| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: NCP1580 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

Semiconductor Components Industries, LLC, 2004

September, 2004- Rev. 2

1

Publication Order Number:

NCP1580/D

NCP1580

Low Voltage Synchronous

Buck Controller

The NCP1580 is a voltage mode PWM controller designed to

operate from a 5.0 V or 12 V supply and produce an output voltage as

low as 0.8 V. This 8-pin device provides an optimal level of

integration to reduce size and cost of the power supply. The NCP1580

has a fixed 350 kHz oscillator and soft-start function. The NCP1580

provides a 1.5 A floating gate driver design to drive N-Channel

MOSFETs in a synchronous configuration. Adaptive non-overlap

circuitry reduces switching losses by preventing simultaneous

conduction of both outputs. Protection features include thermal

shutdown and undervoltage lockout (UVLO). The NCP1580 is

available in an 8-pin SOIC package.

Features

∑

Input Voltage Range from 4.5 V to 13.2 V

∑

350 kHz Internal Oscillator

∑

Boost Pin Operates to 26.5 V

∑

Voltage Mode PWM Control

∑

0.8 V

$1.5% Internal Reference Voltage

∑

Adjustable Output Voltage

∑

Internal Soft-Start

∑

Internal 1.5 A Gate Drivers

∑

Adaptive Non-Overlap Circuit

∑

