| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SMF12AT1 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

Semiconductor Components Industries, LLC, 2003

March, 2003 - Rev. 0

1

Publication Order Number:

SMF5.0AT1/D

SMF5.0AT1 Series

Zener Transient

Voltage Suppressor

SOD-123 Flat Lead Package

The SMF5.0A Series is designed to protect voltage sensitive

components from high voltage, high energy transients. Excellent

clamping capability, high surge capability, low zener impedance and

fast response time. Because of its small size, it is ideal for use in

cellular phones, portable devices, business machines, power supplies

and many other industrial/consumer applications.

Specification Features:

∑

Stand-of f Voltage: 5 - 170 Volts

∑

Peak Power - 200 Watts @ 1 ms (SMF5.0A - SMF58A)

Peak Power

- 175 Watts @ 1 ms (SMF60A - SMF170A)

∑

Maximum Clamp Voltage @ Peak Pulse Current

∑

Low Leakage

∑

Response Time is Typically < 1 ns

∑

ESD Rating of Class 3 (> 16 kV) per Human Body Model

IEC61000-4-2 Level 4 ESD Protection

IEC61000-4-4 40 A ESD Protection

∑

Low Profile - Maximum Height of 1.0 mm

∑

Small Footprint - Footprint Area of 8.45 mm

2

∑

Supplied in 8 mm Tape and Reel - 3,000 Units per Reel

∑

Cathode Indicated by Polarity Band

Mechanical Characteristics:

CASE:

Void-free, transfer-molded, thermosetting plastic

Epoxy Meets UL94, VO

LEAD FINISH:

100% Matte Sn (Tin)

MOUNTING POSITION:

Any

QUALIFIED MAX REFLOW TEMPERATURE:

260

∞

C

Device Meets MSL 1 Requirements

PLASTIC SURFACE MOUNT

ZENER OVERVOLTAGE

TRANSIENT SUPPRESSOR

5 - 170 VOLTS

200 WATT PEAK POWER

Device

Package

Shipping

ORDERING INFORMATION

SMFxxxAT1

SOD-123FL

3,000/Tape & Reel

1

2

1: CATHODE

2: ANODE

LEAD ORIENTATION IN TAPE:

Cathode Lead to Sprocket Holes

http://onsemi.com

SOD-123FL

CASE 498

PLASTIC

MARKING DIAGRAM

1

CATHODE

2

ANODE

XX

D

XX = Specific Device Code

D

= Date Code

Uni-Directional TVS

I

PP

I

F

V

I

I

R

I

T

V

RWM

V

C

V

BR

V

F

SMF5.0AT1 Series

http://onsemi.com

2

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Maximum P

pk

Dissipation (PW-10/1000

m

s) (Note 1) SMF60A - SMF170A

P

pk

175

W

Maximum P

pk

Dissipation (PW-10/1000

m

s) (Note 1) SMF5.0A - SMF58A

P

pk

200

W

Maximum P

pk

Dissipation @ T

A

= 25

∞

C, (PW-8/20

m

s) (Note 2)

P

pk

1000

W

DC Power Dissipation @ T

A

= 25

∞

C (Note 3)

Derate above 25

∞

C

Thermal Resistance from Junction to Ambient (Note 3)

∞

P

D

∞

R

JA

385

4.0

325

∞

mW

mW/

∞

C

∞

C/W

Thermal Resistance from Junction to Lead (Note 3)

R

Jcathode

26

∞

C/W

Operating and Storage Temperature Range

T

J

, T

stg

-55 to +150

∞

C

1. Non-repetitive current pulse at T

A

= 25

∞

C, per waveform of Figure 2.

2. Non-repetitive current pulse at T

A

= 25

∞

C, per waveform of Figure 3.

3. Mounted with recommended minimum pad size, DC board FR-4.

ELECTRICAL CHARACTERISTICS

(T

A

= 25

∞

C unless

otherwise noted, V

F

= 3.5 V Max. @ I

F

(Note 4) = 12 A)

Symbol

Parameter

I

PP

Maximum Reverse Peak Pulse Current

V

C

Clamping Voltage @ I

PP

V

RWM

Working Peak Reverse Voltage

I

R

Maximum Reverse Leakage Current @ V

RWM

V

BR

Breakdown Voltage @ I

T

I

T

Test Current

I

F

Forward Current

V

F

Forward Voltage @ I

F

4. 1/2 sine wave (or equivalent square wave), PW = 8.3 ms,

duty cycle = 4 pulses per minute maximum.

