| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: NE32400 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

1996

DATA SHEET

HETERO JUNCTION FIELD EFFECT TRANSISTOR

NE32400, NE24200

C to Ka BAND SUPER LOW NOISE AMPLIFIER

N-CHANNEL HJ-FET CHIP

DESCRIPTION

NE32400 and NE24200 are Hetero Junction FET chip that utilizes the hetero junction between Si-doped AlGaAs

and undoped InGaAs to create high mobility electrons. Its excellent low noise and high associated gain make it suitable

for commercial systems, industrial and space applications.

FEATURES

∑

Super Low Noise Figure & High Associated Gain

NF = 0.6 dB TYP., G

a

= 11.0 dB TYP. at f = 12 GHz

∑

Gate Length : L

g

= 0.25

µ

m

∑

Gate Width : W

g

= 200

µ

m

ORDERING INFORMATION

PART NUMBER

QUALITY GRADE

APPLICATIONS

NE32400

Standard (Grade D)

Commercial

NE24200

Grade C and B (B is special order)

Industrial, space

ABSOLUTE MAXIMUM RATINGS (T

A

= 25 ∞C)

Drain to Source Voltage

V

DS

4.0

V

Gate to Source Voltage

V

GS

≠3.0

V

Drain Current

I

D

I

DSS

mA

Total Power Dissipation

P

tot

*

200

mW

Channel Temperature

T

ch

175

∞C

Storage Temperature

T

stg

≠65 to +175

∞C

* Chip mounted on a Alumina heatsink (size: 3

◊

3

◊

0.6

t

)

ELECTRICAL CHARACTERISTICS (T

A

= 25 ∞C)

PARAMETER

SYMBOL

MIN.

TYP.

MAX.

UNIT

TEST CONDITIONS

Gate to Source Leak Current

I

GSO

≠

0.5

10

µ

A

V

GS

= ≠3 V

Saturated Drain Current

I

DSS

15

40

70

mA

V

DS

= 2 V, V

GS

= 0 V

Gate to Source Cutoff Voltage

V

GS(off)

≠0.2

≠0.8

≠2.0

V

V

DS

= 2 V, I

D

= 100

µ

A

Transconductance

g

m

45

60

≠

mS

V

DS

= 2 V, I

D

= 10 mA

Thermal Resistance

R

th

*

≠

≠

260

∞C/W

channel to case

Noise Figure

NF

≠

0.6

0.7

dB

V

DS

= 2 V, I

D

= 10 mA, f = 12 GHz

Associated Gain

G

a

10.0

11.0

≠

dB

RF performance is determined by packaging and testing 10 chips per wafer.

Wafer rejection criteria for standard devices is 2 rejects per 10 samples.

Document No. P11345EJ2V0DS00 (2nd edition)

(Previous No. TD-2358)

