| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: AN6609N | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

ICs for Motor

s

Overview

The AN6608, the AN6609N and the AN6609NS are the

electronic governors which incorporate the forward

/reverse rotation and double speed controls of the DC

motors used for radio/cassette tape recorder, and the

functions such as fast forward, rewind, brake, and pause.

They are also available for controlling the video tape deck

mechanisms such as the VCRs and DATs. The AN6608,

the AN6609N and the AN6609NS are identical with each

other except the operating logic by 3-bit input.

s

Features

∑

Operating supply voltage range ; Vcc = 8V to 16V

∑

Stable reference voltage (1.27V) and easy speed

adjustment

∑

Large starting torque and maximum control torque

∑

Built-in power transistor

∑

Forward/reverse constant speed and double speed

controls, and fast forward, brake, and pause functions

available by 3-bit input

s

Applications

VCRs, cassette decks, radio/cassette tape recorders,

car cassette tape players, tape loading DC motor con

trol such as DATs.

AN6608, AN6609N, AN6609NS

DC Motor Forward/Reverse Dual Speed Electronic Governors

1

24

12

13

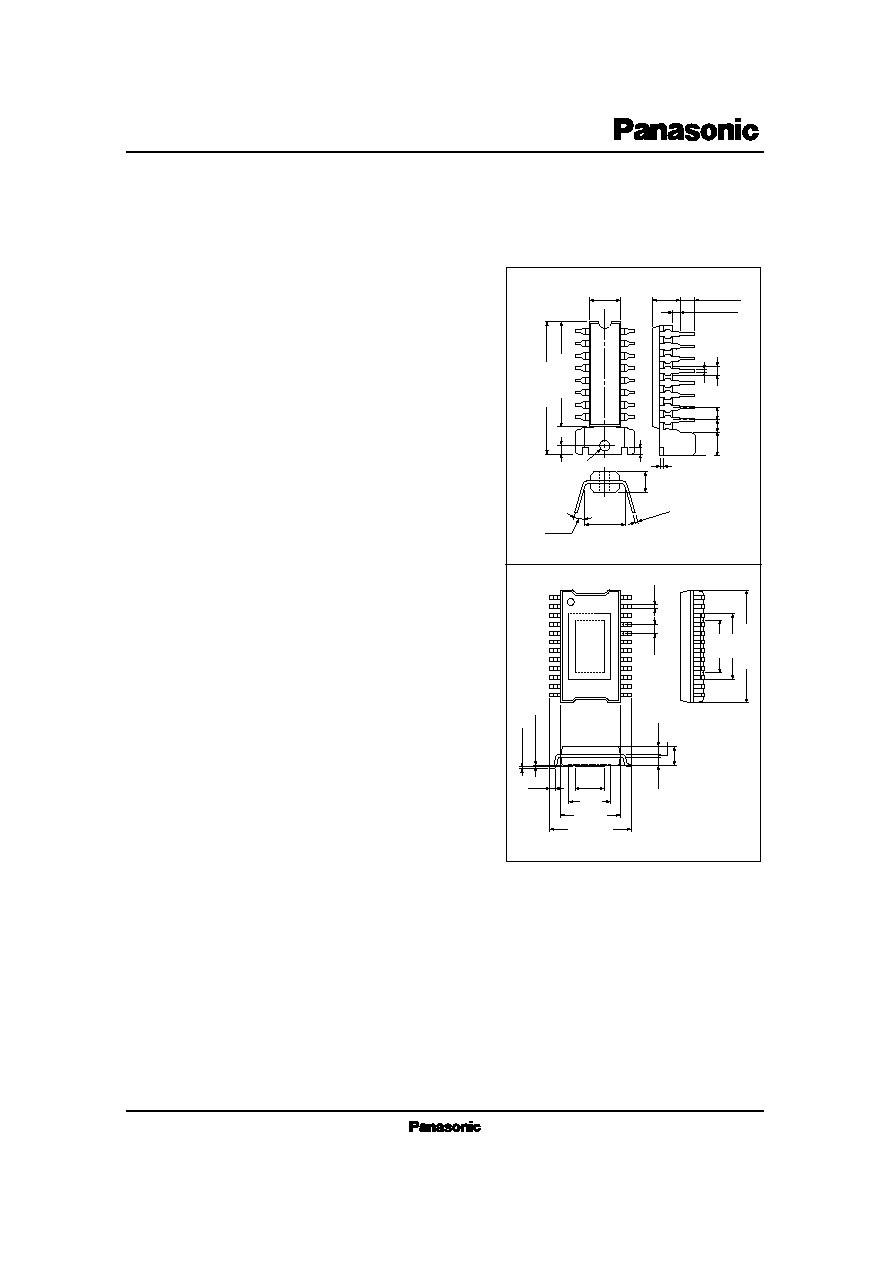

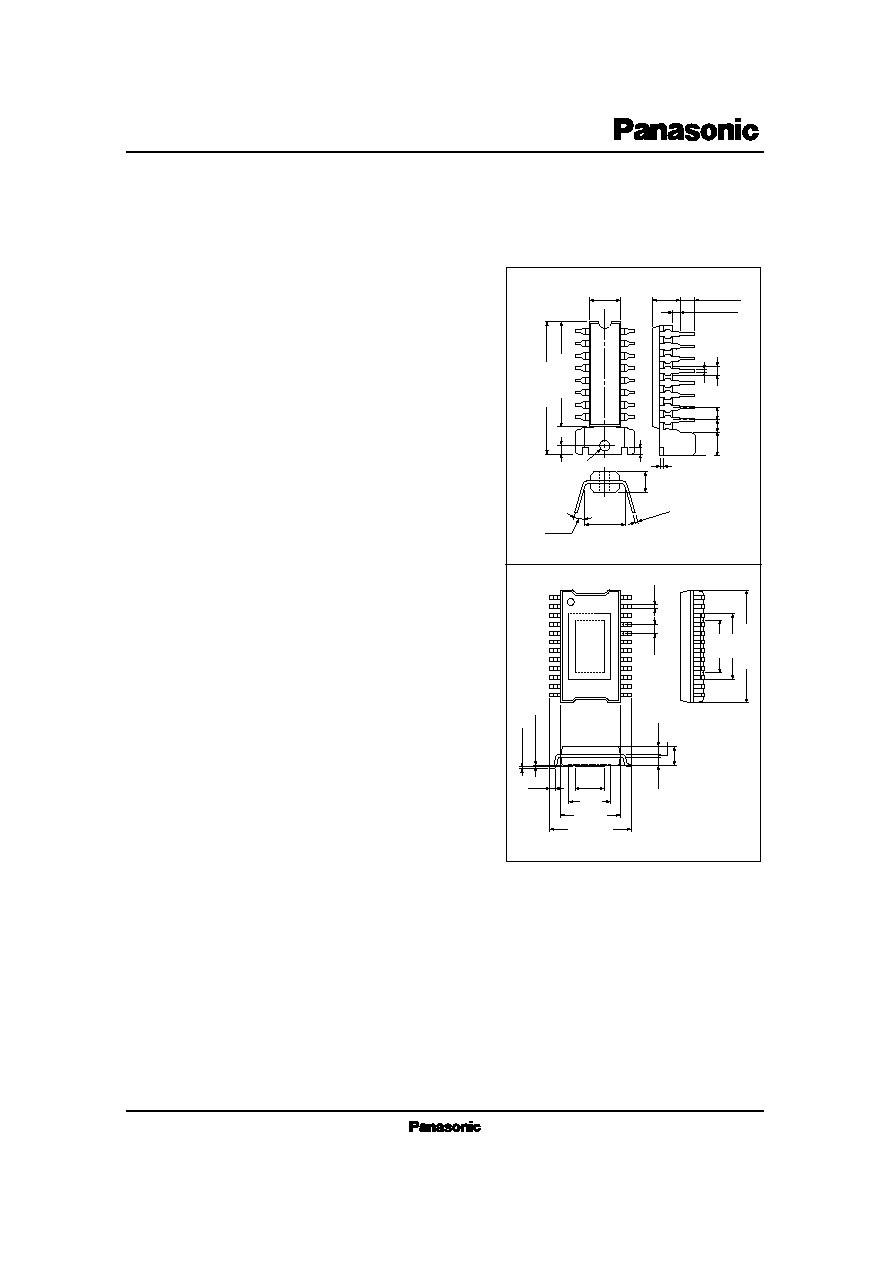

Unit : mm

16.0

±

0.3

(9.2)

