| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LM2795 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

LM2794/LM2795

Current Regulated Switched Capacitor LED Supply with

Analog and PWM Brightness Control

General Description

The LM2794/95 is a fractional CMOS charge-pump that

provides four regulated current sources. It accepts an input

voltage range from 2.7V to 5.5V and maintains a constant

current determined by an external sense resistor.

The LM2794/5 delivers up to 80mA of load current to accom-

modate four White LEDs. The switching frequency is

325kHz. (min.) to keep the conducted noise spectrum away

from sensitive frequencies within portable RF devices.

Brightness can be controlled by both linear and PWM tech-

niques. A voltage between 0V and 3.0V may be applied to

the BRGT pin to linearly vary the LED current. Alternatively,

a PWM signal can be applied to the SD pin to vary the

perceived brightness of the LED. The SD pin reduces the

operating current to 2.3µA (typ.) The LM2794 is shut down

when the SD pin is low, and the LM2795 is shut down when

the SD pin is high.

The LM2794/95 is available in a micro SMD-14 CSP pack-

age.

Features

n

Regulated current sources with

±

0.5% matching

between any two outputs

n

High efficiency 3/2 boost function

n

Drives one, two, three or four white LEDs

n

2.7V to 5.5V Input Voltage

n

Up to 80mA output current

n

Analog brightness control

n

Active-low or high shutdown input ('94/95)

n

Very small solution size and no inductor

n

2.3µA (typ.) shutdown current

n

325kHz switching frequency (min.)