Date Published May 1996 P

Printed in Japan

NE32400, NE24200

2

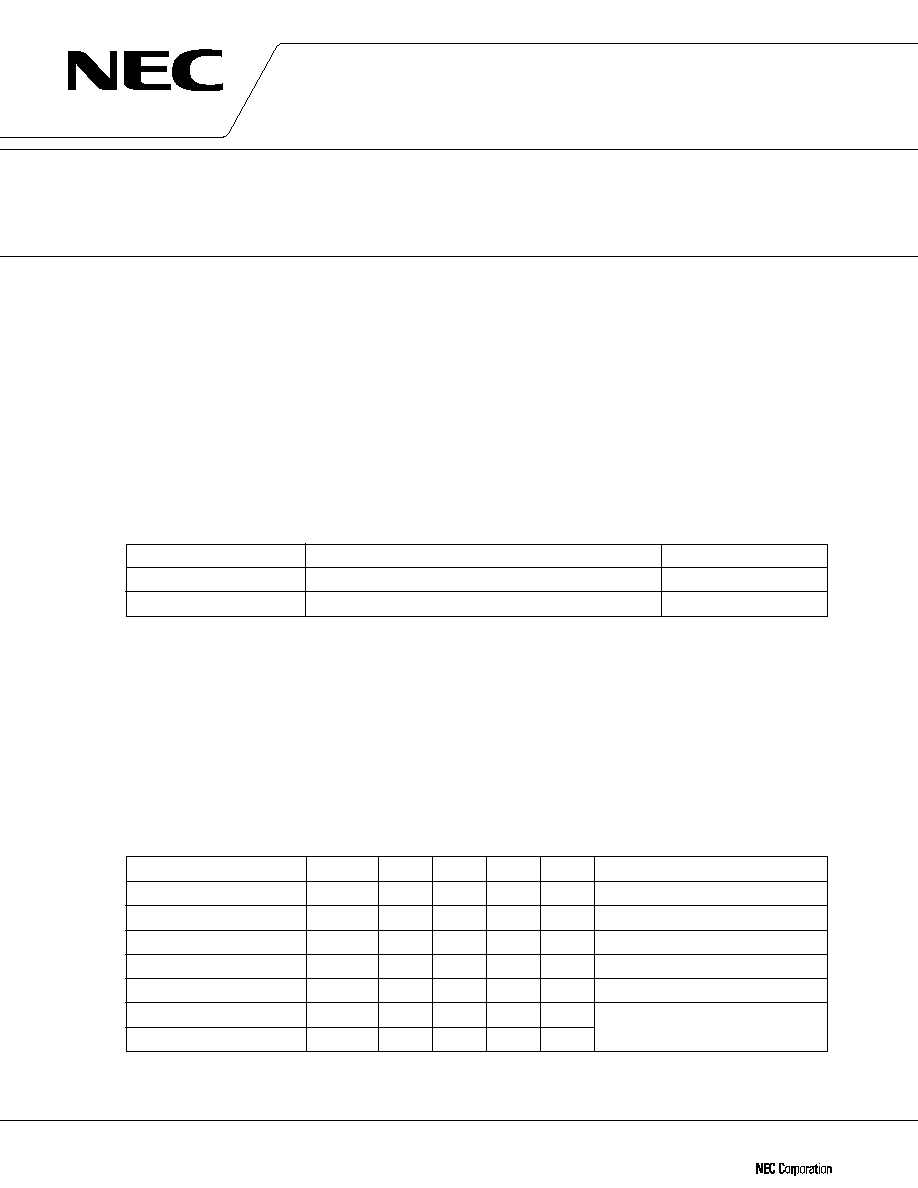

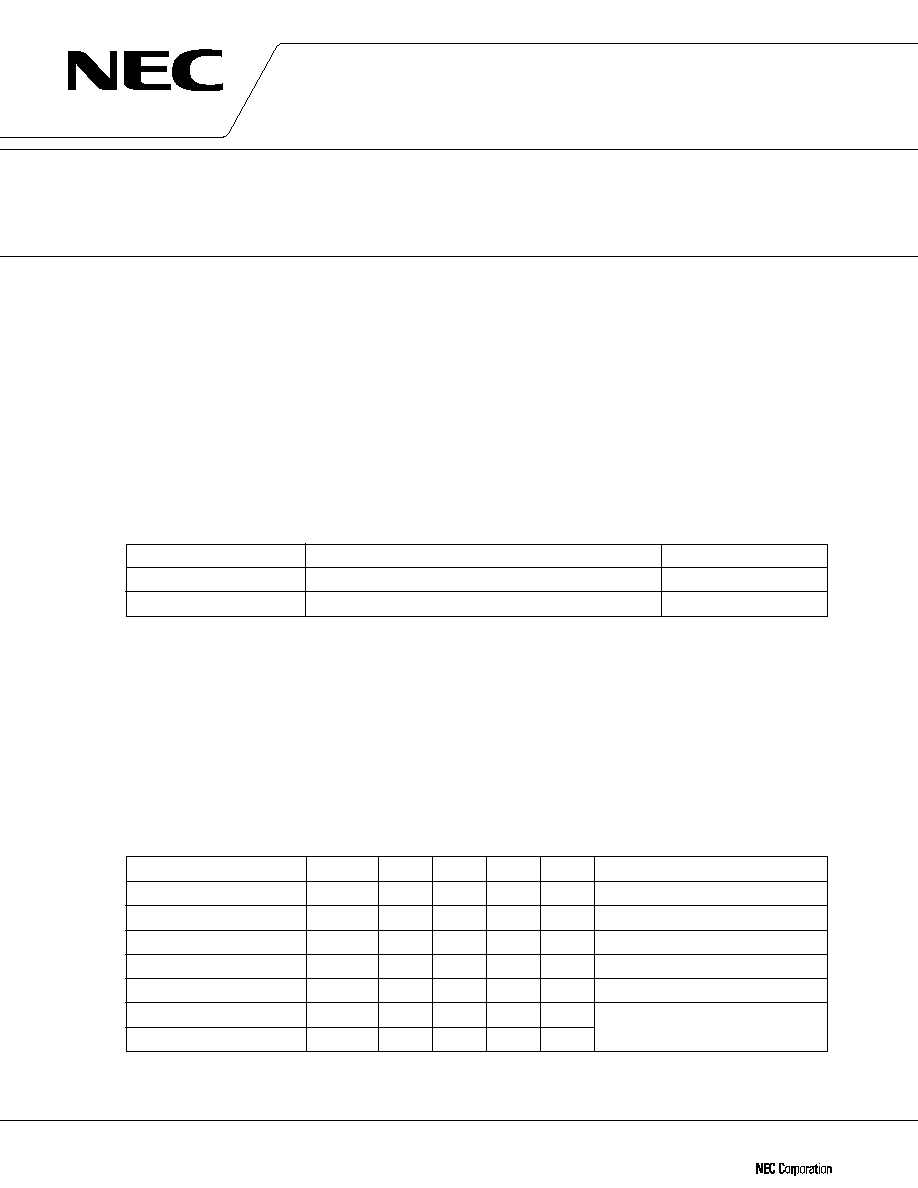

CHIP DIMENSIONS (Unit:

µ

m)

