©

Semiconductor Components Industries, LLC, 2001

September, 2001 ≠ Rev. 5

1

Publication Order Number:

CS51021A/D

CS51021A, CS51022A,

CS51023A, CS51024A

Enhanced Current Mode

PWM Controller

The CS51021A/2A/3A/4A Fixed Frequency PWM Current Mode

Controller family provides all necessary features required for AC≠DC

or DC≠DC primary side control. Several features are included

eliminating the additional components needed to implement them

externally. In addition to low start≠up current (75

µ

A) and high

frequency operation capability, the CS51021A/2A/3A/4A family

includes overvoltage and undervoltage monitoring, externally

programmable dual threshold overcurrent protection, current sense

leading edge blanking, current slope compensation, accurate duty cycle

control and an externally available 5.0 V reference. The CS51021A

and CS51023A feature bidirectional synchronization capability, while

the CS51022A and CS51024A offer a sleep mode with 100

µ

A

maximum IC current consumption. The CS51021A/2A/3A/4A family

is available in a 16 lead narrow body SO package.

Device

Sleep/Synch

V

CC

Start/Stop

CS51021A

Synch

8.25 V/7.7 V

CS51022A

Sleep

8.25 V/7.7 V

CS51023A

Synch

13 V/7.7 V

CS51024A

Sleep

13 V/7.7 V

Features

∑

75

µ

A Max. Startup Current

∑

Fixed Frequency Current Mode Control

∑

1.0 MHz Switching Frequency

∑

Undervoltage Protection Monitor

∑

Overvoltage Protection Monitor with Programmable Hysteresis

∑

Programmable Dual Threshold Overcurrent Protection with

Delayed Restart

∑

Programmable Soft Start

∑

Accurate Maximum Duty Cycle Limit

∑

Programmable Slope Compensation

∑

Leading Edge Current Sense Blanking

∑

1.0 A Sink/Source Gate Drive

∑

Bidirectional Synchronization (CS51021A/3A)

∑

50 ns PWM Propagation Delay

∑

100

µ

A Max Sleep Current (CS51022A/4A)

http://onsemi.com

x

= Specific Device Code

A

= Assembly Location

WL, L

= Wafer Lot

YY, Y

= Year

WW, W = Work Week

SO≠16

D SUFFIX

CASE 751B

1

16

V

FB

I

SET

1

CS5102xA

A

W

L

YWW

16

COMP

R

T

C

T

SS

OV

LGND

UV

V

REF

SLOPE

V

CC

SLEEP or SYNC

PGND

I

SENSE

V

C

GATE

PIN CONNECTIONS AND

MARKING DIAGRAM

Device

Package

Shipping

ORDERING INFORMATION*

CS51021AED16

SO≠16

48 Units/Rail

CS51021AEDR16

SO≠16

2500 Tape & Reel

CS51022AED16

SO≠16

48 Units/Rail

CS51022AEDR16

SO≠16

2500 Tape & Reel

CS51023AED16

SO≠16

48 Units/Rail

CS51023AEDR16

SO≠16

2500 Tape & Reel

CS51024AED16

SO≠16

48 Units/Rail

CS51024AEDR16

SO≠16

2500 Tape & Reel

* Consult your local sales representative for other

package options.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

2

V

C

V

REF

COMP

V

FB

R

T

C

T

SYNC/

C

SS

V

CC

UV

OV

I

SET

SLOPE

GATE

I

SENSE

PGND

CS51021A/2A

LGND

SLEEP

22 k

4700 pF

51 k

10 k

0.01

µ

F

24.3 k,

1.0%

200 k,

1.0%

2.49 k,

1.0%

BA521

IRF6345

6.98 k,

1.0%

6.98 k,

1.0%

470 pF

100 p

100

10 k

62

680 pF

100

µ

F 100

µ

F

V

OUT

SGND

(5 V/5 A)

10

FZT688

SYNC/SLEEP

22

µ

F

18 V

BAS21

51 k

11 V

(36 V to 72 V)