n

Constant Frequency generates predictable noise

spectrum

n

Standard Micro SMD-14 package: 2.08mm X 2.403mm

X 0.845mm High

n

Thin Micro SMD-14 package: 2.08mm X 2.403mm X

0.600mm High

Applications

n

White LED Display Backlights

n

White LED Keypad Backlights

n

1-Cell Li-Ion battery-operated equipment including

PDAs, hand-held PCs, cellular phones

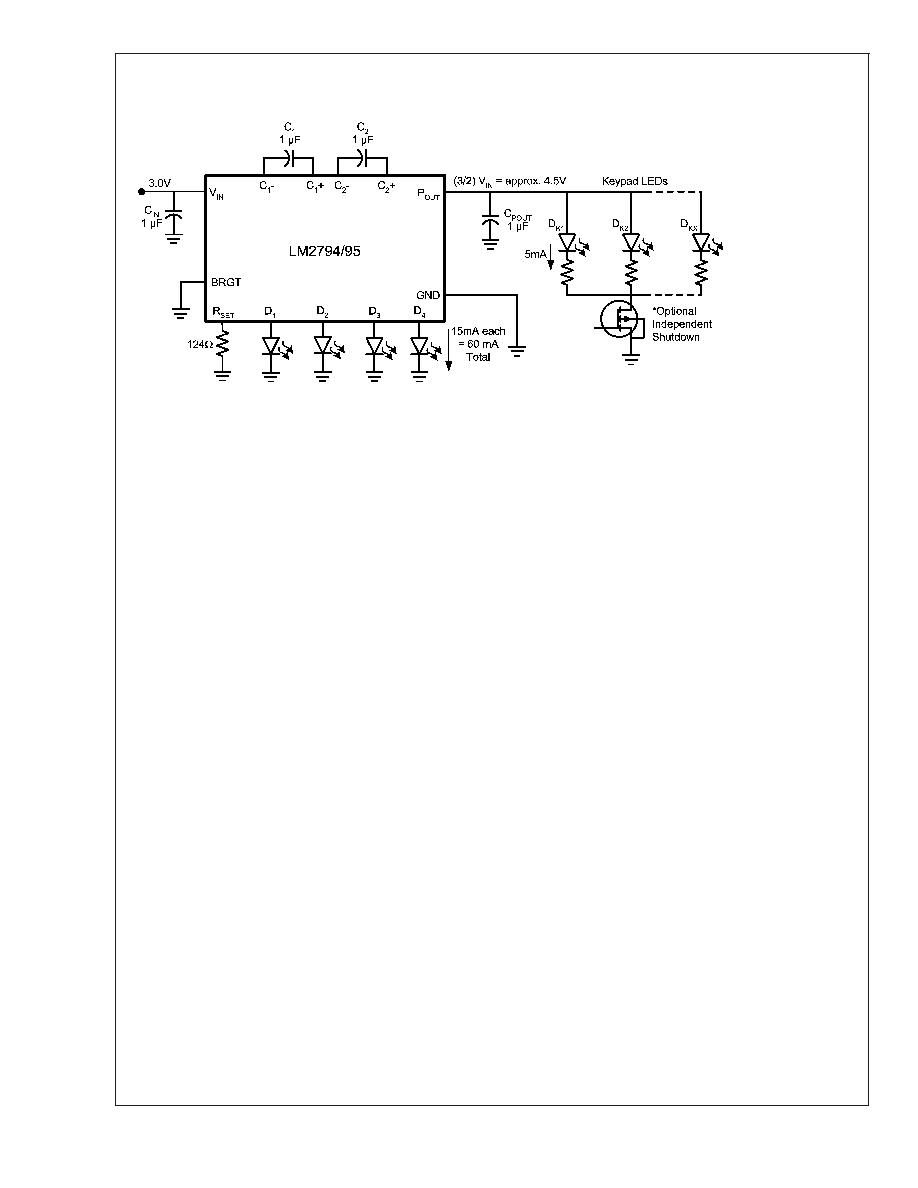

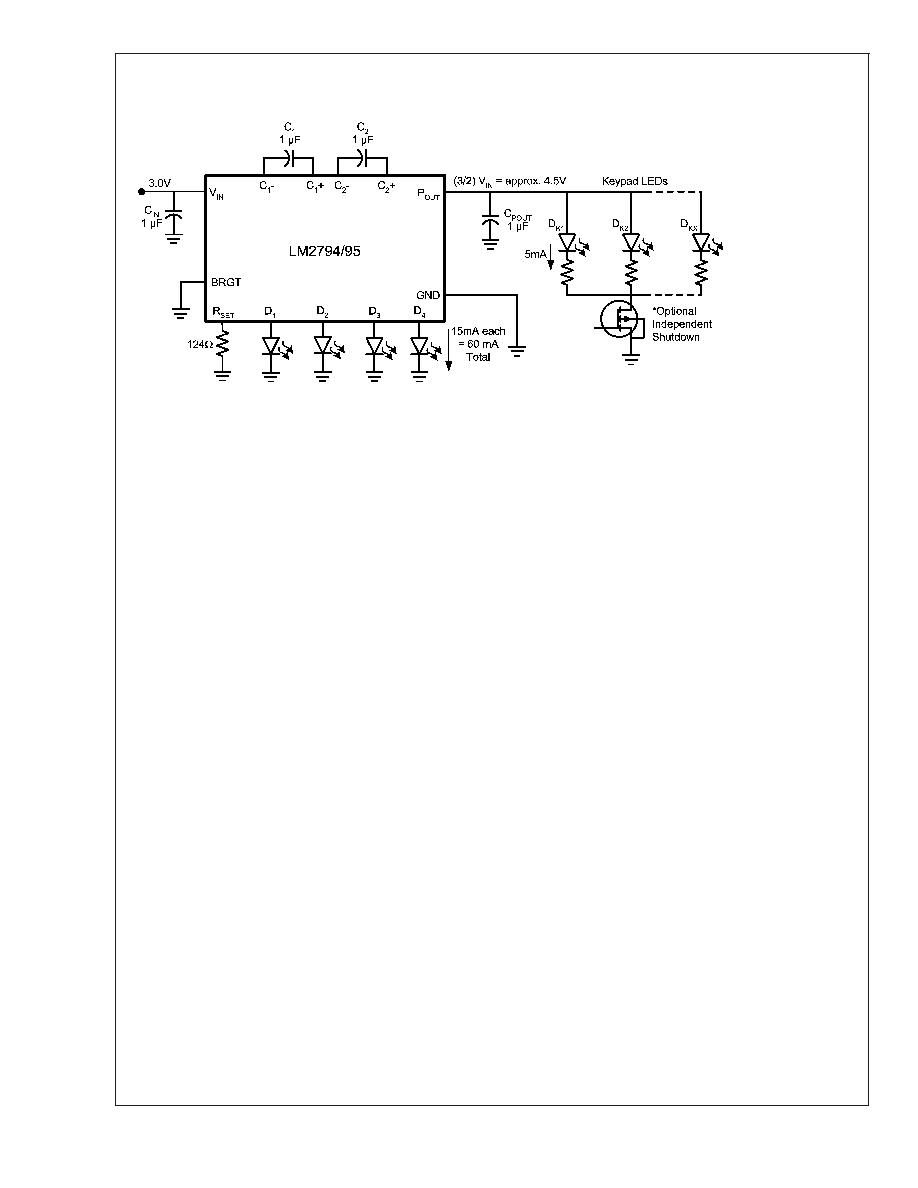

Basic Application Circuit

20028503

May 2003

LM2794/LM2795

Current

Regulated

Switched

Capacitor

LED

Supply

with

Analog

and

PWM

Brightness

Control

© 2003 National Semiconductor Corporation

DS200285

www.national.com

Connection Diagram

20028523

Bottom View

Ordering Information

Standard Micro SMD Package:

Order Number

Shutdown Polarity

Package Number

Package

Marking

Supplied As

LM2794BL

Active Low

BLP14EHB

I LOG

250 Units, Tape and Reel

LM2794BLX

Active Low

BLP14EHB

I LOG

3000 Units, Tape and Reel

LM2795BL

Active High

BLP14EHB

I LOJ

250 Units, Tape and Reel

LM2795BLX

Active High

BLP14EHB

I LOJ

3000 Units, Tape and Reel

Thin Micro SMD Package:

Order Number

Shutdown Polarity

Package Number

Package

Marking

Supplied As

LM2794TL

Active Low

TLP14EHA

I LOG

250 Units, Tape and Reel

LM2794TLX

Active Low

TLP14EHA

I LOG

3000 Units, Tape and Reel

LM2795TL

Active High

TLP14EHA

I LOJ

250 Units, Tape and Reel

LM2795TLX

Active High

TLP14EHA

I LOJ

3000 Units, Tape and Reel

Pin Description

Pin(*)

Name

Function

A1

C1+

Positive terminal of C1

B2

C1-

Negative terminal of C1

C1

V

IN

Power supply voltage input

D2

GND

Power supply ground input

E1

C2-

Negative terminal of C2

E3,E5,E7,D6

D1-4

Current source outputs. Connect directly to LED

C7

I

SET

Current Sense Input. Connect 1% resistor to ground to set constant current through LED

B6

BRGT

Variable voltage input controls output current

A7

SD

The LM2794 has an active-low shutdown pin (LOW = shutdown, HIGH = operating). The

LM2795 has an active-high shutdown pin (HIGH = shutdown, LOW = operating) that has a

pull-up to V

IN

.

A5

C2+

Positive terminal of C2

A3

P

OUT

Charge pump output

(*) Note that the pin numbering scheme for the Micro SMD package was revised in April, 2002 to conform to JEDEC standard. Only the pin numbers were revised.

