| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: AQY212GH | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

PhotoMOS

RELAYS

GU (General Use) Type

1-Channel (Form A)

High Capacity 4-Pin Type

cUL

pending

VDE

pending

mm

inch

4.78

.188

6.4

.252

3.2

.126

1

2

4

3

FEATURES

1. Greatly increased load current.

2. Reinforced insulation 5,000 V type.

3. Greatly improved specs allow you to

use this in place of mercury and

mechanical relays.

4. Compact 4-pin DIP size.

TYPICAL APPLICATIONS

∑ Security market

(use in I/O for alarm and security devices,

etc.)

∑ Measuring instrument market

TYPES

*Indicate the peak AC and DC values.

Note: For space reasons, the initial letters of the product number "AQY", the SMD terminal shape indicator "A" and the package type indicator "X" and

"Z" are omitted from the seal.

Type

I/O isolation

voltage

Output rating*

Part No.

Packing quantity

Through hole

terminal

Surface-mount terminal

Load

voltage

Load

current

Tube packing style

Tape and reel packing style

Tube

Tape and reel

Picked from the

1/2-pin side

Picked from the

3/4-pin side

AC/DC

type

Reinforced

5,000 V

60 V

1.1 A

AQY212GH

AQY212GHA

AQY212GHAX

AQY212GHAZ

1 tube contains

100 pcs.

1 batch contains

1,000 pcs.

1,000 pcs.

RATING

1. Absolute maximum ratings (Ambient temperature: 25

∞

C

77

∞

F

)

Item

Symbol

AQY212GH

Remarks

Input

LED forward current

I

F

50 mA

LED reverse voltage

V

R

5 V

Peak forward current

I

FP

1 A

f = 100 Hz, Duty factor = 0.1%

Power dissipation

P

in

75 mW

Output

Load voltage (peak AC)

V

L

60 V

Continuous load current

(peak AC)

I

L

1.1 A

Peak load current

I

peak

3.0 A

100ms (1 shot), V

L

= DC

Power dissipation

P

out

500 mW

Total power dissipation

P

T

550 mW

I/O isolation voltage

V

iso

5,000 V AC

Temperature limits

Operating

T

opr

≠40

∞

C to +85

∞

C

≠40

∞

F to +185

∞

F

Non-condensing at low temperatures

Storage

T

stg

≠40

∞

C to +100

∞

C

≠40

∞

F to +212

∞

F

AQY212GH.fm1

y [ W Q O O Q N U

S oe @ j oe @

™ P Q

Q T "

AQY212GH

2

2. Electrical characteristics (Ambient temperature: 25

∞

C

77

∞

F

)

Note: Recommendable LED forward current I

F

= 5 to 10 mA.

For type of connection, see Page 4.

*Turn on/Turn off time

Item

Symbol

AQY212GH

Condition

Input

LED operate

current

Typical

I

Fon

1.1 mA

I

L

= 100mA

Maximum

3 mA

LED turn off

current

Minimum

I

Foff

0.3 mA

I

L

= 100mA

Typical

1.0 mA

LED dropout

voltage

Typical

V

F

1.14 V (1.32 V at IF = 50 mA)

I

F

= 5 mA

Maximum

1.5 V

Output

On resistance

Typical

R

on

0.34

I

F

= 5 mA

I

L

= Max.

Within 1 s on time

Maximum

0.7

Off state leakage

current

Maximum

I

Leak

1

µ

A

I

F

= 0

V

L

= Max.

Transfer

characteristics

Turn on time*

Typical

T

on

1.3 ms

I

F

= 5 mA

I

L

= 100 mA

V

L

= 10 V

Maximum

5.0 ms

Turn off time*

Typical

T

off

0.1 ms

I

F

= 5 mA

I

L

= 100 mA

V

L

= 10 V

Maximum

0.5 ms

I/O capacitance

Typical

C

iso

0.8 pF

f = 1 MHz

V

B

= 0

Maximum

1.5 pF

Initial I/O isolation

resistance

Minimum

R

iso

1,000 M

500 V DC

Ton

Input

Output

10%

90%

Toff

REFERENCE DATA

1. Load current vs. ambient temperature

characteristics

Allowable ambient temperature: ≠40

∞

C to +85

∞

C

≠40

∞

F to +185

∞

F

2. On resistance vs. ambient temperature

characteristics

Measured portion: between terminals 3 and 4;