(7.8)

0.4

1.27

11.73

±

0.3

8.4

±

0.3

(6.0)

(4.6)

0.5

0.1

±

0.1

(0.05 ~ 0.1)

3.15

±

0.2

1.45

1.45

(0.2)

AN6609NS

24-Lead HSOP Package (HSOP024-P-0450)

1

2

3

4

5

6

7

8

10

9

11

12

13

14

15

16

27.4

±

0.3

6.35

±

0.3

4.7

±

0.25

3.05

±

0.25

0.5

±

0.1

1.2

±

0.25

2.54

1.5

±

0.1

3.80

±

0.3

17

7.62

±

0.25

0 ~ 6∞

0.45

+ 0.1

≠ 0.05

0.5

±

0.1

¯ 2.1

Unit : mm

1.7

2.54

1.06

±

0.25

21.6

±

0.3

5.08

±

0.1

16-Lead DIP Package with Fin (HDIP016-P-300)

AN6608,

AN6609N

AN6608, AN6609N, AN6609NS

ICs for Motor

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

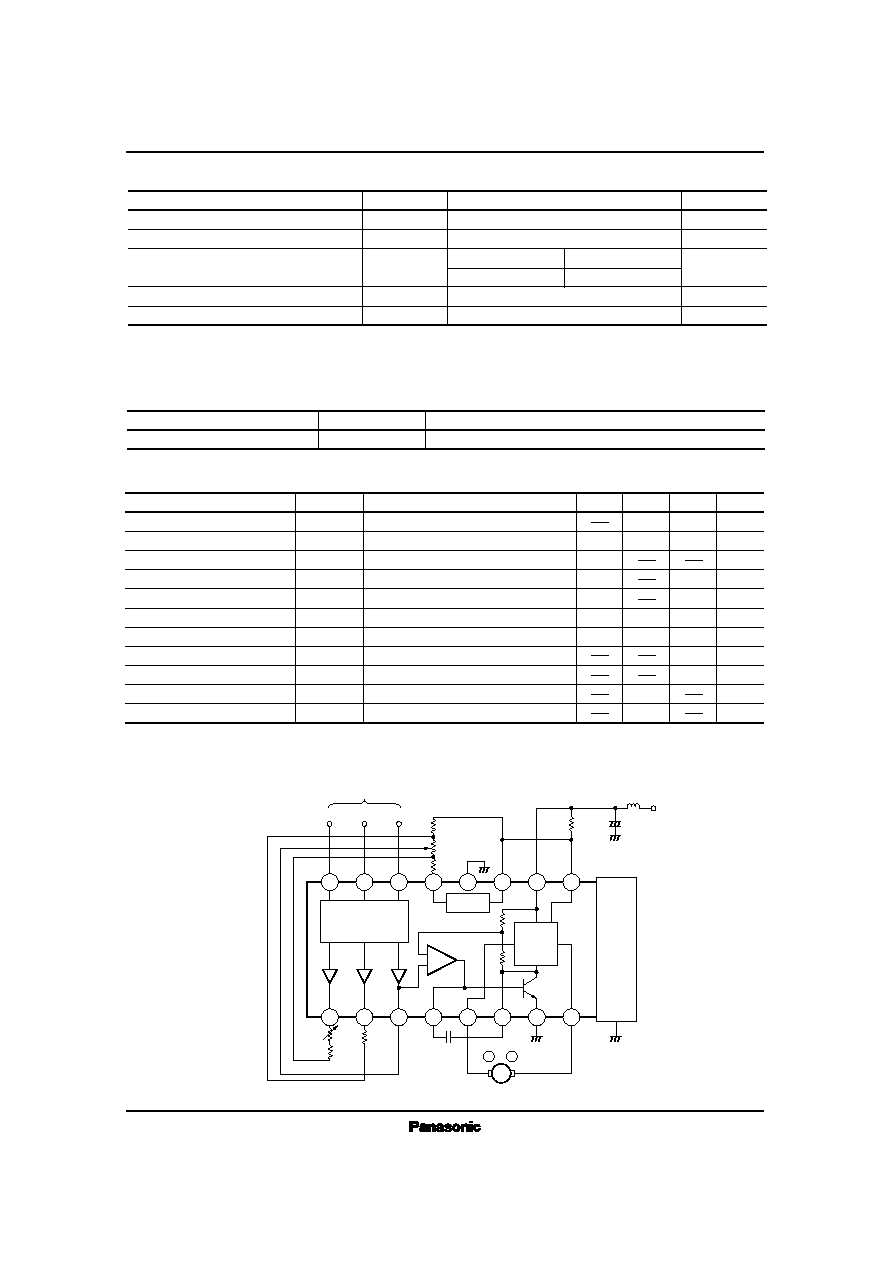

Comp.