SMF5.0AT1 Series

http://onsemi.com

3

ELECTRICAL CHARACTERISTICS

(T

L

= 30

∞

C unless otherwise noted, V

F

= 1.25 Volts @ 200 mA)

V

RWM

(V)

V

BR

@ I

T

(V) (Note 6)

I

T

I

R

@ V

RWM

V

C(Max)

I

PP(Max)

(A)

Device

Marking

(Note 5)

Min

Nom

Max

(mA)

(

m

A)

(V)

(Note 7)

SMF5.0A

KE

5

6.4

6.7

7

10

400

9.2

21.7

SMF6.0A

KG

6

6.67

7.02

7.37

10

400

10.3

19.4

SMF6.5A

KK

6.5

7.22

7.6

7.98

10

250

11.2

17.9

SMF7.0A

KM

7

7.78

8.2

8.6

10

100

12

16.7

SMF7.5A

KP

7.5

8.33

8.77

9.21

1

50

12.9

15.5

SMF8.0A

KR

8

8.89

9.36

9.83

1

25

13.6

14.7

SMF8.5A

KT

8.5

9.44

9.92

10.4

1

10

14.4

13.9

SMF9.0A

KV

9

10

10.55

11.1

1

5

15.4

13.0

SMF10A

KX

10

11.1

11.7

12.3

1

2.5

17

11.8

SMF11A

KZ

11

12.2

12.85

13.5

1

2.5

18.2

11.0

SMF12A

LE

12

13.3

14

14.7

1

2.5

19.9

10.1

SMF13A

LG

13

14.4

15.15

15.9

1

1

21.5

9.3

SMF14A

LK

14

15.6

16.4

17.2

1

1

23.2

8.6

SMF15A

LM

15

16.7

17.6

18.5

1

1

24.4

8.2

SMF16A

LP

16

17.8

18.75

19.7

1

1

26

7.7

SMF17A

LR

17

18.9

19.9

20.9

1

1

27.6

7.2

SMF18A

LT

18

20

21

22.1

1

1

29.2

6.8

SMF20A

LV

20

22.2

23.35

24.5

1

1

32.4

6.2

SMF22A

LX

22

24.4

25.6

26.9

1

1

35.5

5.6

SMF24A

LZ

24

26.7

28.1

29.5

1

1

38.9

5.1

SMF26A

ME

26

28.9

30.4

31.9

1

1

42.1

4.8

SMF28A

MG

28

31.1

32.8

34.4

1

1

45.4

4.4

SMF30A

MK

30

33.3

35.1

36.8

1

1

48.4

4.1

SMF33A

MM

33

36.7

38.7

40.6

1

1

53.3

3.8

SMF36A

MP

36

40

42.1

44.2

1

1

58.1

3.4

SMF40A

MR

40

44.4

46.8

49.1

1

1

64.5

3.1

SMF43A

MT

43

47.8

50.3

52.8

1

1

69.4

2.9

SMF45A

MV

45

50

52.65

55.3

1

1

72.7

2.8

SMF48A

MX

48

53.3

56.1

58.9

1

1

77.4

2.6

SMF51A

MZ

51

56.7

59.7

62.7

1

1

82.4

2.4

SMF54A

NE

54

60

63.15

66.3

1

1

87.1

2.3

SMF58A

NG

58

64.4

67.8

71.2

1

1

93.6

2.1

SMF60A

NK

60

66.7

70.2

73.7

1

1

96.8

1.8

SMF64A

NM

64

71.1

74.85

78.6

1

1

103

1.7

SMF70A

NP

70

77.8

81.9

86

1

1

113

1.5

SMF75A

NR

75

83.3

87.7

92.1

1

1

121

1.4

SMF78A

NT

78

86.7

91.25

95.8

1

1

126

1.4

SMF85A

NV

85

94.4

99.2

104

1

1

137

1.3

SMF90A

NX

90

100

105.5

111

1

1

146

1.2

SMF100A

NZ

100

111

117

123

1

1

162

1.1

SMF110A

PE

110

122

128.5

135

1

1

177

1.0

SMF120A

PG

120

133

140

147

1

1

193

0.9

SMF130A

PK

130

144

151.5

159

1

1

209

0.8

SMF150A

PM

150

167

176

185

1

1

243

0.7

SMF160A

PP

160

178

187.5

197

1

1

259

0.7

SMF170A

PR

170

189

199

209

1

1

275

0.6

5. A transient suppressor is normally selected according to the Working Peak Reverse Voltage (V

RWM

) which should be equal to or greater

than the DC or continuous peak operating voltage level.

6. V

BR

measured at pulse test current I

T

at ambient temperature of 25

∞

C.