90% Max Duty Cycle

∑

Input UVLO

∑

Overtemperature Protection

∑

Fully Specified over -40

∞

C to 85

∞

C

Applications

∑

Graphics Cards

∑

Desktop Computers

∑

Servers/Networking

∑

DSP and FPGA Power Supply

∑

DC-DC Regulator Modules

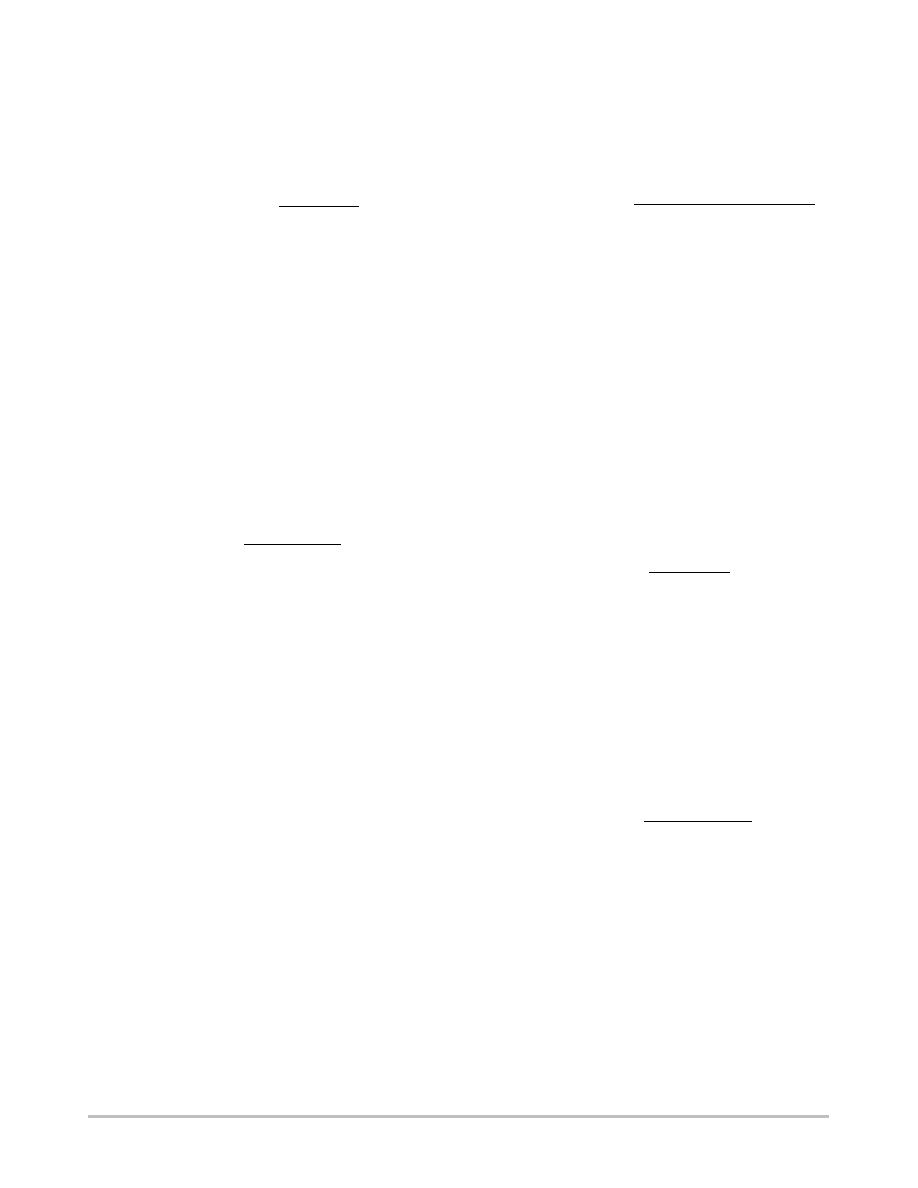

BST

TG

GND

BG

COMP

FB

V

CC

SWN

V

IN

V

OUT

Figure 1. Typical Application Diagram

SO-8

D SUFFIX

CASE 751

1

8

MARKING

DIAGRAM

PIN CONNECTIONS

A

= Assembly Location

L

= Wafer Lot

Y

= Year

W

= Work Week

1

BST

8 PHASE

2

TG

3

GND

4

BG

7 COMP

6 FB

5 V

CC

(Top View)

http://onsemi.com

1580

ALYW

1

8

http://onsemi.com

Device

Package

Shipping

ORDERING INFORMATION

NCP1580DR2

SO-8

2500/Tape & Reel

For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

NCP1580

http://onsemi.com

2

V

IN

V

OUT

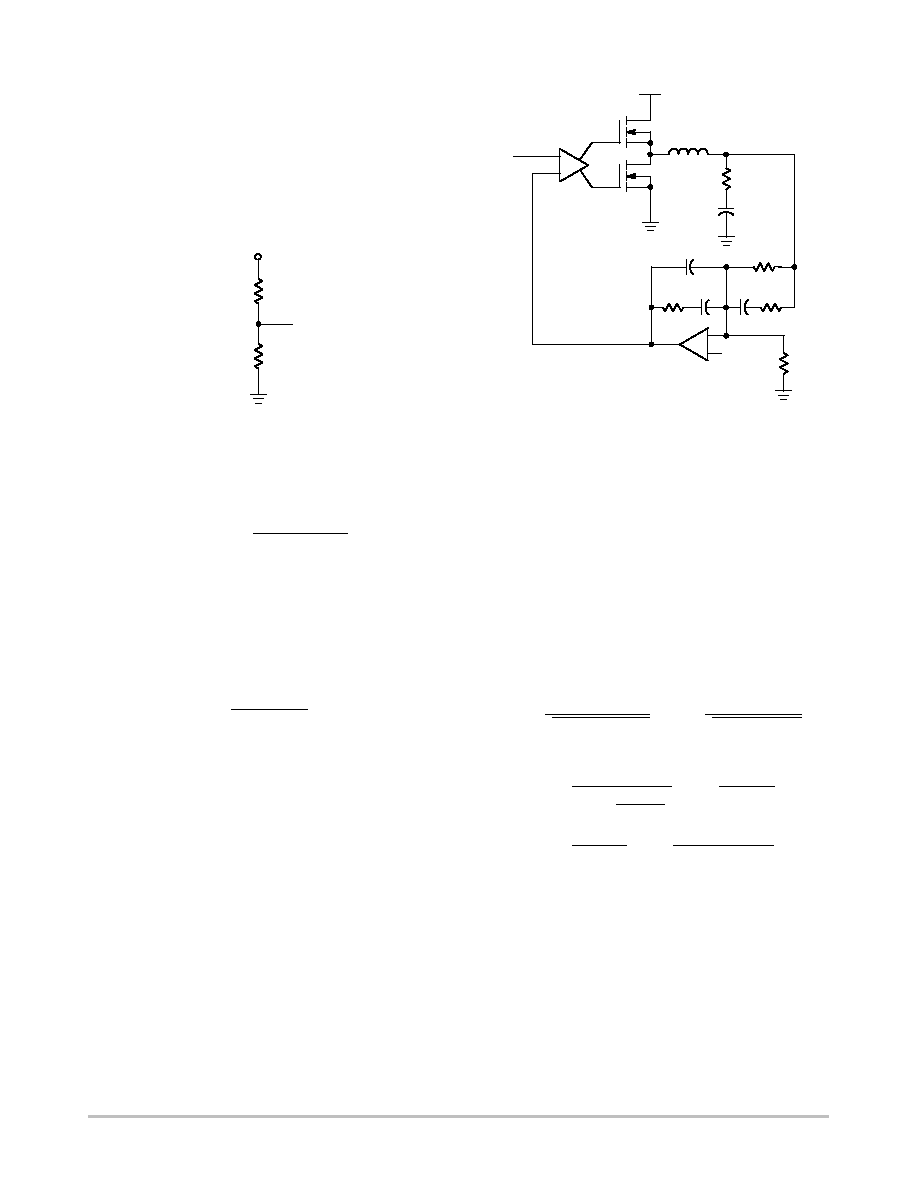

Figure 2. Application Diagram; 12 V Input, 1.0 V at 20 A Output

BST

PHASE

TG

GND

BG

COMP

FB

V

CC

3.3 nF

10 nF

15 k

1

m

F

10 nF

68.1

5.36 k

20 k

0.1

m

F

RB751V40T10

NTD60N02R

NTD1

10N02R

2.2

4.7 nF

2 x

1500

m

F

4 x

22

m

F

2 x

100

m

F

2 x

1800

m

F

MBR130LSFT1

GND

1

m

H

Figure 3. Block Diagram

FAULT

SS

OSC

+

-

+

FB

COMP

Error Amp

0.8 V (V

REF

)