Drain

Source

Gate

Gate

Source

Drain

47

40

113

45

96

53

61

60

150

350

41

112

56

400

Thickness = 140 m

µ

: BONDING AREA

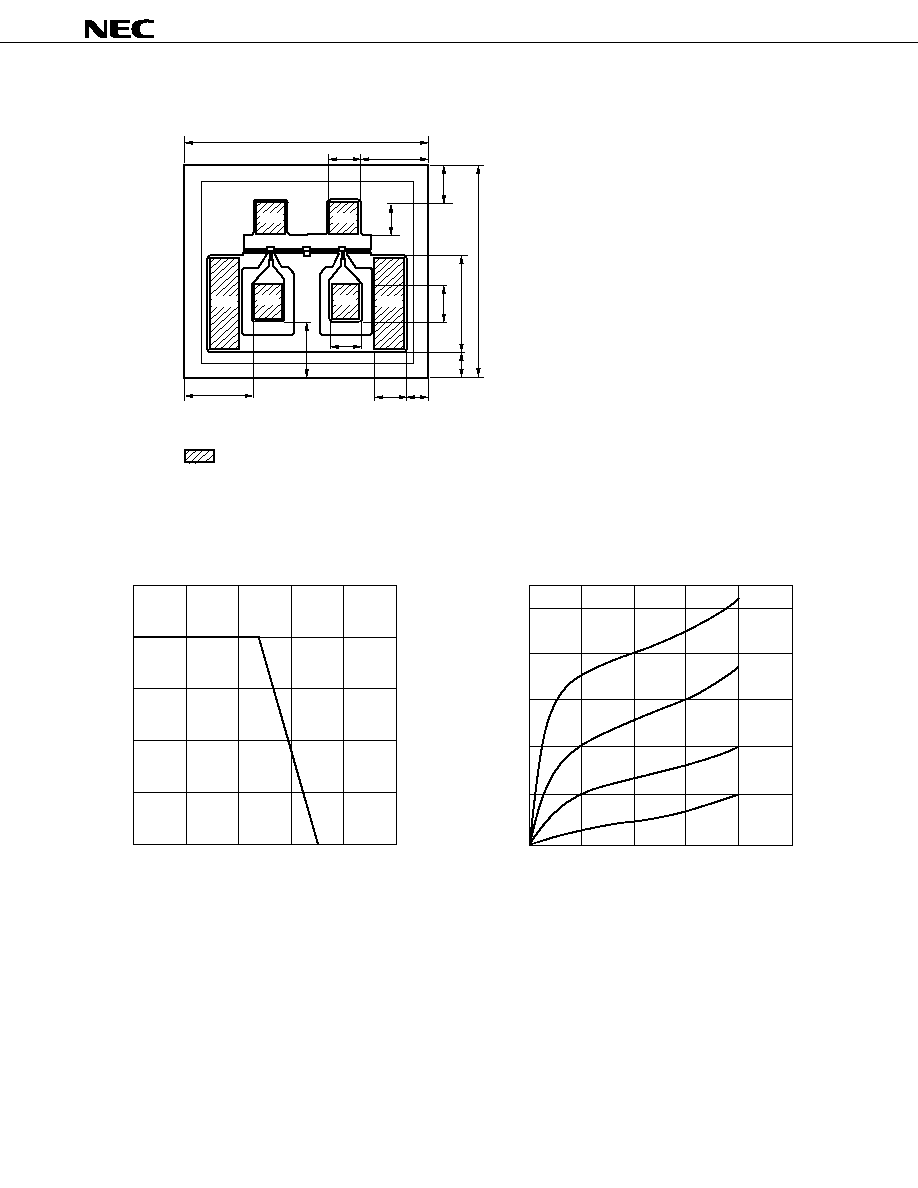