No changes to the physical location of the inputs/outputs were made. For reference purpose, the obsolete numbering had C1+ as pin 1, C1- as pin 2, VIN as pin

3, GND as pin 4, C2- as pin 5, D1-D4 as pin 6,7,8 & 9, Iset as pin 10, BRGT as pin 11, SD as pin 12, C2+ as pin 13, Pout as pin 14

LM2794/LM2795

www.national.com

2

Absolute Maximum Ratings

(Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

-0.5 to 6.2V max

SD

-0.5 to (V

IN

+0.3V) w/

6.2V max

BRGT

-0.5 to (V

IN

+0.3V) w/

6.2V max

Continuous Power Dissipation

(Note 2)

Internally Limited

T

JMAX

(Note 2)

135∞C

JA

(Notes 2, 3)

125∞C/W

Storge Temperature

-65∞C to +150∞C

Lead Temp. (Soldering, 5 sec.)

260∞C

ESD Rating (Note 4)

Human Body Model

2kV

Machine Model

200V

Operating Conditions

Input Voltage (V

IN

)

2.7V to 5.5V

Ambient Temperature (T

A

)

-30∞C to +85∞C

Junction Temperature (T

J

)

-30∞C to +100∞C

Electrical Characteristics

Limits in standard typeface are for T

J

= 25∞C and limits in boldface type apply over the full Operating Junction Temperature

Range (-30∞C

T

J

+100∞C). Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1 µF, V

IN

= 3.6V, BRGT pin = 0V; R

SET

=124

; LM2794:V

SD

= V

IN

(LM2795: V

SD

= 0V).

Symbol

Parameter

Conditions

Min

Typ

Max

Units

I

DX

Available Current at Output Dx

3.0V

V

IN

5.5V

V

DX

3.8V

BRGT = 50mV

15

16.8

mA

2.7V

V

IN

3.0V

V

DX

3.6V

BRGT = 0V

10

mA

V

DX

3.8V

BRGT = 200mV

20

mA

V

DX

Available Voltage at Output Dx

3.0V

V

IN

5.5V

I

DX

15mA

BRGT = 50mV

3.8

V

I

DX

Line Regulation of Dx Output

Current

3.0V

V

IN

5.5V

V

DX

= 3.6V

14.18

15.25

16.78

mA

3.0V

V

IN

4.4V

V

DX

= 3.6V

14.18

15.25

16.32

mA

I

DX

Load Regulation of Dx Output

Current

V

IN

= 3.6V

3.0V

V

DX

3.8V

14.18

15.25

16.32

mA

I

D-MATCH

Current Matching Between Any

Two Outputs

V

IN

= 3.6V, V

DX

= 3.6V

0.5

%

I

Q

Quiescent Supply Current

3.0V

V

IN

4.2V, Active, No

Load Current

R

SET

= OPEN

5.5

8.2

mA

I

SD

Shutdown Supply Current

3.0V

V

IN

5.5V, Shutdown

2.3

5

µA

I

PULL-SD

Shutdown Pull-Up Current

(LM2795)

V

IN

= 3.6V

1.5

µA

V

CP

Input Charge-Pump Mode To

Pass Mode Threshold

4.7

V

V

CPH

Input Charge-Pump Mode To

Pass Mode Hysteresis

(Note 5)

250

mV

V

IH

SD Input Logic High (LM2794)

3.0V

V

IN

5.5V

1.0

V

SD Input Logic High (LM2795)

0.8V

IN

V

IL

SD Input Logic Low (LM2794)

3.0V

V

IN

5.5V

0.2

V

SD Input Logic Low (LM2795)

0.2V

IN

I

LEAK-SD

SD Input Leakage Current

0V

V

SD

V

IN

100

nA

R

BRGT

BRGT Input Resistance

240

k

I

SET

I

SET

Pin Output Current

I

DX

/10

mA

LM2794/LM2795

www.national.com

3

Electrical Characteristics

(Continued)

Limits in standard typeface are for T

J

= 25∞C and limits in boldface type apply over the full Operating Junction Temperature

Range (-30∞C

T

J

+100∞C). Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1 µF, V

IN

= 3.6V, BRGT pin = 0V; R

SET

=124

; LM2794:V

SD

= V

IN

(LM2795: V

SD

= 0V).

Symbol

Parameter

Conditions

Min

Typ

Max

Units

f

SW

Switching Frequency (Note 6)

3.0V

V

IN

4.4V

325

515

675

kHz

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Electrical specifications do not apply when operating the device

beyond its rated operating conditions.

Note 2: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at T

J

=150∞C (typ.) and disengages at

T

J

=140∞C (typ.). D1, D2, D3 and D4 may be shorted to GND without damage. P

OUT

may be shorted to GND for 1sec without damage.

Note 3: The value of

JA

is based on a two layer evaluation board with a dimension of 2in. x1.5in.

Note 4: In the test circuit, all capacitors are 1.0µF, 0.3

maximum ESR capacitors. Capacitors with higher ESR will increase output resistance, reduce output

voltage and efficiency.

Note 5: Voltage at which the device switches from charge-pump mode to pass mode or pass mode to charge-pump mode. For example, during pass mode the

device output (Pout) follows the input voltage.

Note 6: The output switches operate at one eigth of the oscillator frequency, f

OSC

= 1/8f

SW

.

LM2794/LM2795

www.national.com

4

Typical Performance Characteristics

Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1µF,

V

IN

= 3.6V, BRGT pin = 0V, R

SET

= 124

.

