| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: SS24T3 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

Semiconductor Components Industries, LLC, 2005

July, 2005 - Rev. 2

1

Publication Order Number:

SS24/D

SS22, SS24

Surface Mount

Schottky Power Rectifier

SMB Power Surface Mount Package

These devices employ the Schottky Barrier principle in a

metal-to-silicon power rectifier. Features epitaxial construction with

oxide passivation and metal overlay contact. Ideally suited for low

voltage, high frequency switching power supplies; free wheeling

diodes and polarity protection diodes.

Features

∑

Compact Package with J-Bend Leads Ideal for Automated Handling

∑

Highly Stable Oxide Passivated Junction

∑

Guardring for Over-Voltage Protection

∑

Low Forward Voltage Drop

∑

Pb-Free Package is Available

Mechanical Characteristics

∑

Case: Molded Epoxy

∑

Epoxy Meets UL 94 V-0 @ 0.125 in

∑

Weight: 95 mg (approximately)

∑

Cathode Polarity Band

∑

Lead and Mounting Surface Temperature for Soldering Purposes:

260

∞C Max. for 10 Seconds

∑

Available in 12 mm Tape, 2500 Units per 13 in Reel, Add "T3"

Suffix to Part Number

∑

Finish: All External Surfaces Corrosion Resistant and Terminal

Leads are Readily Solderable

∑

ESD Ratings: Machine Model = C

ESD Ratings:

Human Body Model = 3B

SMB

CASE 403A

PLASTIC

SCHOTTKY BARRIER

RECTIFIER

2 AMPERES

20, 40 VOLTS

http://onsemi.com

SS2x

= Specific Device Code

x

= 2 or 4

A

= Assembly Location

Y

= Year

WW

= Work Week

G

= Pb-Free Package

(Note: Microdot may be in either location)

AYWW

SS2x

G

G

Device

Package

Shipping

ORDERING INFORMATION

SS22T3

SMB

2500/Tape & Reel

MARKING DIAGRAM

SS24T3

SMB

2500/Tape & Reel

For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

SS24T3G

SMB

(Pb-Free)

2500/Tape & Reel

SS22, SS24

http://onsemi.com

2

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

SS22

SS24

V

RRM

V

RWM

V

R

20

40

V

Average Rectified Forward Current

(At Rated V

R

, T

L

= 100

∞

C)

I

O

2.0

A

Peak Repetitive Forward Current

(At Rated V

R

, Square Wave,

100 kHz, T

C

= 105

∞

C)

I

FRM

3.0

A

Non-Repetitive Peak Surge Current

(Surge Applied at Rated Load Conditions Halfwave, Single Phase, 60 Hz)

I

FSM

75

A

Storage/Operating Case Temperature

T

stg

, T

C

-55 to +150

∞

C

Operating Junction Temperature

T

J

-55 to +125

∞

C

Voltage Rate of Change

(Rated V

R

, T

J

= 25

∞

C)

dv/dt

10,000

V/

m

s

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

THERMAL CHARACTERISTICS

Characteristic

Symbol

Value

Unit

Thermal Resistance,

Junction-to-Lead (Note 1)

Thermal Resistance,

Junction-to-Ambient (Note 2)

R

q

JL

R

q

JA

24

80

∞

C/W

ELECTRICAL CHARACTERISTICS

Maximum Instantaneous Forward Voltage

(Note 3)

see Figure 2

(i

F

= 2.0 A)

v

F

T

J

= 25

∞

C

T

J

= 125

∞

C

V

0.50

0.46

Maximum Instantaneous Reverse Current (Note 3)

see Figure 4

(V

R

= 40 V)

I

R

T

J

= 25

∞

C

T

J

= 100

∞

C

mA

0.4

5.7

1. Mounted with minimum recommended pad size, PC Board FR4.

2. 1 inch square pad size (1 x 0.5 inch for each lead) on FR4 board.

3. Pulse Test: Pulse Width

250

m

s, Duty Cycle

2.0%.