V

CC

+

-

Clock

Ramp

OSC

OSC

R

S

Q

POR

FAULT

FAULT

+

-

Comparator

2 V

+

-

2 V

FAULT

TG

BST

PHASE

V

CC

BG

GND

DETAILED BLOCK DIAGRAM

TSD

(V

SS

)

6

7

5

1

2

8

4

3

NCP1580

http://onsemi.com

3

PIN FUNCTION DESCRIPTION

Pin No.

Symbol

Description

1

BST

Supply rail for the floating top gate driver. To form a boost circuit, use an external diode to bring the

desired input voltage to this pin (cathode connected to BST pin). Connect a capacitor (C

BST

) between this

pin and the PHASE pin. Typical values for C

BST

range from 0.1

m

F to 1

m

F. Ensure that C

BST

is placed

near the IC.

2

TG

Top gate MOSFET driver pin. Connect this pin to the gate of the top N-Channel MOSFET.

3

GND

IC ground reference. All control circuits are referenced to this pin.

4

BG

Bottom gate MOSFET driver pin. Connect this pin to the gate of the bottom N-Channel MOSFET.

5

V

CC

Supply rail for the internal circuitry. Operating supply range is 4.5 V to 13.2 V. Decouple with a 1

m

F

capacitor to GND. Ensure that this decoupling capacitor is placed near the IC.

6

FB

This pin is the inverting input to the error amplifier. Use this pin in conjunction with the COMP pin to

compensate the voltage-control feedback loop. Connect this pin to the output resistor divider (if used) or

directly to Vout.

7

COMP

Compensation Pin. This is the output of the error amplifier (EA) and the non-inverting input of the PWM

comparator. Use this pin in conjunction with the FB pin to compensate the voltage-control feedback loop.

This pin should not be shorted to ground to disable switching.

8

PHASE

Switch node pin. This is the reference for the floating top gate driver. Connect this pin to the source of the

top MOSFET. A Schottky diode between this pin and ground is recommended to reduce negative transient

voltages which is common in a power supply system.

ABSOLUTE MAXIMUM RATINGS

Pin Name

Symbol

V

MAX

V

MIN

Main Supply Voltage Input

V

CC

15 V

-0.3 V

Bootstrap Supply Voltage Input

BST

30 V wrt/GND

15 V wrt/PHASE

-0.3 V

Switching Node (Bootstrap Supply Return)

PHASE

30 V

-0.7 V

High-Side Driver Output (Top Gate)

TG

30 V wrt/GND

15 V wrt/PHASE

-0.3 V

wrt/PHASE

Low-Side Driver Output (Bottom Gate)

BG

15 V

-0.3 V

Feedback

FB

5.5 V

-0.3 V

COMP

COMP

5.5 V

-0.3 V

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Thermal Resistance, Junction-to-Ambient

R

q

JA

165

∞

C/W

Thermal Resistance, Junction-to-Case

R

q

JC

45

∞

C/W

Operating Junction Temperature Range

T

J

-40 to 150

∞

C

Operating Ambient Temperature Range

T

A

-40 to 85

∞

C

Storage Temperature Range

T

stg

-55 to +150

∞

C

ESD Susceptibility

Human Body Model

Charge Device Model

2.0

200

kV

V

Moisture Sensitivity Level

MSL

1

-

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

NCP1580

http://onsemi.com

4

ELECTRICAL CHARACTERISTICS

(-40

∞

C < T

A

< 85

∞

C, -40

∞

C < T

J

< 125

∞

C (Note 1), 4.5 V < V

CC

< 13.2 V, 4.5 V < BST < 26.5 V,

C

TG

= C

BG

= 1.0 nF, for min/max values unless otherwise noted.)

