©

Semiconductor Components Industries, LLC, 2004

April, 2004 - Rev. 5

1

Publication Order Number:

1.5SMC6.8AT3/D

1.5SMC6.8AT3 Series

1500 Watt Peak Power

Zener Transient Voltage

Suppressors

Unidirectional*

The SMC series is designed to protect voltage sensitive

components from high voltage, high energy transients. They have

excellent clamping capability, high surge capability, low zener

impedance and fast response time. The SMC series is supplied in

ON Semiconductor's exclusive, cost-effective, highly reliable

Surmetic

TM

package and is ideally suited for use in communication

systems, automotive, numerical controls, process controls, medical

equipment, business machines, power supplies and many other

industrial/consumer applications.

Specification Features:

∑

Working Peak Reverse Voltage Range - 5.8 to 77.8 V

∑

Standard Zener Breakdown Voltage Range - 6.8 to 91 V

∑

Peak Power - 1500 Watts @ 1.0 ms

∑

ESD Rating of Class 3 (>16 kV) per Human Body Model

∑

Maximum Clamp Voltage @ Peak Pulse Current

∑

Low Leakage < 5.0

mA Above 10 V

∑

UL 497B for Isolated Loop Circuit Protection

∑

Maximum Temperature Coefficient Specified

∑

Response Time is Typically < 1.0 ns

∑

Pb-Free Packages are Available

Mechanical Characteristics:

CASE:

Void-free, transfer-molded, thermosetting plastic

FINISH:

All external surfaces are corrosion resistant and leads are

readily solderable

MAXIMUM CASE TEMPERATURE FOR SOLDERING PURPOSES:

260

∞

C for 10 Seconds

LEADS:

Modified L-Bend providing more contact area to bond pads

POLARITY:

Cathode indicated by molded polarity notch

MOUNTING POSITION:

Any

MAXIMUM RATINGS

Please See the Table on the Following Page

PLASTIC SURFACE MOUNT

ZENER OVERVOLTAGE

TRANSIENT SUPPRESSORS

5.8 - 78 VOLTS

1500 WATT PEAK POWER

Device**

Package

Shipping

ORDERING INFORMATION

1.5SMCxxxAT3

SMC

2500/Tape & Reel

SMC

CASE 403

PLASTIC

Cathode

Anode

Y

= Year

WW

= Work Week

xxxA

= Specific Device Code

=

(See Table on Page 3)

YWW

xxxA

MARKING DIAGRAM

*Bidirectional devices will not be available in this se-

ries.

**The "T3" suffix refers to a 13 inch reel.

http://onsemi.com

Individual devices are listed on page 3 of this data sheet.

For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

1.5SMCxxxAT3G

SMC

(Pb-Free)

2500/Tape & Reel

1.5SMC6.8AT3 Series

http://onsemi.com

2

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Peak Power Dissipation (Note 1) @ T

L

= 25

∞

C, Pulse Width = 1 ms

P

PK

1500

W

DC Power Dissipation @ T

L

= 75

∞

C

Measured Zero Lead Length (Note 2)

Derate Above 75

∞

C

Thermal Resistance from Junction-to-Lead

P

D

R

q

JL

4.0

54.6

18.3

W

mW/

∞

C

∞

C/W

DC Power Dissipation (Note 3) @ T

A

= 25

∞

C

Derate Above 25

∞

C

Thermal Resistance from Junction-to-Ambient

P

D

R

q

JA

0.75

6.1

165

W

mW/

∞

C

∞

C/W

Forward Surge Current (Note 4) @ T

A

= 25

∞

C

I

FSM

200

A

Operating and Storage Temperature Range

T

J

, T

stg

-65 to +150

∞

C

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. 10 X 1000

m

s, non-repetitive

2. 1

square copper pad, FR-4 board

3. FR-4 board, using ON Semiconductor minimum recommended footprint, as shown in 403 case outline dimensions spec.

4. 1/2 sine wave (or equivalent square wave), PW = 8.3 ms, duty cycle = 4 pulses per minute maximum.