SS22, SS24

http://onsemi.com

3

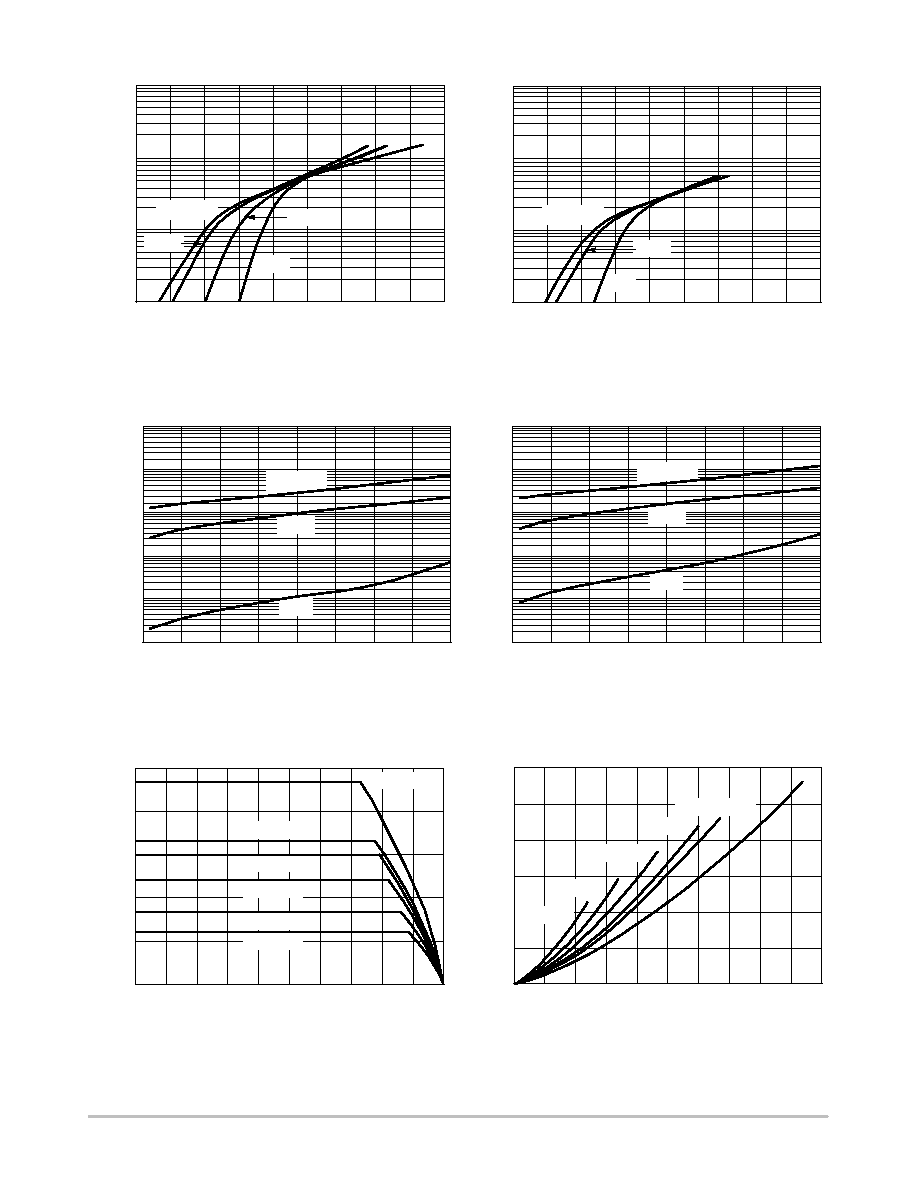

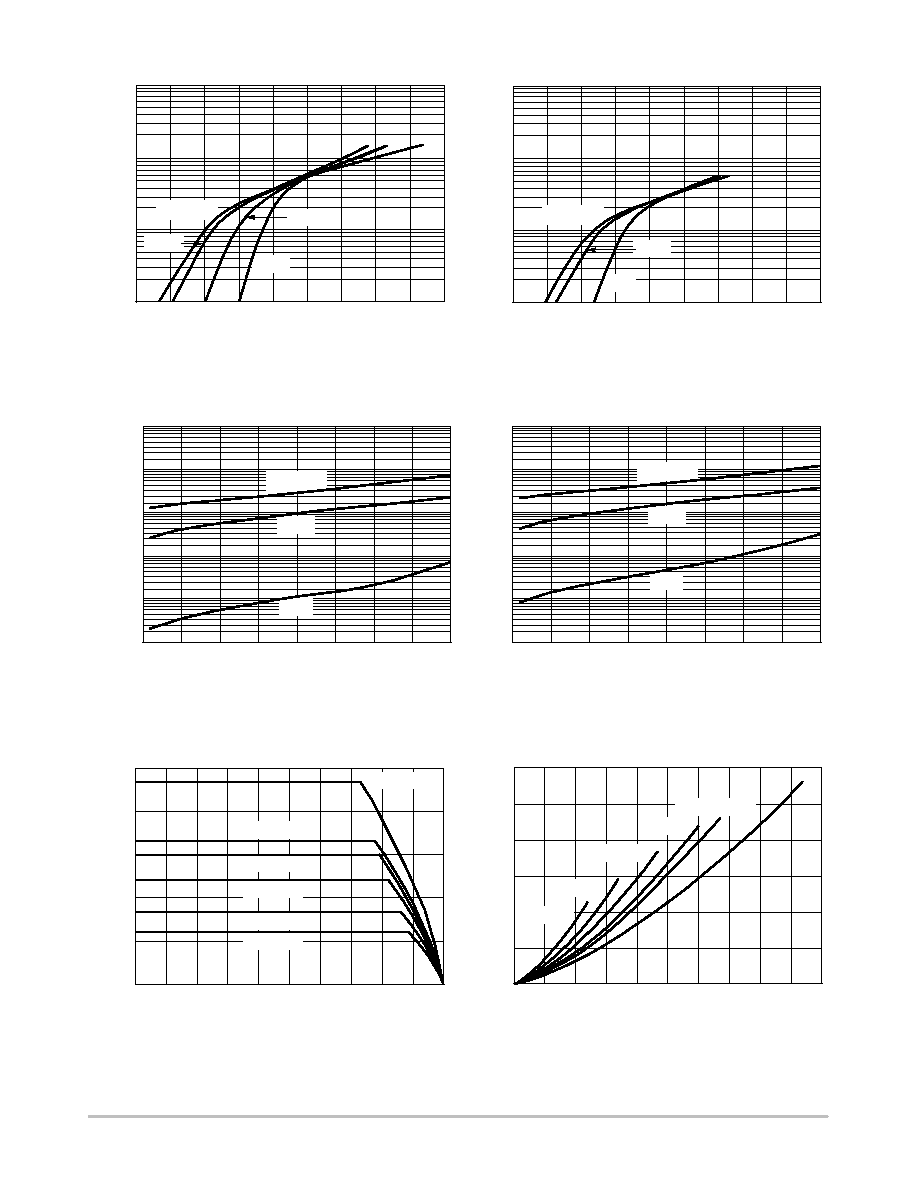

Figure 1. Typical Forward Voltage

Figure 2. Maximum Forward Voltage

Figure 3. Typical Reverse Current

Figure 4. Maximum Reverse Current

Figure 5. Current Derating

Figure 6. Forward Power Dissipation

0.7

0.1

v

F

, INSTANTANEOUS FORWARD VOLTAGE (VOLTS)

10

1.0

40

0

V

R

, REVERSE VOLTAGE (VOLTS)

100E-3

10E-3

1.0E-3

100E-6

10E-6

1.0E-6

45

85

25

T

L

, LEAD TEMPERATURE (∞C)

2.5

1.5

1.0

0.5

0

I

O

, AVERAGE FORWARD CURRENT (AMPS)

0.5

2.0

0

1.2

1.0

0.8

0.6

0.2

0

65

i F

, INST

ANT

ANEOUS

FOR

W

ARD

CURRENT

(AMPS)