7. Surge current waveform per Figure 2 and derate per Figure 3.

SMF5.0AT1 Series

http://onsemi.com

4

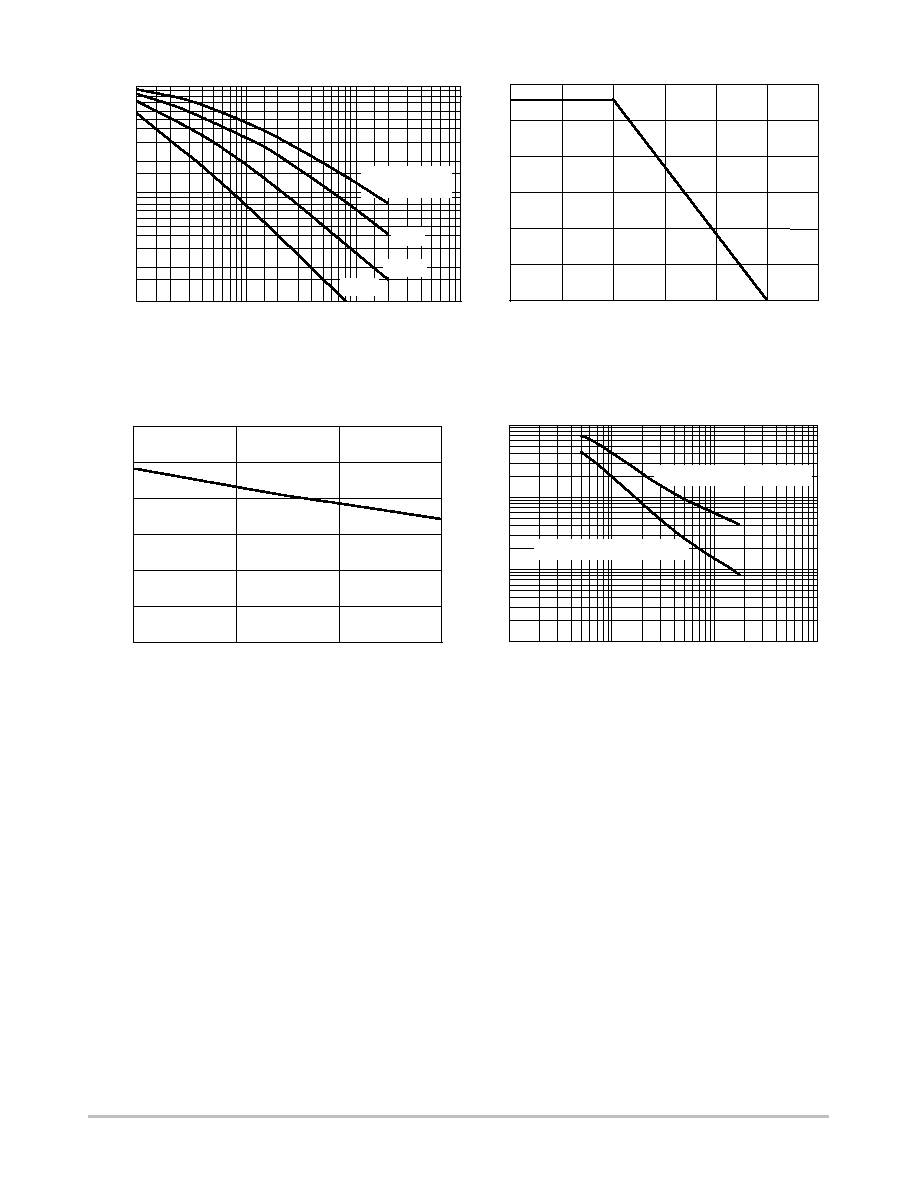

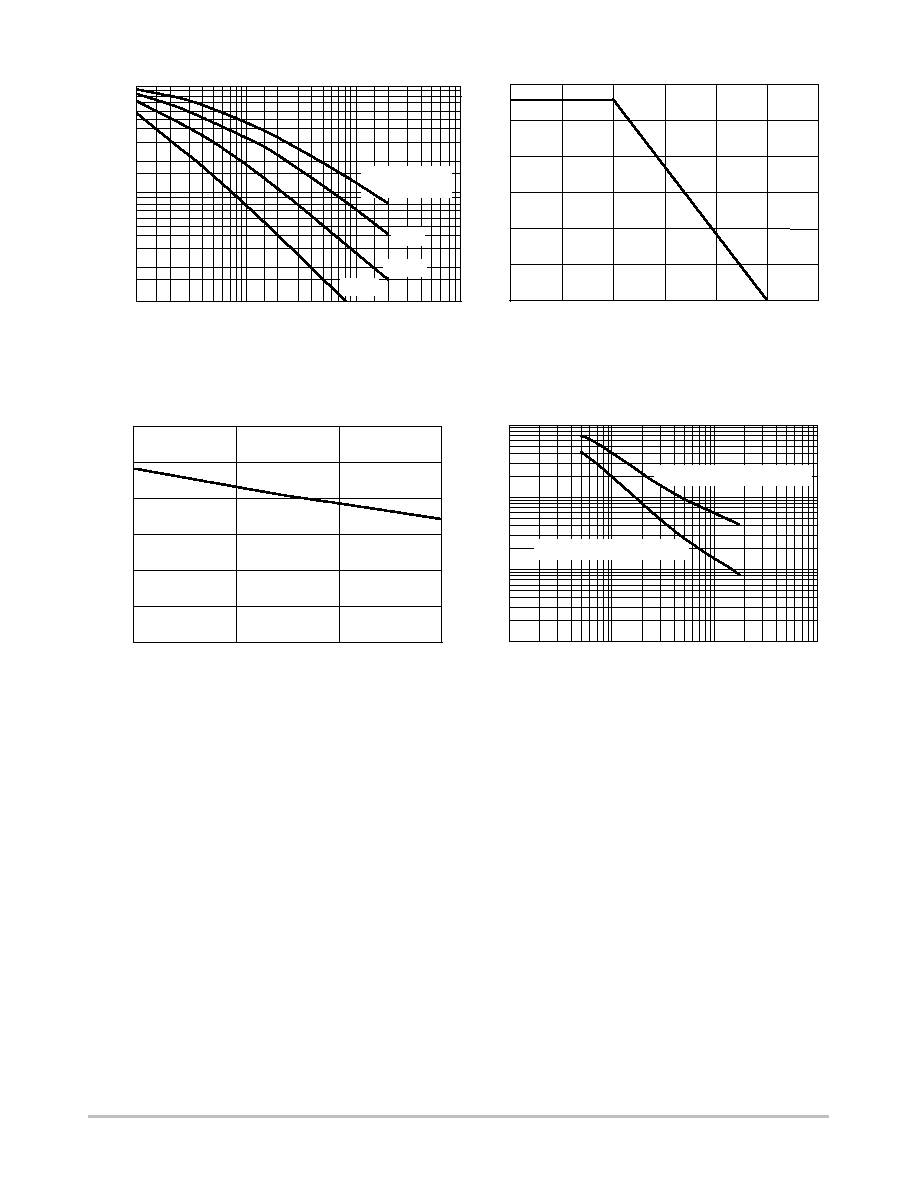

t

P

, PULSE WIDTH (

m

s)

100

1000

10,000

1.0

10

100

10

0

1

2

3

4

0

50

100

t, TIME (ms)

V

ALUE (%)

HALF VALUE -

I

RSM

2

PEAK VALUE - I

RSM

t

r

TYPICAL PROTECTION CIRCUIT

V

in

V

L

Z

in

LOAD

t

P

PULSE WIDTH (t

P

) IS DEFINED

AS THAT POINT WHERE THE PEAK

CURRENT DECAYS TO 50%

OF I

RSM

.

Figure 1. Pulse Rating Curve

Figure 2. 10 X 1000

m

s Pulse Waveform

1000

10,000

Figure 3. 8 X 20

m

s Pulse Waveform

P

P

, PEAK POWER (W

A

TTS)

t

r

10

µ

s

100

80

60

40

20

0

0

25

50

75

100

125

150

T

A

, AMBIENT TEMPERATURE (

∞

C)

120

140

160

Figure 4. Pulse Derating Curve

PEAK PULSE DERA

TING IN % OF

PEAK POWER OR CURRENT @ T

A

= 25

∞

C

100

90

80

70

60

50

40

30

20

10

0

0

20

40

60

80

t, TIME (

m

s)