I

DIODE

vs V

IN

I

DIODE

vs BRGT

20028512

20028509

I

DIODE

vs V

IN

BRGT = 3V

I

DIODE

vs R

SET

20028507

20028508

I

DIODE

vs R

SET

V

BRGT

= 0V

I

DIODE

vs V

DIODE

20028541

20028524

LM2794/LM2795

www.national.com

5

Typical Performance Characteristics

Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1µF, V

IN

= 3.6V, BRGT pin = 0V, R

SET

= 124

. (Continued)

V

SET

vs V

BRGT

R

SET

= 1K

Duty Cycle vs. Led Current (LM2794)

I

DIODE

1- 4 = 15mA

20028506

20028532

Supply Current vs V

IN

I

DIODE

1-4 = 15mA

Supply Current vs V

IN

I

DIODE

1-4 = Open

20028514

20028515

Shutdown Supply Current vs V

IN

Shutdown Threshold vs V

IN

20028513

20028505

LM2794/LM2795

www.national.com

6

Typical Performance Characteristics

Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1µF, V

IN

= 3.6V, BRGT pin = 0V, R

SET

= 124

. (Continued)

Start-Up Response

@

V

IN

= 2.7V (LM2794)

Start-Up Response

@

V

IN

= 2.7V (LM2795)

20028517

20028520

Start-Up Response

@

V

IN

= 3.6V (LM2794)

Start-Up Response

@

V

IN

= 3.6V (LM2795)

20028518

20028522

Start-Up Response

@

V

IN

= 4.2V (LM2794)

Start-Up Response

@

V

IN

= 4.2V (LM2795)

20028519

20028521

LM2794/LM2795

www.national.com

7

Typical Performance Characteristics

Unless otherwise specified, C1 = C2 = C

IN

= C

HOLD

= 1µF, V

IN

= 3.6V, BRGT pin = 0V, R

SET

= 124

. (Continued)

Available Additional Current

@

P

OUT

I

DIODE

1- 4 = 15mA, R

SET

= 124

Switching Frequency

20028531

20028516

LM2794/LM2795

www.national.com

8

Functional Block Diagram

20028530

LM2794/LM2795

www.national.com

9

Application Information

CIRCUIT DESCRIPTION

The LM2794/5 is a 1.5x/1x CMOS charge pump with four

matched constant current outputs, each capable of driving

up to 20mA through White LEDs. This device operates over

the extended Li-Ion battery range from 2.7V to 5.5V. The

LM2794/5 has four regulated current sources connected to

the device's 1.5x charge pump output (P

OUT

). At input volt-

ages below 4.7V (typ.), the charge-pump provides the

needed voltage to drive high forward voltage drop White

LEDs. It does this by stepping up the P

OUT

voltage 1.5 times

the input voltage. The charge pump operates in Pass Mode,

providing a voltage on P

OUT

equal to the input voltage, when

the input voltage is at or above 4.7V (typ.). The device can

drive up to 80mA through any combination of LEDs con-

nected to the constant current outputs D

1

-D

4

.

To set the LED drive current, the device uses a resistor

connected to the I

SET

pin to set a reference current. This

reference current is then multiplied and mirrored to each

constant current output. The LED brightness can then be

controlled by analog and/or digital methods. Applying an

analog voltage in the range of 0V to 3.0V to the Brightness

pin (BRGT) adjusts the dimming profile of the LEDs. The

digital technique uses a PWM (Pulse Width Modulation)

signal applied to the Shutdown pin (SD). (see I

SET

and

BRGT PINS section).

SOFT START

Soft start is implemented internally by ramping the reference

voltage more slowly than the applied voltage. During soft

start, the current through the LED outputs will ramp up in

proportion to the rate that the reference voltage is being

ramped up.

SHUTDOWN MODE

The shutdown pin (SD) disables the part and reduces the

quiescent current to 2.3µA (typ.).

The LM2795 has an active-high shutdown pin (HIGH =

shutdown, LOW = operating). An internal pull-up is con-

nected between SD and V

IN

of the LM2795. This allows the

use of open-drain logic control of the LM2795 shutdown, as

shown in Figure 1. The LM2795 SD pin can also be driven

with a rail-to-rail CMOS logic signal.

The LM2794 has an active-low shutdown pin (LOW = shut-

down, HIGH = operating). The LM2794 SD pin can be driven

with a low-voltage CMOS logic signal (1.5V logic, 1.8V logic,

etc). There is no internal pull-up or pull-down on the SD pin

of the LM2794.

CAPACITOR SELECTION

The LM2794/5 requires 4 external capacitors for proper

operation. Surface-mount multi-layer ceramic capacitors are

recommended. These capacitors are small, inexpensive and

have very low equivalent series resistance (ESR,

15m

typ.). Tantalum capacitors, OS-CON capacitors, and alumi-

num electrolytic capacitors are generally not recommended

for use with the LM2794/5 due to their high ESR, as com-

pared to ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM2794/5. These capacitors have tight capacitance toler-

ance (as good as

±

10%), hold their value over temperature

(X7R:

±

15% over -55∞C to 125∞C; X5R:

±

15% over -55∞C

to 85∞C), and typically have little voltage coefficient. Capaci-

tors with Y5V or Z5U temperature characteristic are gener-

ally not recommended for use with the LM2794/5. Capaci-

tors with these temperature characteristics typically have

wide capacitance tolerance (+80%, -20%), vary significantly

over temperature (Y5V: +22%, -82% over -30∞C to +85∞C

range; Z5U: +22%, -56% over +10∞C to +85∞C range), and

have poor voltage coefficients. Under some conditions, a

nominal 1µF Y5V or Z5U capacitor could have a capacitance

of only 0.1µF. Such detrimental deviation is likely to cause

Y5V and Z5U capacitors to fail to meet the minimum capaci-

tance requirements of the LM2794/5. Table 1 lists suggested

capacitor suppliers for the typical application circuit.

TABLE 1. Ceramic Capacitor Manufacturers

Manufacturer

Contact

TDK

www.component.tdk.com

Murata

www.murata.com

Taiyo Yuden

www.t-yuden.com

LED SELECTION

The LM2794/5 is designed to drive LEDs with a forward

voltage of about 3.0V to 4.0V. The typical and maximum

diode forward voltage depends highly on the manufacturer

and their technology. Table 2 lists two suggested manufac-

turers. Forward current matching is assured over the LED

process variations due to the constant current output of the

LM2794/5.