Characteristic

Conditions

Min

Typ

Max

Unit

Input Voltage Range

-

4.5

-

13.2

V

Boost Voltage Range

-

4.5

-

26.5

V

Supply Current

Quiescent Supply Current

V

FB

= 1.0 V, No Switching

V

CC

= 13.2 V

-

1.0

1.75

mA

Boost Quiescent Current

V

FB

= 1.0 V, No Switching

-

140

-

m

A

Undervoltage Lockout

UVLO Threshold

V

CC

Rising Edge

3.85

4.2

-

V

UVLO Hysteresis

-

-

0.5

-

V

Switching Regulator

VFB Feedback Voltage,

Control Loop in Regulation

T

A

= 0 to 70

∞

C

T

A

= -40 to 85

∞

C

0.788

0.784

0.800

-

0.812

0.816

V

Oscillator Frequency

-

288

350

412

kHz

Ramp-Amplitude Voltage

-

-

1.1

-

V

Minimum Duty Cycle

-

-

0

-

%

Maximum Duty Cycle

-

85

90

95

%

Minimum Pulse Width

Static Operating (Note 2)

50

100

150

nsec

Error Amplifier

DC Gain

(Note 2 )

70

80

-

dB

Gain-Bandwidth Product

(Note 2)

8.0

10

-

MHz

Slew Rate

COMP_GND = 100 pF (Note 2)

2.0

4.0

-

V/

m

S

FB Bias Current

VFB = 1 V (Note 2)

-

0.1

1.0

m

A

Gate Drivers

TG Rise Time

-

6.0

15

ns

TG Fall Time

Load = 1.0 nF

-

15

30

ns

BG Rise Time

Load = 1.0 nF

V

CC

= 8.0 V

-

6.0

15

ns

BG Fall Time

-

6.0

15

ns

TG Sink Current

-

1.0

-

A

TG Source Current

V

CC

= 12 V

V

TG

= V

BG

= 2 0 V

-

1.5

-

A

BG Sink Current

V

TG

= V

BG

= 2.0 V

(Note 2)

-

1.5

-

A

BG Source Current

(

)

-

1.5

-

A

PHASE falling to BG rising delay

V

CC

= 12 V

PHASE < 2.0 V

BG > 2.0 V

-

30

90

ns

BG falling to TG rising delay

V

CC

= 12 V

BG < 2.0 V

TG > 2.0 V

-

30

40

ns

Internal Soft-Start

Time

-

1.0

2.0

3.0

ms

Thermal Shutdown

Overtemperature Trip Point

(Note 2)

-

160

-

∞

C

1. Specifications to -40

∞

C are guaranteed via correlation using standard statistical quality control (SQC), not tested in production.

2. Guaranteed by design, not tested in production.

NCP1580

http://onsemi.com

5

TYPICAL CHARACTERISTIC CURVES

400

390

380

370

360

350

340

330

320

310

410

-50

-25

0

25

50

75

100

125

150

T

J

, JUNCTION TEMPERATURE (

∞

C)

f

SW

, FREQUENCY (kHz)

816

-50

-25

0

25

50

75

100

125

150

T

J

, JUNCTION TEMPERATURE (

∞

C)

V

REF

, REFERENCE (mV)

812

808

804

800

796

792

788

784

Figure 4. Reference Voltage (V

REF

) vs.

Temperature

Figure 5. Oscillator Frequency (f

SW

) vs.

Temperature

300

290

V

CC

= 5.0 V

V

CC

= 12 V

2.15

2.10

2.05

2.00

1.95

1.90

1.85

1.80

2.20

-50

-25

0

25

50

75

100

125

150

T

J

, JUNCTION TEMPERATURE (

∞

C)

t

SS

, SOFT-ST

AR

T TIME (ms)

1.25

-50

-25

0

25

50

75

100

125

150

T

J

, JUNCTION TEMPERATURE (

∞

C)

I

CC

, SUPPL

Y CURRENT (mA)

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.75

-50

-25

0

25

50

75

100

125

150

T

J

, JUNCTION TEMPERATURE (

∞

C)

I

CC

, SUPPL

Y CURRENT (mA)

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

Figure 6. Soft-Start Time (t

SS

) vs. Temperature

Figure 7. Quiescent Current (I

CC

) vs. Temperature

(No Switching)

Figure 8. Quiescent Current (I

CC

) vs. Temperature

(Switching)

100

80

60

40

20

0

-20

-40

-60

1.E+02

1.E+03

1.E+04

1.E+05

1.E+06

1.E+07

Figure 9. Error Amplifier

0.80

0.85

V

CC

= 5.0 V

V

CC

= 12 V

V

CC

= 5.0 V

V

CC

= 12 V

V

CC

= 5.0 V

V

CC

= 12 V

V

CC

= 8.0 V

NCP1580

http://onsemi.com

6

DETAILED OPERATING DESCRIPTION

General

The NCP1580 is an 8-pin PWM controller intended for

DC-DC conversion from 5.0 V and 12 V buses. The

NCP1580 has a 1.5 A internal floating gate driver circuit

designed to drive N-Channel MOSFETs in a

synchronous-rectifier buck topology. The internal floating

gate driver simplifies design, improves performance, and

minimizes board area. The output voltage of the converter

can be precisely regulated down to 800 mV

$ 1.5% when

the V

FB

pin is tied to V

OUT

. The switching frequency, which

is internally set to 350 kHz, and soft-start are completely

integrated. The voltage error amplifier features a 10 MHz

unity gain bandwidth and 4 V/

msec slew rate for fast

transient response.