LED current: 5 mA; Load voltage: Max. (DC)

Continuous load current: Max.(DC)

3. Turn on time vs. ambient temperature

characteristics

LED current: 5 mA; Load voltage: 10 V (DC);

Continuous load current: 100 mA (DC)

0

1

2

Ambient temperature,

∞

C

Load current, A

2.5

3

0

20

40

60

8085 100

≠40 ≠20

0.5

1.5

0

≠40 ≠20

0.2

0

20

40

60

80

Ambient temperature,

∞

C

On resistance,

85

0.6

0.8

1

0.4

0

2

Ambient temperature,

∞

C

Turn on time, ms

≠40

≠20

5

0

20

40

60

80

1

3

4

85

AQY212GH.fm2

y [ W Q O O Q N U

S oe @ j oe @

™ P Q

Q T "

AQY212GH

3

4. Turn off time vs. ambient temperature

characteristics

LED current: 5 mA; Load voltage: 10 V (DC);

Continuous load current: 100 mA (DC)

5. LED operate current vs. ambient

temperature characteristics

Load voltage: 10 V (DC);

Continuous load current: 100mA (DC)

6. LED turn off current vs. ambient temperature

characteristics

Load voltage: 10 V (DC);

Continuous load current: 100mA (DC)

0

0.4

0.8

0.6

Ambient temperature,

∞

C

Turn off time, ms

≠40

≠20

1

0

20

40

60

80

0.2

85

0

2

3

Ambient temperature,

∞

C

LED operate current, mA

≠40

≠20

5

0

20

40

60

80 85

1

4

0

2

3

Ambient temperature,

∞

C

LED turn off current, mA

≠40

≠20

0

20

40

60

80

1

5

4

85

7. LED dropout voltage vs. ambient

temperature characteristics

LED current: 5 to 50 mA

8. Voltage vs. current characteristics of output

at MOS portion

Measured portion: between terminals 3 and 4;

Ambient temperature: 25

∞

C

77

∞

F

9. Off state leakage current

Measured portion: between terminals 3 and 4;

Ambient temperature: 25

∞

C

77

∞

F

1

1.1

1.2

1.3

1.4

Ambient temperature,

∞

C

LED dropout voltage, V

≠40 ≠20

0

20

40

60

80 85

1.5

50mA

30mA

20mA

10mA

5mA

Voltage, V

Current, mA

1

≠1

3

2

≠3

≠2

1

0.5

≠1

≠0.5

0

30

40

60

Load voltage, V

Off state leakage current, A

10

10

-12

10

-10

10

20

10

-6

10

-8

50

-4

10. LED forward current vs. turn on time

characteristics

Measured portion: between terminals 3 and 4;

Load voltage: 10 V (DC);

Continuous load current: 100 mA (DC);

Ambient temperature: 25

∞

C

77

∞

F

11. LED forward current vs. turn off time

characteristics

Measured portion: between terminals 3 and 4;

Load voltage: 10 V (DC);

Continuous load current: 100 mA (DC);

Ambient temperature: 25

∞

C

77

∞

F

12. Applied voltage vs. output capacitance

characteristics

Measured portion: between terminals 3 and 4;

Frequency: 1 MHz;

Ambient temperature: 25

∞

C

77

∞

F

0

1

2

3

5

LED forward current, mA

Turn on time, ms

10

20

30

40

50

4

0

LED forward current, mA

Turn off time, ms

0

0.1

0.3

0.2

10

20

30

40

0.5

50

0

0.4

0

100

200

800

Applied voltage, V

Output capacitance, pF

10

20

30

40

50

500

400

300

600

0

700

60

AQY212GH.fm3

y [ W Q O O Q N U

S oe @ j oe @

™ P Q

Q T "

AQY212GH

4

DIMENSIONS

mm

inch

Through hole terminal type

Terminal thickness = 0.2

.008

General tolerance:

±

0.1

±

.004

Surface mount terminal type

Terminal thickness = 0.2

.008

General tolerance:

±

0.1

±

.004

4.78

.188

6.4

.252

2.7

.106

7.62

±

0.05

.300

±

.002

Max. 10

∞

Max. 10

∞

1.0

.039

0.33

.013

0.2

.008

3.0

.118

0.47

.019

3.2

±

0.1

.126

±

.004

0.47

.019

2.54

.100

4.78

.188

6.4

.252

1.0

.039

2.7

.106

7.62

±

0.05

.300

±

.002

Max. 10

∞

1.0

.039

1.0

.039

2.7

.106

0.47

.019

0.47

.019

2.54

.100

0.2

.008

±

0.2

0

±

.008

0

PC board pattern (BOTTOM VIEW)

Tolerance:

±

0.1

±

.004

Mounting pad (TOP VIEW)

Tolerance:

±

0.1

±

.004

4-0.8 dia.