I

0.1

0.3

0.5

0.9

10

20

30

, A

VERAGE

FOR

W

ARD

CURRENT

(AMPS)

I O

125

105

1.0

2.5

1.5

0.4

P

FO

,

A

VERAGE POWER DISSIP

A

TION

(W

A

TTS)

100

T

J

= 125∞C

100∞C

25∞C

-40 ∞C

0.7

0.1

V

F

, MAXIMUM INSTANTANEOUS FORWARD VOLTAGE (VOLTS)

10

1.0

I F

, INST

ANT

ANEOUS

FOR

W

ARD

CURRENT

(AMPS)

0.1

0.3

0.5

0.9

100

T

J

= 125∞C

100∞C

25∞C

, REVERSE CURRENT

(AMPS)

R

40

0

V

R

, REVERSE VOLTAGE (VOLTS)

100E-3

10E-3

1.0E-3

100E-6

10E-6

1.0E-6

I

10

20

30

, MAXIMUM REVERSE CURRENT

(AMPS)

R

2.0

FREQ = 20 kHz

T

J

= 125∞C

100∞C

25∞C

T

J

= 125∞C

100∞C

25∞C

dc

SQUARE WAVE

Ipk/Io = p

Ipk/Io = 5.0

Ipk/Io = 10

Ipk/Io = 20

dc

SQUARE WAVE

Ipk/Io = p

Ipk/Io = 5.0

Ipk/Io = 10

Ipk/Io = 20

SS22, SS24

http://onsemi.com

4

Figure 7. Capacitance

Figure 8. Typical Operating Temperature Derating*

Figure 9. Thermal Response -- Junction to Case

Figure 10. Thermal Response -- Junction to Ambient

30

0

V

R

, REVERSE VOLTAGE (VOLTS)

1000

100

10

V

R

, DC REVERSE VOLTAGE (VOLTS)

25

40

0

105

85

75

65

C, CAP

ACIT

ANCE

(pF)

T

15

5.0

10

20

25

35

40

30

35

5.0

10

20

15

95

115

125

,

DERA

TED

OPERA

TING TEMPERATURE ( C)

J

∞

* Reverse power dissipation and the possibility of thermal runaway must be considered when operating this device under any re-

verse voltage conditions. Calculations of T

J

therefore must include forward and reverse power effects. The allowable operating

T

J

may be calculated from the equation:

T

J

= T

Jmax

- r(t)(Pf + Pr) where

r(t) = thermal impedance under given conditions,

Pf = forward power dissipation, and

Pr = reverse power dissipation

This graph displays the derated allowable T

J

due to reverse bias under DC conditions only and is calculated as T

J

= T

Jmax

- r(t)Pr,

where r(t) = Rthja. For other power applications further calculations must be performed.

R

tja

= 24∞C/W

43∞C/W

63∞C/W

80∞C/W

93∞C/W

T

J

= 25∞C

0.1

0.00001

t, TIME (s)

1.0E+00

1.0E-01

1.0E-02

1.0E-03

1.0E-04

R

0.0001

0.001

0.01

, TRANSIENT

THERMAL

RESIST

ANCE

(NORMALIZED)

T

1.0

10

100

1000

50%

20%

10%

5.0%

2.0%

1.0%

R

tjl(t)

= R

tjl*r(t)

0.1

0.00001

t, TIME (s)

1.0E+00

1.0E-01

1.0E-02

1.0E-03

1.0E-04

0.0001

0.001

0.01

1.0

10

100

1000

50%

20%

10%

5.0%

2.0%

1.0%

R

tjl(t)

= R

tjl*r(t)

R

,

TRANSIENT

THERMAL

RESIST

ANCE

(NORMALIZED)