TABLE 2. White LED Selection

Manufacturer

Contact

Osram

www.osram-os.com

Nichia

www.nichia.com

I

SET

AND BRGT PINS

An external resistor, R

SET

, is connected to the I

SET

pin to set

the current to be mirrored in each of the LED outputs. The

internal current mirror sets each LED output current with a

10:1 ratio to the current through R

SET

. The current mirror

circuitry matches the current through each LED to within

0.5%.

In addition to R

SET

, a voltage may be applied to the V

BRGT

pin to vary the LED current. By adjusting current with the

Brightness pin (BRGT), the brightness of the LEDs can be

smoothly varied.

20028536

FIGURE 1. Open-Drain Logic Shutdown Control

LM2794/LM2795

www.national.com

10

Application Information

(Continued)

Applying a voltage on BRGT between 0 to 3 volts will linearly

vary the LED current. Voltages above 3V do not increase the

LED current any further. The voltage on the V

BRGT

pin is fed

into an internal resistor network with a ratio of 0.385. The

resulting voltage is then summed with a measured offset

voltage of 0.188V, which comes from the reference voltage

being fed through a resistor network (See Functional Block

Diagram). The brightness control circuitry then uses the

summed voltage to control the voltage across R

SET

. An

equation for approximating the LED current is:

20028540

I

LED

CURRENT SELECTION PROCEDURES

The following procedures illustrate how to set and adjust

output current levels. For constant brightness or analog

brightness control, go to "Brightness control using BRGT".

Otherwise refer to "Brightness control using PWM".

Brightness Control Using PWM

1.

Set the BRGT pin to 0V.

2.

Determine the maximum desired I

LED

current. Use the

I

LED

equation to calculate R

SET

by setting BRGT to 0V or

use Table 3 to select a value for R

SET

when BRGT

equals 0V.

3.

Brightness control can be implemented by pulsing a

signal at the SD pin. LED brightness is proportional to

the duty cycle (D) of the PWM signal. For linear bright-

ness control over the full duty cycle adjustment range,

the PWM frequency (f) should be limited to accommo-

date the turn-on time (T

ON

= 100µs) of the device.

D x (1/f)

>

T

ON

f

MAX

= D

MIN

˜ T

ON

If the PWM frequency is much less than 100Hz, flicker

may be seen in the LEDs. For the LM2794, zero duty

cycle will turn off the LEDs and a 50% duty cycle will

result in an average I

LED

being half of the programmed

LED current. For example, if R

SET

is set to program

15mA, a 50% duty cycle will result in an average I

LED

of

7.5mA. For the LM2795 however, 100% duty cycle will

turn off the LEDs and a 50% duty cycle will result in an

average I

LED

being half the programmed LED current.

Brightness Control Using BRGT

1.

Choose the maximum I

LED

desired and determine the

max voltage to be applied to the BRGT pin. For constant

brightness, set BRGT to a fixed voltage between 0V to

3V.

2.

Use Table 3 to determine the value of R

SET

required or

use the I

LED

equation above to calculate R

SET

.

3.

Use Table 4 as a reference for the dimming profile of the

LEDs, when BRGT ranges from 0V to 3V.

TABLE 3. R

SET

Values

LED Current

BRGT

5mA

10mA

15mA

20mA

0.0V

374

187

124

93.1

0.5V

768

383

255

191

1.0V

1.15K

576

383

287

1.5V

1.54K

768

511

383

2.0V

1.91K

953

624

475

2.5V

2.32K

1.15K

768

576

3.0V

2.67K

1.33K

909

665

R

SET

values are rounded off to the nearest 1% standard values.

TABLE 4. LED Current

R

SET

Values

BRGT

2.67K

1.33K

909

665

0.0V

0.7mA

1.4mA

2.1mA

2.8mA

0.5V

1.4mA

2.9mA

4.2mA

5.7mA

1.0V

2.1mA

4.3mA

6.3mA

8.6mA

1.5V

2.9mA

5.8mA

8.4mA

11.5mA

2.0V

3.6mA

7.2mA

10.5mA

14.4mA

2.5V

4.3mA

8.7mA

12.7mA

17.3mA

3.0V

5.0mA

10.1mA

14.8mA

20.2mA

CHARGE PUMP OUTPUT (P

OUT

)

The LM2794/5 charge pump is an unregulated switched

capacitor converter with a gain of 1.5. The voltage at the

output of the pump (the P

OUT

pin) is nominally 1.5 x V

IN

. This

rail can be used to deliver additional current to other circuitry.

Figure 2 shows how to connect additional LEDs to P

OUT

. A

ballast resistor sets the current through each LED, and LED

current matching is dependent on the LED forward voltage

matching. Because of this, LEDs driven by P

OUT

are recom-

mended for functions where brightness matching is not criti-

cal, such as keypad backlighting.

Since P

OUT

is unregulated, driving LEDs directly off P

OUT

is

usually practical only with a fixed input voltage. If the input

voltage is not fixed (Li-Ion battery, for example), using a

linear regulator between the P

OUT

pin and the LEDs is

recommended. National Semiconductor's LP3985-4.5V low-

dropout linear regulator is a good choice for such an appli-

cation.

The voltage at P

OUT

is dependent on the input voltage

supplied to the LM2794/5, the total LM2794/5 output current,

and the output resistance (R

OUT

) of the LM2794/5 charge

pump. Output resistance is a model of the switching losses

of the charge pump. Resistances of the internal charge

pump switches (MOS transistors) are a primary component

of the LM2794/5 output resistance. Typical LM2794/5 output

resistance is 3.0

. For worst-case design calculations, using

an output resistance of 3.5

is recommended. (Worst-case

recommendation accounts for parameter shifts from part-to-

part variation and applies over the full operating temperature

range).