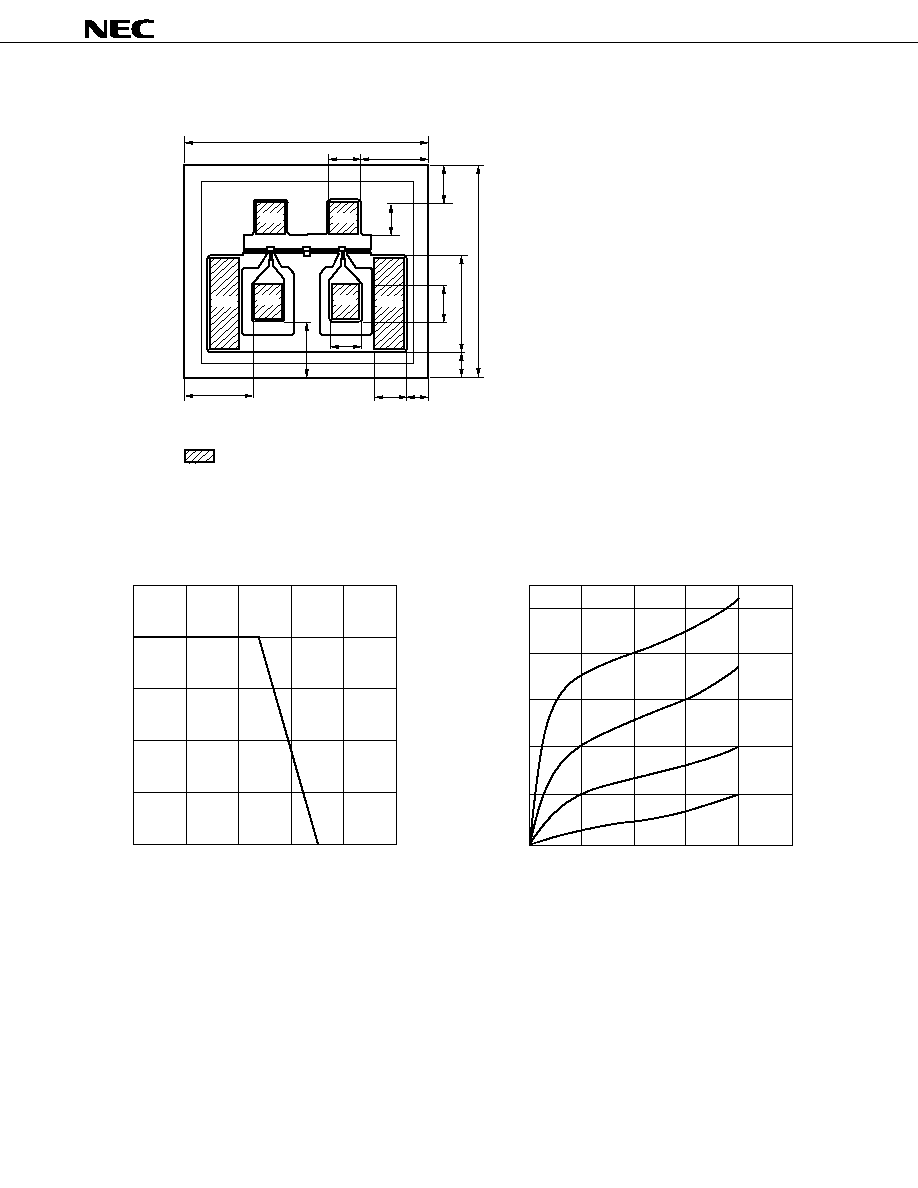

TYPICAL CHARACTERISTICS (T

A

= 25 ∞C)

0

1

2

3

4

5

V

DS

≠ Drain to Source Voltage ≠ V

50

40

30

20

10

I

D

≠ Drain Current ≠ mA

DRAIN CURRENT vs.

