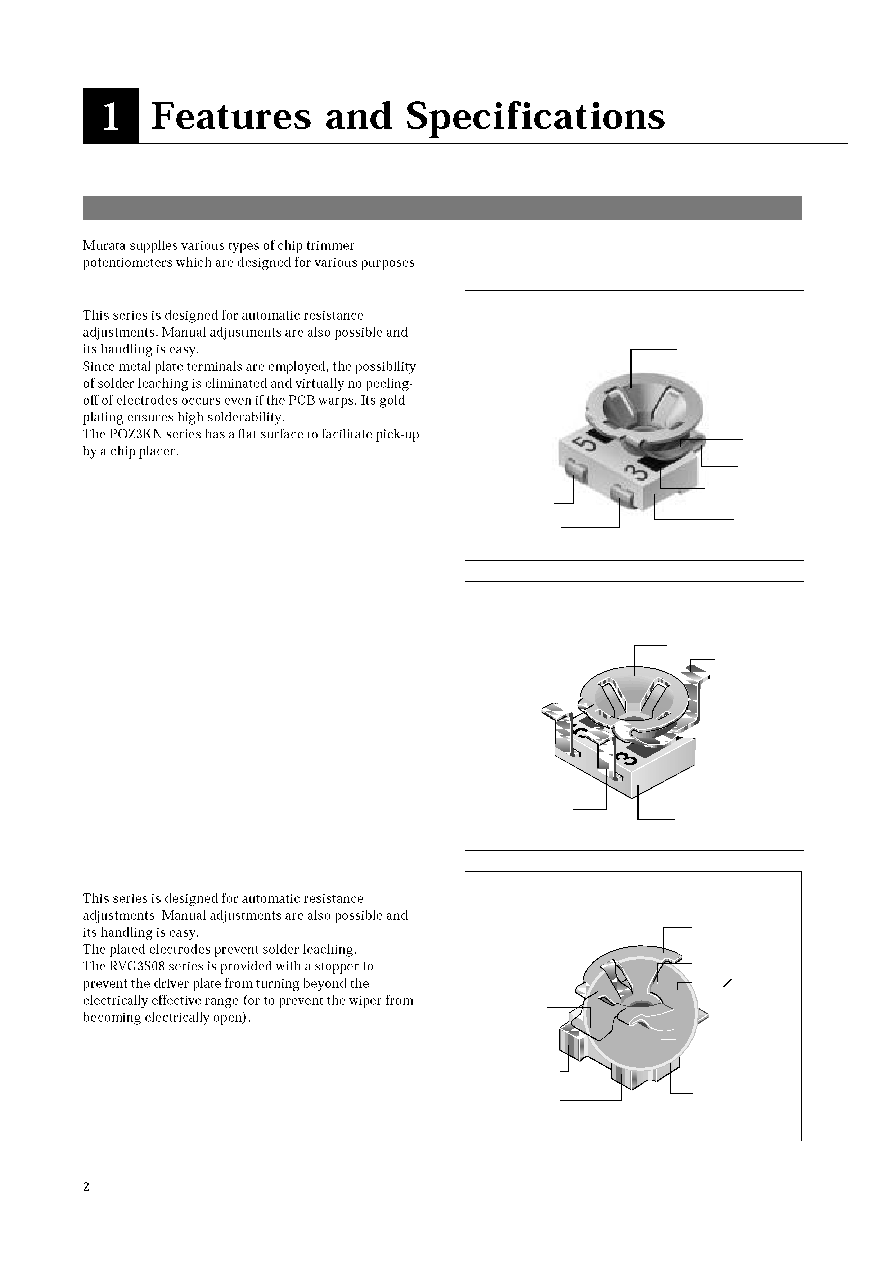

POZ3AN (Top adjustment type for reflow soldering)

POZ3KN (Rear adjustment type for reflow soldering)

Driver plate

Wiper

Terminal (2)

Resistive element (carbon)

Resin substrate

Terminal (3)

Terminal (1)