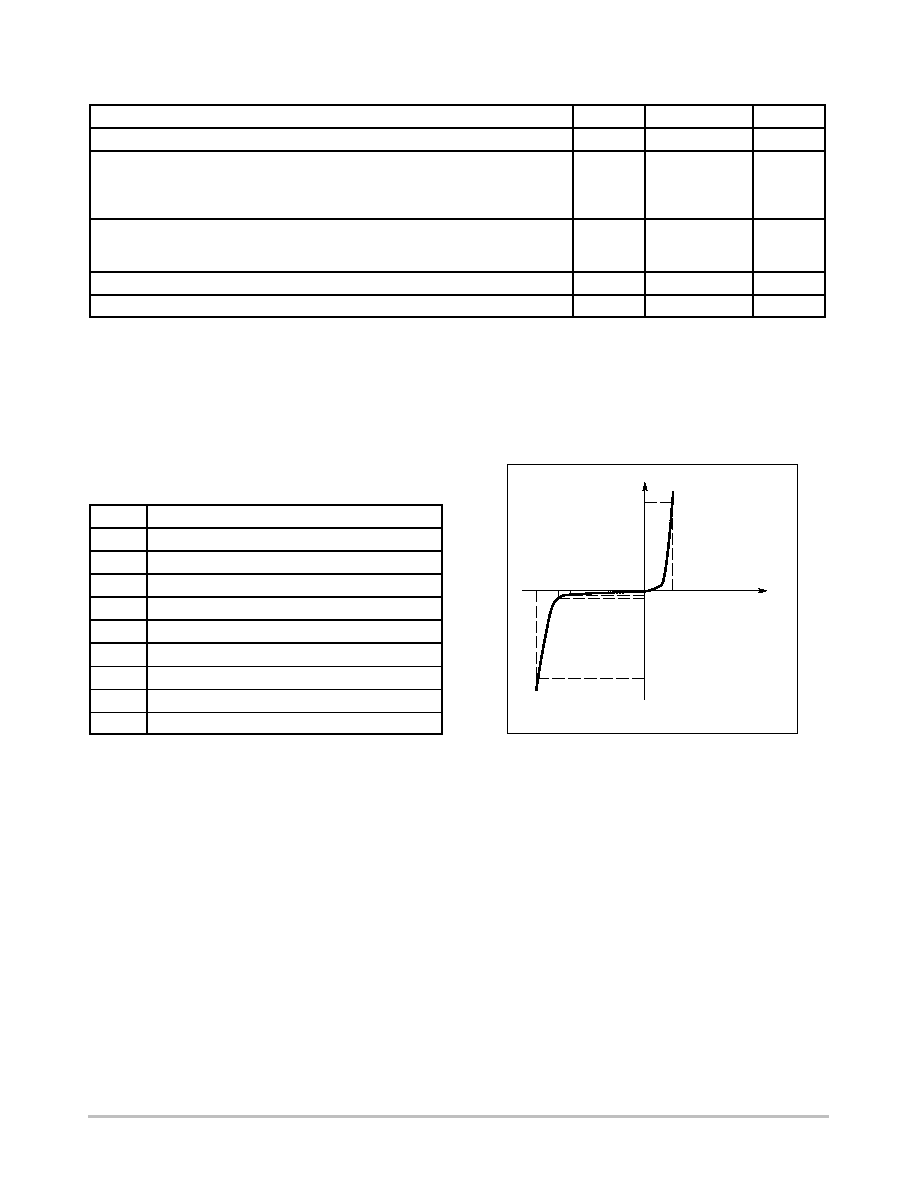

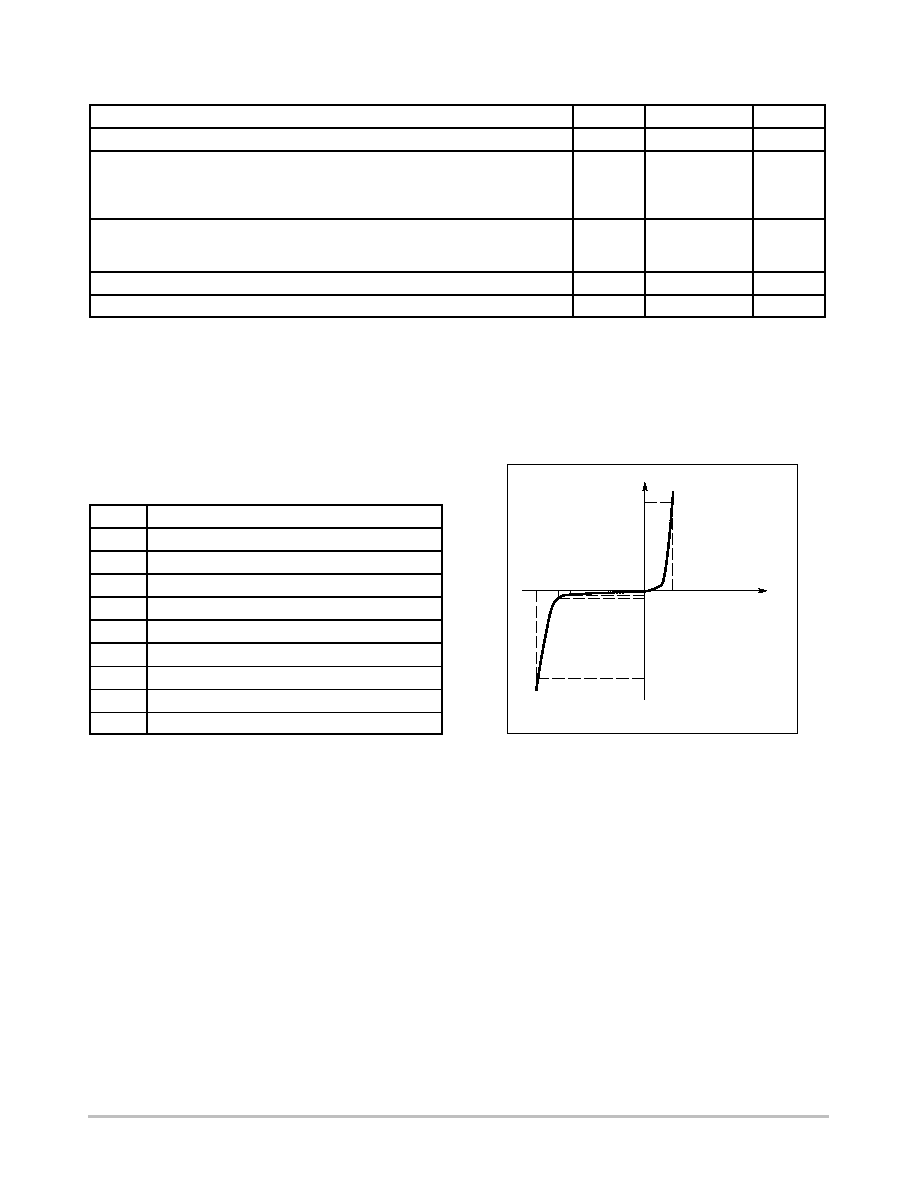

ELECTRICAL CHARACTERISTICS

(T

A

= 25

∞

C unless

otherwise noted, V

F

= 3.5 V Max. @ I

F

(Note 5) = 100 A)