DRAIN TO SOURCE VOLTAGE

V

GS

= 0 V

≠0.2 V

≠0.4 V

≠0.6 V

TOTAL POWER DISSIPATION vs.

AMBIENT TEMPERATURE

0

50

100

150

200

250

T

A

≠ Ambient Temperature ≠ ∞C

250

200

150

100

50

P

tot

≠ Total Power Dissipation ≠ mW

NE32400, NE24200

3

Gain Calculations

MSG.

=

|

|

|

|

S

S

21

12

K

1 |

|

| S

|

| S

|

2 | S

|| S

|

2

11

2

22

2

12

21

=

+

-

-

MAG.

| S

|

| S

|

(K

K

1)

21

12

2

=

±

-

=

-

S

S

S

S

11

22

21

12

50

40

30

20

10

≠1.0

0

V

GS

≠ Gate to Source Voltage ≠ V

I

D

≠ Drain Current ≠ mA

DRAIN CURRENT vs.

GATE TO SOURCE VOLTAGE

≠2.0

0

V

DS

= 2 V

MAXIMUM AVAILABLE GAIN, FORWARD

INSERTION GAIN vs. FREQUENCY

V

DS

= 2.0 V

I

D

= 10 mA

24

20

16

12

8

40

f ≠ Frequency ≠ GHz

MSG. ≠ Maximum Stable Gain ≠ dB

|S

21s

|

2

≠ Foward Insertion Gain ≠ dB

4

30

20

10

8

6

4

2

1

MSG.

|S

21s

|

2

5

4

3

2

1

30

f ≠ Frenquency ≠ GHz

NF ≠ Noise Figure ≠ dB

NOISE FIGURE ASSOCIATED vs.