PGND

0.01

µ

F

1.0

µ

F

100

100:1

4:1

2:5

10

V

IN

MOC81025

TL431

1000 pF

5.1 k

0.1

µ

F

2.0 k, 1.0%

2.0 k,

1.0%

1.0 k

180

1.0 K

10 K

330 pF

Figure 1. Typical Application Diagram, 36≠72 V to 5.0 V, 5.0 A DC≠DC Converter

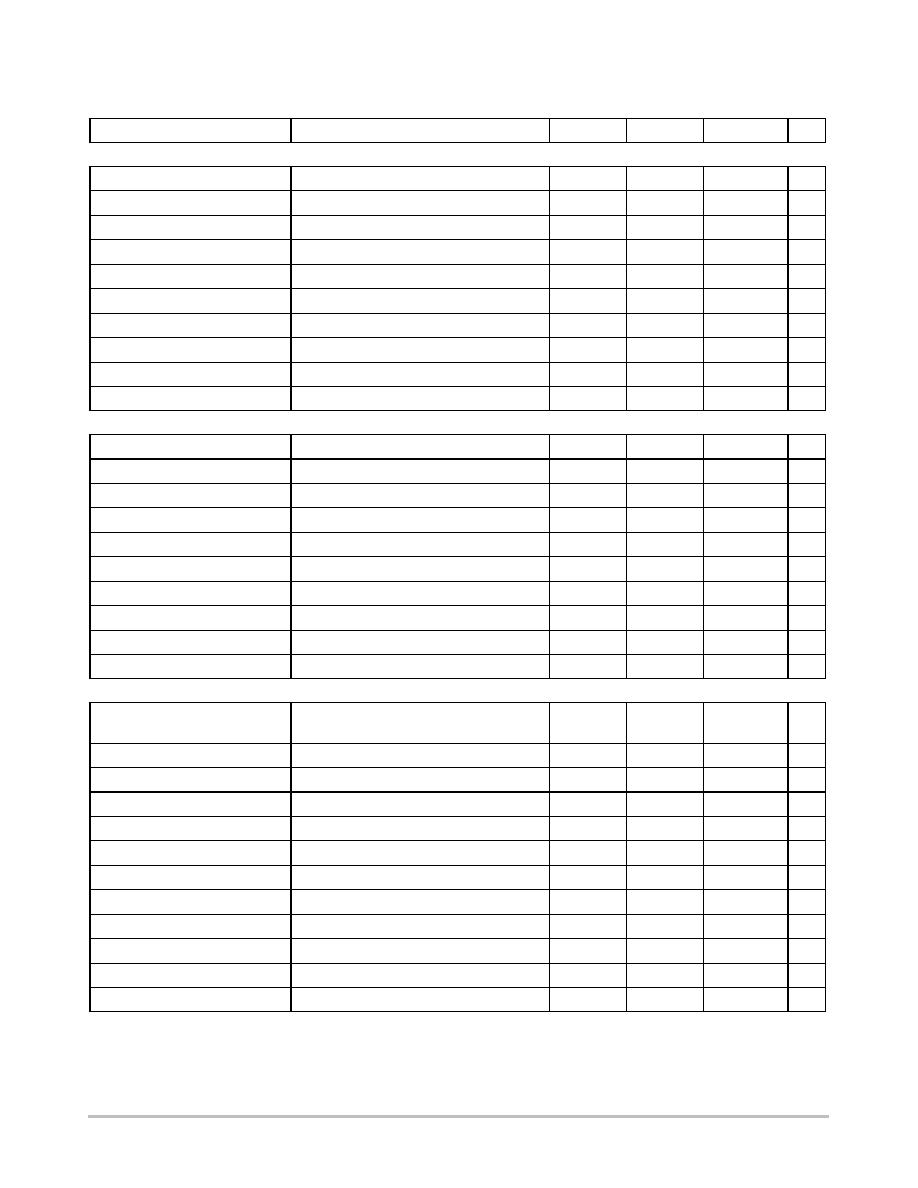

MAXIMUM RATINGS*

Rating

Value

Unit

Power Supply Voltage, V

CC

≠0.3, 20

V

Driver Supply Voltage, V

C

≠0.3, 20

V

SYNC, SLEEP, R

T

C

T

, SOFT START, V

FB

, SLOPE, I

SENSE

, UV, OV, I

SET

(Logic Pins)

0.25 to V

REF

V

Peak GATE Output Current

1.0

A

Steady State Output Current

±

0.2

A

Operating Junction Temperature, T

J

150

∞

C

Storage Temperature Range, T

S

≠65 to +150

∞

C

ESD (Human Body Model)

2.0

kV

Lead Temperature Soldering:

Reflow: (SMD styles only) (Note 1)

230 peak

∞

C

1. 60 second maximum above 183

∞

C.

*The maximum package power dissipation must be observed.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

3

ELECTRICAL CHARACTERISTICS

(Unless otherwise stated, specifications apply for ≠40

∞

C < T

A

< 85

∞

C,

≠40

∞

C < T

J

< 150

∞

C, 3.0 V < V

C

< 20 V, 8.2 V < V

CC

< 20 V, R

T

= 12 k

, C

T

= 390 pF)

Characteristic

Test Conditions

Min

Typ

Max

Unit

Under Voltage Lockout

START Threshold (CS51021A/2A)

≠

7.95

8.25

8.8

V

START Threshold (CS51023A/4A)

≠

12.4

13

13.4

V

STOP Threshold

≠

7.4

7.7

8.2

V

Hysteresis (CS51021A/2A)

≠

0.50

0.75

1.00

V

Hysteresis (CS51023A/4A)

≠

4.0

5.0

6.0

V

I

CC

@ Startup (CS51021A/2A)

V

CC

< UV

START

Threshold

≠

40

75

µ

A

I

CC

@ Startup (CS51023A/4A)

V

CC

< UV

START

Threshold

≠

45

75

µ

A

I

CC

Operating (CS51021A/3A)

≠

≠

7.0

9.0

mA

I

CC

Operating (CS51022A/4A)