Drive Mode

Switching Logic

V

CC

GND

V

REF

Forward/

Reverse

Drive

Circuit

1k

1

0

k

GND

Fin

AN6608, AN6609N

s

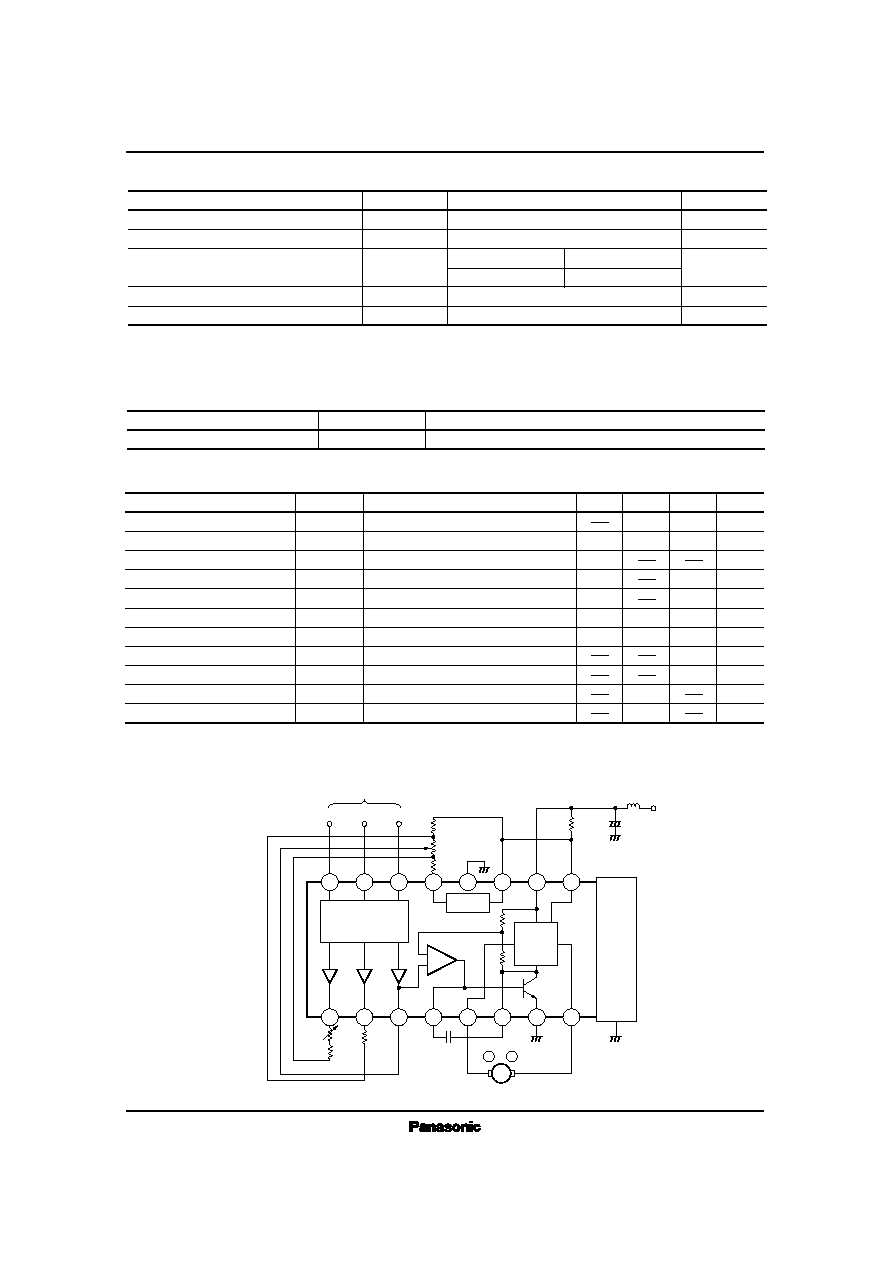

Block Diagram

24

13

14

15

16

17

18

19

20

21

22

23

1

12

11

10

9

8

7

6

5

4

3

2

V

REF

Comp.

M

P

1

P

2

P

3

V

CC

AN6609NS

P

T

Note) For motor lock, V

CC

=13V or less, Motor coil resistance

= 8

or more,

Lock time =1s or less.

Drive Mode

Switching Logic

Forward/

Reverse

Drive Circuit

ICs for Motor

AN6608, AN6609N, AN6609NS

s

Absolute Maximum Ratings

(Ta= 25∞C)

V

CC

I

CC

T

opr

T

stg

Supply Voltage

Supply Current

Operating Ambient Temperature

Storage Temperature

V

mA

∞C

∞C

Parameter

Symbol

Rating

Unit

18

1800

Note 1)

≠20 ~ + 70

≠50 ~ +150

Note 1) t

200ms

Note 2) Mounting on PCB (20mm

◊

20mm of copperfoil is used for heat sink)

Note 3) Glass epoxy PCB (50mm

◊

50mm

◊

1.2mm)

Power Dissipation

P

D

W

2

Note 2)

2.08

Note 3)

AN6608, AN6609N

AN6609NS

Parameter

Symbol

Range

Operating Supply Voltage Range

V

CC

8V ~ 16V

s

Recommended Operating Range

(Ta = 25∞C)

s