LM2794/LM2795

www.national.com

11

Application Information

(Continued)

20028535

FIGURE 2. Keypad LEDs Connected to P

OUT

LM2794/LM2795

www.national.com

12

Application Information

(Continued)

Output resistance results in droop in the P

OUT

voltage pro-

portional to the amount of current delivered by the pump.

The P

OUT

voltage is an important factor in determining the

total output current capability of an application. Taking total

output current to be the sum of all D

X

output currents plus

the current delivered through the P

OUT

pin, the voltage at

P

OUT

can be predicted with the following equations:

I

TOTAL

= I

D1

+ I

D2

+ I

D3

+ I

D4

+ I

POUT

V

POUT

= 1.5 x V

IN

- I

TOTAL

x R

OUT

LED HEADROOM VOLTAGE (V

HR

)

Four current sources are connected internally between P

OUT

and D

1

-D

4

. The voltage across each current source, (V

POUT

- V

DX

), is referred to as headroom voltage (V

HR

). The cur-

rent sources require a sufficient amount of headroom voltage

to be present across them in order to regulate properly.

Minimum required headroom voltage is proportional to the

current flowing through the current source, as dictated by the

equation:

V

HR-MIN

= k

HR

x I

DX

The parameter k

HR

, typically 20mV/mA in the LM2794/5, is a

proportionality constant that represents the ON-resistance of

the internal current mirror transistors. For worst-case design

calculations, using a k

HR

of 25mV/mA is recommended.

(Worst-case recommendation accounts for parameter shifts

from part-to-part variation and applies over the full operating

temperature range). Figure 3 shows how output current of

the LM2794/5 varies with respect to headroom voltage.

On the flat part of the graph, the currents regulate properly

as there is sufficient headroom voltage for regulation. On the

sloping part of the graph the headroom voltage is too small,

the current sources are squeezed, and their current drive

capability is limited. Changes in headroom voltage from one

output to the next, possible with LED forward voltage mis-

match, will result in different output currents and LED bright-

ness mismatch. Thus, operating the LM2794/5 with insuffi-

cient headroom voltage across the current sources should

be avoided.

OUTPUT CURRENT CAPABILITY

The primary constraint on the total current capability is the

headroom voltage requirement of the internal current

sources. Combining the V

POUT

and V

HR

equations from the

previous two sections yields the basic inequality for deter-

mining the validity of an LM2794/5 LED-drive application:

V

POUT

= 1.5 x V

IN

- I

TOTAL

x R

OUT

V

HR-MIN

= k

HR

x I

DX

V

POUT

- V

DX

V

HR-MIN

1.5 x V

IN

- I

TOTAL

x R

OUT

- V

DX

(k

HR

x I

DX

)

Rearranging this inequality shows the estimated total output

current capability of an application:

I

TOTAL

[(1.5 x V

IN-MIN

) - V

DX-MAX

- (k

HR

x I

DX

)] ˜ R

OUT

Examining the equation above, the primary limiting factors

on total output current capability are input and LED forward

voltage. A low input voltage combined with a high LED

voltage may result in insufficient headroom voltage across

the current sources, causing them to fall out of regulation.

When the current sources are not regulated, LED currents

will be below desired levels and brightness matching will be

highly dependent on LED forward voltage matching.

Typical LM2794/5 output resistance is 3.0

. For worst-case

design calculations, using an output resistance of 3.5

is

recommended. LM2794/5 has a typical k

HR

constant of

20mV/mA. For worst-case design calculations, use k

HR

=

25mV/mA. (Worst-case recommendations account for pa-

rameter shifts from part-to-part variation and apply over the

full operating temperature range). R

OUT

and k

HR

increase

slightly with temperature, but losses are typically offset by

the negative temperature coefficient properties of LED for-

ward voltages. Power dissipation and internal self-heating

may also limit output current capability but is discussed in a

later section.

PARALLEL Dx OUTPUTS FOR INCREASED CURRENT

DRIVE

Outputs D

1

through D

4

may be connected together in any

combination to drive higher currents through fewer LEDs.

For example in Figure 4, outputs D

1

and D

2

are connected

together to drive one LED while D

3

and D

4

are connected

together to drive a second LED.

20028539

FIGURE 3. I

LED

vs V

HR

4 LEDs, V

IN

= 3.0V

20028533

FIGURE 4. Two Parallel Connected LEDs

LM2794/LM2795

www.national.com

13

Application Information

(Continued)

With this configuration, two parallel current sources of equal

value provide current to each LED. R

SET

and V

BRGT

should

therefore be chosen so that the current through each output

is programmed to 50% of the desired current through the

parallel connected LEDs. For example, if 30mA is the de-

sired drive current for 2 parallel connected LEDs , R

SET

and

V

BRGT

should be selected so that the current through each of

the outputs is 15mA. Other combinations of parallel outputs

may be implemented in similar fashions, such as in Figure 5.

Connecting outputs in parallel does not affect internal opera-

tion of the LM2794/95 and has no impact on the Electrical

Characteristics and limits previously presented. The avail-

able diode output current, maximum diode voltage, and all

other specifications provided in the Electrical Characteristics

table apply to parallel output configurations, just as they do

to the standard 4-LED application circuit.

THERMAL PROTECTION

When the junction temperature exceeds 150∞C (typ.), the

LM2794/5 internal thermal protection circuitry disables the

part. This feature protects the device from damage due to

excessive power dissipation. The device will recover and

operate normally when the junction temperature falls below

140∞C (typ.). It is important to have good thermal conduction

with a proper layout to reduce thermal resistance.

POWER EFFICIENCY

Figure 6 shows the efficiency of the LM2794/5. The change

in efficiency shown by the graph comes from the transition

from Pass Mode to a gain of 1.5.