% OF PEAK PULSE CURRENT

t

P

t

r

PULSE WIDTH (t

P

) IS DEFINED

AS THAT POINT WHERE THE

PEAK CURRENT DECAY = 8 ms

PEAK VALUE I

RSM

@ 8 ms

HALF VALUE I

RSM

/2 @ 20 ms

SMF5.0AT1 Series

http://onsemi.com

5

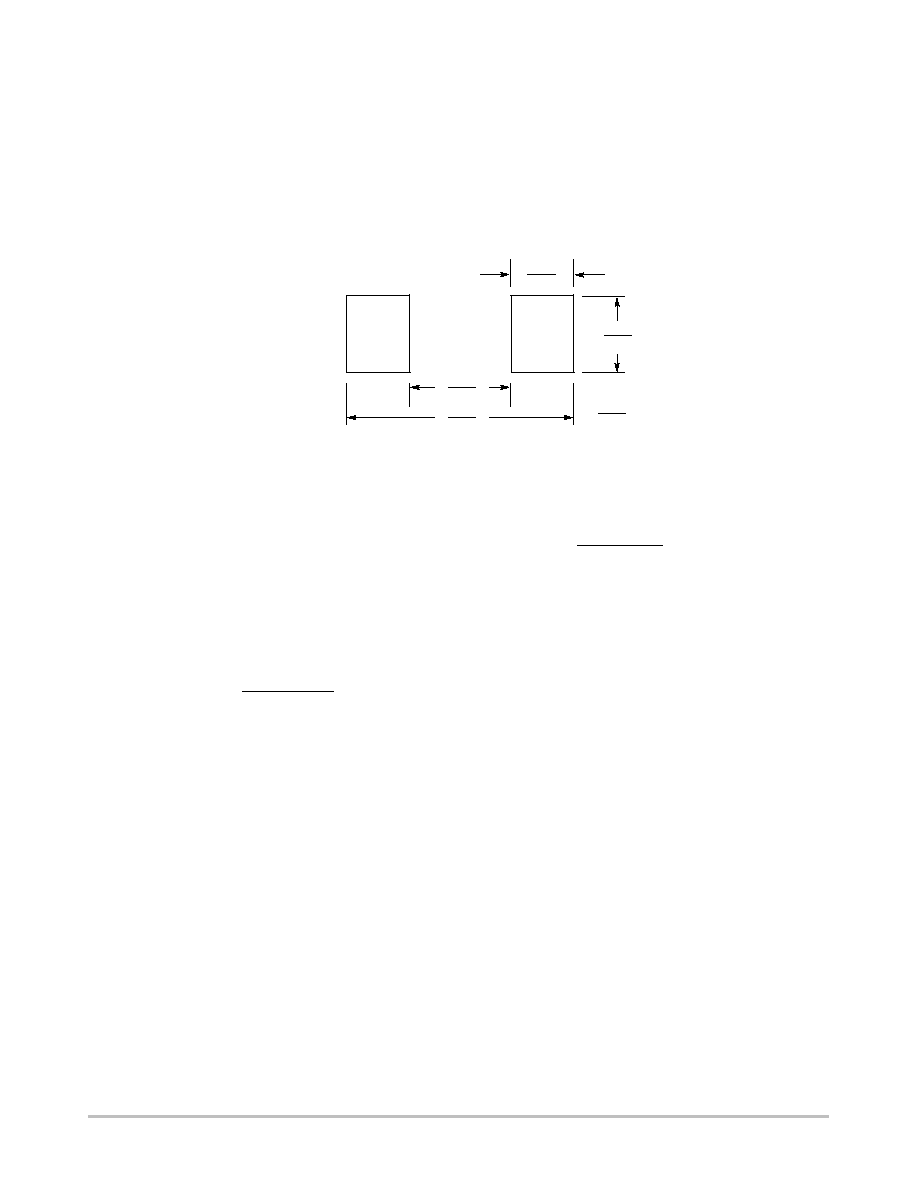

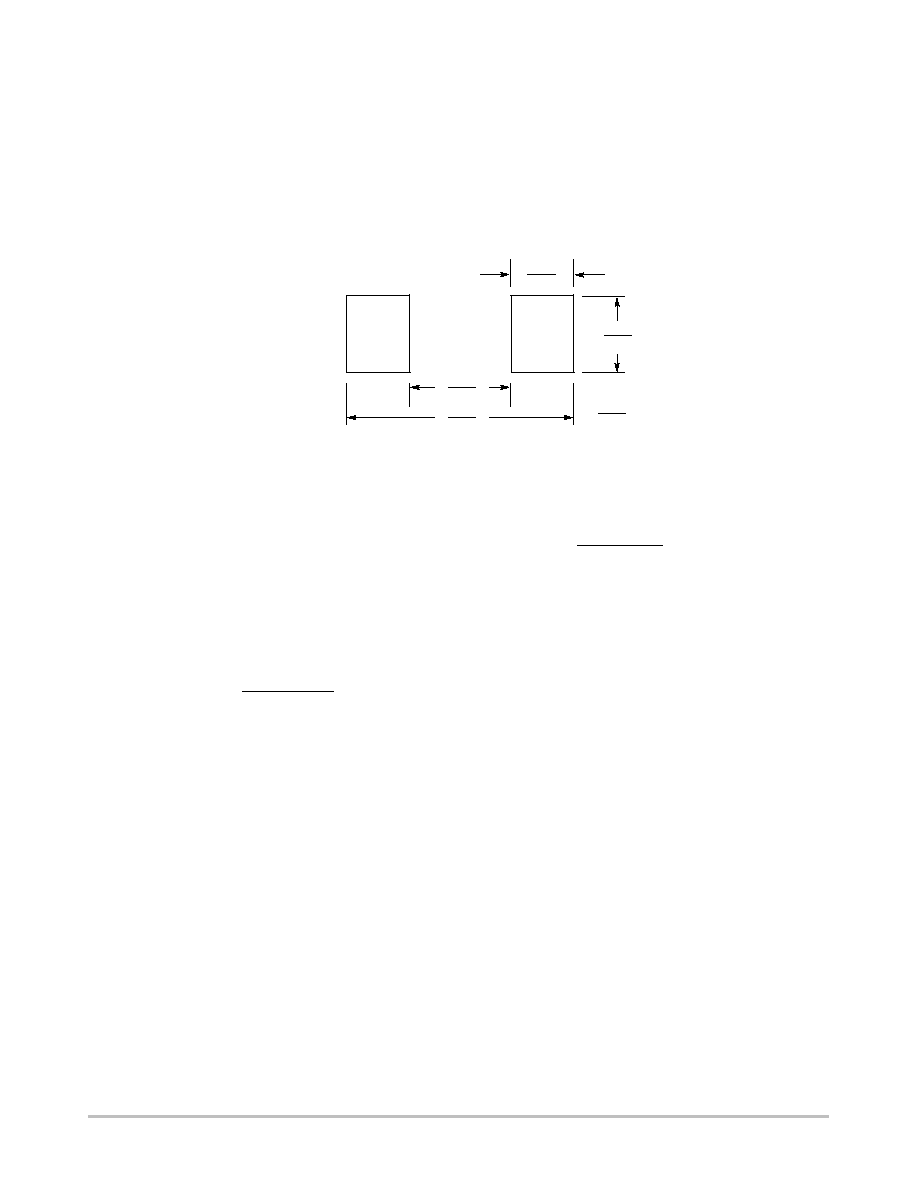

1.2

1.0

0.8

0.6

0.4

0.2

0

-55

25

85

150

T, TEMPERATURE (

∞

C)

V

,

TYPICAL

FOR

W

ARD VOL

T

AGE (VOL

TS)

F

25

50

75

100

125

175

2.5

2

1.5

1

0

T, TEMPERATURE (

∞

C)

P

, MAXIMUM POWER DISSIP

A

TION (W)

D

0.5

T

L

150

3

1000

100

1

1

10

1000

WORKING PEAK REVERSE VOLTAGE (VOLTS)

C, CAP

ACIT

ANCE (pF)

MEASURED @ 50% V

RWM

MEASURED @ ZERO BIAS

Figure 5. Typical Derating Factor for Duty Cycle

DERA

TING F

ACT

OR

1 ms

10

µ

s

1

0.7

0.5

0.3

0.05

0.1

0.2

0.01

0.02

0.03

0.07

100

µ

s

0.1 0.2

0.5

2

5

10

50

1

20

100

D, DUTY CYCLE (%)