≠

≠

6.0

8.0

mA

I

CC

Operating

Includes 1.0 nF Load

≠

7.0

12

mA

Voltage Reference

Initial Accuracy

T

A

= 25

∞

C, I

REF

= 2.0 mA, V

CC

= 14 V, Note 2

4.95

5.0

5.05

V

Total Accuracy

1.0 mA < I

REF

< 10 mA

4.9

5.0

5.15

V

Line Regulation

8.2 V < V

CC

< 18 V, I

REF

= 2.0 mA

≠

6.0

20

mV

Load Regulation

1.0 mA < I

REF

< 10 mA

≠

6.0

15

mV

NOISE Voltage

Note 2

≠

50

≠

µ

V

OP Life Shift

T = 1000 Hours, Note 2

≠

4.0

20

mV

FAULT Voltage

Force V

REF

0.90

◊

V

REF

0.93

◊

V

REF

0.95

◊

V

REF

V

OK Voltage

Force V

REF

0.94

◊

V

REF

0.96

◊

V

REF

0.985

◊

V

REF

V

OK Hysteresis

Force V

REF

75

165

250

mV

Current Limit

Force V

REF

≠20

≠

≠

mA

Error Amplifier

Initial Accuracy

T

A

= 25

∞

C, I

REF

= 2.0 mA, V

CC

= 14 V,

V

FB

= COMP, Note 2

2.465

2.515

2.565

V

Reference Voltage

V

FB

= COMP

2.440

2.515

2.590

V

V

FB

Leakage Current

V

FB

= 0 V

≠

≠0.2

≠2.0

µ

A

Open Loop Gain

1.4 V < COMP < 4.0 V, Note 2

60

90

≠

dB

Unity Gain Bandwidth

Note 2

1.5

2.5

≠

MHz

COMP Sink Current

COMP = 1.5 V, V

FB

= 2.7 V

2.0

6.0

≠

mA

COMP Source Current

COMP = 1.5 V, V

FB

= 2.3 V

≠0.2

≠0.5

≠

mA

COMP High Voltage

V

FB

= 2.3 V

4.35

4.8

5.0

V

COMP Low Voltage

V

FB

= 2.7 V

0.4

0.8

1.2

V

PS Ripple Rejection

FREQ = 120 Hz, Note 2

60

85

≠

dB

SS Clamp, V

COMP

V

SS

= 2.5 V, V

FB

= 0 V, I

SET

= 2.0 V

2.4

2.5

2.6

V

I

LIM(SET)

Clamp

Note 2

0.95

1.0

1.15

V

2. Guaranteed by design, not 100% tested in production.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

4

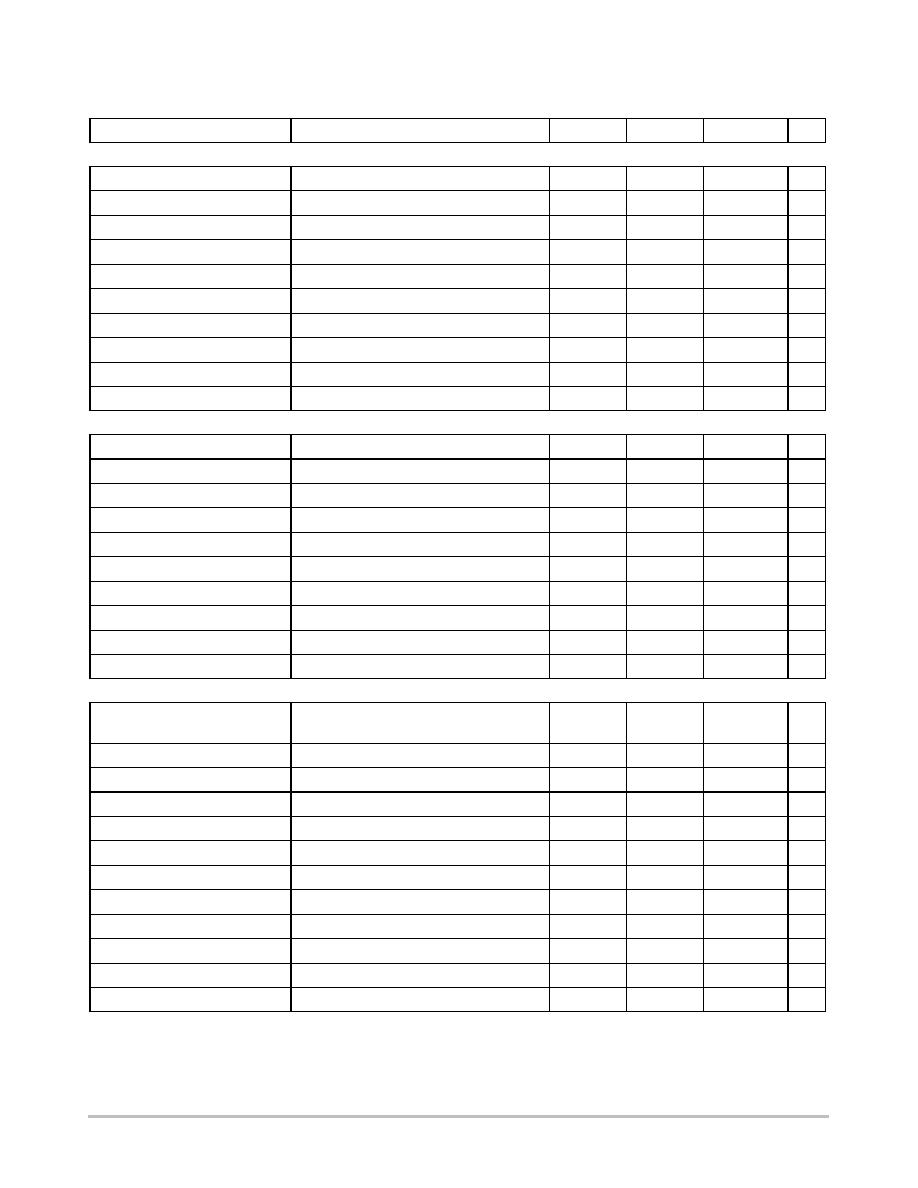

ELECTRICAL CHARACTERISTICS (continued)

