| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: NE8500100 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

1996

PRELIMINARY DATA SHEET

GaAs MES FET

NE85001 SERIES

1 W C-BAND POWER GaAs FET

N-CHANNEL GaAs MES FET

Document No. P10968EJ1V0DS00 (1st edition)

Date Published June 1996 P

Printed in Japan

DESCRIPTION

The NE8500199 Power GaAs FET covers 2 GHz to 10 GHz frequency range for commercial amplifier, oscillator

applications and so on.

NE8500100 is the two-cells recessed gate chip used in `99' package.

The device incorporates Ti-Al gate and silicon dioxide glassivation. To reduce the thermal resistance, the device

has a PHS. (Plated Heat Sink)

NEC's strigent quality assurance and test procedures assure the highest reliability and performance.

FEATURES

∑

Class A operation

∑

High power output

∑

High reliability

SELECTION CHART

PERFORMANCE SPECIFIED

PART NUMBER

FORM

Pout (**)

G

L

(**)

USABLE

(dBm)

(dB)

FREQUENCY

(GHz)

NE8500100(*)

chip

28.5 min

9.0 typ

2.0 to 10

NE8500100-WB

NE8500100-RG

NE8500199

package

28.5 min

9.0 typ

2.0 to 10

*

WB, RG indicate a type of containers for chips.

WB: black carrier, RG: ring,: gel-pack,

** Specified at the condition at the last page.

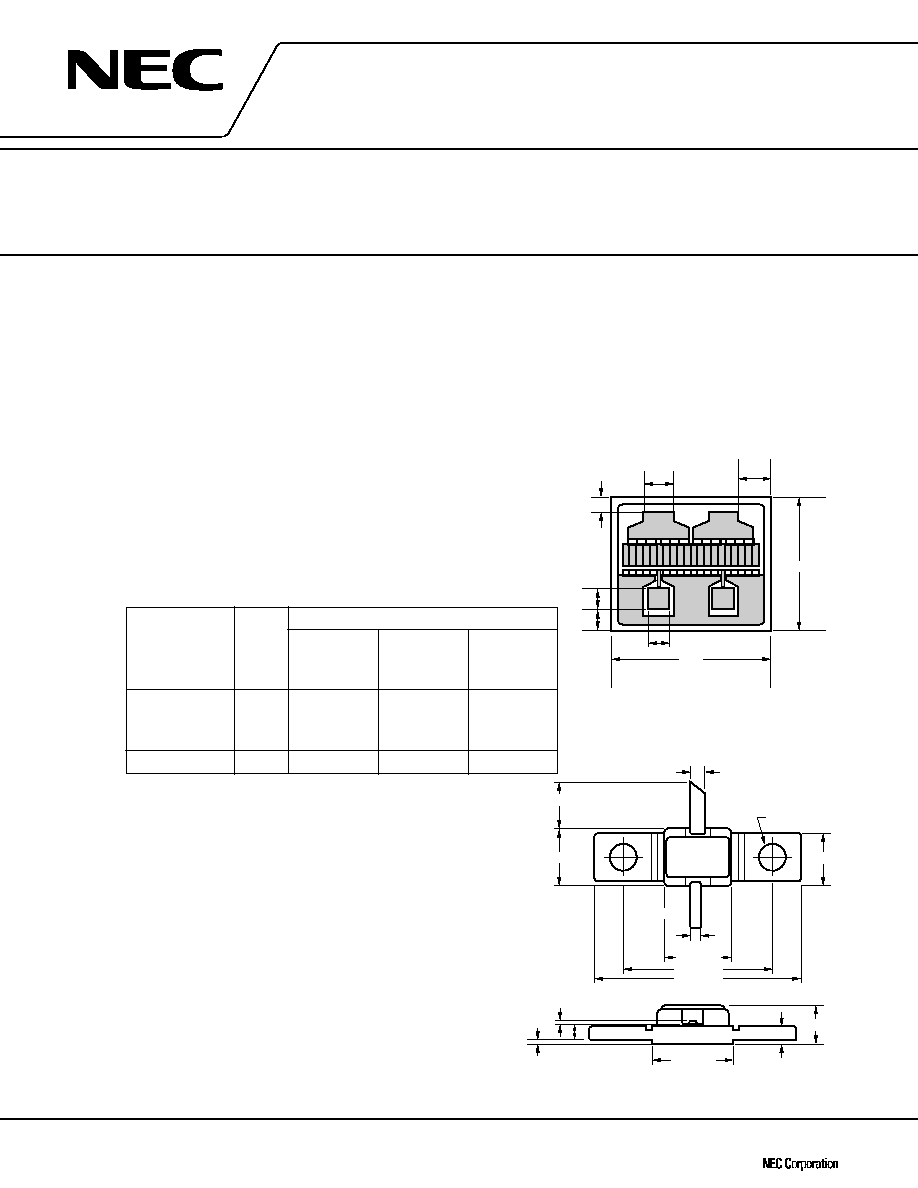

PHYSICAL DIMENSIONS

NE8500100 (CHIP) (unit:

µ

m)

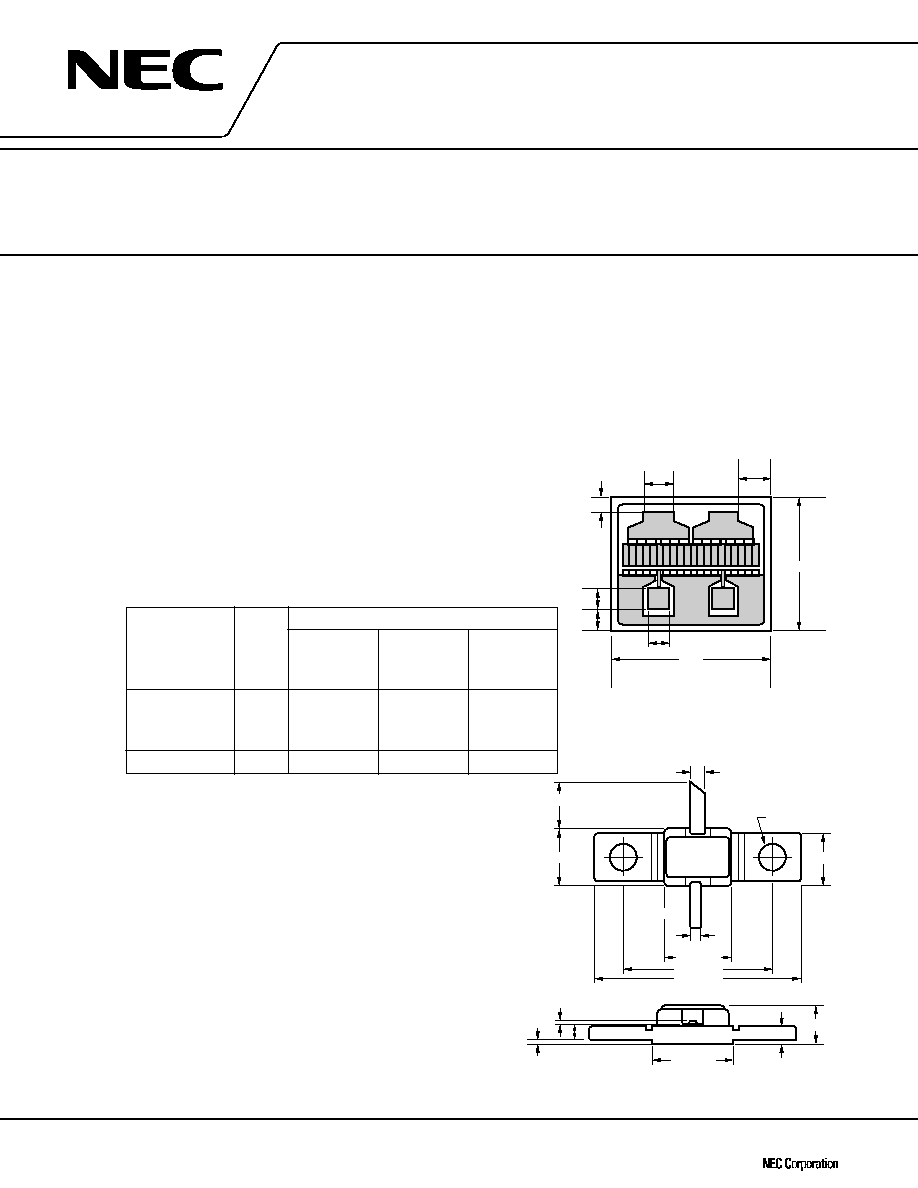

PACKAGE CODE-99 (unit: mm)

4.0 MIN BOTH LEADS

SOURCE

GATE

DRAIN

0.6 ±0.1

5.2 ±0.3

6.0 ±0.2

11.0 ±0.3

15.0 ±0.3

0.1

1.2

0.2 MAX.

1.0 ±0.1

2.2 ±0.3

2 PLACES

4.3 ±0.2

1.7 ±0.15

4.0

5.0 MAX.

780

640

170

100

146

100

65

100

NE85001 SERIES

2

ABSOLUTE MAXIMUM RATINGS (T

A

= 25 ∞C)