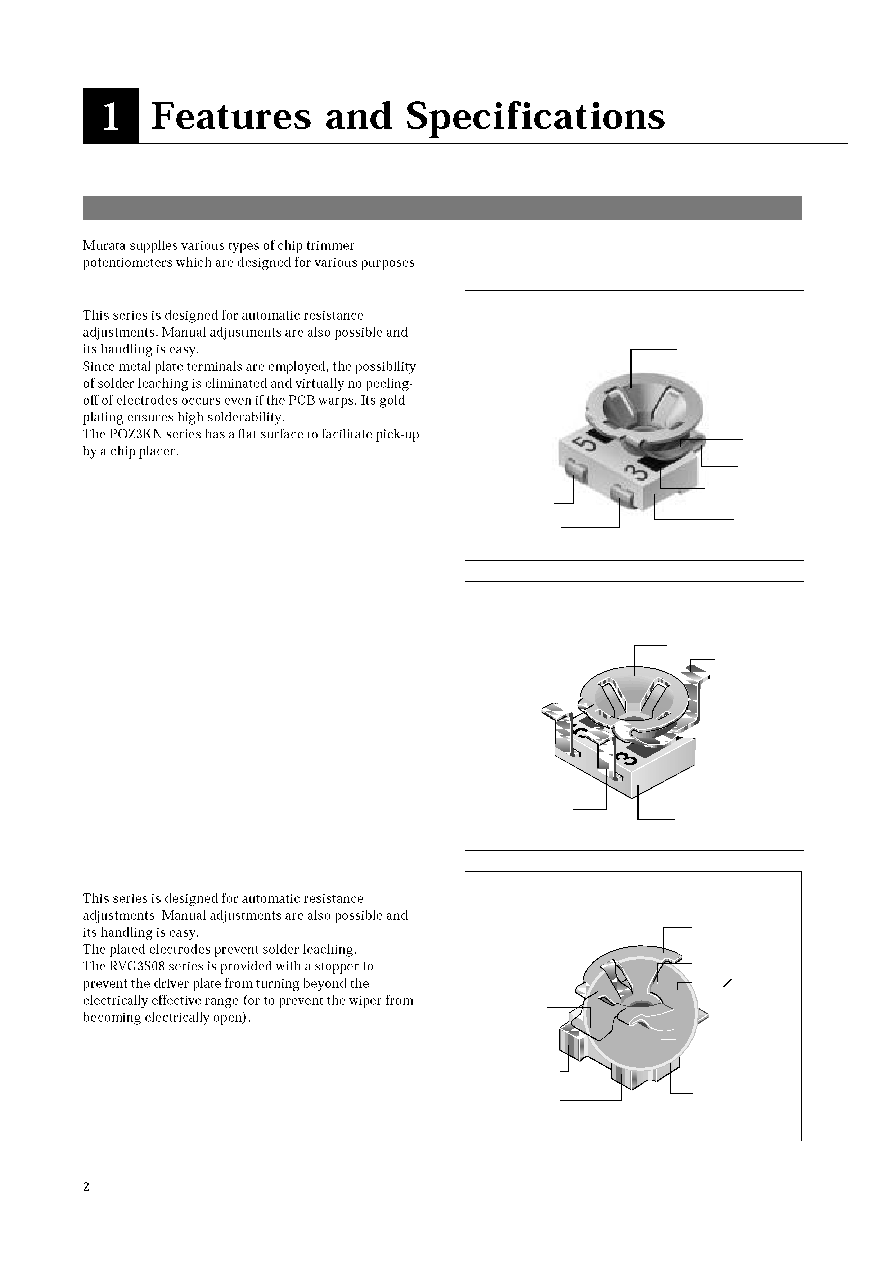

Driver plate

Wiper

Stopper Terminal (2)

Resistive element (cermet)

Ceramic substrate

Terminal (3)

Terminal (1)

Stopper

RVG3 Series

R82E2.pdf 97.09.29

This is the PDF file of catalog No.R82E-2.

RVG4M Series

RVG4M (for flow and reflow soldering)

Driver plate

Wiper

Terminal (2)

Resistive element (cermet)

Ceramic substrate

Terminal (3)

Terminal (1)

RVG3A08 (for flow and reflow soldering)

Driver plate

Wiper

Rubber

Terminal (2)

Ceramic substrate

Resistive element (cermet)

Terminal (3)

Terminal (1)