(Unless otherwise stated, specifications apply for ≠40

∞

C < T

A

< 85

∞

C,

≠40

∞

C < T

J

< 150

∞

C, 3.0 V < V

C

< 20 V, 8.2 V < V

CC

< 20 V, R

T

= 12 k

, C

T

= 390 pF)

Characteristic

Unit

Max

Typ

Min

Test Conditions

Oscillator

Accuracy

R

T

= 12 k, C

T

= 390 pF

230

255

280

kHz

Voltage Stability

Delta Frequency 8.2 V < V

CC

< 20 V

≠

2.0

3.0

%

Temperature Stability

T

MIN

< T

A

< T

MAX,

Note

3

≠

8.0

≠

%

Min Charge & Discharge Time

Note 3

0.333

≠

≠

µ

s

Duty Cycle Accuracy

R

T

= 12 k, C

T

= 390 pF

70

77

83

%

Peak Voltage

Note 3

≠

3.0

≠

V

Valley Voltage

Note 3

≠

1.5

≠

V

Valley Clamp Voltage

10 k Resistor to ground on R

T

C

T

1.2

1.4

1.6

V

Discharge Current

≠

0.8

1.0

1.2

mA

Discharge Current

TA = 25

∞

C, Note 3

0.925

1.0

1.075

mA

Synchronization (CS51021A/3A)

Input Threshold

≠

1.0

1.5

2.7

V

Output Pulsewidth

≠

160

260

400

ns

Output High Voltage

I

SYNC

= 100

µ

A

3.5

4.3

4.8

V

Input Resistance

Note 3

35

70

140

k

Drive Delay

SYNC to GATE RESET

80

120

150

ns

Output Drive Current

1.0 k Load

1.25

2.0

3.5

mA

SLEEP (CS51022A/4A)

SLEEP Input Threshold

Active High

1.0

1.5

2.7

V

SLEEP Input Current

V

SLEEP

= 4.0 V

11

25

46

µ

A

I

CC

@ SLEEP

V

CC

15 V

≠

50

100

µ

A

GATE Driver

HIGH Voltage

Measure V

C

≠ GATE, V

C

= 10 V, 150 mA Load

≠

1.5

2.2

V

LOW Voltage

Measure GATE ≠ PGND, 150 mA SINK

≠

1.2

1.5

V

HIGH Voltage Clamp

V

C

= 20 V, 1.0 nF

11

13.5

16

V

LOW Voltage Clamp

Measured at 10 mA Output Current

≠

0.6

0.8

V

Peak Current

V

C

= 20 V, 1.0 nF, Note 3

≠

1.0

≠

A

UVL Leakage

V

C

= 20 V measured at 0 V

≠

≠1.0

≠50

µ

A

RISE Time

Load = 1.0 nF, 1.0 V < GATE < 9.0 V,

V

C

= 20 V, T

A

= 25

∞

C

≠

60

100

ns

FALL Time

Load = 1.0 nF, 9.0 V > GATE > 1 .0 V,

V

C

= 20 V

≠

15

40

ns

SLOPE Compensation

Charge Current

SLOPE = 2.0 V

≠63

≠53

≠43

µ

A

COMP Gain

Fraction of slope voltage added to I

SENSE

,

Note 3

0.095

0.100

0.105

V/V

Discharge Voltage

SYNC = 0 V

≠

0.1

0.2

V

3. Guaranteed by design, not 100% tested in production.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

5

ELECTRICAL CHARACTERISTICS (continued)

(Unless otherwise stated, specifications apply for ≠40

∞

C < T

A

< 85

∞

C,

≠40

∞

C < T

J

< 150

∞

C, 3.0 V < V

C

< 20 V, 8.2 V < V

CC

< 20 V, R

T

= 12 k

, C

T

= 390 pF)

Characteristic

Unit

Max

Typ

Min

Test Conditions

Current Sense

OFFSET Voltage

Note 4

0.09

0.10

0.11

V

Blanking Time

≠

≠

55

160

ns

Blanking Disable Voltage

Adjust V

FB

1.8

2.0

2.2

V

Second Current Threshold Gain

≠

1.21

1.33

1.45

V/V

I

SENSE

Input Resistance

≠

≠

5.0

≠

k

Minimum On Time

GATE High to Low

30

70

110

ns

Gain

Note 4

0.78

0.80

0.82

V/V

OV & UV Voltage Monitors

OV Monitor Threshold

≠

2.4

2.5

2.6

V

OV Hysteresis Current

≠

≠10

≠12.5

≠15

µ

A

UV Monitor Threshold

≠

1.38

1.45

1.52

V

UV Monitor Hysteresis

≠

25

75

100

mV

SOFT START (SS)

Charge Current

SS = 2.0 V

≠70

≠55

≠40

µ

A

Discharge Current

SS = 2.0 V

250

1000

≠

µ

A

Charge Voltage, V

SS

≠

4.4

4.7

5.0

V

Discharge Voltage, V

SS

≠

0.25

0.27

0.30

V

4. Guaranteed by design, not 100% tested in production.

PACKAGE PIN DESCRIPTION

PACKAGE PIN #

PIN SYMBOL

FUNCTION

16 Lead SO Narrow

1

GATE

External power switch driver with 1.0 A peak capability.