Duty Cycle and Maximum Pulse Width Limits

In steady state DC operation, the duty cycle will stabilize

at an operating point defined by the ratio of the input to the

output voltage. The NCP1580 can achieve a 90% duty cycle.

There is a built in off-time which ensures that the bootstrap

supply is charged every cycle. The NCP1580, which is

capable of a 100 nsec minimum pulse width (typ), can allow

a 12 V to 1.0 V conversion at 350 kHz.

Input Voltage Range (V

CC

and BST)

The input voltage range for both V

CC

and BST is 4.5 V to

13.2 V with respect to GND and PHASE, respectively.

Although BST is rated at 13.2 V with respect to PHASE, it

can also tolerate 26.5 V with respect to GND.

Normal Shutdown Behavior

Normal shutdown occurs when the IC stops switching

because the input supply reaches UVLO threshold. In this

case, switching stops, the internal SS is discharged, and all

GATE pins go low. The switch node enters a high impedance

state and the output capacitors discharge through the load

with no ringing on the output voltage.

Internal Soft-Start

The NCP1580 features an internal soft-start function,

which reduces inrush current and overshoot of the output

voltage. Figure 10 shows a typical soft-start sequence.

Soft-start is achieved by ramping up the internal soft-start

voltage (V

SS

) which is applied to the input of the error

amplifier. This ramp is generated by applying 0.5

mA to a

100 pf capacitor for 1

msec on every fourth clock pulse. This

sequence begins once V

CC

surpasses its UVLO threshold

(see Figure 11). The typical soft-start time is 2 msec. The

internal soft-start voltage is held low when the part is in

UVLO.

Figure 10. Normal Startup

4.2 V

2 ms

V

CC

TG

V

OUT

UVLO

Startup

Normal Operation

Figure 11. Achieving Internal Soft-Start

4.2 V

1

m

S

V

CC

V

SS

5 mV

SS

CLK

NCP1580

http://onsemi.com

7

UVLO

Undervoltage Lockout (UVLO) is provided to ensure that

unexpected behavior does not occur when V

CC

is too low to

support the internal rails and power the converter. For the

NCP1580, the UVLO is set to ensure that the IC will start up

when V

CC

reaches 4.2 V and shutdown when V

CC

drops

below 3.7 V. This permits operation when converting from

a 5.0 V input voltage.

Thermal Shutdown

The NCP1580 also provides Thermal Shutdown (TSD)

for added protection. The TSD circuit monitors the die

temperature and turns off the top and bottom gate drivers if

an over temperature condition is detected. The internal soft-

start capacitor is also discharged. This is a latched state and

requires a power cycle to reset.

Drivers

The NCP1580 includes 1.5 A gate drivers to switch

external N-Channel MOSFETs. This allows the NCP1580

to address high-power as well as low-power conversion

requirements. The gate drivers also include adaptive

non-overlap circuitry. The non-overlap circuitry increases

efficiency, which minimizes power dissipation, by

minimizing the body diode conduction time.