Electrical Characteristics

(Ta = 25∞C)

V

CC

=12V

V

CC

=12V

Supply voltage with which a motor starts rotating

V

CC

=12V, N=1600rpm

V

CC

=8V, I

L

=55mA ~ 120mA

V

CC

=8V ~ 16V, N=1600rpm

V

CC

=12V, N=3200rpm

V

CC

=8V, I

O

=1A

V

CC

=8V, I

O

=1A

V

CC

=12V, Ta= ≠10∞C ~ + 60∞C

V

CC

=12V, t=15s ~ 10ms

Parameter

Symbol

Condition

min.

typ.

max.

Unit

7

1.27

0

0

100

0.4

Bias Current at No Load

Reference Voltage

Rated Load Start Voltage

Rated r.p.m.

r.p.m. Characteristics on Load Change

r.p.m. Characteristics on Voltage Change

Double Speed Forward/Reverse r.p.m. Difference

Output Saturation Voltage 1

Output Saturation Voltage 2

r.p.m. Characteristics on Temperature Change

r.p.m. Drift Characteristics by Time

I

bias

V

ref

V

CC (s)

N

L

DN

L

DN

V

DN

Logi

V

sat (1)

V

sat (2)

DN

A

DN

T

mA

V

V

%

rpm

rpm

%

V

V

rpm/∞C

%

1.15

6.5

≠8.75

≠100

≠22

≠3

15

1.4

8.75

100

22

3

2

1.5

s

Application Circuit

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

M

P

1

P

2

P

3

+

≠

0.022

µ

F

C

2

R

5

1.5k

5kB

5.6k

R

4

1k

1

0

k

V

REF

Comp.