2

I

SENSE

Current sense amplifier input.

3

SYNC (CS51021A/3A)

Bi≠directional synchronization. Locks to the highest frequency.

3

SLEEP (CS51022A/4A)

Active high chip disable. In sleep mode, V

REF

and GATE are turned off.

4

SLOPE

Additional slope to the current sense signal. Internal current source

charges the external capacitor.

5

UV

Undervoltage protection monitor.

6

OV

Overvoltage protection monitor.

7

R

T

C

T

Timing resistor R

T

and capacitor C

T

determine oscillator frequency and

maximum duty cycle, D

MAX.

8

I

SET

Voltage at this pin sets pulse≠by≠pulse overcurrent threshold, and sec-

ond threshold (1.33 times higher) with Soft Start retrigger (hiccup mode).

9

V

FB

Feedback voltage input. Connected to the error amplifier inverting input.

10

COMP

Error amplifier output. Frequency compensation network is usually

connected between COMP and V

FB

pins.

11

SS

Charging external capacitor restricts error amplifier output voltage dur-

ing the start or fault conditions (hiccup).

12

LGND

Logic ground.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

6

PACKAGE PIN DESCRIPTION (continued)

PACKAGE PIN #

FUNCTION

PIN SYMBOL

16 Lead SO Narrow

13

V

REF

5.0 V reference voltage output.

14

V

CC

Logic supply voltage.

15

PGND

Output power stage ground connection.

16

V

C

Output power stage supply voltage.