4-.031 dia.

7.62

.300

6.4

.252

2.54

.100

2.54

.100

8.3

.327

1.9

.075

1.5

.059

2.54

.100

SCHEMATIC AND WIRING DIAGRAMS

Notes: E

1

: Power source at input side; I

F

: LED forward current; V

L

: Load voltage; I

L

: Load current;

Schematic

Output

configura-

tion

Load

Connec-

tion

Wiring diagram

1a

AC/DC

--

1

2

4

3

1

IF

IL

2

3

4

VL (AC,DC)

Load

Load

IL

4

3

VL (AC,DC)

E1

AQY212GH.fm4

y [ W Q O O Q N U

S oe @ j oe @

™ P Q

Q T "

AQY212GH

5

Cautions for Use

SAFETY WARNINGS

∑ Do not use the product under conditions

that exceed the range of its specifications.

It may cause overheating, smoke, or fire.

∑ Do not touch the recharging unit while

the power is on. There is a danger of

electrical shock. Be sure to turn off the

power when performing mounting,

maintenance, or repair operations on the

relay (including connecting parts such as

the terminal board and socket).

∑ Check the connection diagrams in the

catalog and be sure to connect the

terminals correctly. Erroneous

connections could lead to unexpected

operating errors, overheating, or fire.

NOTES

1. Short across terminals

Do not short circuit between terminals

when relay is energized. There is

possibility of breaking the internal IC.

2. Surge voltages at the input

If reverse surge voltages are present at

the input terminals, connect a diode in

reverse parallel across the input terminals

and keep the reverse voltages below the

reverse breakdown voltage.

3. Recommended LED forward current

(I

F

)

It is recommended that the LED forward

current (I

F

) be kept at 5mA.