T

SS22, SS24

http://onsemi.com

5

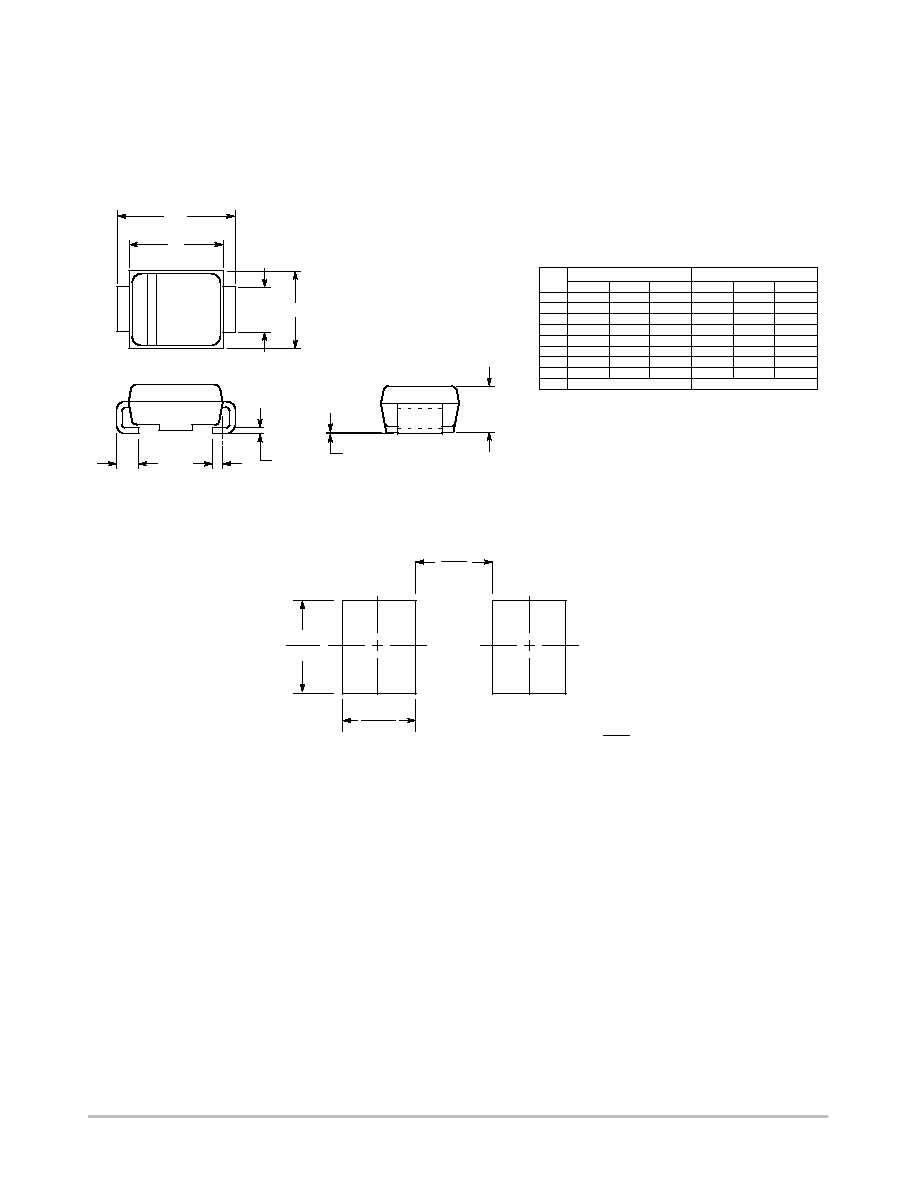

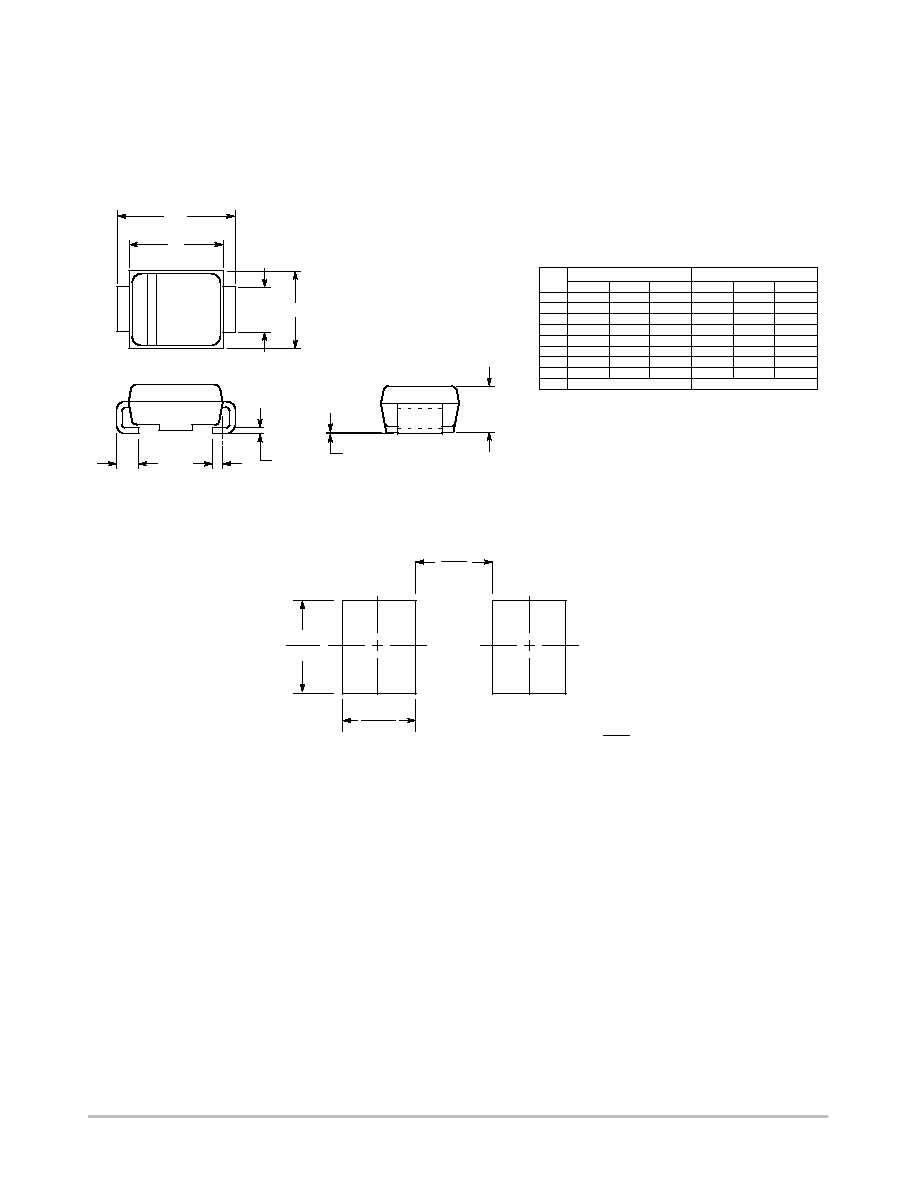

PACKAGE DIMENSIONS

SMB

CASE 403A-03

ISSUE E

2.261

0.089

2.743

0.108

2.159

0.085

mm

inches

SCALE 8:1

*For additional information on our Pb-Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

SOLDERING FOOTPRINT*

E

b

D

c

L1

L

A

A1

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. D DIMENSION SHALL BE MEASURED WITHIN DIMENSION P.

DIM

A

MIN

NOM

MAX

MIN

MILLIMETERS

1.90

2.13

2.41

0.075

INCHES

A1

0.05

0.10

0.15

0.002

b

1.96

2.03

2.11

0.077

c

0.15

0.23

0.30

0.006

D

3.30

3.56

3.81

0.130

E

4.06

4.32

4.57

0.160

L

0.76

1.02

1.27

0.030

0.084

0.095

0.004

0.006

0.080

0.083

0.009

0.012

0.140

0.150

0.170

0.180

0.040

0.050

NOM

MAX

5.21

5.44

5.59

0.205

0.214

0.220

H

E

0.51 REF

0.020 REF

D

L1

H

E