Efficiency (E) of the LM2794/5 is defined here as the ratio of

the power consumed by LEDs (P

LED

) to the power drawn

from the input source (P

IN

). In the equations below, I

Q

is the

quiescent current of the LM2794/5, I

LED

is the current flowing

through one LED, V

LED

is the forward voltage at that LED

current, and N is the number of LEDs connected to the

regulated current outputs. In the input power calculation, the

1.5 represents the switched capacitor gain configuration of

the LM2794/5.

P

LED

= N x V

LED

x I

LED

P

IN

= V

IN

x I

IN

P

IN

= V

IN

x (1.5 x N x I

LED

+ I

Q

)

E = (P

LED

˜ P

IN

)

Efficiency, as defined here, is in part dependent on LED

voltage. Variation in LED voltage does not affect power

consumed by the circuit and typically does not relate to the

brightness of the LED. For an advanced analysis, it is rec-

ommended that power consumed by the circuit (V

IN

x I

IN

) be

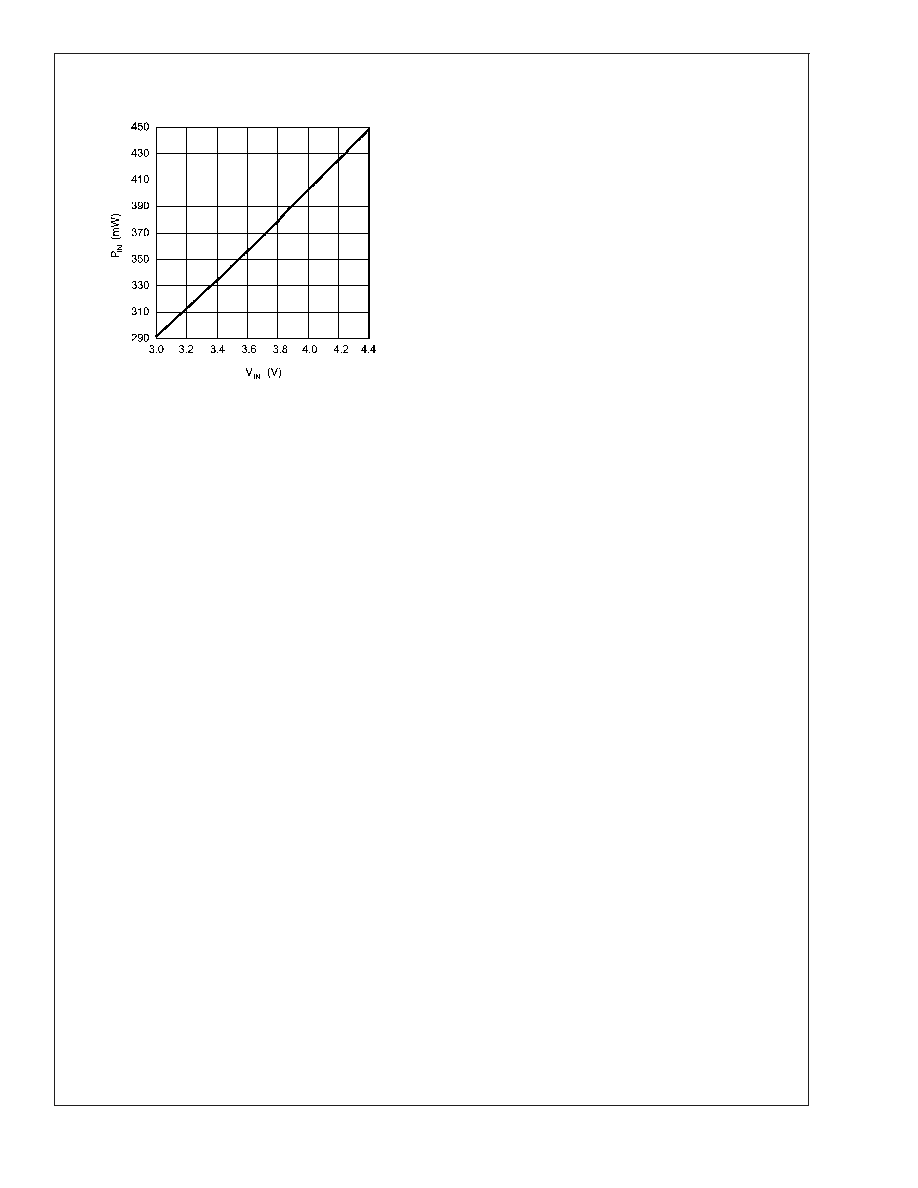

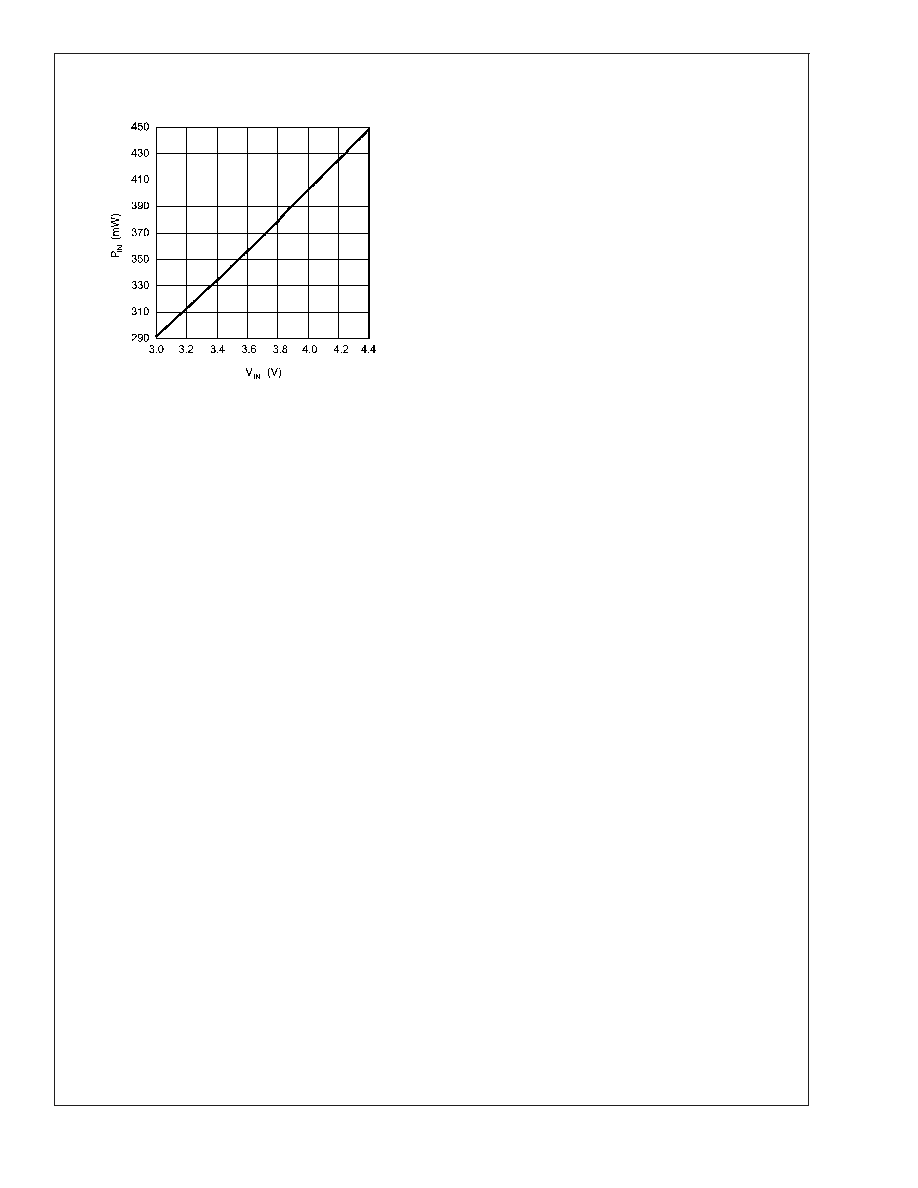

evaluated rather than power efficiency. Figure 7 shows the

power consumption of the LM2794/5 Typical Application Cir-

cuit.

20028534

FIGURE 5. One Parallel Connected LED

20028537

FIGURE 6. Efficiency vs V

IN

4 LEDs, V

LED

= 3.6V, I

LED

= 15mA

LM2794/LM2795

www.national.com

14

Application Information

(Continued)

POWER DISSIPATION

The power dissipation (P

DISSIPATION

) and junction tempera-

ture (T

J

) can be approximated with the equations below. P

IN

is the power generated by the 1.5x charge pump, P

LED

is the

power consumed by the LEDs, P

POUT

is the power provided

through the P

OUT

pin, T

A

is the ambient temperature, and

JA

is the junction-to-ambient thermal resistance for the micro

SMD-14 package. V

IN

is the input voltage to the LM2794/5,

V

DX

is the LED forward voltage, I

DX

is the programmed LED

current, and I

POUT

is the current drawn through P

OUT

.

P

DISSIPATION

= P

IN

- P

LED

- P

POUT

= [1.5xV

IN

x(4I

DX

+ I

POUT

)] - (V

DX

x4I

DX

) - (1.5xV

IN

xI

POUT

)

T

J

= T

A

+ (P

DISSIPATION

x

JA

)

The junction temperature rating takes precedence over the

ambient temperature rating. The LM2794/5 may be operated

outside the ambient temperature rating, so long as the junc-

tion temperature of the device does not exceed the maxi-