PULSE WIDTH

10 ms

Figure 6. Steady State Power Derating

Figure 7. Forward Voltage

Figure 8. Capacitance versus Working Peak

Reverse Voltage

10

100

SMF5.0AT1 Series

http://onsemi.com

6

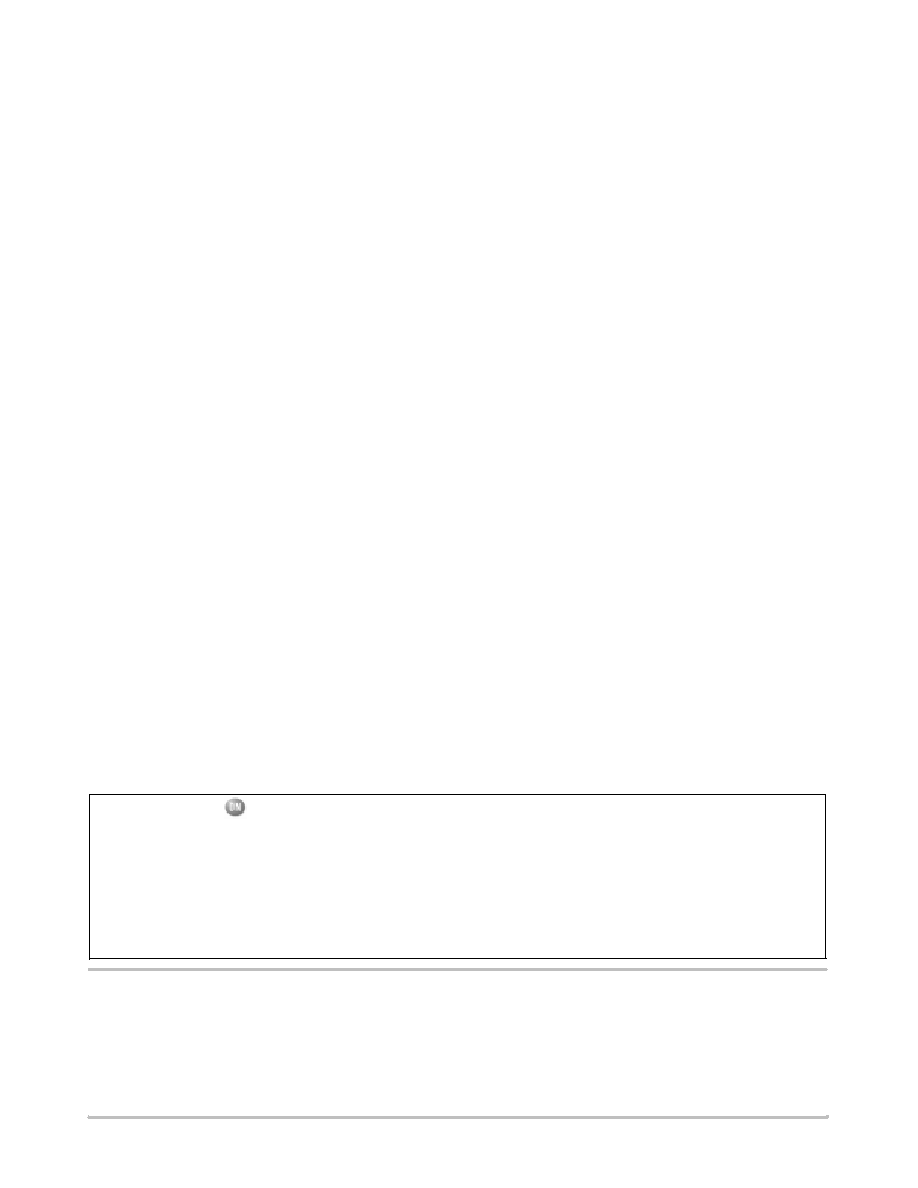

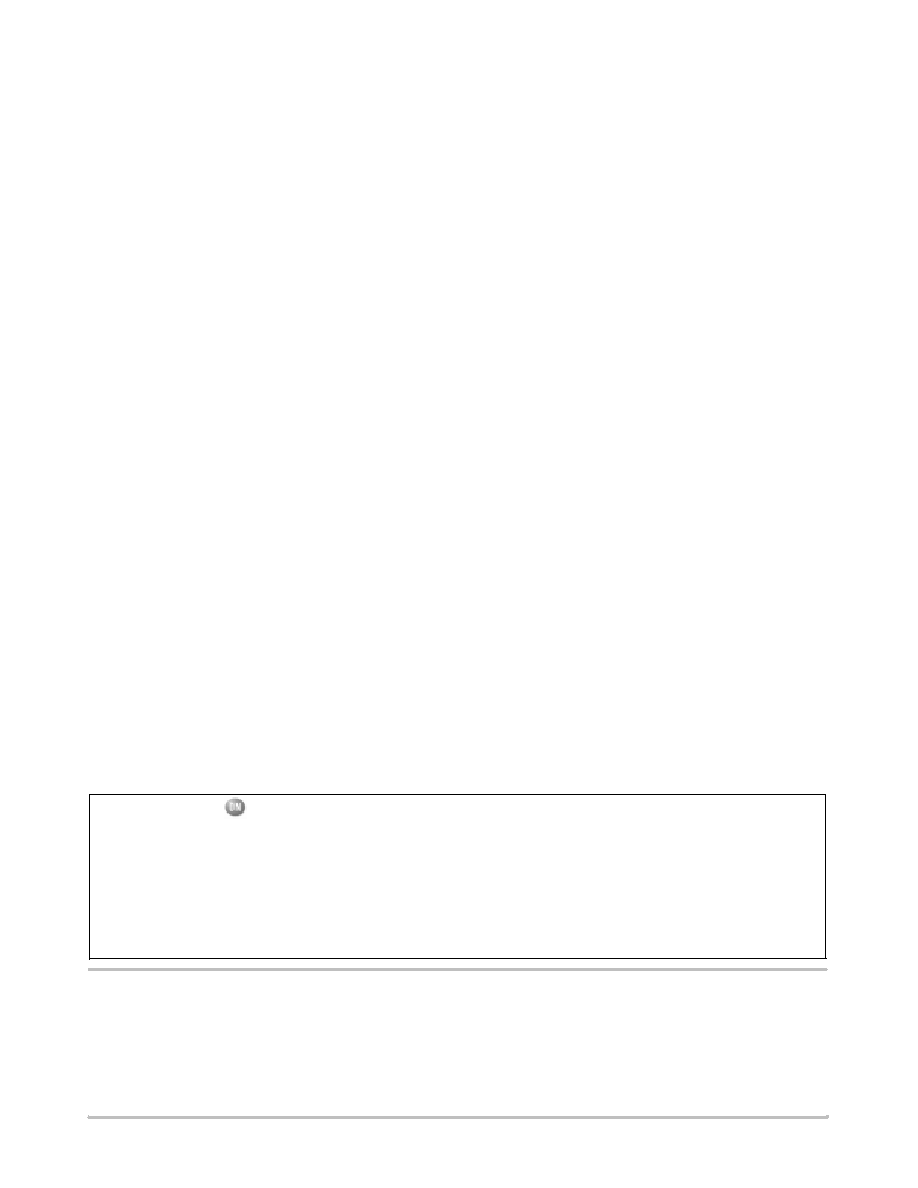

INFORMATION FOR USING THE SOD-123 FLAT LEAD SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the

total design. The footprint for the semiconductor packages

must be the correct size to insure proper solder connection

interface between the board and the package. With the

correct pad geometry, the packages will self align when

subjected to a solder reflow process.

RECOMMENDED FOOTPRINT FOR SOD-123FL

………

………

………

………

………

………

………

………

………

………

mm

inches

0.91

0.036

1.22

0.048

2.36

0.093

4.19

0.165

POWERMITE POWER DISSIPATION

The power dissipation of the SOD-123 Flat Lead is a

function of the mounting pad size. This can vary from the

minimum pad size for soldering to a pad size given for

maximum power dissipation. Power dissipation for a

surface mount device is determined by T

J(max)

, the

maximum rated junction temperature of the die, R

JA

, the

thermal resistance from the device junction to ambient, and

the operating temperature, T

A

. Using the values provided

on the data sheet for the SOD-123 Flat Lead package, P

D

can be calculated as follows:

P

D

=

T

J(max)

- T

A

R

JA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values

into the equation for an ambient temperature T

A

of 25

∞

C,

one can calculate the power dissipation of the device which

in this case is 385 milliwatts.

P

D

= 150

∞

C - 25

∞

C = 385 milliwatts

325

∞

C/W

The 325

∞

C/W for the SOD-123 Flat Lead package

assumes the use of the recommended footprint on a glass

epoxy printed circuit board to achieve a power dissipation

of 385 milliwatts. There are other alternatives to achieving

higher power dissipation from the SOD-123 Flat Lead

package. Another alternative would be to use a ceramic

substrate or an aluminum core board such as Thermal

Clad

Æ

. Using a board material such as Thermal Clad, an

aluminum core board, the power dissipation can be doubled

using the same footprint.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within