Symbol

Parameter

I

PP

Maximum Reverse Peak Pulse Current

V

C

Clamping Voltage @ I

PP

V

RWM

Working Peak Reverse Voltage

I

R

Maximum Reverse Leakage Current @ V

RWM

V

BR

Breakdown Voltage @ I

T

I

T

Test Current

Q

V

BR

Maximum Temperature Coefficient of V

BR

I

F

Forward Current

V

F

Forward Voltage @ I

F

5. 1/2 sine wave or equivalent, PW = 8.3 ms

non-repetitive duty cycle

Uni-Directional TVS

I

PP

I

F

V

I

I

R

I

T

V

RWM

V

C

V

BR

V

F

1.5SMC6.8AT3 Series

http://onsemi.com

3

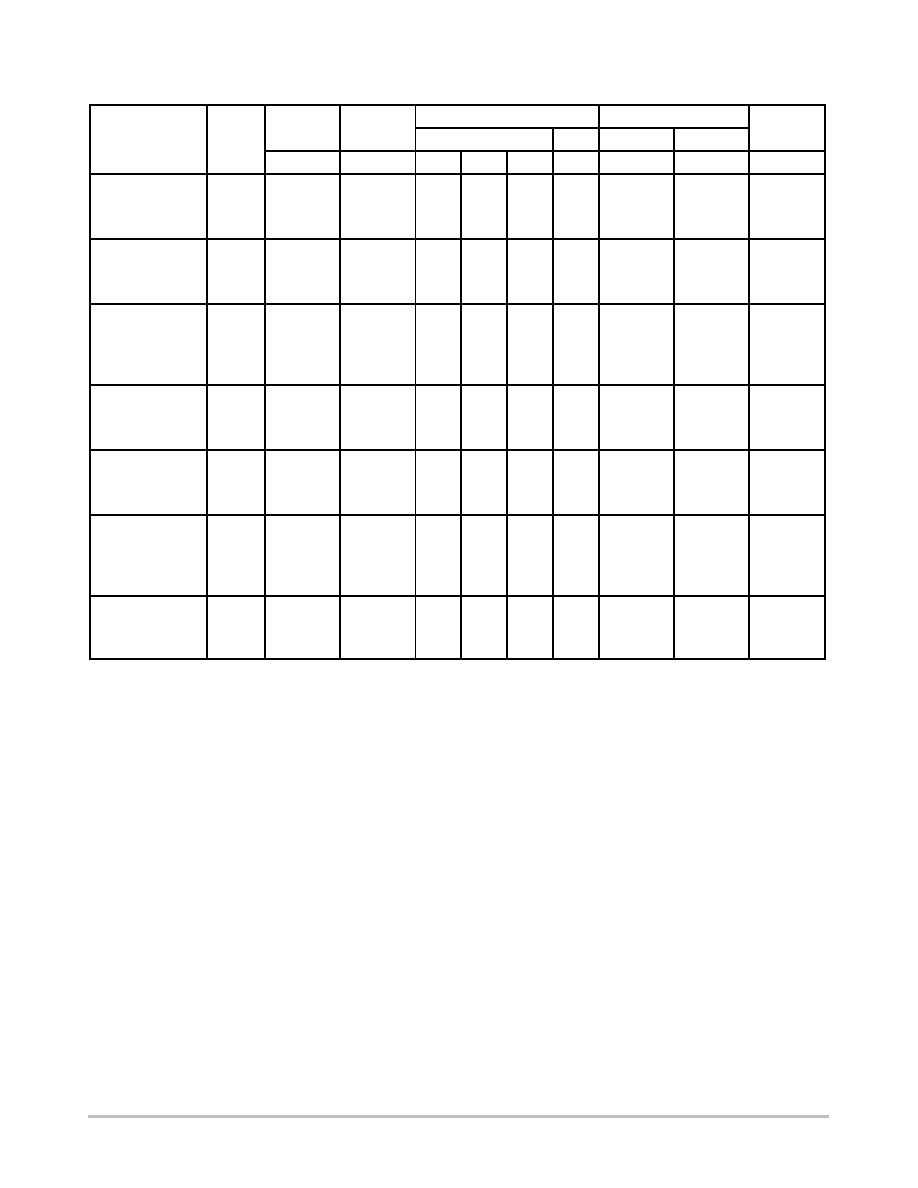

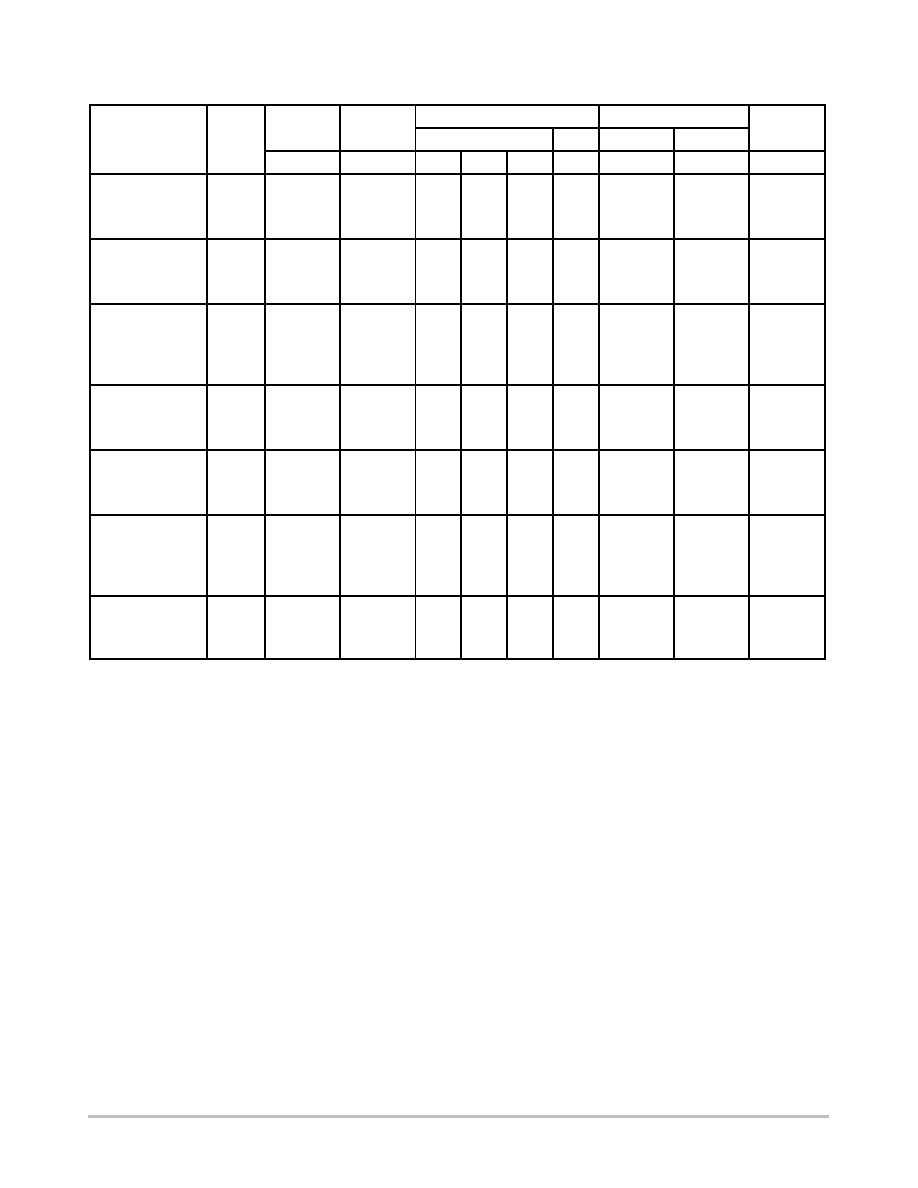

ELECTRICAL CHARACTERISTICS

(Devices listed in bold, italic are ON Semiconductor Preferred devices.)

V

RWM

Breakdown Voltage

V

C

@ I

PP

(Note 8)

Device

V

RWM

(Note 6)

I

R

@ V

RWM

V

BR

Volts (Note 7)