mum operating rating of 100∞C. The maximum ambient tem-

perature rating must be derated in applications where high

power dissipation and/or poor thermal resistance causes the

junction temperature to exceed 100∞C.

MICRO SMD MOUNTING

The LM2794/5 is a 14-bump micro SMD with a bump size of

300 micron diameter. The micro SMD package requires

specific mounting techniques detailed in National Semicon-

ductor Application Note (AN -1112). NSMD (non-solder mask

defined) layout pattern is recommended over the SMD (sol-

der mask defined) since the NSMD requires larger solder

mask openings over the pad size as opposed to the SMD.

This reduces stress on the PCB and prevents possible

cracking at the solder joint. For best results during assembly,

alignment ordinals on the PC board should be used to

facilitate placement of the micro SMD device. Micro SMD is

a wafer level chip size package, which means the dimen-

sions of the package are equal to the die size. As such, the

micro SMD package lacks the plastic encapsulation charac-

teristics of the larger devices and is sensitive to direct expo-

sure to light sources such as infrared, halogen, and sun light.

The wavelengths of these light sources may cause unpre-

dictable operation.

20028538

FIGURE 7. P

IN

vs V

IN

4 LEDs, 2.5

V

DX

3.9V, I

DX

= 15mA

LM2794/LM2795

www.national.com

15

Physical Dimensions

inches (millimeters) unless otherwise noted

Standard Micro SMD Package

For Ordering, Refer to Ordering Information Table

NS Package Number BLP14

The dimensions for X1, X2, X3 are given as:

X1 = 2.08mm

±

0.03mm

X2 = 2.403mm

±

0.03mm

X3 = 0.845mm

±

0.01mm

LM2794/LM2795

www.national.com

16

Physical Dimensions

inches (millimeters) unless otherwise noted (Continued)

Thin Micro SMD Package

For Ordering, Refer to Ordering Information Table

NS Package Number TLP14

The dimensions for X1, X2, X3 are given as:

X1 = 2.08mm

±

0.03mm

X2 = 2.403mm

±

0.03mm

X3 = 0.600mm

±

0.075mm

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English

Tel: +44 (0) 870 24 0 2171

FranÁais Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

LM2794/LM2795

Current

Regulated

Switched

Capacitor

LED

Supply

with

Analog

and

PWM

Brightness

Control

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.