FREQUENCY

0

20

14

10

8

6

4

2

1

24

20

15

12

8

4

G

a

≠ Associated Gain ≠ dB

Ga

NF

3

2

1

100

I

DS

/I

DSS

≠ Ratio of Drain Current to Zero-Gate Voltage Current ≠ %

NF ≠ Noise Figure ≠ dB

NOISE FIGURE, ASSOCIATED GAIN vs. RATIO

OF DRAIN CURRENT TO ZERO-GATE

VOLTAGE CURRENT

0

60

40

20

8

6

4

2

1

5

0

G

a

≠ Associated Gain ≠ dB

V

DS

= 2 V

I

D

= 10 mA

10

15

NF

Ga

V

DS

= 2 V

f = 12 GHz

NE32400, NE24200

4

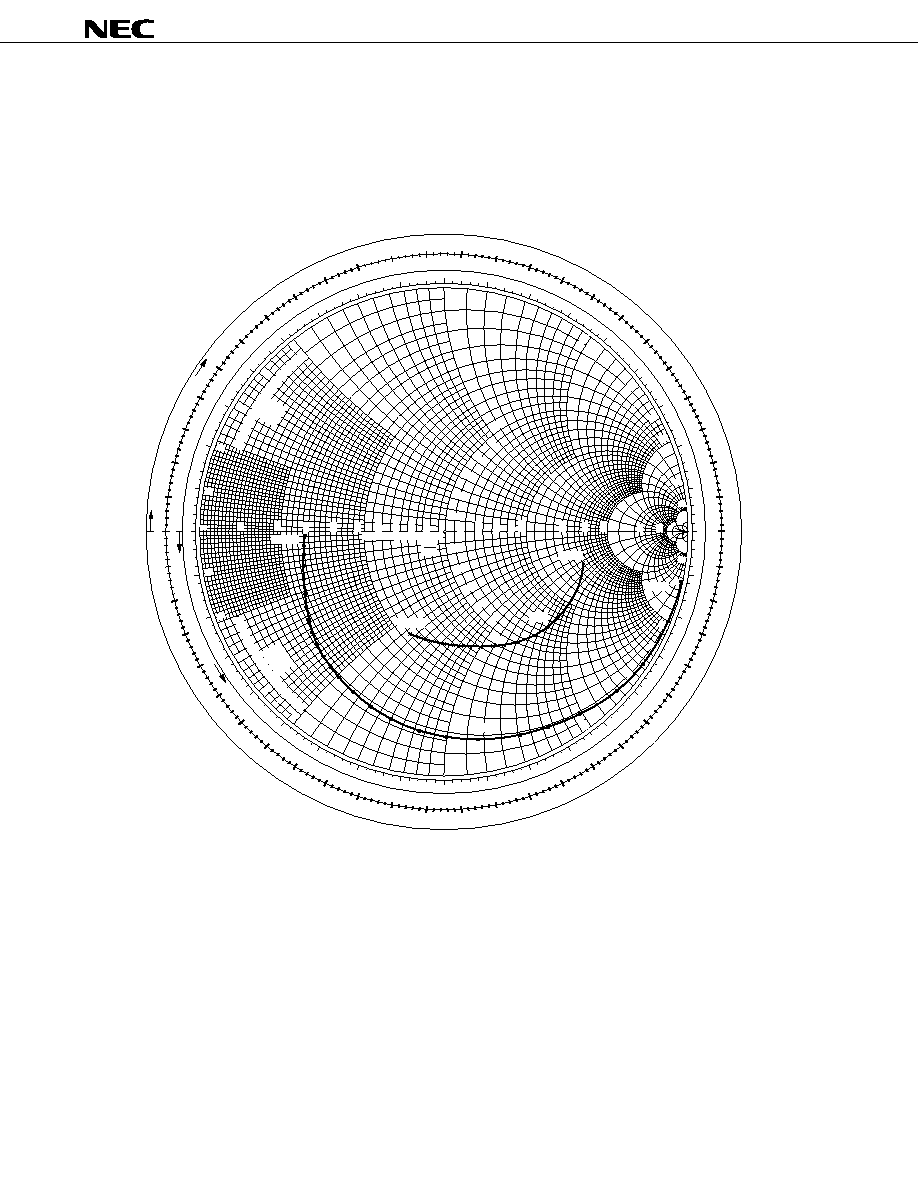

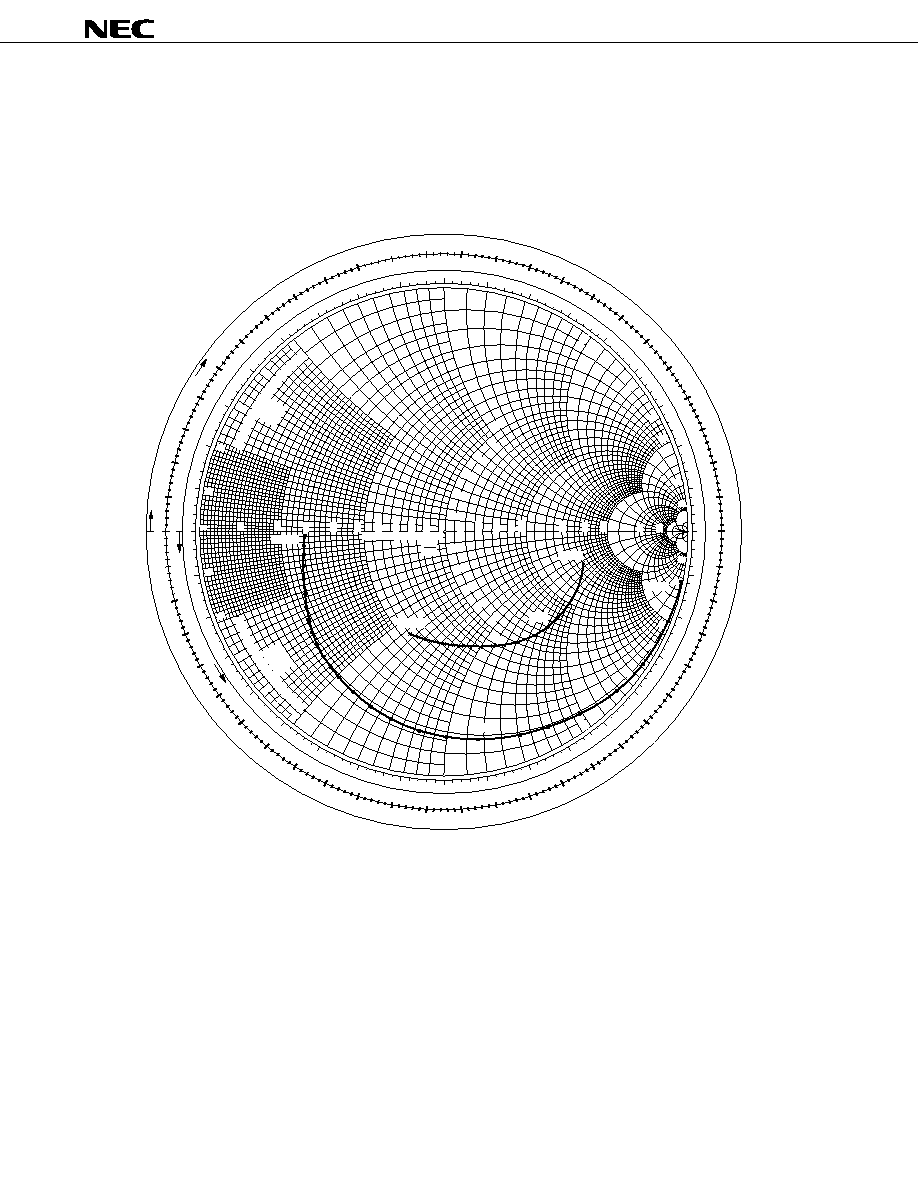

S-PARAMETERS

V

DS

= 2 V, I

D

= 10 mA

START 1 GHz, STOP 26 GHz, STEP 1 GHz

A

N

G

L

E

O

F

R

E

F

L

E

C

T

I

O

N

C

O

E

F

F

C

I

E

N

T

IN

D

E

G

R

E

E

S

≠160

≠150

≠140

≠130

≠120

≠110

≠100

≠90

≠80

≠70

≠60

≠50

≠40

≠30

≠20

≠10

0

10

20

30

40

50

00

60

70

80

90

100

110

120

130

140

150

0

0.02

0.48

0.04

0.46

0.06

0.44

0.08

0.42

0.10

0.40

0.12

0.38

0.04

0.36

0.16

0.34

0.18

0.32

0.20

0.30

0.22

0.28

0.24

0.26

0.26

0.24

0.28

0.22

0.30

0.20

0.32

0.18

0.34

0.16

0.36

0.14

0.38

0.12

0.40

0.10

0.42

0.08

0.44

0.06

0.46

0.04