D

2

Start

+

≠

Stop

SS

+

≠

Clamp

E/A

+

≠

I

SET

≠

+

Clamp

D

3

D

1

20 k

10 k

V

FB

≠

+

Monitor

G

4

PWM

≠

+

Comp

55 ns

Blank

I

SENSE

SLOPE

V

FB

COMP

R

T

C

T

2nd

+

≠

Threshold

OV

+

≠

Monitor

DISABLE

0.1

0.8

Q

2

1.33

53

µ

A

I

SET

OV

12.5

µ

A

V

REF

2.5 V

+

≠

+

≠

2.0 V

+

≠

2.5 V

V

REF

V

ISENSE

SS

≠

+

Monitor

Discharge

Latch

UV

≠

+

Monitor

1.45 V

+

≠

4.7 V

+

≠

S

R

Q

F

1

G

1

G

2

D

4

ZD

1

13.5 V

V

C

GATE

PGND

SS

UV

G

3

FAULT

55

µ

A

V

REF

OSC

SYNC

4.3 V

200 ns

≠

+

V

REF

_OK

+

≠

4.75 V

V

REF

= 5.0 V

+

≠

+

≠

0.1 V

V

CC

_OK

V

REF

SLEEP

LGND

V

CC

Figure 2. Block Diagram

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

7

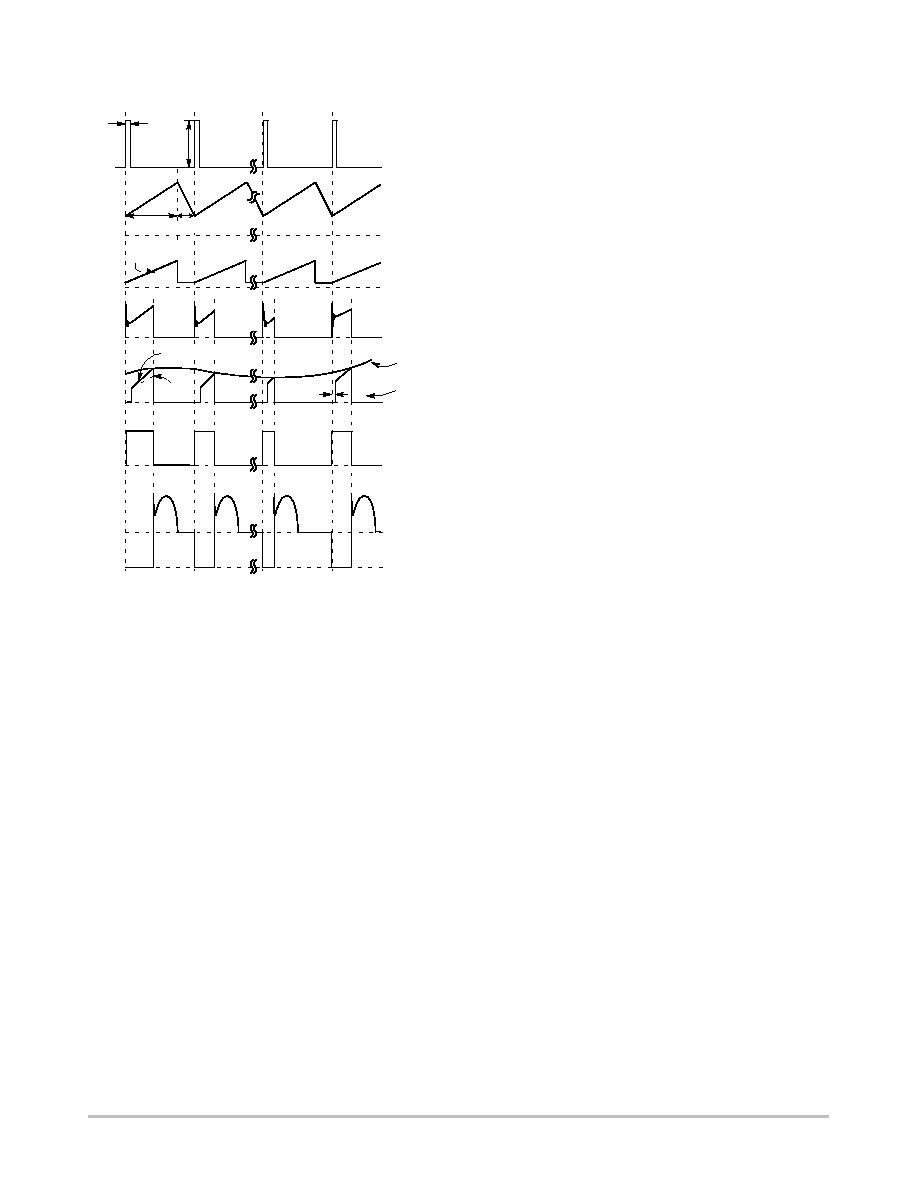

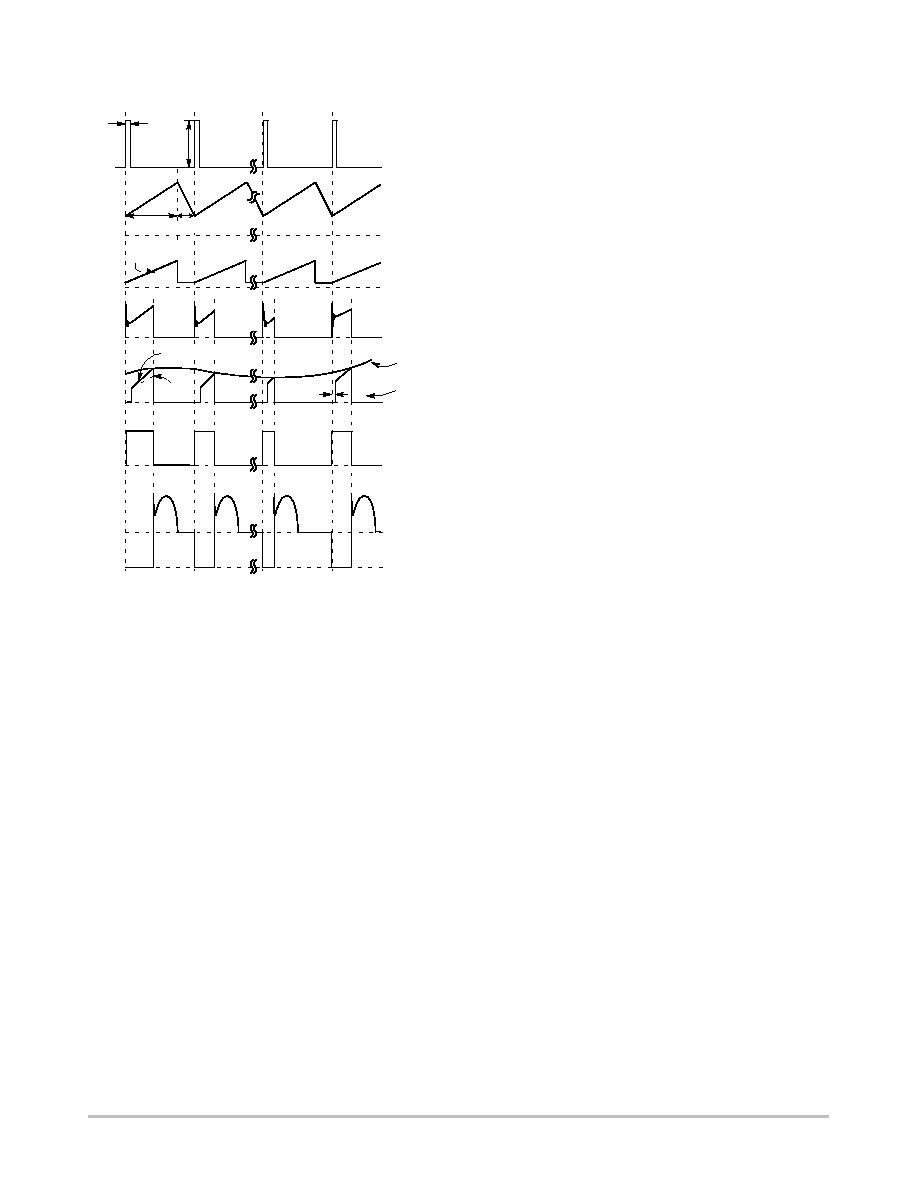

CIRCUIT DESCRIPTION

SYNC

R

T

C

T

SLOP

E

IS

V

DS

0 V

0 V

0 V

0 V

0 V

V

IN

0 V

V

COMP

PWM COMP

GATE

4.3 V

200 ns

T

CH

T

DIS

V

SLOPE

55 ns

Blanking

IS + 0.1 SLOPE

IS

Figure 3. Typical Waveforms

THEORY OF OPERATION

Powering the IC

The IC has two supply and two ground pins. V

C

and

PGND pins provide high speed power drive for the external

power switch. V

CC

and LGND pins power the control

portion of the IC. The internal logic monitors the supply

voltage, V

CC

. During abnormal operating conditions, the

output is held low. The CS51021A/2A/3A/4A requires only

75

µ

A of startup current.