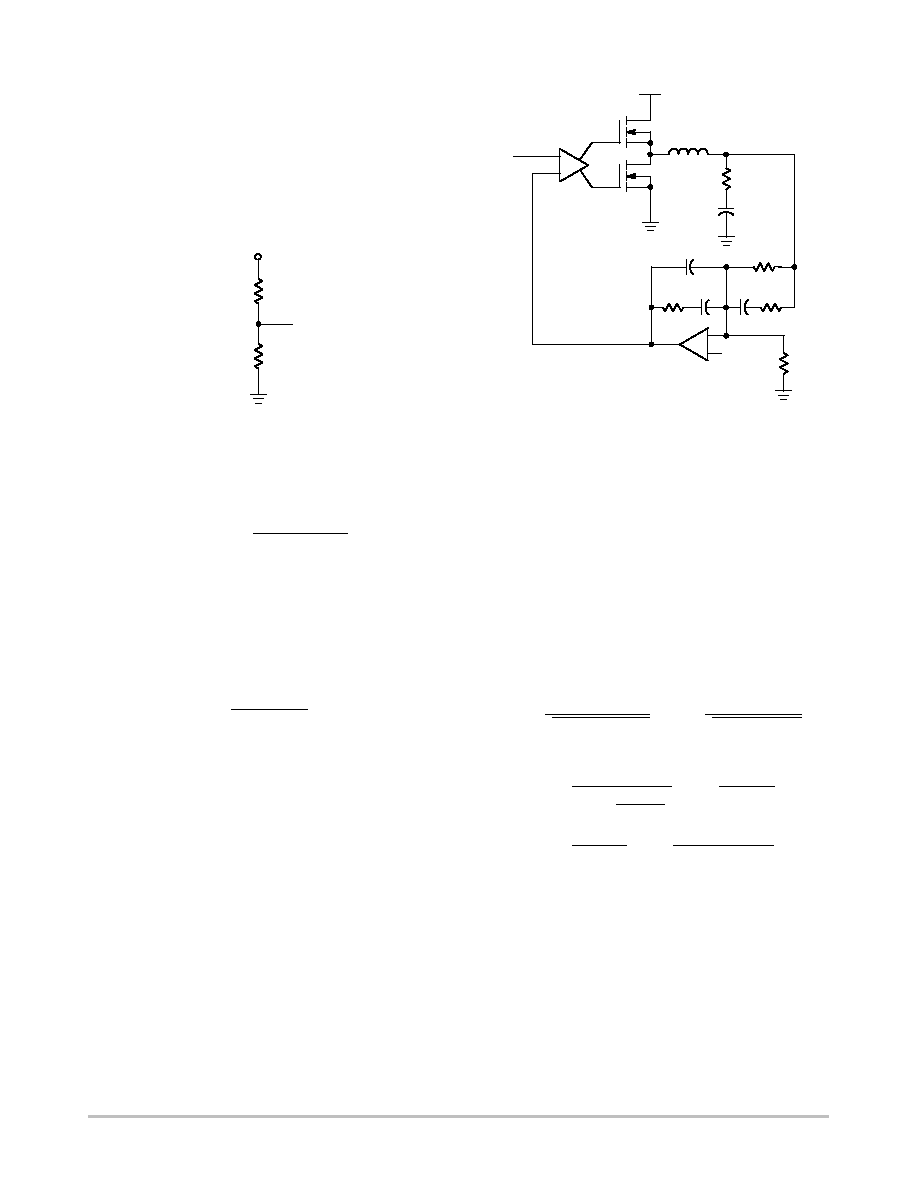

A detailed block diagram of the non-overlap and gate

drive circuitry used in the chip is shown in Figure 12.

Careful selection and layout of external components is

required, to realize the full benefit of the onboard drivers.

The capacitors between V

CC

and GND and between BST

and SWN must be placed as close as possible to the IC. The

current paths for the TG and BG connections must be

optimized. A ground plane should be placed on the closest

layer for return currents to GND in order to reduce loop area

and inductance in the gate drive circuit.

Figure 12. Block Diagram

UVLO

FAULT

+

-

2 V

+

-

2 V

PHASE

TG

BST

V

CC

BG

GND

UVLO

FAULT

PWM

OUT

NCP1580

http://onsemi.com

8

APPLICATION SECTION

Input Capacitor Selection

The input capacitor has to sustain the ripple current

produced during the on time of the upper MOSFET, so it

must have a low ESR to minimize the losses. The RMS value

of this ripple is:

IinRMS

+

IOUT D

(1

*

D) ,

where D is the duty cycle, I

inRMS

is the input RMS current,

and I

OUT

is the load current. The equation reaches its

maximum value with D = 0.5. Losses in the input capacitors

can be calculated with the following equation:

PCIN

+

ESRCIN

IinRMS2,

where P

CIN

is the power loss in the input capacitors and

ESR

CIN

is the effective series resistance of the input

capacitance. Due to large dI/dt through the input capacitors,

electrolytic or ceramics should be used. If a tantalum must

be used, it must be surge protected. Otherwise, capacitor

failure could occur.

Calculating Input Startup Current

To calculate the input startup current, the following

equation can be used.

Iinrush

+

COUT

VOUT

tSS

,

where I

inrush

is the input current during startup, C

OUT

is

the total output capacitance, V

OUT

is the desired output

voltage, and t

SS

is the internal soft-start interval.

If the inrush current is higher than the steady state input

current during max load, then the input fuse should be rated

accordingly, if one is used.

Output Capacitor Selection

The output capacitor is a basic component for the fast

response of the power supply. In fact, during load transient,

for the first few microseconds it supplies the current to the

load. The controller immediately recognizes the load

transient and sets the duty cycle to maximum, but the current

slope is limited by the inductor value.

During a load step transient the output voltage initially

drops due to the current variation inside the capacitor and the

ESR. (neglecting the effect of the effective series inductance

(ESL)):

D

VOUT-ESR

+ D

IOUT

ESRCOUT,

where V

OUT-ESR

is the voltage deviation of V

OUT

due to the

effects of ESR and the ESR

COUT

is the total effective series

resistance of the output capacitors.