a short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

∑

Always preheat the device.

∑

The delta temperature between the preheat and

soldering should be 100

∞

C or less.*

∑

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering

method, the difference shall be a maximum of 10

∞

C.

∑

The soldering temperature and time shall not exceed

260

∞

C for more than 10 seconds.

∑

When shifting from preheating to soldering, the

maximum temperature gradient shall be 5

∞

C or less.

∑

After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and

result in latent failure due to mechanical stress.

∑

Mechanical stress or shock should not be applied

during cooling.

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

SMF5.0AT1 Series

http://onsemi.com

7

OUTLINE DIMENSIONS

Transient Voltage Suppressor - Surface Mounted

SOD-123FL

CASE 498-01

ISSUE O

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

FLASH.

4. DIMENSIONS D AND J ARE TO BE MEASURED

ON FLAT SECTION OF THE LEAD: BETWEEN 0.10

AND 0.25 MM FROM THE LEAD TIP.

A

B

K

D

C

H

E

L

J

L

DIM

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

A

1.50

1.80

0.059

0.071

B

2.50

2.90

0.098

0.114

C

0.90

1.00

0.039

D

0.70

1.10

0.028

0.043

E

0.55

0.95

0.022

0.037

H

0.00

0.10

0.000

0.004

J

0.10

0.20

0.004

0.008

K

3.40

3.80

0.134

0.150

L

0

8

∞

∞

0

8

∞

∞

POLARITY INDICATOR

OPTIONAL AS NEEDED

0.035

200 Watt Peak Power

SMF5.0AT1 Series

http://onsemi.com

8

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make

changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. "Typical" parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including "Typicals" must be

validated for each customer application by customer's technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

JAPAN: ON Semiconductor, Japan Customer Focus Center

2-9-1 Kamimeguro, Meguro-ku, Tokyo, Japan 153-0051

Phone: 81-3-5773-3850

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

SMF5.0AT1/D

Thermal Clad is a registered trademark of the Bergquist Company.

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303-675-2175 or 800-344-3860 Toll Free USA/Canada

Fax: 303-675-2176 or 800-344-3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800-282-9855 Toll Free USA/Canada