Drain to Source Voltage

V

DSX

15

V

Gate to Drain Voltage

V

GDX

≠18

V

Gate to Source Voltage

V

GSX

≠12

V

Total Power Disipation(*)

P

T

6.0

W

Drain Current

I

D

1.12

A

Gate Current

I

G

6.0

mA

Channel Temperature

T

ch

175

∞C

Storage Temperature

T

stg

≠65 to 175

∞C

*T

C

= 25 ∞C

RECOMMENDING OPERATION RANDGE

CHARACTERISTIC

SYMBOL

MIN.

TYP.

MAX.

UNIT

Drain to Source Voltage

V

DS

9

≠

10

V

Channel Temperature

T

ch

≠

≠

130

∞C

Input Power

Gcomp

≠

≠

3

dBcomp

Gate Resistance

Rg

≠

≠

1

k

ELECTRICAL CHARACTERISTICS (T

A

= 25 ∞C)

CHARACTERISTIC

SYMBOL

MIN.

TYP.

MAX.

UNIT

TEST CONDITIONS

Saturated Drain Current

Idss

430

≠

860

mA

Vds = 2.5 V, Vgs = 0 V

Pinch-off Voltage

V

P

≠3.0

≠

≠1.0

V

Vds = 2.5 V, Ids = 4 mA

Transconductance

gm

≠

300

≠

mS

Vds = 2.5 V, Ids = Idss

Thermal Resistance

R

th

≠

≠

30

∞C/W

PERFORMANCE SPECIFICATIONS (T

A

= 25 ∞C)

PART NUMBER

PACKAGE CODE

CHARACTERISTIC

SYMBOL

Output Power

P

O

Gate to source

Igs

Current

Linear Gain

G

L

*

Pin for Pout specification.

** The same conditions as the above except this.

NE8500100

NE8500100-WG

NE8500100-RG

CHIP

MIN.

TYP.

MAX.

28.5

≠

≠

≠2.0

≠

2.0

≠

9

≠

NE8500199

99

MIN.

TYP.

MAX.

28.5

≠

≠

≠2.0

≠

2.0

≠

9

≠

UNIT

dBm

mA

dB

TEST CONDITIONS

Pin

11 dBm (**)

f = 7.2 GHz

Vds = 10 V

Ids = 200 mA set

Rg = 1 k

Pin = 21.0 dBm(*)

NE85001 SERIES

3

TYPICAL CHARACTERISTICS (T

A

= 25 ∞C)

NE8500199

OUTPUT POWER vs. INPUT POWER

P

out

- Output Power - dBm

10

P

in

- Input Power - dBm

25

20

15

30

15

20

300

250

200

I

D

(mA)