A minimum capacitor value is required to sustain the

current during the load transient without discharging it. The

voltage drop due to output capacitor discharge is given by

the following equation:

D

VOUT

*

DISCHARGE

+

D

IOUT2

LOUT

2

COUT

(VIN

D

*

VOUT)

,

where V

OUT-DISCHARGE

is the voltage deviation of V

OUT

due to the effects of discharge, L

OUT

is the output inductor

value and V

IN

is the input voltage.

It should be noted that

DV

OUT-DISCHARGE

and

DV

OUT-ESR

are out of phase with each other, and the larger

of these two voltages will determine the maximum deviation

of the output voltage (neglecting the effect of the ESL).

Inductor Selection

Both mechanical and electrical considerations influence

the selection of an output inductor. From a mechanical

perspective, smaller inductor values generally correspond to

smaller physical size. Since the inductor is often one of the

largest components in the regulation system, a minimum

inductor value is particularly important in

space-constrained applications. From an electrical

perspective, the maximum current slew rate through the

output inductor for a buck regulator is given by:

SlewRateLOUT

+

VIN

*

VOUT

LOUT

This equation implies that larger inductor values limit the

regulator's ability to slew current through the output

inductor in response to output load transients. Consequently,

output capacitors must supply the load current until the

inductor current reaches the output load current level. This

results in larger values of output capacitance to maintain

tight output voltage regulation. In contrast, smaller values of

inductance increase the regulator's maximum achievable

slew rate and decrease the necessary capacitance, at the

expense of higher ripple current. The peak-to-peak ripple

current is given by the following equation:

Ipk-pkLOUT

+

VOUT(1

*

D)

LOUT

350 kHZ

,

where Ipk-pk

LOUT

is the peak to peak current of the output.

From this equation it is clear that the ripple current increases

as L

OUT

decreases, emphasizing the trade-off between

dynamic response and ripple current.

NCP1580

http://onsemi.com

9

Feedback and Compensation

The NCP1580 allows the output of the DC-DC converter

to be adjusted from 0.8 V to 5.0 V via an external resistor

divider network. The controller will try to maintain 0.8 V at

the feedback pin. Thus, if a resistor divider circuit was

placed across the feedback pin to V

OUT

, the controller will

regulate the output voltage proportional to the resistor

divider network in order to maintain 0.8 V at the FB pin.

VOUT

FB

R1

R2

Figure 13.

The relationship between the resistor divider network in

Figure 13 and the output voltage is shown in the following

equation:

R2

+

R1

VREF

VOUT

*

VREF

.

Resistor R1 is selected based on a design trade off between

efficiency and output voltage accuracy. For high values of

R1 there is less current consumption in the feedback

network, However the trade off is output voltage accuracy

due to the bias current in the error amplifier. The output

voltage error of this bias current can be estimated using the

following equation (neglecting resistor tolerance):

Error%

+

0.1

m

A

R1

VREF

100%

Once R1 has been determined, R2 can be calculated.

The NCP1580 utilizes voltage mode control. This is to

say, the control loop regulates V

OUT

by monitoring V

OUT

and controlling the output current. However, since the

control loop is controlling the output current to regulate the

output voltage, there are some stability concerns since the

inductor current is 90 degrees out of phase with the voltage.

It is inherent with all voltage-mode control loops to have a

compensation network.

Figure 14. Simplified Diagram of Control Loop

V

IN

V

OUT

L

OUT

-

+

-

+

V

RAMP

PWM

COMPARATOR

C1

C2

C3

R1

R4

R3

R2

V

REF

C

OUT

ESR

The compensation network consists of the internal error

amplifier and the impedance networks Z

IN

(R1, R3 and C3)

and Z

FB

(R4, C1 and C2). The compensation network has to

provide a closed loop transfer function with the highest 0 dB

crossing frequency to have fast response (but always lower

than f

SW

/8) and the highest gain in DC conditions to

minimize the load regulation. A stable control loop has a

gain crossing with -20 dB/decade slope and a phase margin

greater than 45

∞

. Include worst-case component variations

when determining phase margin. To place the poles and

zeroes of the compensation networks, the following

equations may be used:

Modulator frequencies:

w

LC

+

1

LOUT

COUT

w

ESR

+

1

ESR

COUT

Compensation network frequency:

w

P1

+

1

R4

C1

C2

C1

)

C2

w

P2

+

1

R3

C3

w

Z1

+

1

R4

C2

w

Z2

+

1

(R1

)

R3)

C3

NCP1580

http://onsemi.com

10

Place

w

Z1

, and

w

Z2

around the output filter resonance

w

LC

; Place

w

P1

at the output capacitor ESR zero

w

ESR

; Place

w

P2

at one half of the switching frequency;

The modulator transfer function is the small-signal

transfer function of V

OUT

/V

COMP

. This function has a

double pole at frequency

w

LC

and a zero at

w

ESR

. The DC

Gain of the modulator is simply the input voltage V

IN

divided by the peak-to-peak oscillator voltage

DV

OSC

.