Voltage Feedback

The output voltage is monitored via the V

FB

pin and is

compared with the internal 2.5 V reference. The error

amplifier output minus one diode drop is divided by 3 and

connected to the negative input of the PWM comparator.

The positive input of the PWM comparator is connected to

the modified current sense signal. The oscillator turns the

external power switch on at the beginning of each cycle.

When current sense ramp voltage exceeds the reference side

of PWM comparator, the output stage latches off. It is turned

on again at the beginning of the next oscillator cycle.

Current Sense and Protection

The current is monitored at the I

SENSE

pin. The

CS51021A/2A/3A/4A has leading edge blanking circuitry

that ignores the first 55 ns of each switching period.

Blanking is disabled when V

FB

is less than 2.0 V so that the

minimum on≠time of the controller does not have an

additional 55 ns of delay time during fault conditions. For

the remaining portion of the switching period, the current

sense signal, combined with a fraction of the slope

compensation voltage, is applied to the positive input of the

PWM comparator where it is compared with the divided by

three error amplifier output voltage. The pulse≠by≠pulse

overcurrent protection threshold is set by the voltage at the

I

SET

pin. This voltage is passed through the I

SET

Clamp and

appears at the non≠inverting input of the PWM comparator,

limiting its dynamic range according to the following

formula:

Overcurrent Threshold

+

0.8

VI(SENSE)

)

0.1 V

)

0.1 VSLOPE

where

VI(SENSE) is voltage at the ISENSE pin.

and

VSLOPE is voltage at the SLOPE pin.

During extreme overcurrent or short circuit conditions,

the slope of the current sense signal will become much

steeper than during normal operation. Due to loop

propagation delay, the sensed signal will overshoot the

pulse≠by≠pulse threshold eventually reaching the second

overcurrent protection threshold which is 1.33 times higher

than the first threshold and is described by the following

equation:

2nd Threshold

+

1.33

VI(SET)

Exceeding the second threshold will reset the Soft Start

capacitor C

SS

and reinitiate the Soft Start sequence,

repeating for as long as the fault condition persists.

Soft Start

During power up, when the output filter capacitor is

discharged and the output voltage is low, the voltage across

the Soft Start capacitor (V

SS

) controls the duty cycle. An

internal current source of 55

µ

A charges C

SS

. The maximum

error amplifier output voltage is clamped by the SS Clamp.

When the Soft Start capacitor voltage exceeds the error

amplifier output voltage, the feedback loop takes over the

duty cycle control. The Soft Start time can be estimated with

the following formula:

tSS

+

9

10

4

CSS

The Soft Start voltage, V

SS

, charges and discharges

between 0.25 V and 4.7 V.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

8

Slope Compensation

DC≠DC converters with current mode control require a

current sense signal with slope compensation to avoid

instability at duty cycles greater than 50%. Slope capacitor

C

S

is charged by an internal 53

µ

A current source and is

discharged during the oscillator discharge time. The slope

compensation voltage is divided by 10 and is added to the

current sense voltage, V

I(SENSE)

. The signal applied to the

input of the PWM comparator is a combination of these two

voltages. The slope compensation, dV

SLOPE

/dt

,

is

calculated using the following formula:

dVSLOPE

dt

+

0.1

53

m

A

CS

It should be noted that internal capacitance of the IC will

cause an error when determining slope compensation

capacitance C

S

. This error is typically small for large values

of C

S

, but increases as C

S

becomes small and comparable to

the internal capacitance. The effect is apparent as a reduction

in charging current due to the need to charge the internal

capacitance in parallel with C

S

.Figure 4 shows a typical

curve indicating this decrease in available charging current.

Figure 4. The Slope Compensation Pin Charge

Current Reduces When a Small Capacitor Is Used.

10

100

1000

60

55

50

45

40

35

30

25

20

Charging

Current (

µ

A)

Compensation Cap (pF)

Undervoltage (UV) and Overvoltage (OV) Monitor

Two independent comparators monitor OV and UV

conditions. A string of three resistors is connected in series

between the monitored voltage (usually the input voltage)

and ground (see Figure 5). When voltage at the OV pin

exceeds 2.5 V, an overvoltage condition is detected and

GATE shuts down. An internal 12.5

µ

A current source turns

on and feeds current into the external resistor, R

3

, creating

a hysteresis determined by the value of this resistor (the

higher the value, the greater the hysteresis). The hysteresis

voltage of the OV monitor is determined by the following

formula:

VOV(HYST)

+

12.5

m

A

R3

where R

3

is a resistor connected from the OV pin to ground.

When the monitored voltage is low and the UV pin is less

than 1.45 V, GATE shuts down. The UV pin has fixed 75 mV

hysteresis.

Both OV and UV conditions are latched until the Soft Start

capacitor is discharged. This way, every time a fault

condition is detected the controller goes through the power

up sequence.