0.48

0.02

0

0.49

0.47

0.45

0.43

0.41

0.39

0.37

0.35

0.33

0.31

0.29

0.27

0.25

0.23

0.21

0.19

0.17

0.15

0.13

0.11

0.09

0.07

0.05

0.03

0.01

0.01

0.03

0.05

000.07

0.09

0.11

0.13

0.15

0.17

0.19

000.21

0.23

0.25

0.27

0.29

0.31

0.33

0.35

0.37

0.39

0.41

0.43

0.45

0.47

0.49

W

A

V

E

L

E

N

G

T

H

S

T

O

W

A

R

D

L

O

A

D

W

A

V

E

L

E

N

G

T

H

S

T

O

W

A

R

D

G

E

N

E

R

A

T

O

R

2.0

5.0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.2

1.4

1.6

1.8

2.0

3.0

4.0

10

50

20

50

10

5.0

4.0

3.0

1.8

1.6

1.4

0.2

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

20

(

+JX

≠≠≠≠

Z

O

)

0.2

1.0

0.8

0.6

0.4

0.2

0.4

0.6

0.8

1.0

2.0

50

10

6.0

4.0

3.0

1.8

1.6

1.4

1.2

1.0

0.9

0.8

0.7

0.6

0.3

0.2

0.1

20

1.0

0.8

0.6

0.4

0.2

0.4

0.6

0.8

1.0

0.4

0.5

NE

GA

TI

VE

R

EA

CT

A

N

C

E

C

O

M

P

O

N

E

N

T

(

≠ JX

≠≠≠≠

Z

O

)

P

O

S

IT

IV

E

R

E

A

C

TA

N

C

E

CO

M

PO

NE

NT

RESTSTANCE COMPONENT

R

Z

O

( (

0.2

26 GHz

S

22

S

11

26 GHz

1 GHz

1 GHz

NE32400, NE24200

5

S-PARAMETERS MAG. AND ANG.