Error Amplifier

Modulator Gain

Closed Loop

Gain

Compensation

Network

w

Z1

w

Z2

w

P1

w

P2

w

LC

w

ESR

Figure 15.

Visit http://www.onsemi.com/pub/Collateral/COMPCALC

for self extracting compensation program for design

assistance.

Thermal Considerations

The power dissipation of the NCP1580 varies with the

MOSFETs used, V

CC

, and the boost voltage (V

BST

). The

average MOSFET gate current typically dominates the

control IC power dissipation. The IC power dissipation is

determined by the formula:

PIC

+

(ICC

VCC)

)

PTG

)

PBG.

Where:

P

IC

= Control IC power dissipation,

I

CC

= IC measured supply current,

V

CC

= IC supply voltage,

P

TG

= Top gate driver losses,

P

BG

= Bottom gate driver losses.

The upper (switching) MOSFET gate driver losses are:

PTG

+

QTG

fSW

VBST.

Where:

Q

TG

= Total upper MOSFET gate charge at VBST,

f

SW

= The switching frequency,

V

BST

= The BST pin voltage.

The lower (synchronous) MOSFET gate driver losses are:

PBG

+

QBG

fSW

VCC.

Where:

Q

BG

= total lower MOSFET gate charge at V

CC

.

The junction temperature of the control IC can then be

calculated as:

TJ

+

TA

)

PIC

q

JA.

Where:

T

J

= The junction temperature of the IC,

T

A

= The ambient temperature,

JA

= The junction-to-ambient thermal resistance of the

IC package.

The package thermal resistance can be obtained from the

specifications section of this data sheet and a calculation can

be made to determine the IC junction temperature. However,

it should be noted that the physical layout of the board, the

proximity of other heat sources such as MOSFETs and

inductors, and the amount of metal connected to the IC,

impact the temperature of the device. Use these calculations

as a guide, but measurements should be taken in the actual

application.

NCP1580

http://onsemi.com

11

Layout Considerations

As in any high frequency switching converter, layout is

very important. Switching current from one power device to

another can generate voltage transients across the

impedances of the interconnecting bond wires and circuit

traces. These interconnecting impedances should be

minimized by using wide, short printed circuit traces. The

critical components should be located as close together as

possible using ground plane construction or single point

grounding. Figure 16 shows the critical power components

of the converter. To minimize the voltage overshoot the

interconnecting wires indicated by heavy lines should be

part of ground or power plane in a printed circuit board. The

components shown in Figure 16 should be located as close

together as possible. Please note that the capacitors C

IN

and

C

OUT

each represent numerous physical capacitors. It is

desirable to locate the NCP1580 within 1 inch of the

MOSFETs, Q1 and Q2. The circuit traces for the MOSFETs'

gate and source connections from the NCP1580 must be

sized to handle up to 2.0 A peak current.

Figure 16.

V

IN

V

OUT

L

OUT

R1

C

OUT

Q1

Q2

D2

C

IN

TG

PHASE

BG

GND

NCP1580

RETURN

LOAD

NCP1580

http://onsemi.com

12

PACKAGE DIMENSIONS

SO-8

D SUFFIX

CASE 751-07

ISSUE AB

SEATING

PLANE

1

4

5

8

N

J

X 45

_

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751-01 THRU 751-06 ARE OBSOLETE. NEW

STANDARD IS 751-07.

A

B

S

D

H

C

0.10 (0.004)

DIM

A

MIN

MAX

MIN

MAX

INCHES

4.80

5.00

0.189

0.197

MILLIMETERS

B

3.80

4.00

0.150

0.157

C

1.35

1.75

0.053

0.069

D

0.33

0.51

0.013

0.020

G

1.27 BSC

0.050 BSC

H

0.10

0.25

0.004

0.010

J

0.19

0.25

0.007

0.010

K

0.40

1.27

0.016

0.050

M

0

8

0

8

N

0.25

0.50

0.010

0.020

S

5.80

6.20

0.228

0.244

-X-

-Y-

G

M

Y

M

0.25 (0.010)

-Z-

Y

M

0.25 (0.010)

Z

S

X

S

M

_

_

_

_

1.52

0.060

7.0

0.275

0.6

0.024

1.270

0.050

4.0

0.155

mm

inches

SCALE 6:1

SOLDERING FOOTPRINT

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

"Typical" parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including "Typicals" must be validated for each customer application by customer's technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

N. American Technical Support: 800-282-9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2-9-1 Kamimeguro, Meguro-ku, Tokyo, Japan 153-0051

Phone: 81-3-5773-3850

NCP1580/D

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082-1312 USA

Phone: 480-829-7710 or 800-344-3860 Toll Free USA/Canada

Fax: 480-829-7709 or 800-344-3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.