V

DS

= 10 V

I

ds

= 200 mA set

f = 7.2 GHz

NE85001 SERIES

4

S-PARAMETER

V

DS

= 10 V, I

DS

= 200 mA, V

GS

= ≠1.260 V, I

G

= 0.0 mA, R

G

= 1 k

FREQUENCY

S

11

S

21

S

12

S

22

GHz

MAG

ANG

MAG

ANG

MAG

ANG

MAG

ANG

0.100

0.990

≠22.7

14.418

165.5

0.007

70.1

0.065

≠64.6

0.500

0.916

≠91.1

10.211

123.3

0.024

47.7

0.175

≠126.4

1.000

0.869

≠132.1

6.444

94.8

0.031

33.6

0.221

≠149.1

1.500

0.851

≠152.9

4.610

76.6

0.034

29.0

0.241

≠159.2

2.000

0.840

≠166.1

3.591

61.9

0.038

28.1

0.260

≠165.6

2.500

0.831

≠175.9

2.975

49.1

0.042

26.7

0.278

≠170.8

3.000

0.826

176.0

2.601

37.3

0.047

25.4

0.296

≠174.6

3.500

0.824

168.8

2.341

26.0

0.053

27.4

0.313

≠177.8

3.600

0.825

167.5

2.291

23.4

0.055

27.0

0.317

≠179.2

3.700

0.825

166.0

2.253

20.7

0.056

26.5

0.323

179.8

3.800

0.827

164.4

2.230

18.1

0.059

26.8

0.333

179.4

3.900

0.829

162.8

2.187

16.1

0.063

26.5

0.340

178.7

4.000

0.829

161.0

2.127

13.4

0.066

25.4

0.345

176.3

4.200

0.821

157.2

2.053

8.6

0.072

20.1

0.353

171.0

4.400

0.808

153.9

1.976

5.6

0.074

16.8

0.343

167.3

4.500

0.803

152.5

1.963

3.4

0.075

15.2

0.337

166.2

4.600

0.799

151.0

1.970

0.8

0.077

13.9

0.340

164.8

4.800

0.790

147.9

1.944

≠3.1

0.080

12.6

0.341

163.2

5.000

0.784

144.7

1.929

≠8.6

0.084

9.3

0.340

159.8

5.200

0.777

141.4

1.923

≠12.8

0.089

7.4

0.349

158.6

5.400

0.771

137.7

1.897

≠18.5

0.093

4.5

0.347

155.6

5.500

0.767

135.9

1.916

≠20.7

0.097

3.1

0.358

154.2

5.600

0.764

133.9

1.916

≠22.7

0.100

1.8

0.363

154.5

5.800

0.758

130.1

1.887

≠28.5

0.105

≠1.9

0.358

151.6

6.000

0.751

125.8

1.928

≠33.5

0.113

≠4.8

0.381

149.5

6.200

0.742

121.3

1.896

≠39.1

0.116

≠8.0

0.369

146.8

6.400

0.731

116.6

1.951

≠44.8

0.126

≠11.6

0.397

144.2

6.500

0.726

114.1

1.951

≠47.2

0.130

≠13.2

0.396

144.2

6.600

0.721

111.6

1.936

≠50.6

0.133

≠15.9

0.387

141.8

6.800

0.707

106.1

1.973

≠56.8

0.143

≠20.4

0.411

138.6

7.000

0.689

100.2

1.957

≠62.4

0.149

≠23.9

0.402

137.1

7.200

0.676

93.9

2.004

≠69.1

0.163

≠28.9

0.424

133.8

7.400

0.657

87.1

2.002

≠74.9

0.171

≠33.3

0.425

132.3

7.500

0.649

83.4

2.013

≠78.8

0.177

≠36.8

0.431

129.4

7.600

0.640

79.9

2.045

≠82.4

0.185

≠39.6

0.448

127.2

7.800

0.621

71.8

2.042

≠88.6

0.195

≠45.0

0.452

123.8

8.000

0.604

63.2

2.067

≠96.6

0.206

≠51.8

0.465

117.2

8.200

0.590

53.4

2.078

≠103.5

0.216

≠57.8

0.478

112.7

8.400

0.584

42.7

2.088

≠112.0

0.227

≠65.4

0.492

104.8

8.500

0.577

37.0

2.102

≠115.5

0.232

≠68.0

0.500

102.7

8.600

0.574

31.2

2.083

≠119.1

0.237

≠71.2

0.501

100.1

8.800

0.570

18.8

2.088

≠127.8

0.246

≠78.3

0.519

93.0

9.000

0.571

5.9

2.072

≠135.7

0.253

≠84.7

0.534

87.2

9.200

0.583

≠7.6

2.044

≠144.6

0.264

≠92.3

0.545

80.1

9.400

0.599

≠21.4

2.040

≠153.1

0.274

≠99.3

0.568

73.6

9.500

0.611

≠28.5

2.030

≠157.9

0.277

≠103.2

0.577

69.7

9.600

0.619

≠35.9

2.008

≠162.9

0.281

≠107.4

0.583

65.8

9.800

0.631

≠50.4

1.943

≠173.2

0.284

≠115.9

0.600

56.3

10.000

0.631

≠62.9

1.812

177.3

0.280

≠123.6

0.587

47.0

NE85001 SERIES

5

CHIP HANDLING

DIE ATTACHMENT

Die attach can be accomplished with a Au-Sn (300

±

10 ∞C) performs in a forming gas environment. Epoxy die

attach is not recommended.

BONDING

Gate and drain bonding wires should be minimum length, semi-hard gold wire (3 - 8 % elongation) 30 microns or

less in diameter.

Bonding should be performed with a wedge tip that has a taper of approximately 15 %.

Die attach and bonding time should be kept to a minimum. As a general rule, the bonding operation should be

kept within a 280 ∞C _ 5 minute curve. If longer periods are required, the temperature should be lowered.

PRECAUTIONS

The user must operate in a clean, dry environment.

The chip channel is glassivated for mechanical protection only and does not preclude the necessity of a clean

environment.

The bonding equipment should be periodically checked for sources of surge voltage and should be properly

grounded at all times. In fact, all test and handling equipment should be grounded to minimize the possibilities of static

discharge.

2

NE85001 SERIES

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special:

Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

M4 94.11