@ I

T

V

C

I

PP

Q

V

BR

Device

Device

Marking

Volts

m

A

Min

Nom

Max

mA

Volts

Amps

%/

∞

C

1.5SMC6.8AT3

1.5SMC7.5AT3

1.5SMC8.2AT3

1.5SMC9.1AT3

6V8A

7V5A

8V2A

9V1A

5.8

6.4

7.02

7.78

1000

500

200

50

6.45

7.13

7.79

8.65

6.8

7.5

8.2

9.1

7.14

7.88

8.61

9.55

10

10

10

1

10.5

11.3

12.1

13.4

143

132

124

112

0.057

0.061

0.065

0.068

1.5SMC10AT3

1.5SMC11AT3

1.5SMC12AT3

1.5SMC13AT3

10A

11A

12A

13A

8.55

9.4

10.2

11.1

10

5

5

5

9.5

10.5

11.4

12.4

10

11

12

13

10.5

11.6

12.6

13.7

1

1

1

1

14.5

15.6

16.7

18.2

103

96

90

82

0.073

0.075

0.078

0.081

1.5SMC15AT3

1.5SMC15AT3G

1.5SMC16AT3

1.5SMC18AT3

1.5SMC20AT3

15A

15A

16A

18A

20A

12.8

12.8

13.6

15.3

17.1

5

5

5

5

5

14.3

14.3

15.2

17.1

19

15

15

16

18

20

15.8

15.8

16.8

18.9

21

1

1

1

1

1

21.2

21.2

22.5

25.2

27.7

71

71

67

59.5

54

0.084

0.084

0.086

0.088

0.09

1.5SMC22AT3

1.5SMC24AT3

1.5SMC27AT3

1.5SMC30AT3

22A

24A

27A

30A

18.8

20.5

23.1

25.6

5

5

5

5

20.9

22.8

25.7

28.5

22

24

27

30

23.1

25.2

28.4

31.5

1

1

1

1

30.6

33.2

37.5

41.4

49

45

40

36

0.092

0.094

0.096

0.097

1.5SMC33AT3

1.5SMC36AT3

1.5SMC39AT3

1.5SMC43AT3

33A

36A

39A

43A

28.2

30.8

33.3

36.8

5

5

5

5

31.4

34.2

37.1

40.9

33

36

39

43

34.7

37.8

41

45.2

1

1

1

1

45.7

49.9

53.9

59.3

33

30

28

25.3

0.098

0.099

0.1

0.101

1.5SMC47AT3

1.5SMC51AT3

1.5SMC56AT3

1.5SMC62AT3

1.5SMC62AT3G

47A

51A

56A

62A

40.2

43.6

47.8

53

53

5

5

5

5

5

44.7

48.5

53.2

58.9

58.9

47

51

56

62

62

49.4

53.6

58.8

65.1

65.1

1

1

1

1

1

64.8

70.1

77

85

85

23.2

21.4

19.5

17.7

17.7

0.101

0.102

0.103

0.104

0.104

1.5SMC68AT3

1.5SMC75AT3

1.5SMC82AT3

1.5SMC91AT3

68A

75A

82A

91A

58.1

64.1

70.1

77.8

5

5

5

5

64.6

71.3

77.9

86.5

68

75

82

91

71.4

78.8

86.1

95.5

1

1

1

1

92

103

113

125

16.3

14.6

13.3

12

0.104

0.105

0.105

0.106

NOTE:

Devices listed in

bold, italic are ON Semiconductor Preferred devices. Preferred devices are recommended choices for future

use and best overall value.

* The "G" suffix indicates Pb-Free package available.

6. A transient suppressor is normally selected according to the working peak reverse voltage (V

RWM

), which should be equal to or greater than

the DC or continuous peak operating voltage level.

7. V

BR

measured at pulse test current I

T

at an ambient temperature of 25

∞

C.

8. Surge current waveform per Figure 2 and derate per Figure 3 of the General Data - 1500 Watt at the beginning of this group.