V

DS

= 2 V, I

D

= 10 mA

FREQUENCY

S

11

S

21

S

12

S

22

K

MSG/MAG

MAG.

ANG.

MAG.

ANG.

MAG. ANG.

MAG.

ANG.

(MHz)

(deg.)

(deg.)

(deg.)

(deg.)

(dB)

1000

0.996

≠12

4.680

171

0.015

83

0.616

≠10

0.05

24.9

2000

0.994

≠23

4.603

161

0.032

76

0.613

≠16

0.07

21.6

3000

0.979

≠34

4.486

152

0.046

70

0.601

≠23

0.08

19.9

4000

0.963

≠44

4.314

143

0.059

65

0.592

≠30

0.10

18.6

5000

0.929

≠54

4.118

135

0.071

59

0.580

≠36

0.18

17.7

6000

0.904

≠62

3.872

127

0.076

55

0.578

≠40

0.28

17.1

7000

0.882

≠70

3.759

120

0.092

51

0.574

≠46

0.30

16.1

8000

0.851

≠81

3.632

111

0.097

45

0.557

≠52

0.35

15.7

9000

0.836

≠89

3.423

104

0.098

40

0.543

≠55

0.40

15.5

10000

0.809

≠97

3.290

97

0.102

40

0.529

≠59

0.42

15.1

11000

0.792

≠105

3.179

91

0.107

37

0.523

≠62

0.44

14.7

12000

0.774

≠112

3.059

84

0.112

35

0.511

≠67

0.45

14.4

13000

0.762

≠119

2.940

78

0.118

31

0.489

≠72

0.46

14.0

14000

0.745

≠124

2.807

73

0.121

28

0.479

≠77

0.49

13.6

15000

0.729

≠128

2.698

68

0.124

26

0.468

≠81

0.51

13.4

16000

0.717

≠133

2.616

63

0.129

24

0.464

≠85

0.54

13.1

17000

0.697

≠137

2.526

58

0.134

21

0.462

≠90

0.58

12.8

18000

0.685

≠141

2.421

54

0.137

19

0.460

≠94

0.63

12.5

19000

0.665

≠146

2.315

49

0.135

19

0.460

≠96

0.68

12.3

20000

0.647

≠150

2.220

45

0.136

18

0.460

≠98

0.70

12.1

21000

0.625

≠156

2.159

40

0.138

18

0.459

≠100

0.71

11.9

22000

0.612

≠160

2.046

34

0.138

17

0.457

≠102

0.72

11.7

23000

0.596

≠166

1.892

30

0.139

17

0.455

≠103

0.73

11.5

24000

0.592

≠170

1.866

27

0.140

16

0.455

≠105

0.74

11.3

25000

0.587

≠174

1.780

25

0.141

21

0.454

≠107

0.74

11.2

26000

0.584

≠178

1.751

21

0.141

22

0.453

≠108

0.75

11.0

NE32400, NE24200

6

CHIP HANDLING

DIE ATTACHMENT

Die attach operation can be accomplished with Au-Sn (within a 300 ∞C ≠ 10 s) performs in a forming gas

environment.

Epoxy die attach is not recommend.

BONDING

Bonding wires should be minimum length, semi hard gold wire (3-8 % elongation) 20 microns in diameter.

Bonding should be performed with a wedge tip that has a taper of approximately 15 %. Bonding time should be

kept to minimum.

As a general rule, the bonding operation should be kept within a 280 ∞C, 2 minutes for all bonding wires.

If longer periods are required, the temperature should be lowered.

PRECAUTIONS

The user must operate in a clean, dry environment. The chip channel is glassivated for mechanical protection only

and does not preclude the necessity of a clean environment.

The bonding equipment should be periodically checked for sources of surge voltage and should be properly

grounded at all times. In fact, all test and handling equipment should be grounded to minimize the possibilities of static

discharge.

Avoid high static voltage and electric fields, because this device is Hetero Junction field effect transistor with shottky

barrier gate.

CAUTION

The Great Care must be taken in dealing with the devices in this guide.

The reason is that the material of the devices is GaAs (Gallium Arsenide), which is

designated as harmful substance according to the law concerned.

Keep the Japanese law concerned and so on, especially in case of removal.

NE32400, NE24200

7

[MEMO]

2

NE32400, NE24200

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special:

Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

M4 94.11