2000

ppm/∞C

R

1

11k

R

2

2.7k

VR

1

1kB

R

1

1.0

(3900ppm/∞C)

C

1

4.7

µ

F

≠

+

L

1

47

µ

H

V

CC

To Mechanism Control

AN6608

AN6609N

Drive Mode

Switching Logic

Forward/

Reverse

Drive

Circuit

Fin

AN6608, AN6609N, AN6609NS

ICs for Motor

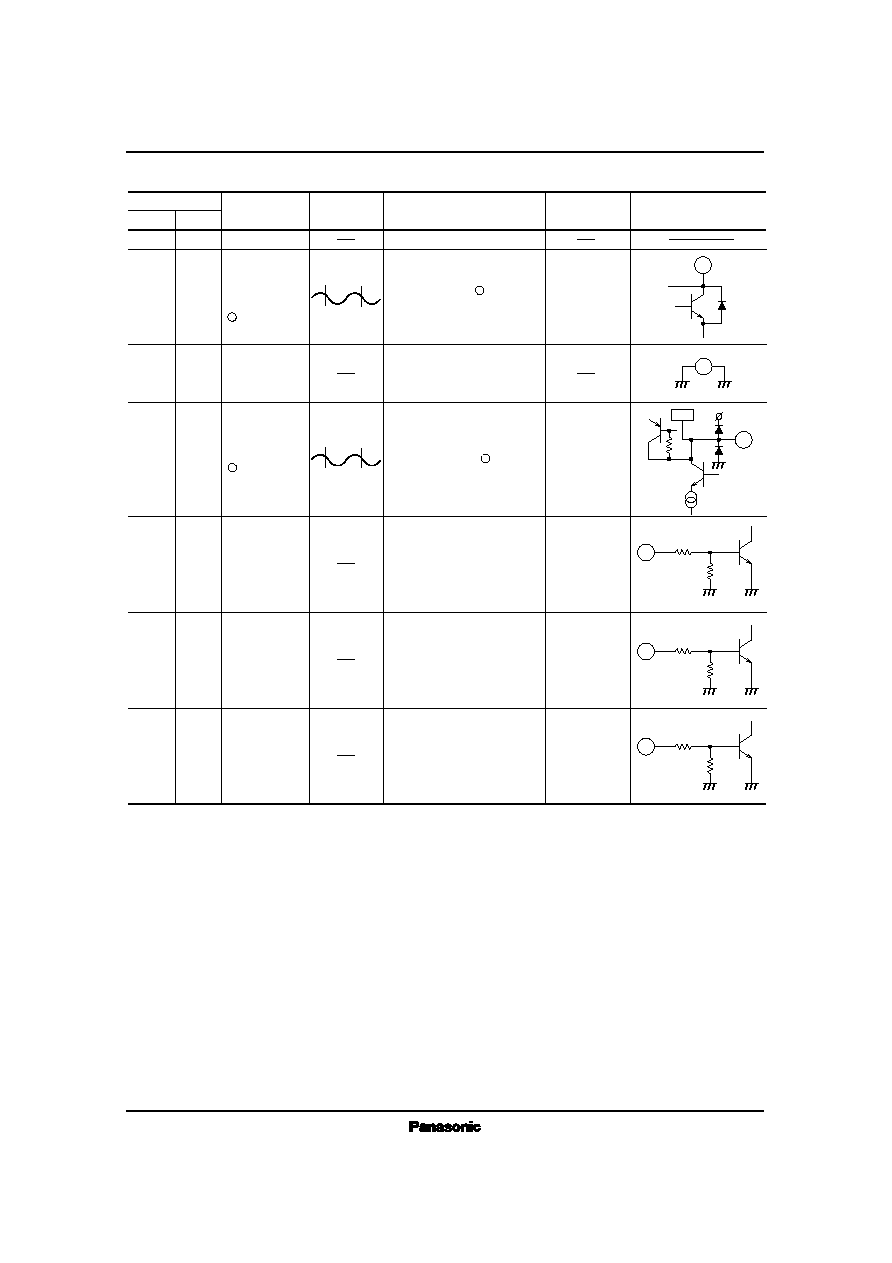

Equivalent Circuit

Description

Pin No.