Figure 5. UV/OV Monitor Divider

V

IN

V

UV

V

OV

R

1

R

2

R

3

To calculate the OV?UV resistor divider :

1. Solve for R

3

, based on OV hysteresis requirements.

R3

+

VOV(HYST)

2.5 V

VMAX

12.5

m

A

where V

OV(HYST)

is the desired amount of

overvoltage

hysteresis, and V

MAX

is the input voltage

at which the supply will shut down.

2. Find the total impedance of the divider.

RTOT

+

R1

)

R2

)

R3

+

VMAX

R3

2.5

3. Determine the value of R

2

from the UV threshold

conditions.

R2

+

1.45

RTOT

VMIN

*

R3

where V

MIN

is the UV voltage at which the supply

will shut down.

4. Calculate R

1

.

R1

+

RTOT

*

R2

*

R3

5. The undervoltage hysteresis is given by :

VUV(HYST)

+

VMIN

0.075

1.45

V

REF

Monitor

The 5.0 V reference voltage is internally monitored to

ensure that it remains within specifications. The monitor,

which outputs a fault, can be tripped by two methods:

∑

If the reference voltage drops below 4.75 V

∑

If V

CC

falls below the STOP threshold

As indicated in the block diagram, any fault causes the

output to stop switching and begins the discharge of the Soft

Start capacitor C

SS

.

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

9

Synchronization

A bi≠directional synchronization is provided to

synchronize several controllers. When SYNC pins are

connected together, the converters will lock to the highest

switching frequency. The fastest controller becomes the

master, producing a 4.3 V, 200 ns pulse train. Only one, the

highest frequency SYNC signal, will appear on the SYNC

line.

Sleep

The sleep input is an active high input. The CS51022A/4A

is placed in sleep mode when SLEEP is driven high. In sleep

mode, the controller and MOSFET are turned off. Connect

to GND for normal operation. The sleep mode operates at

VCC

15 V.

Oscillator and Duty Cycle Limit

The switching frequency is set by R

T

and C

T

connected to

the R

T

C

T

pin. C

T

charges and discharges between 3.0 V and

1.5 V.

The maximum duty cycle is set by the ratio of the on time,

t

ON

, and the whole period, T = t

ON

+ t

OFF

. Because the

timing capacitor's discharge current is trimmed, the

maximum

duty cycle is well defined. It is determined by the

ratio between the timing resistor R

T

and the timing capacitor

C

T

. Refer to figures 6 and 7 to select appropriate values for

R

T

and C

T

.

fSW

+

1

TSW

; TSW

+

tCH

)

tDIS

5

2500

Frequency

(kHz)

R

T

(k

)

2000

1500

1000

500

0

100

90

80

70

60

50

40

10

15

20

25

30

35

40

45

50

5

10

15

20

25

30

35

40

45

50

55

R

T

(k

)

Duty Cycle (%)

1

2

3

4

5

6

8

7

2

1

3

4

8

7

5

6

1. C

T

= 47 pF

2. C

T

= 100 pF

3. C

T

= 150 pF

4. C

T

= 220 pF

5. C

T

= 390 pF

6. C

T

= 470 pF

7. C

T

= 560 pF

8. C

T

= 680 pF

1. C

T

= 47 pF

2. C

T

= 100 pF

3. C

T

= 150 pF

4. C

T

= 220 pF

5. C

T

= 390 pF

6. C

T

= 470 pF

7. C

T

= 560 pF

8. C

T

= 680 pF

Figure 6. Frequency vs. R

T

for Discrete

Capacitor Values

Figure 7. Duty Cycle vs. R

T

for Discrete

Capacitor Values

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

10

PACKAGE DIMENSIONS

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

1

8

16

9

SEATING

PLANE

F

J

M

R

X 45

_

G

8 PL

P

≠B≠

≠A≠

M

0.25 (0.010)

B

S

≠T≠

D

K

C

16 PL

S

B

M

0.25 (0.010)

A

S

T

DIM

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

A

9.80

10.00

0.386

0.393

B

3.80

4.00

0.150

0.157

C

1.35

1.75

0.054

0.068

D

0.35

0.49

0.014

0.019

F

0.40

1.25

0.016

0.049

G

1.27 BSC

0.050 BSC

J

0.19

0.25

0.008

0.009

K

0.10

0.25

0.004

0.009

M

0

7

0

7

P

5.80

6.20

0.229

0.244

R

0.25

0.50

0.010

0.019

_

_

_

_

SO≠16

D SUFFIX

CASE 751B≠05

ISSUE J

PACKAGE THERMAL DATA

Parameter

SO≠16

Unit

R

JC

Typical

28

∞

C/W

R

JA

Typical

115

∞

C/W

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

11

Notes

CS51021A, CS51022A, CS51023A, CS51024A

http://onsemi.com

12

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. "Typical" parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including "Typicals" must be

validated for each customer application by customer's technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

JAPAN: ON Semiconductor, Japan Customer Focus Center

4≠32≠1 Nishi≠Gotanda, Shinagawa≠ku, Tokyo, Japan 141≠0031

Phone: 81≠3≠5740≠2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

CS51021A/D

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303≠675≠2175 or 800≠344≠3860 Toll Free USA/Canada

Fax: 303≠675≠2176 or 800≠344≠3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800≠282≠9855 Toll Free USA/Canada