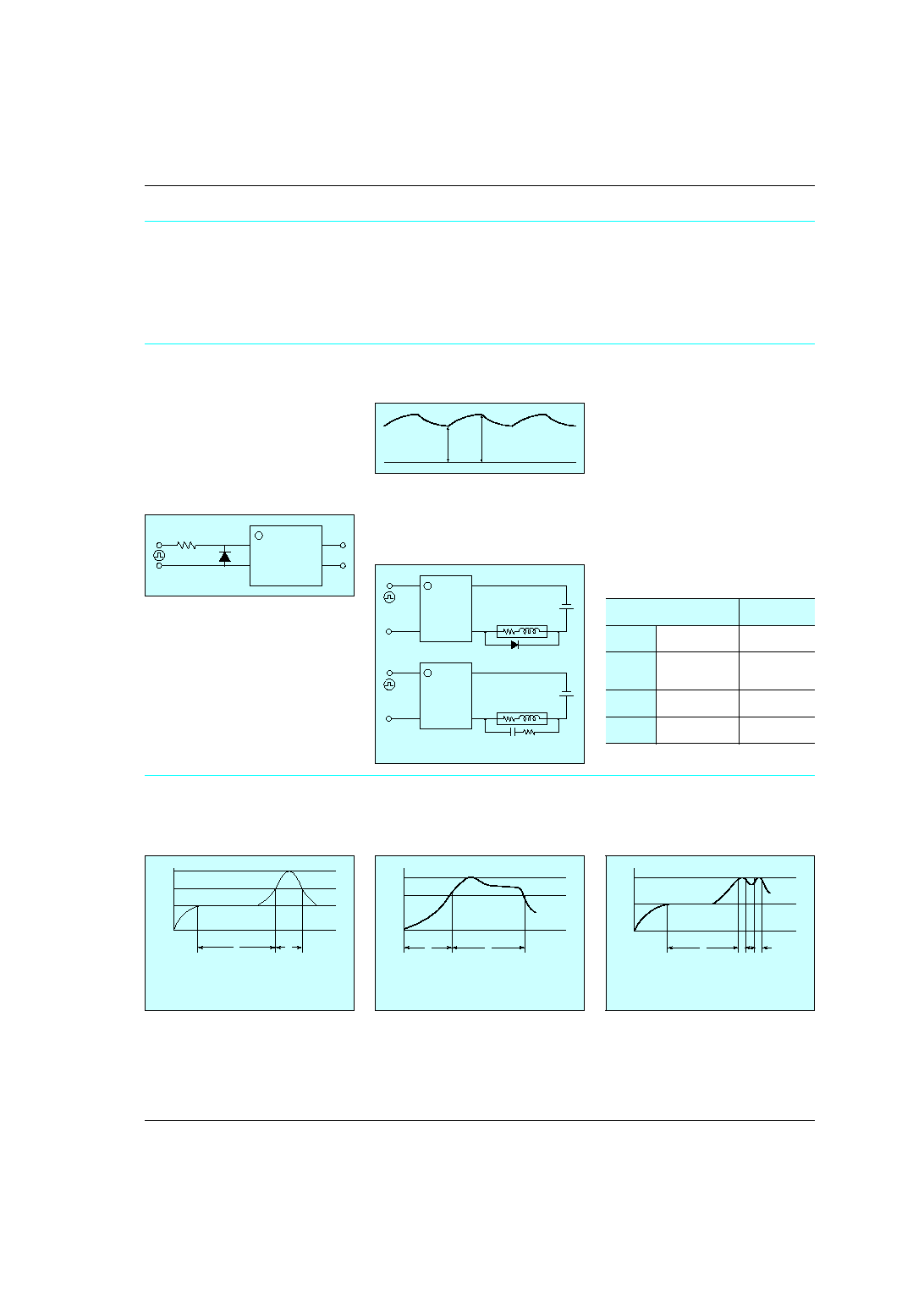

4. Ripple in the input power supply

If ripple is present in the input power

supply, observe the following:

1) For LED operate current at E

min

,

maintain the value mentioned in the table

of "Note 3. Recommended LED forward

current (I

F

)."

2) Keep the LED operate current at 50

mA or less at E

max

.