1.5SMC6.8AT3 Series

http://onsemi.com

4

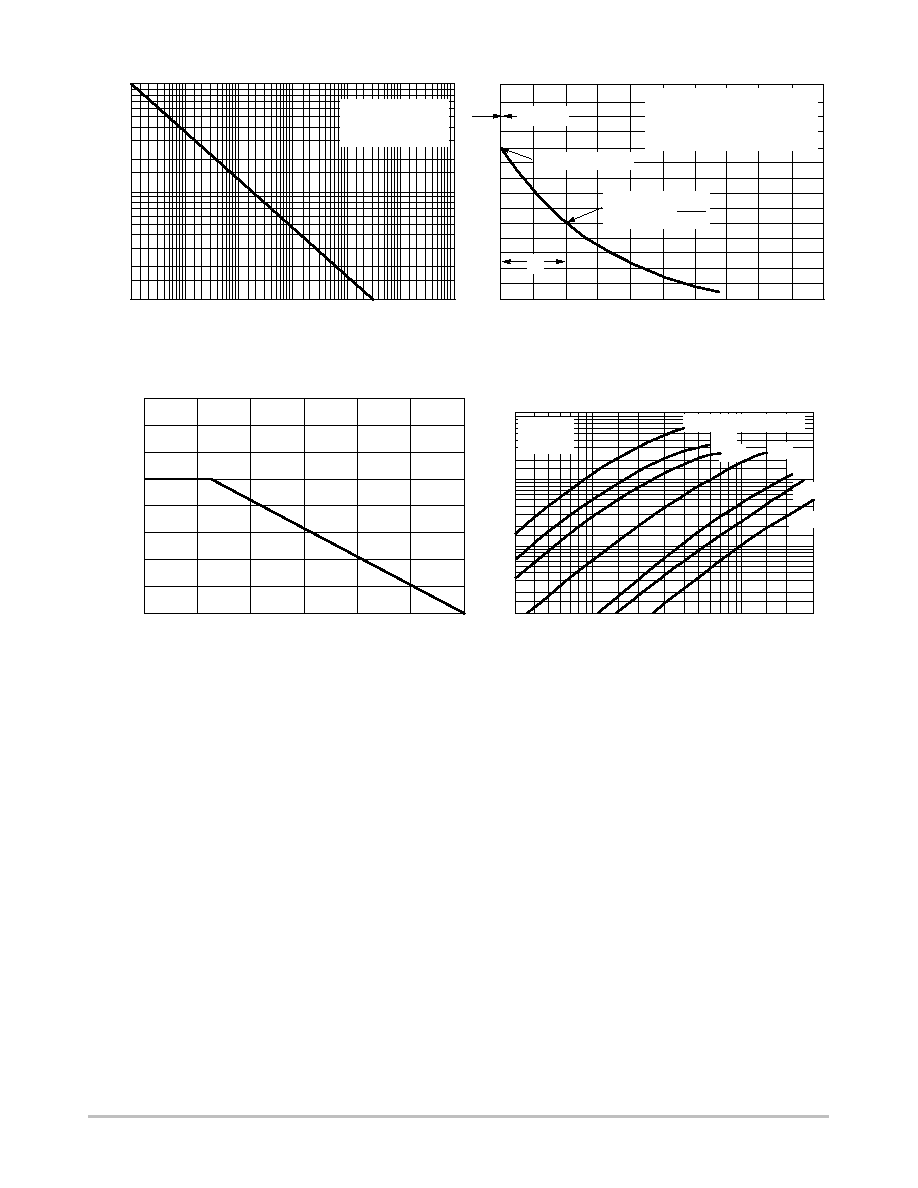

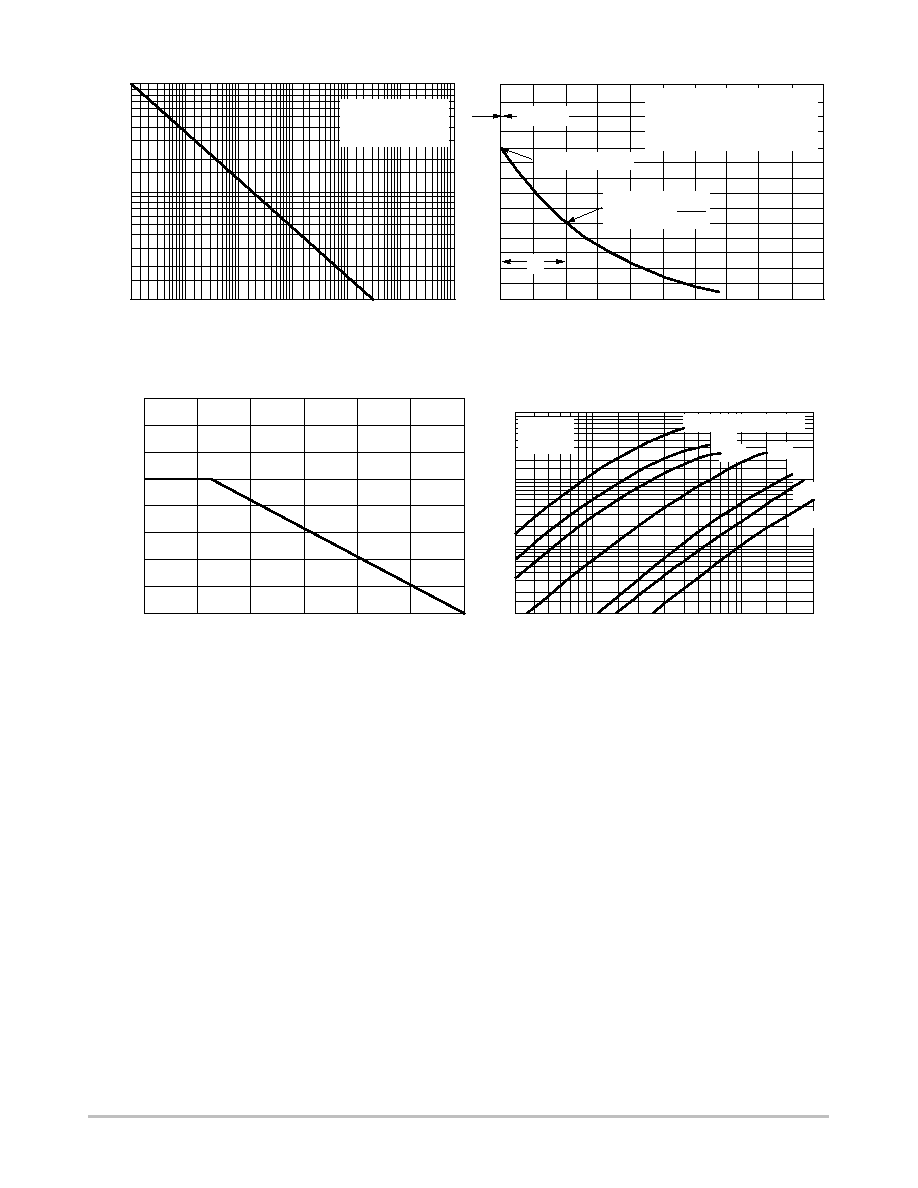

NONREPETITIVE

PULSE WAVEFORM

SHOWN IN FIGURE 2

t

P

, PULSE WIDTH

1

10

100

0.1

ms 1

ms

10

ms

100

ms

1 ms

10 ms

Figure 1. Pulse Rating Curve

0

1

2

3

4

0

50

100

t, TIME (ms)