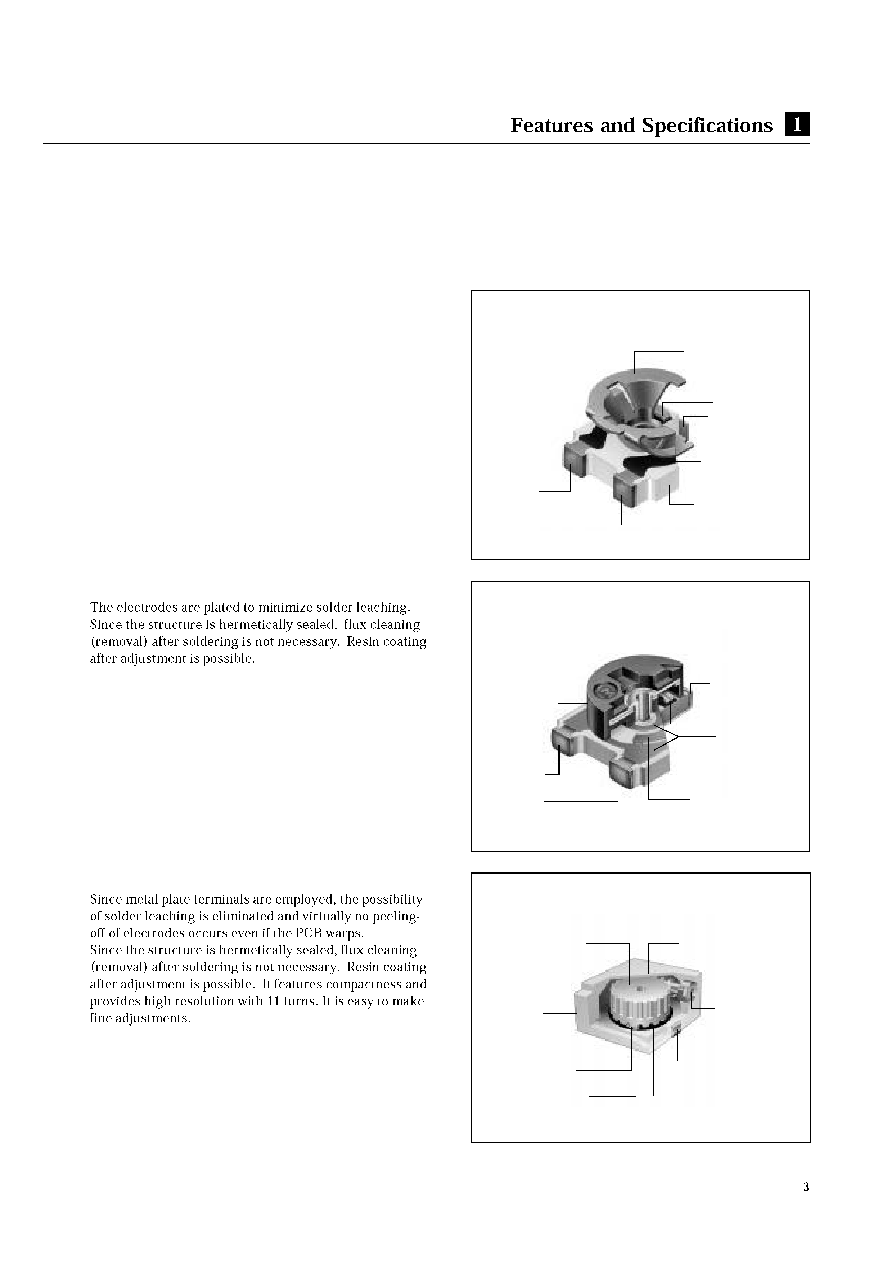

Gear

Case

Adjustment screw

Terminal (2)

Terminals(1) and (3)

Resistive element (cermet)

Ceramic substrate

Wiper

POG5 (for reflow soldering)

POG5 Series

82E2.pdf 97.09.29

This is the PDF file of catalog No.R82E-2.

2. Specifications

Cermet

Carbon

Triangular

3 (divider type)

1

Automatic

Manual

Reflow soldering

Flow soldering

Gold plating(nickel undercoating)

Solder plating (nickel undercoating)

3

3

3

3

Solder plating (copper undercoating)

3 mm square

4 mm square

5 mm square

1.50mm

1.85mm

2.00mm

2.10mm

3.70mm

5.00mm

0.040g(40mg)

0.080g(80mg)

0.180g(180mg)

Necessary

2

Not necessary

Possible

Not possible

250 pcs./reel

500 pcs./reel

1500 pcs./reel

2000 pcs./reel

2500 pcs./reel

POZ3 Series

RVG3 Series

RVG4M Series

POG5 Series

P

O

Z

3A

N

R

V

G

3S

08

R

V

G

3A

08

R

V

G

4M

08

R

V

G

4M

58

P

O

G

5A

N

P

O

G

5H

N

Item

Series

Resistive element

material

Terminal layout

No. of terminals

Adjustment method

Soldering

Electrode surface

treatment

Size

Product thickness

Product weight

Cleaning

Lock painting

Taping packaging

(reel with a diameter

of 180 mm)

1 They can be used as the rheostat type by connecting lands (2) and (3). (2 terminals (rheostat type) )

2 Cleaning is needed only when there is an adhesion of foreign matter such as flux on the resistive element.

3 Only terminal (2) is gold-plated with a nickel undercoat.

(1)

(3)

(2)

P

O

Z

3K

N

(1)

(2)