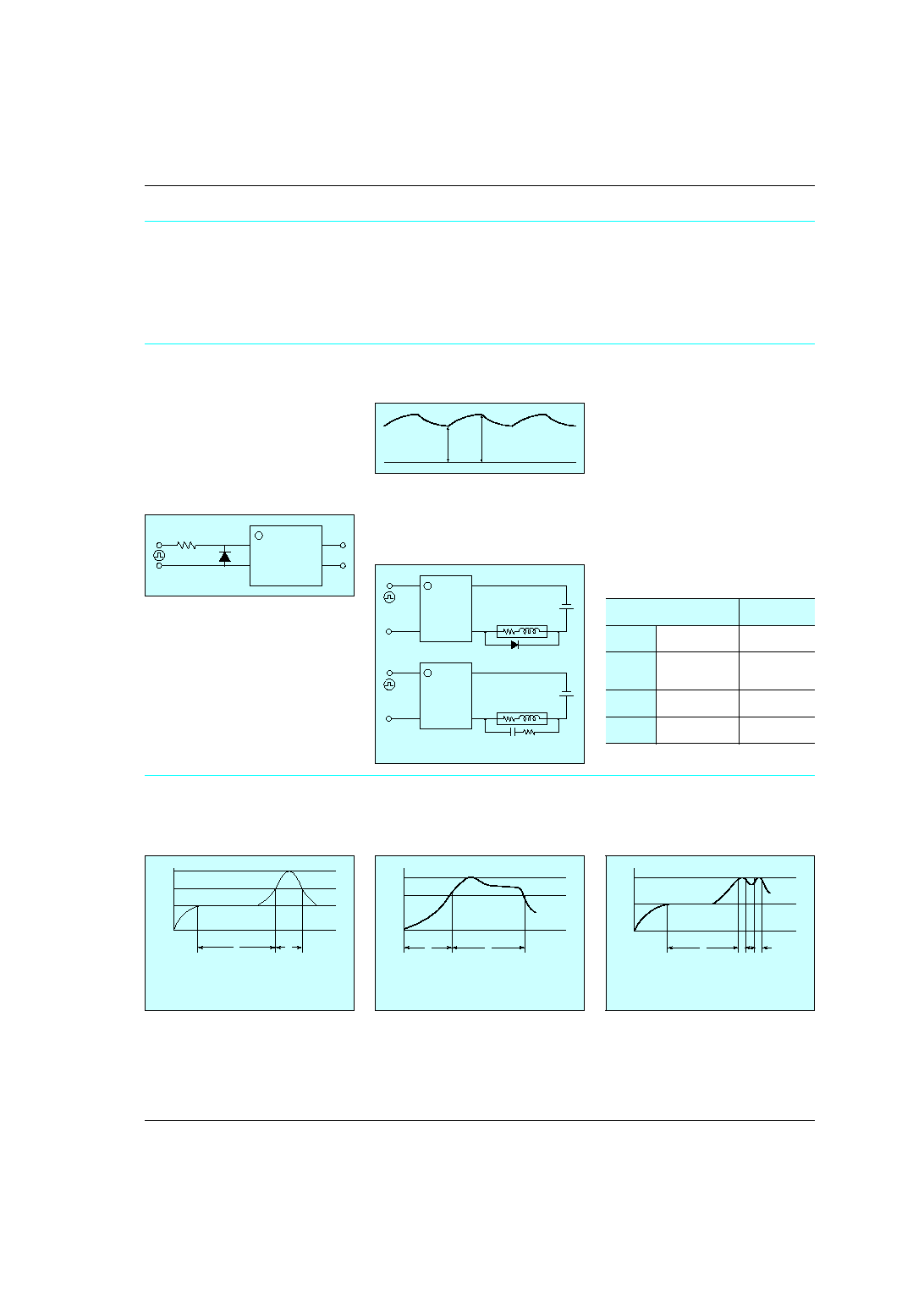

5. Output spike voltages

1) If an inductive load generates spike

voltages which exceed the absolute

maximum rating, the spike voltage must

be limited.

Typical circuits are shown below.

2) If spike voltages generated at the load

are limited with a clamp diode and the

circuit wires are long, spike voltages will

occur by inductance. Keep wires as short

as possible to minimize inductance.

6. Cleaning solvents compatibility

Dip cleaning with an organic solvent is

recommended for removal of solder flux,

dust, etc. Select a cleaning solvent from

the following table. If ultrasonic cleaning is

used, the severity of factors such as

frequency, output power and cleaning

solvent selected may cause loose wires

and other defects. Make sure these

conditions are correct before use. For

details, please consult us.

1

2

4

3

E

min.

E

max.

1

2

4

Load

Add a clamp diode

to the load

Add a CR snubber

circuit to the load

Load

3

1

2

4

3

Cleaning solvent

Compatibility

(

r

: Yes

!

: No)

Chlorine-

base

∑ Trichlene

∑ Chloroethlene

r

Adueous

∑ Indusco

∑ Hollis

∑ Lonco Terg

r

Alcohol-

base

∑ IPA

∑ Ethanol

r

Others

∑ Thinner

∑ Gasoline

!

7. Soldering

1) When soldering PC board terminals,

keep soldering time to within 10 s at

260

∞

C

500

∞

F

.

2) When soldering surface-mount

terminals, the following conditions are

recommended.

(1) IR (Infrared reflow) soldering method

(2) Vapor phase soldering method

(3) Double wave soldering method

T

1

T

2

T

3

T

1

= 155 to 165

∞

C

311 to 329

∞

F

T

2

= 180

∞

C 200

∞

C

356 to 392

∞

F

T

3

= 245

∞

C

473

∞

F

or less

t

1

= 120 s or less

t

2

= 30 s or less

t

1

t

2

T

2

T

1

t

1

t

2

T

1

= 180 to 200

∞

C

366 to 392

∞

F

T

2

= 215

∞

C

419

∞

F

or less

t

1

= 40 s

t

2

= 90 s or less

T

2

T

1

t

1

t

2

t

3

T

1

= 155 to 165

∞

C

311 to 329

∞

F

T

2

= 260

∞

C

500

∞

F

or less

t

1

= 60 s or less

t

2+

t

3

= 5 s or less

(4) Soldering iron method

Tip temperature: 280 to 300

∞

C

536 to

572

∞

F

Wattage: 30 to 60 W

Soldering time: within 5 s

(5) Others

Check mounting conditions before using

other soldering methods (hot-air, hot

plate, pulse heater, etc.)

∑ The temperature profile indicates the

temperature of the soldered terminal on

the surface of the PC board. The ambient

temperature may increase excessively.

Check the temperature under mounting

conditions.

∑ The conditions for the infrared reflow

soldering apply when preheating using

the VPS method.

AQY212GH.fm5

y [ W Q O O Q N U

S oe @ j oe @

™ P Q

Q T "