1

Double Speed

Setting

Pin to set the double speed r.p.m.

Input Impedance

Pin Name

Typ. Waveform

AN6608

AN6609N AN6609NS

2

Tr

C

2

FF, REW

Speed Setting

Pin to set the FF/REW r.p.m.

4

Tr

C

3

Speed Control

Speed control pin

A fixed resistor will do if fine

adjustment is unnecessary.

5

Tr

E

4

Phase

Adjustment

Motor

Connection

Phase adjustment pin for

oscillation prevention

6

Tr

E

5

Pin to connect the motor side

7

6

Phase

Adjustment

Phase adjustment pin for

oscillation prevention

8

7

GND

Motor

Connection

GND pin for the power section

inside the IC

9

8

11

9

Load

Characteristics

Setting

Pin to set the load characteristics

(S≠T curve) of the motor

14

Pin to connect the motor side

Tr

E

Tr

C

Tr

C

Tr

E

Tr

E

Tr

C

Tr

C

1

V

CC

2

V

CC

3

V

CC

4

V

CC

5

6

7

8

9

+

≠

s

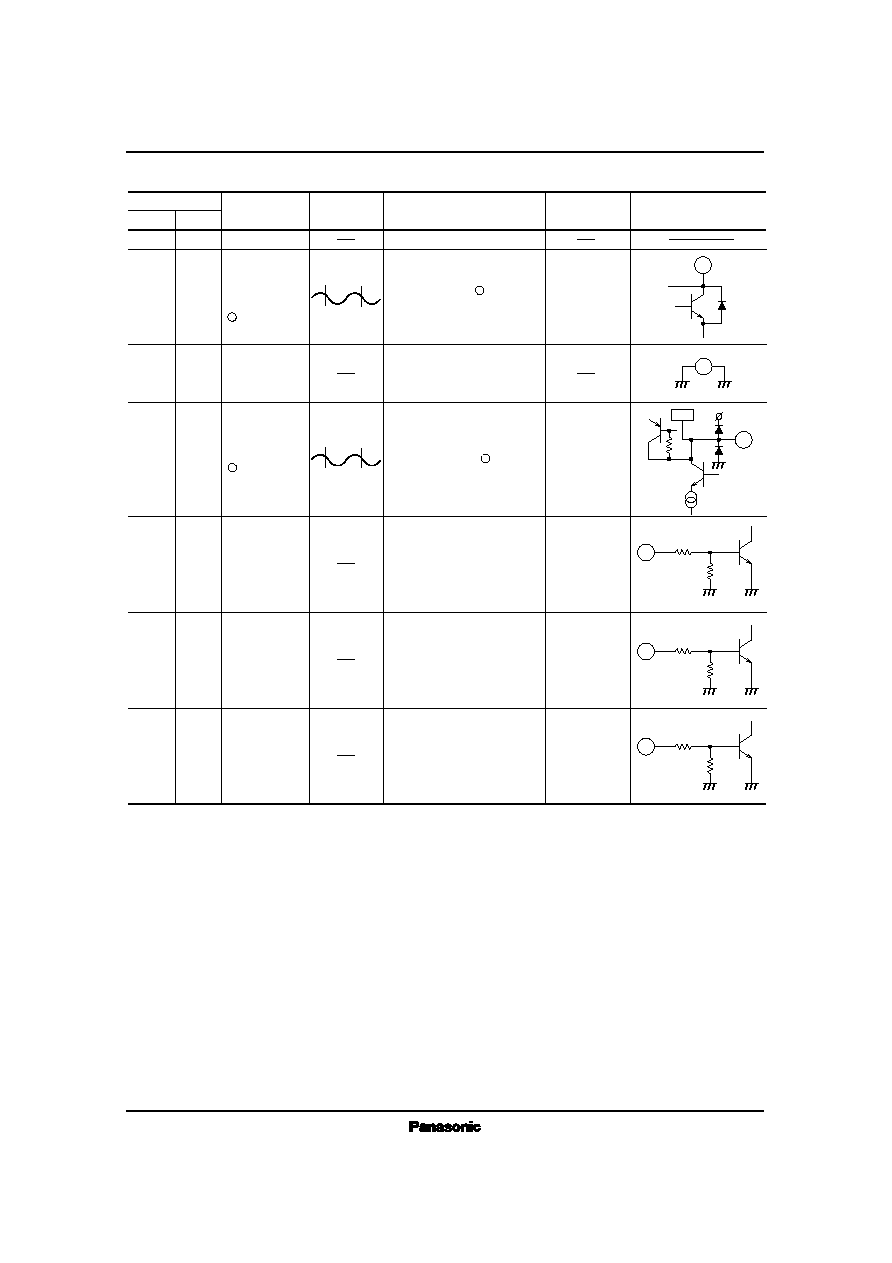

Pin Descriptions

+

≠

ICs for Motor

AN6608, AN6609N, AN6609NS

s

Pin Descriptions (Cont.)

Equivalent Circuit

Description

Pin No.

10

V

CC

IC power pin

Input Impedance

Pin Name

Typ. waveform

AN6608

AN6609N AN6609NS

17

11

Connect to

Pin9 .

Ref. Voltage

Output

Reference voltage output pin

when connecting to the pin9.

19

Tr

C

12

GND

GND pin for the IC bias section

20

14

Logic Input P

3

Logic input pin P

3

to set

the motor control state

23

15

Logic Input P

2

Logic input pin P

2

to set

the motor control state

24

16

Logic Input P

1

Logic input pin P

1

to set

the motor control state

1

60k

60k

60k

13

Ref. Voltage

Output

Reference voltage output pin

21

Tr

C

11

12

13

V