V

ALUE (%)

HALF VALUE - I

PP

2

PEAK VALUE - I

PP

Figure 2. Pulse Waveform

Figure 3. Pulse Derating Curve

PEAK PULSE DERA

TING IN % OF

PEAK POWER OR CURRENT

@

T A

= 25

C

∞

100

80

60

40

20

0

0

25

50

75

100

125

150

T

A

, AMBIENT TEMPERATURE (

∞

C)

120

140

160

t

P

PULSE WIDTH (t

P

) IS DEFINED

AS THAT POINT WHERE THE PEAK

CURRENT DECAYS TO 50%

OF I

PP

.

DV

BR

, INSTANTANEOUS INCREASE IN V

BR

ABOVE V

BR

(NOM) (VOLTS)

0.3

0.5 0.7 1

2

3

5

7 10

20 30

1000

500

200

100

50

1

2

5

10

20

T

L

= 25

∞

C

t

P

= 10 ms

V

BR

(NOM) = 6.8 TO 13 V

20 V

24 V

43 V

75 V

120 V

180 V

Figure 4. Dynamic Impedance

P

pk

, PEAK POWER (kW)

t

r

10 ms

I

T

, TEST CURRENT (AMPS)

UL RECOGNITION

The entire series has Underwriters Laboratory

Recognition for the classification of protectors (QVGV2)

under the UL standard for safety 497B and File #116110.

Many competitors only have one or two devices recognized

or have recognition in a non-protective category. Some

competitors have no recognition at all. With the UL497B

recognition, our parts successfully passed several tests

including Strike Voltage Breakdown test, Endurance

Conditioning, Temperature test, Dielectric Voltage-Withstand

test, Discharge test and several more.

Whereas, some competitors have only passed a

flammability test for the package material, we have been

recognized for much more to be included in their Protector

category.

1.5SMC6.8AT3 Series

http://onsemi.com

5

APPLICATION NOTES

RESPONSE TIME

In most applications, the transient suppressor device is

placed in parallel with the equipment or component to be

protected. In this situation, there is a time delay associated

with the capacitance of the device and an overshoot

condition associated with the inductance of the device and

the inductance of the connection method. The capacitive

effect is of minor importance in the parallel protection

scheme because it only produces a time delay in the

transition from the operating voltage to the clamp voltage as

shown in Figure 5.

The inductive effects in the device are due to actual

turn-on time (time required for the device to go from zero

current to full current) and lead inductance. This inductive

effect produces an overshoot in the voltage across the

equipment or component being protected as shown in

Figure 6. Minimizing this overshoot is very important in the

application, since the main purpose for adding a transient

suppressor is to clamp voltage spikes. The SMC series have

a very good response time, typically < 1.0 ns and negligible

inductance. However, external inductive effects could

produce unacceptable overshoot. Proper circuit layout,

minimum lead lengths and placing the suppressor device as

close as possible to the equipment or components to be

protected will minimize this overshoot.

Some input impedance represented by Z

in

is essential to

prevent overstress of the protection device. This impedance

should be as high as possible, without restricting the circuit

operation.

DUTY CYCLE DERATING

The data of Figure 1 applies for non-repetitive conditions

and at a lead temperature of 25

∞

C. If the duty cycle increases,

the peak power must be reduced as indicated by the curves

of Figure 7. Average power must be derated as the lead or

ambient temperature rises above 25

∞

C. The average power

derating curve normally given on data sheets may be

normalized and used for this purpose.

At first glance the derating curves of Figure 7 appear to be

in error as the 10 ms pulse has a higher derating factor than

the 10

ms pulse. However, when the derating factor for a

given pulse of Figure 7 is multiplied by the peak power value

of Figure 1 for the same pulse, the results follow the

expected trend.