CC

V

REF

14

60k

40k

15

60k

40k

16

60k

40k

+

≠

≠

+

AN6608, AN6609N, AN6609NS

ICs for Motor

Input Pins

14

Output Pins (AN6608)

Output Pins (AN6609N)

15

16

5

8

1

2

5

8

1

2

Operating Mode

Operating Mode

H

H

H

H

L

OFF

ON

--

--

OFF

OFF

FF

Pause

L

H

H

L

H

OFF

ON

H

L

ON

OFF

REW

Double speed

H

L

H

H

L

OFF

OFF

H

L

OFF

OFF

Constant speed

Constant speed

H

H

L

H

H

OFF

OFF

H

H

OFF

OFF

Brake

Brake

L

L

H

H

L

ON

OFF

H

L

OFF

ON

Double speed

FF

L

H

L

L

H

ON

OFF

L

H

ON

OFF

Reverse double speed

Reverse double speed

H

L

L

L

H

OFF

OFF

L

H

OFF

OFF

Reverse constant speed

Reverse constant speed

L

L

L

--

--

OFF

OFF

--

--

OFF

OFF

Pause

Pause

* Input level H : 3V or more, Input level L : 0.7V or less

For the AN6609NS, the above pin numbers must be replaced.

P

D

≠ Ta

2.5

2.0

1.5

1.0

0.5

0

Ambient Temperature Ta (∞C)

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

P

D

(

W

)

40

0

20

60

100

140

≠20

80

120

160

(1)

(2)

(1) 10mm

◊

20mm, with

Solder Plated Copper Foil,

Heat Sink

(2) Without Heat Sink

P

D

≠ Ta

2,400

2,200

2,000

1,800

1,600

1,400

1,200

1,000

800

600

400

200

0

Ambient Temperature Ta (∞C)

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

P

D

(

m

W

)

25

0

75

125

Glass epoxy PCB (50

◊

50

◊

1.2mm)

R

thj ≠ a

= 60∞C/W

P

D

= 2083mW (25∞C)

150

100

50

2,083

1,420

Without PCB

R

thj ≠ a

= 88∞C/W

P

D

= 1420mW (25∞C)

AN6608, AN6609N

AN6609NS

s

Supplementary Explanation

∑ Operating Logic

∑ Characteristics Curve